Method for manufacturing environment-friendly type geothermal heat floor

A geothermal floor, environmentally friendly technology, used in buildings, building structures, floors, etc., can solve the problems of weak interface connection, easy cracking, shortened service life, etc., and achieve the effect of saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

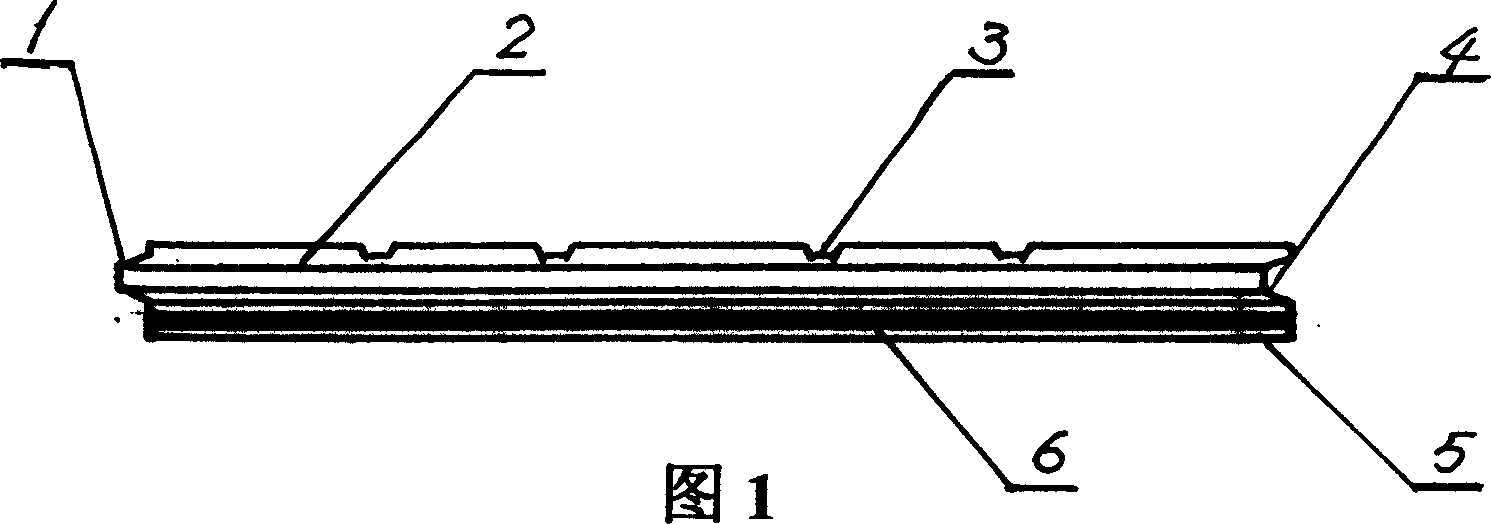

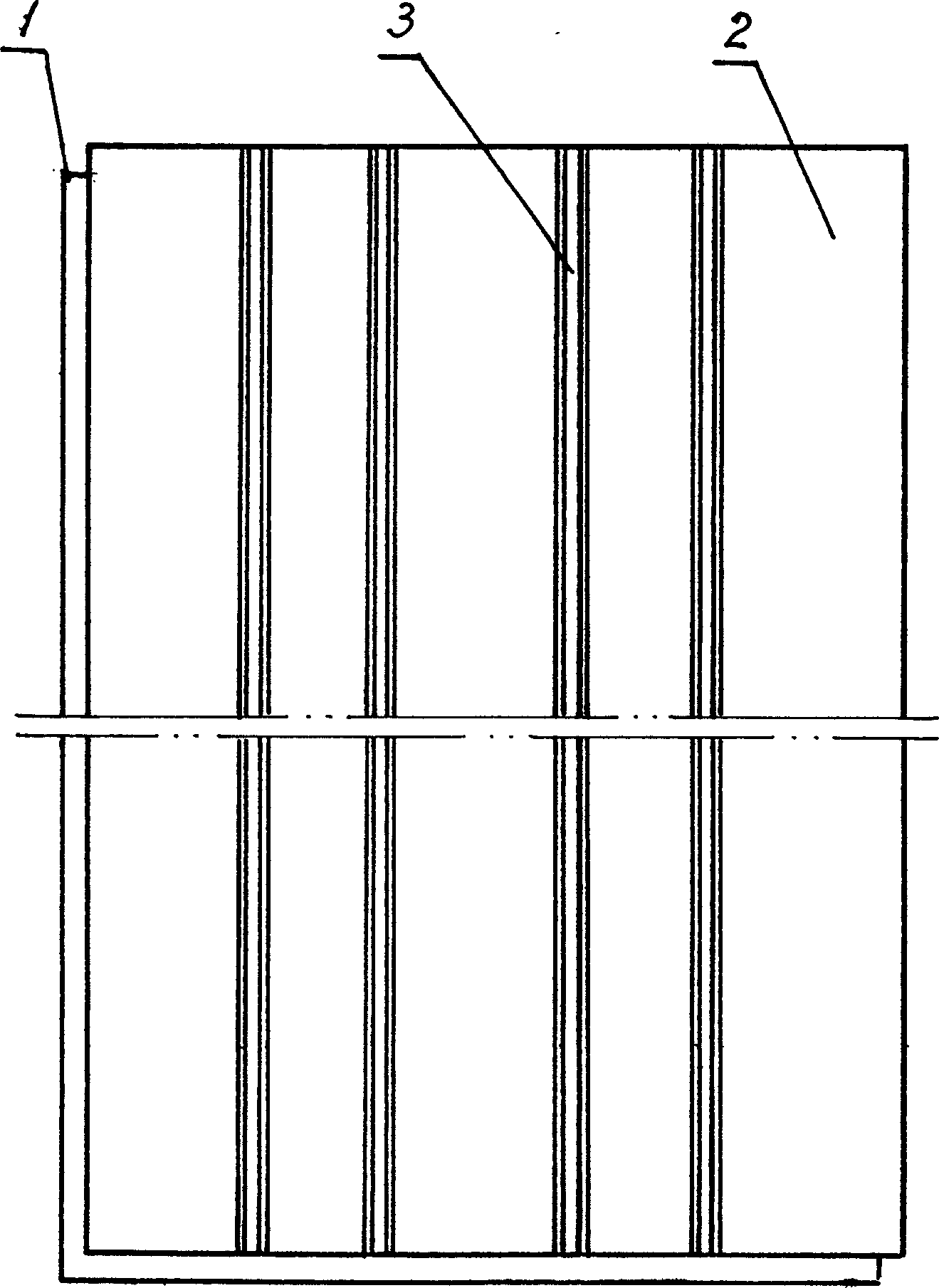

[0027] Embodiment 1 Prepare a geothermal floor with a specification of 900×100×6

[0028] During the production, according to the actual use requirements and various performance indicators, considering the main performance of the raw materials used and the synergistic effect of each other, each component is optimized, and the raw materials are weighed according to the formula: the regeneration of base material waste polyethylene plastic film 100 parts of raw materials, 70 parts of filler lignocellulose straw, 25 parts of light calcium carbonate, 6 parts of processing modifier acrylate copolymer, 0.4 part of surface treatment agent stearic acid, 0.6 part of heat stabilizer calcium stearate , Light stabilizer titanium dioxide 3 parts, internal lubricant liquid paraffin 0.2 parts, external lubricant solid paraffin 0.6 parts, 2,6-tert-butyl-4-methyl powder 0.4 parts. Then weigh each component according to the formula, put it into a hot mixing kneader, mix evenly, granulate, extrud...

Embodiment approach 2

[0029] Embodiment 2 Prepare a geothermal floor with a specification of 750×100×6

