Patents

Literature

242results about How to "Meet the standard requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

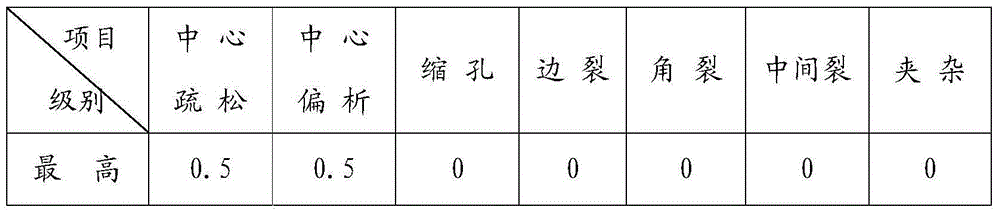

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

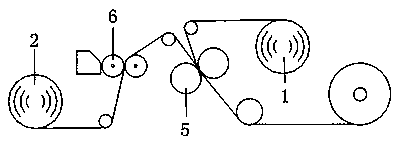

Production method of high-strength steel rope

InactiveCN103352381AMeet the standard requirementsUniform tissueFurnace typesQuenching agentsWater bathsQuenching

The invention provides a production method of a high-strength steel rope. The production method of the high-strength steel rope is characterized that low carbon is selected and used as raw materials of the steel rope, and the production technology comprises a first step of surface processing, wherein wire materials are placed on a pay-off rack, the diameter of the wire materials is 5.5mm, hot-rolled oxide-scale is eliminated through mechanical dephophorization equipment, high-power ultrasonic cleaning is conducted on the wire materials, the wire materials enter phosphating equipment, phosphating is conducted on the wire materials, the wire materials enter drying equipment and are dried finally, and preprocessed wire materials are obtained; a second step of drawing, wherein the preprocessed wire materials obtained from the first step are placed on a drawing machine, multi-pass drawing is conducted on the preprocessed wire materials, semi-finished wire materials are obtained, and winding up is conducted through a spool; a third step of water bath heat treatment and galvanization, wherein the semi-finished wire materials obtained in the second step are placed on the pay-off rack, the semi-finished wire materials are heated in a four-section form heat treatment furnace, quenching, drying, galvanization and cooling are conducted on the semi-finished wire materials, semi-finished wire materials are obtained, and winding up is conducted; a fourth step of wet type drawing, wherein the semi-finished wire materials obtained in the third step are placed on the drawing machine, multi-pass drawing is conducted on the semi-finished wire materials, the compression angle of a wire-drawing die of each pass is 13-14 degrees, dedicated lubricating agent is used as lubricating agent, the concentration of the dedicated lubricating agent is 2%-3%, finished wire materials are obtained, and winding up is conducted through a spool; a fifth step of stranding and rope forming, wherein the finished wire materials are placed on a stranding machine, stranding and laying-up are conducted, and the finished steel stranded rope is obtained.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

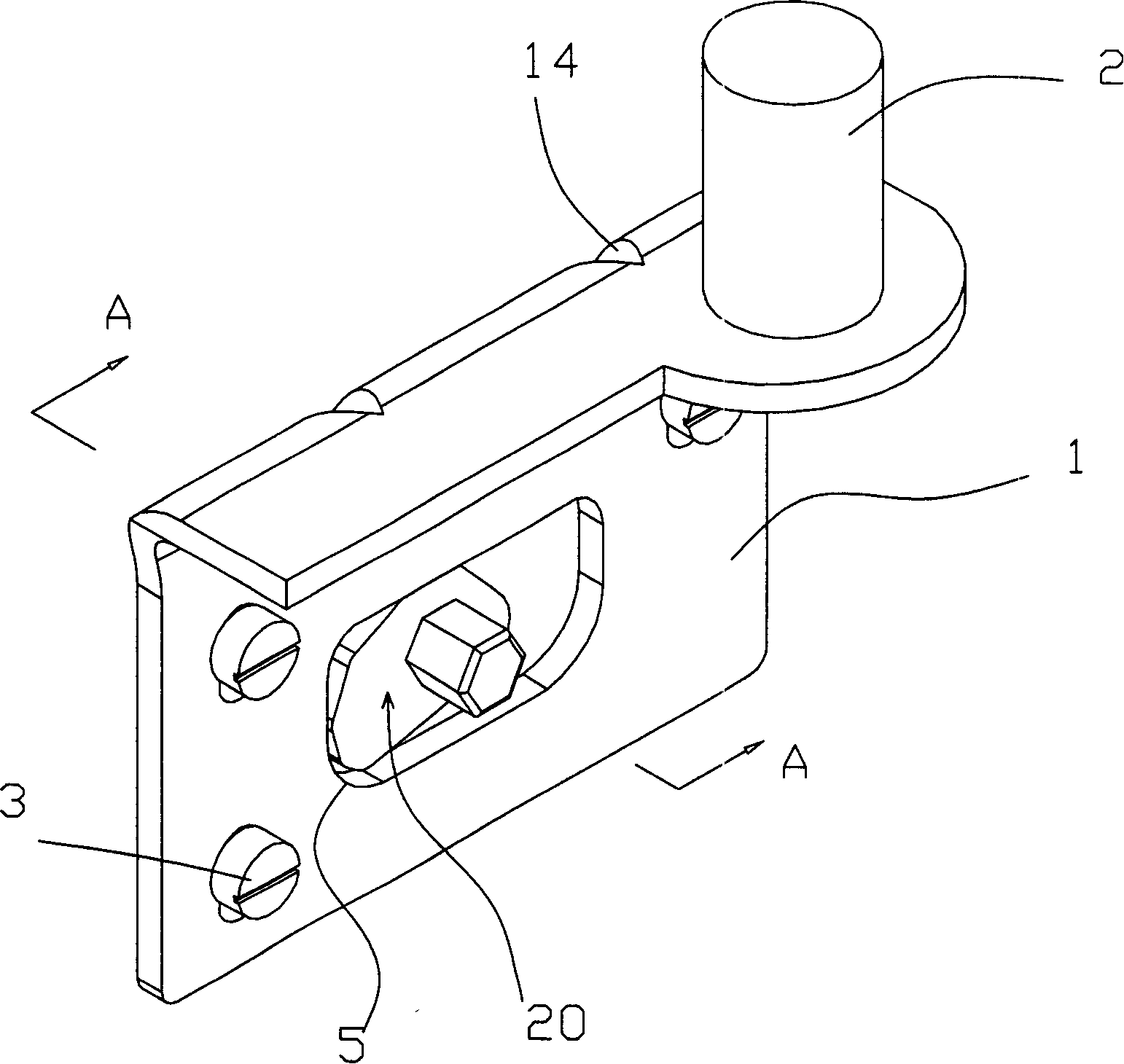

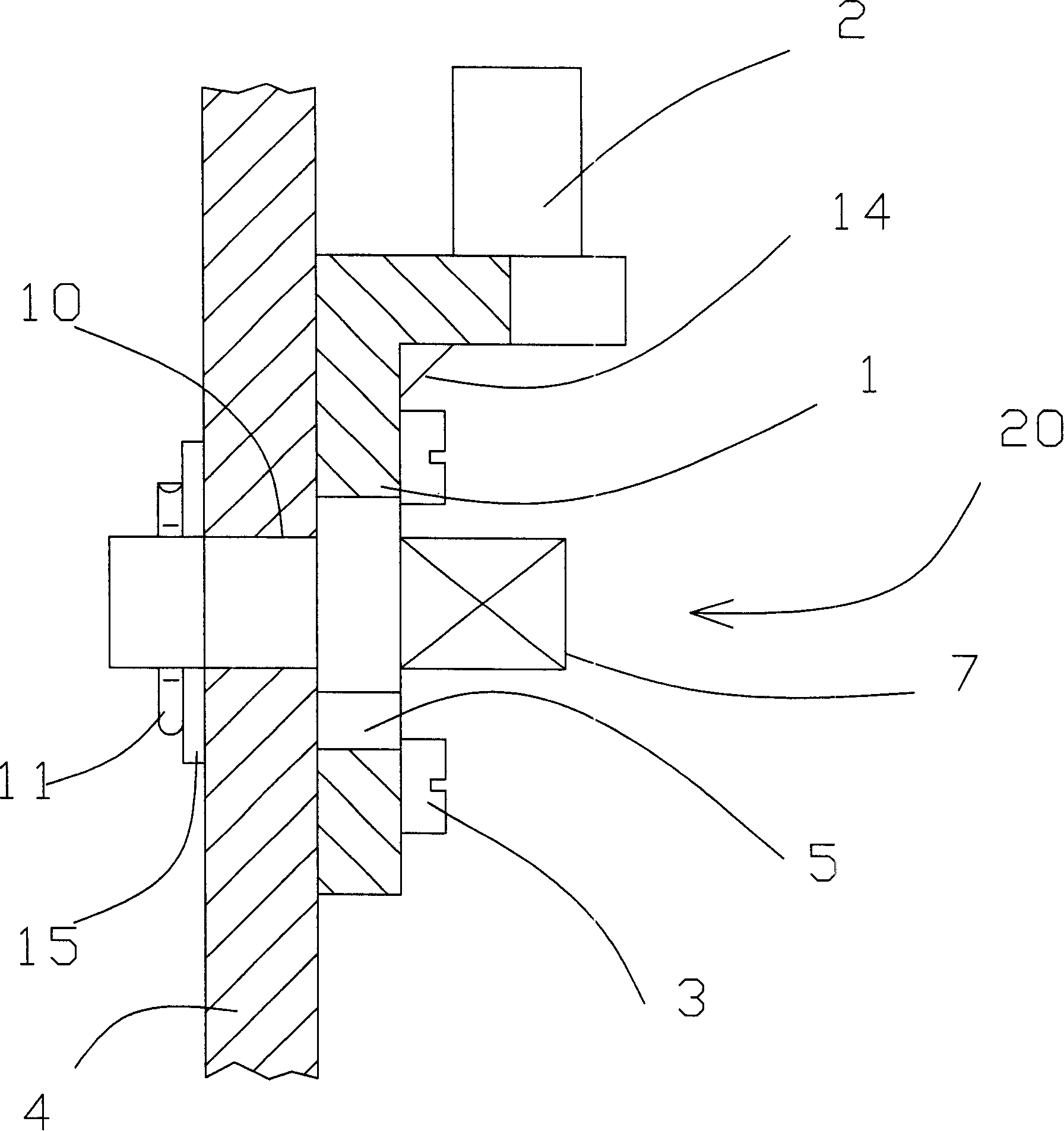

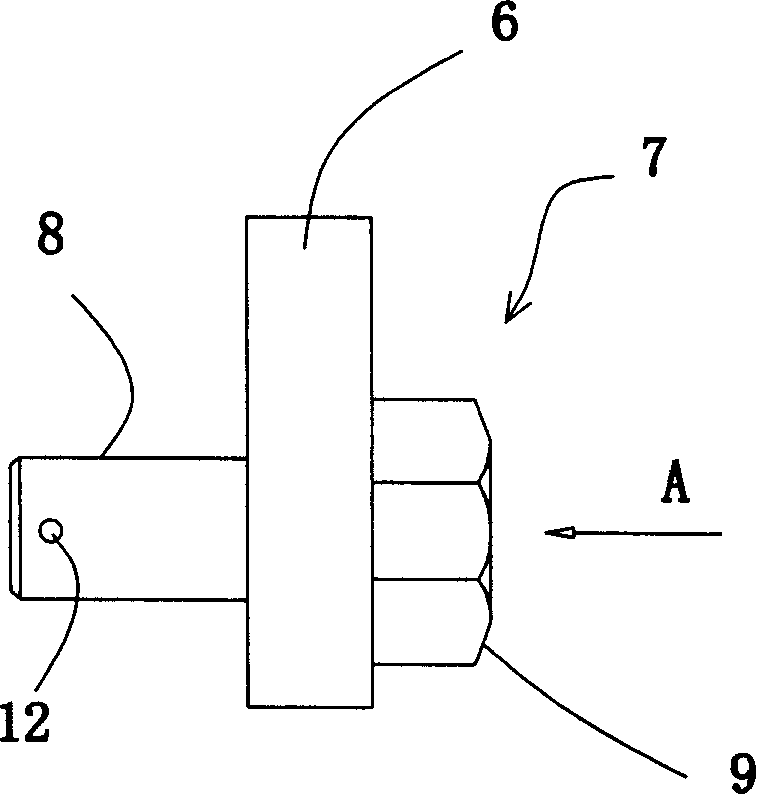

Height adjustable lower hinge used for refrigerator

ActiveCN101191396AMeet the standard requirementsMeet the requirementsDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HAIER GRP CORP +1

