Patents

Literature

35 results about "Vinyon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyon is a synthetic fiber made from polyvinyl chloride. In some countries other than the United States, vinyon fibers are referred to as polyvinyl chloride fibers. It can bind non-woven fibers and fabrics. It was invented in 1939.

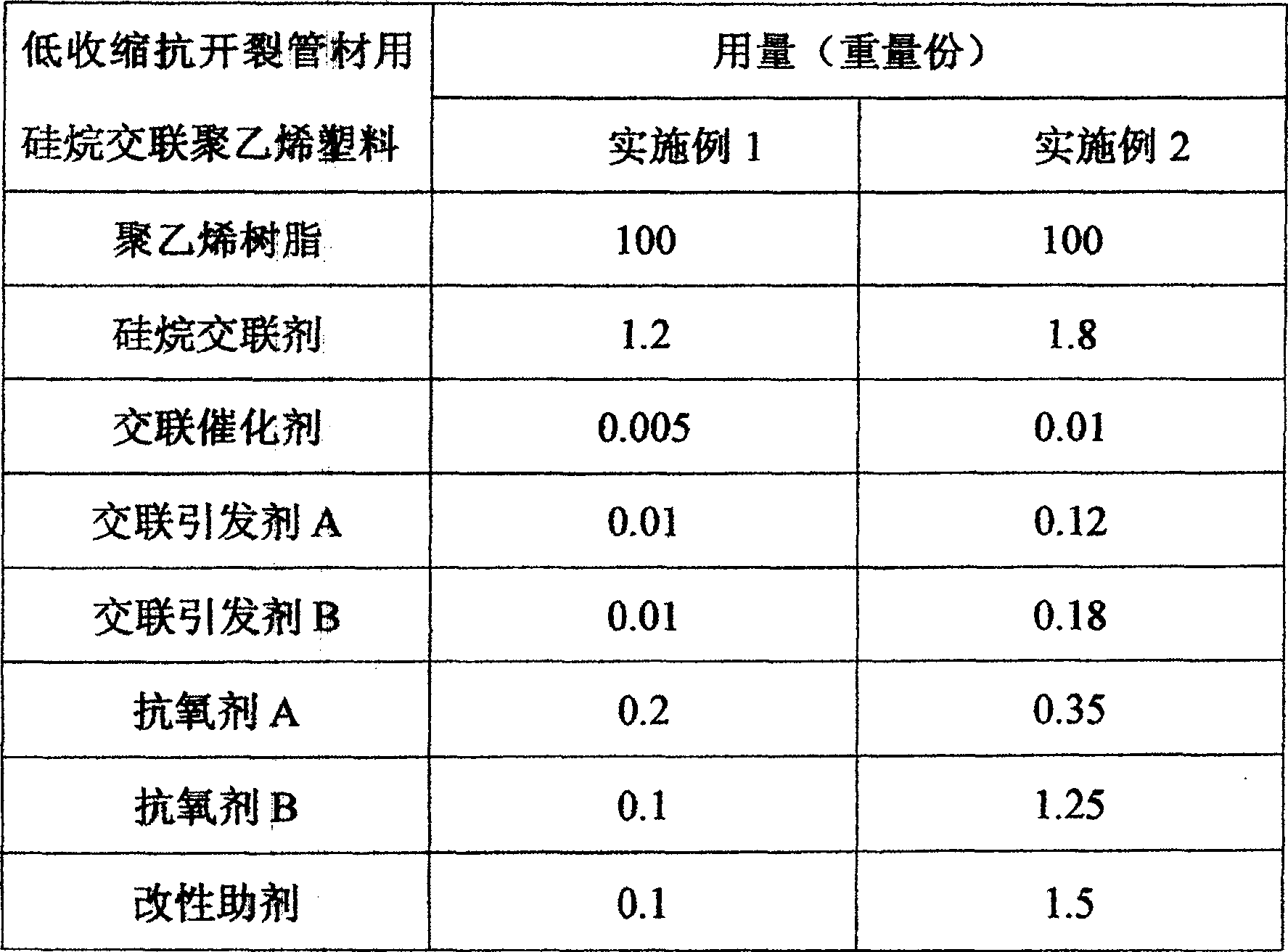

Silane crosslinked polyethylene plastic for low shrinkage anti-crack tube and its preparation method

ActiveCN1876706ASolve the defect of excessive shrinkageOvercome degummingBulk chemical productionTubular articlesCross-linkWater baths

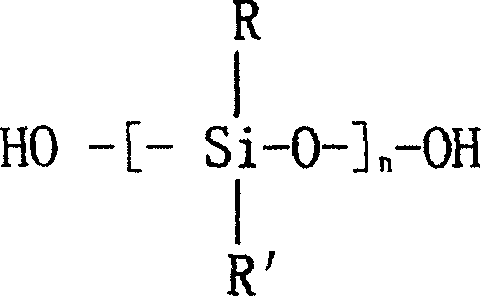

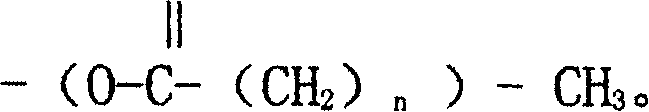

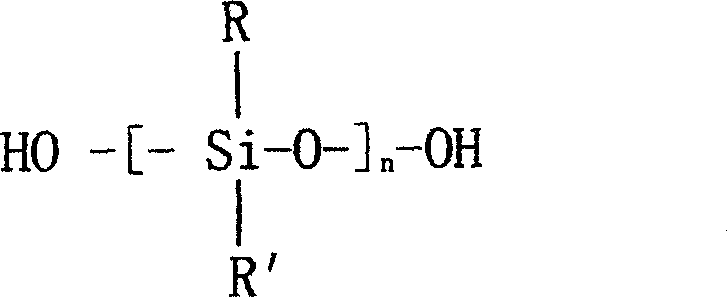

The invention relates the silicon alky cross-linking low-middle-high density vinyon. The components comprises 0.8-3.0wt% silicon alky cross linking agent, 0.02-2.0wt% cross linking initiating agent, 0.02-1.0wt% cross linking catalyst, 0.01-3.0wt% anti-oxidant and 0.05-3.0wt% modified auxiliary agent. The method comprises the following steps: preparing silicon alky grafting material A, mixing A and B materials, handing with extrusion machine to get tubing product, keeping it in water bath at 85Deg.C or vaporium for 8 hours, and getting the product. The invention overcomes the defects of big contraction percentage and degelatinizing phenomena between polythene layer and metal layer; the invention has the advantages of short production circle, stable technology and high rate of finished products.

Owner:上海高分子功能材料研究所

Light-degradable and biodegradable nano antibacterial plastics prepared by using waste plastics and process for preparing same

InactiveCN1702110ASolve the pollution of the environmentTake advantage ofPhotosensitizerVinyl fibers

The invention relates to a controllable light-biodegradation nanometer antibiotic plastic and its preparation. The invention comprises waste and old vinyon, modified nanometer TiO2, modified amidon, calcium carbonate and photosensitizer. The invention reduces pollution of waste and old vinyon, avoids resource extravagant and can produce new plastic products with antibiosis and degradability.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Diaphragm paper for mercury-free alkaline zinc-manganese dioxide cell, and preparation method of diaphragm paper

ActiveCN104631198AImprove densification performanceHigh strengthWater-repelling agents additionPaper coatingPapermakingManganese

The invention discloses diaphragm paper for a mercury-free alkaline zinc-manganese dioxide cell, and a preparation method of the diaphragm paper, and belongs to the technical field of fiber-containing paper and a preparation method thereof. A sizing agent comprises the following raw materials in parts by weight: 40-55 parts of superfine nylon fibers, 25-35 parts of tencel fibers and 20-30 parts of pulp fibers; the sizing agent is prepared by dispersing a dispersing agent by adopting a papermaking machine wet-process papermaking technology. The three types of fibers are mixed to prepare an alkaline zinc-manganese dioxide cell diaphragm, so that not only can the physical strength performance of the diaphragm paper be improved and the relatively good alkaline absorption performance can be guaranteed; due to the improvement of the strength of the diaphragm paper, the usage amount of the sizing agent can be properly reduced, so that the quantitation and the thickness fluctuation of the diaphragm paper can be favorably stabilized, and thus guarantee for meeting the use of the mercury-free alkaline zinc-manganese dioxide cell can be provided.