[0030] During production, according to the actual use requirements and various performance indicators, considering the main properties of the raw materials used and the synergistic effect of each other, each component is optimized, and the raw materials are weighed according to the formula: recycled materials from waste polyethylene plastic products 100 90 parts of lignocellulose pine leaves, 15 parts of light calcium carbonate, 5 parts of acrylate copolymer, 0.6 parts of stearic acid, 0.9 parts of calcium stearate, 5 parts of titanium dioxide, 0.3 parts of liquid paraffin, 0.8 parts of solid paraffin, 4 parts of medical stone, 25 parts of magnesium hydroxide, 0.6 parts of 2,6-tert-butyl-4-methyl powder. Other operation steps are the same as those in Embodiment 1.

Embodiment approach

[0031] Embodiment 3 Prepare a geothermal floor with a specification of 600×100×6

[0032] During production, according to the actual use requirements and various performance indicators, considering the main properties of the raw materials used and the synergistic effect of each other, each component is optimized, and the raw materials are weighed according to the formula: recycled materials from waste polyethylene plastic products 100 80 parts, 80 parts of lignocellulose sawn, 20 parts of light calcium carbonate, 4 parts of acrylate copolymer, 0.8 parts of stearic acid, 0.8 parts of calcium stearate, 4 parts of titanium dioxide, 0.4 parts of liquid paraffin, 0.9 parts of solid paraffin, 3 parts of medical stone, 22 parts of magnesium hydroxide. Other operation steps are the same as the embodiment.

[0033] Embodiment 4 Prepare a geothermal floor with a specification of 450×100×6

[0034] During production, according to the actual use requirements and various performance indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com