Road delayed-coagulation cement and preparation method thereof

A technology for retarding setting and cement, applied in the field of road retarding cement and its preparation, can solve the problems of limiting the application scope and scale of phosphogypsum, its performance is inferior to natural gypsum, polluting the ecological environment, etc., achieving suitable setting time and improving flammability. , the effect of reducing the impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method of the present invention is used to carry out road retarding cement production test in the new dry precalcining kiln of Gezhouba Songzi Cement Co., Ltd. The specific steps are:

[0037] (1) 78wt% limestone, 15wt% carbon-containing shale, 5wt% iron raw materials (3 parts iron ore + 1 part sulphuric acid slag), 2wt% phosphogypsum are mixed uniformly and ground to prepare cement raw meal.

[0038] (2) The cement raw meal is sent into the precalcining kiln system to be preheated and decomposed, calcined at high temperature, and quickly cooled to make cement clinker.

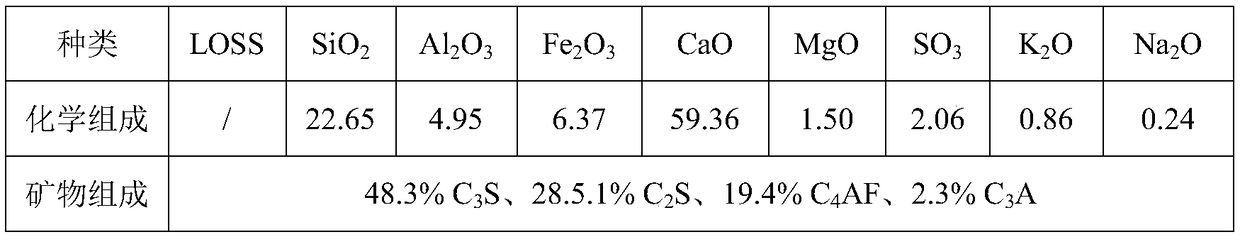

[0039] The chemical composition of the raw materials in Example 1 is shown in Table 1-1:

[0040] Name

LOSS

SiO 2

Al 2 O 3

Fe 2 O 3

CaO

MgO

SO 3

K 2 O

Na 2 O

Limestone

39.17

7.26

0.91

0.32

49.76

0.80

0.12

0.13

0.04

Carbon shale

6.73

61.52

16.40

5.88

2.51

2.25

0.22

2.81

0.82

Iron raw materials

6.37

6.12

2.93

63.42

8.32

1.00

9.30

0.98

0.17

19.53

7.16

1.73

0.44

29.99

0.08

40....

Embodiment 2

[0046] The method of the present invention is used to carry out road retarding cement production test in the new dry precalcining kiln of Gezhouba Songzi Cement Co., Ltd. The specific steps are:

[0047] (1) 80wt% limestone, 14wt% carbon-containing shale, 5wt% iron raw materials (3 parts iron ore + 1 part sulphuric acid slag), 1wt% phosphogypsum are mixed uniformly and ground to prepare cement raw meal.

[0048] (2) The cement raw meal is sent into the precalcining kiln system to be preheated and decomposed, calcined at high temperature, and quickly cooled to make cement clinker.

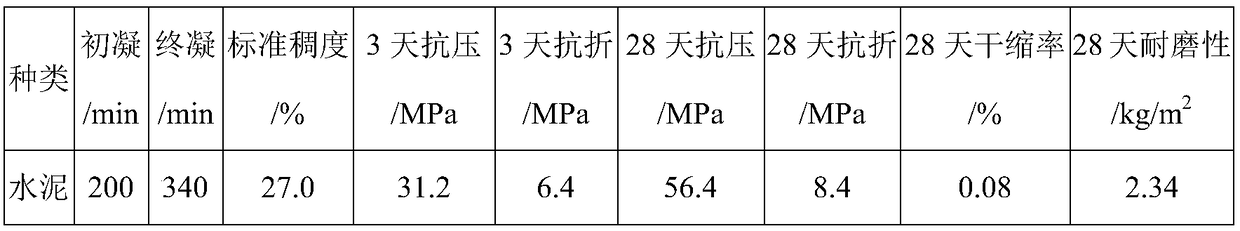

[0049] The chemical composition of the raw materials in Example 2 is shown in Table 2-1:

[0050] Name

LOSS

SiO 2

Al 2 O 3

Fe 2 O 3

CaO

MgO

SO 3

K 2 O

Na 2 O

Limestone

39.17

7.26

0.91

0.32

49.76

0.80

0.12

0.13

0.04

Carbon shale

6.73

61.52

16.40

5.88

2.51

2.25

0.22

2.81

0.82

Iron raw materials

6.37

6.12

2.93

63.42

8.32

1.00

9.30

0.98

0.17

19.53

7.16

1.73

0.44

29.99

0.08

40....

Embodiment 3

[0056] The method of the present invention is used to carry out road retarding cement production test in the new dry precalcining kiln of Gezhouba Songzi Cement Co., Ltd. The specific steps are:

[0057] (1) 82wt% limestone, 13wt% carbon-containing shale, 4wt% iron raw materials (3 parts iron ore+1 part sulphuric acid slag), 1wt% phosphogypsum are mixed uniformly and ground to prepare cement raw meal.

[0058] (2) The cement raw meal is sent into the precalcining kiln system to be preheated and decomposed, calcined at high temperature, and quickly cooled to make cement clinker.

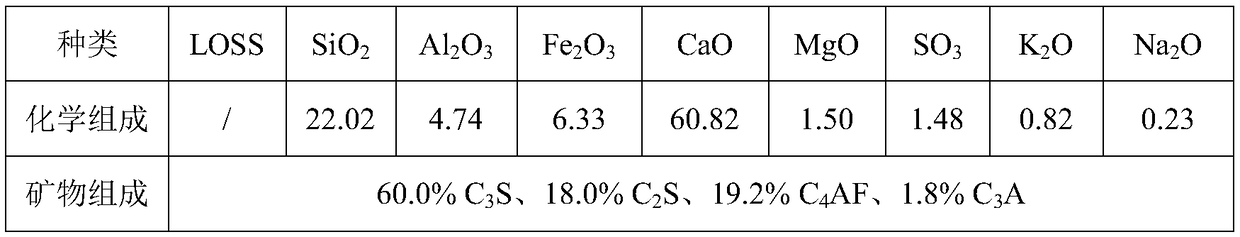

[0059] The chemical composition of the raw materials in Example 3 is shown in Table 3-1:

[0060] Name

LOSS

SiO 2

Al 2 O 3

Fe 2 O 3

CaO

MgO

SO 3

K 2 O

Na 2 O

Limestone

39.17

7.26

0.91

0.32

49.76

0.80

0.12

0.13

0.04

Carbon shale

6.73

61.52

16.40

5.88

2.51

2.25

0.22

2.81

0.82

Iron raw materials

6.37

6.12

2.93

63.42

8.32

1.00

9.30

0.98

0.17

Phosphogypsum

19.53

7.16

1.73

0.44

29.99

0.08

40.19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com