Patents

Literature

92results about How to "Appropriate setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurated gypsum self-leveling material and preparation method thereof

InactiveCN101054284ASufficient construction timeHigh strengthSolid waste managementEmulsionPortland cement

The invention discloses a desulfurizing plaster self-leveling material, which main component weight percent are as follows: 30-65% desulfurizing plaster, 25-60% high-alumina cement, 0-30% ordinary portland cement, 0-20% fly ash, 0-8.0% redispersing emulsion powder. The material comprises an amount of additive and fine aggregate. Blending each component at determined weight percent fully and uniformly in a blender, packing to get self-leveling material. The invention can prepare self-leveling material by desulfurizing plaster massively, has more simple manufacturing technique, less energy consumptions, low cost, moderate coagulation time, strong and better water resistance, microswelling performance, can be widely applied to kinds of leveling execution.

Owner:ZHEJIANG UNIV

Phosphorous slag activation modifier

InactiveCN1457937ALow costImprove grinding effectSolid waste managementSolid waste disposalPhosphorous acidNitrate

The phosphorous slag activating modifier is precipitant comprising one or several kinds of oxide, hydroxide, chloride and nitrate of Ca, Mg and Ba, and prepared through crushing. It is added into phosphorous slag to convert the slowly coagulating components in phosphorous slag into insoluble precipitate as stuffing component. The present invention makes it possible to utilize phosphorous slag to produce high-quality and low-cost cement and other building material.

Owner:尹小林

Titanium gypsum composite binding material and preparation method thereof

InactiveCN103043985AStandard consistency requires little waterAppropriate setting timeWater requirementTitanium

The invention discloses a titanium gypsum composite binding material and a preparation method thereof, wherein the titanium gypsum composite binding material comprises a binding material, water, an admixture and a modifying agent. The preparation method comprises the following steps of: (1) drying titanium gypsum; (2) breaking and grinding the titanium gypsum; (3) calcining the titanium gypsum; (4) aging the titanium gypsum; (5) weighing various components in proportion; (6) adding the processed titanium gypsum in a stirrer, starting the stirrer, and under a low-speed stirring state, sequentially adding coal ash, cement, quick lime, bone glue and a naphthalene water reducer, meanwhile adding water in proportion, and stirring for 5 minutes at a high speed after all materials are added; and (7) casting and forming. The titanium gypsum composite binding material disclosed by the invention has the advantages of low water requirement of normal consistency, proper coagulation time, comparative high early fracture resistance and compressive strength, and the like, and is applicable to production of building indoor partition walls, sandwiched panels, and the like.

Owner:UNIV OF JINAN

Gypsum-base self-flatting ground making level material and preparation process thereof

A self-leveling gypsum-based floor-leveling material for building is proportionally prepared from natural anhydrous gypsum, alkaline exciter, acidic exciter, water preserving agent, water decreasing agent and defoamer through grinding anhydrous gypsum, premixing others, mixing the anhydrous gypsum powder with the premixture, and stirring.

Owner:安徽恒泰非金属材料科技有限责任公司

Whitewashing gypsum and preparing method thereof

The invention relates to a building brushing plaster and preparing method, including semiwater plaster and water retention agent, its character: also anhydrite powder and exciter is added to it, where wt% of each component: anhydrite powder 80-90, semwater plaster 3-13, exciter 1-7 and water retention agent 0.1-0.3. its preparing method: 1), milling natural anhydrite into powders by industrial ball mill, where the particle size is that the rest is less than 3% by 200 eye screen and the specific surface area is 4500-7000 sq cm / g; 2), preparing raw material: according to the demand, additionally adds in hydraulic cementitous material, which accounts for 0-15% of total weight; 3) weighing all the raw materials, mixing in the mixer to make the brushing plaster powder at once. The fine sand less than 5 mm can be added to mixed raw materials according to the demand to make the bushing substrate. It has water proofness.