Owner:浙江鹏辰造纸研究所有限公司

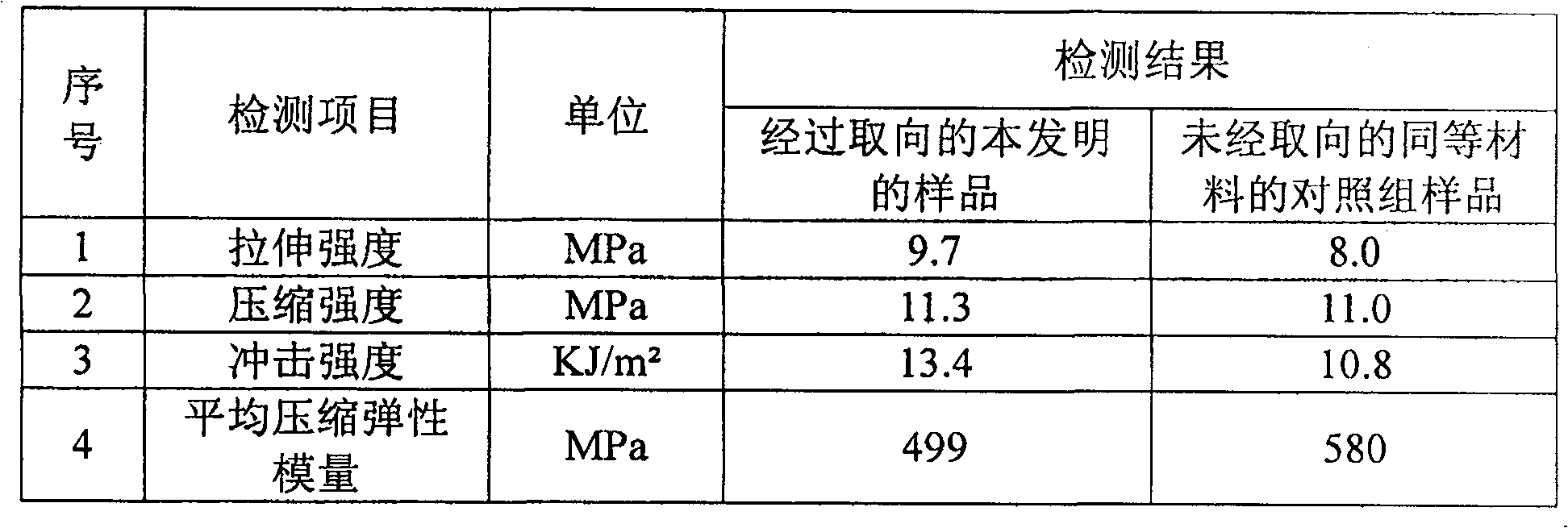

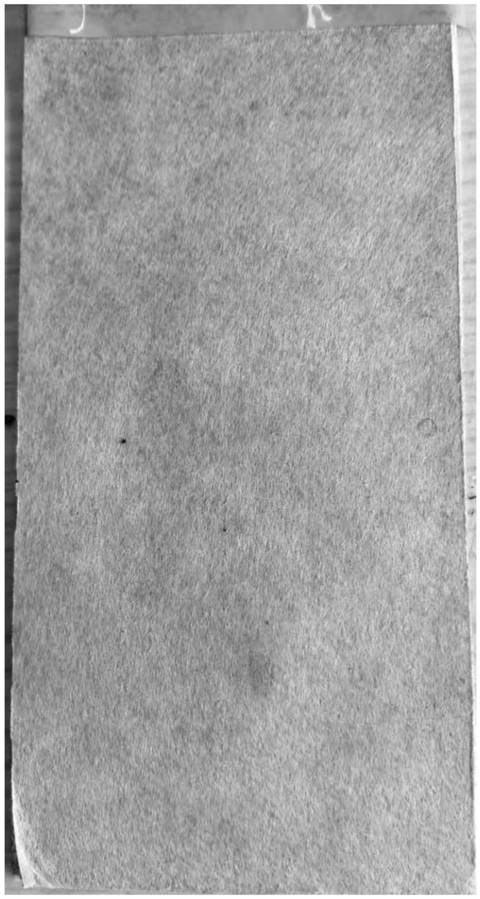

Manufacturing method of artificial sclerite shaping implant with polyvinyl plastics

The present invention relates to a method for making a vinyon artificial bone fragment molding implant, and the method comprises the steps of: (a) preparing the raw material: filtrating the thin particle vinyon in initial state, the surface of the obtained particle has a plurality of prominent bulges which is irregular ellipse grain shape; (b) preparing the mold which is composed of a mold frame, a top mold board and a lower mold plate; (c) adding material: spreading the filtrated raw material uniformly in the mold cavity after weighting; (d) orientating the electrostatic: opening the electrical power switch of the electrostatic generator and adjusting the electrical voltage, executing slow horizontal moving scanning with the electrode bar at the voltage output end at the upper side of the mold, the upright particles inclines along with the moving direction of the electrode bar and the plastic particles are arranged with regulated cross net shape; (e) closing the mold cover and inputting the mold to the heating furnace to sinter when the process of the electrostatic orientating has finished. The artificial bone fragment made with the method of the invention has a cellular structure with a definite shape, facilitates the adhering and growing of the human organization, has an excellent bioavailability and physical property.

Owner:张勇

Paper pulp for sized diaphragm paper of alkaline cell and preparation technique for applying paper pulp to prepare diaphragm paper

ActiveCN101581054AImprove compactnessImprove uniformityDefoamers additionWater-repelling agents additionFiberWater soluble

The invention discloses a paper pulp which is used for sized diaphragm paper of an alkaline cell and has the function of separating a positive electrode and a negative electrode in the alkaline cell and a preparation technique for applying the pulp material to prepare the diaphragm paper. The paper pulp consists of pulp materials and auxiliary materials; the pulp materials consist of ultrafine vinylon fiber, ultrafine viscose fiber, water soluble vinylon fiber and cotton pulp; and the auxiliary materials consist of an antifoaming agent and a dispersing agent. The sized diaphragm paper of the alkaline cell prepared by the paper pulp can greatly reduce the defects of lumps, air bubble holes and the like, thus improving the tube-making performance and discharge performance of the diaphragm paper in producing the alkaline cell and stability of the diaphragm paper product; and the technique for applying the paper pulp to produce the diaphragm paper not only has high production efficiency, but also has little environmental pollution.

Owner:WELBON SPECIAL MATERIALS CO LTD

Processing Method of A Non-PVA Hollow Yarn and The Tubular Fabric

InactiveUS20150284881A1Low shrinkageLayered productsPedestrian/occupant safety arrangementHigh densityEngineering

The invention discloses the processing method of a non-PVA fiber hollow yarn and the tubular fabric. The fiber shall include filament yarn, staple yarn and ribbon. The processing method applies degradable fiber which is controllable in degradation conditions and has none formaldehyde residue to produce hollow yarn, in contrast with conventional soluble Vinylon hollow yarn, which is environmentally friendly and cheap while has low shrinkage and distinct hollow effect as can be made into high density textile and single yarn textile through sizing process. Furthermore, the tubular fabric as described in this invention spinned with the non-PVA fiber hollow yarn is feature with lightness, fluffy sense, warmth, moisture absorption and softness.

Owner:YU YANPING +1

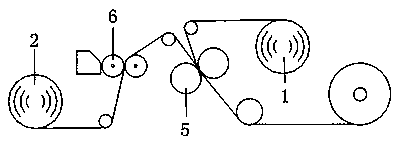

Water soluble paper and its making process

InactiveCN1337492ANot easy to scratchImprove sealingPaper coatingPaper/cardboardFiberPolyvinyl alcohol

The present invention relates to a water soluble paper and its production method. Its production method adopts the processes of making pulp, pulp-coating, vacuum dehydration, drying and calendering, and includes two steps: first step: making screen paper: making water soluble vinylon fibre into pulp and making it into fine fibre, adopting wet paper-making process to form screen, vacuum dehydration and drying to obtain screen paper; then second step: making water soluble paper; placing the screen paper into the saturated solution of polyvinyl alcohol to coat pulp, vacuum dehydration, drying and calendering by means of calender to obtain the invented water soluble paper. The invented water soluble paper comprises water soluble vinylon fibre and polyvinyl alcohol, and possesses good water soluble effect, under the condition of water temp. of 70 deg.c it it can completely dissolved. Its production process is simple, and its air permeability is zero, and the bag made of said water soluble paper has no leakage, can be used for holding medical utensil to make disinfection.

Owner:金周敏

Highly visible arc protective multilayer composite fabric

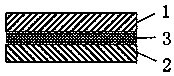

PendingCN108943944AImprove visibilityMeet the standard requirementsProtective equipmentSynthetic resin layered productsYarnAdhesive

The invention discloses a highly visible arc protective multilayer composite fabric which at least comprises a surface fabric and an inner fabric, wherein the surface fabric and the inner fabric are adhered by a flame retardant adhesive; the surface fabric is woven from two or more than two of vinyon N, Lenzing flame retardant viscose and flame retardant cotton; the inner fabric is blended from one or two yarns of silicon nitrogen series flame retardant viscose, para-aramid as well as polysulfonamide and polyimide; and the flame retardant adhesive is flame retardant polyurethane or flame retardant EVA (Ethylene-Vinyl Acetate). According to the manner, the fabric disclosed by the invention can achieve long-term and excellent flame retardant and arc protective effects, and the fabric has theeffects of being humidity-absorbing and breathable, comfortable to wear, antibacterial and healthy.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Multifunctional protection knitted fabric

PendingCN109706606APermanent Flame RetardancyImprove flame retardant performanceWeft knittingYarnYarnPolyester

The invention relates to a multifunctional protection knitted fabric and belongs to the field of spinning. According to the multifunctional protection knitted fabric, the gram weight of the fabric is190-230 g / m<2>, the surface layer and the inner layer are connected through connection yarn to form a dual-layer structure, the surface layer is woven through polyester yarn and flame-retardant yarn,6 pieces of polyester yarn and 2 pieces of flame-retardant yarn are used for alternative circulation weaving, needle drawing weave is adopted for the surface-layer fabric, the surface-layer fabric isin a grid shape, and the polyester yarn is dyed with the fluorescent color; the flame-retardant yarn is blended yarn with 60% of vinyon and 40% of cotton and dyed with the fluorescent color, the inner-layer yarn is formed by blending 60% of vinyon, 27% of flame-retardant viscose, 10% of para-aramid and 3% of transparent conductive fibers, and the inner-layer yarn is in a natural color; the connection yarn and the inner-layer yarn belongs to the same yarn. The fabric has high-temperature-resistance and high warning functions and has excellent anti-arc performance, the inner-layer fabric is formed through carbonization burning, and the fabric is comfortable, soft and good in heat retention property and can be worn next to the skin.

