Patents

Literature

70results about How to "Fast growth in strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphogypsum-based gelling material and its application in mine tailing filling

ActiveCN104211313ARealize high-quality utilizationWide variety of sourcesMaterial fill-upRed mudPhosphogypsum

The invention relates to a gelling material for mine tailing filling. The gelling material for mine tailing filling used for improving the early stage strength of a filler and having good water segregation performance is obtained through the steps of respectively milling phosphogypsum, red mud, phosphorus residues and clinker to 800m<2> / kg, 700m<2> / kg, 300m<2> / kg and above 300m<2> / kg respectively, uniformly mixing the above milled raw materials, and adding an exciting agent. The gelling material is used to carry out mine tailing filling, and the raw materials are from various industrial waste residues, so the gelling material has the advantages of low cost, simple technology, strong maneuverability, low filling cost, effective utilization of various industrial waste residues of the metallurgy industry, energy saving, emission reduction and environmental protection.

Owner:CHINA THREE GORGES UNIV

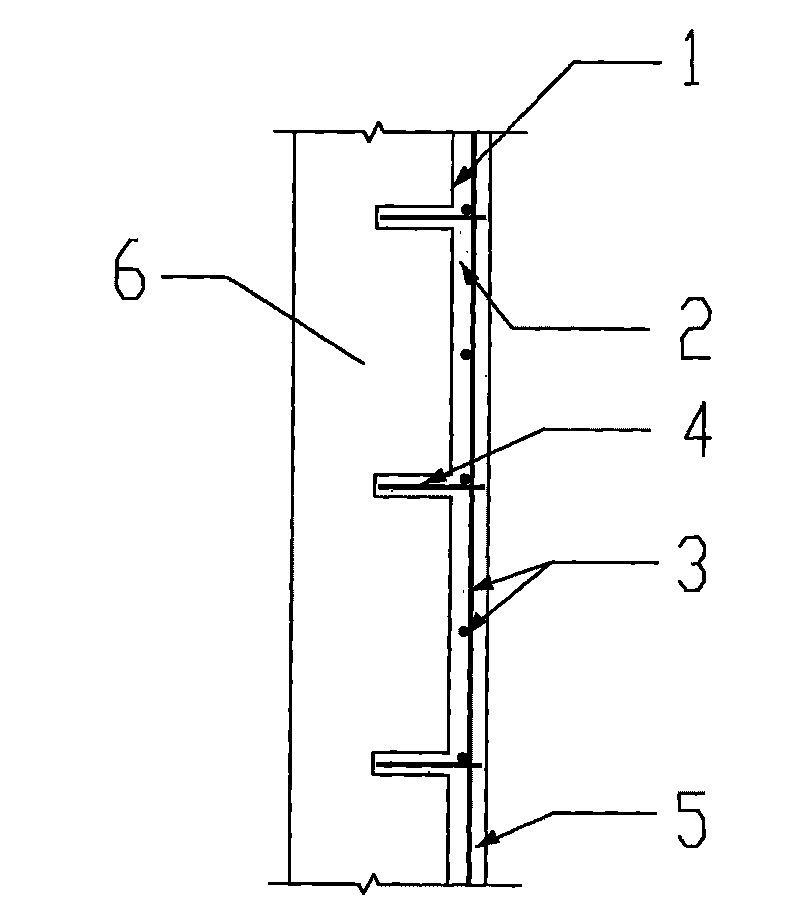

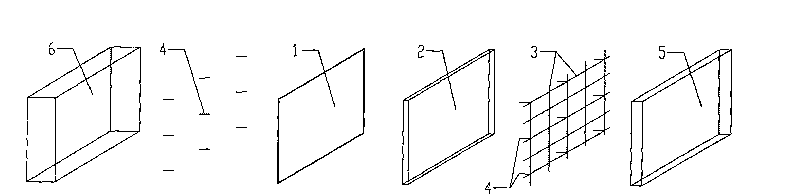

Building strengthening method

InactiveCN101691818AGood reinforcing effectWork together wellBuilding repairsPolymer modifiedFireproofing

The invention discloses a building strengthening method, which comprises the following steps of: 1) clearing the surface of a structure to be strengthened to expose a hard part; 2) carrying out water spray wetting on the structure to be strengthened; 3) implanting pins connecting a reinforcing steel bar net and the structure to be strengthened, and bonding the reinforcing steel bar net; 4) spraying an interface agent coating on the surface of the structure to be strengthened; and 5) spraying a polymer modified cement mortar bond layer and a polymer modified cement mortar protective layer by layers on the interface agent coating. The method can effectively improve the bearing capacity of the structure to be strengthened, improves the rigidity of the structure to be strengthened, and has less occupied space; a molded surface strengthening structure and the structure to be strengthened have the advantages of reliable bond, compactness, no crack, waterproofing, permeability resistance, fireproofing, high-temperature resistance, Cl-corrosion resistance, carbonization prevention, rust resistance and good durability; and a construction process is simple, formworks are not needed to be built, the speed of improving the strength of polymer modified cement mortar is high, and a construction period is greatly shortened. The method can be simultaneously applied to repairing and strengthening of the existing concrete structures and masonry structures, and solves the problems of breakage and aging of materials and insufficient structural strength of an old building.

Owner:上海维固工程实业有限公司

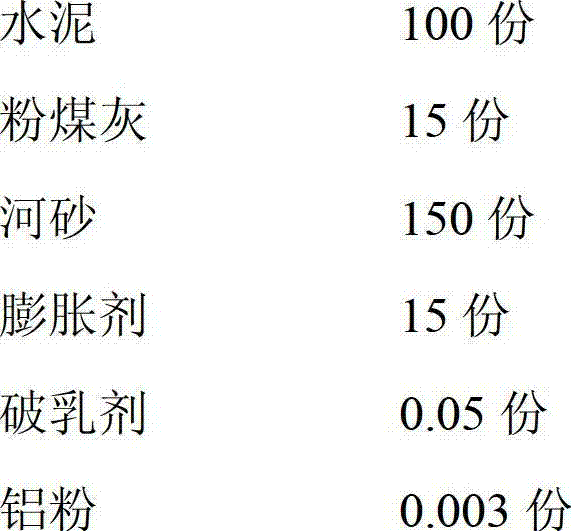

Silicate-based light-weight foam concrete and preparation method thereof

ActiveCN106966670AImproved carbonation resistanceImprove the stability of mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses silicate-based light-weight foam concrete and a preparation method thereof. The silicate-based light-weight foam concrete is prepared from silicate cement, an inorganic admixture, water, a foaming agent and an additive, wherein the mass ratio of the inorganic admixture to the silicate cement is 0.3 to 1.3; the water accounts for 35 to 65 percent by mass; and the foaming agent accounts for 3 to 10 percent by mass. The silicate-based light-weight foam concrete has the beneficial effects that the silicate cement is used as a cementing material; and compared with a sulfoaluminate-based material, the silicate-based light-weight foam concrete has the advantages that the carbonation resistance, the mechanical performance stability, the temperature tolerance and other properties are improved. By adjustment of the contents of all functional components (a thickening time control agent, a foam stabilizer, a water reducing agent, an anti-cracking component, an expanding agent and the like), the silicate-based light-weight foam concrete can conform to various preparation conditions of the silicate cement used as a base material.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

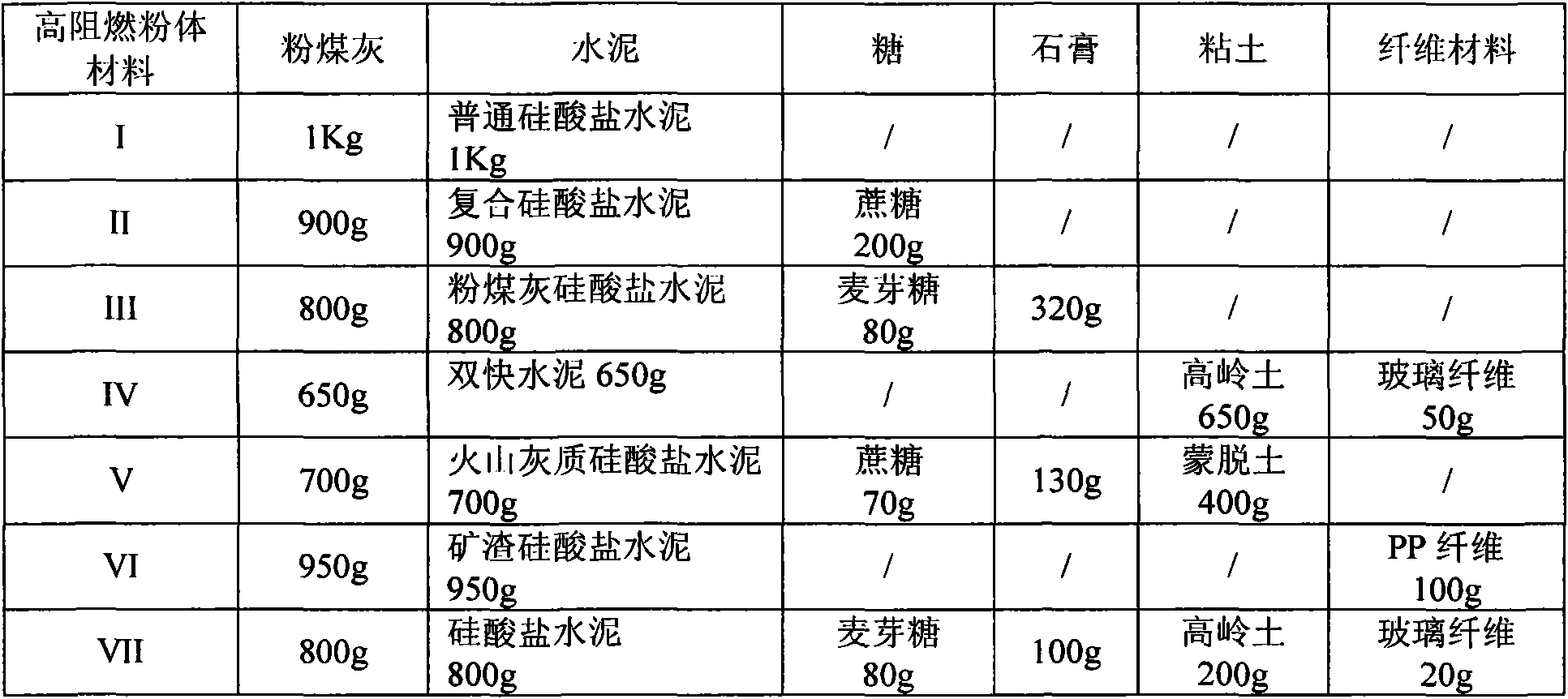

Spray-coating sealing material for coal rock mass

The invention provides a spray-coating sealing material for coal rock mass, belonging to the technical field of organic / inorganic compound materials. The spray-coating sealing material for the coal rock mass is a complex of high-molecular emulsion and high-flame-retardant powder materials, without any toxic and harmful substances, free of springback for construction, safe and environmental protective. When sprayed at vertical surfaces and top surfaces, the material does not flow and sag, and is good in overall effect. After curing, the coating has advantages of strong adhesion stress, high tensile strength, large tensile deformation, and excellent sealing performance. The material can be used for surface protection of the coal rock mass, air leakage prevention, gas leakage prevention, and rapid surface protection and moistureproof treatment after tunneling of swelling rock.

