Arrangement method for cable-hanging of single parallel steel strand wires

A technology of parallel steel strands and layout methods, which is applied to bridge parts, erection/assembly bridges, bridges, etc., which can solve the problems of slow progress and poor tension control, so as to ensure construction quality, reduce labor intensity and construction cost , Eliminate the effect of human interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

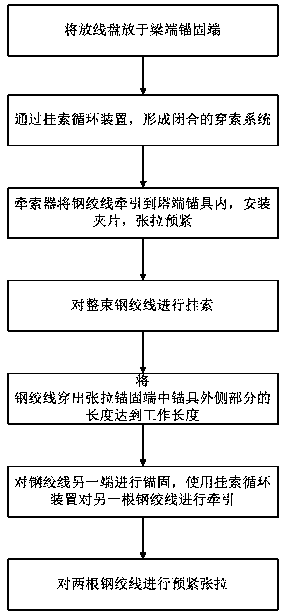

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] The hanging cable circulation device includes a pay-off reel, a winch, a traction device, and a cable puller, wherein the pulley is arranged on the beam, and the cable puller is arranged at the tower end, and the cable puller and the pulley are connected by a wire rope, and the wire rope passes through two A set of guide wheels is used for steering. When in use, one end of the steel strand on the pay-off reel is connected to one end of the traction groove of the traction device, and the other end of the traction device is connected to the hoist through a wire rope to form a closed rope system. The cable puller is used for tensioning the pre-tensioned steel strand.

[0024] The anchoring system of the cable-stayed cables of the parallel steel strands adopts a sealing cylinder to replace the combination of the support cylinder and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com