GH4169 high-temperature alloy bar and manufacturing method thereof

The invention discloses a GH4169 high-temperature alloy bar. The specification of the bar is phi 200-300 mm, the flaw detection level of the bar is not smaller than phi 1.2-9 dB, and the grain size is at the level 6 to the level 8. The invention further discloses a manufacturing method for the GH4169 high-temperature alloy bar. The method includes the steps that billet forging of the first heating number is carried out on a GH4169 ingot which is subjected to homogenizing heat treatment, and the ingot is subjected to two-upsetting and one-drawing processes; an obtained billet is subjected to reversing upsetting-drawing forging of the second and third heating numbers; drawing-out forging of the fourth and fifth heating numbers is carried out; and then chamfering and rolling forging of the sixth and seventh heating numbers is carried out to obtain the GH4169 high-temperature alloy bar. By means of the manufacturing method, the structure homogeneity of the bar is effectively improved, and the flaw detection level of the bar with the specification being phi 200-300 mm is made to reach more than phi 1.2-9 dB; after the bar is subjected to heat treatment, the macrostructure is uniform, and the grain size reaches the level 6 to the level 8; meanwhile, the performance of the large-specification bar subjected to standard heat treatment can meet corresponding standard requirements.

Owner:西部超导材料科技股份有限公司

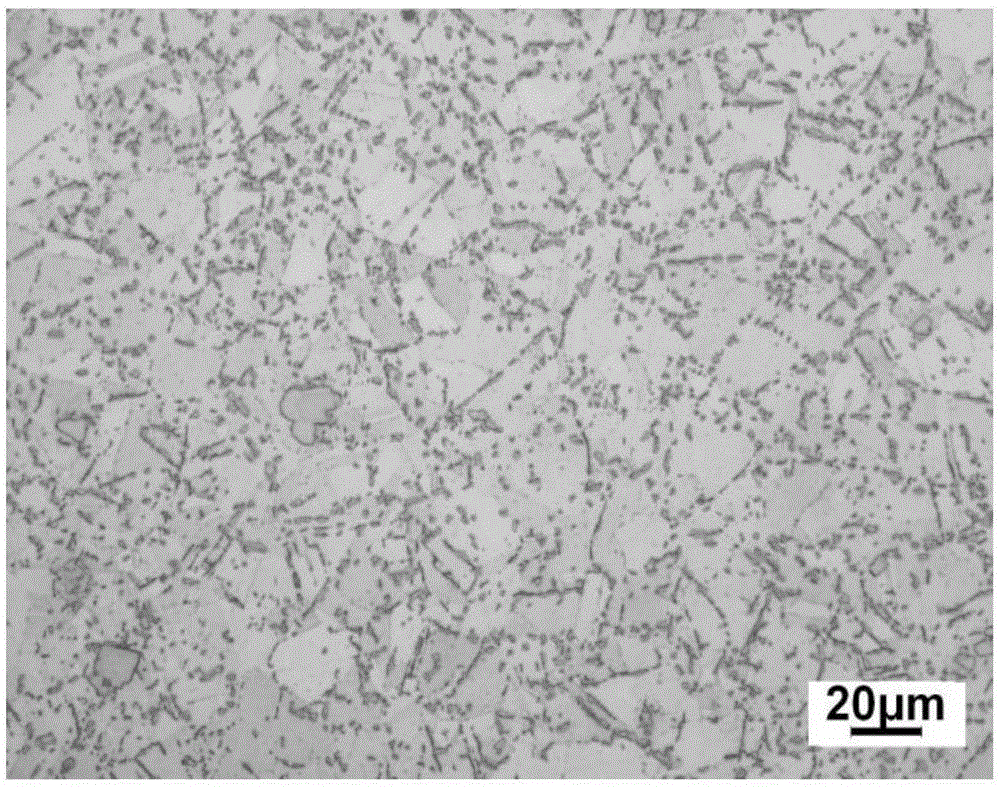

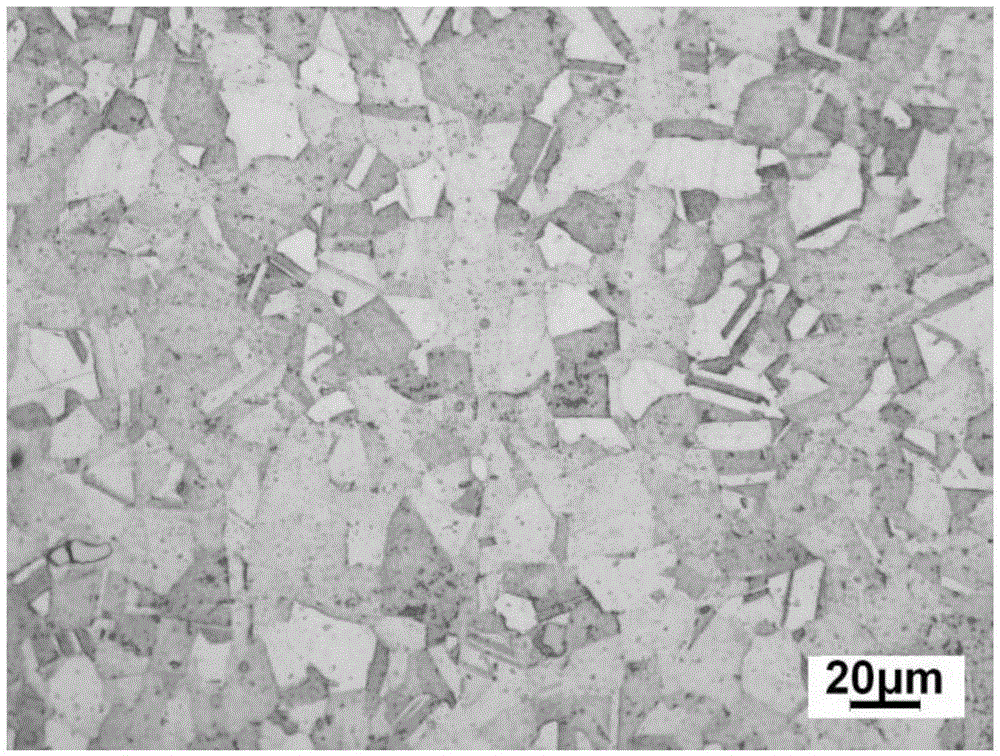

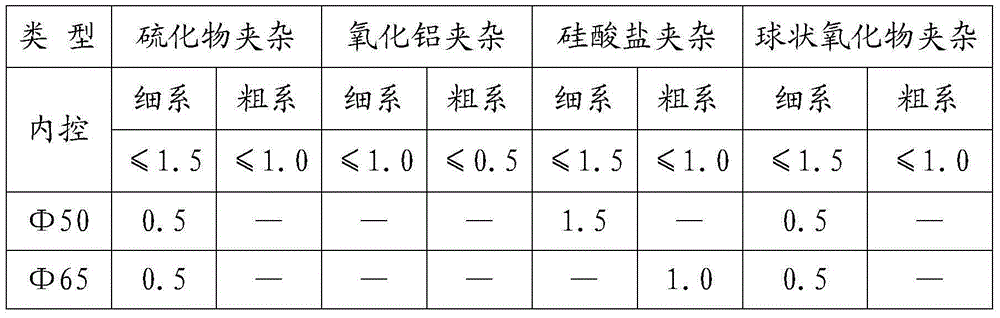

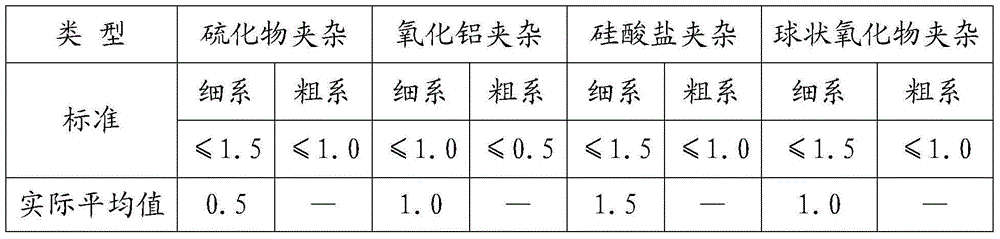

Method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb

InactiveCN105200349AImprove corrosion resistanceReduce hardnessManufacturing convertersProcess efficiency improvementChemical compositionSmelting process

The invention discloses a method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb, wherein the method comprises the following steps: 1) reasonably determining the chemical composition and the inclusion control level of round steel 09CrCuSb; 2) determining the revolving furnace smelting process and N, H and O gas contents; 3) formulating an appropriate continuous casting secondary cooling schedule to make a casting blank keep away from a cracking temperature in a straightening zone, reasonably adopting crystallizer cooling water parameters and vibration negative slip parameters, and controlling casting blank surface cracks; and 4) determining a reasonable heating schedule and a rolling process, choosing low temperature for fast sintering, and reasonably distributing materials, so as to reduce enrichment of Cu elements on the steel surface and avoid the round steel from generating star-shaped cracks; and by controlling the rhythm of steel rolling, avoiding scratches of the round steel surface. By adding alloy elements such as Cr, Cu and Sb, a passivation film is formed on the steel surface; by formulating reasonable smelting, continuous casting and steel rolling processes, the round steel composition is effectively ensured, corrosion resistance can conform to relevant standards and requirements; and through the process, generation of the cracks of the copper-containing steel is avoided.

Owner:TIANJIN IRON & STEEL GRP

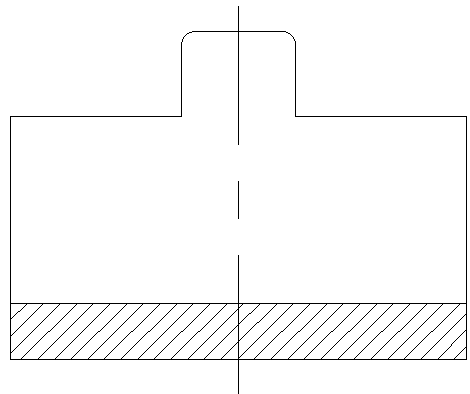

Forging method of valve cover part of valve

ActiveCN102974741AMeet the external dimension requirementsMeet the standard requirementsValve arrangementsMetal-working apparatusEngineeringMachining

The invention relates to the forging technic of valve covers, in particular to a forging method of a valve cover of a valve, and belongs to the field of mechanical processing. Through a way of forging forming, the requirements on boundary dimension of products can be met at one time, a trouble of machining is left out, production efficiency is high, streamlines of the products are smooth, standard requirements on performance are completely met, and appearance is attractive.