Owner:山东固安特新材料科技股份有限公司

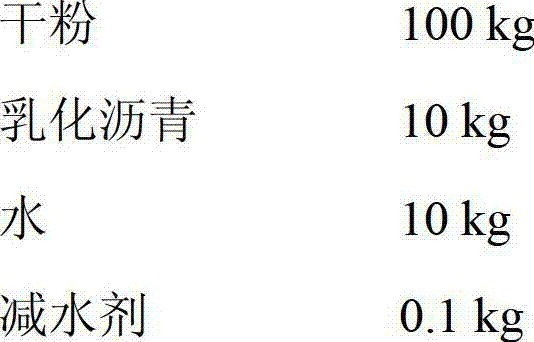

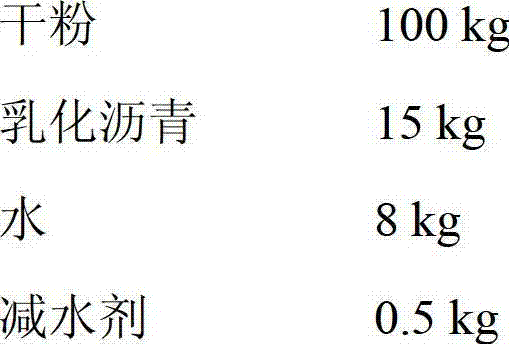

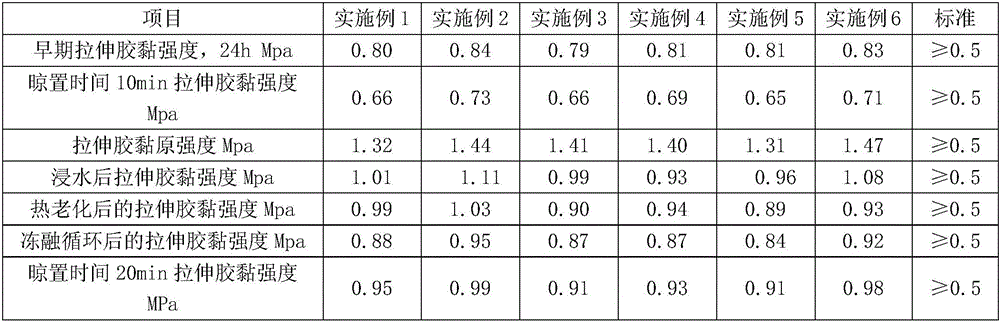

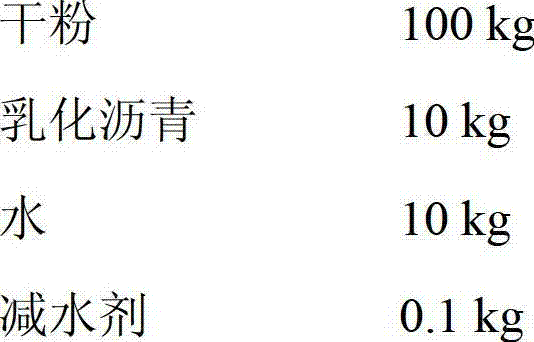

Repair material for bituminous pavement pot holes and method for preparing same

The invention discloses a repair material for bituminous pavement pot holes and a method for preparing the same, wherein the material is prepared by mixing and stirring the following raw materials according to parts by weight: 100 parts of dry powder, 10-20 parts of emulsified asphalt, 5-10 parts of water and 0.1-0.5 part of water reducer. The method for preparing the material comprises the steps of putting the dry powder, the water reducer and water in a stirring machine and stirring at a speed of 200 r / min for 60 s at first, and then adding the emulsified asphalt thereto and stirring at the speed of 200 r / min for 30 s, and finally, stirring at a speed of 400 r / min for 180 s, thereby obtaining the repair material for the bituminous pavement pot holes. The repair material for bituminous pavement pot holes provided by the invention is convenient for storage and does not need to be heated in use, and further is capable of quickly repairing the damaged bituminous pavement pot holes at different temperatures and under the wet conditions; as a result, the repair material can be selected for repairing when the traffic flow is small, so that the normal traffic capacity of the road cannot be affected.

Owner:CHANGAN UNIV

Quickly-solidified tile adhesive

A quickly-solidified tile adhesive comprises the raw materials in parts by weight: 20-40 parts of quick-hardening cement, 40-50 parts of quartz sand, 10-20 parts of fly ash, 10-20 parts of calcium carbonate, 2-4 parts of redispersible latex powder, 0.2-0.5 part of cellulose ether, 0.1-0.3 part of starch ether, 0.2-0.5 part of water repellent, 0.1-0.4 part of retarder and 1-5 parts of early strength agent. The quick-hardening cement, the quartz sand and the fly ash are used as raw materials to prepare the quickly-solidified tile adhesive, the adhesive is short and adjustable in initial setting time, the strength growth is fast, the fixed waste fly ash generated by thermal power plants is effectively utilized, the adhesive also contains organic high-molecular polymer capable of being compounded with the ceramic tile and the indoor environment pollution cannot be caused.

Owner:山东汉诺宝嘉新材料科技有限公司

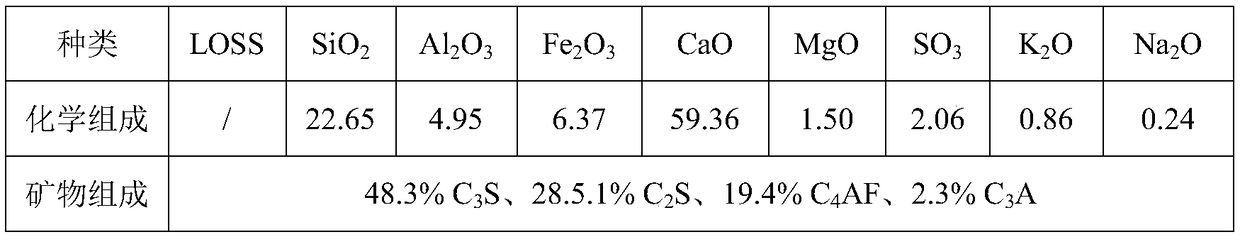

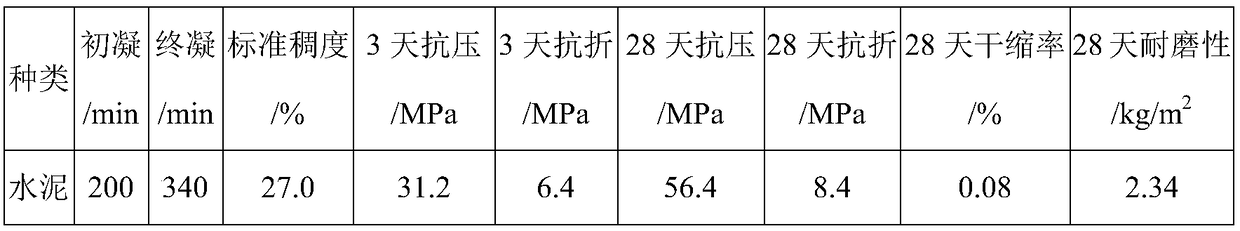

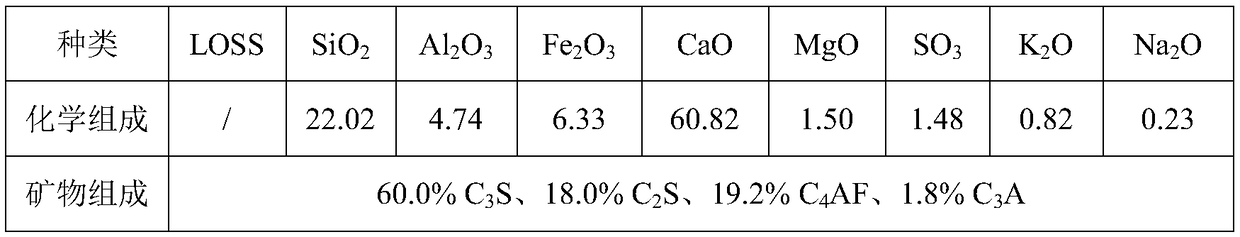

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

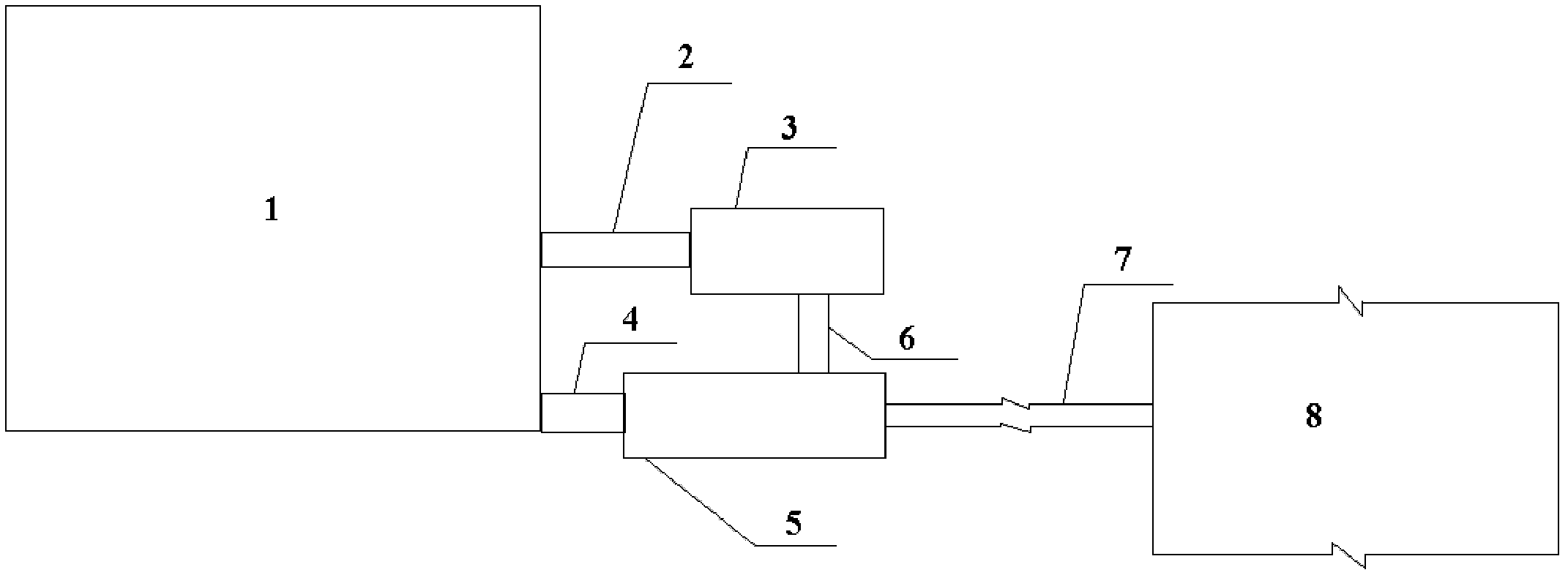

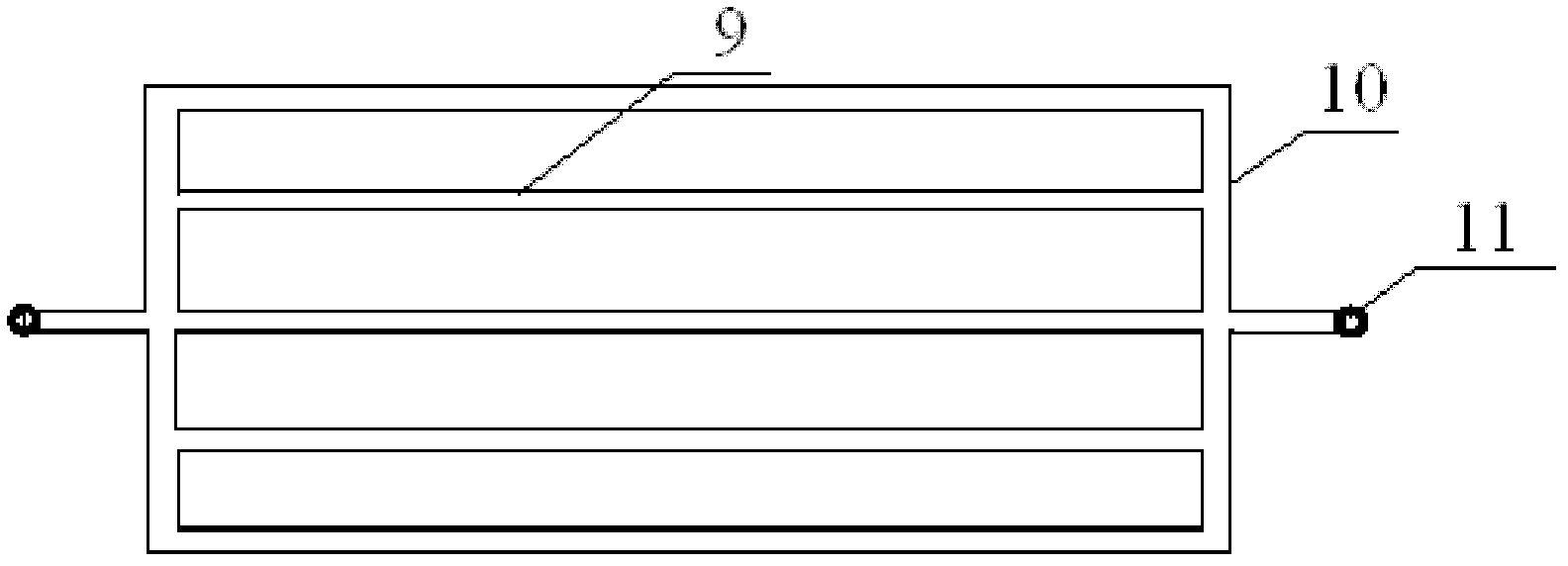

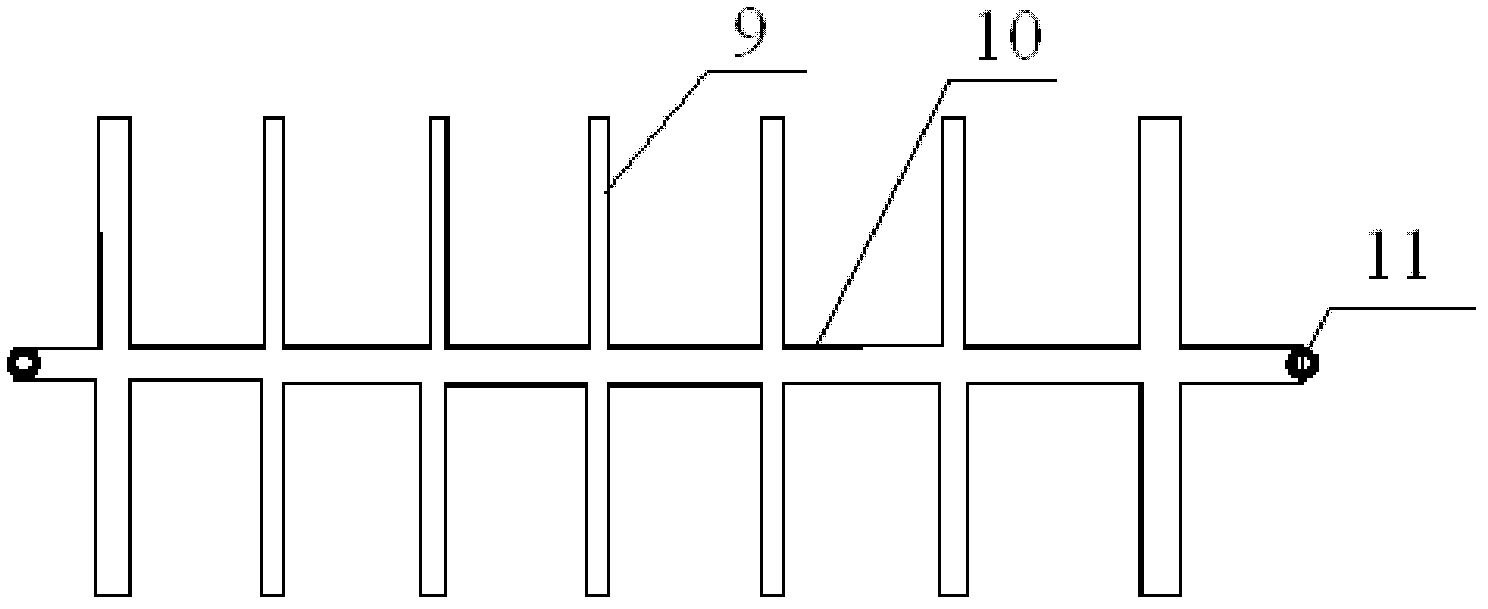

Large-sized filling bag embanking method and equipment for filling embankment by using dredged soil

