Large-sized filling bag embanking method and equipment for filling embankment by using dredged soil

A technology for filling equipment and dredging soil, which is used in the field of large-scale filling bags for embankment construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

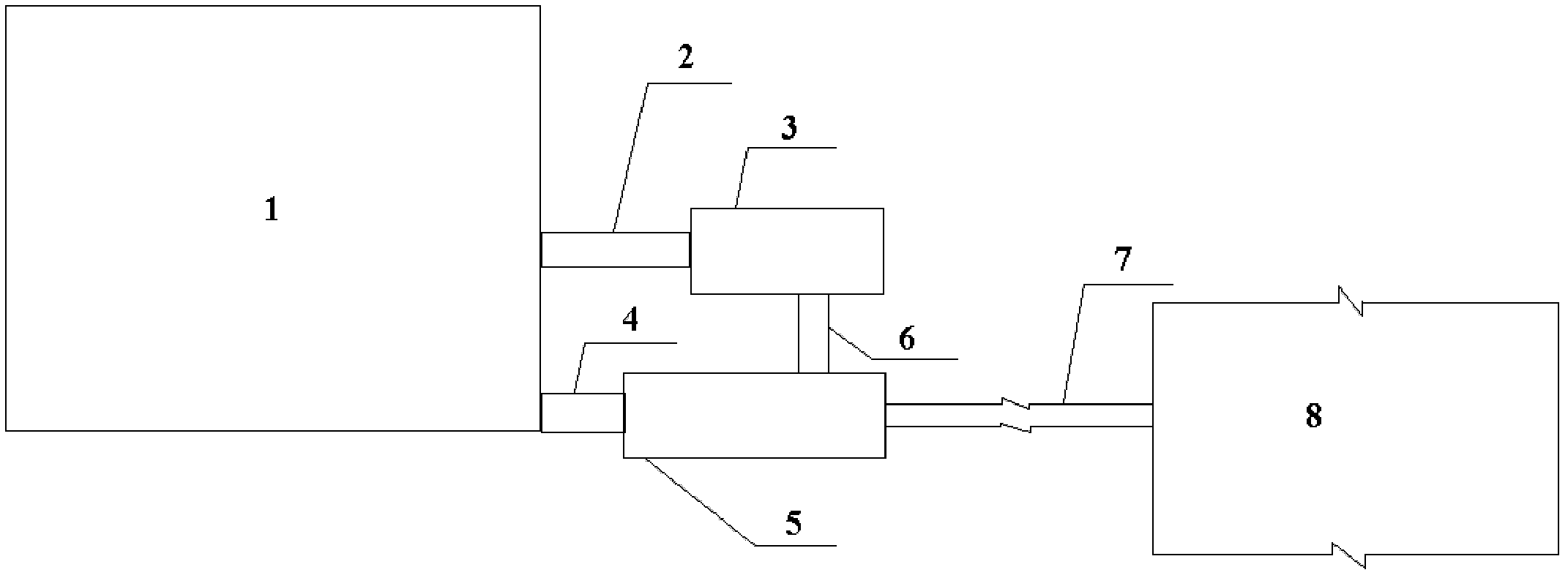

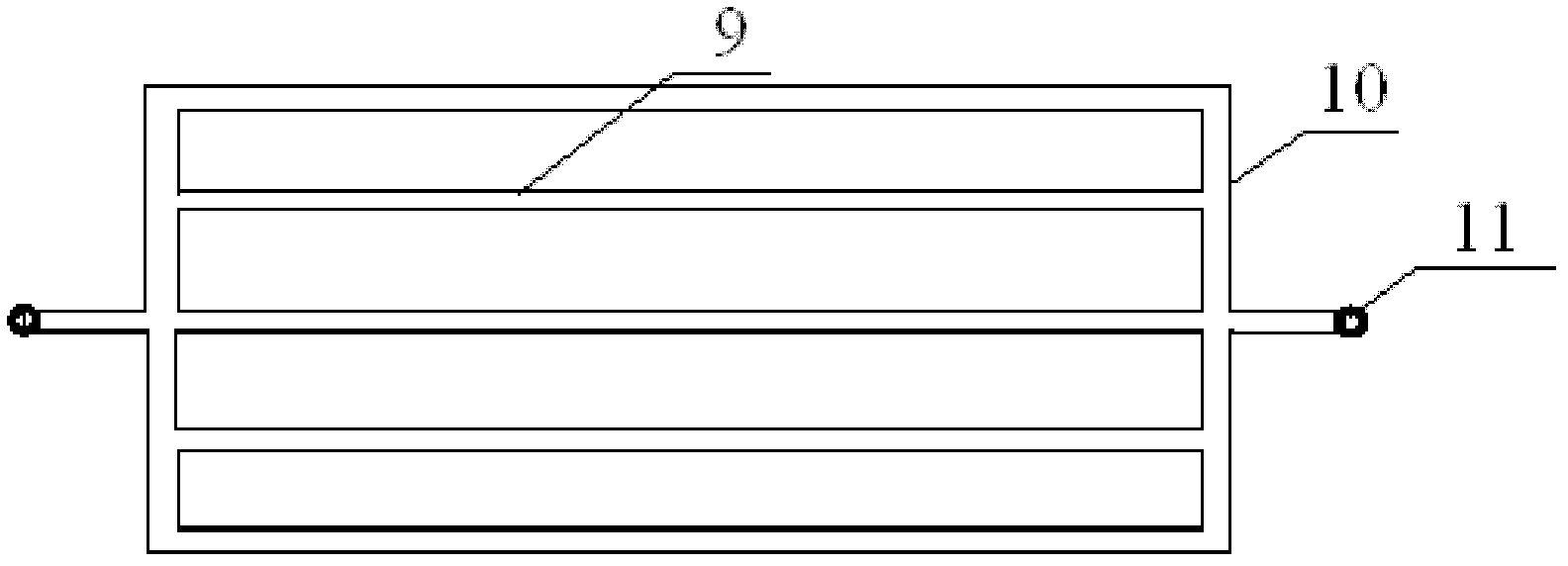

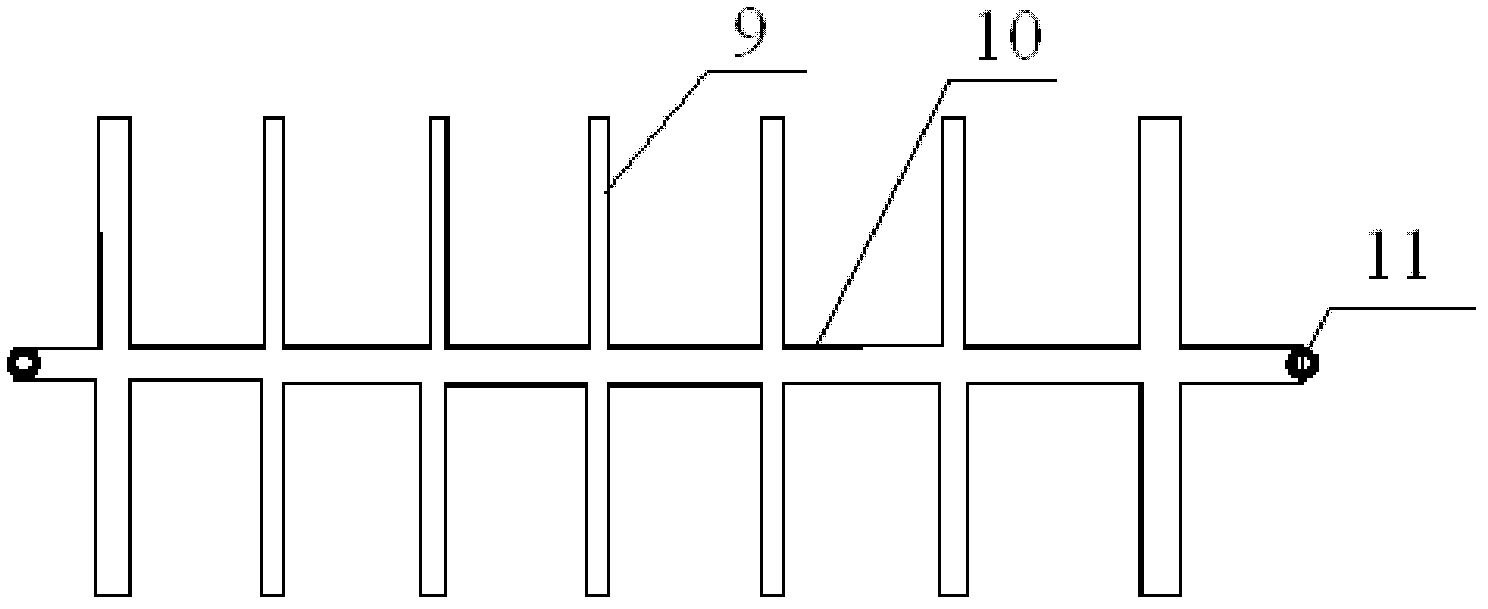

[0039] Such as image 3 As shown, the large-scale filling bag embankment technology of filling the embankment with dredged soil includes the following steps:

[0040] ⑴. Design and calculate the depth and spacing of the plastic drainage boards on the soft soil foundation under the embankment, complete the construction of the drainage boards and install the monitoring facilities in the soft soil foundation according to the design requirements;

[0041] ⑵. Complete the construction of each layer of sand quilt layer and soft soil row;

[0042] ⑶. Calculate the size and quantity of the required filling bags according to the design and use the polyester woven fabrics required by the design to process large filling bags for standby;

[0043] ⑷. Install dredged soil filling equipment, including silos (pools) and mud pumps, mud pumps, thick slurry pumps, and rigid feed pipelines for interconnection and installation, commissioning and trial operation. The connection of dredged soi...

Embodiment 2

[0053] It is basically the same as in Example 1, except that the filter pipe under the dredged soil filling bag is changed to a Φ76mm water-permeable corrugated hose, and the four-way and three-way connections between the main pipe and the filter pipe are U-PVC four-way and three-way.

Embodiment 3

[0055] It is basically the same as Example 1, except that according to the difference in clay content of the dredged soil, the embankment structure of one layer of sand-filled bags and two layers of dredged soil-filled bags is used instead of soil (bags) and sand (bags) alternately. The structure type of the embankment body with layers, or the structure type of the embankment body with all dredged soil filling bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com