Owner:DALIAN DAGAO VALVE

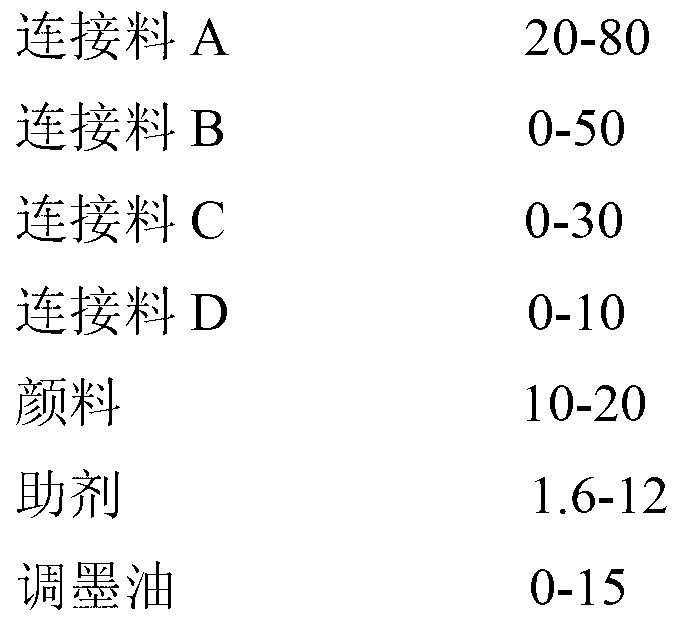

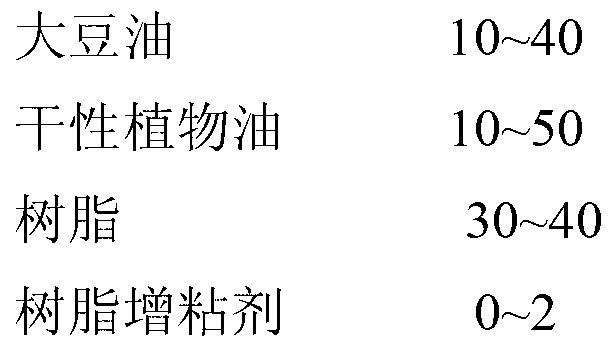

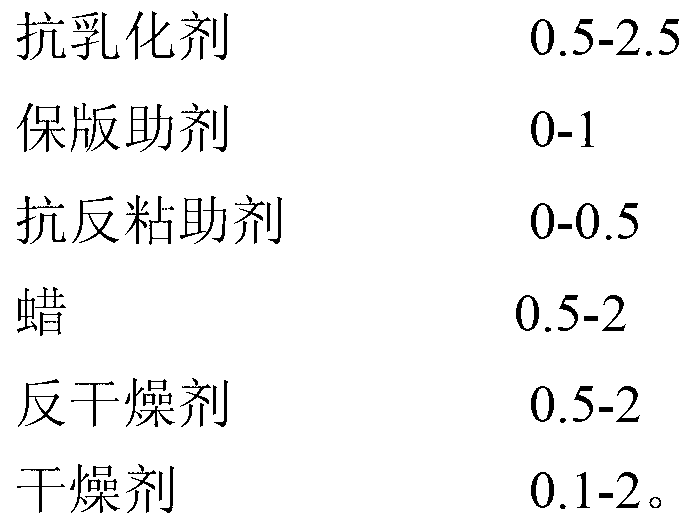

All vegetable oil high-speed planographic printing ink

The invention relates to all vegetable oil high-speed planographic printing ink. The all vegetable oil high-speed planographic printing ink comprises the following components in parts by weight: 20-80 parts of a binder A, 0-50 parts of a binder B, 0-30 parts of a binder C, 0-10 parts of a binder D, 10-20 parts of a pigment, 1.6-12 parts of an auxiliary and 0-15 parts of a vanish, wherein the binder A, the binder B, the binder C and the binder D are respectively composed of soybean oil, dry vegetable oil, resin and / or a resin tackifier. According to the all vegetable oil high-speed planographic printing ink, vegetable oil is used for substituting petroleum base mineral oil in the traditional printing ink, and no petroleum solvent is contained, so that the all vegetable oil high-speed planographic printing ink has excellent environmental protection property; and under middle and high speed printing conditions, the all vegetable oil high-speed planographic printing ink has the advantages of good suitability, high speed, stability on a printing machine and quick drying on a piece of paper and can meet the requirement of a printing company on an increasing printing speed as the modern printing machine is improved.

Owner:XINXIANG WENDE XIANGCHUAN PRINTING INK

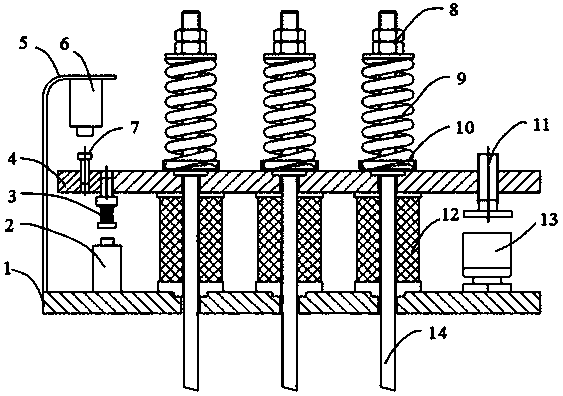

Elevator weighing device

The invention relates to an elevator weighing device which comprises a rope hitch plate and a middle supporting plate. A plurality of rubber drums which are distributed side by side are arranged between the rope hitch plate and the middle supporting plate, a plurality of rope hitch springs corresponding to the rubber drums are arranged at the upper end of the middle supporting plate, an eddy current sensor, an overload detector switch, a rope loosening detector switch support and a rope loosening detector switch are arranged on the rope hitch plate, and an eddy current sensor magnetism blocking plate, an overload detector switch touch plate and a rope loosening detector switch touch plate are installed on the middle supporting plate. The elevator weighing device further comprises a plurality of rope hitch pull rods corresponding to the rubber drums and the rope hitch springs, the rope hitch pull rods sequentially penetrate through through holes of the rope hitch plate, the rubber drums, the middle supporting plate and the rope pitch springs, one end of each rope hitch pull rod is provided with a loosening-fastening nut for fixing the corresponding rope hitch spring, and the other end of each rope hitch pull rod is connected with the corresponding elevator lifting car lateral hauling rope through a connecting assembly. The elevator weighing device is simple in structure, high in lifting car weighing detection accuracy, low in cost, capable of saving shaft space, convenient to install, debug and operate and high in safety performance.

Owner:HITACHI ELEVATOR CHINA

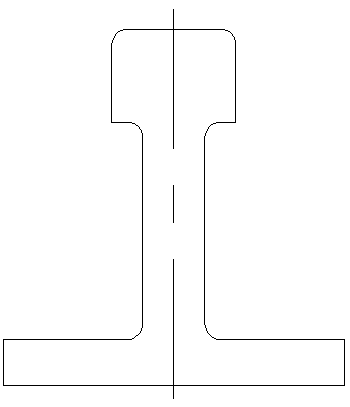

Aluminium alloy material for louvre window and manufacturing method therefor

InactiveCN101182610AImprove performanceImprove reuseVentilation arrangementRoll mill control devicesImpurityAluminium alloy

The invention relates to a blind aluminum alloy and a preparation method hereof; the materials comprise Al, Si, Fe, Cu, Mn, Mg, Zn, Ti and other impurities; the weight percents of the components are as follows that 0.1 percent to 0.6 percent of Si, 0.1 percent to 0.8 percent of Fe, 0.05 percent to 0.25 percent of Cu, 0.8 percent to 1.5 percent of Mn, 0.8 percent to 1.3 percent of Mg, no more than 0.25 percent of Zn, no more than 0.1 percent of Ti, the single weight content of other impurity is not more than 0.05 percent and the total weight content of other impurities is not more than 0.15 percent and the rest is aluminum. The blind aluminum alloy and the preparation method of the invention have the following advantages that the product function is stable and the index meets the standard requirements of the blind aluminum material; the tensile strength and extension rate are comparatively high and the board shape and the quality of the board surface are good; the processing is comparatively easy and the cost is low; moreover, the recovery rate of the scrap is high.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

Spectrum standard sample for detecting coin-manufacturing non-corrosive steel and its manufacture method

InactiveCN101149333ALow costGood uniformityPreparing sample for investigationColor/spectral properties measurementsFerrosiliconStandard samples

The invention relates to a kind of stainless steel spectrum standard sample, especially the spectrum standard sample used to detect the coinage stainless steel and the manufacturing method. It computes the each material additive quantity according to the formula based on the impurity element C, Si, Mn, P, S and additive element B, Ni, Cu, Cr; Fe is the base material. The material is added into the vacuum induction smelting furnace to cast. When the material is smelted to 95%, the sample is analyzed; then it adjust the steel liquid chemical component according to the analyzing result; it adjusts the Si content using the ferrosilicium when 7-10min before tapping; the ferroboron is pre-added into the steel ingot mould; after each element meeting the request, it controls the tapping temperature: 1520-1540deg.C, the steel liquid is poured into the steel ingot mould, after cooling, the sample number is printing on. The spectrum standard has the good uniformity, wide compound content and many element kinds; the process is advance and the value is accurate; the content grads are in reason. So it is better than the other same sample in analyzing the coinage stainless material.