The invention provides a large-sized filling bag embanking method and equipment for filling an embankment by using dredged soil. The method comprises the following steps: (1) designing the depths and the distances of soft soil foundation plastic water drainage plates under the embankment, finishing the construction of the water drainage plates, and mounting monitoring facilities in the soft soil foundation; (2) finishing one layer construction of a sand quilt layer and a soft soil row; (3) processing large-sized filling bags for future use for by using polyester woven fabric; (4) mounting dredged soil filling equipment; (5) mounting an evacuating device; (6) laying an evacuating water drainage pipe network; (7) laying the filling bags and carrying out filling construction; (8) mounting an embankment surface sealing system; (9) opening an evacuating system to accelerate drainage consolidation of a dredged soil filling body and simultaneously developing relevant monitoring and detecting works; and (10) finishing an open sea side protective surface structure and an inland sea side protective slope structure in time by using the full embankment body rising process so as to reinforce the protection of the embankment body. The equipment used by the method provided by the invention is filling equipment for the dredger fill filling bags. According to the invention, the embankment building cost is reduced, the environment is protected, the stability of the embankment is guaranteed, and the clay particle content of the filling body is 10%.

Owner:NANJING HYDRAULIC RES INST

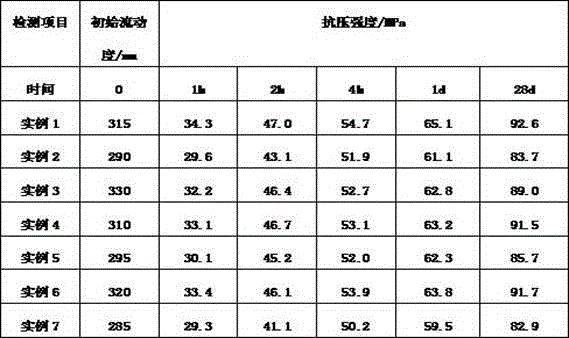

Super early-strength mortar

The invention discloses super early-strength mortar. The key point of the technical scheme is that the super early-strength mortar is prepared from the following components in percentage by weight: 40-50% of an inorganic bond material, 1-3% of an enhancer, 45-55% of aggregates, 0.3-1.5% of an early-strength agent, 0.05-0.4% of a retarder, 0.1-0.5% of a water reducer and 0.03-0.15% of anti-cracking fibers. The invention provides the super early-strength mortar which does not bleed or shrink and is high in liquidity; in addition, the 1h compressive strength can reach 30MPa and the long-term strength is not decreased.

Owner:苏州大乘环保新材有限公司

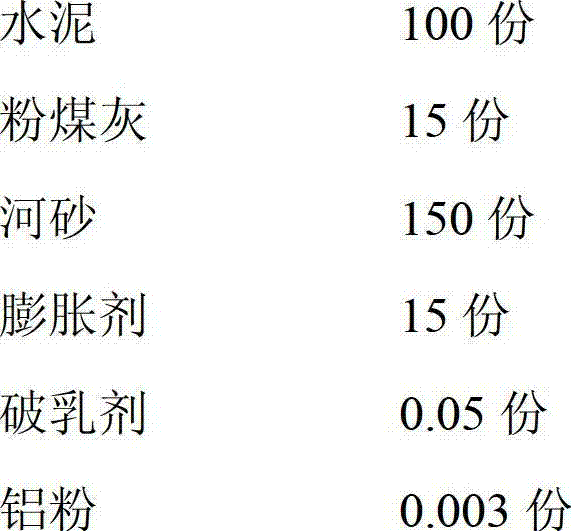

Highly anti-bending and wearing-resistant lightweight concrete

The invention discloses highly anti-bending and wearing-resistant lightweight concrete, which comprises the following raw material constituents in parts by weight: 200-250 parts of cement, 100-150 parts of coal ash, 150-200 parts of river sand, 100-180 parts of manganese residue, 150-200 parts of ceramsite, 20-50 parts of silicon carbide, 15-35 parts of plant fiber, 200-250 parts of water, 0.3-1.5 parts of dipropyl ethylene glycol monobutyl ether, 3-6 parts of silicon resin polyether emulsion, 0.3-1.8 parts of sodium chloride, 2-5 parts of triethanolamine, 0.3-1 part of sodium sulfate, 1-3 parts of epoxy resin, 1-3.5 parts of waste polyurethane, 1-2.3 parts of sodium stearate, 5-16 parts of nano calcium oxide, 0.3-0.9 part of coagulant, 2-5 parts of melamine water reducer and 5-18 parts of foaming agent. The highly anti-bending and wearing-resistant lightweight concrete provided by the invention has high anti-bending strength, good wear resistance, light weight and excellent water resistance.