Owner:WUHAN UNIV OF TECH +1

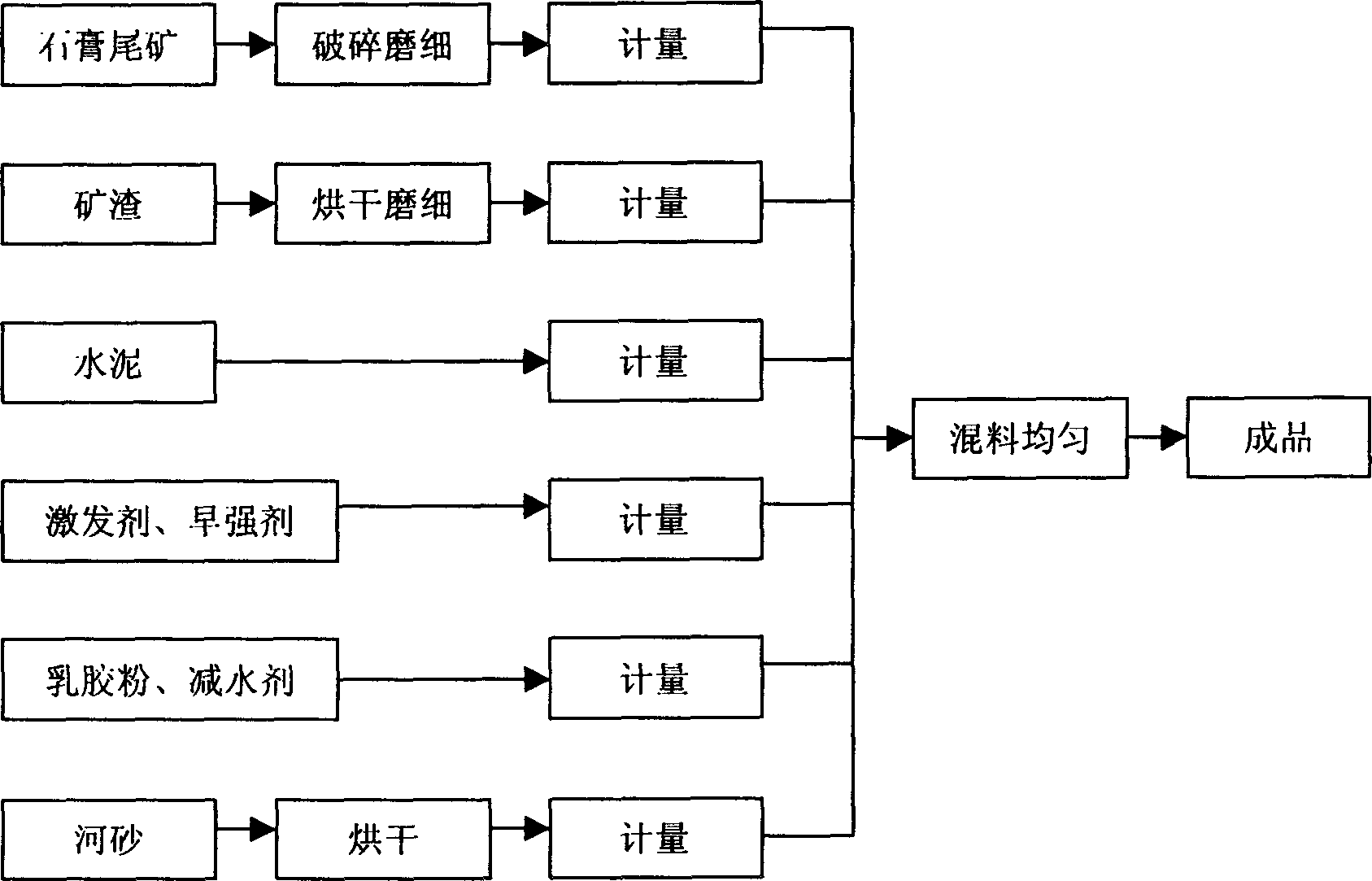

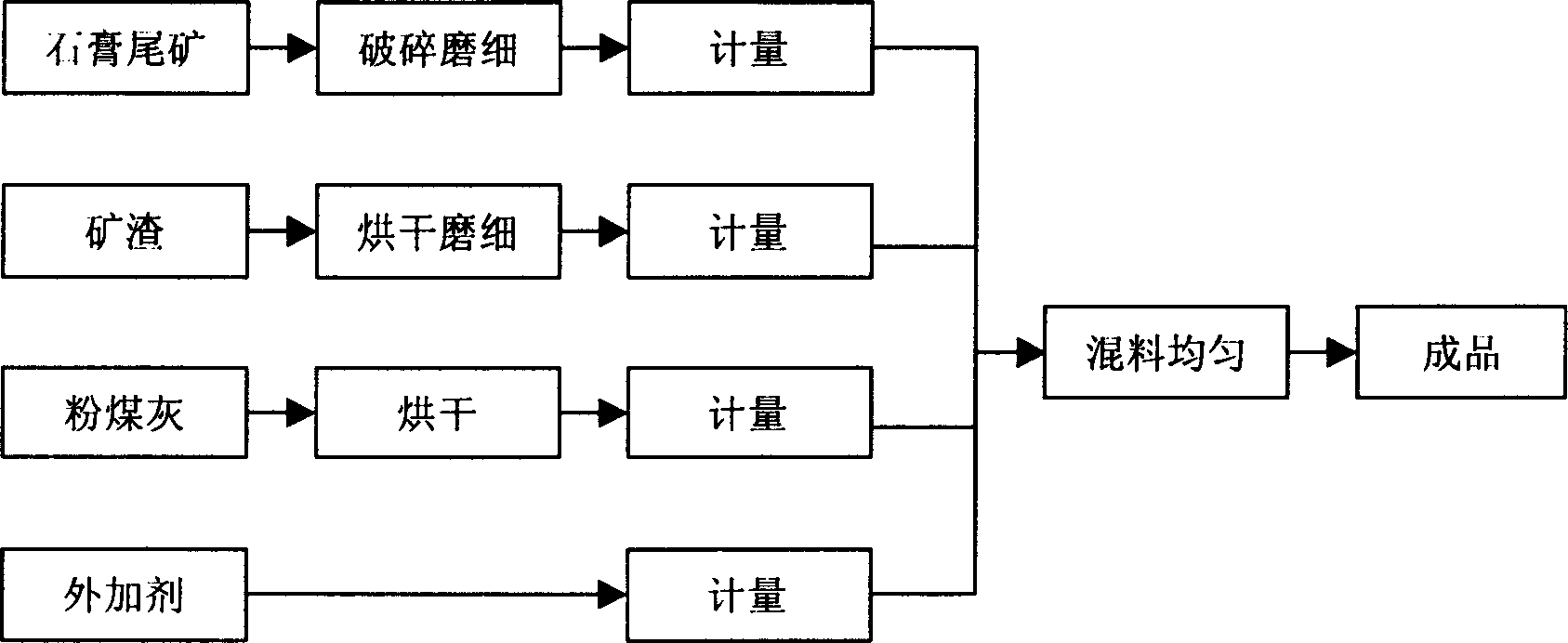

Self-flatting material of gypsum mine and preparation process thereof

InactiveCN1792983ASimple production processReduce manufacturing costSolid waste managementGypsumSlag

A self-leveling material is proportionally prepared from the gypsum ore tailings, slag powder, ordinary silicate cement, river sand, trigger, early-strengthening agent, redispersible colloid powder, and efficient water-reducing agent.