Owner:钱俊瑜

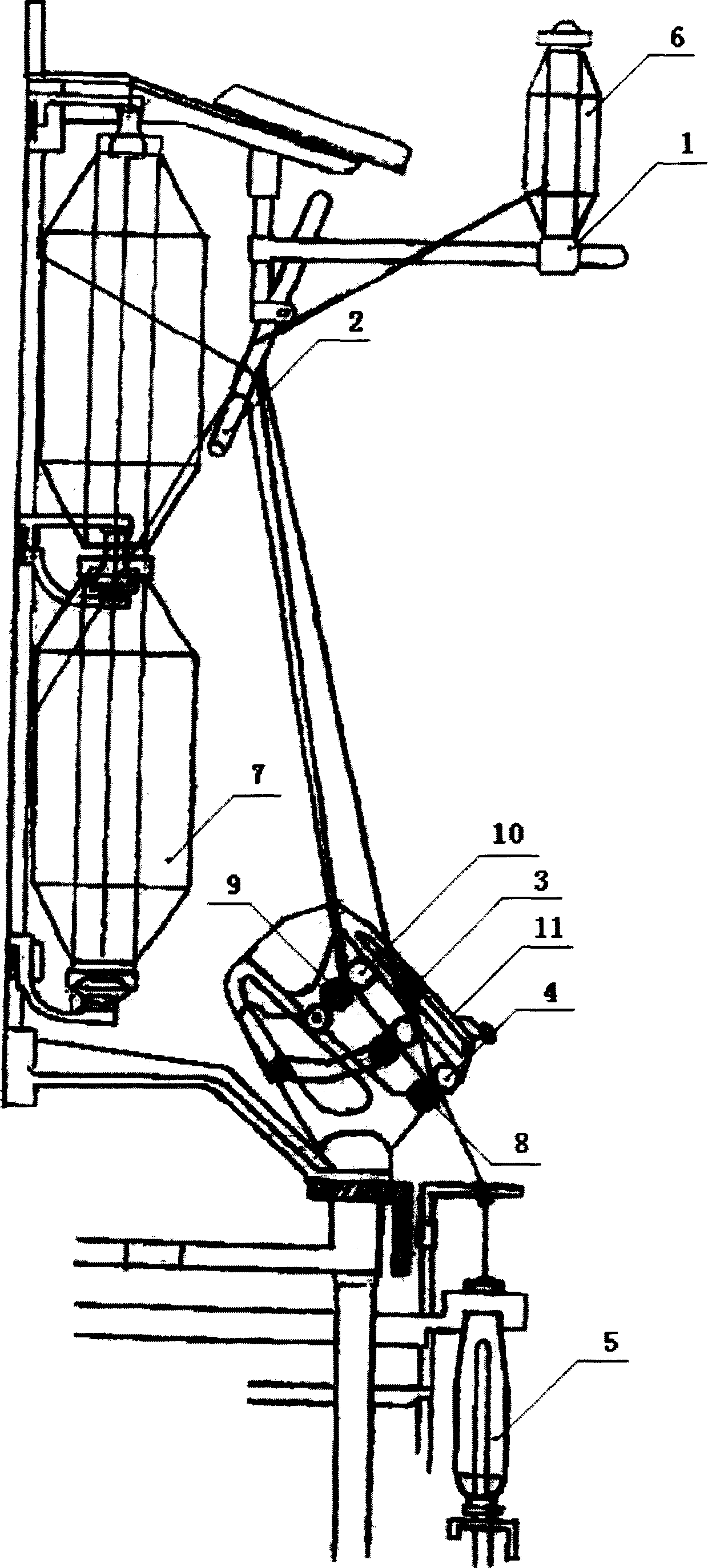

Method for manufacturing environment-friendly type geothermal heat floor

This invention relates to a method for preparing an environment-friendly type geothermal floor, which comprises the following steps: a) preparing the base material including the regenerative material of the waste vinyon, ligno-cellulose, light calcium carbonate, acrylate polymer, geoceric acid, calcium stearate, titanium dioxide, atoleine and solid paraffin; b) spreading nontoxic binder on the base material, stitching the base material with the wood slice of the same size, between the base material and the veneer is the binder layer with nontoxic binder; c) setting corresponding tenon and beard around the base material, arranging dump discharging venting slot along the long edge direction in the bottom of the base material, and then getting the end product.

