Mortar additive, mortar additive preparation method and method for preparing mortar with mortar additive

An additive and mortar technology, applied in the product field, can solve the problems of high cost and high cost of applying polymer waterproof coatings, and achieve the effects of improved wear resistance, rapid strength growth, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

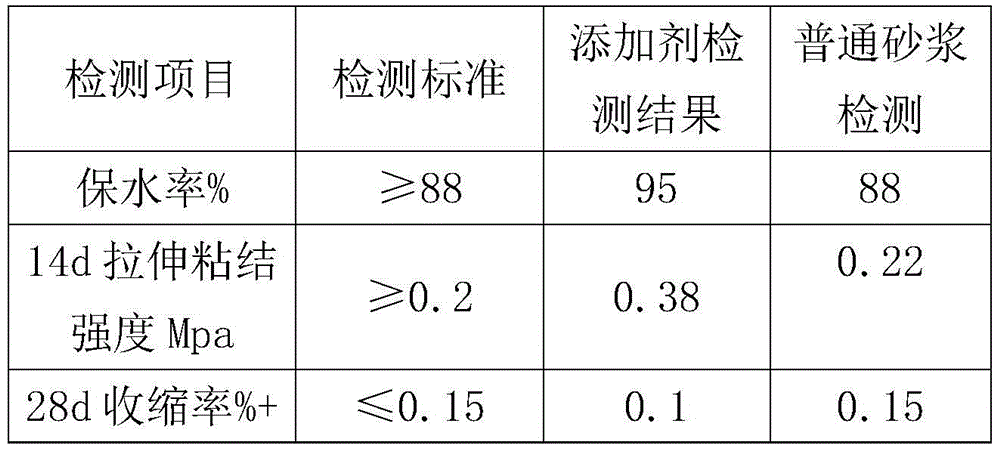

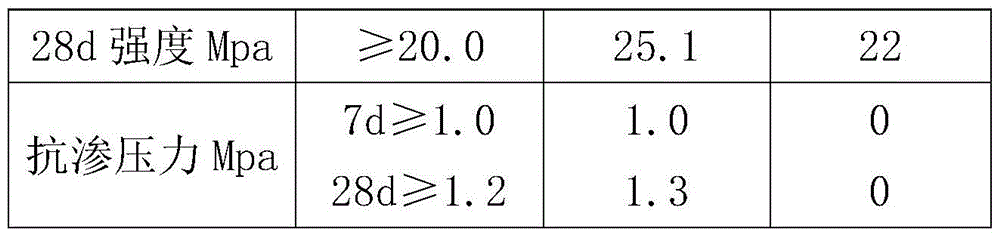

Examples

Embodiment 1

[0029] An anti-seepage additive for dry-mixed mortar, comprising: 0.8 parts of silicone water-repellent agent, 0.8 parts of redispersible latex powder, 0.6 parts of hydroxypropyl methylcellulose ether, 0.3 parts of polycarboxylic acid water reducer, 0.1 part of modified starch ether, 0.3 part of polypropylene fiber and 0.1 part of filler.

[0030] The filler is cement.

[0031] A method for preparing dry-mixed mortar anti-seepage additive, comprising the following steps:

[0032] Step A: raw materials are weighed in proportion;

[0033] Step B: Mix the raw materials in a sealed mixing device and stir at 22°C±0.5°C to obtain a powdery substance.

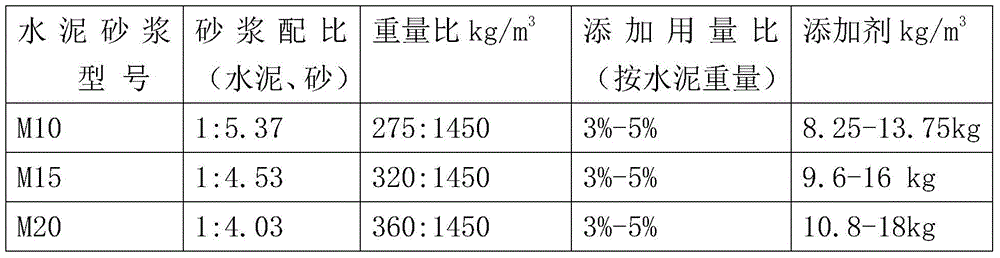

[0034] A kind of method that adopts additive as raw material to prepare mortar, comprises the following steps:

[0035] Step (1): Mix in a semi-open mixer, pour the cement into water and stir for 2-3 minutes;

[0036] Step (2): Add additives, stir until the additives are completely dissolved, the dosage ratio is 3%-5%, and stir fo...

Embodiment 2

[0040] An anti-seepage additive for dry-mixed mortar, comprising: 1.2 parts of silicone water-repellent agent, 1.2 parts of redispersible latex powder, 0.8 part of hydroxypropyl methylcellulose ether, and 0.58 parts of polycarboxylate water reducer , 0.13 parts of modified starch ether, 0.58 parts of polypropylene fiber and 0.3 parts of filler.

[0041] The filler is cement.

[0042] A method for preparing dry-mixed mortar anti-seepage additive, comprising the following steps:

[0043] Step A: raw materials are weighed in proportion;

[0044] Step B: Mix the raw materials in a sealed mixing device and stir at 22°C±0.5°C to obtain a powdery substance.

[0045] A kind of method that adopts additive as raw material to prepare mortar, comprises the following steps:

[0046] Step (1): Mix in a semi-open mixer, pour the cement into water and stir for 2-3 minutes;

[0047] Step (2): adding additives, stirring until the additives are completely dissolved; according to the weight o...

Embodiment 3

[0050] An anti-seepage additive for dry-mixed mortar, comprising: 1 part of silicone water-repellent agent, 1 part of redispersible latex powder, 0.7 part of hydroxypropyl methylcellulose ether, and 0.4 part of polycarboxylate water reducer , 0.12 parts of modified starch ether, 0.4 parts of polypropylene fiber and 0.2 parts of filler.

[0051] The filler is cement.

[0052] A method for preparing dry-mixed mortar anti-seepage additive, comprising the following steps:

[0053] Step A: raw materials are weighed in proportion;

[0054] Step B: Mix the raw materials in a sealed mixing device and stir at 22°C±0.5°C to obtain a powdery substance.

[0055] A kind of method that adopts additive as raw material to prepare mortar, comprises the following steps:

[0056] Step (1): Mix in a semi-open mixer, pour the cement into water and stir for 2-3 minutes;

[0057] Step (2): adding additives, stirring until the additives are completely dissolved; according to the weight of cement,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com