Concrete and preparation method thereof

A concrete and cement technology, applied in the field of building materials, can solve the problems of high total gel material consumption, short setting time, and difficulty in saving costs, and achieve the effects of ideal pumping performance, low preparation cost, and rapid strength growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

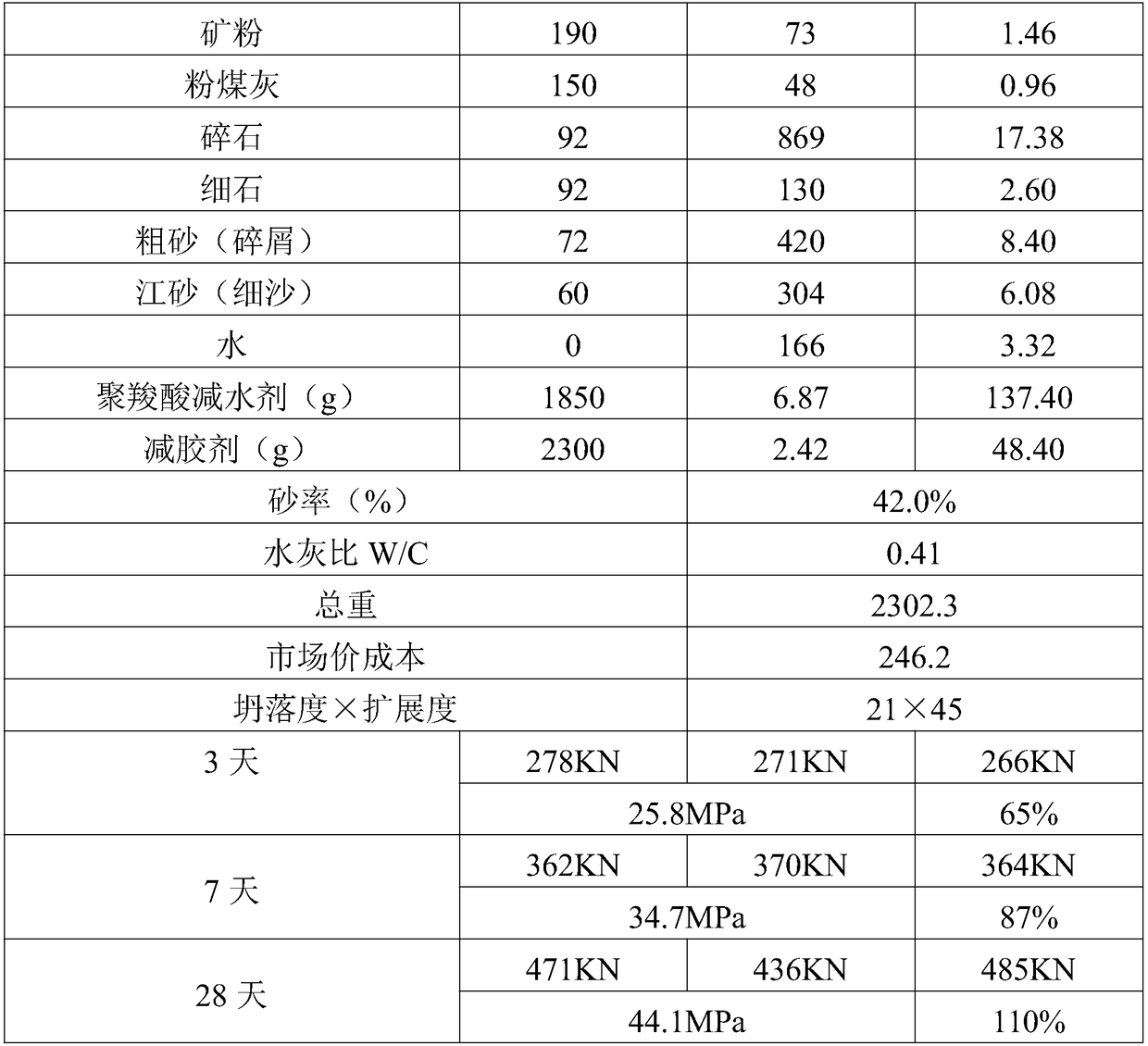

Examples

Embodiment Construction

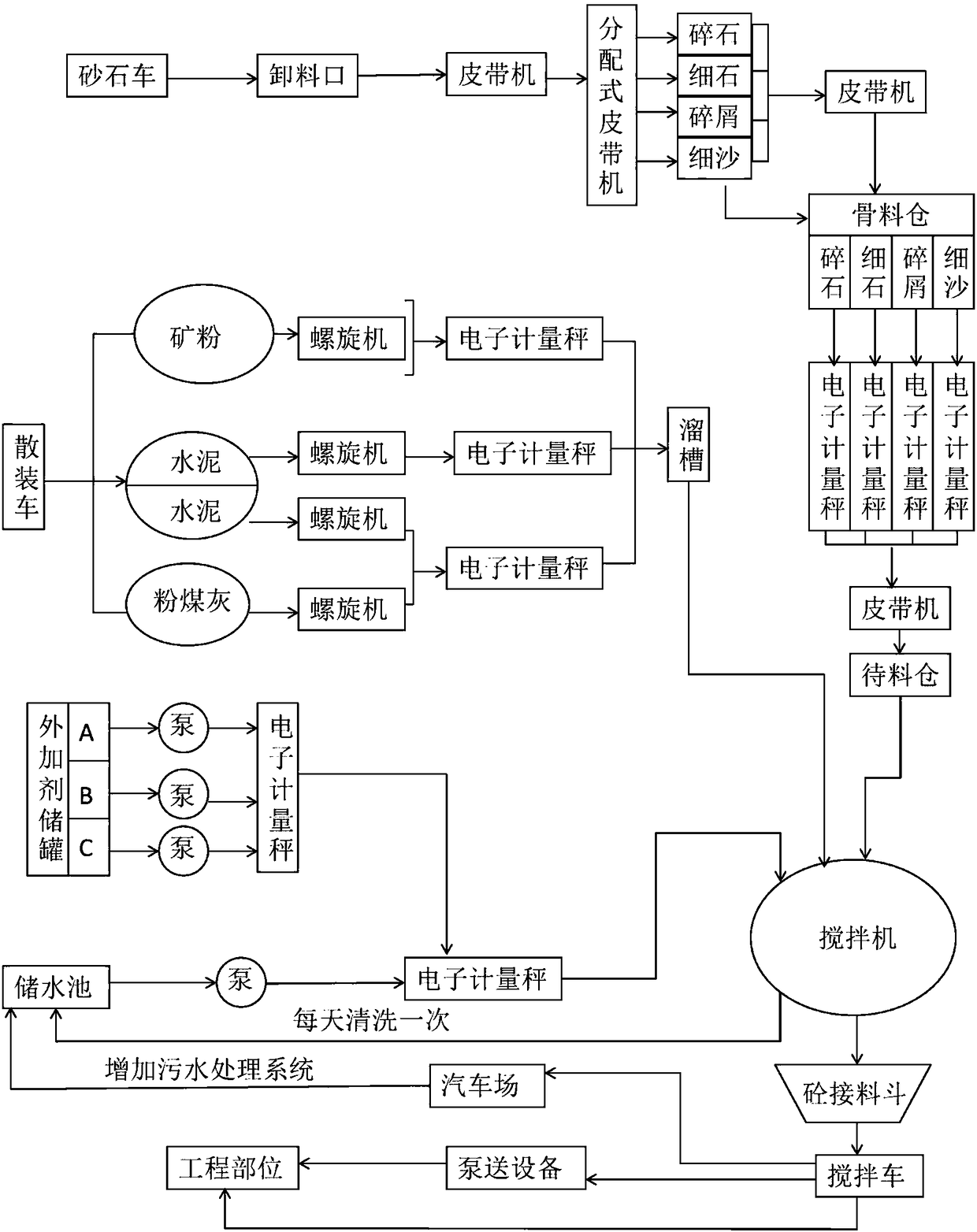

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] Such as figure 1 Shown, a preferred embodiment of the present invention provides a kind of preparation method of concrete, comprising:

[0030] 1) Preparation and weighing of raw materials:

[0031] The raw materials include cement, mineral powder, fly ash, crushed stone, fine stone, debris, fine sand, water, polycarboxylate water reducer and glue reducer;

[0032] The crushed stones, fine stones, chips and fine sand are transported to the respective warehouses in the aggregate bin through the belt conveyor, and each warehouse is equipped with electronic weighing scales, and the required crushed stones are weighed through the corresponding electronic weighing scales , fine stone, debris and fine sand, and then transport the weighed gravel, fine stone, debris and fine sand to the storage bin;

[0033] The mineral powder is conveyed to the miner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com