Owner:无为县严桥双龙建材厂

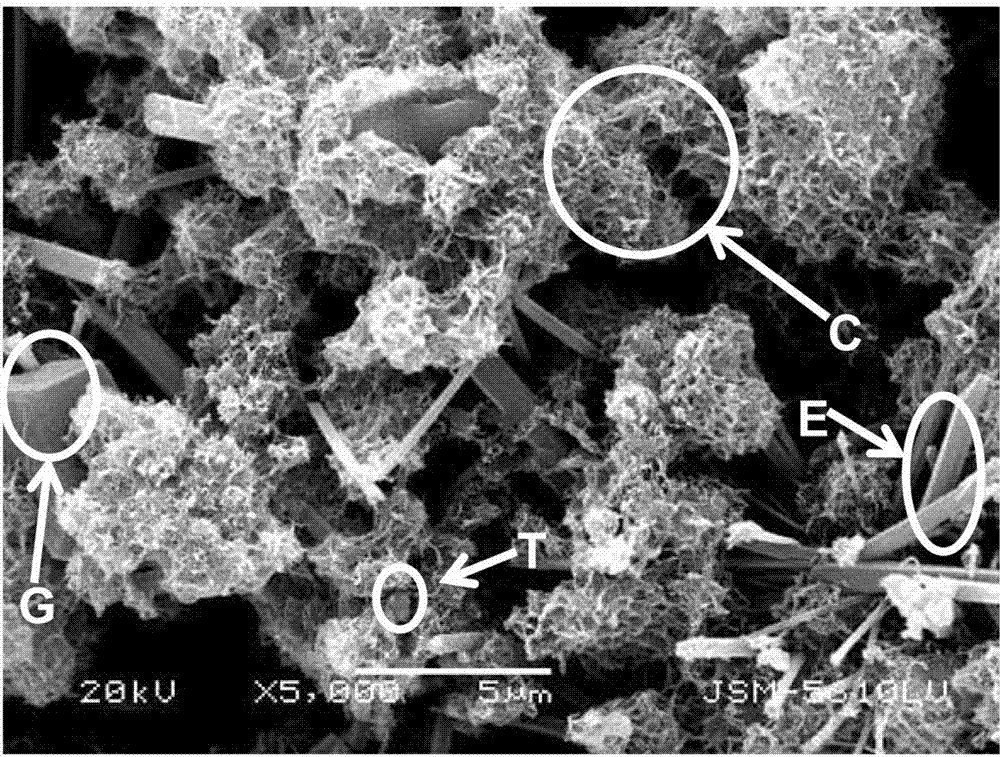

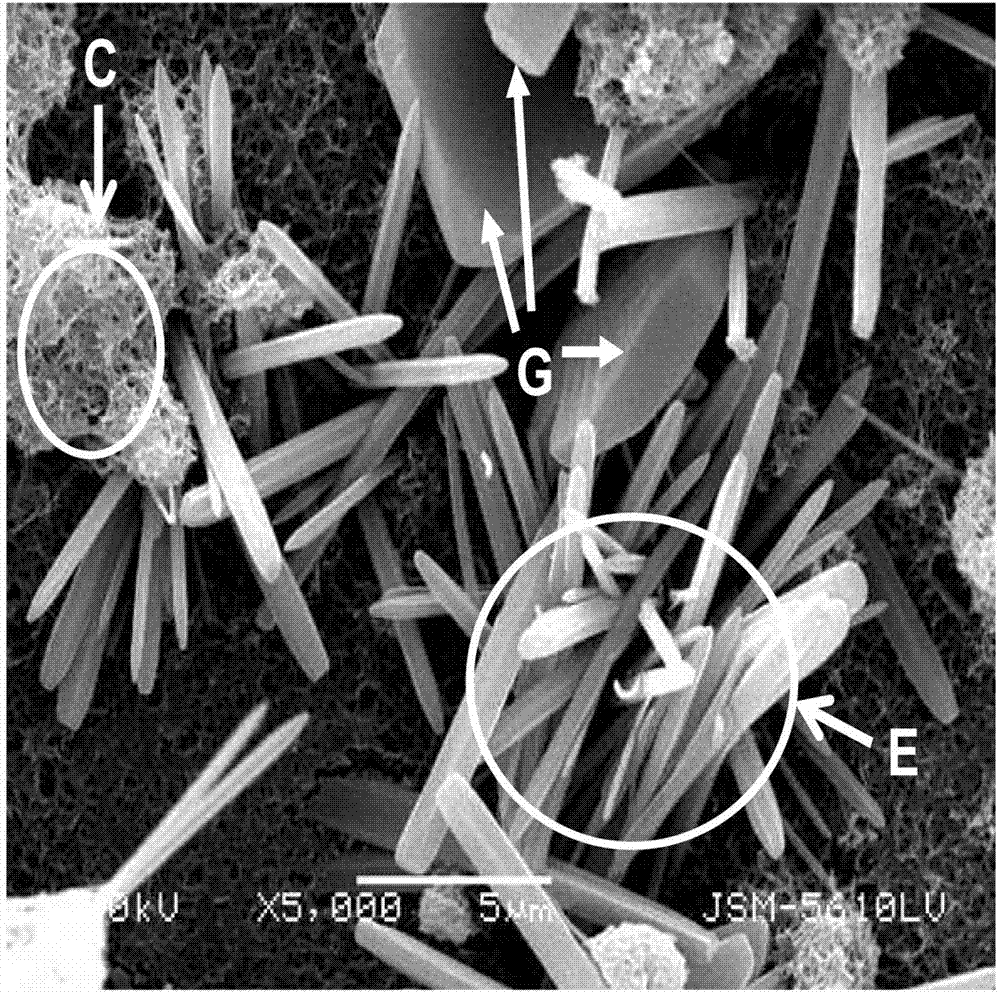

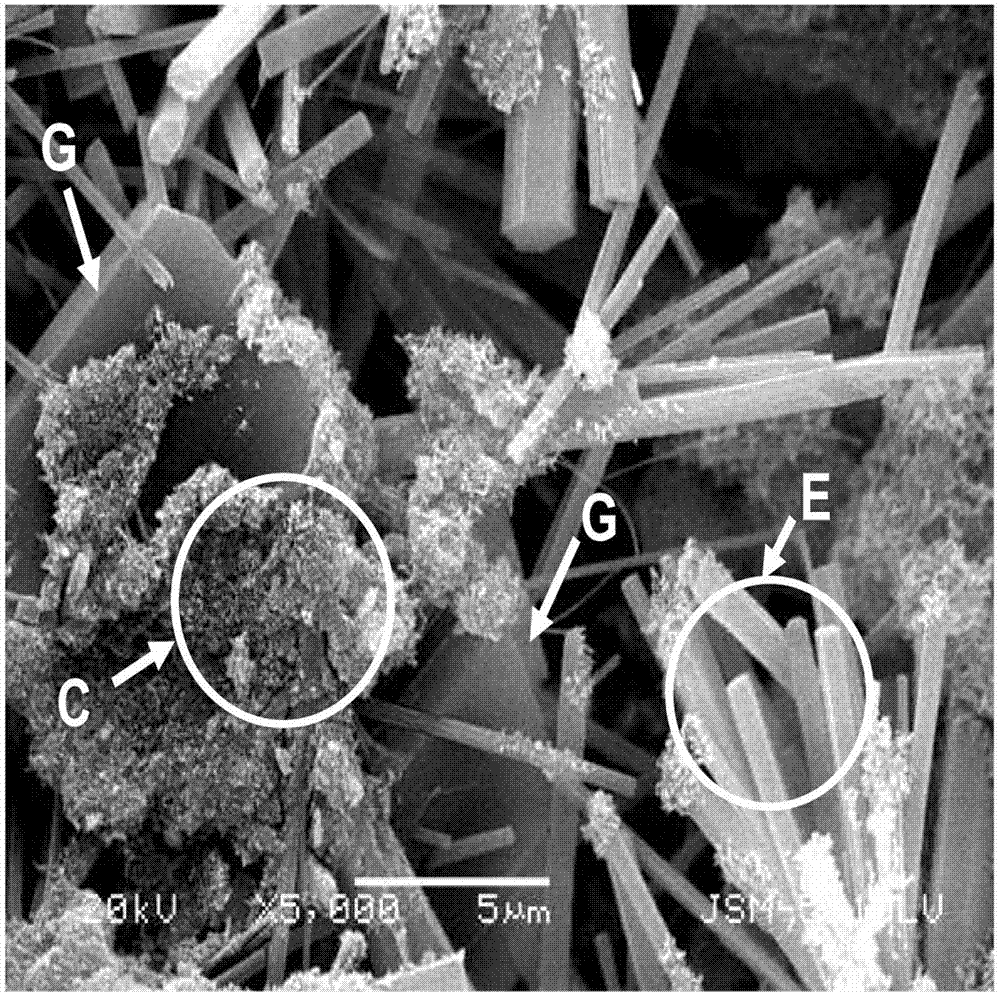

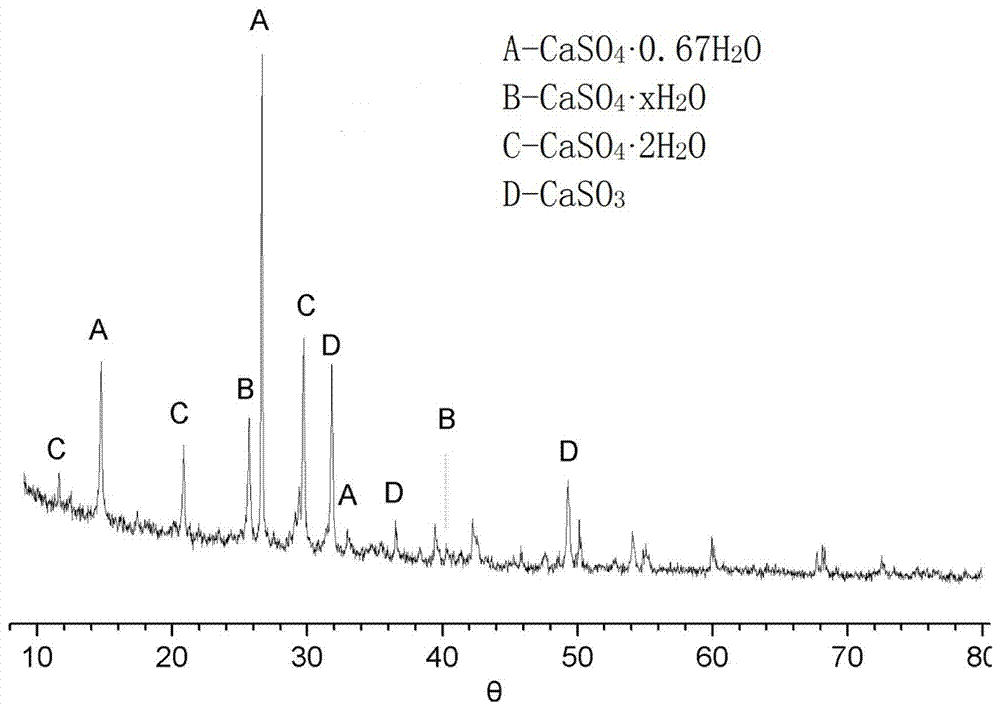

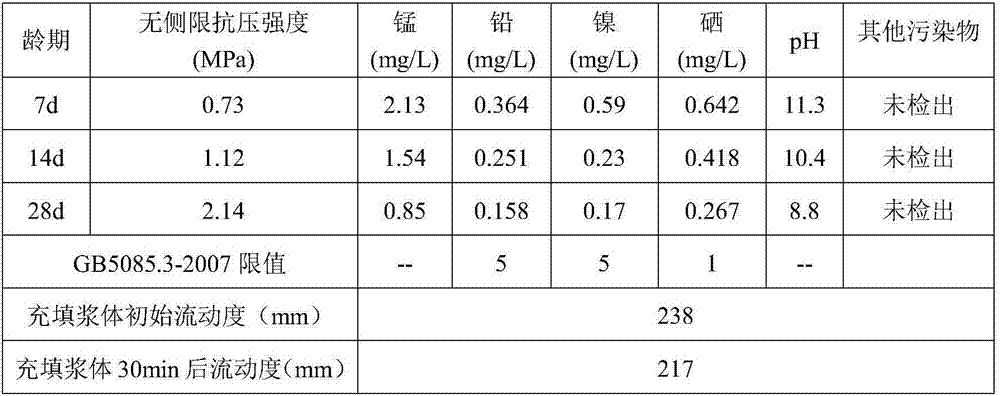

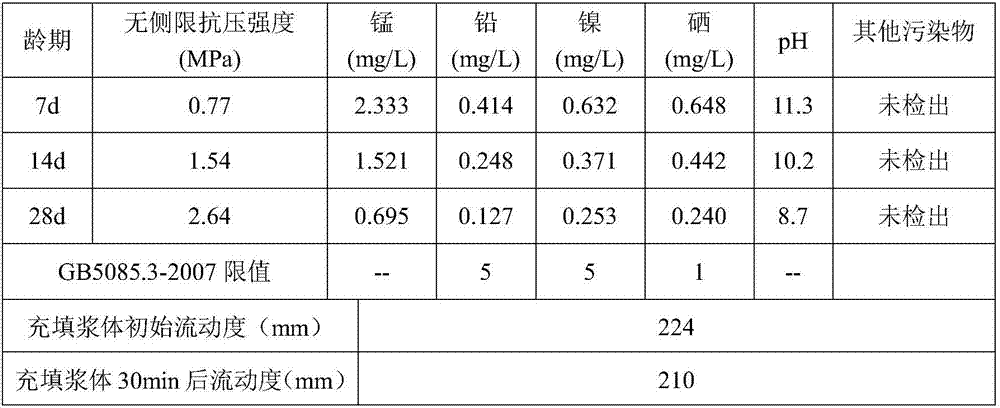

Electrolytic manganese residue-based ointment filling material and preparation method thereof

ActiveCN107129203AGood filling fluidityFast growth in strengthSolid waste managementWater contentHeavy metals

The invention provides an electrolytic manganese residue-based ointment filling material which comprises original electrolytic manganese residues, carbide slag and an electrolytic manganese residue cementing agent, wherein the electrolytic manganese residue cementing agent comprises ground electrolytic manganese residue powder, boiling furnace slag, cement kiln ash, phosphorus slag powder, petroleum coke desulfurized fly ash and additives. A preparation method of the material comprises the following steps: by taking the original electrolytic manganese residues as a basic raw material, adding the carbide slag and the electrolytic manganese residue cementing agent, rapidly stirring for 10-20 minutes, adding water till the water content of the filling material meets a provided value, and further stirring for 10-30 minutes, thereby obtaining the electrolytic manganese residue-based ointment filling material. Compared with a cement type mine filling material, the electrolytic manganese residue-based ointment filling material provided by the invention is good in filling mobility, relatively rapid in strength increase, good in slight swelling property and low in heavy metal leaching concentration.

Owner:CHINA THREE GORGES UNIV

Preparation technology and application of high performance composite material activated superfine fly ash

InactiveCN104370486AImprove early strengthIncreased durabilitySolid waste managementPolymer scienceUltimate tensile strength

High performance composite activated superfine fly ash is prepared by adding a small amount of an activator and a grinding assistant agent for grinding together while super fine grinding of secondary or tertiary ash, and can meet the requirement that the ratio of particles with the size less than 10 mu m is more than 95%. 10-20% of the superfine fly ash is added into 32.5 cement, 10-15% of the superfine fly ash is added into 42.5 cement, and after even mixing, the grades of the produced cement are unchanged. The superfine fly ash is added into grade 52.5 pure clinker Portland cement for cement production by even mixing, 40-50% of the superfine fly ash is added for production of 42.5 cement, and 60-70% of the superfine fly ash is added for production of 32.5 cement. By addition of 50-70% of the superfine fly ash into C40 and C30 grade commercial concrete for replacement of winnowing ash, fine ore and cement and other cementitious materials, the strength of 28 days is 3-6MPa higher than reference C40 and C30 concrete strength.

Owner:山西和正环保建材有限公司

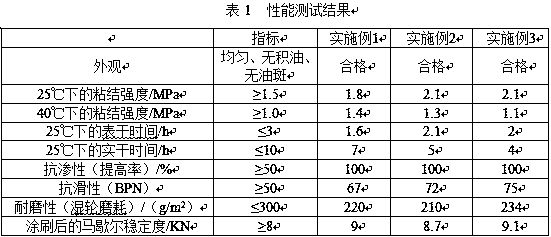

Polymer emulsified asphalt ultrathin surface sealing layer material, and preparation method and application thereof

The invention belongs to the technical field of compositions of asphalt materials, and concretely relates to a polymer emulsified asphalt ultrathin surface sealing layer material. The main componentsof the sealing layer material are epoxy modified acrylic resin and asphalt. The material has the advantages of good compatibility, uniform appearance, no oil accumulation, no oil spots, high strength,good impermeability, good anti-slip property and good wear resistance.

Owner:重庆市智翔铺道技术工程有限公司

Pit interface repairing agent and preparation method thereof

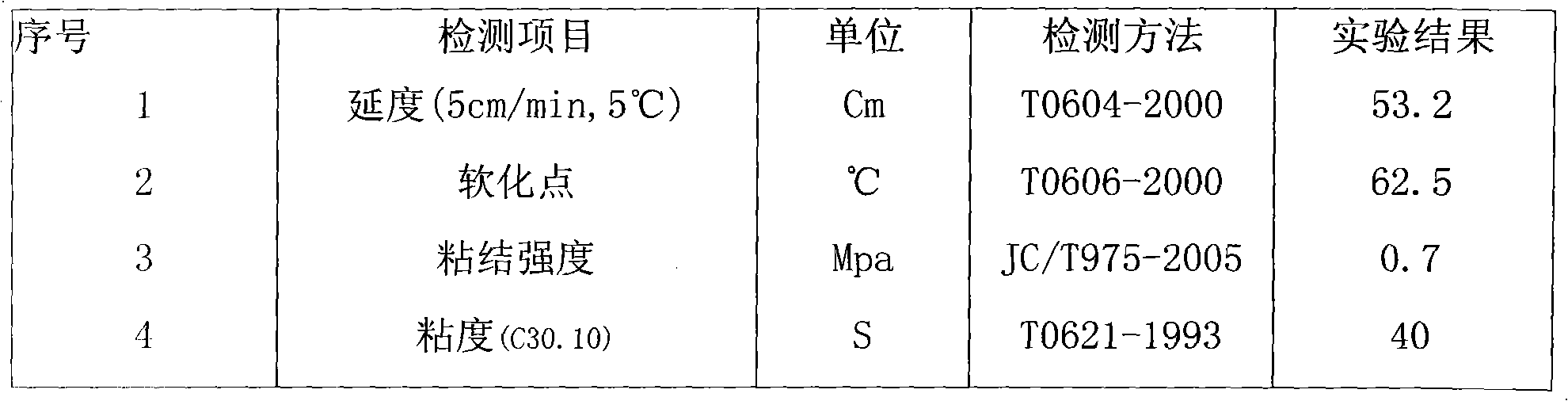

InactiveCN102031000AEasy to useFast growth in strengthRoads maintainenceBuilding insulationsKeroseneBituminous materials

The invention relates to a modified asphalt material for road rehabilitation and road construction, in particular to a pit interface repairing agent and a preparation method thereof. In the preparation method comprises, 65 parts by weight of asphalt is utilized as a main raw material; (2) modified solution prepared from 6.92-7.42 parts by weight of solvent oil, 2.5-3.0 by weight parts of a styrene-butadiene-styrene block copolymer, 0.05 part by weight of Na2SO3 and 0.03 part by weight of 1-aminoethyl-2-heptadecyl-imidazoline is utilized as a modifier; and (3) 25 parts by weight of kerosene as a diluent; and the preparation method comprises the following steps: mixing and stirring the components to obtain the pit interface repairing agent. The pit interface repairing agent provided by the invention is convenient in use and fast in strength growth; after the interface repairing agent is brushed, 95% of modified indexes can be reached within 1 hour at room temperature of 15 DEG C; and the repairing agent does not need to be heated on the site, and the repaired road surface is slightly different from the original road surface.

