Wet non-woven fabric for filter, filter medium for filter, and filter

A technology of wet non-woven fabrics and filters, which is applied in the direction of membrane filters, filtration separation, and dispersed particle filtration, etc. It can solve the problems of difficult filter reuse and foreign matter cannot be easily removed, and achieves easy cleaning and simple removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

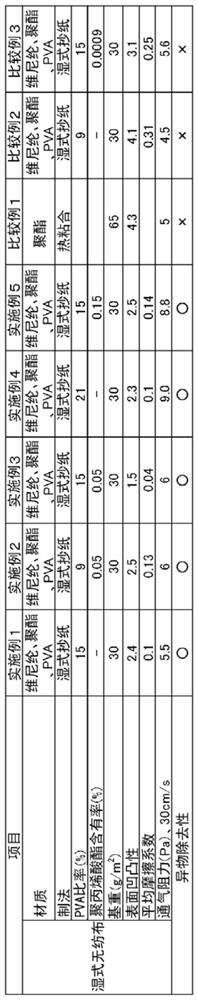

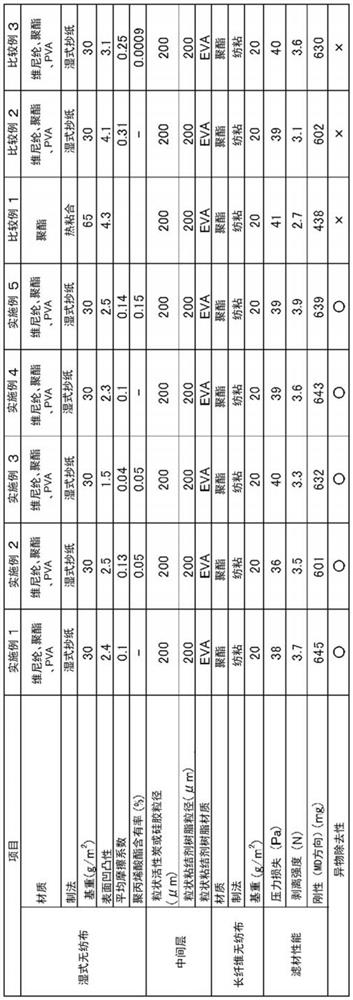

Embodiment 1

[0070] Vinylon fiber (17dtex, average fiber length 12mm, average fiber diameter 40μm), vinylon fiber (7dtex, average fiber length 10mm, average fiber diameter 25μm), vinylon fiber (2.2dtex, average fiber length 6mm, average fiber diameter 15μm) polyester fiber (0.6dtex, average fiber length 5mm, average fiber diameter 8μm), polyester fiber (2.2dtex, average fiber length 5mm, average fiber diameter 15μm), PVA fiber (1.1dtex, average fiber length 3mm, average The fiber diameter is 10 μm) mixed with a weight ratio of 26:31.25:5.25:11.25:11.25:15, and dispersed in water with a pulper to prepare a stock solution for wet papermaking.

[0071] The stock solution for wet papermaking was made into a wet web (wet web) by short-wire papermaking method, then lightly squeezed with a press roll and dried with a drying drum at 140°C to obtain a basis weight 40g / m 2 , The wet-laid nonwoven fabric of Example 1 with a thickness of 0.3 mm.

[0072] Then, on the downstream side of the obtained ...

Embodiment 2

[0074] Vinylon fiber (7dtex, average fiber length 10mm, average fiber diameter 25μm), vinylon fiber (2.2dtex, average fiber length 6mm, average fiber diameter 15μm), polyester fiber (0.6dtex, average fiber length 5mm, average fiber Diameter 8μm), polyester fiber (2.2dtex, average fiber length 5mm, average fiber diameter 15μm), PVA fiber (1.1dtex, average fiber length 3mm, average fiber diameter 10μm) with a weight of 51:7.6:16.2:16.2:9 Then, the polyacrylate was weighed so as to be 0.05% relative to the weight of the injected fibers, and dispersed in water with a pulper to prepare a stock solution for wet papermaking.

[0075] The stock solution for wet papermaking was made into a wet wire by the short wire papermaking method, then lightly squeezed with a press roll and dried with a drying drum at 140°C to obtain a basis weight of 30g / m 2 , The wet-laid nonwoven fabric of Example 2 with a thickness of 0.2 mm.

[0076] Then, except having used the wet-laid nonwoven fabric of E...

Embodiment 3

[0078] Vinylon fiber (7dtex, average fiber length 10mm, average fiber diameter 25μm), vinylon fiber (2.2dtex, average fiber length 6mm, average fiber diameter 15μm) polyester fiber (0.6dtex, average fiber length 5mm, average fiber diameter 8μm), polyester fiber (2.2dtex, average fiber length 5mm, average fiber diameter 15μm), PVA fiber (1.1dtex, average fiber length 3mm, average fiber diameter 10μm) at a weight ratio of 45:7.6:16.2:16.2:15 After mixing and weaving, the polyacrylate was weighed so as to be 0.05% with respect to the weight of the fibers charged, and dispersed in water with a pulper to prepare a stock solution for wet papermaking.

[0079] The stock solution for wet papermaking was made into a wet wire by the short wire papermaking method, then lightly squeezed with a press roll and dried with a drying drum at 140°C to obtain a basis weight of 30g / m 2 , The wet-laid nonwoven fabric of Example 3 with a thickness of 0.2 mm.

[0080] Then, except having used the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com