Owner:元太喜

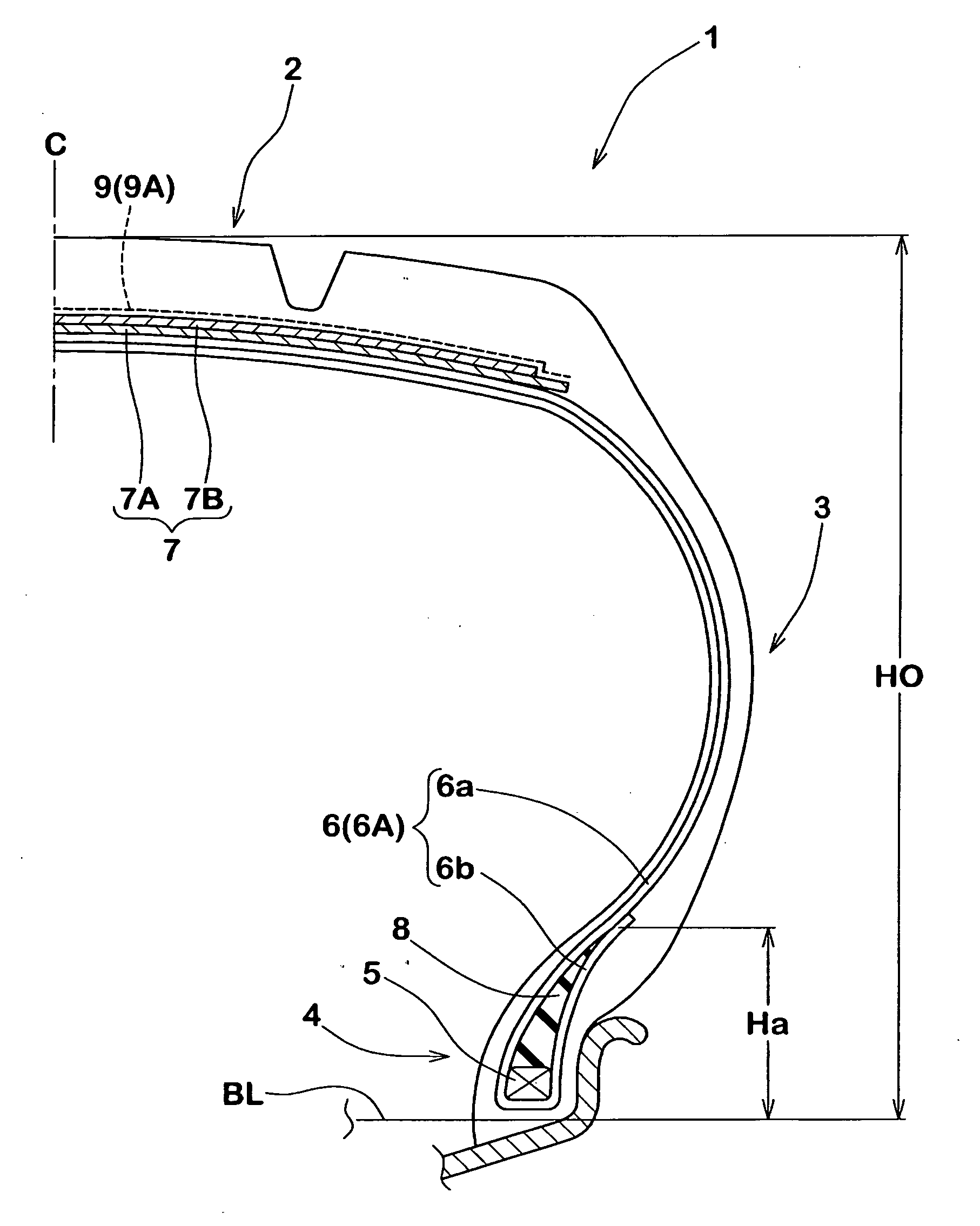

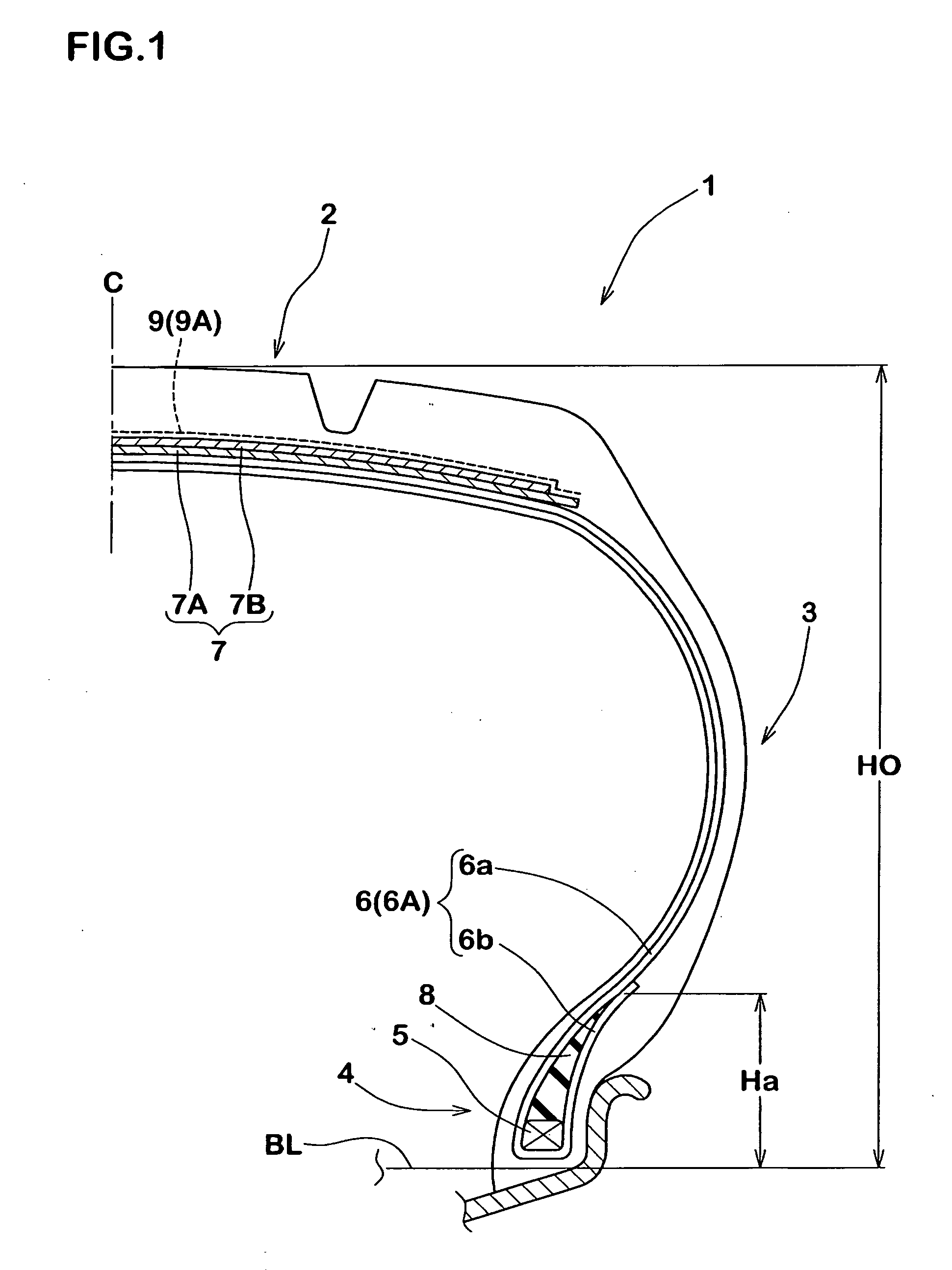

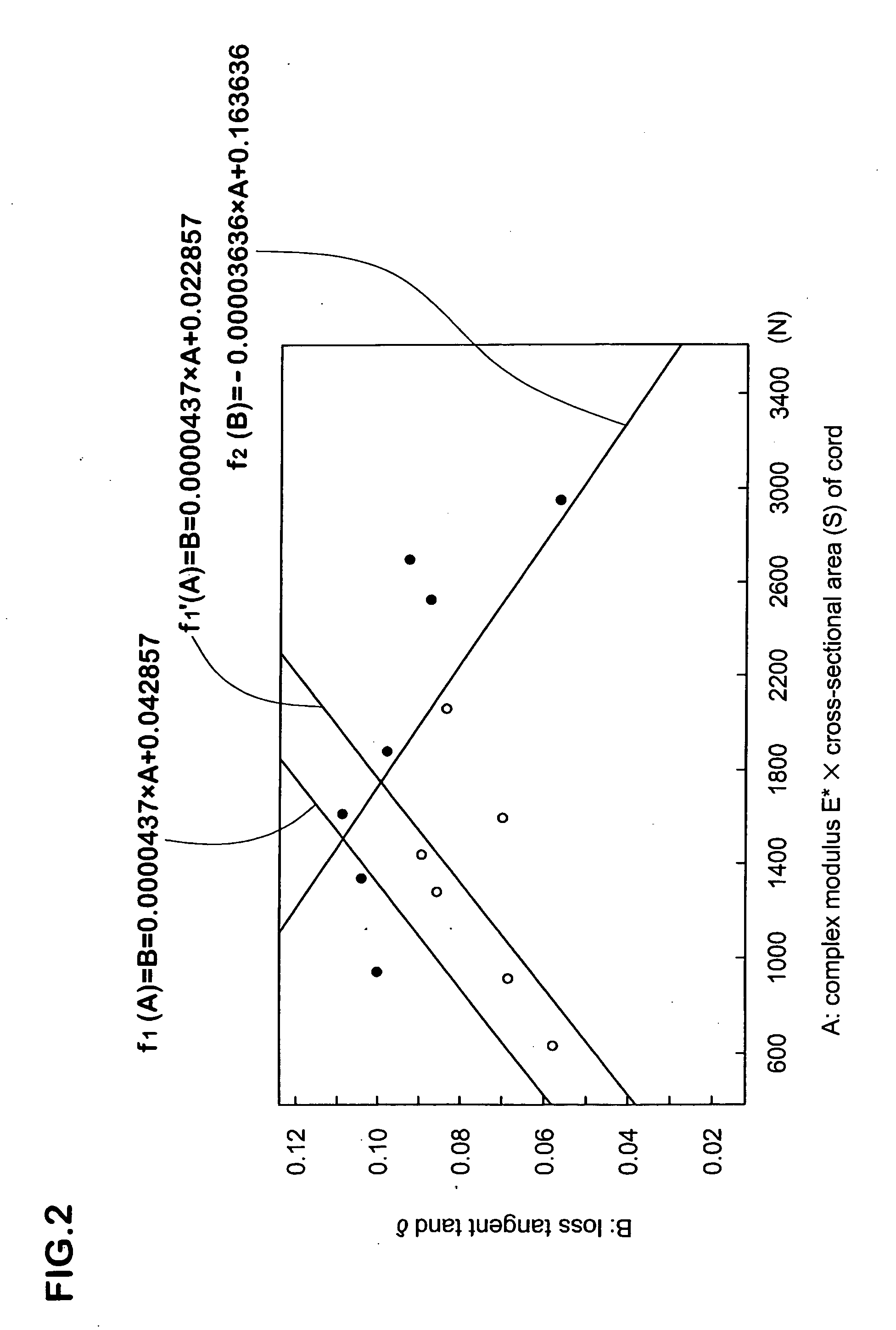

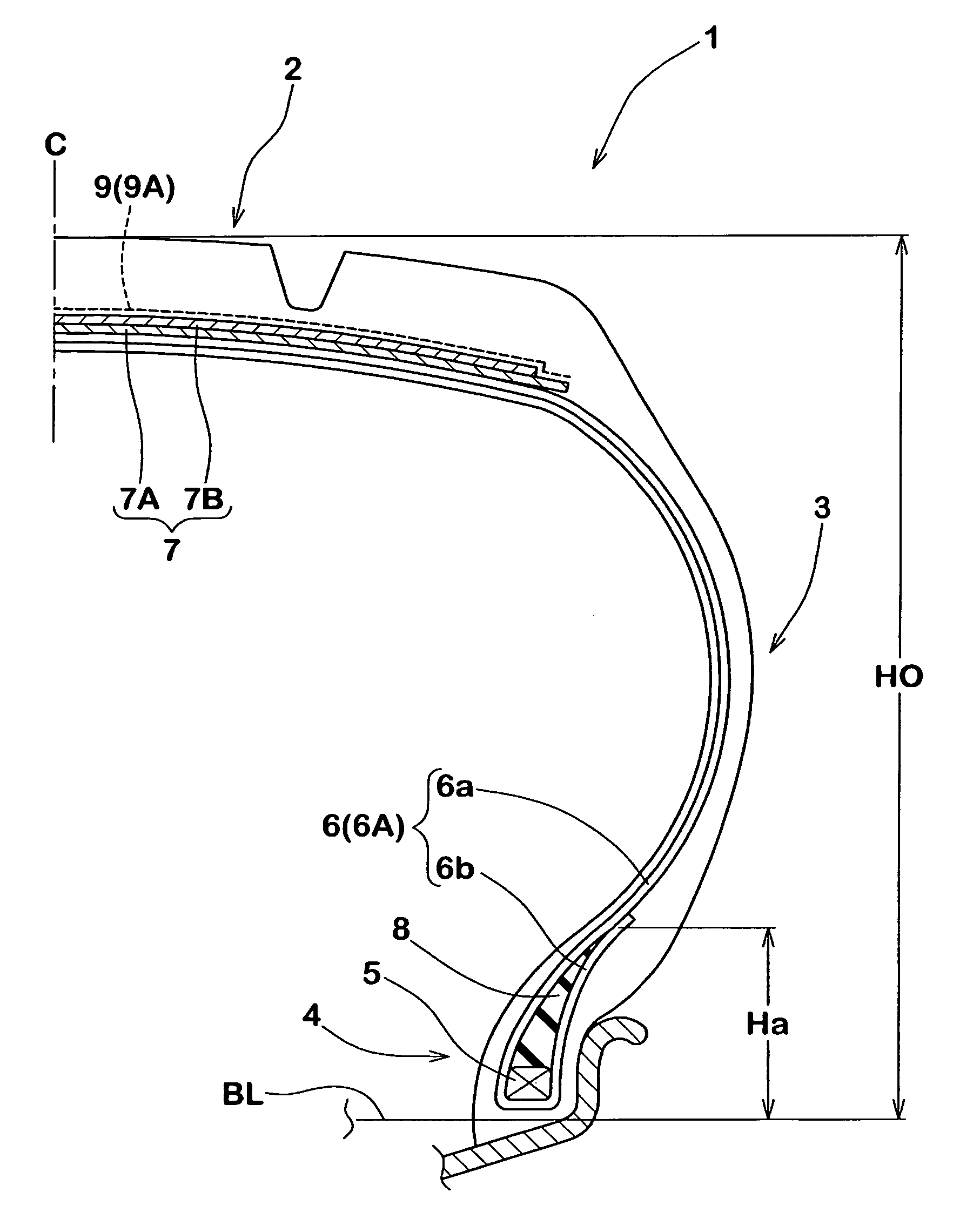

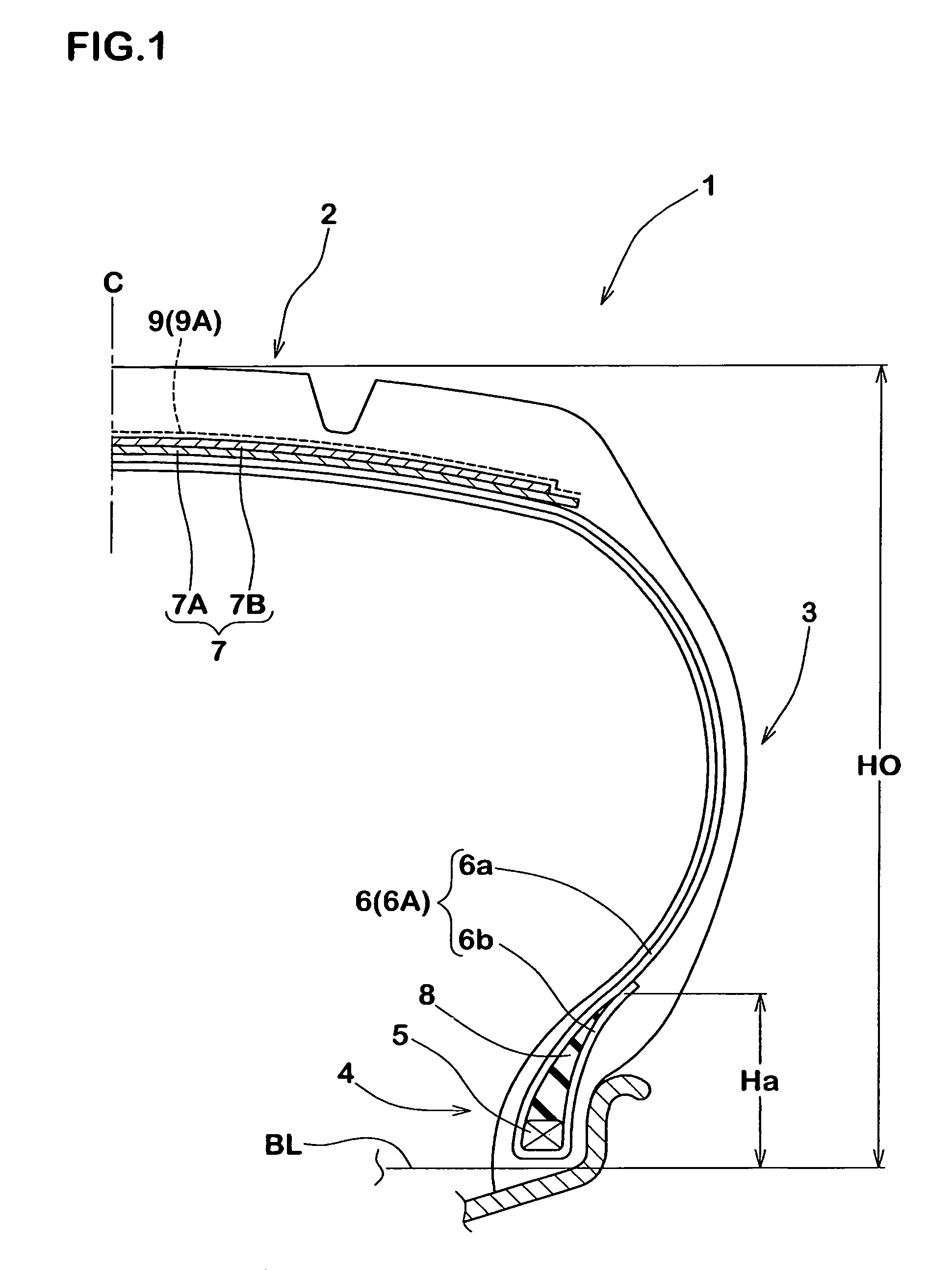

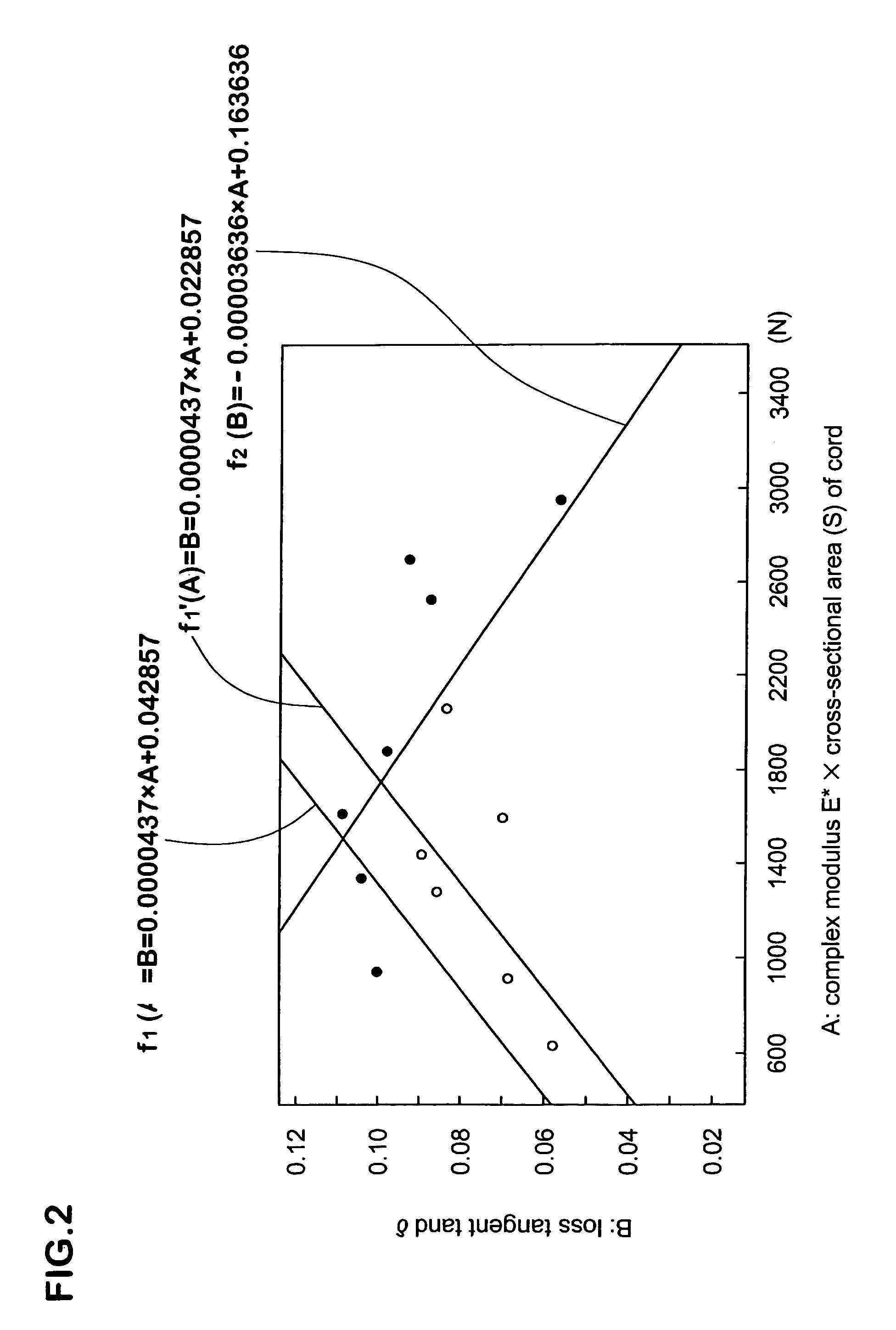

Pneumatic Tire

InactiveUS20070131334A1Increase elasticityImprove steering stabilitySpecial tyresPneumatic tyre reinforcementsFiberEngineering

A pneumatic tire includes a carcass ply with carcass cords. The carcass cords comprise high tenacity vinylon fiber, polyethylene naphthalate fiber or polyalylate fiber. viscoelasticity characteristics per one cord at 120° C. of the carcass cord satisfy the following equations (1) to (3): B>0 (1) B≦0.0000437×A+0.042857 (2) B≦−0.00003636×A+0.163636 (3) (wherein “A” represents a product of complex modulus E*(N / cm2) and cross-sectional area “S” (cm2) of cord), and “B” represents a loss tangent tanδ).

Owner:SUMITOMO RUBBER IND LTD

Blended yarn between filament of glass fiber and short fibre of Vinyon N, and production method

The present invention relates to a glass fibre filament and vinylchloride acrylonitrile copolymer fibre short fibre blended yarn and its production method. It uses glass fibre filament and vinylchloride acrylonitrile copolymer fibre short fibre as raw material and its production method includes the following steps: pretreatment, scotching, carding, drawing, roving and spinning. The weight percentage of glass fibre filament is 23-55%, the specification of said glass fibre filament is 75D-165D, the weight percentage of the vinylchloride acrylonitrile copolymer fibre short fibre is 45-77%, and its specification is 1.5D-3D and its length is 38mm-76mm.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

