CPE/CPVC rubber-plastic thermal-insulation material and preparation method thereof

A thermal insulation material, rubber and plastic technology, applied in the field of polymer material synthesis and processing application, can solve the problems of inconvenient industrial production, complex production process, high production cost, and achieve the advantages of simple and continuous preparation method, low thermal conductivity, and prevention of heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

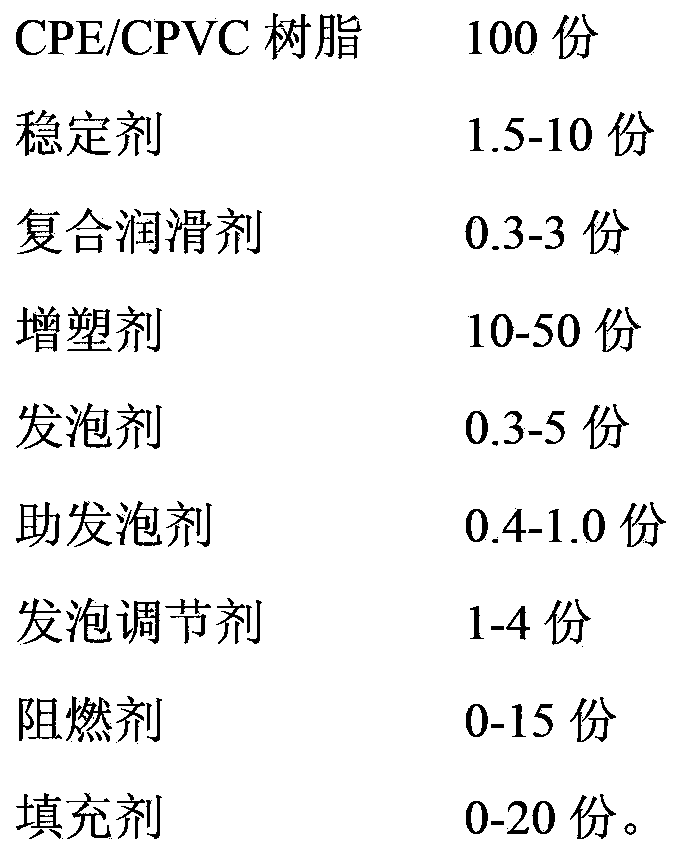

Method used

Image

Examples

Embodiment 1-7

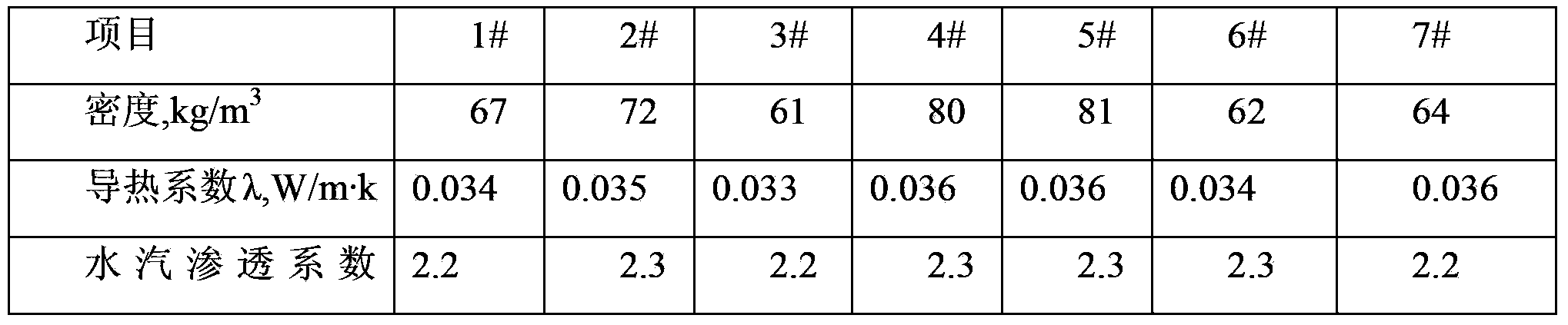

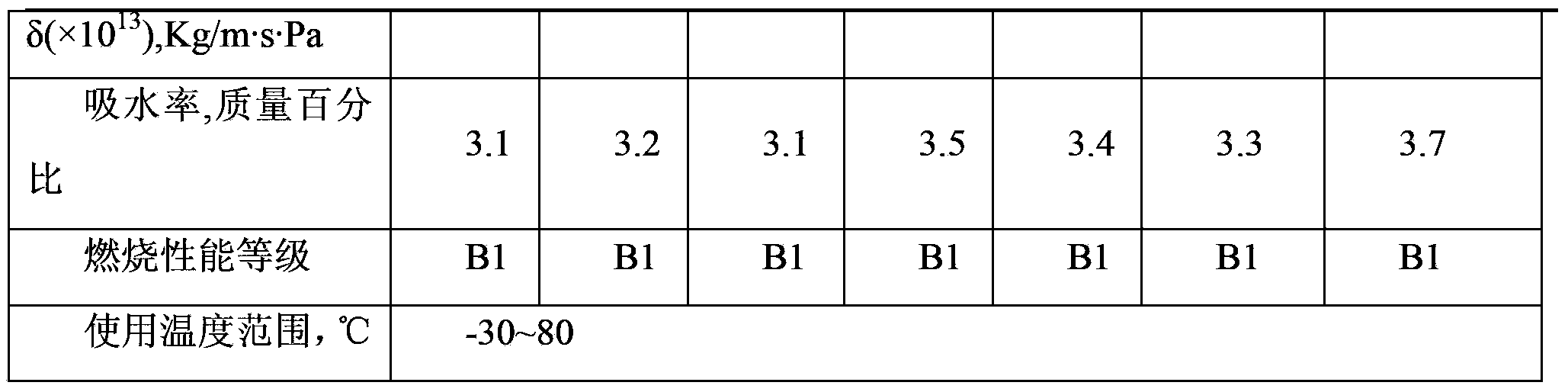

[0025] The insulation materials prepared in Examples 1-7 are represented by 1#-7# respectively.

Embodiment 1

[0026] The composite lubricant in Example 1 is formed by mixing calcium stearate and PE wax with a mass ratio of 1:4, and in Examples 2-7 is formed by mixing calcium stearate and PE wax with a mass ratio of 1:3.

[0027] Table 1 Embodiment 1-6 formula

[0028] material name

1#

2#

3#

4#

5#

6#

7#

[0029] CPE135B / H829 (10 / 90)

100

CPE135B / H829 (50 / 50)

100

CPE135B / H829 (30 / 70)

100

100

100

100

CPE140B / J-700(30 / 70)

100

Composite lead stabilizer TX

6

6

Organotin Stabilizer TM-181

1.5

1.5

1.5

1.5

1.5

compound lubricant

1.5

1.6

2.4

2.4

2.4

2.4

2.4

Plasticizer TCP

50

10

30

30

10

10

Plasticizer Chlorine W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com