Waterproof flame-retardant cable material and preparation method thereof

A technology of flame retardant cable material and flame retardant, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of threatening life and property safety, short service life, poor mechanical properties, etc., and achieve low permeability , smooth appearance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

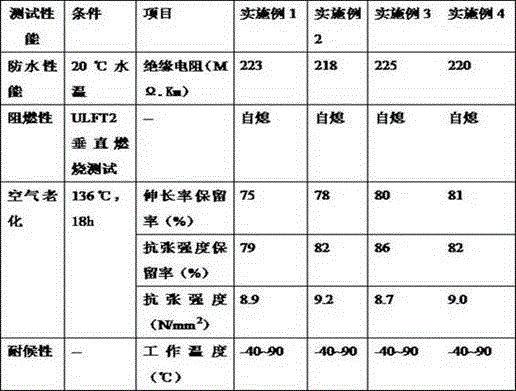

Examples

Embodiment 1

[0024] A waterproof and flame-retardant cable material, which is made of the following raw materials in parts by weight: 30 parts of tetrapropylene fluoride rubber, 40 parts of EPDM rubber, 20 parts of chlorinated polyethylene, 30 parts of ammonium polyphosphate, 10 parts of kaolin, nano 30 parts of carbon black, 1 part of sulfur, 30 parts of flame retardant, 1 part of dilauryl thiodipropionate and 5 parts of polyethylene wax.

[0025] The flame retardant is prepared by mixing the following raw materials in parts by weight: 20 parts of magnesium hydroxide, 10 parts of melamine borate, 10 parts of pentaerythritol and 1 part of nanometer zinc oxide.

[0026] The present invention also provides a preparation method of waterproof and flame-retardant cable material, which consists of the following steps:

[0027] (1) Mix chlorinated polyethylene, kaolin, and nano-carbon black in proportion, and send them to a twin-screw extruder for granulation, and set aside;

[0028] (2) Put tet...

Embodiment 2

[0031] A waterproof and flame-retardant cable material, which is made of the following raw materials in parts by weight: 60 parts of tetrapropylene fluoro rubber, 25 parts of EPDM rubber, 35 parts of chlorinated polyethylene, 10 parts of ammonium polyphosphate, 20 parts of kaolin, nano 20 parts of carbon black, 5 parts of sulfur, 15 parts of flame retardant, 5 parts of tris[2.4-di-tert-butylphenyl] phosphite and 1 part of calcium stearate.

[0032] The flame retardant is prepared by mixing the following raw materials in parts by weight: 10 parts of magnesium hydroxide, 15 parts of melamine borate, 5 parts of pentaerythritol and 5 parts of nanometer zinc oxide.

[0033] The present invention also provides a preparation method of waterproof and flame-retardant cable material, which consists of the following steps:

[0034] (1) Mix chlorinated polyethylene, kaolin, and nano-carbon black in proportion, and send them to a twin-screw extruder for granulation, and set aside;

[0035...

Embodiment 3

[0038] A waterproof and flame-retardant cable material, which is made of the following raw materials in parts by weight: 55 parts of tetrapropylene fluoride rubber, 30 parts of EPDM rubber, 25 parts of chlorinated polyethylene, 20 parts of ammonium polyphosphate, 15 parts of kaolin, nano 25 parts of carbon black, 3 parts of sulfur, 20 parts of flame retardant, 3 parts of dilauryl thiodipropionate and 3 parts of zinc stearate.

[0039] The flame retardant is prepared by mixing the following raw materials in parts by weight: 10 parts of magnesium hydroxide, 15 parts of melamine borate, 5 parts of pentaerythritol and 5 parts of nanometer zinc oxide.

[0040] The present invention also provides a preparation method of waterproof and flame-retardant cable material, which consists of the following steps:

[0041] (1) Mix chlorinated polyethylene, kaolin, and nano-carbon black in proportion, and send them to a twin-screw extruder for granulation, and set aside;

[0042] (2) Put tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com