Pit interface repairing agent and preparation method thereof

A repairing agent and pothole technology, which is applied in road repairing, building components, building insulation materials, etc., can solve the problems of low strength, low efficiency, and inconvenient heating and use, and achieve fast strength growth, convenient use, and small differences Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

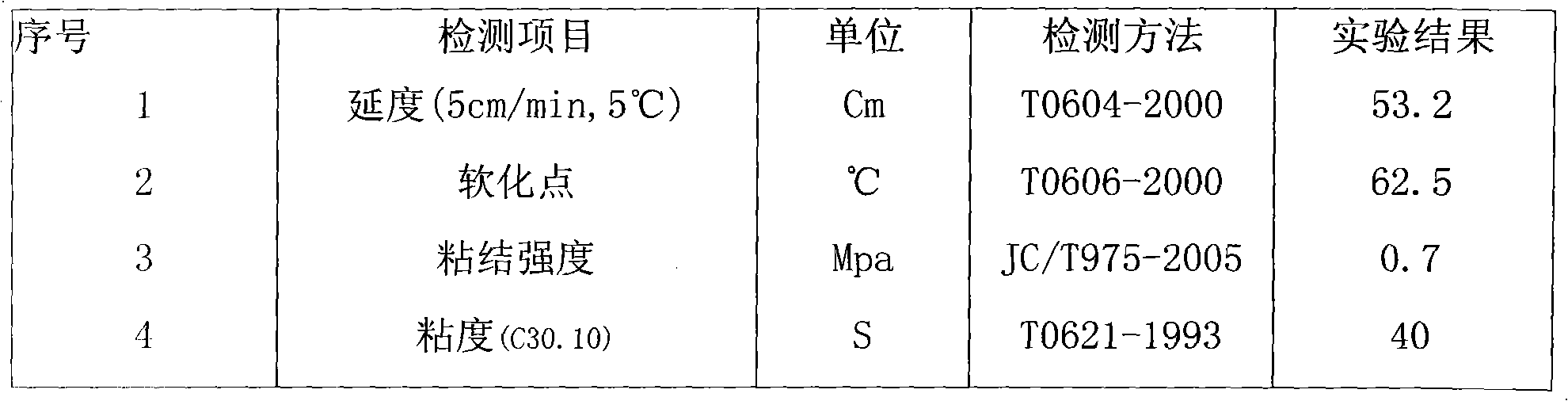

Image

Examples

Embodiment 1

[0015] A pothole interface repair agent, (1) is based on 65 grams of asphalt as the main raw material; (2) is based on 6.92 grams of cycloalkane with a density of 0.74--0.76, 3.0 grams of styrene-butadiene-benzene Ethylene block copolymer, 0.05 g Na 2 SO 3 , 0.03 gram of 1-aminoethyl-2-heptadecyl imidazoline mixed modified solution made as a modifier; (3) 25 grams of kerosene is used as a diluent, and the above-mentioned components are mixed and stirred to prepare Pits and grooves interface repair agent.

[0016] The preparation method of this kind of groove interface restoration agent is as follows:

[0017] 1) the styrene-butadiene-styrene block copolymer described in (2), Na 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline is added to the solvent naphtha described in (2), and is stirred to make a modifier;

[0018] 2) mixing the bitumen described in (1) with the modifying agent described in (2) and stirring to make a matrix;

[0019] 3) Add the diluent described in (3) in...

Embodiment 2

[0021] A pothole interface repair agent, (1) is based on 65 grams of asphalt as the main raw material; (2) is based on 7.42 grams of cycloalkane with a density of 0.74--0.76, 2.5 grams of styrene-butadiene-benzene Ethylene block copolymer, 0.05 g Na 2 SO 3 , 0.03 gram of 1-aminoethyl-2-heptadecyl imidazoline mixed modified solution made as a modifier; (3) 25 grams of kerosene is used as a diluent, and the above-mentioned components are mixed and stirred to prepare Pits and grooves interface repair agent.

[0022] The preparation method of this kind of groove interface restoration agent is as follows:

[0023] 1) the styrene-butadiene-styrene block copolymer described in (2), Na 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline is added to the solvent naphtha described in (2), and is stirred to make a modifier;

[0024] 2) mixing the bitumen described in (1) with the modifying agent described in (2) and stirring to make a matrix;

[0025] 3) Add the diluent described in (3) in...

Embodiment 3

[0027] A pothole interface repair agent, (1) is based on 65 grams of asphalt as the main raw material; (2) is a linear alkane with a density of 7 grams of 0.72-0.74, 2.92 grams of styrene-butadiene-benzene Ethylene block copolymer, 0.05 g Na 2 SO 3 , 0.03 gram of 1-aminoethyl-2-heptadecyl imidazoline mixed modified solution made as a modifier; (3) 25 grams of kerosene is used as a diluent, and the above-mentioned components are mixed and stirred to prepare Pits and grooves interface repair agent.

[0028] The preparation method of this kind of groove interface restoration agent is as follows:

[0029] 1) the styrene-butadiene-styrene block copolymer described in (2), Na 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline is added to the solvent naphtha described in (2), and is stirred to make a modifier;

[0030] 2) mixing the bitumen described in (1) with the modifying agent described in (2) and stirring to make a matrix;

[0031] 3) Add the diluent described in (3) into the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com