Owner:WUHAN UNIV OF TECH

Hydraulicity cementitious materials and preparation method thereof

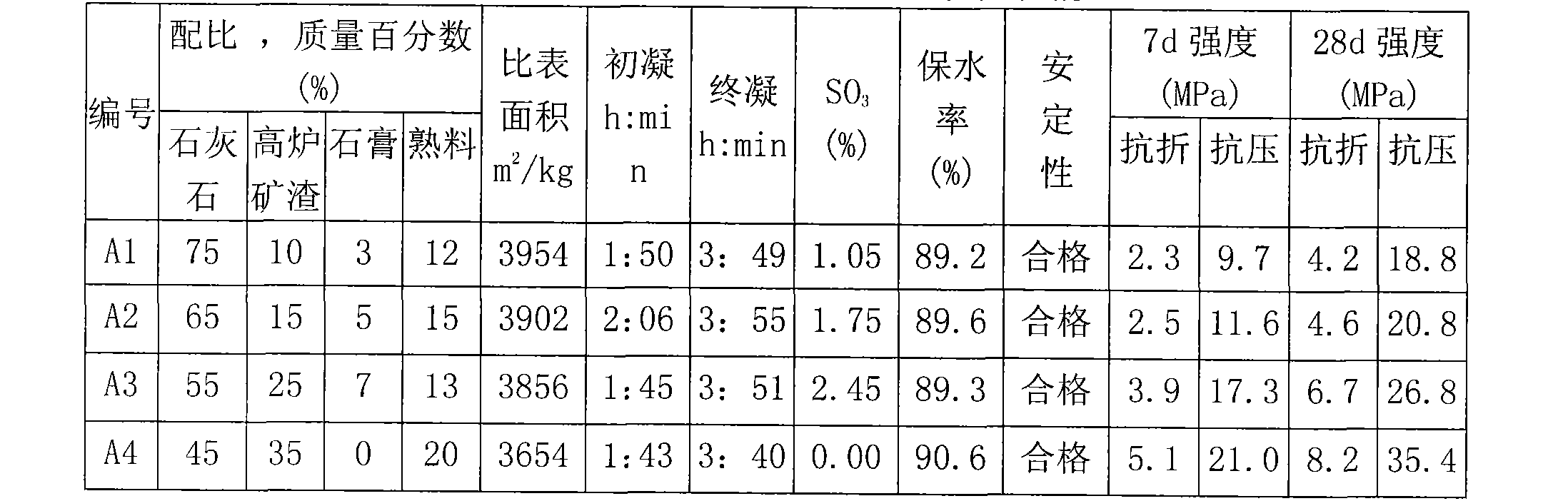

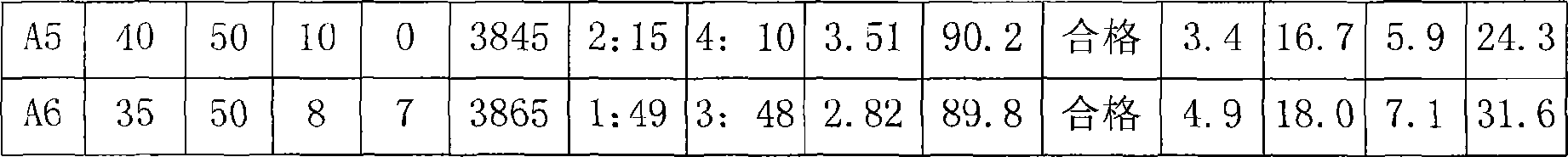

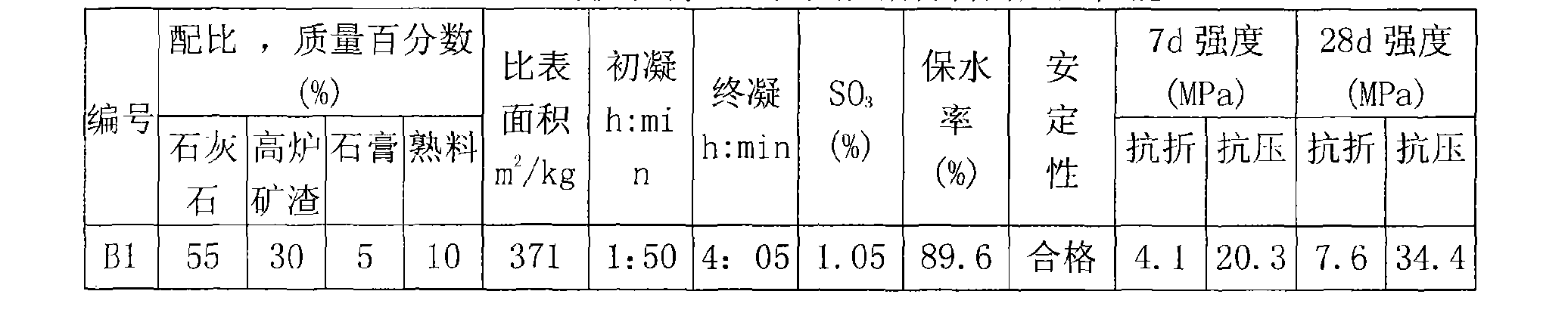

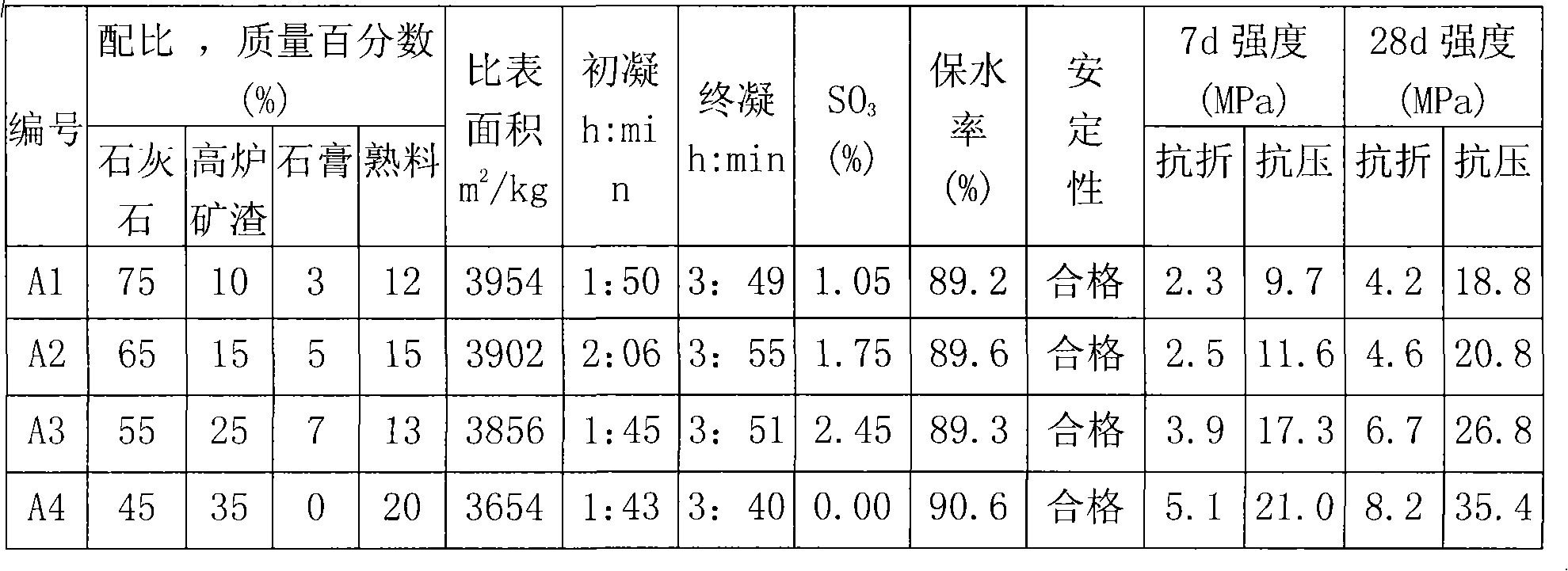

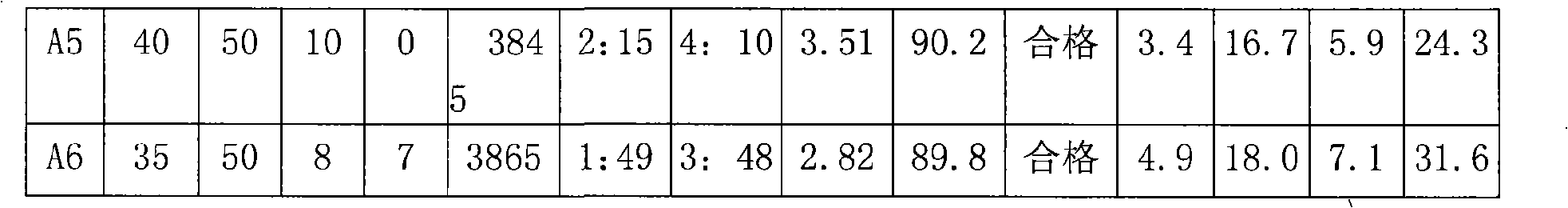

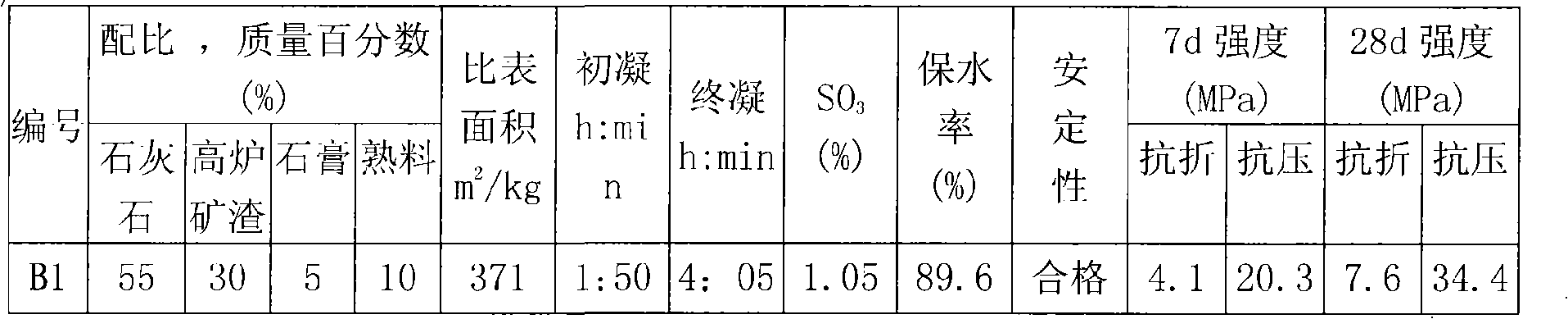

The invention belongs to the field of building materials, and in particular relates to a hydraulic cementing material and a method for preparing the same. The hydraulic cementing material is characterized in that the cementing material is prepared from raw materials of limestone, industrial residue, gypsum and admixture through mixing, and the mass percents of the raw materials are as follows: 35 to 75 percent of the limestone, 5 to 50 percent of the industrial residue, 0 to 10 percent of the gypsum, and 0 to 20 percent of the admixture, wherein the mass percents of the gypsum and the admixture cannot be 0 simultaneously, and the summation of the mass percent of each raw material is 100 percent. The invention can make full use of a large number of the limestone, and the method has the advantages of simple process, low cost, less energy consumption and environmental protection.

Owner:WUHAN UNIV OF TECH +1

Natural anhydrite based lightweight interior wall plastering gypsum material and preparation method thereof