Owner:CHINA BANKNOTE PRINTING & MINTING

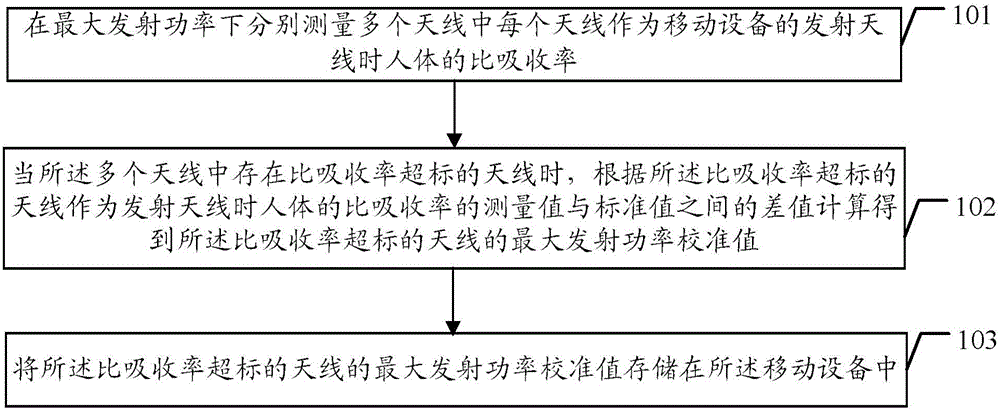

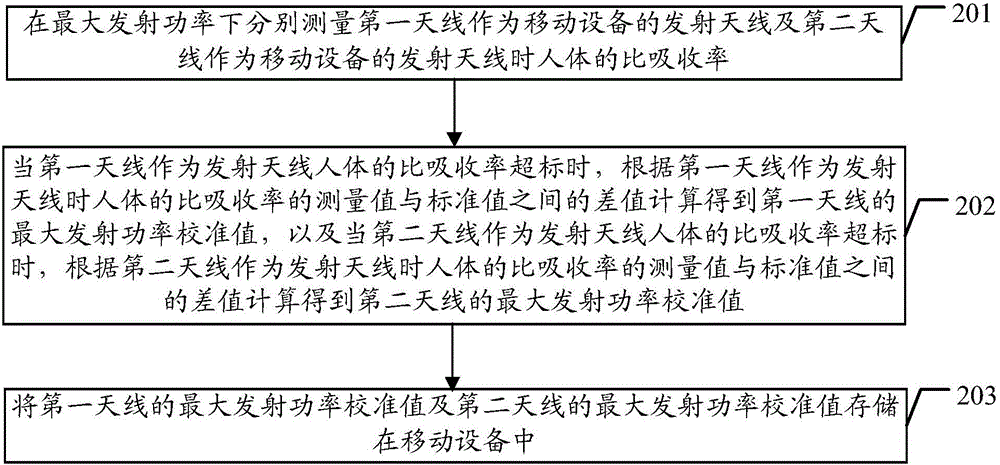

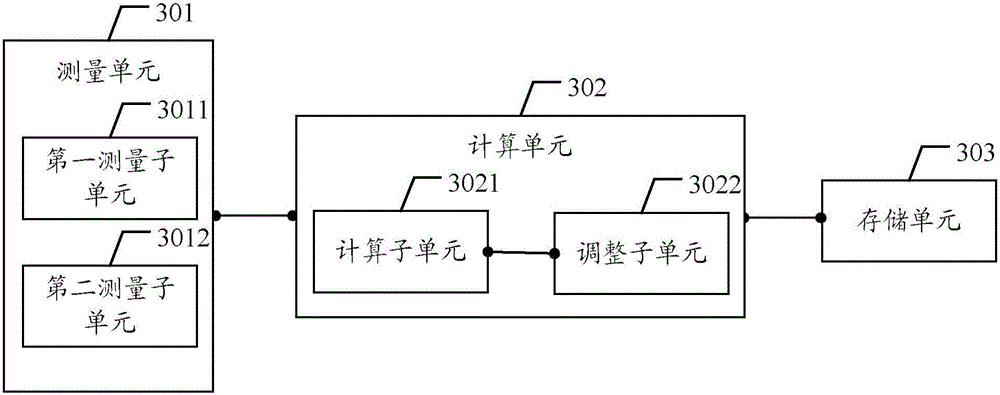

Method and device for preventing specific absorption rate from being beyond standard, and mobile equipment

ActiveCN105978635AImprove experienceMeet the SAR standard requirementsTransmitters monitoringPower managementTransmitted powerMobile device

Embodiments of the invention disclose a method and a device for preventing the specific absorption rate from being beyond the standard, and a piece of mobile equipment. The method comprises the following steps: measuring the specific absorption rate of the human body when each of multiple antennas is used as the transmitting antenna of mobile equipment under maximum transmitted power; when there is an antenna making the specific absorption rate beyond the standard in the multiple antennas, calculating the calibrated value of maximum transmitted power of the antenna making the specific absorption rate beyond the standard according to the difference between the measured value of specific absorption rate of the human body when the antenna making the specific absorption rate beyond the standard is used as the transmitting antenna and a standard value; and storing the calibrated value of maximum transmitted power of the antenna making the specific absorption rate beyond the standard in the mobile equipment. According to the embodiments of the invention, the requirements of the SAR standard are satisfied, and the user experience is enhanced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

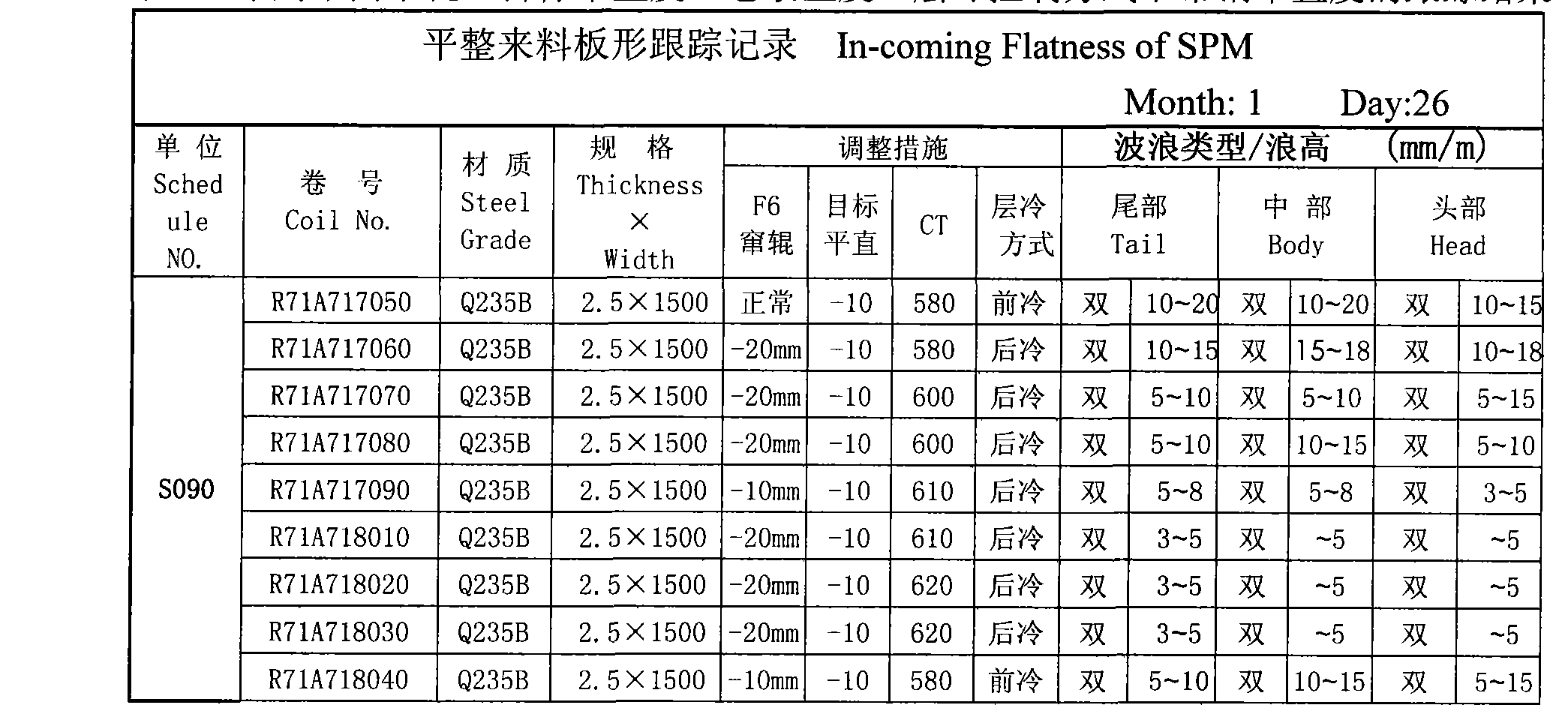

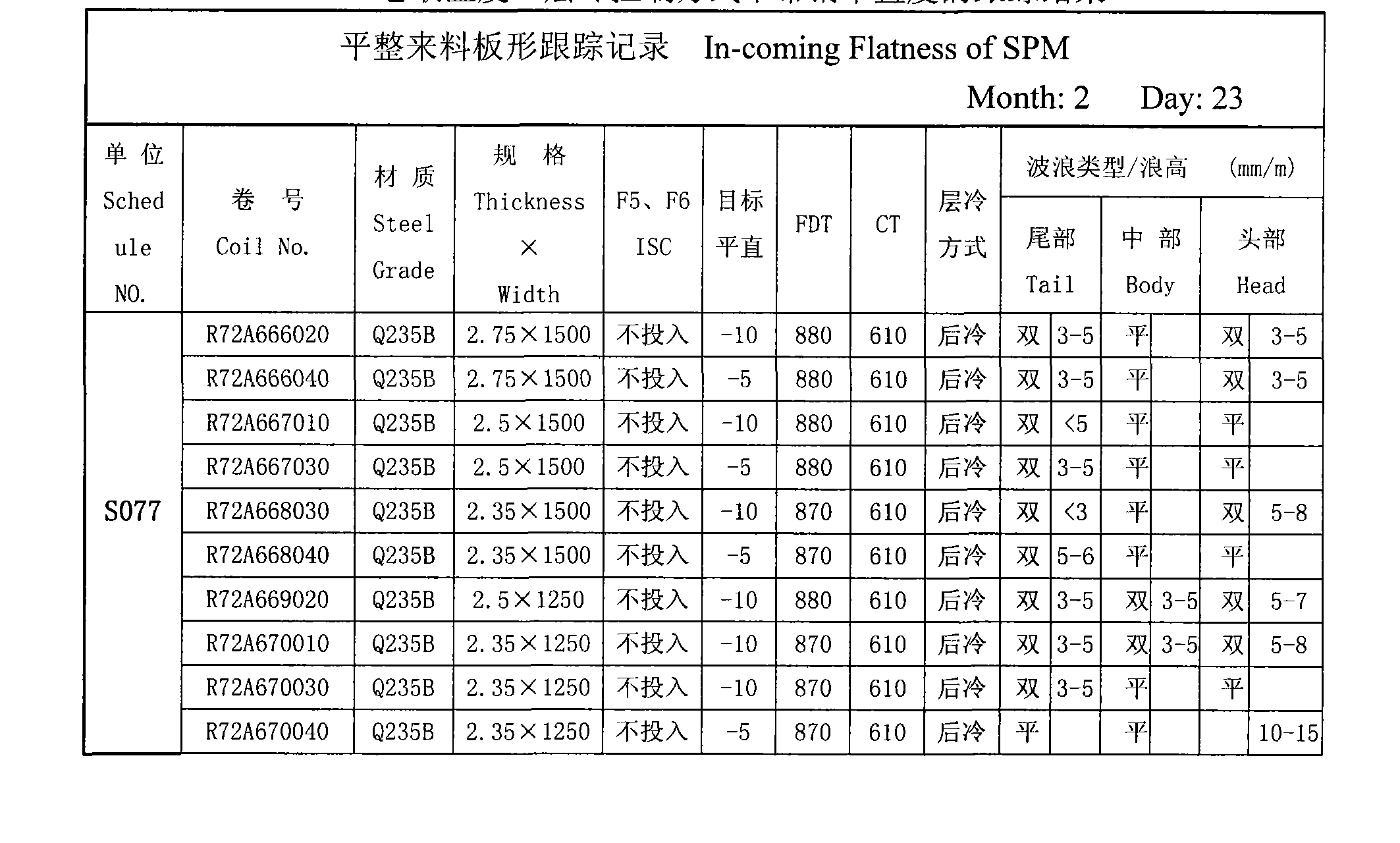

Diversified cross-connection control method for plate shape of hot rolling band steel

InactiveCN101372018AEasy to controlMeet the standard requirementsProfile control deviceProduction lineThermal state

A hot rolling bandprofil pluralism intersect control method is suitable for controlling the shape of strip in the hot rolling band steel production line. The purpose is to improve the potential shape of the hot rolling band steel and increase the product quality; the method aims at the hot rolling band steel production line of a fining mill set which is provided with seven rolling mills (F1-F7), firstly, the rolling loading and the bowed roll force dynamic control are adjusted; the thermal state target alignment controlling value is modified; micro-waves are used for rolling; the alignment target reference value is 0 I-unit; the target alignment -5 I-unit- -10 I-unit is taken; laminated cooling CTC adopts aftercooling mode; the heat stress of the band steel generated in a run out table ROT is reduced; the reeling target temperature CT is mended within 600 DEG C-650 DEG C; the working roll of the sixth rolling mill (F6) of the fining mill set shifts rolls for compensation; the use of cooling water among the rolling mills is optimized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

