Earth and rockfill dam milling excitation frequency and excitation force real-time monitoring system and monitoring method

A technology of excitation frequency and real-time monitoring, applied in signal transmission systems, soil protection, instruments, etc. Vibration frequency and other issues to achieve the effect of preventing interference from human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

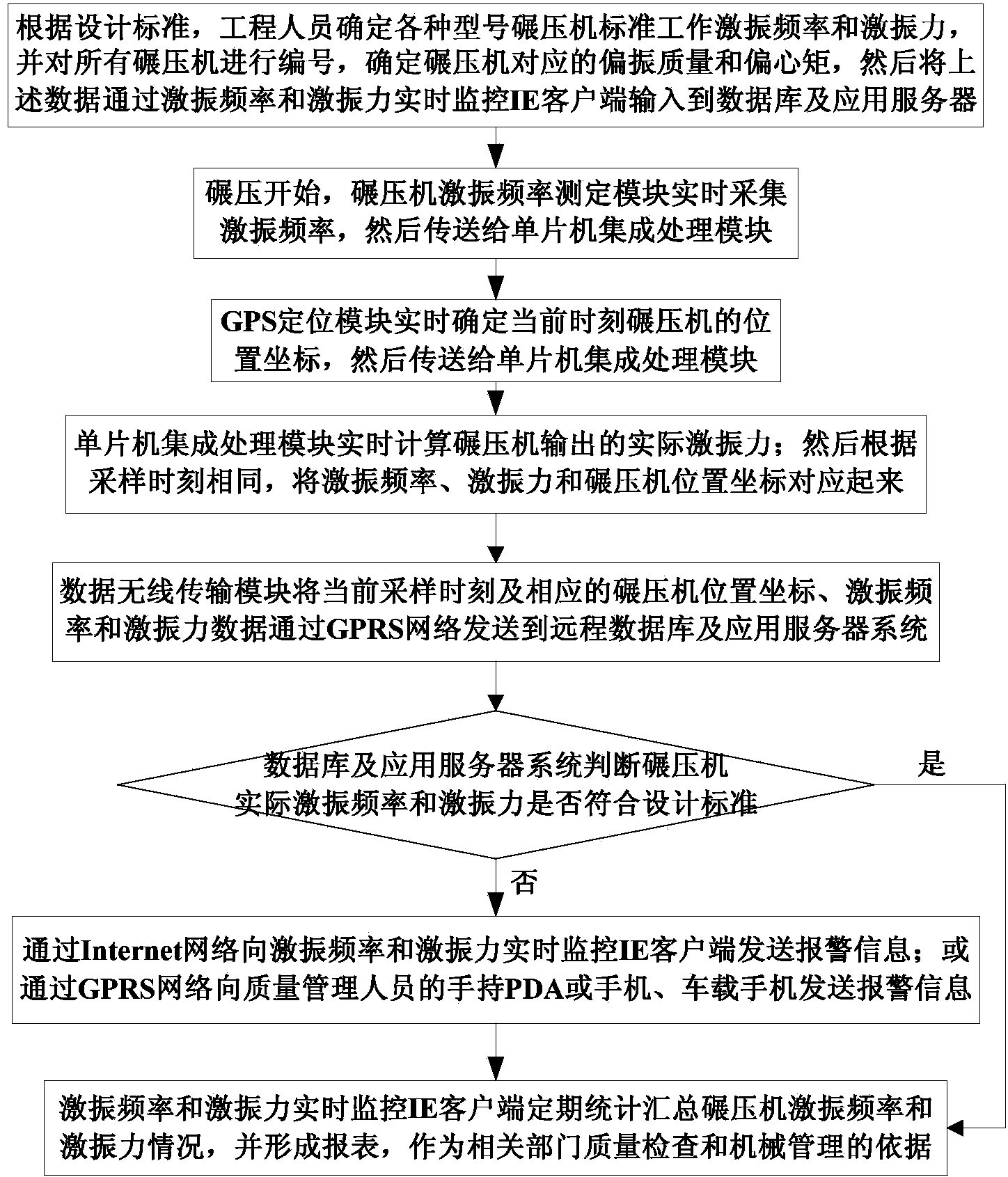

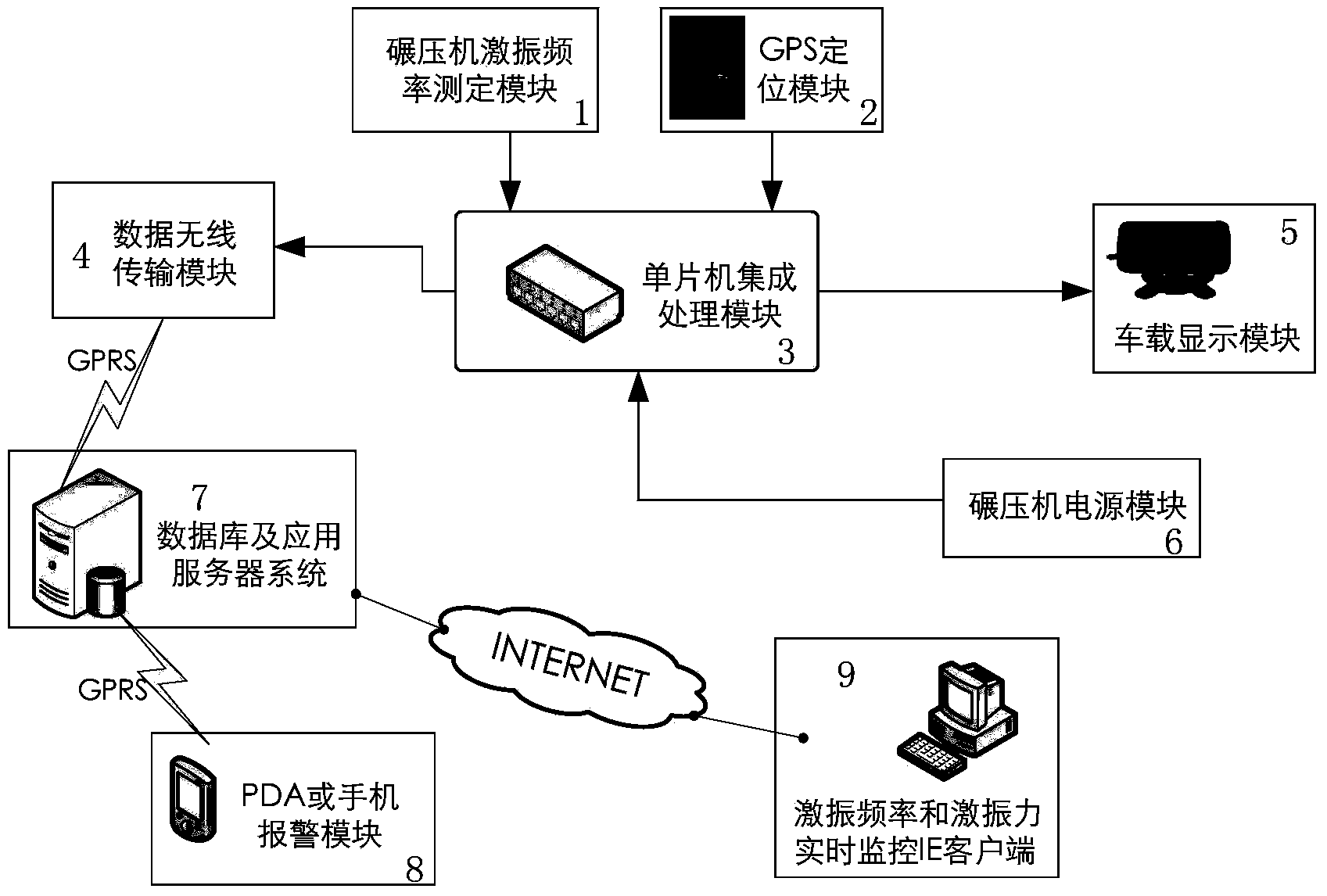

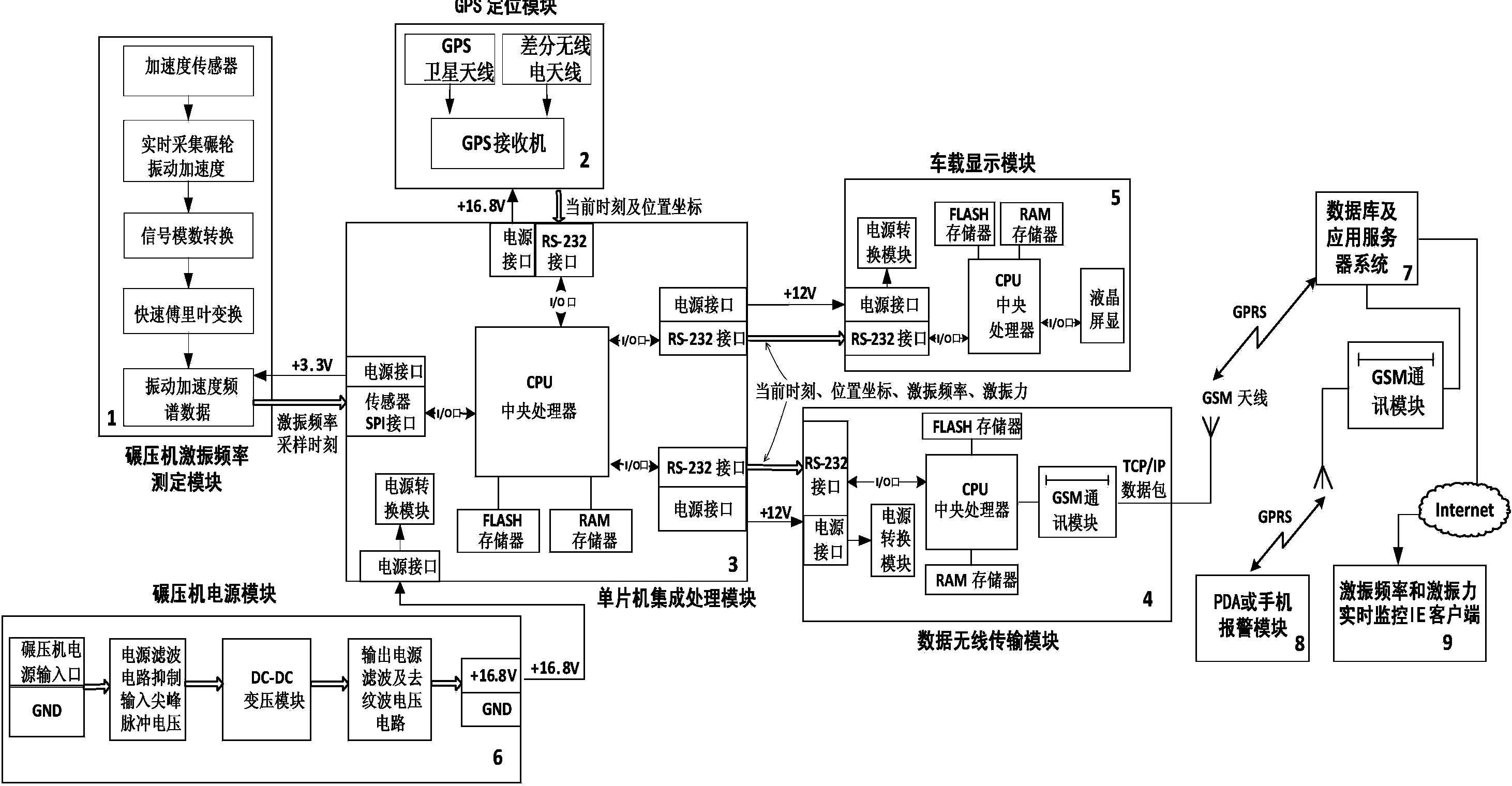

Method used

Image

Examples

Embodiment Construction

[0050] This invention is further developed on the basis of the previously applied patent "a real-time monitoring device for earth-rock dam material compaction quality (application number 201310036698.8)", in which the GPS positioning module and data wireless transmission module (DTU) in this invention It is similar to the power module of the roller compactor and the previous patent application (application number 201310036698.8); the difference is that the previous patent application mainly uses the real-time monitoring of the acceleration process of the roller to calculate the compaction quality of the earth-rock dam material. solidity monitoring value (CV), and the present invention uses the real-time monitored wheel acceleration process to calculate the working frequency of the wheel vibration, and then calculates the actual output excitation force of the rolling machine, and then through wireless communication technology, the Internet Technology, etc., to realize the synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com