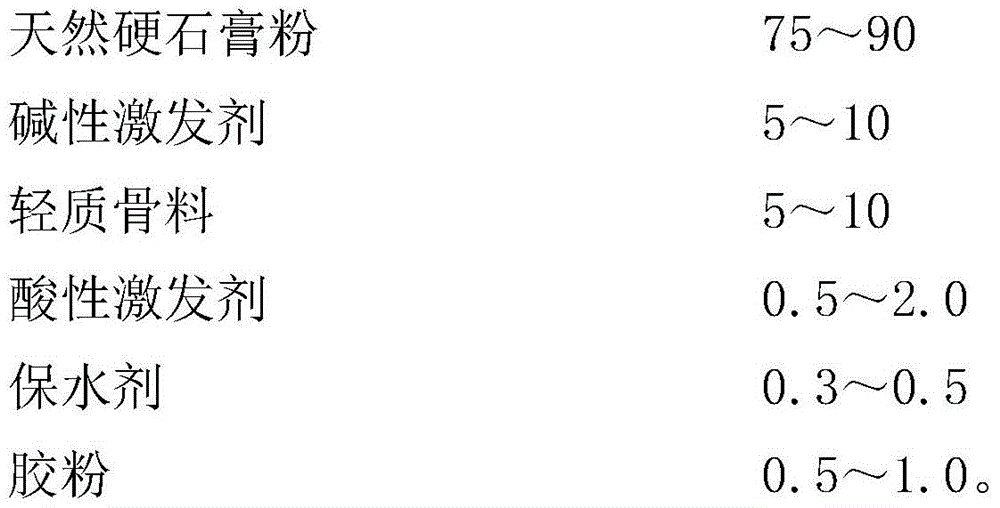

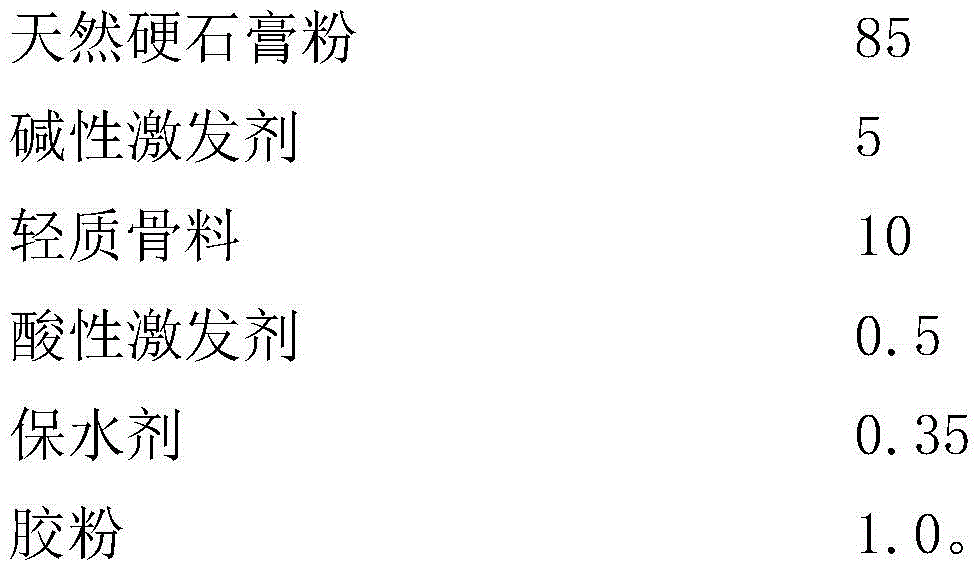

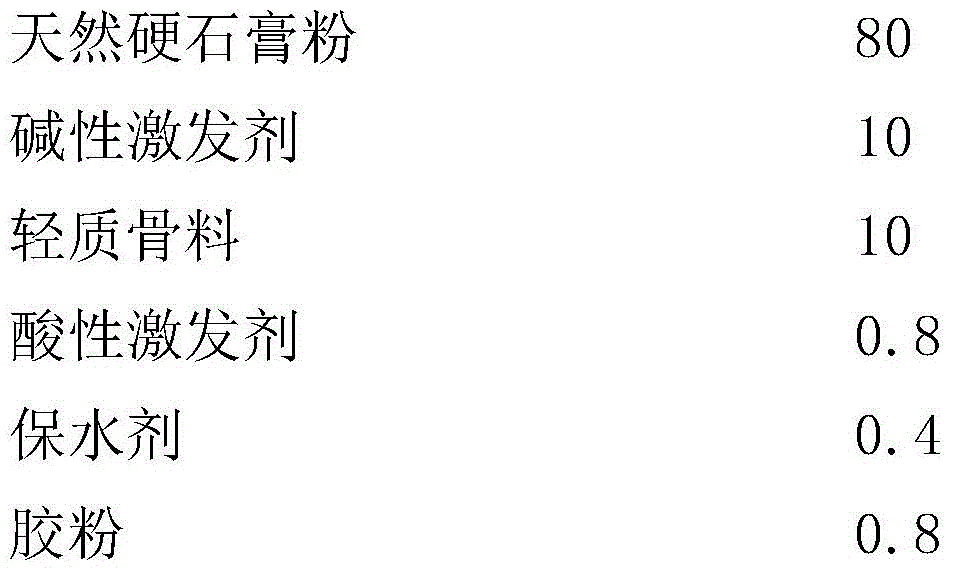

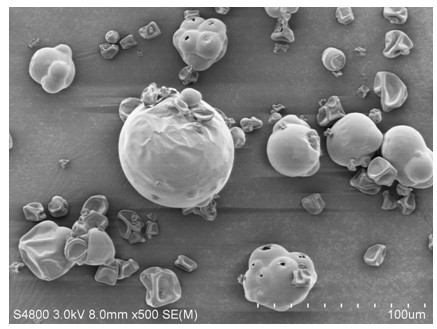

The invention discloses a natural anhydrite based lightweight interior wall plastering gypsum material used in the field of construction, and a preparation method thereof. The natural anhydrite based lightweight interior wall plastering gypsum material is prepared from the following components in percentage by weight: 75-85% of natural gypsum powder, 5-10% of alkali activator, 5-10% of lightweight aggregate, 0.5-2.0% of acidic activator, 0.3-0.5% of water-retaining agent and 0.50-1.0% of cement powder. The preparation method of the natural anhydrite based lightweight interior wall plastering gypsum material comprises the following steps: weighing well-ground gypsum powder based on the weight percentage according to claim 1; uniformly mixing the gypsum powder in a mixer to obtain the natural anhydrite based lightweight interior wall plastering gypsum material. The natural anhydrite based lightweight interior wall plastering gypsum material disclosed by the invention has the advantages of good stability, water-retaining capacity, sagging capacity, large unit plastering area, light weight, heat preservation, good adhesive performance, firm adhesiveness, slight expansibility, convenience for construction, and capabilities of greatly enhancing the adhesiveness between the product and a base material, avoiding undesirable effects such as cracks and realizing both manual construction and mechanized construction.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

Silk fibroin/calcium phosphate bone cement-based porous composite material and preparation method thereof

InactiveCN102552985AImprove toughnessAppropriate setting timeProsthesisAdditive ingredientBiocompatibility Testing

The invention discloses a silk fibroin / calcium phosphate bone cement-based porous composite material and a preparation method thereof. The composite material comprises calcium phosphate, silk fibroin and calcium sulfate. The preparation method comprises the following steps of: adding silk fibroin grains with a hollow structure into composite powder of calcium phosphate and calcium sulfate to prepare a composite material solid phase; and adding a solidified liquid into the solid phase in a certain liquid-solid ratio, and blending into paste, wherein a final product is hydroxyapatite similar to the ingredient of human bone. The composite material can be directly injected into surgical sites by an injector, and can be accurately molded and solidified to form a bone repairing filling material; or the composite material can perform self-solidification at in vitro environment and then is implanted into the human body to be used as a bone repairing implanting material. According to the invention, a pore structure is formed by swelling and deformation of silk fibroin in the solidification process of calcium phosphate bone cement base, so that the composite material is good in toughness and biocompatibility, and the pore structure of calcium phosphate bone cement is improved, and the calcium phosphate bone cement is more close to an artificial bone. Thus the composite material disclosed by the invention has wide application prospect.

Owner:SUZHOU UNIV

Portland cement made from self-pulverized clinker and slag and preparation method for Portland cement

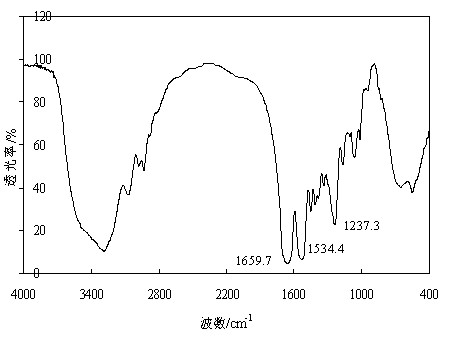

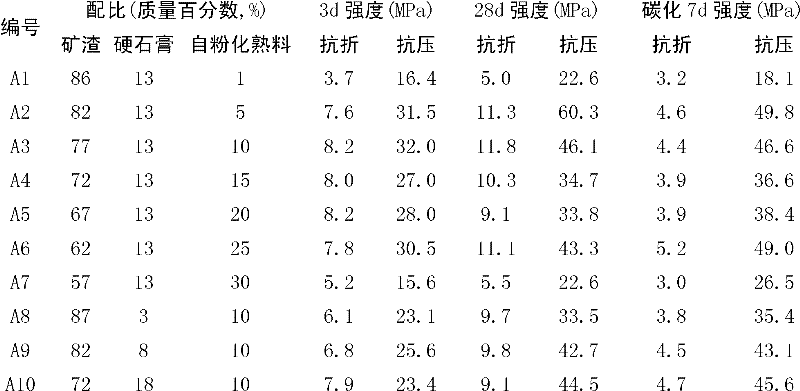

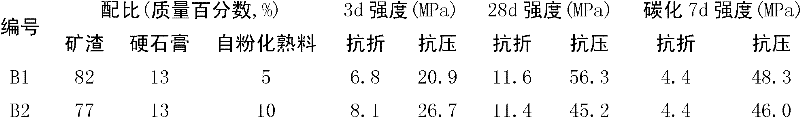

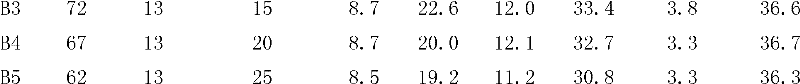

The invention belongs to the technical field of building materials, and particularly relates to a Portland cement made from self-pulverized clinker and slag and a preparation method for the Portland cement. The Portland cement made from the self-pulverized clinker and the slag is characterized in that the Portland cement is made from the slag, plaster and the self-pulverized clinker by means of mixing and comprises 57%-87% of the slag, 3%-18% of the plaster and 1%-30% of the self-pulverized clinker in weight percent. The self-pulverized clinker is prepared according to the steps of preparing cement raw materials by means of arbitrary combination of the lime saturation coefficient ranging from 0.589 to 0.823, the silica ratio ranging from 2.5 to 4.0 and the alumina ratio ranging from 1.0 to 2.8 of the clinker; and grinding the cement raw materials to the degree with screen residues smaller than 18% by means of sieving of a sieve with the 0.08mm side length of a sieve mesh, calcining the grinded cement raw materials for 0.5 hour to 1.5 hours at the high temperature ranging from 1200 DEG C to 1380 DEG C prior to slowly cooling to the room temperature with the cooling rate of 15-45 DEG C / min, and obtaining the self-pulverized clinker. The method is simple in process, low in calcining temperature and low in grinding power consumption, and carbonization resistance of the Portland cement can be improved by the method.