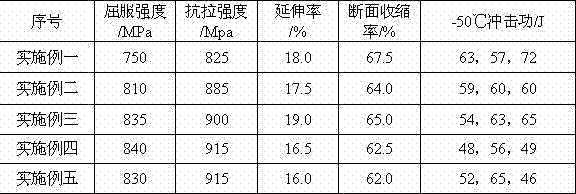

Copper-containing high-strength high-toughness welding rod deposited metal

InactiveCN102728966ASimple welding processMeet the standard requirementsWelding/cutting media/materialsSoldering mediaChemical compositionShrinkage rate

The invention discloses a copper-containing high-strength high-toughness welding rod deposited metal. The deposited metal belongs to a Mn-Ni-Cr-Cu system which comprises the following chemical components in percentage by weight: C (0.030 / 0.080), Mn (0.60 / 0.90), Si (0.15 / 0.35), Ni( 2.20 / 2.85), Cr (0.62 / 1.00), Mo (0.40 / 0.60), Cu (0.70 / 1.10) and Fe (the balance). Compared with other high-strength hand-made welding rods, the metal provided by the invention contains a proper amount of C, a proper amount of Ni, and a higher amount of Cu. The deposited metal disclosed by the invention is used for welding 10CrNi5MoV steel, the welding process is good, the yield strength of the deposited metal is above 735Mpa, the elongation coefficient is over 16 percent, the cross section shrinkage rate is greater than 50 percent, and the low-temperature impact at -50 DEG C is over 34J and the deposited metal meets related standards.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Digital printing process for polyester-cotton fabric

InactiveCN107090724ASolve contaminationColorfulDry-cleaning apparatus for textilesGrip property fibresCooking & bakingDisperse dye

The invention relates to a digital printing process for a polyester-cotton fabric. The digital printing process comprises the following process steps: (1) sizing a polyester-cotton fabric; (2) digital printing: carrying out spray printing according to a pattern requirement of rip printing software, generating cyan by virtue of color card generation software (C:100, M:100, Y:100 and K:100), and carrying out unreeling and sequential digital printing on the fabric reeled in the step (1), wherein a printer comprises a first spray head and a second spray head, the first spray head is used for spraying and printing disperse dye ink, the second spray head is used for spraying and printing active dye ink, and a printing condition is that bidirectional four channels are adopted; (3) high-temperature baking: baking the digital-printed fabric in the step (2) at 180-190 DEG C for 40-50 seconds; (4) cotton-cloth steaming; (5) a washing and soaping process: carrying out open-width washing on the fabric processed in the step (4); and (6) shaping and drying: adding a softening agent and a color fixation agent into the fabric processed in the step (5) for shaping, and drying at a temperature of 150-160 DEG C, wherein the speed of a drying vehicle is 40m / min-50m / min.

Owner:杭州科迈数码纺织技术有限公司

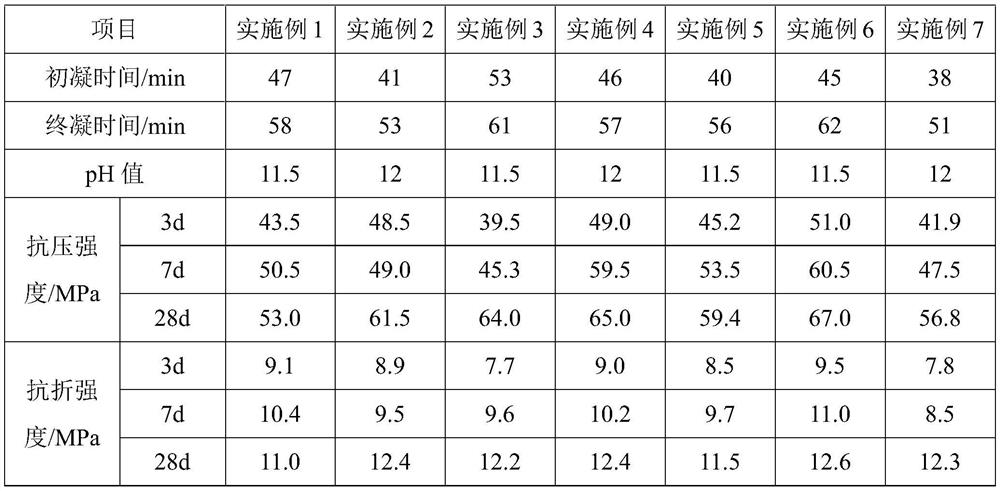

Method for producing high-iron sulphoaluminate cement by using red mud and aluminum ash

The invention relates to the technical field of special cement, in particular to a method for producing high-iron sulphoaluminate cement by utilizing red mud and aluminum ash. The method for producingthe high-iron sulphoaluminate cement by utilizing the red mud and the aluminum ash comprises the following steps: mixing carbide slag and waste sulfuric acid, reacting, and drying to obtain calcium sulfate-containing waste residues; mixing red mud, secondary aluminum ash, waste cathode carbon blocks, calcium sulfate-containing waste residues and / or waste gypsum, adopting limestone as a correctionmaterial, grinding and drying to obtain a cement raw material, and calcining the cement raw material to obtain cement clinker; mixing the modified red mud and the waste gypsum to obtain a mixture A;mixing the modified red mud, waste gypsum and limestone to obtain a mixture B; and mixing the cement clinker with the mixture A or the mixture B, and grinding to obtain the high-iron sulphoaluminate cement. Waste sulfuric acid is treated and utilized while industrial solid waste is utilized, and the produced high-iron sulphoaluminate cement is high in strength, free of heavy metal dissolution andlow in cost.

Owner:淄博海慧工程设计咨询有限公司

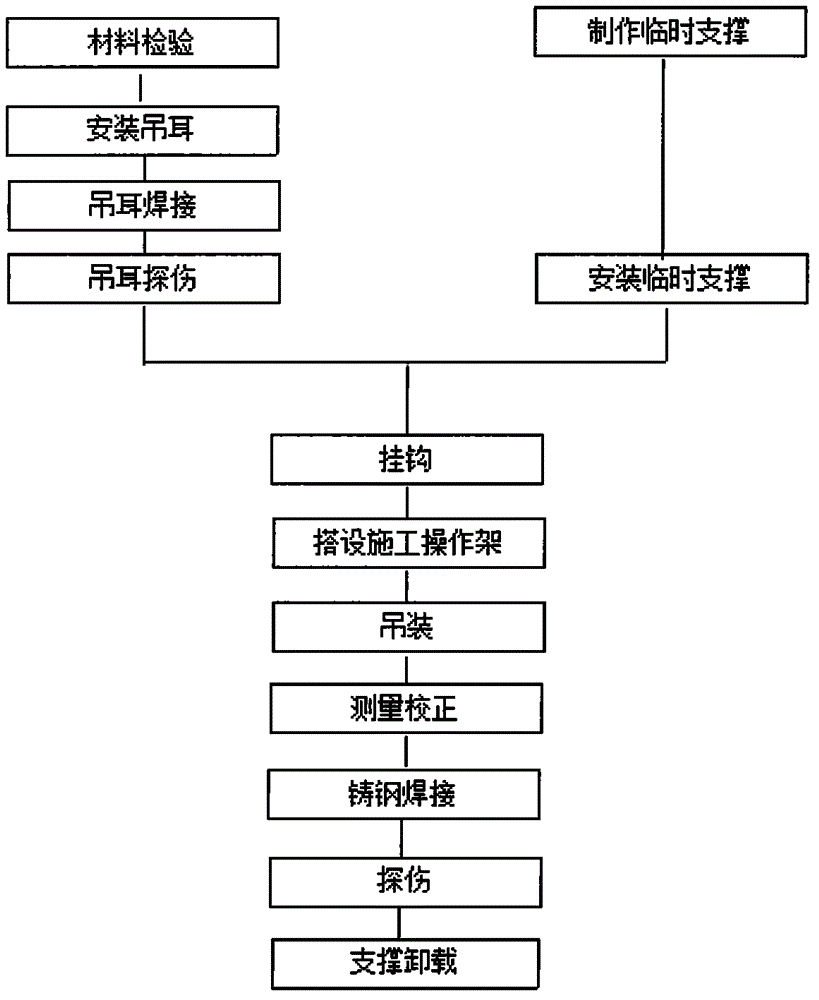

Method for installing and constructing special-shaped large-tonnage steel castings

InactiveCN104631837AGuarantee the construction qualityThe connection is reasonable and validWelding/cutting auxillary devicesAuxillary welding devicesVertical displacementWelding joint

The invention discloses a method for installing and constructing special-shaped large-tonnage steel castings. The large-tonnage steel castings are complex in shape and are hoisted through a heavy crawler crane. Before the steel castings are hoisted, a symmetric method is adopted to analyze and determine the installing positions of lifting lugs of the steel castings, and a welding work platform is arranged on the welding portions of the steel castings in advance. In the installing and constructing process, a sling of the crawler crane is used for controlling the vertical displacement of the steel castings, a wind cable is used for adjusting the horizontal displacement of the steel castings, and the installation accuracy and construction safety of the steel castings are guaranteed by means of temporary support and other measures; after the steel castings are installed in place, the quality of weld joints is guaranteed through a series of processes such as weld preheating, in-process heat preservation and postweld heat treatment according to the material characteristics of the steel castings and up-down welding structures. By means of the method, the standard requirements for joints of the special-shaped large-tonnage steel castings are met, the construction quality is ensured, connection is more reasonable and effective, the consumption of steel is reduced, and meanwhile the appearance quality of a building is improved.