Owner:河南金欧特实业集团股份有限公司

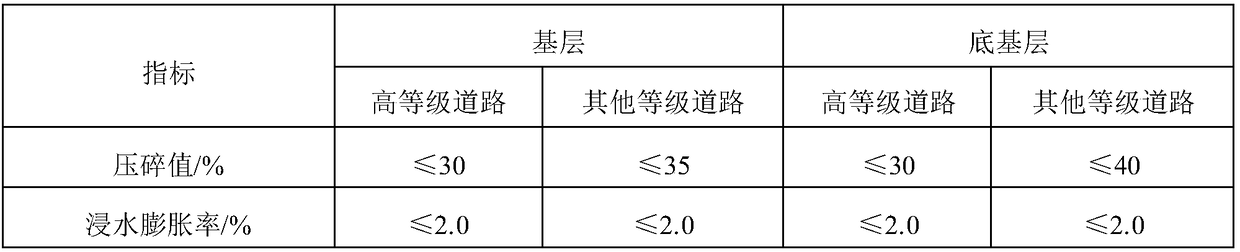

Titanium-extracting slag lime stabilized crushed stone material and preparation method thereof

The invention provides a titanium-extracting slag lime stabilized crushed stone material and a preparation method thereof. The material is prepared from a binder, crushed stones, an admixture and water, wherein the mass ratio of the binder and the crushed stones is (20-40) to (50-70); the binder is prepared from the following components in percentage by mass: 50-70 percent of titanium-extracting slag, 4-16 percent of lime, 15-30 percent of steel slag powder and 0-20 percent of fly ash; the crushed stones include graded crushed stones or steel slag crushed stones; the admixture is 4-6 percent of the mass of the lime and includes one or more of gypsum, sodium carbonate, water glass, sodium sulfate and calcium formate; and the mass of the water is 4-18 percent of the total sum of the masses of the binder, the crushed stones and the admixture in a dry state. The preparation method can adopt the raw materials to perform preparation. The preparation method has the beneficial effects that thecost of the raw materials is low, and the cost is low; a great quantity of industrial waste slag including titanium-extracting slag can be utilized; the construction technology is simple and convenient; the material strength increases rapidly, the construction period can be shortened, and the engineering cost is lowered.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Plugging agent for plugging oil-water well blast holes and casing pipe leakage parts in oil field

ActiveCN103864389ASafe on-site preparationSafe Site ConstructionSolid waste managementDrilling compositionOil waterWater well

The invention provides a plugging agent for plugging oil-water well blast holes and casing pipe leakage parts in an oil field. The plugging agent comprises a plugging preparation and a retarder. The plugging preparation is hydraulic concrete powder prepared from 40-80 parts by weight of sulphoaluminate clinker or fluoroaluminate clinker, 5-20 parts by weight of anhydrite, 10-40 parts by weight of silica fume and 5-10 parts by weight of anhydrous sodium sulfate. The retarder is a retarder aqueous solution comprising 0.1-5 parts by weight of tartaric acid, 0.1-15 parts by weight of citric acid, 5-10 parts by weight of boric acid and 80-95 parts by weight of water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for carrying out water expelling and powder spray piling composite foundation ground

InactiveCN1490469AImprove permeabilityImprove effectivenessBulkheads/pilesIsoetes triquetraCrushed stone

A method for reinforcing the soft foundation by draining water and using powder-spraying piles includes such steps as positioning the powder-spraying piles in such manner that the piles are longitudinally arranged at intervals and transversely arranged to form equilateral triangles, positioning the drainage plates between two adjacent piles arranged longitudinally, positioning draining ditches inclined between two piles, digging the draining ditches, filling sand in them, inserting the drainage plates into ground, forming piles, and spreading broken stone and sand layer on the ground.

Owner:SOUTHEAST UNIV

C20 concrete for preliminary bracing of tunnel steel shotcrete and die-cast shotcrete technology

InactiveCN106747080AReduce rebound rateModerate slumpUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses C20 concrete for preliminary bracing of tunnel steel shotcrete and a die-cast shotcrete technology. The concrete is prepared from cement, gravel, sand, an additive and water. The technology comprises the steps of firstly performing anchor rod hole construction on a tunnel wall according to designed intervals and performing anchor rod pouring construction in holes within hole depths; then performing outer layer reinforcing mesh laying construction, wherein a reinforcing mesh is tightly attached to a rock surface and fixed to anchor rods; then installing a steel arch in a tunnel; installing an inner layer reinforcing mesh between the steel arch, wherein the two sides of the inner layer reinforcing mesh are fixed to the steel arch; finally pressing a detachable formwork on the arch from the bottoms of the two sides of the steel arch, installing and fixing, forming a concrete cabin, spraying concrete into the concrete cabin in a mode perpendicular to the rock surface, disassembling the formwork after concrete solidifies, circularly pressing, installing and fixing the formwork to parts where concrete is not sprayed of the steel arch and performing continuous spray operation. The concrete has the characteristics of low rebound rate and moderate slump degree.