Owner:WUHAN UNIV OF TECH +1

Hydraulic gelate material and method for preparing same

The invention belongs to the field of a constructional material, in particular relates to a hydraulic binding material and a preparation method thereof. The hydraulic binding material is characterized in that the hydraulic binding material is prepared with 35 percent to 75 percent of limestone by mass, 5 percent to 50 percent of industrial residue by mass, 0 percent to 10 percent of plaster by mass and 0 percent to 20 percent of additives by mass through mixing. The mass percents of the plaster and the additives are not 0 at the same time, and the total of the mass percents of the raw materials is 100%. The hydraulic binding material and the preparation method can make use of much limestone; the preparation method is simple in process; the cost is low; little energy is consumed; and the hydraulic binding material is environment-friendly.

Owner:WUHAN UNIV OF TECH +1

A method of using naphthalene-based water reducer cement to solidify radioactive waste resin

InactiveCN102262911AMobility is suitableAppropriate setting timeRadioactive decontaminationSuperplasticizerRadioactive waste

The invention discloses a method for solidifying radioactive waste resins with a naphthalene series water reducer and cement in the technical field of radioactive waste resin solidification with cement. The method comprises the following steps of: uniformly mixing sulphate aluminum cement, compound additives and a UNF-5 water reducer; mixing the mixture with radioactive waste resins in an agitating kettle and agitating for 3 minutes; transferring to a die with the diameter phi of 50mm*50mm; and flatting and maintaining for 7 days in a maintenance box to obtain a solidified product. According to the method disclosed by the invention, water does not need to be added to the mixture in the solidification process of the radioactive waste resins, slurry has proper fluidity and setting time, andthe solidified product has higher compression strength.

Owner:TSINGHUA UNIV

Subway tunnel grouting admixture and preparation method thereof

The invention belongs to the field of new materials for construction, and particularly relates to a subway tunnel grouting admixture and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking 1000 parts by weight of modified lignosulfonate concrete high-efficiency water reducing agent, dissolving 1000-2000 parts by weight of water, heating to 60-100 DEG C while stirring, adding 20-200 parts by weight of crosslinking agent, and performing polycondensation reaction for 0.5-10 hours; adding 1-50 parts by weight of air entraining agent, 100-500 parts by weight of inorganic salt reinforcer and 10-50 parts by weight of water-soluble high-molecular polymer, and stirring for 10-60 minutes; and cooling to obtain a liquid product, and drying to obtain a solid powder product, wherein the modified lignosulfonate concrete high-efficiency water reducing agent can be prepared according to the ZL98116516.8 patent, the crosslinking agent is one of or a mixture of more than one of formaldehyde, melamine, polyalcohol and polyamine, and the air entraining agent is one of or a mixture of more than one of turpentine soap, rosin thermopolymer, anionic surfactant or multi-element compounds thereof.

Owner:张淑华

High-polymer easy plaster

The invention discloses high-polymer easy plaster and belongs to the field of polymer waterproof mortar. The easy plaster comprises raw materials in parts by weight as follows: 30-50 parts of cement, 40-80 parts of quartz sand, 10-25 parts of ash calcium powder, 3-7 parts of polyvinyl alcohol and 2-4 parts of re-dispersible emulsion powder. The raw materials of the high-polymer easy plaster are simple and easy to obtain, and the product is environment-friendly, has excellent bonding strength, prominent impermeability, suitable setting time and water retention and alkali-resistant properties and the like and can be widely applied to permeability and damp resistance and waterproof plugging of positions such as internal and external walls, basements, swimming pools, toilets, water reservoirs and the like.

Owner:FUZHOU UNIV

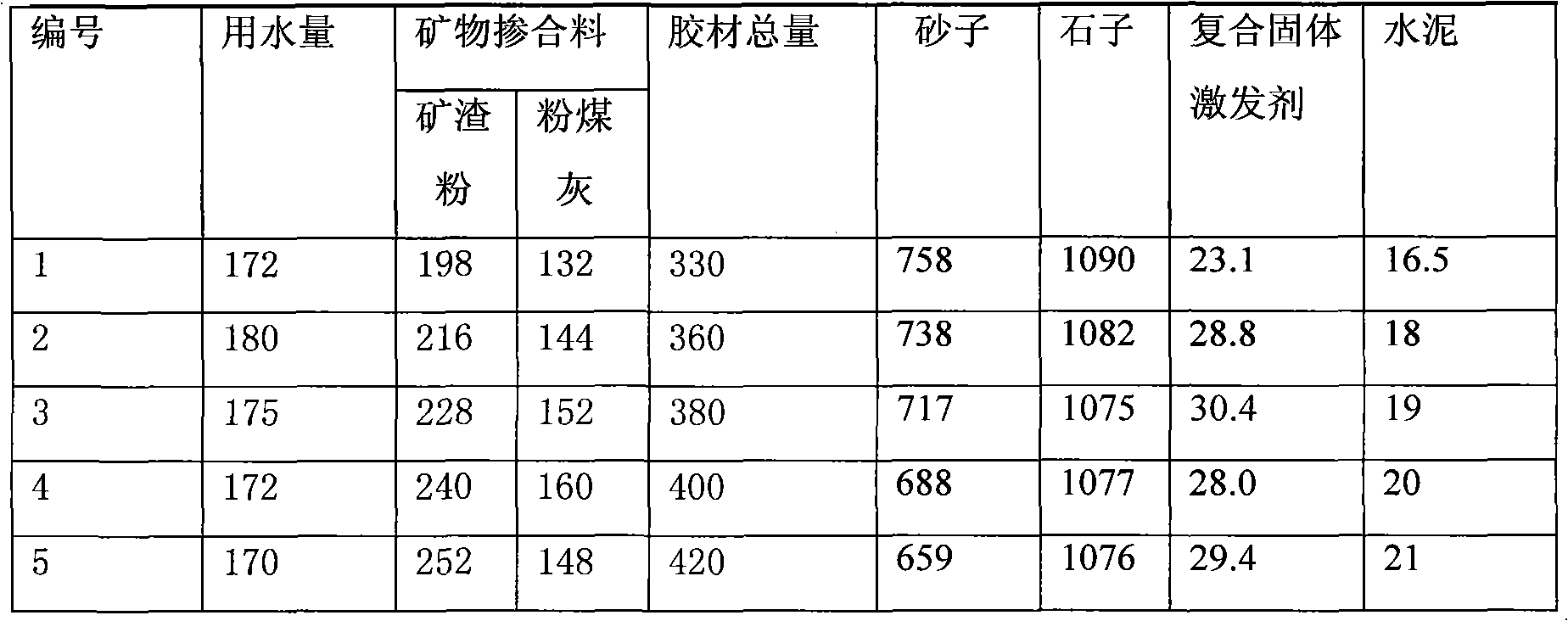

Mineral admixture concrete and preparation method thereof

The invention relates to mineral admixture concrete and a preparation method thereof and belongs to the field of building materials. The preparation method is characterized in that a composite solid exciting agent is utilized to excite potential activity of a mineral admixture and produces a synergistic effect with common cement so that the mineral admixture concrete having strength of C30-C70 and excellent durability such as anti-permeability and frost-resistance and allowing normal setting time is obtained. The composite solid exciting agent can greatly improve the strength and the durability of the mineral admixture concrete. Through replacement of 90 to 95% of cement with a large amount of an industrial waste residue-slag powder-fly ash admixture, a production cost is reduced obviously. The mineral admixture of a cementing agent, a sand aggregate and the composite solid exciting agent is pre-stirred and then is added with mixing water so that the composite solid exciting agent is dispersed uniformly and after addition of the mixing water, the mineral admixture can be fully excited. In construction, the mineral admixture concrete has good workability and no ropiness, can be operated easily, has high strength after setting and hardening, good durability and a low cost, and can be used in various engineering construction and concrete products.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Gypsum-based internal heat insulation material

ActiveCN102503342AReduce pollutionReduce consumptionSolid waste disposalUltimate tensile strengthPollution

The invention discloses a gypsum-based internal heat insulation material, which comprises, by weight, 80-90 parts of desulfurized gypsum powder, 6-10 parts of vitrified small balls, 4-6 parts of polyphenyl particles, 0.2-0.5 part of water-retaining agent, 0.1-0.4 part of retarder and 0.2-0.5 part of exciting agent. The gypsum-based internal heat insulation material has the advantages of high hardening strength, high water resistance and proper setting time, and requires no grinding but mixing. The gypsum-based internal heat insulation material is energy-saving, pollution-reducing and low in additive usage, so that production cost can be reduced.

