Super early-strength mortar

A technology of early-strength mortar and early-strength agent, which is applied in the field of super-early-strength mortar, can solve the problems that cannot meet the requirements of early strength, high strength, high fluidity, and slow strength growth, and achieve good fluidity, fast strength growth, and fast setting time. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

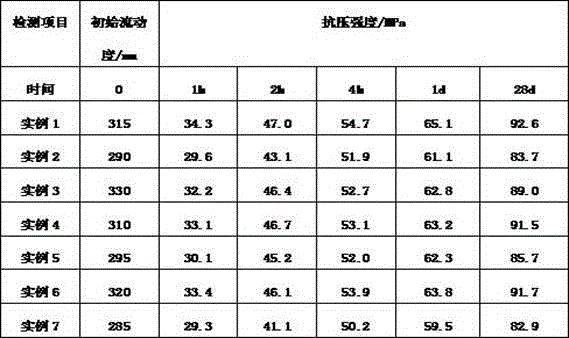

Embodiment 1

[0016] Embodiment one: take each raw material by weight respectively: sulfoaluminate cement 380kg, construction gypsum 80kg, P. 30-mesh aggregate, 188kg of 30-60-mesh aggregate, 47kg of 70-140-mesh aggregate), 0.5kg of tartaric acid, 0.5kg of citric acid, 0.7kg of calcium formate, and 1.6kg of polycarboxylic acid superplasticizer. 0.5kg of PP fibers with a length of 3mm. The above raw materials are added into a dry powder mixer and stirred evenly to obtain the product. Referring to "GBT 2419-2005 Method for Determination of Fluidity of Cement Mortar Sand", the measured initial fluidity of super early strength mortar is 315mm. The compressive strength is measured with reference to "GBT 17671-1999 Cement Mortar Strength Test", the measured compressive strength of super early strength mortar is 34.3MPa in 1h, 47MPa in 2h, 54.7MPa in 4h, and 1d compressive strength It is 65.1MPa, and the 28d compressive strength is 92.6MPa. Its strength increases rapidly. The existing ultra-ea...

Embodiment 2

[0020] Embodiment two: take each raw material by weight respectively: sulfoaluminate cement 300kg, construction gypsum 50kg, P. 0.2kg, calcium formate 1.2kg, naphthalene sulfonate superplasticizer 1.5kg. 0.7 kg of PP fiber with a length of 5 mm, the above raw materials are added into a dry powder mixer and stirred evenly to obtain the product. Referring to "GBT 2419-2005 Method for Determination of Fluidity of Cement Mortar Sand", the measured initial fluidity of super early strength mortar is 290mm. The compressive strength is measured with reference to "GBT 17671-1999 Cement Mortar Strength Test". The measured compressive strength of super early strength mortar is 29.6MPa in 1h, 43.1MPa in 2h, 51.9MPa in 4h, and 51.9MPa in 1d. The strength is 61.1MPa, and the 28d compressive strength is 83.7MPa. Its strength increases rapidly, and its strength is stable in the later stage, and the fluidity of the slurry is good.

[0021] Naphthalene sulfonate high-efficiency water reducer...

Embodiment 3

[0022] Embodiment three: take each raw material by weight respectively: sulfoaluminate cement 340kg, construction gypsum 75kg, P. Calcium formate 1kg, polycarboxylate superplasticizer 1.8 kg. 1 kg of PP fiber with a length of 3 mm, the above raw materials are added into a dry powder mixer and stirred evenly to obtain the product. Referring to "GBT 2419-2005 Method for Determination of Fluidity of Cement Mortar Sand", the measured initial fluidity of super early strength mortar is 330mm. The compressive strength is measured with reference to "GBT 17671-1999 Cement Mortar Strength Test". The measured compressive strength of ultra-early-strength mortar is 32.3MPa in 1h, 46.4MPa in 2h, 52.7MPa in 4h, and 52.7MPa in 1d. The strength is 62.8MPa, and the 28d compressive strength is 89MPa. Its strength increases rapidly. The existing ultra-early-strength mortar has a strength of about 20 MPa after 2 hours. The ultra-early-strength mortar of the present invention can reach a maximum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com