Method for installing and constructing special-shaped large-tonnage steel castings

A construction method and technology of steel castings, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to use multi-directional oblique components, lack of flexibility of steel castings, single use parts, etc., and achieve improvement The effect of visual quality, ensuring construction quality and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

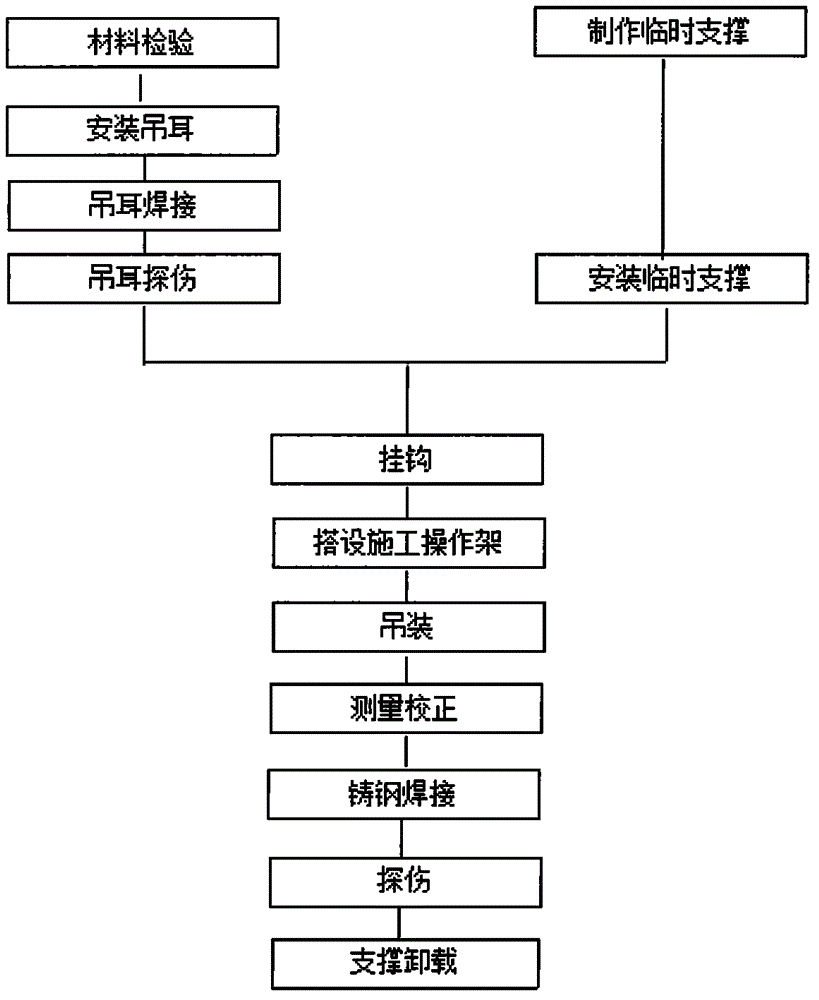

[0023] Embodiment 1: as attached figure 1 As shown, during the construction process, while making temporary supports and installing temporary supports, material inspection, installation of lifting lugs, welding of lifting lugs and flaw detection of lifting lugs are carried out simultaneously; Correction, cast steel welding, flaw detection and support unloading complete the construction process.

[0024] Specific steps include:

[0025] ①Raw material inspection; steel castings must pass the quality inspection of the factory when they leave the factory, and issue a factory quality certificate. After entering the site, inspections of external dimensions, internal structures, wall thickness and all-round external surface magnetic powder must be carried out on site. Non-destructive testing, etc., to ensure that the steel castings can be used only after there are no defects;

[0026] ②Installation and welding of hoisting lugs; steel castings are not assembled with hoisting lugs be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com