Owner:安徽省恒泰新材料有限公司

Neutral sodium salt alkali-activation low-calcium fly ash cement and use method of same

InactiveCN105130224AAvoid the disadvantage of too fast setting timeAppropriate setting timeCement productionPortland cementPhysical chemistry

The invention discloses a neutral sodium salt alkali-activation low-calcium fly ash cement and a use method of the same. The cement is prepared from low-calcium fly ash and ordinary Portland cement as main raw materials with addition of neutral sodium salt as an activating agent. The raw materials are added with water with stirring to obtain neutral sodium salt alkali-activation low-calcium fly ash cement clear slurry, wherein a curing technology of standard curing for one day and then autoclaved curing is employed. The cement is low-carbon and environment-protective, is low in cost and is high in compressive strength, is excellent in economic, social and environment-protective benefit and is suitable for being popularized and applied in the field of concrete products and prefabricated members in large scale.

Owner:FUZHOU UNIV

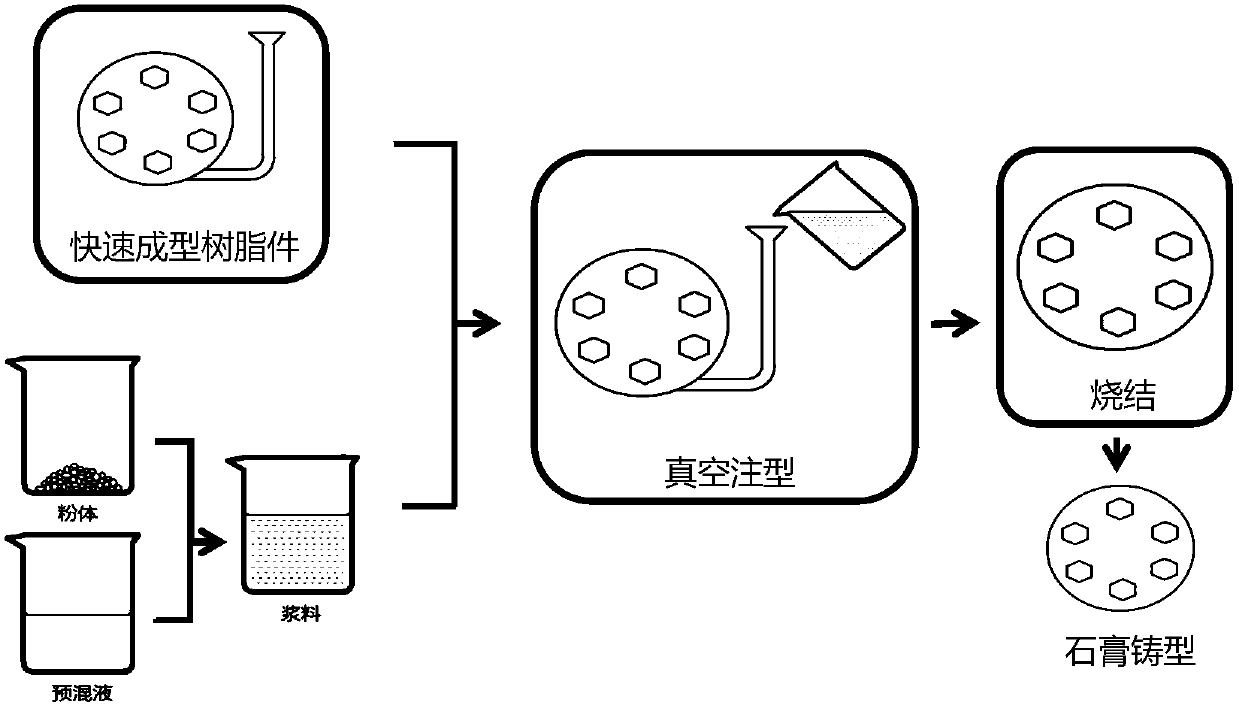

Core-shell type integrated gypsum casting mold manufacturing method based on rapid light-curing molding

ActiveCN107745077AHigh speedImprove manufacturing precisionFoundry mouldsFoundry coresFiberHigh surface

The invention discloses a core-shell type integrated gypsum casting mold manufacturing method based on rapid light-curing molding, and belongs to the field of rapid manufacturing of gypsum casting molds. The core-shell type integrated gypsum casting mold manufacturing method comprises: 1) manufacturing a resin member mold for gypsum casting mold fillinga by using rapid light curing molding equipment; 2) preparing a slurry, wherein the slurry comprises alpha calcium sulfate hemihydrate, quartz powder, bauxite, talc powder, C fiber, silica sol, magnesium sulfate and the balance of water; 3) in avacuum injection molding machine, carrying out mold filling casting on the resin member mold prepared in the step 1) and the slurry prepared in the step 2), and standing until solidifying after the casting so as to prepare a gypsum billet; and 4) sintering the gypsum billet to removing the resin member mold so as to prepare the gypsum casting mold. According to the present invention, with the method, the rapid manufacturing of the complex-structure part gypsum casting mold is achieved, the production process with characteristics of low cost and short production period is provided for the manufacturing of the low-melting point metal casting member with characteristics of complex structure and high surface quality, and the problems in the suspension beam, the inner cavity channel and othertraditional sand mold processes can be solved.

Owner:XI AN JIAOTONG UNIV

Energy-saving type impervious waterproof building concrete and preparation method thereof

The invention discloses an energy-saving type impervious waterproof building concrete and a preparation method thereof. The raw materials comprise, by weight part, 68-75 of Portland cement, 23-25 of black soil powder, 12-15 of graphite powder, 8-10 of aluminum nitride powder, 3-4 of iron oxide red powder, 10-15 of a mushrooms cultivation material, 0.4-0.6 of tetramethyl guanidine, 2-4 of calcium stearate, 1.5-2.0 of sodium tripolyphosphate, 0.8-1.0 of sodium tartrate, 1.2-1.5 of amino sulfonic acid, 2-4 of a milky white glue, 4-5 of zinc chloride, 1.0-1.5 of sodium alginate and a proper amount of water. The concrete provided by the invention has the characteristics of high hardening strength, good water resistance, impermeability and watertightness, and suitable setting time. The concrete provided by the invention adopts a variety of waste materials as the raw materials, saves energy, reduces pollution, and has small dosage of additives, thus reducing the production cost.