Owner:GUIZHOU HIGHWAY ENG GRP

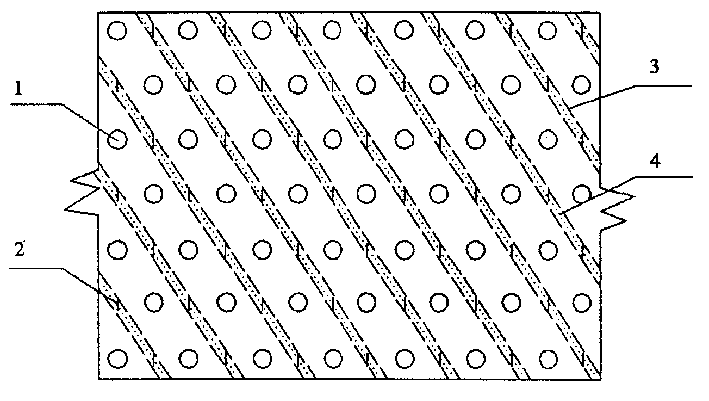

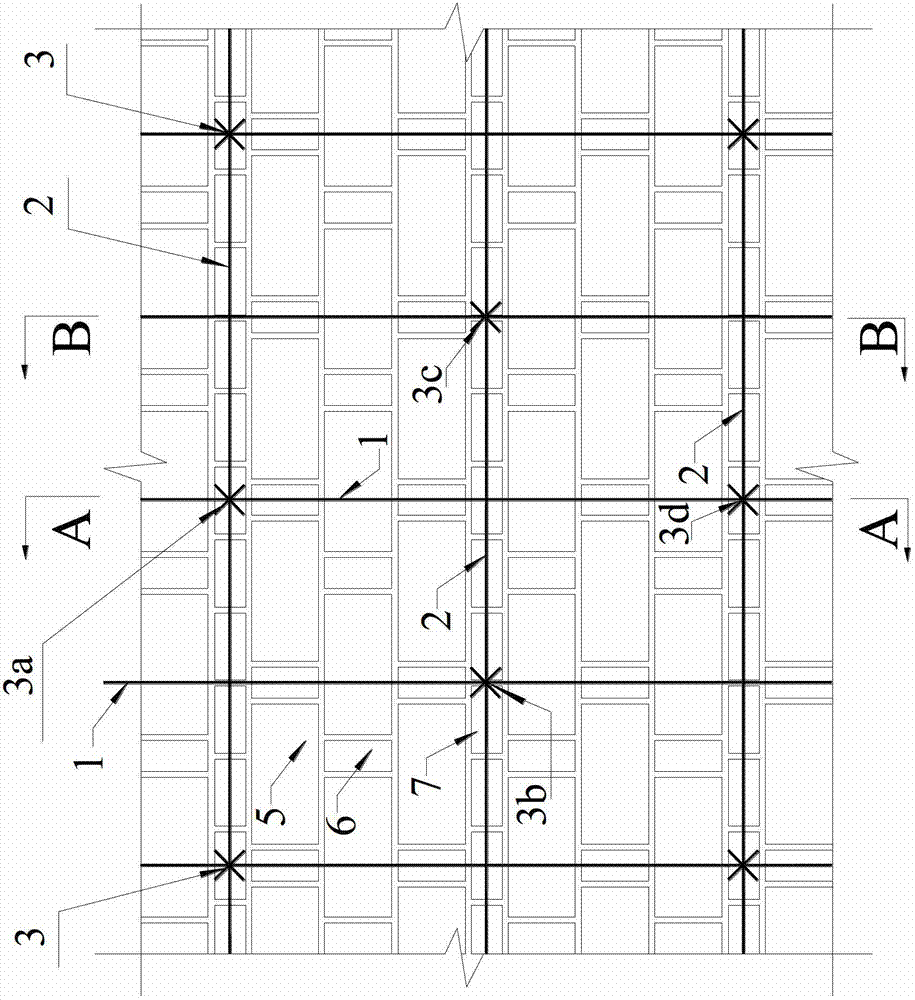

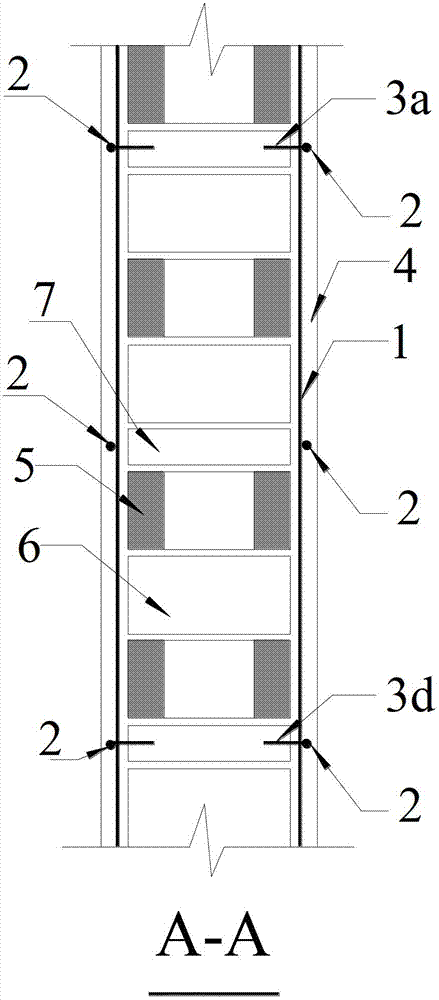

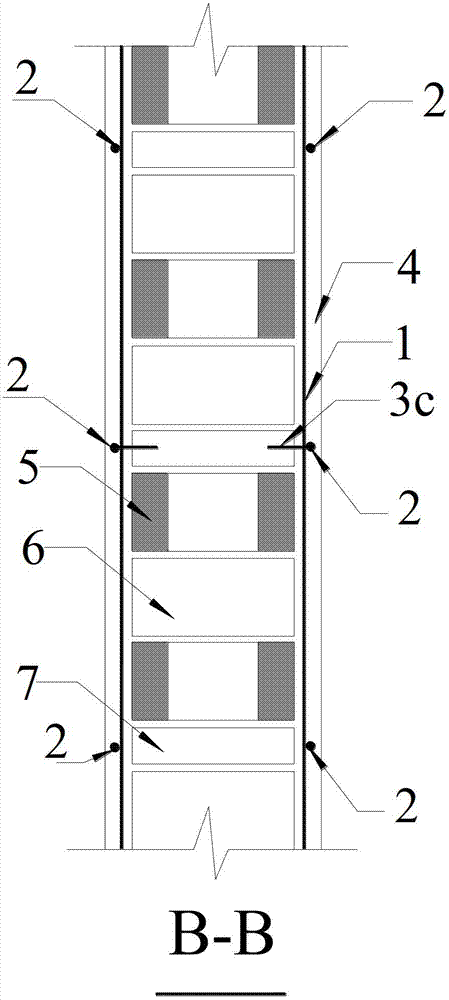

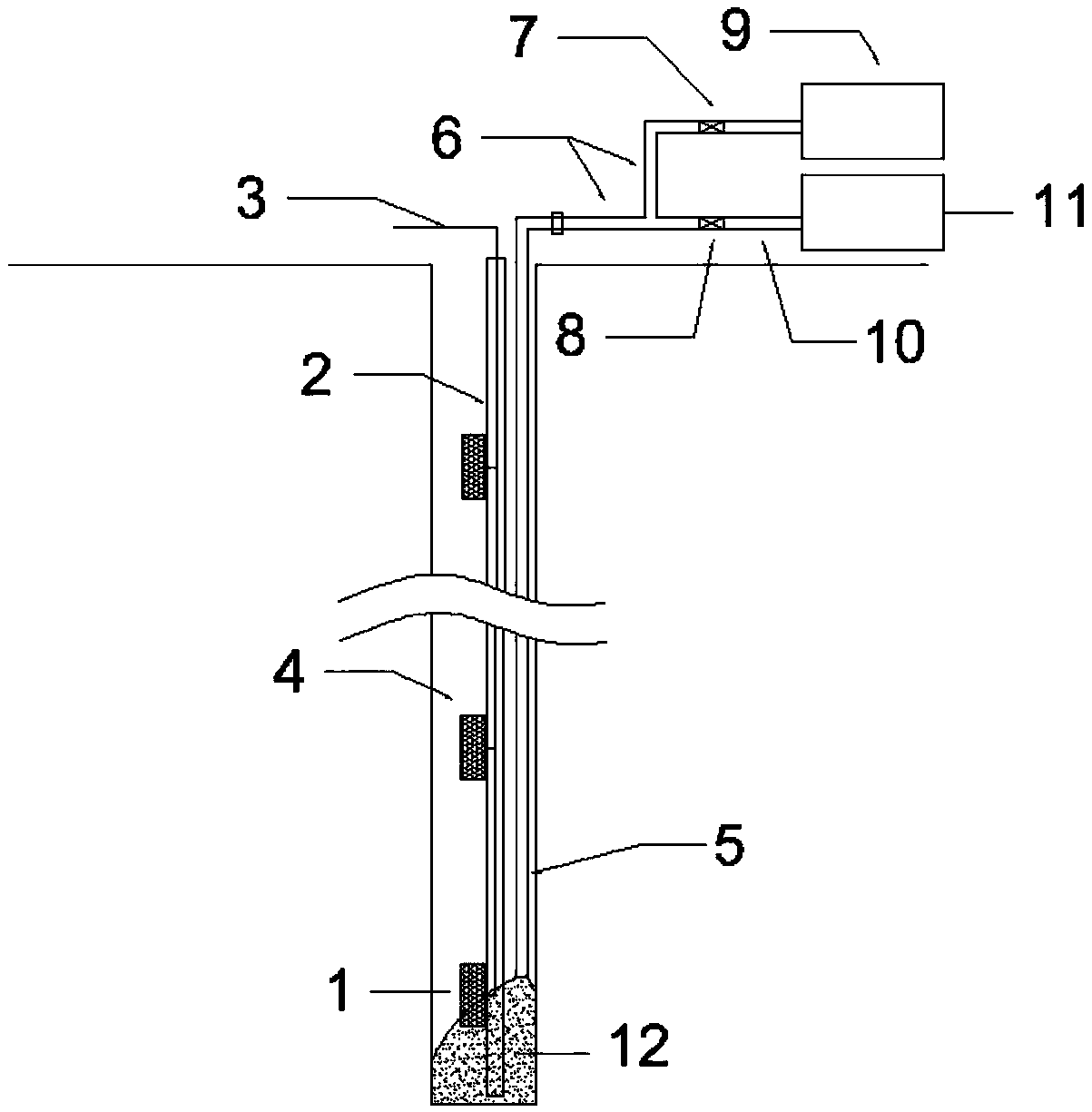

Method for reinforcing row-lock wall through steel strands and polymer mortar

InactiveCN102926552AFast growth in strengthShort construction periodBuilding repairsShock proofingBrickUltimate tensile strength

The invention relates to the field of construction engineering, and discloses a method for reinforcing a row-lock wall through steel strands and polymer mortar. The method includes the following steps: embedding oblique keys in bricks on flat as per the actual masonry method of the row-lock wall; fixing a steel strand net on the wall surface through the embedded oblique keys; and constructing a polymer mortar protective layer on the surface of the wall body. The method greatly improves the bearing capacity and resistance to vibration of the row-lock wall, and the testing result shows that the horizontal limit bearing capacity of the reinforced row-lock wall body is improved by more than 80% than that of an unreinforced wall body; and meanwhile, the intensity is greatly improved, the construction period is short, the construction technology is simple, templates do not need to be erected, and the method is particularly suitable for solving the problems of poor intensity and weak resistance to vibration of the masonry structure of the row-lock wall, as well as the problem of improving the cracking and ageing of the existing row-lock wall structure at the same time.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

Aliphatic concrete water reducing agent and preparation process thereof

Owner:JIANGSU NIGAO SCI & TECH +1

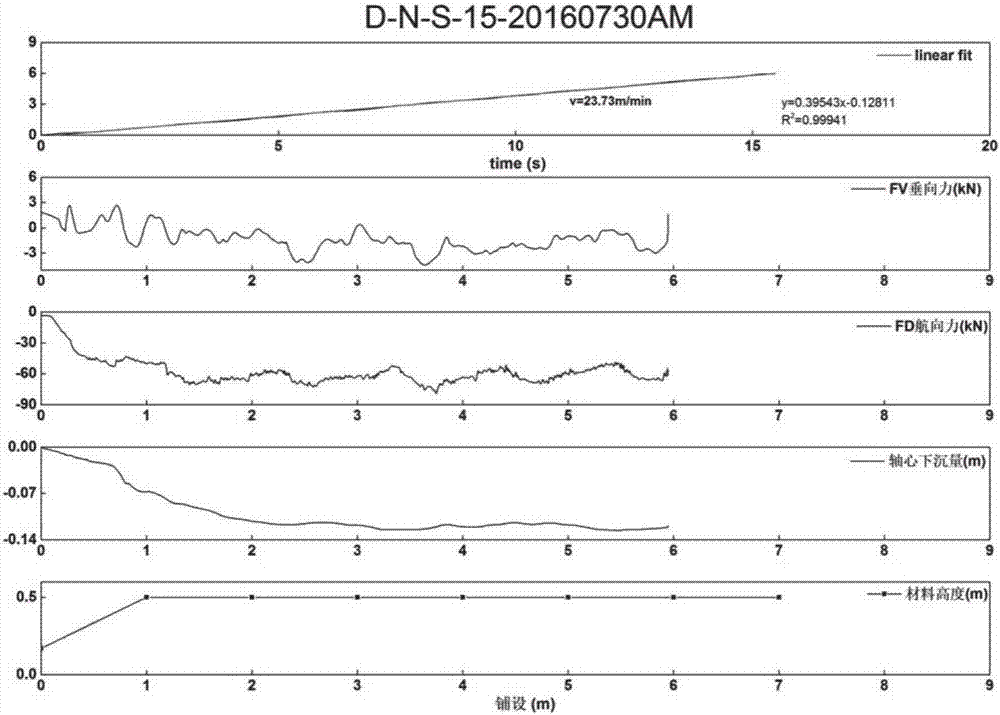

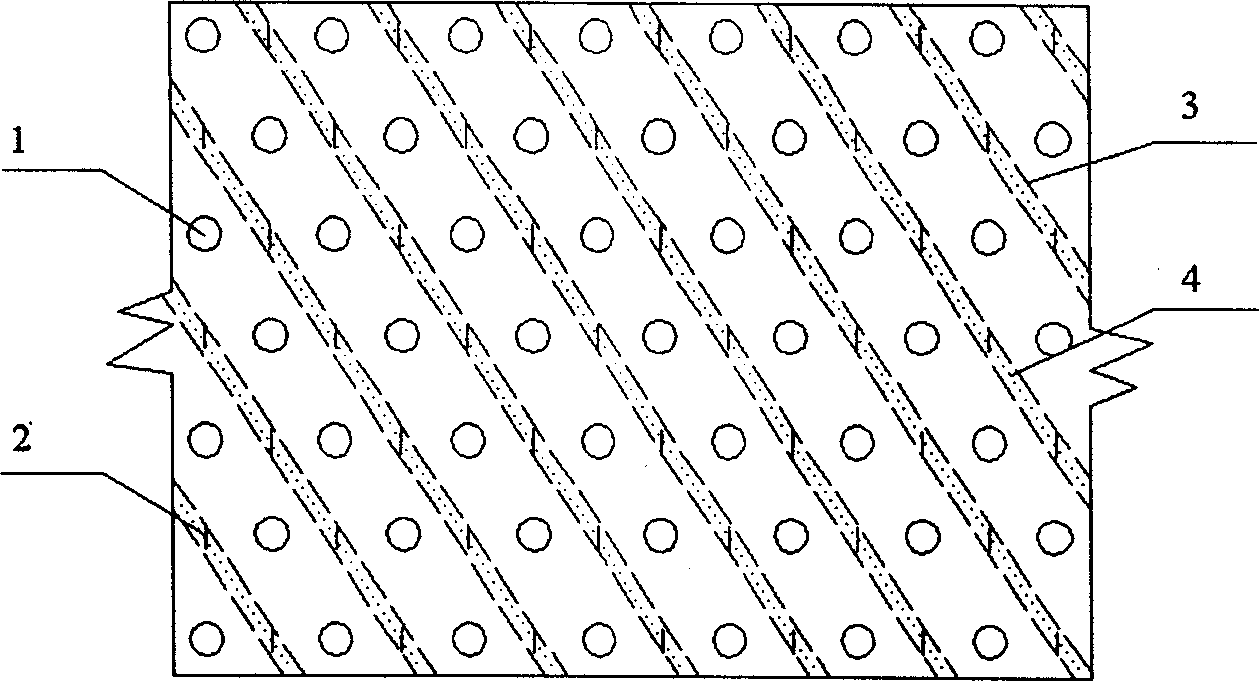

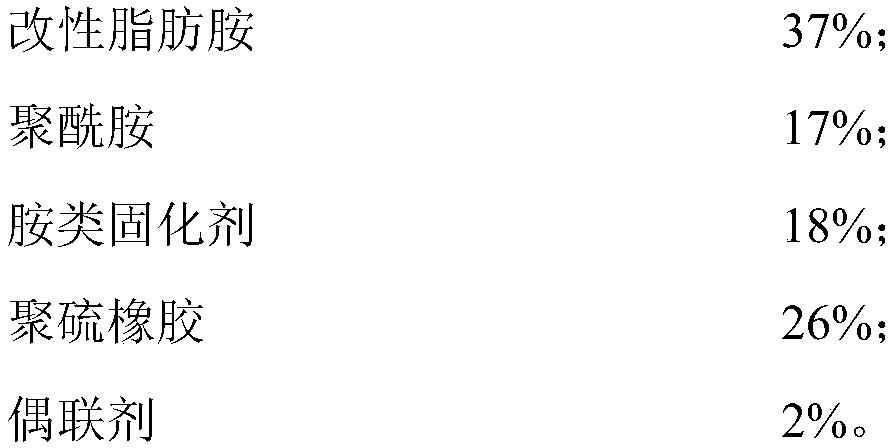

Asphalt pavement assembly type rapid repairing technology interlayer bonding material and preparation method thereof

The invention discloses an asphalt pavement assembly type rapid repairing technology interlayer bonding material and a preparation method thereof. The preparation method comprises the following steps:blending bisphenol-A epoxy resin and nanometer SiO2 according to a certain proportion at 50 DEG C till a mixture is milky white and is free from powdery particles; sequentially adding modified aliphatic amine, polyamide, an amine curing agent, polysulfide rubber and a coupling agent according to a certain proportion at room temperature for mixing, stirring till group B materials are pale brown, and storing at room temperature and under a drying condition for 1.5 months; and mixing group A materials, the group B materials and a promoter in parts by mass according to a ratio of 100 to (30 to 35) to (5 to 7) to obtain the asphalt pavement assembly type rapid repairing technology interlayer bonding material. The asphalt pavement assembly type rapid repairing technology interlayer bonding material has the advantages of longer construction time, good fluidity, simple construction, quick increase in strength after spreading, good bonding performance with different pavement materials under awet interface condition, short traffic opening time, and controllable gelation time and curing rate.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

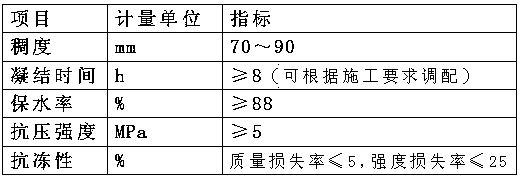

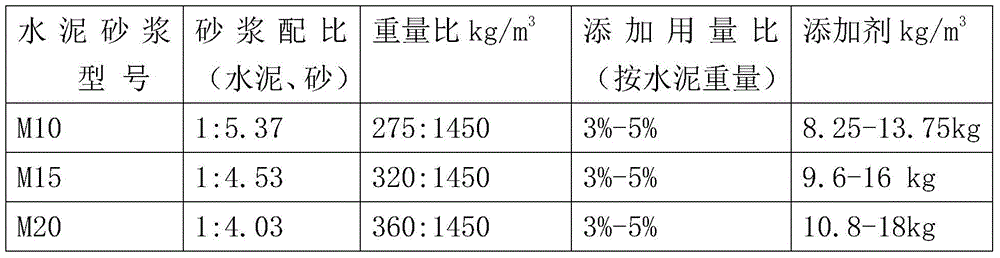

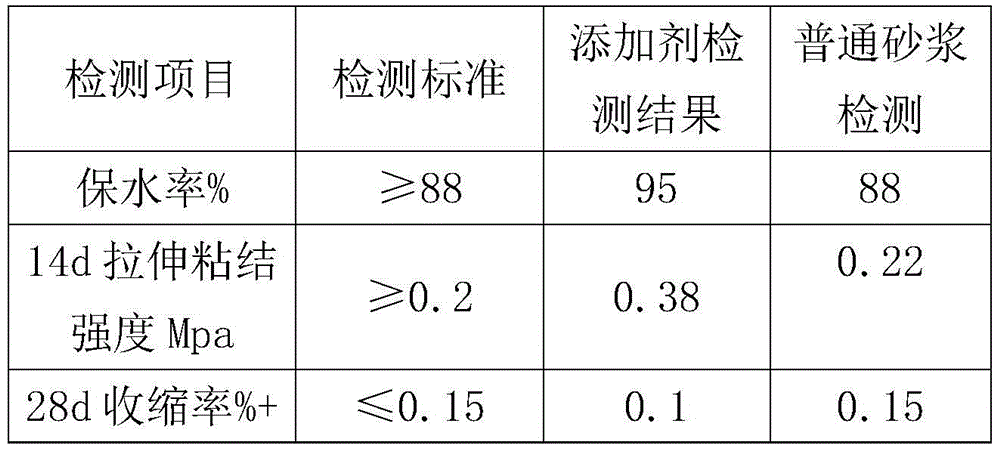

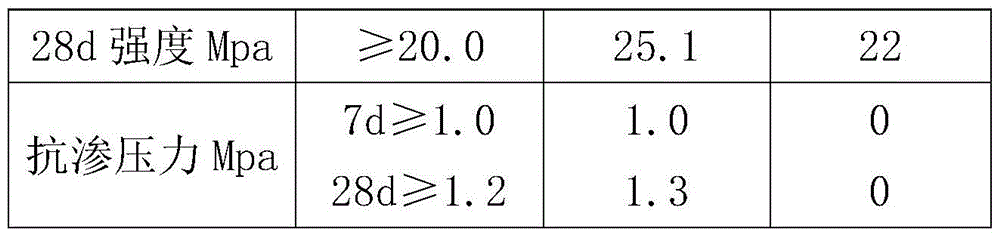

Mortar specially used for fly ash steam-pressing brisk construction, and preparation method thereof