Owner:YONGSHENG CONSTR GRP +1

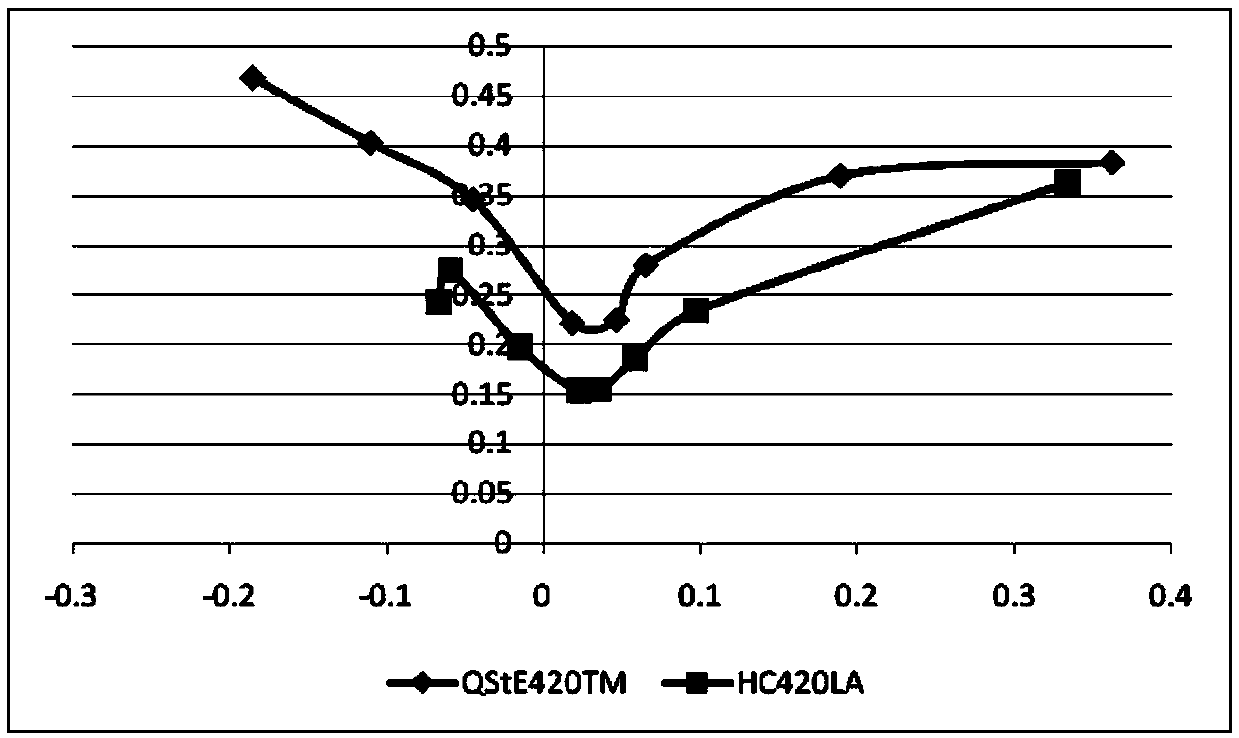

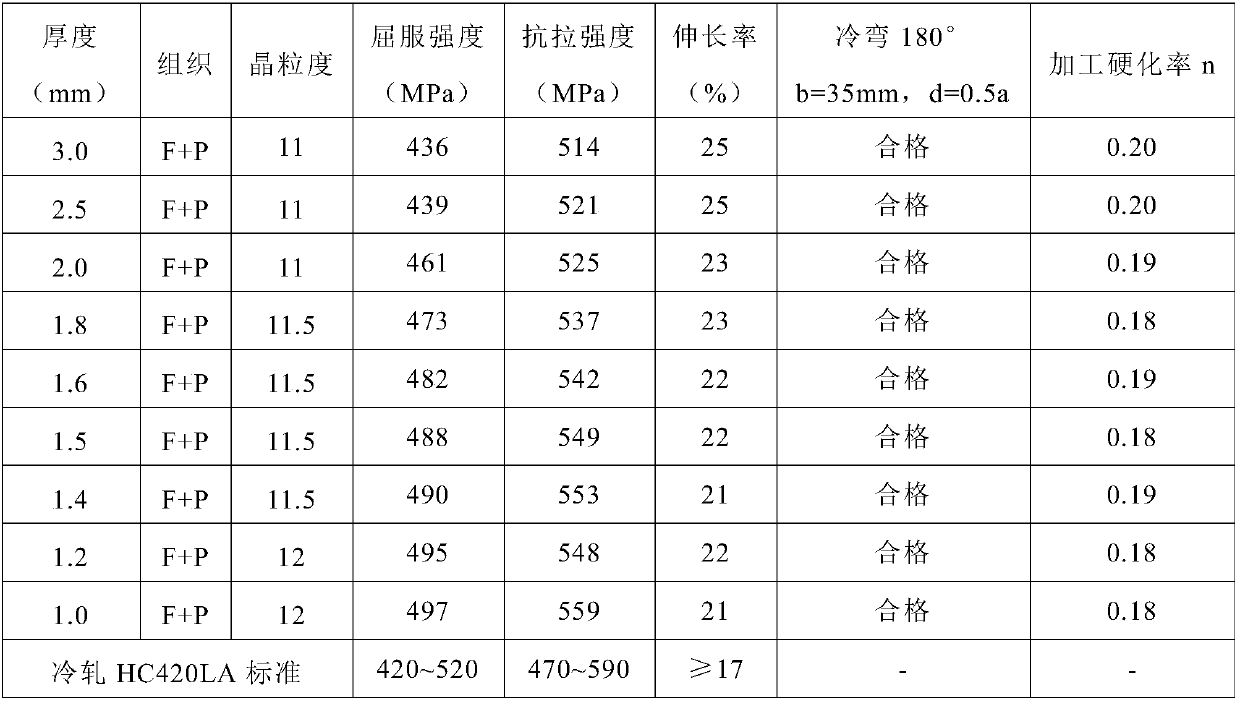

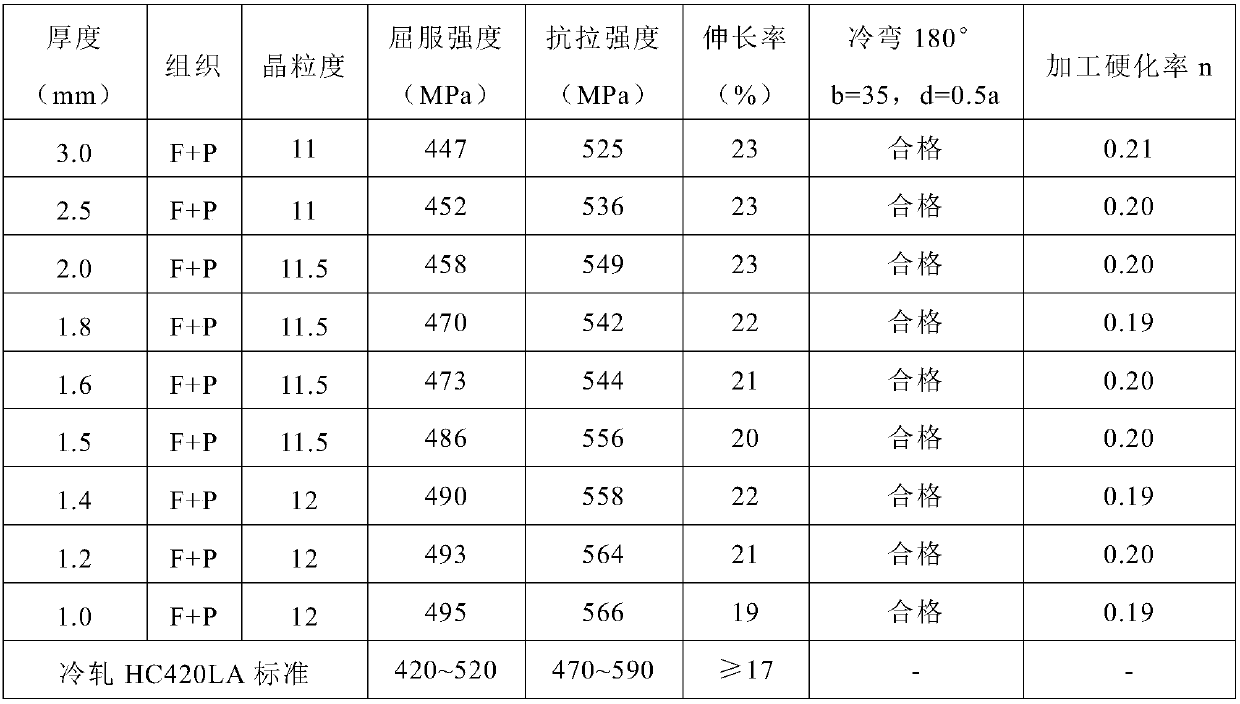

Hot-rolled automobile structural steel plate with yield strength of 420MPa and excellent cold-forming performance and manufacturing method

The invention discloses a hot-rolled automobile structural steel plate with the yield strength of 420MPa and excellent cold-forming performance and a manufacturing method. The hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance comprises, by weight, 0.03-0.06% of carbon, 0.7-0.9% of manganese, 0.020-0.030% of niobium, 0.020-0.030% of titanium, less than 0.10% of silicon, no more than 0.005% of sulfur, no more than 0.015% of phosphorus, no more than 40 ppm of nitrogen, 0.025-0.050% of acid soluble aluminum, and the balance iron and inevitable impurities. According to the hot-rolled automobile structural steel plate with the yield strength of 420MPa and the excellent cold-forming performance and the manufacturing method, the Nb-Ti microalloying technique is adopted for a short process, S and N (S<=0.005%, and N<=40 ppa) in steel are fixed through a trace of Ti, the grain refining effect of Nb is brought into full playto obtain a fine F+P structure, and thus the cold-forming performance of the steel is improved while high strength is obtained.

Owner:武汉钢铁有限公司

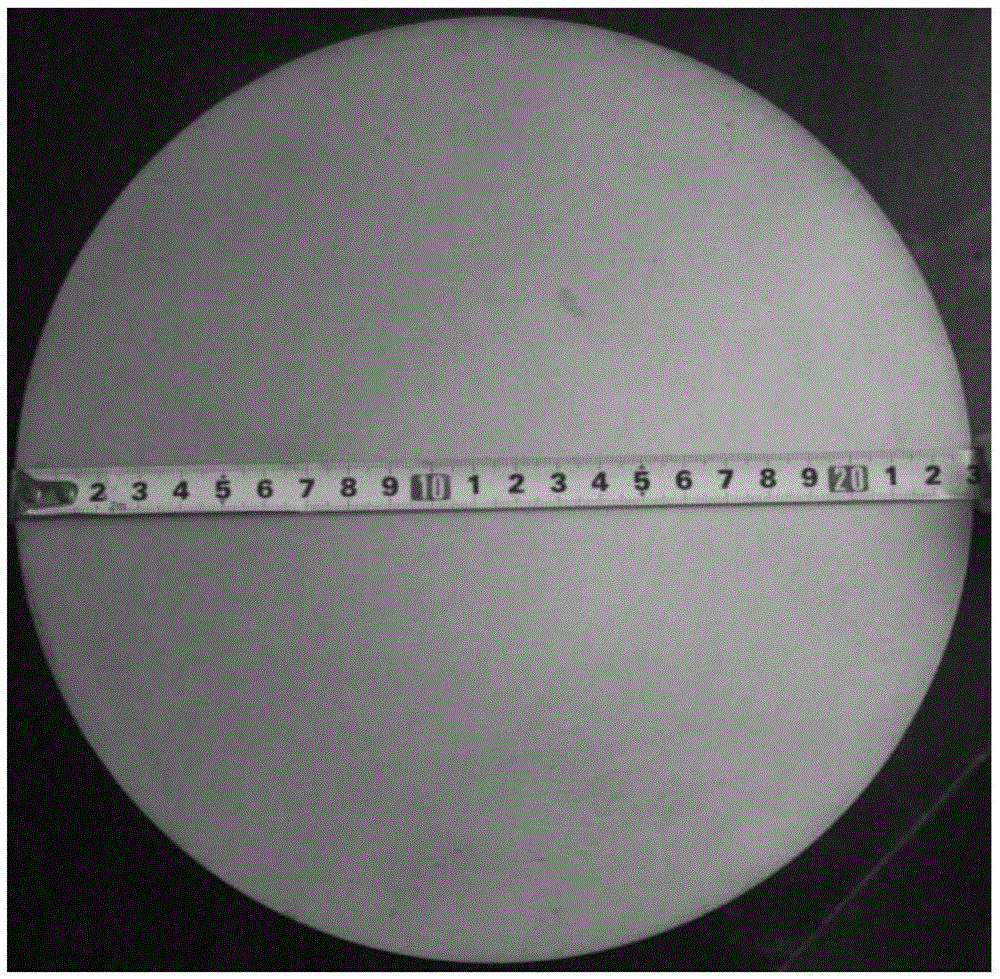

Method for utilizing waste HDPE plastic to prepare large-caliber double-wall bellow

InactiveCN101549535AHigh mechanical strengthIncreased ring stiffnessPlastic recyclingElastomerDouble wall

The invention discloses a method for utilizing waste HDPE plastic to prepare a large-caliber double-wall bellow, essentially comprising the following steps of: using waste high-density polyethylene (HDPE) to prepare a double-wall bellow with the caliber of 1200mm; carrying out cooperative combination to strip, fibrous and spherical fillers; adopting novel elastomer as basic resin; preparing modified master batch which has functions of reinforcing and toughening to the waste HDPE; and using the functional master batch to carry out modification to the waste HDPE so as to lead the mechanical performance thereof to reach the level of new resin of HDPE; and an extrusion mould of the large-caliber double-wall bellow adopts arc structure at peak part, thus improving the ring stiffness of the product and leading the product parameters to meet standard requirements.

