High-performance and long-life zinc-nickel battery negative electrode paste

A zinc-nickel battery and negative electrode slurry technology, which is applied to nickel storage batteries, battery electrodes, alkaline storage batteries, etc., can solve the problems of not being able to improve the cycle performance of zinc negative electrodes, and achieve small material migration and settlement deformation, and prolong the life of the battery. Cycle life, effect of reducing gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] High-performance long-life zinc-nickel battery negative electrode slurry, including the following components:

[0029] Mix 40g of zinc oxide, 45g of calcium zincate, 2.5g of graphite, 2.5g of carbon black, 2g of indium oxide, 2g of bismuth oxide, and 1.5g of vinylon, and mix evenly to obtain a mixed material;

[0030] Add 0.5g TSP-515 (acrylic acid vinyl alcohol copolymer), 0.5g CMC, and 0.5g sodium polyacrylate to 500g distilled water to obtain a bonding solvent;

[0031] Add the mixed material to the bonding solvent, and then use 3g of PTFE emulsion to prepare negative electrode slurry;

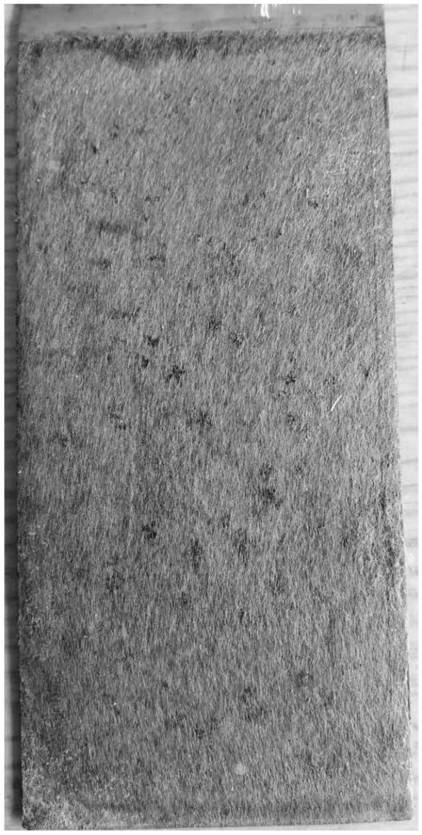

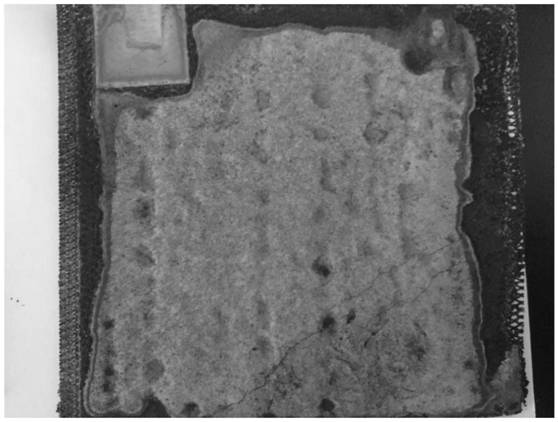

[0032] The negative electrode slurry was coated on both sides of the copper grid, pressed and dried to form a negative electrode, which was used as the experimental group A.

Embodiment 2

[0034] High-performance and long-life zinc-nickel battery negative electrode paste:

[0035] Mix 50g of zinc powder, 45g of calcium zincate, 0.5g of acetylene black, 0.5g of carbon black, 0.5g of aluminum oxide, 0.5g of lead oxide and 0.1g of PP, and mix evenly to obtain a mixed material;

[0036] Add 0.1g of PVA, 0.1g of TSP-515 (acrylic acid vinyl alcohol copolymer), 0.1g of CMC and 0.1g of sodium polyacrylate into 500g of distilled water to obtain a bonding solvent;

[0037] Add the mixed material into the bonding solvent, and then prepare the negative electrode slurry with 0.5g of PTFE emulsion and 2.0g of SBR emulsion;

[0038] The negative electrode slurry was coated on both sides of the copper grid, and pressed and dried to form a negative electrode, which was used as the experimental group B.

Embodiment 3

[0040] High-performance long-life zinc-nickel battery negative electrode slurry, including the following components:

[0041] Zinc oxide 35g, calcium zincate 35g, zinc powder 20g, conductive ceramic 3g, bismuth oxide 1.2g, aluminum oxide 1.3g, nylon 1g, PTFE emulsion 2.5g, CMC 0.3g, sodium polyacrylate 0.3g, PVA 0.4g,

[0042] The manufacturing method is the same as in Example 1, adopting 500g distilled water to prepare negative electrode slurry,

[0043] Mix 45g of zinc powder, 45g of zinc oxide, 3g of conductive ceramics, 1.2g of bismuth oxide, 1.3g of aluminum oxide and 1g of nylon fiber, and mix evenly to obtain a mixed material;

[0044] Add 0.4g of PVA, 0.3g of CMC and 0.3g of sodium polyacrylate into 500g of distilled water to obtain a bonding solvent;

[0045] Add the mixed material into the bonding solvent, and then prepare the negative electrode slurry with 2.5g of PTFE emulsion;

[0046] The negative electrode slurry was coated on both sides of the copper grid, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com