The invention discloses a mortar specially used for fly ash steam-pressing brisk construction. The special mortar comprises following raw materials, by weight, 1350 to 1550kg of natural sand, 183 to 337kg of cement, 32 to 60kg of fly ash, 2.15 to 7.15kg of an additive specially used for the mortar which is specially used for fly ash steam-pressing brisk construction, and 215 to 250kg of water. The preparation method comprises following steps: (1) natural sand, cement, fly ash, the additive and water are uniformly mixed via mechanical mixing according to the weight ratio; and (2) the mortar obtained in step (1) is subjected to mechanical stirring for 3min. The preparation method is simple; water consumption of common masonry mortar is reduced; workability is improved; compactibility is increased; later phase strength increasing is rapid, and water penetration resistance, frost resistance and durability are all improved. The surfaces of fly ash steam-pressing bricks are smooth, and bonding of the fly ash steam-pressing bricks with mortar is difficult. A certain proportion of fly ash and the additive are added into the mortar, so that performances of the mortar are improved effectively, cost is reduced, and binding power of the mortar with the fly ash steam-pressing bricks is increased.

Owner:SHUANGLIAO GUOFENG CEMENT PROD CO LTD

A plugging agent for oil-water well plugging blast hole and casing plugging in oil field

ActiveCN103864389BCongeal fastFast growth in strengthSolid waste managementDrilling compositionOil waterBoric acid

The invention provides a plugging agent for plugging oil-water well blast holes and casing pipe leakage parts in an oil field. The plugging agent comprises a plugging preparation and a retarder. The plugging preparation is hydraulic concrete powder prepared from 40-80 parts by weight of sulphoaluminate clinker or fluoroaluminate clinker, 5-20 parts by weight of anhydrite, 10-40 parts by weight of silica fume and 5-10 parts by weight of anhydrous sodium sulfate. The retarder is a retarder aqueous solution comprising 0.1-5 parts by weight of tartaric acid, 0.1-15 parts by weight of citric acid, 5-10 parts by weight of boric acid and 80-95 parts by weight of water.

Owner:CHINA PETROLEUM & CHEM CORP +1

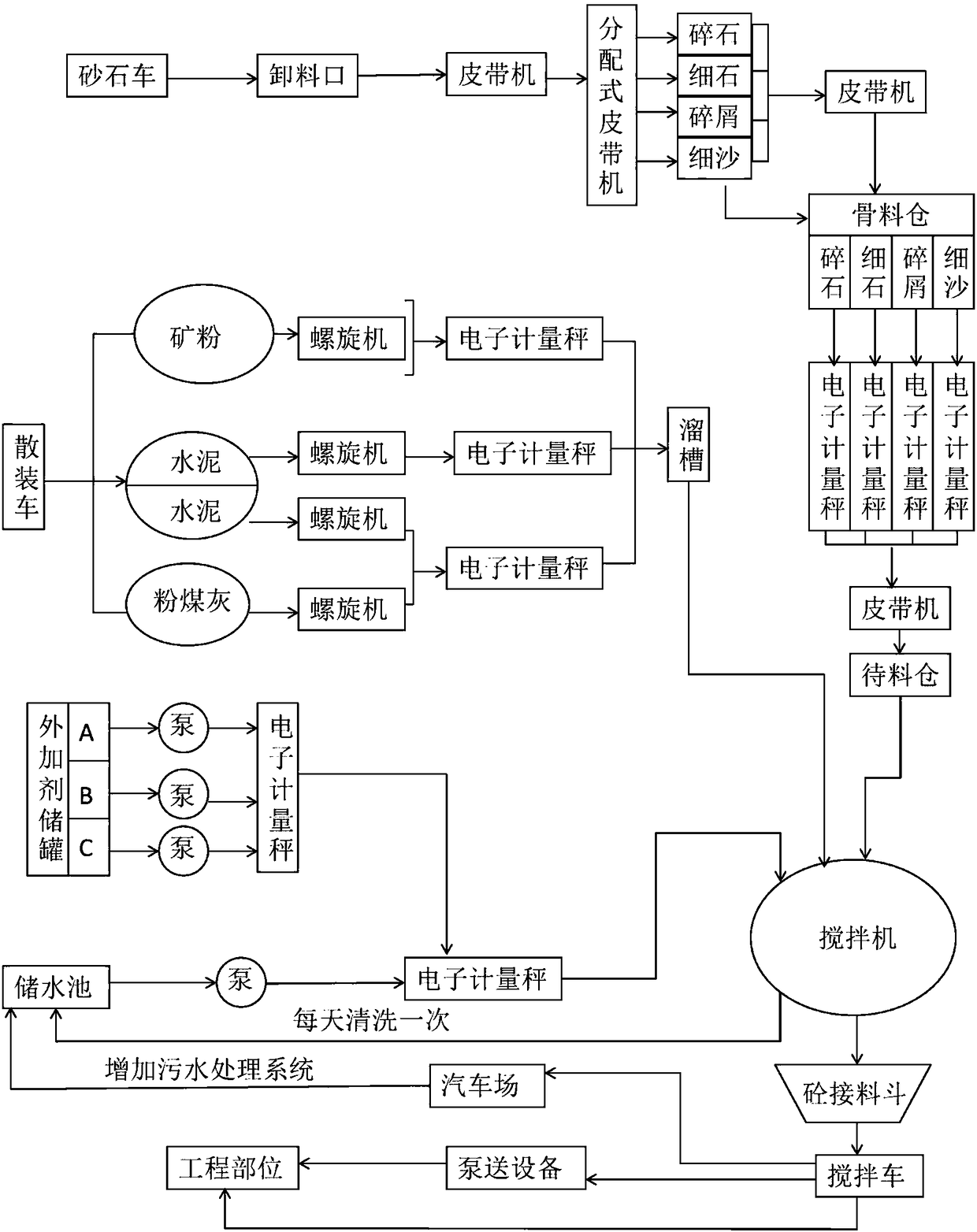

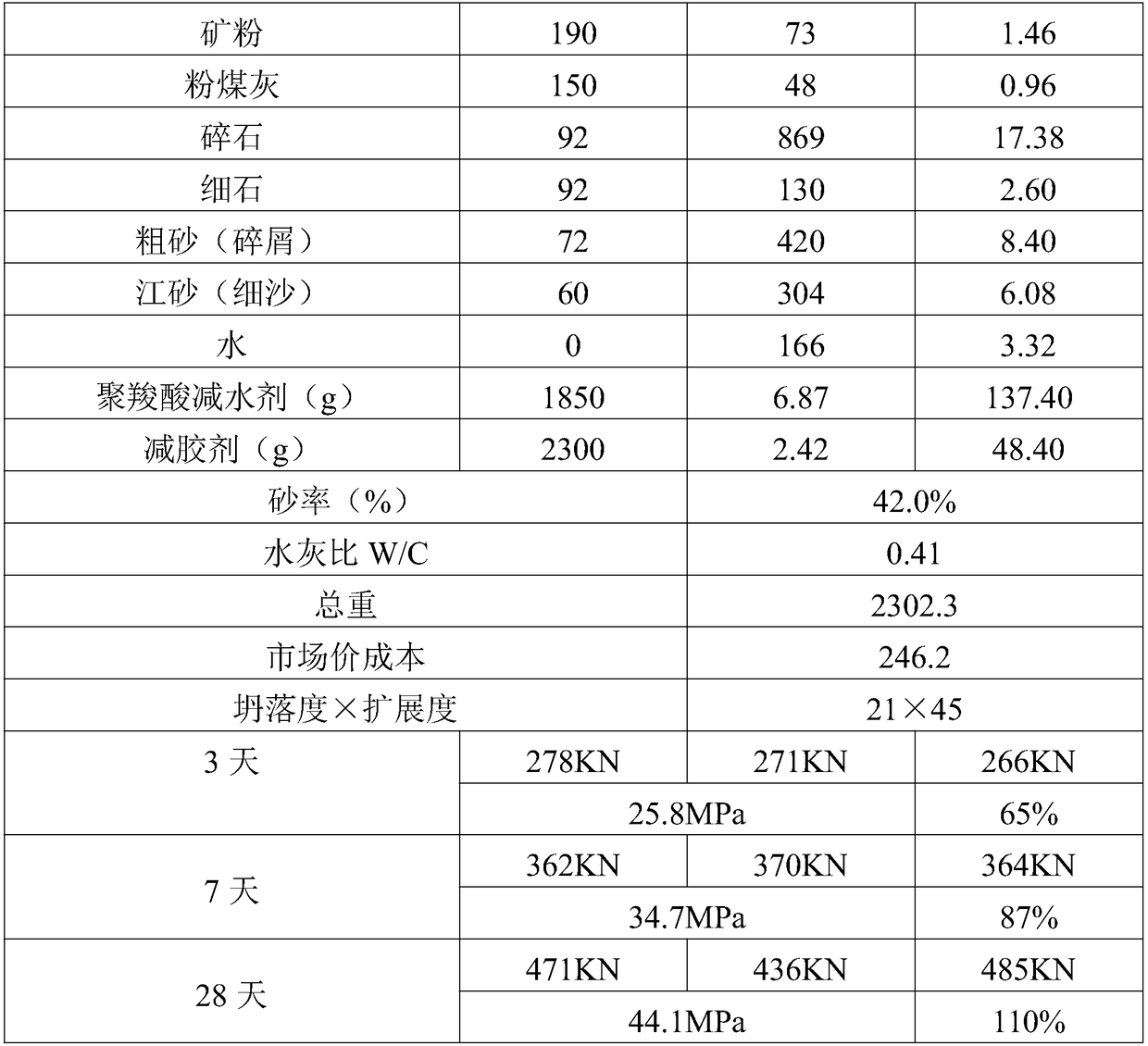

Concrete and preparation method thereof

The invention discloses concrete. The concrete comprises the following materials in percentages by mass: 12.3% of cement, 3.2% of mineral powder, 2.1% of fly ash, 37.7% of crushed stones, 5.7% of finestone, 18.2% of fragments, 13.2% of fine sand, 7.2% of water, 0.3% of a polycarboxylate superplasticizer and 0.1% of a glue reducing agent. The invention further provides a preparation method of theconcrete. The concrete has the advantages of low preparation cost, good peaceability and high growth of compressive strength.