Owner:青阳县天工预拌商品砂浆有限公司

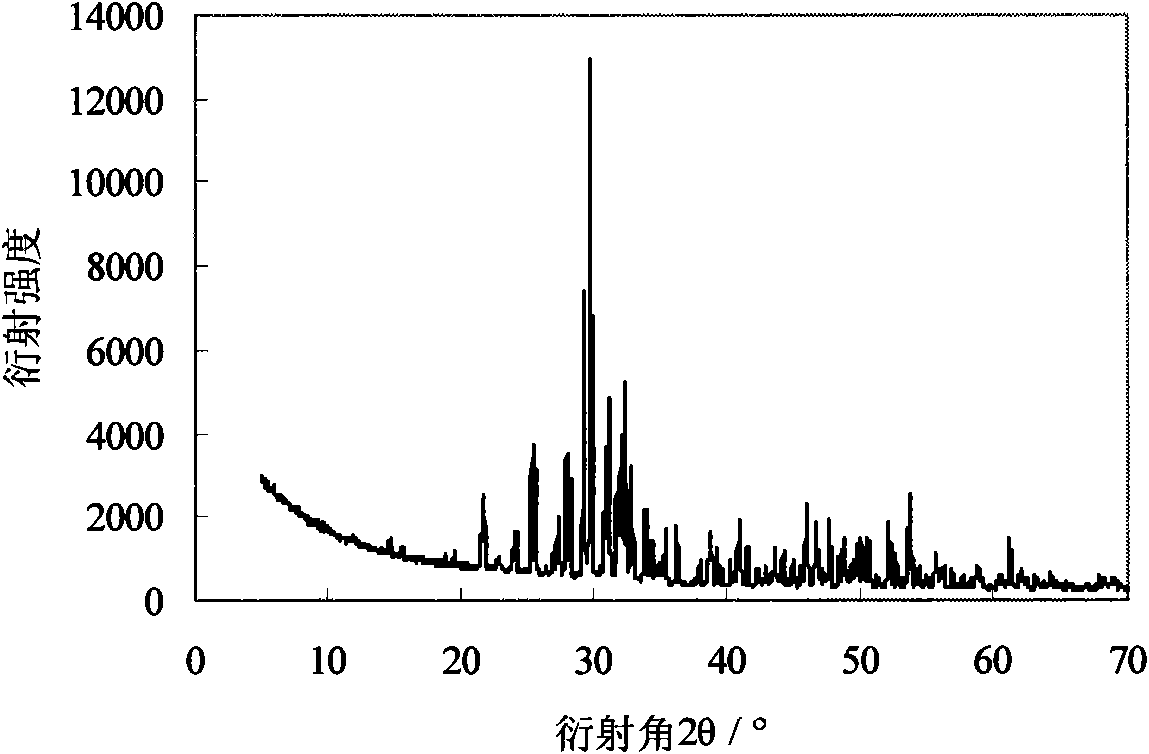

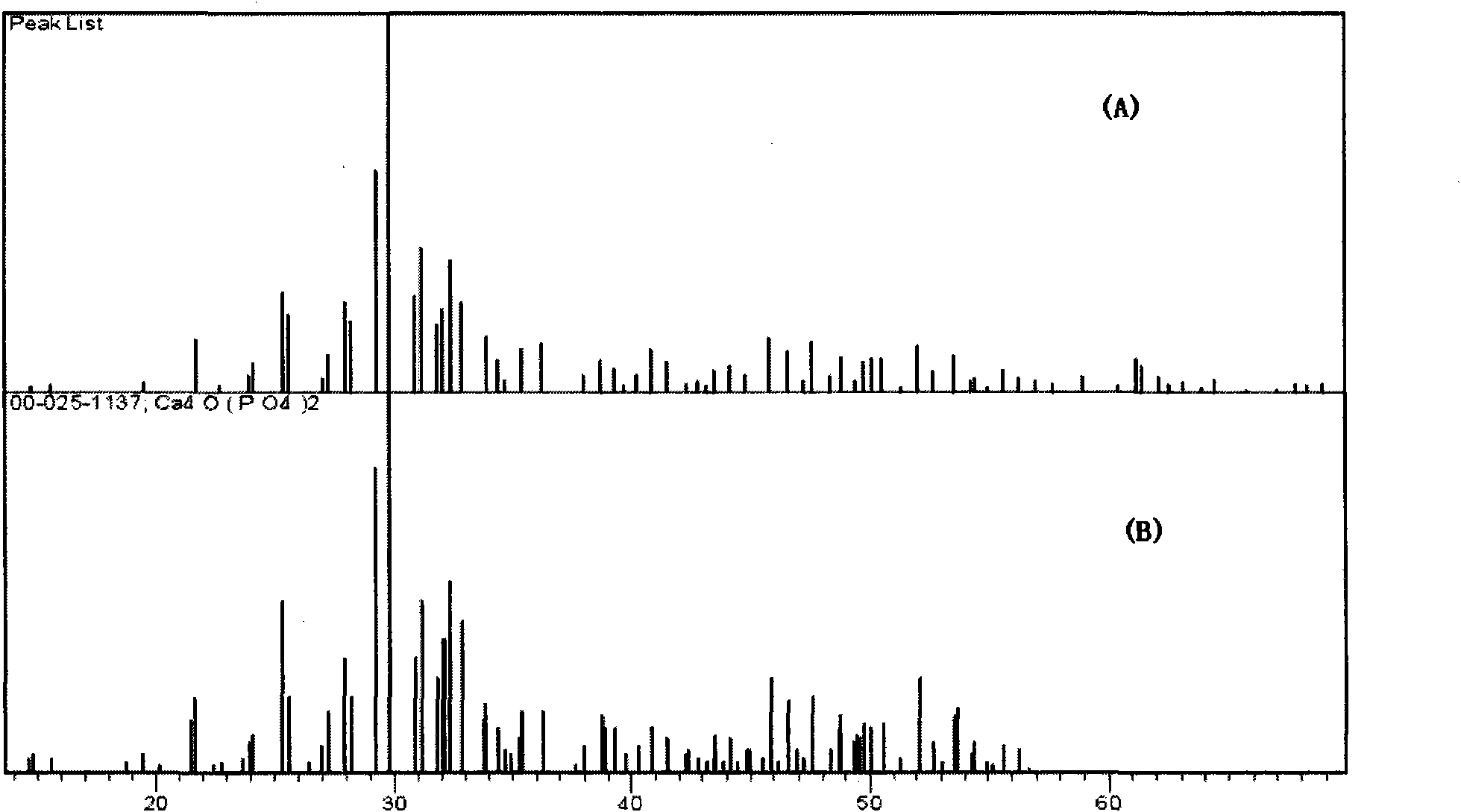

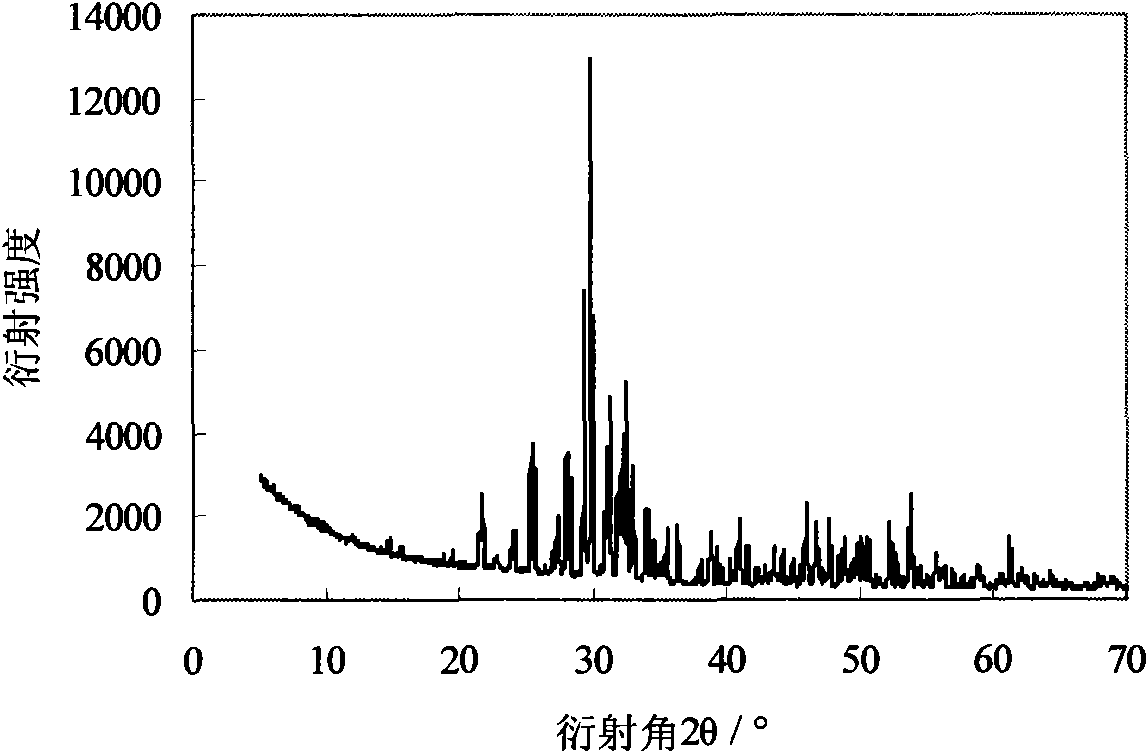

Silk fibroin/calcium phosphate bone cement composite material and preparation method thereof

InactiveCN101961509AImprove preparation working conditionsReduce manufacturing costProsthesisWater insolubleBiocompatibility Testing

The invention discloses a silk fibroin / calcium phosphate bone cement composite material and a preparation method thereof. In the preparation of the main component of tracalcium phosphate of calcium phosphate bone cement, the tracalcium phosphate is prepared in a mode of cooling by stages after calcining a tracalcium phosphate precursor which is synthesized by adopting a liquid-phase reaction method; composite powder is prepared by adding water-insoluble silk fibroin powder into the calcium phosphate bone cement; and the silk fibroin / calcium phosphate bone cement composite material with a similar structure to a bone is converted by blending the composite powder in a certain liquid-solid ratio to form paste. The silk fibroin / calcium phosphate bone cement composite material has high mechanical property and biocompatibility, is directly injected in a surgical site by using a syringe, and can be molded and cured accurately to serve as a filling material for bone repair; or the composite material can be implanted into a body to be used as an implant material for the bone repair after being self-cured in the in vitro environment. The technical scheme of the invention greatly improves preparation working conditions of the calcium phosphate bone cement, reduces preparation cost, and expands the medical application of silk fibroin.