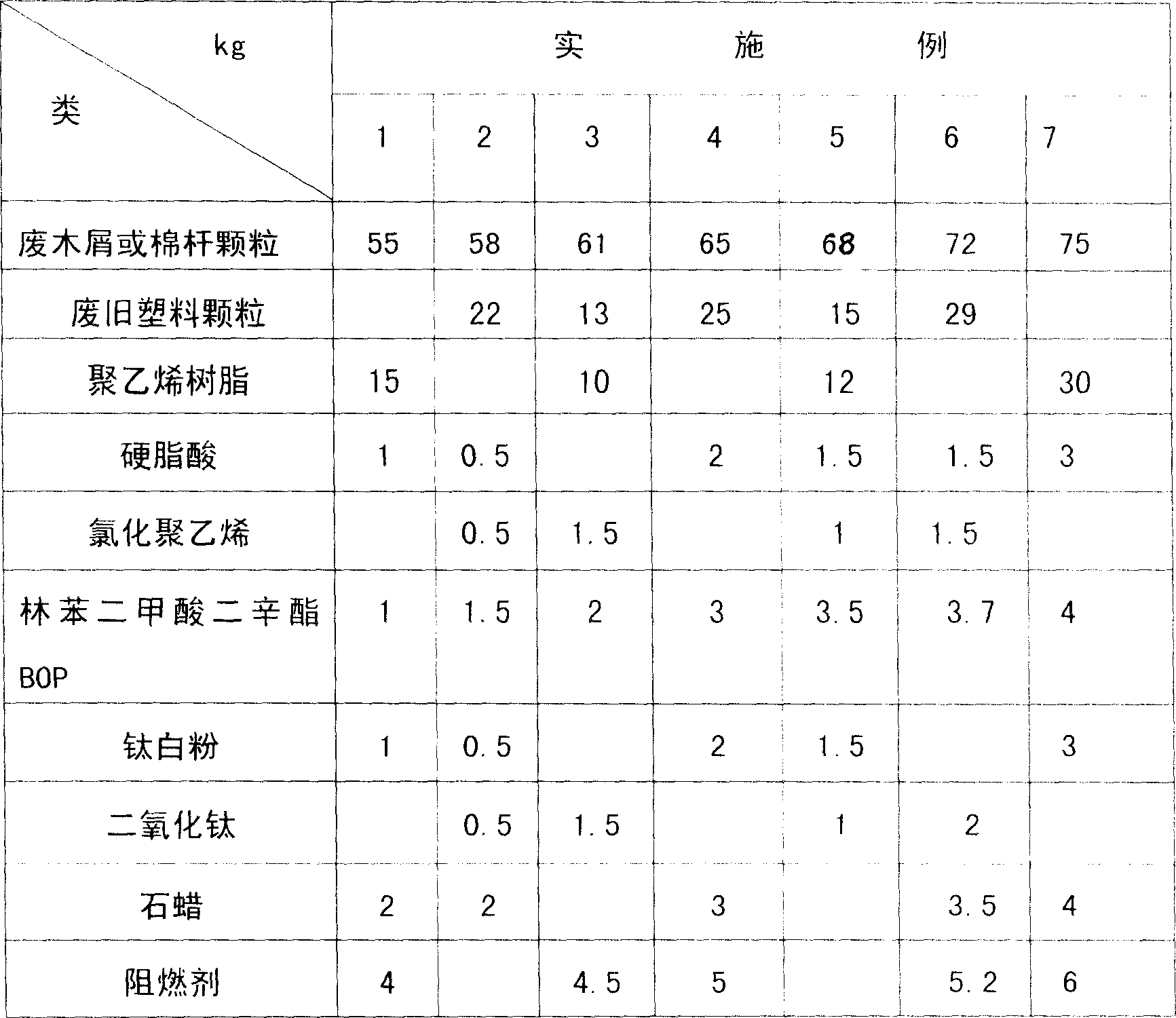

Plastic wood template and associated method of production

The invention provides the preparing method of wood mold. The method comprises 55-75 parts waste wood slag, 55-75 parts cotton particles, waste vinyon and 15-30 parts polyvinyl resin and auxiliary agent; the bending strength of product is above 45N / mm2, impact strength is above 35KJ / m2, elasticity modulus is above 3*103N / mm3, and retention intensity is above 35N / mm2. The method comprises the following steps: pelleting, mixing, adding auxiliary agent, and moulding. The mold has the advantages of high strength, non-deforming, repetitive-use, easy dismounting, high economic profit and wide usage. The method has the advantages of simple technology, low cost, and environmental protection.

Owner:吴新玥

Self-cleaning cement-based composite material and production method thereof

The invention discloses a self-cleaning cement-based composite material and a production method thereof, and the production method comprises the following steps: aramid fibers containing 18-38% wt of inorganic basalt fibers, glass fibers and ceramic fibers, fibers, aramid fibers, a photocatalytic material, nylon fibers, vinylon fibers are input in a fiber twisting machine for being knitted to 64 fiber threads; the obtained fiber lines can be input into a fiber cloth knitting machine to be knitted into net-shaped fiber cloth with the mesh being 1 m*1 m and the breadth being 2.00 m; a large amount of CO2 can be sucked in the curing process of fresh concrete, calcium silicate and a small amount of hydration products in cement clinker react with CO2 to generate calcium carbonate and silica gel, high early strength can be obtained, the concrete curing time is greatly shortened, good size stability and other performance are achieved, the process of emission reduction is achieved by introducing tailings as a modifying component, the nano-modified concrete component can continuously absorb carbon dioxide in the atmosphere, and meanwhile, the overall mechanical property and durability of the building material can be improved.

Owner:苏州阔凭环保科技有限公司

Arc protecting knitting fabric and manufacturing method thereof

PendingCN107723910AImprove flame retardant performanceImprove antistatic performanceWeft knittingDyeing processYarnBobbin

The invention provides an arc protecting knitting fabric and a manufacturing method thereof. The arc protecting knitting fabric is knitted by 60 percent of vinyon N fiber, 38 percent of cotton fiber and 2 percent of dark conductive fiber. The manufacturing method of the arc protecting knitting fabric comprises the following steps of 1, performing machine debugging; installing a yarn bobbin; simultaneously feeding scribbled yarns into a work needle of a knitting machine in the weft direction; bending the scribbled yarns into loops according to the sequence; performing mutual penetration and sleeving; completing the fabric blank cloth manufacturing; 2, performing dyeing. Through the arc protecting knitting fabrics, the fabric fire resistance, the anti-static performance and the arc protection performance are optimum; the knitting process is sued; the fabric has good comfort performance.

Owner:营口俊安防护服装有限公司 +1

High-toughness double-fiber blended fabric and processing technology thereof

InactiveCN108796771AImprove performanceImprove toughnessFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsPolyesterPhosphate

The invention provides a high-toughness double-fiber blended fabric and a processing technology thereof. The fabric is prepared by interweaving warp yarn and weft yarn, wherein the warp yarn is prepared from a polyester fiber, a cotton fiber, magnesium borate whisker, aminomethyl styrene resin, plant extract, composite phosphate and an additive; the weft yarn is prepared from a cotton fiber, a Vinyon N fiber, an acetate fiber, isooctanol phosphate, nano titanate and an additive; the yarn count is 60s / 2*60, and the thread count is 110-120*90. The high-toughness double-fiber blended fabric and the processing technology thereof have the advantages that the raw materials are reasonably selected and mixed, and the technology is improved, so that the performance of the warp yarn and weft yarn isobviously improved, the toughness of the yarn is improved by 2 times or above, the comprehensive abrasion performance and fastness are obviously improved, the antibacterial property and fire resistance are excellent, people wear the fabric comfortably, and the fabric is worth promoting.

Owner:安徽职业技术学院

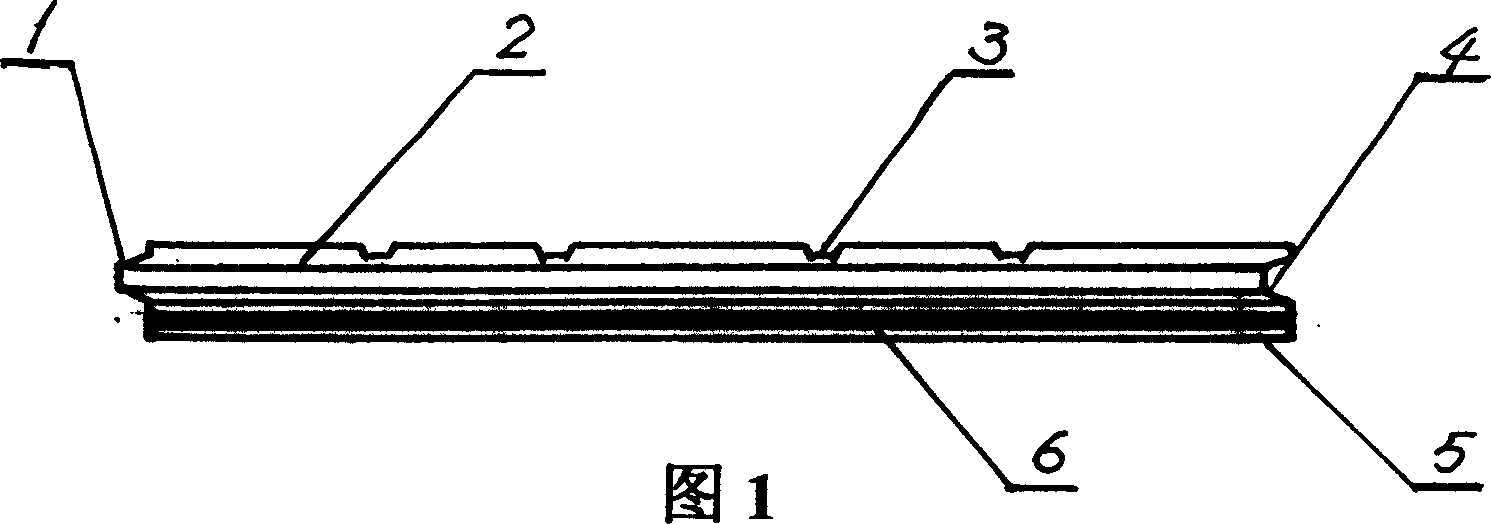

A composite separator for secondary alkaline zinc-manganese battery and preparation method thereof

ActiveCN105098127BGood chemical stabilityGood resistance to zinc oxide dendritesCell component detailsPolyolefinManganese

A composite separator for secondary alkaline zinc-manganese batteries and a preparation method thereof, belonging to the technical field of battery separators, the composite separator is composed of polypropylene microporous membranes, and wet-process non-woven fabrics containing ultrafine polyolefin fibers and vinylon fibers. A two-layer composite structure made of woven cloth, and the thickness of the composite diaphragm is 0.08mm to 0.12mm. The composite diaphragm of the present invention has the following performances: (1) the existence of the microporous membrane makes it have good zinc oxide dendrite resistance; (2) the composite diaphragm can be easily processed into a diaphragm tube by an automatic winding machine; (3) ) The composite diaphragm is endowed with carboxyl and / or sulfonic acid hydrophilic functional groups on the inner and outer surfaces by radiation grafting of acrylic acid and / or sodium styrene sulfonate, which has permanent hydrophilicity; (4) The composite diaphragm has good chemical stability .

