Building strengthening method

A technology for building and strengthening structures, which is applied in the direction of building construction, construction, building maintenance, etc., can solve the problems of complex steel strand mesh construction, long construction period, high cost of steel strand materials, etc., to solve the problem of material damage, aging and Insufficient structural strength, guaranteed reinforcement performance, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

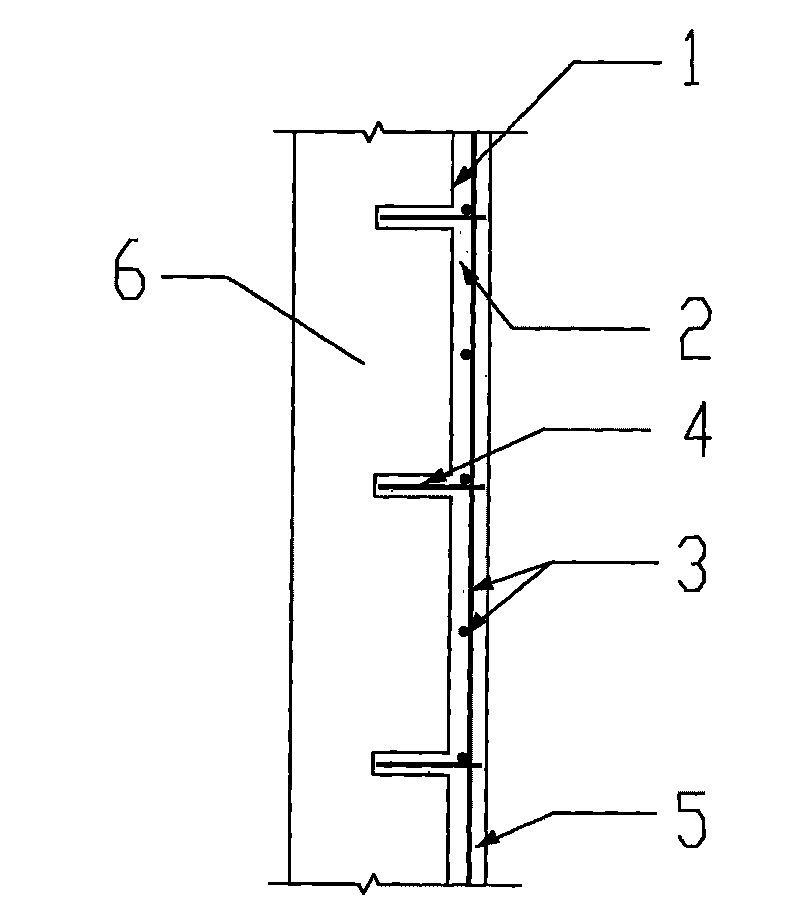

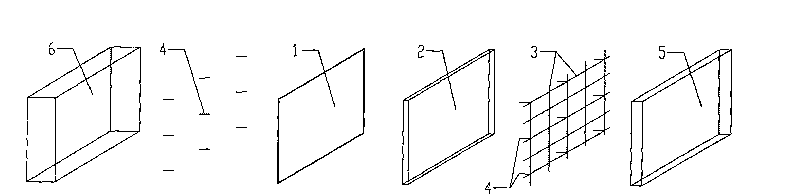

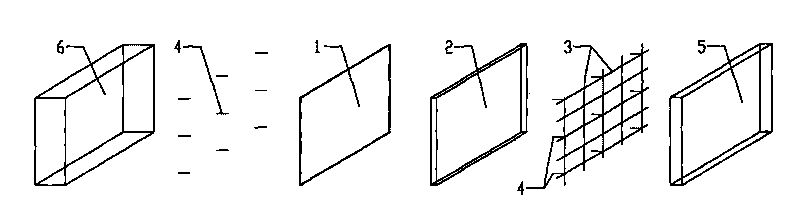

[0035] The implementation steps of the reinforcement method involved in the present invention are as follows:

[0036] 1) Remove peeling, loose, honeycomb, corrosion and other parts on the surface of the reinforced concrete structure or masonry structure (collectively referred to as the reinforced structure 6) to expose the solid surface;

[0037] 2) Wet the surface of the reinforced concrete or masonry structure with water 24 hours in advance to ensure that there is no open water on the surface before spraying;

[0038] 3) implanting the pin 4 connecting the steel mesh 3 and the reinforced structure 6, and binding the steel mesh 3;

[0039] 4) On the surface of concrete structure or masonry structure, spray interface agent coating 1;

[0040] 5) Spray polymer-modified cement mortar between the interface agent coating 1 and the steel mesh 3, and outside the steel mesh 3 to form a polymer-modified cement mortar bonding layer 2 and a polymer-modified cement mortar protective la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com