Mortar specially used for fly ash steam-pressing brisk construction, and preparation method thereof

A technology of fly ash and autoclaved bricks, which is applied in the field of special mortar and preparation of fly ash autoclaved brick masonry, which can solve problems such as pollution and unstable mixing ratio, reduce water consumption, reduce cost, and improve compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

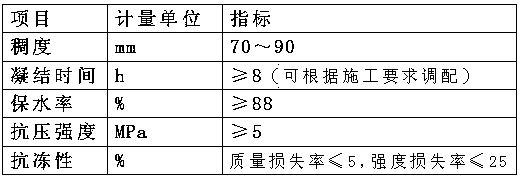

Image

Examples

Embodiment 1

[0015] Weigh the raw materials according to the ratio (raw materials are dry materials), sand 1550kg, cement 183 kg, fly ash 32 kg, admixture 2.15 kg, water 215 kg.

[0016] The sand has a bulk density of 1550 kg / m 3 The sand in the river sand, the cement is a composite portland cement with a strength grade of 32.5, the fly ash is a grade I fly ash, and the admixture is a special mortar for masonry with fly ash autoclaved bricks. agent (KDH-L type produced by Shanxi Kaidi Building Materials Company), and the water is drinking water.

[0017] The preparation method is: ① 1550 kg of sand, 183 kg of cement, 32 kg of fly ash, 2.15 kg of admixture, and 215 kg of water are uniformly mixed by weight; ② The mortar mixed in step ① is mechanically stirred for 3 minutes.

Embodiment 2

[0019] Weigh the raw materials according to the ratio (the raw materials are dry materials), 1500 kg of sand, 208 kg of cement, 37 kg of fly ash, 2.94 kg of admixture, and 220 kg of water.

[0020] The sand has a bulk density of 1500 Kg / m 3 The sand in the river sand, the cement is a composite portland cement with a strength grade of 32.5, the fly ash is a grade I fly ash, and the admixture is a special mortar for masonry with fly ash autoclaved bricks. agent (KDH-L type produced by Shanxi Kaidi Building Materials Company), and the water is drinking water.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] Weigh the raw materials according to the ratio (the raw materials are dry materials), 1450 kg of sand, 234 kg of cement, 41 kg of fly ash, 3.85 kg of admixture, and 230 kg of water.

[0024] The sand has a bulk density of 1450 Kg / m 3 The sand in the river sand, the cement is a composite portland cement with a strength grade of 32.5, the fly ash is a grade I fly ash, and the admixture is a special mortar for masonry with fly ash autoclaved bricks. agent (KDH-L type produced by Shanxi Kaidi Building Materials Company), and the water is drinking water.

[0025] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com