Owner:江苏和远电力科技有限公司

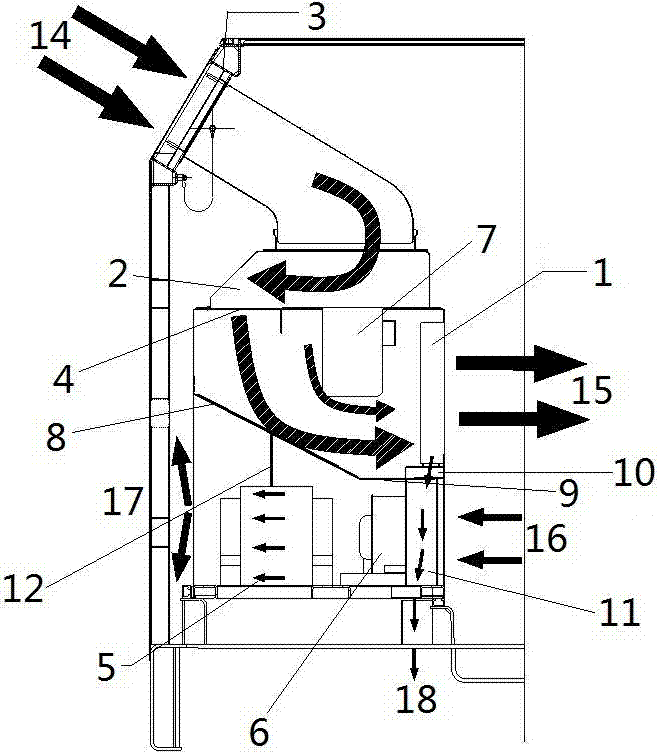

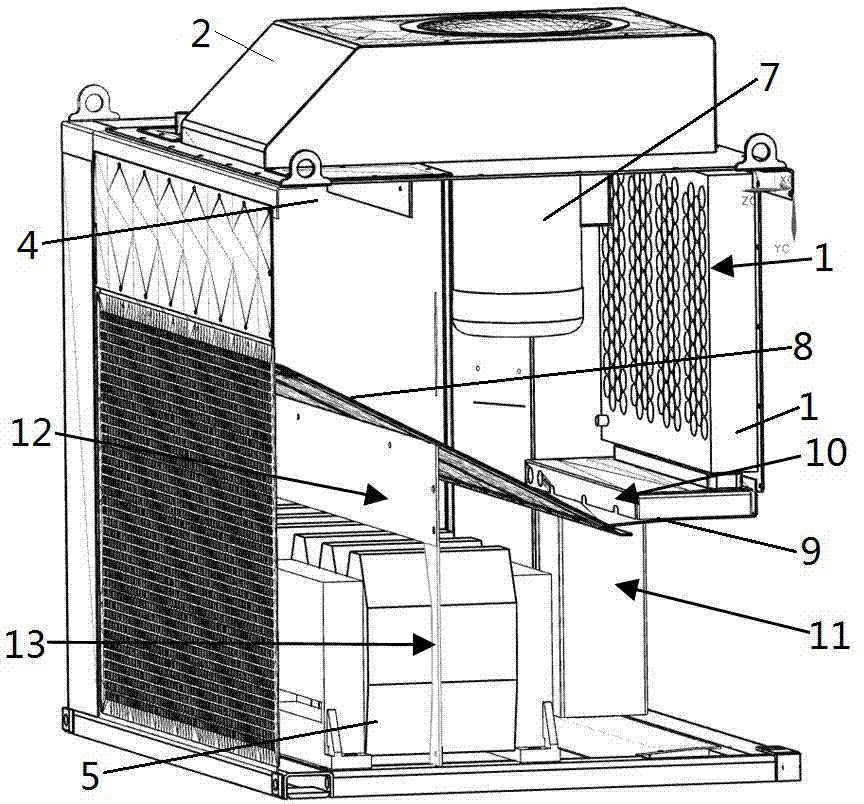

Double-circulation ventilation cabinet of auxiliary transformer for locomotive

InactiveCN104228852AImprove filtering effectEliminate vortexLocomotivesTransformerWorking environment

The invention discloses a double-circulation ventilation cabinet of an auxiliary transformer for a locomotive. The double-circulation ventilation cabinet comprises a cabinet body, a cabinet top fan and the transformer, and further comprises a clapboard structure, a cyclone dust remover, a dust removal box, a dust exhaust air duct and a heat dissipation fan of the auxiliary transformer, wherein the clapboard structure comprises an inclined plate, a horizontal plate and a vertical plate; one end of the inclined plate is connected with the interior of the cabinet body, and the other end of the inclined plate is connected with one end of the horizontal plate; the angle formed by the inclined plate and the horizontal plate is 130-160 degrees; the other end of the horizontal plate is connected with the dust removal box; one end of the vertical plate is connected with the inclined plate, and the other end of the vertical plate clings to the transformer; the cyclone dust remover and the heat dissipation fan of the auxiliary transformer are arranged at the inner side of the cabinet body; the cyclone dust remover and the dust removal box are both communicated with the dust exhaust air duct. The double-circulation ventilation cabinet disclosed by the invention greatly improves the working environment of the auxiliary transformer, and thoroughly solves the grounding faults of the auxiliary transformer, due to water inlet and dust inlet.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

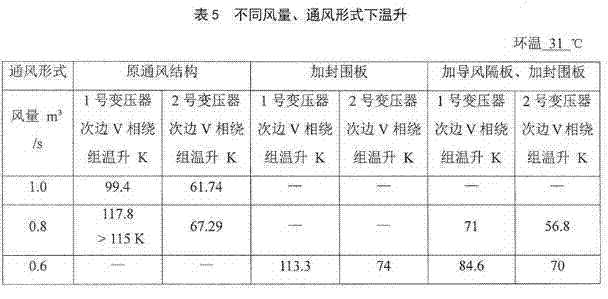

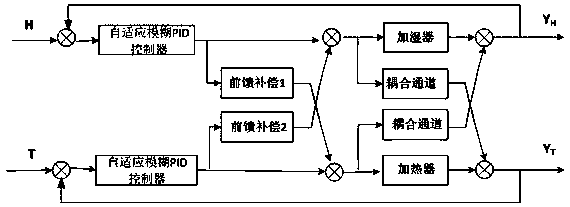

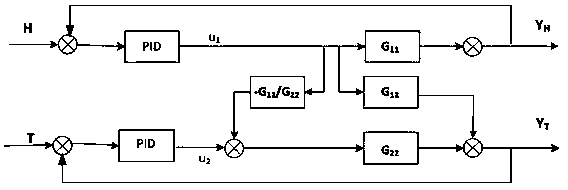

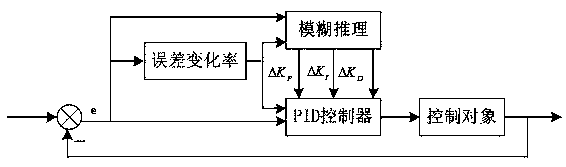

Enthalpy difference temperature and humidity decoupling control method based on adaptive fuzzy PID decoupling control

InactiveCN109283958AAchieve decouplingVerify simplicity and practicalitySimultaneous control of multiple variablesDecoupling controllerModel parameters

The invention relates to an enthalpy difference temperature and humidity decoupling control method based on adaptive fuzzy PID decoupling control. The method comprises the following steps: (1) determining a model of a temperature and humidity coupling object in an enthalpy difference lab system, and using an identification model parameter; (2) performing enthalpy difference lab temperature and humidity decoupling design; (3) designing an adaptive fuzzy PID controller; and (4) designing an enthalpy difference lab temperature and humidity decoupling controller. The method can realize the complete decoupling of the temperature and humidity of the enthalpy difference lab, and further proves the simple practicability of the feedforward compensation algorithm, can shorten the adjustment time ofthe system, meets the requirements of national standards, and improves the working efficiency of the enthalpy difference lab. The method can improve the stability of the system and reduce the steady-state errors, so that the average variation range of the dry bulb temperature is less than or equal to + / -0.3 DEG C, and the average variation range of the wet bulb temperature is less than or equal to+ / -0.2 DEG C. The temperature and humidity adjustment accuracy of the enthalpy difference lab can be improved.

Owner:UNIV OF JINAN

Cold-rolled non-oriented electrical steel 35WD1900 and production method thereof

ActiveCN109825775AEasy to controlStable productionRoll force/gap control deviceTemperature control deviceElectrical steelSheet steel

The invention discloses a cold-rolled non-oriented electrical steel 35WD1900 and a production method thereof. The cold-rolled non-oriented electrical steel 35WD1900 comprises the following chemical components by weight: <= 0.005% of C, 2.0-2.5% of Si, 0.2-0.4% of Mn, 0.08-0.12% of P, <= 0.008% of S, 0.3-0.5% of Al, 0.004-0.006% of B and the balance of Fe and unavoidable impurities. The productionmethod includes the following steps: (1) a steel plate is subjected to continuous casting to form a continuously-cast billet, which is heated in a heating furnace after being cooled, and then subjected to hot rolling; (2) the hot-rolled billet is subjected to acid pickling, first cold rolling, decarburizing annealing and second cold rolling; and (3) after being subjected to the second cold rolling, the electrical steel is subjected to secondary annealing and coating to obtain the product. The performance of the cold-rolled non-oriented electrical steel 35WD1900 of the invention can meet the requirements of the high-strength non-oriented electrical steel used in the drive motors of new energy automobiles; and the welding performance and the stamping performance are good.

Owner:GUANGDONG ZHONGSHENG ELECTROMAGNETIC TECH CO LTD

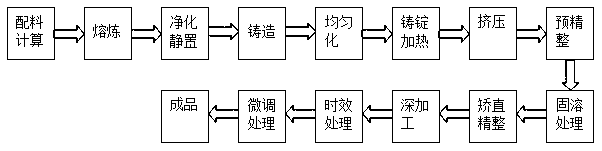

Aluminum alloy variable section extruded profile for spaceflight and preparation method of aluminum alloy variable section extruded profile

The invention discloses an aluminum alloy variable section extruded profile for spaceflight and a preparation method of the aluminum alloy variable section extruded profile. The profile consists of the following elements of, in percentage by weight, 5.0%-6.0% of Zn, 1.0%-2.0% of Cu, 0.04%-0.1% of Mn, 2.0%-3.0% of Mg, 0.15%-0.25% of Cr, 0.35%-0.42% of Fe, less than or equal to 0.25% of Si, and thebalance Al. During preparation, a finished product is obtained after being subjected to smelting, purifying, standing, casting, homogenizing treatment, ingot heating, extrusion, pre-finishing, solution treatment, straightening finishing, deep machining, aging treatment and fine adjustment treatment. According to the method, by setting specific alloy composition and the preparation process, the aluminum alloy variable section extruded profile formed by once is obtained, the strength, fatigue resistance, corrosion resistance and stress corrosion resistance of the aluminum alloy profile are greatly improved, comprehensive performance requirements of a carrier rocket launcher on the variable section aluminum alloy profile can be met, the bottleneck of extrusion forming of the variable sectionprofile at present is broken, various indexes of the aluminum alloy profile are ensured to meet standards and use requirements, and material guarantee is provided for research of new carrier rockets in China.