Owner:HENAN KEGAO RADIATION CHEM TECH

Pneumatic tire

InactiveUS7926531B2Securing excellent riding comfortIncrease elasticitySpecial tyresPneumatic tyre reinforcementsFiberEngineering

A pneumatic tire includes a carcass ply with carcass cords. The carcass cords comprise high tenacity vinylon fiber, polyethylene naphthalate fiber or polyalylate fiber. Viscoelasticity characteristics per one cord at 120° C. of the carcass cord satisfy the following equations (1) to (3):B>0 (1)B≦0.0000437×A+0.042857 (2)B≦−0.00003636×A+0.163636 (3)(wherein “A” represents a product of complex modulus E*(N / cm2) and cross-sectional area “S” (cm2) of cord), and “B” represents a loss tangent tanδ).

Owner:SUMITOMO RUBBER IND LTD

Flame-retarding composite material

The invention relates to a flame-retarding composite material including, by weight, 25-35% of polyethylene glycol terephthalate, 2-18% of polyhedral silsesquioxane, 10-30% of a butadiene-styrene bromide copolymer, 5-13% of poly-p-phenylenebenzobisoxazole, 3-8% of melamine fibers, 6-10% of phenolic fibers, 5-10% of Vinyon N fibers, 5-10% of pre-oxidized fibers, and 6-10% of silicon carbide fibers. The composite material has flame-retarding effects and is environment-friendly, is anti-aging, has excellent waterproofing property, and has excellent mechanical and thermal performances.

Owner:ANHUI NEWT FIRE EQUIP

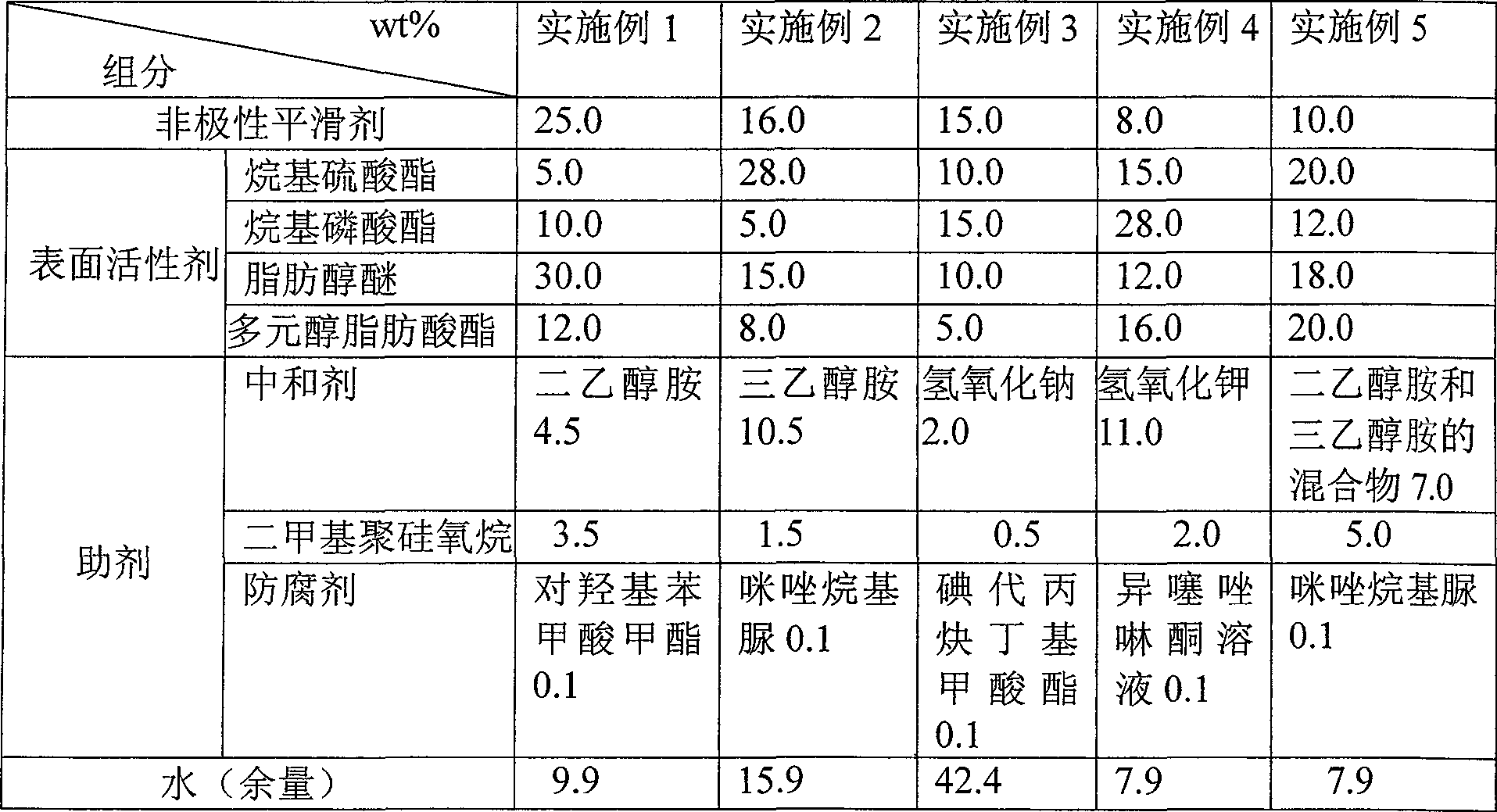

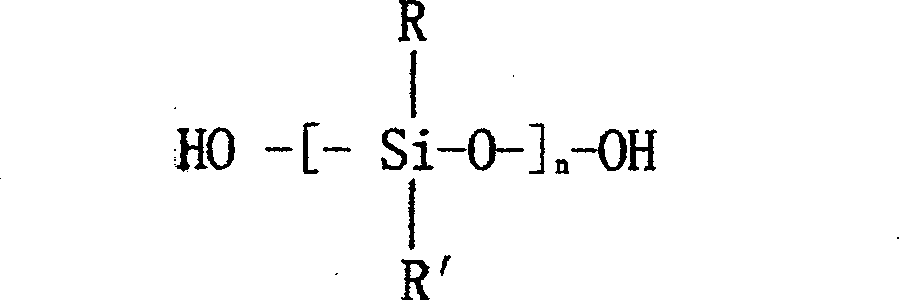

Vinylon pure-spinning fibre oil solution and preparing method thereof

InactiveCN100510241CReduce pollutionAvoid smelly and spoiledFibre typesPhosphoric Acid EstersActive agent

The invention provides a vinylon pure spinning fiber oil and its preparation method, which is composed of non-polar smoothing agent, surfactant, auxiliary agent and water, wherein the content of each component is: non-polar smoothing agent: 8-25%; in surfactants: 5-28% sulfate esters, 5-28% phosphate esters, 5-20% polyol fatty acid esters, 10-30% fatty alcohol ethers; in additives: neutralizer 2 ~11%, high molecular silicone polymer 0.5~5.0%, preservative 0.1%; the balance is water; all are calculated by weight percentage. Since the oil agent of the invention does not contain alkylphenol surfactants, environmental pollution is reduced. The fiber product treated with the oil agent of the present invention has good smoothness, softness, suitable cohesion (or clustering property), antistatic property, etc., so that the fiber can pass through various post-processing procedures smoothly, and has good spinnability; Moreover, it can be widely adapted to the process conditions of fiber production, such as heat resistance, oxidation resistance, corrosion resistance, and prevention of oily odor and deterioration caused by bacterial reproduction. The preparation method in the present invention is simple and does not need heating during preparation.

Owner:徐元萍 +1

Silane crosslinked polyethylene plastic for low shrinkage anti-crack tube and its preparation method

ActiveCN100532441CSolve the defect of excessive shrinkageOvercome degummingBulk chemical productionTubular articlesCross-linkWater baths

The invention relates the silicon alky cross-linking low-middle-high density vinyon. The components comprises 0.8-3.0wt% silicon alky cross linking agent, 0.02-2.0wt% cross linking initiating agent, 0.02-1.0wt% cross linking catalyst, 0.01-3.0wt% anti-oxidant and 0.05-3.0wt% modified auxiliary agent. The method comprises the following steps: preparing silicon alky grafting material A, mixing A and B materials, handing with extrusion machine to get tubing product, keeping it in water bath at 85Deg.C or vaporium for 8 hours, and getting the product. The invention overcomes the defects of big contraction percentage and degelatinizing phenomena between polythene layer and metal layer; the invention has the advantages of short production circle, stable technology and high rate of finished products.

Owner:上海高分子功能材料研究所

Manufacturing method of artificial sclerite shaping implant made of polyvinyl plastics

ActiveCN100577218CHigh tensile strengthHigh impact strengthBone implantPower switchingArtificial bone

The present invention relates to a method for making a vinyon artificial bone fragment molding implant, and the method comprises the steps of: (a) preparing the raw material: filtrating the thin particle vinyon in initial state, the surface of the obtained particle has a plurality of prominent bulges which is irregular ellipse grain shape; (b) preparing the mold which is composed of a mold frame, a top mold board and a lower mold plate; (c) adding material: spreading the filtrated raw material uniformly in the mold cavity after weighting; (d) orientating the electrostatic: opening the electrical power switch of the electrostatic generator and adjusting the electrical voltage, executing slow horizontal moving scanning with the electrode bar at the voltage output end at the upper side of the mold, the upright particles inclines along with the moving direction of the electrode bar and the plastic particles are arranged with regulated cross net shape; (e) closing the mold cover and inputting the mold to the heating furnace to sinter when the process of the electrostatic orientating has finished. The artificial bone fragment made with the method of the invention has a cellular structure with a definite shape, facilitates the adhering and growing of the human organization, has an excellent bioavailability and physical property.

Owner:张勇

Anti-crack SMW construction method pile and construction method thereof

PendingCN113605382AImprove toughnessReduce crackingExcavationsBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to the technical field of deep foundation pit supporting, in particular to an anti-crack SMW construction method pile and a construction method thereof. The anti-crack SMW construction method pile is characterized in that a certain quantity of vinylon staple fibers are arranged in a pile body of the SMW construction method pile, the vinylon staple fibers are put in the pile body construction process of the SMW construction method pile, and the vinylon staple fibers are uniformly mixed with cement soil of the SMW construction method pile. The anti-crack SMW construction method pile has the advantages that the toughness of the cement soil is greatly improved, so that the deformation of the cement soil can be coordinated with the deformation of interpolated profile steel, and cracks are reduced; and the construction is convenient, existing construction method pile construction equipment can be used without transformation, and existing processes do not need to be changed.