Owner:郑涛涛

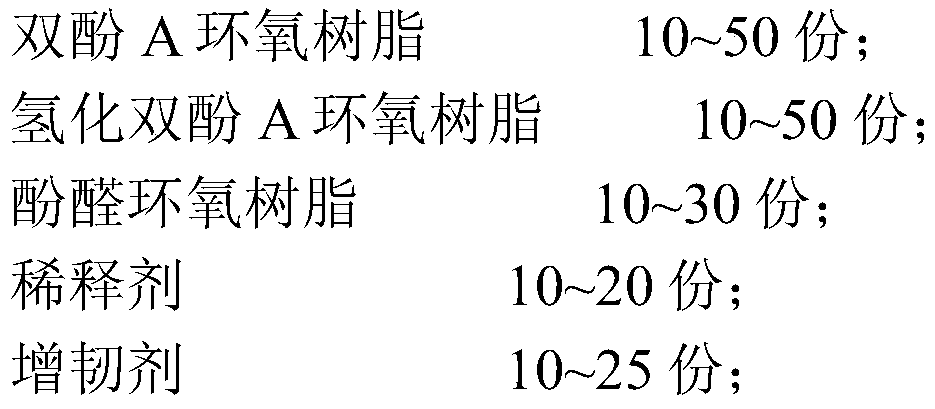

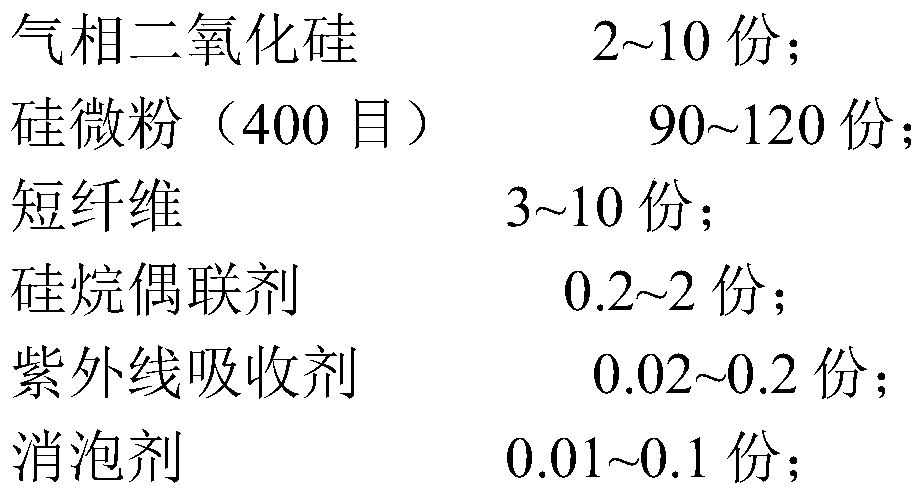

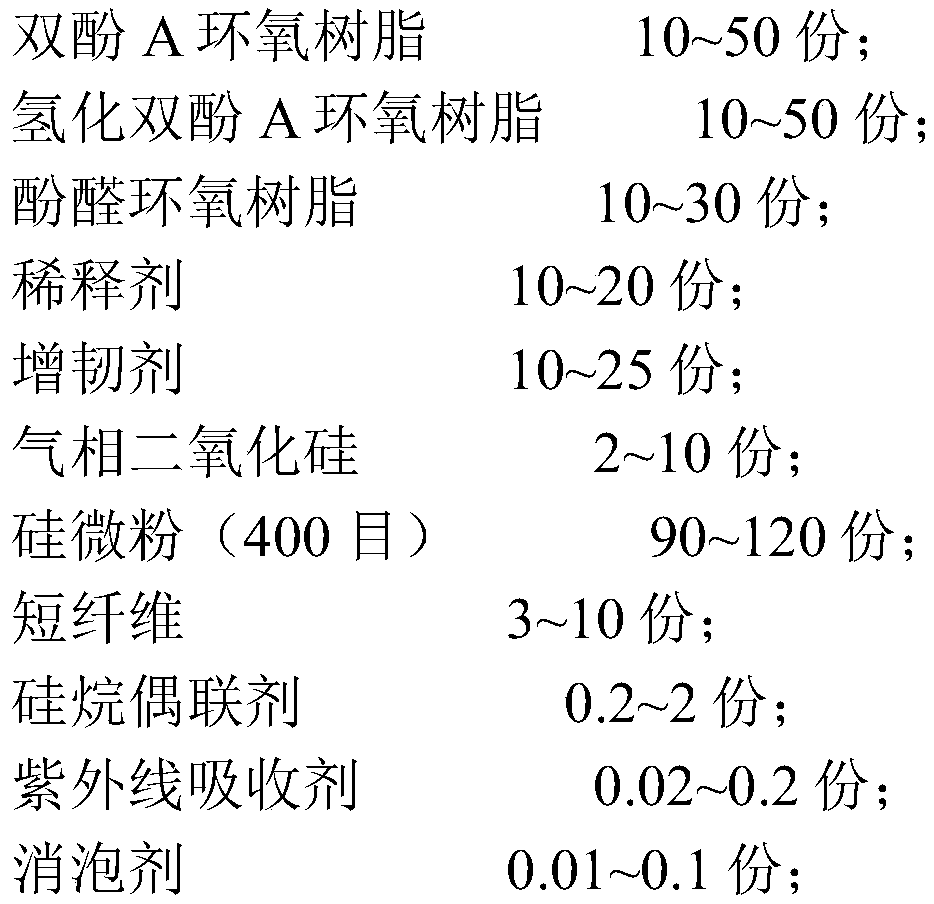

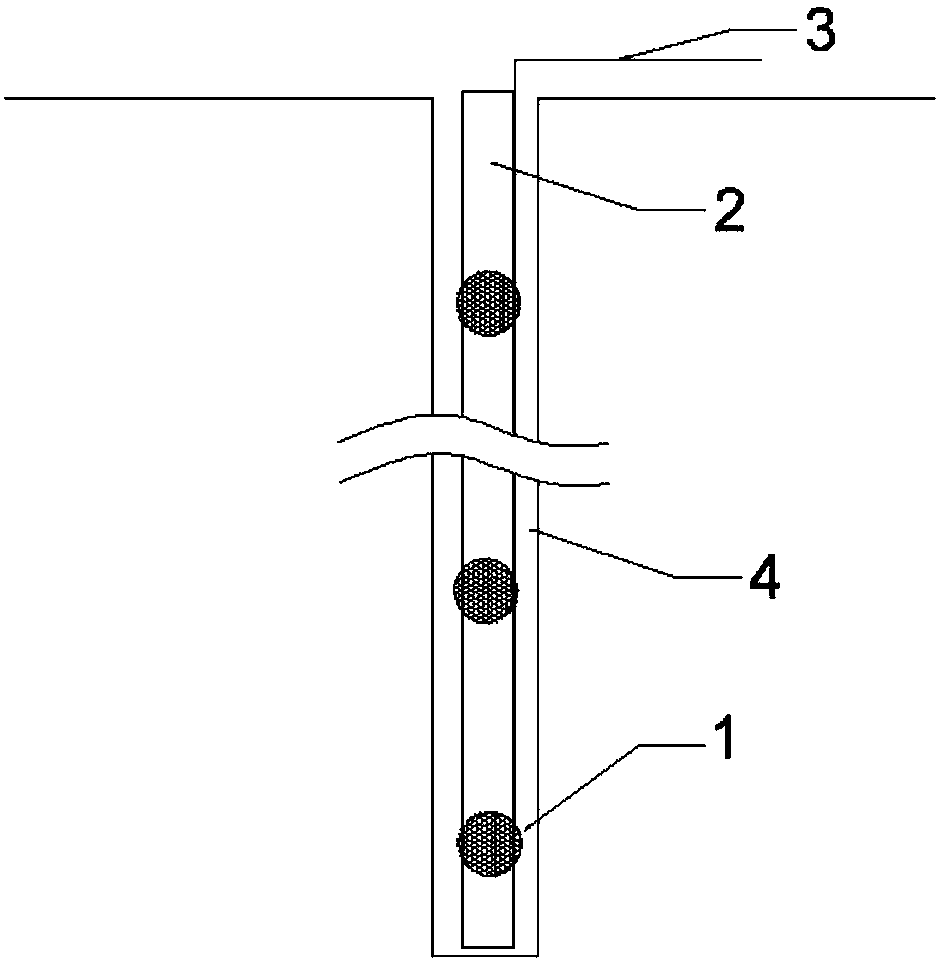

Epoxy-structure adhesive for prefabrication and splicing of bridge segment

ActiveCN110205069ALong operating timeFast growth in strengthNon-macromolecular adhesive additivesEpoxynovolac adhesivesFiberAdhesive

The invention discloses an epoxy-structure adhesive for prefabrication and splicing of a bridge segment. The epoxy-structure adhesive is prepared by mixing a component A and a component B, and duringconstruction, the components A and B are mixed according to the mixing ratio of 3:1, wherein the component A comprises bisphenol A epoxy resin, hydrogenated bisphenol A epoxy resin, novolac epoxy resin, a diluent, a flexibilizer, fumed silicon dioxide, silica powder, short fibers, a silane coupling agent, an ultraviolet light absorber and a defoaming agent, and the component B comprises phenolic-aldehyde-modified polyamide-amine, autocatalytic modified alicyclic amine, cardanol polyacetals amine and a high-activity silane coupling agent. According to the epoxy-structure adhesive, through compounding between the bisphenol A epoxy resin, the hydrogenated bisphenol A epoxy resin and the novolac epoxy resin and the diluent, the flexibilizer and the like, and addition of the short fibers, a filler and the like, the epoxy-structure adhesive has the advantages that the operable time is long, the strength increase is quick, and the adhesive can adapt to different operation environment temperatures, and has good resistance to damp-heat aging and long service life; the epoxy-structure adhesive is more suitable for being applied to prefabrication and splicing construction of the bridge segment.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Embedding material and method suitable for embedding earth pressure cell

PendingCN107816029ALow costCompliant with landfill material requirementsIn situ soil foundationPressure cellDrill hole

The invention discloses an embedding material and method suitable for embedding an earth pressure cell. The embedding material comprises, by weight, 0.08-0.12 part of cement, 0.16-0.28 part of bentonite, 4.6-4.8 parts of fine sand and 1.5-1.6 parts of water, and the above raw materials are mixed evenly to prepare the embedding material. The method for embedding the soil pressure cell through the above embedding material includes the following steps that firstly, mud protection wall drilling is conducted on a site where the earth pressure cell needs to be embedded, and the calibrated earth pressure cell and a support are put into a drilled hole; then a grout outlet of a grout pouring pump is connected with a hard long pipe through a soft pipe, the hard long pipe is inserted in the drill hole, a lower pipe opening of the hard long pipe goes deep into the bottom of the drill hole, and low-concentration grout is used for replacing high-concentration grout; and then the grout outlet of thegrout pouring pump is connected to the hard long pipe through the soft pipe, the grout pouring pump is started, the embedding material begins to be injected, and the hard long pipe is gradually elevated in the embedding material injecting process till the drill hole is filled with the embedding material.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

Mortar additive, mortar additive preparation method and method for preparing mortar with mortar additive

The invention provides a mortar additive, a mortar additive preparation method and a method for preparing mortar with the mortar additive.The mortar additive is composed of organic silicon type water repellents, redispersible latex powder, hydroxypropyl methyl cellulose ether, polycarboxylic type water reducer, modified starch ether, polypropylene fibers and fillers according to a weight ratio of 0.8-1.2:0.8-1.2:0.6-0.8:0.3-0.58:0.1-0.13:0.3-0.58:0.1-0.3.Compared with a common additive, the mortar additive has the advantages that reaction is quicker and more complete, strength increase is quicker and higher, abrasion resistance, durability, cracking resistance and seepage proofing performances of concrete can be evidently improved, functions of water reduction, early strengthening and air entrainment are realized, and the mortar additive is higher in adaptability to various concretes and extensive in application prospect.

Owner:广东金能建筑节能材料科技有限公司

Novel fireproof coating

InactiveCN107285719AFast growth in strengthImprove fire performanceFireproof paintsCrack resistanceFire retardant

The invention relates to a novel fireproof coating, which is especially suitable for the fireproof coating on the outer surface of steel structure materials. It belongs to the technical field of fire-fighting materials. Using modified calcined gypsum as binder, expanded vermiculite, perlite, mica, special additive (WH), composite modifier (FH), light calcium carbonate, by weight 450‑430: 115‑130: 160‑ 140: 30‑40: 3‑5: 8‑12, and the above materials are put into the mixer in sequence and stirred for 20 seconds. The invention has the advantages of non-shrinking coating, fast strength growth, obvious improvement of fireproof performance and crack resistance, and the like.

Owner:吴林

Pre-activated clay-fluoroaluminate cement-based grouting material and preparation method thereof

ActiveCN114436604AGood expansion performanceGood dispersionSolid waste managementAluminateMining engineering

The invention discloses a pre-activated clay-fluoroaluminate cement-based grouting material and a preparation method thereof, and relates to a grouting material and a preparation method thereof. The mass ratio of the component A to the component B is (0.4-0.7): 1, the component A is prepared from the following raw materials in parts by mass: 197-199 parts of silty clay and 1-3 parts of strong base, and the component B is prepared from the following raw materials in parts by mass: 30-60 parts of cement, 15-30 parts of fly ash, 10-20 parts of mineral admixture, 8 parts of thixotropic agent and 4-10 parts of water-resistant dispersant. The strength of a stone body can be improved, the setting time is short, the strength is rapidly increased, the stability is high, the bleeding rate is extremely low, and the performance requirement of reservoir dam crack plugging grouting is met.

Owner:HARBIN INST OF TECH +4

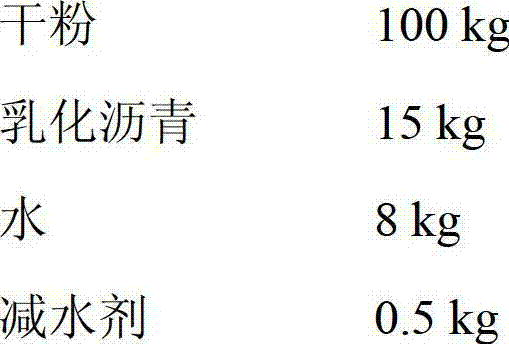

A kind of asphalt pavement pothole repair material and preparation method thereof

The invention discloses a repair material for bituminous pavement pot holes and a method for preparing the same, wherein the material is prepared by mixing and stirring the following raw materials according to parts by weight: 100 parts of dry powder, 10-20 parts of emulsified asphalt, 5-10 parts of water and 0.1-0.5 part of water reducer. The method for preparing the material comprises the steps of putting the dry powder, the water reducer and water in a stirring machine and stirring at a speed of 200 r / min for 60 s at first, and then adding the emulsified asphalt thereto and stirring at the speed of 200 r / min for 30 s, and finally, stirring at a speed of 400 r / min for 180 s, thereby obtaining the repair material for the bituminous pavement pot holes. The repair material for bituminous pavement pot holes provided by the invention is convenient for storage and does not need to be heated in use, and further is capable of quickly repairing the damaged bituminous pavement pot holes at different temperatures and under the wet conditions; as a result, the repair material can be selected for repairing when the traffic flow is small, so that the normal traffic capacity of the road cannot be affected.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com