Owner:西北铝业有限责任公司

Submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and preparation method thereof

ActiveCN104551446ASimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsSlagNuclear power

The invention discloses a submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and a preparation method thereof. The submerged arc welding flux comprises the following components in parts by weight: 8-15 parts of SiO2 (silicon dioxide), 20-30 parts of MgO (magnesium oxide), 20-30 parts of CaF2 (calcium fluoride), 20-30 parts of Al2O3 (aluminum oxide), 6-10 parts of CaO (calcium oxide), 2-4 parts of MnO2 (manganese dioxide), 0.3-1 parts of BaO (barium oxide), 1-2 parts of rare earth oxides, 0.014-0.016 part of S (sulfur), 0.013-0.015 part of P (phosphor), and 22-24 parts of water glass. Compared with the prior art, the submerged arc welding flux has the advantages that the welding technological property is excellent, the slag removal property is excellent, the forming appearance is attractive, and the mechanical property is more excellent.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

SA516Gr70 steel plate meeting high mold welding conditions and production method thereof

The invention discloses a SA516Gr70 steel plate meeting high mold welding conditions and a production method of the SA516Gr70 steel plate meeting the high mold welding conditions. The SA516Gr70 steel plate meeting the high mold welding conditions is composed of the following components including, by weight, 0.18%-0.21% of C, 0.20%-0.40% of Si, 1.10%-1.20% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.020%-1.20% of TAl, 0.015%-0.020% of Nb and the balance Fe and inevitable impurities. The production method comprises the working steps of rolling, water cooling and heat treatment. According to the working step of rolling, the II-type controlled rolling technology is adopted, and rolling is conducted through two stages. The SA516Gr70 steel plate meeting the high mold welding conditions and the production method of the SA516Gr70 steel plate meeting the high mold welding conditions aim to achieve that for different performance requirements and thickness specifications, corresponding internal control components and rolling and heat treatment technologies are determined, the performance yield of the steel plate is improved, the actual performance yield is not higher than 85% at present, and the performance yield is improved to be equal to or higher than 90% through tackling the key problem.

Owner:WUYANG IRON & STEEL

Substrate layer prepared from dry desulfurized ash, aldehyde-free reinforced board and preparation methods

ActiveCN102504383ARetains antioxidant propertiesReduce aging speedCovering/liningsLaminationThermoplasticFluidized bed

The invention provides a substrate layer prepared from dry desulfurized ash for a reinforced board. The preparation raw materials comprise the following components by weight percent: 61%-81% of dry desulfurized ash, 18%-38% of thermoplastic plastic and 0.7%-1% of coupling agent. The invention also provides an aldehyde-free reinforced board containing the substrate layer and a wear-resisting layer. The preparation method of the substrate layer for the reinforced board comprises the following steps of: a) carrying out thermal treatment on the dry desulfurized ash by using a circulating fluidized bed process; b) mixing the coupling agent with the dry desulfurized ash subjected to thermal treatment, heating and stirring, then adding the thermoplastic plastic, and stirring; and c) extruding and pelleting the prepared mixture, and carrying out mould pressing or extrusion molding in a flat extruder after pelleting. The prepared aldehyde-free reinforced board does not release harmful aldehydegases, and has the characteristics of oxidation resistance, ageing resistance, watertightness, mildew resistance and warping resistance; and in the production process, secondary pollution is not generated, and wood does not need to be used, thus the production process is environment-friendly and energy-saving, and the standard requirement of a reinforced board industry is reached.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

A production method of a fertilizer having an antibiotic degrading effect

InactiveCN106518326AIncrease vitalityImprove decomposition abilityOrganic fertilisersPotassium fertilisersMicroorganismAntibiotic Y

The invention relates to a production method of a fertilizer having an antibiotic degrading effect. Microbes and a photocatalyst or organic matters containing the microbes and the photocatalyst are added into a fertilizer to obtain the fertilizer having the antibiotic degrading effect. Through cooperation of the photocatalyst and the microbes, the objective of degrading antibiotics in fertilizers or soil is achieved.

Owner:烟台市昊星晟信息技术有限公司

Preparing method of high-pressure shell aluminum alloy die forging for submersible

ActiveCN107931498AMeet manufacturing requirementsMeet the standard requirementsHeating/cooling devicesIngotHigh pressure

The invention relates to a preparing method of a high-pressure shell aluminum alloy die forging for a submersible, and is applied to the aluminum alloy forging field. The method aims at solving the problems that the high-pressure shell aluminum alloy die forging for the submersible is poor in stress corrosion resistance, strength and breaking toughness. The method comprises the steps of firstly, aluminum alloy casting ingot heating, secondly, forging of a workblank for die forging molding, thirdly, lubricating mold pressing molding to obtain the forging, fourthly, corrosive washing and degreasing of the forging formed through die forming and neutralizing and whitening of the forging in an acid tank, fifthly, heat treatment and sixthly, metallographic structure detection and performance detection of the die forging obtained after heat treatment, and detection of qualified die forging. The standard requirements can be met, the pressure resistance of the shell is improved, strength, breaking toughness and other properties of the high-pressure die forging for the submersible can be improved, and the service life of the shell is prolonged.

Owner:NORTHEAST LIGHT ALLOY CO LTD

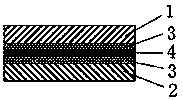

Highly visible arc protective multilayer composite fabric

PendingCN108943944AImprove visibilityMeet the standard requirementsProtective equipmentSynthetic resin layered productsYarnAdhesive

The invention discloses a highly visible arc protective multilayer composite fabric which at least comprises a surface fabric and an inner fabric, wherein the surface fabric and the inner fabric are adhered by a flame retardant adhesive; the surface fabric is woven from two or more than two of vinyon N, Lenzing flame retardant viscose and flame retardant cotton; the inner fabric is blended from one or two yarns of silicon nitrogen series flame retardant viscose, para-aramid as well as polysulfonamide and polyimide; and the flame retardant adhesive is flame retardant polyurethane or flame retardant EVA (Ethylene-Vinyl Acetate). According to the manner, the fabric disclosed by the invention can achieve long-term and excellent flame retardant and arc protective effects, and the fabric has theeffects of being humidity-absorbing and breathable, comfortable to wear, antibacterial and healthy.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

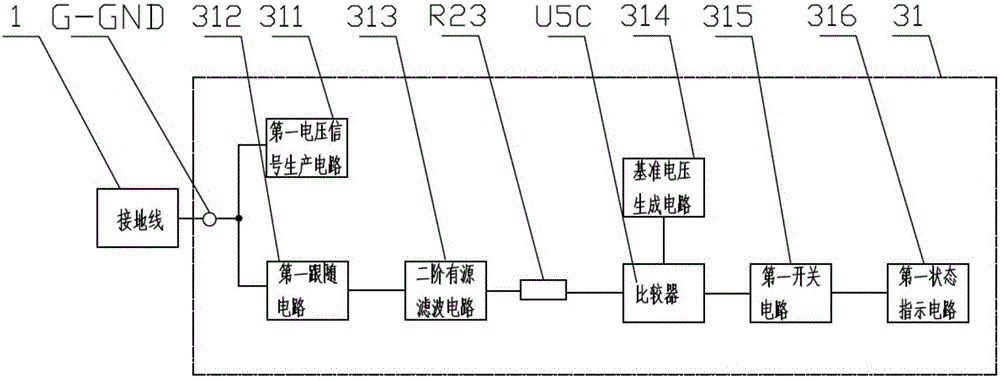

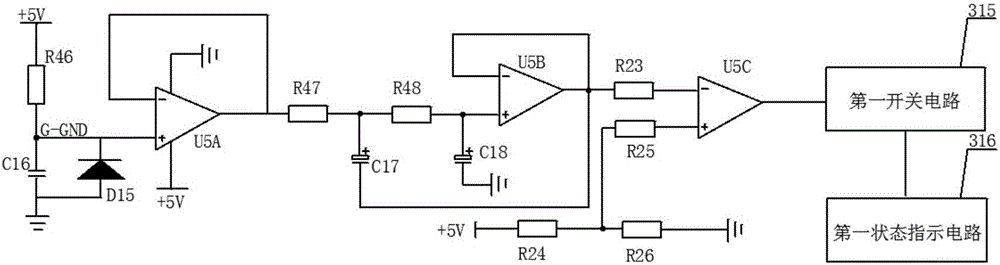

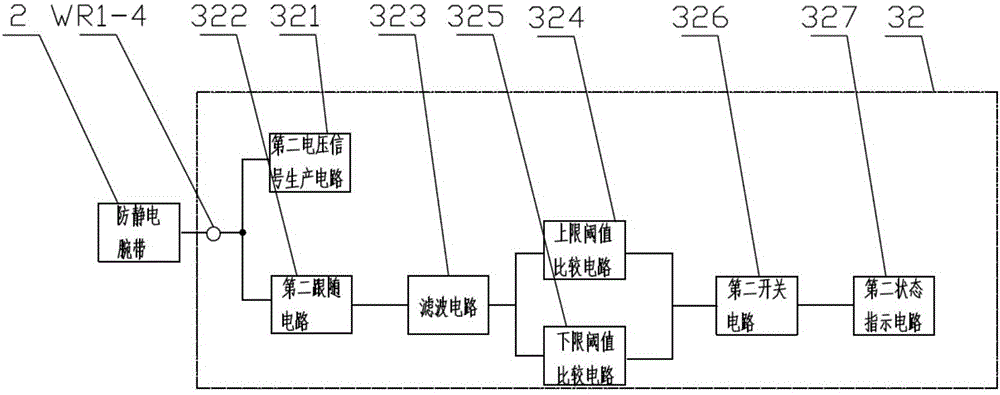

Anti-static wrist-strap grounding-state real-time monitoring method and monitor

InactiveCN105785219AMeet monitoring requirementsExquisite designElectrical testingElectrical resistance and conductanceGround system

The invention discloses an anti-static wrist-strap grounding-state real-time monitor and a monitoring method thereof. A grounding wire connection state monitoring circuit connecting a grounding wire and an anti-static wrist strap grounding system resistor monitoring circuit connecting an anti-static wrist strap are included. During working, the method comprises the following steps that S1, the grounding wire connection state monitoring circuit monitors a grounding wire connection condition, and when the grounding wire is in a connection state, a S2 step is executed and a green light is turned on; when the grounding wire is in a disconnected state, sound-light alarm is emitted and the S2 step is not executed; S2, the anti-static wrist strap grounding system resistor monitoring circuit monitors a grounding resistance of a human body which is connected to the circuit through the anti-static wrist strap, a converted voltage signal is compared to a preset standard voltage signal, and according to a comparison result, a second state indication circuit is controlled to work. In the invention, monitoring requirements of two kinds of anti-static wrist straps can be effectively satisfied, versatility is good, and grounding wire state monitoring and grounding resistor monitoring are realized so that a monitoring result is accurate and a standard requirement is satisfied.

Owner:SUZHOU TA&A ULTRA CLEAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com