Owner:杭州铁路设计院有限责任公司

Glue preparation method by dissolving chitin and vinylon fiber with ionic liquid

PendingCN114737277ASolve the problem of blending rubberReduce manufacturing costConjugated synthetic polymer artificial filamentsBulk chemical productionPolymer scienceSpinning

The invention relates to a glue preparation method by dissolving chitin and vinylon fibers with an ionic liquid, which comprises the following steps: adding crushed chitin and polyvinyl butyral into a container filled with the ionic liquid, stirring and dissolving under the condition of 120 DEG C oil bath until a transparent glue solution is formed, the concentration of the transparent glue solution is 5-25%, and the transparent glue solution is free from layering and impurities; then carrying out vacuum defoaming in an environment of-0.95 MPa to obtain a spinning glue solution; vinylon and chitin can be dissolved in the same ionic liquid at the same time, the problem of blending of chitin and vinylon for glue preparation is well solved, and the production cost is greatly reduced.

Owner:LUOYANG CHANGLONG CHEM TECH

High-performance and long-life zinc-nickel battery negative electrode paste

High-performance and long-life zinc-nickel battery negative electrode slurry, including the following components according to weight percentage: active material 85-95%, conductive agent 1-5%, additive 1-4%, auxiliary material 0.1-1.5%, auxiliary binder 2.5% ‑3% and binder 0.4‑1.5%, active materials include one or more of zinc oxide, calcium zincate and zinc powder, additives include one or more of indium oxide, bismuth oxide, aluminum oxide and lead oxide The conductive agent includes one or more of graphite, carbon black, acetylene black and conductive ceramics, the auxiliary materials include short fibers and inorganic fibers, the short fibers include one or more of vinylon, PP, and nylon, and the adhesive includes acrylic acid Any three or four of vinyl alcohol copolymers TSP, CMC, sodium polyacrylate, and PVA, and the auxiliary binder is PTFE and SBR emulsion. The zinc-nickel battery negative electrode slurry provided by the invention has stable state, good fluidity, The excellent performance of not forming zinc dendrites, less material migration and settlement deformation, and longer life can better meet the needs of development.

Owner:森克创能(天津)新能源科技有限公司

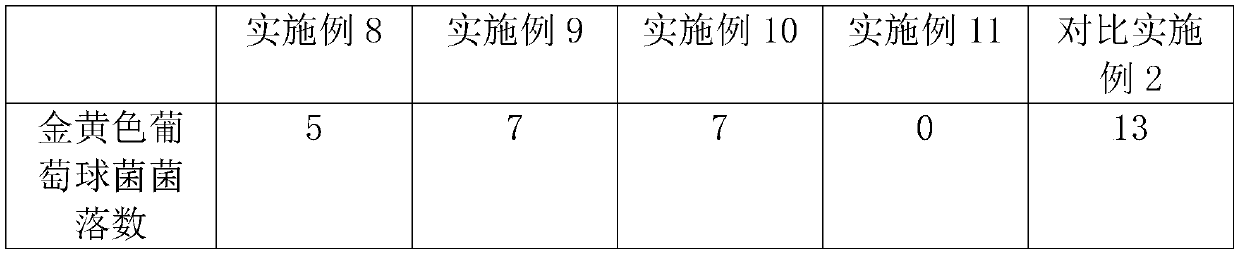

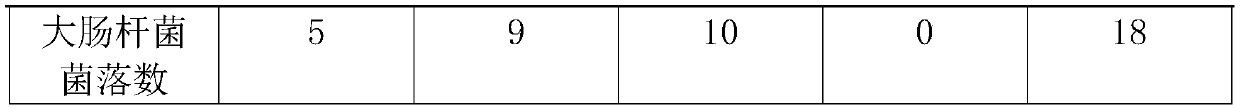

A kind of antibacterial textile material and preparation method thereof

ActiveCN110629401BIncrease elasticityGood biocompatibilityConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyesterPolymer science

Owner:JINJIANG DAYI WARP KNITTING

Spinning glue preparation method for dissolving animal hair and vinylon by ionic liquid

PendingCN114737273AGreen dissolveEffective dissolutionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention relates to a spinning glue-making method by dissolving animal hair and vinylon with an ionic liquid, which comprises the following steps: cleaning the animal hair with water, soaking with ethanol or acetone to degrease for 1-12 hours, drying at 60-90 DEG C, crushing into fine powder by a crusher, adding the treated animal hair and polyvinyl butyral into a container filled with the ionic liquid, and uniformly stirring to obtain the spinning glue-making method. The preparation method comprises the following steps: dissolving keratin in an oil bath at 120 DEG C until a transparent glue solution is formed to obtain a keratin solution, and then defoaming the keratin solution in a vacuum environment of-0.95 MPa to obtain a spinning glue solution after vacuum defoaming; according to the method, keratin and vinylon can be dissolved in a green and efficient mode, degradation of the keratin is controlled to obtain regenerated keratin with large molecular weight, the strength of keratin spinning is greatly improved, keratin molecules are made into filaments independently, the application range of the keratin spinning is widened, meanwhile, pollution to the environment is avoided, and the method is suitable for industrial production. The requirements of modern green chemical development are met.

Owner:LUOYANG CHANGLONG CHEM TECH

Double-faced adhesive tape and use method thereof

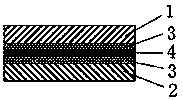

PendingCN113265204AEasy to useImprove adsorption capacityFilm/foil adhesivesPolymer sciencePolyvinyl alcohol

The invention discloses a double-faced adhesive tape and a use method thereof. The double-faced adhesive tape has a five-layer structure which sequentially comprises a bottom release film, an adhesive, foam, an acrylate polymer layer and water-soluble paper. The preparation of the water-soluble paper comprises the following steps: preparing net paper, pulping water-soluble vinylon fibers into fine fibers, performing wet-process papermaking to form a net, and performing vacuum dehydration and drying; preparing the water-soluble paper, wherein the mesh paper is subjected to pulp hanging in a saturated solution of polyvinyl alcohol so that the water-soluble paper is prepared through vacuum dewatering, drying and calendering of a calender; according to the double-faced adhesive tape and the use method thereof, most of the double-faced adhesive tape is made of natural environment-friendly materials, zero release of formaldehyde is achieved, the double-faced adhesive tape is green and environmentally friendly, indoor air is not polluted, the living comfort is improved, meanwhile, the use method of the double-faced adhesive tape is simple and feasible, and after the double-faced adhesive tape is used, the adsorption capacity is large, and the phenomena of falling, tearing and the like cannot occur.

Owner:王佳胶带科技(海安)有限公司

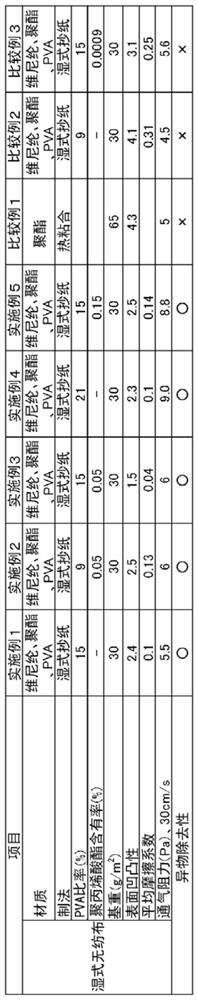

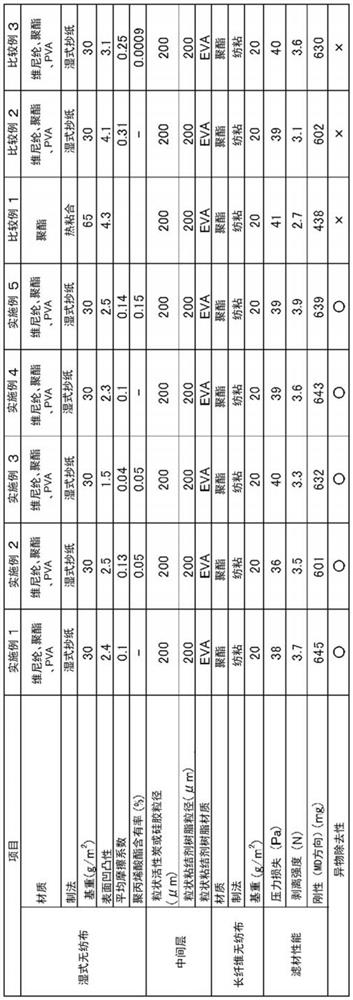

Wet non-woven fabric for filter, filter medium for filter, and filter

PendingUS20210016213A1Easy to disassembleEasy to cleanNon-fibrous pulp additionGas treatmentVinyonPolyester

The wet non-woven fabric for a filter of the present invention comprises vinylon, polyester, and polyvinyl alcohol, the wet non-woven fabric comprises 10 to 20% by weight of the polyvinyl alcohol, and a surface, of the wet non-woven fabric, that is located on an upstream side of air flow has a surface roughness (SMD) of not larger than 2.7 μm.

Owner:TOYO TOYOBO CO LTD

Wet non-woven fabric for filter, filter medium for filter, and filter

PendingCN111971105AEasy to removeImprove cleanlinessNon-fibrous pulp additionGas treatmentPolyesterPolymer science

A wet non-woven fabric for a filter according to the present invention is formed of vinylon, polyester, and polyvinyl alcohol and contains 10 to 20% of the polyvinyl alcohol by weight, and the surfaceroughness (SMD) of a surface of the wet non-woven fabric, the surface being disposed at the upstream side in ventilation, is 2.7 [mu]m or less.

Owner:TOYOBO MC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com