Owner:SUZHOU UNIV

Bisphosphonate type self-setting composite bone graft and preparation method thereof

ActiveCN111544655AConform to the formation cycleGood shaping and solidification performanceTissue regenerationProsthesisFluid phaseFunction recovery

The invention belongs to the field of bone repair materials, and particularly relates to a bisphosphonate type self-setting composite bone graft for osteoporosis repair and reconstruction and a preparation method thereof. The invention provides the bisphosphonate type self-setting composite bone graft which is a calcium bisphosphonate / self-setting calcium salt compound, the calcium bisphosphonate / self-setting calcium salt compound is composed of a solid phase part and a liquid phase part, and the solid-to-liquid ratio is 1: 0.3-1.0 g / ml, wherein the solid phase part comprises calcium bisphosphonate and a self-setting calcium salt, and the mass ratio of the calcium bisphosphonate to the self-setting calcium salt is 1: (1-6). The diphosphonate and the self-setting composite material are compounded for the first time to obtain the bone graft, and the self-setting composite bone graft has excellent injectability, proper setting time, slow diphosphonate release and excellent biological activity, and can be used for repairing, reconstructing and functional recovery of bone defects caused by osteoporosis and wounds.

Owner:中鼎凯瑞科技成都有限公司

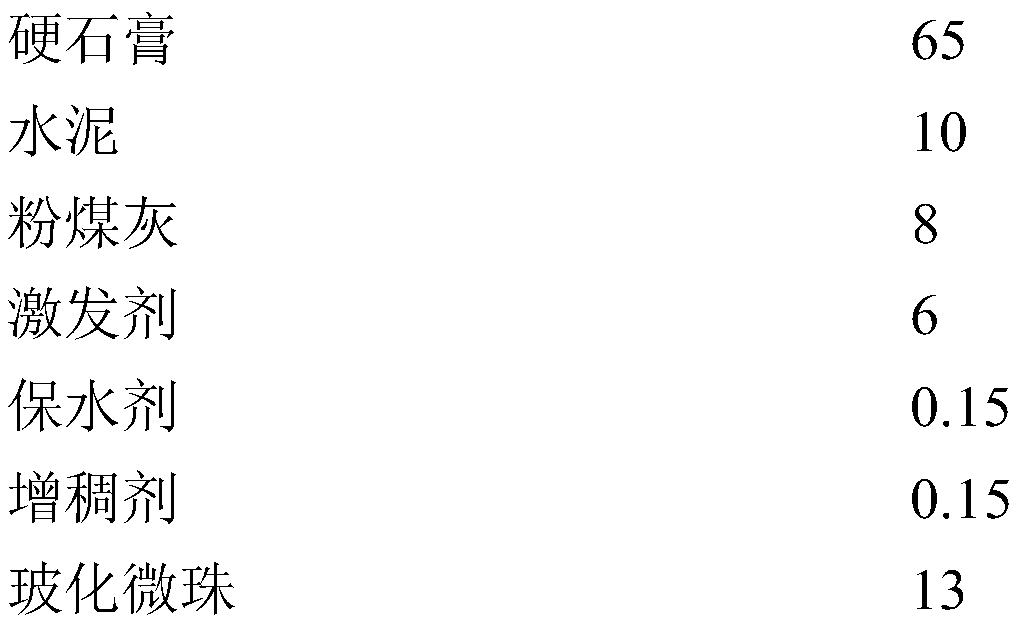

Anhydrite-based light plastering mortar and preparation method thereof

ActiveCN111410502ALow hardening strengthHigh hardening strengthSolid waste managementMining engineeringMaterials science

The invention discloses anhydrite-based light plastering mortar and a preparation method thereof. The anhydrite-based light plastering mortar which is light, energy-saving, good in comprehensive performance and simple in process and is prepared by taking anhydrite as a main material is researched and developed, and the anhydrite-based light plastering mortar has important practical significance. The anhydrite-based light plastering mortar is composed of anhydrite, cement, fly ash, an excitant, vitrified microbead, a thickening agent and a water-retaining agent. The concrete is composed of thefollowing components in parts by weight: 65-70 parts of the anhydrite, 8-10 parts of the cement, 4-8 parts of the fly ash, 4-6 parts of the excitant, 0.15-0.2 parts of the water-retaining agent, 0.1-0.15 part of the thickening agent, and 13-16 parts of vitrified microbead. The anhydrite-based light plastering mortar is prepared by adopting anhydrite associated in a pyrite production process as a main material, calcination treatment is not needed, only physical grinding and mixing are needed, the preparation process is simple, energy is saved, and pollution is reduced; and the problems of hollowing and cracking of the traditional mortar are fundamentally solved.

Owner:安徽合信大环保科技有限公司

Bone repair material and preparation method and application thereof

ActiveCN111870738AGood biocompatibilityGood osteogenic propertiesPharmaceutical delivery mechanismTissue regenerationAnti osteoporosisBiocompatibility

The invention discloses a bone repair material composition, a bone repair material and a preparation method and application of the bone repair material. The bone repair material composition comprisesa bone cement component and curing liquid, wherein the bone cement comprises magnesium oxide, calcium hydrophosphate, sodium dihydrogen phosphate and hydroxyapatite, and the curing liquid is a sodiumphytate aqueous solution. The bone repair material disclosed by the invention is simple to prepare and proper in coagulation time, has good biocompatibility, osteogenesis and degradability, can be directly injected into a bone defect part, has anti-osteoporosis performance and has an obvious osteogenesis effect.

Owner:上海禾麦医学科技有限公司

Gypsum plaster for mechanical spray and preparation method of gypsum plaster

The invention relates to gypsum plaster for mechanical spray and a preparation method of the gypsum plaster. The gypsum plaster is prepared from the following components in parts by weight: 50 to 70 parts of gypsum powder, 20 to 35 parts of quartz sand, 5 to 15 parts of heavy calcium carbonate powder, 20 to 30 parts of perlite, 0.1 to 0.4 part of water retaining agent, 2 to 5 parts of re-dispersible latex powder, 0.1 to 0.5 part of retarder, 0.1 to 0.4 part of starch, and 0.05 to 0.3 part of aluminum hydroxide. The gypsum plaster has the beneficial effects that the gypsum plaster prepared by the invention can be constructed in a mechanical spray manner, saves time and labor and has the characteristics of environmental protection, energy conservation and no pollution. The content of chlorine ions of the gypsum plaster is greatly reduced, the gypsum plaster is ensured not to corrode a wall easily, the binding performance is good, the mechanical spray construction process requirement can be met, the condensation time is appropriate, the water retention performance is good, the bubbling and cracking phenomenon is avoided, and the gypsum plaster is environment-friendly, energy-saving, pollution-free and convenient in construction.

Owner:湖北萨利赫新材料有限公司

Green and environment-friendly masonry mortar

The invention belongs to the field of environmental protection, and in particular relates to green and environment-friendly masonry mortar, consisting of the following raw materials in percentage by weight: 20-25% of phosphorus slag powder, 15-20% of modified alum sludge, 8-12% of cement, 0.01-0.05% of a tackifying water retention agent, 0.2-1% of a thixotropic lubricant, 0.02-0.08% of an intensity excitant, 0.01-0.1% of a dispersant, and the balance of river sand. The green and environment-friendly masonry mortar provided by the invention ingeniously makes use of a coagulation accelerating property of an aluminum-containing compound in the alum sludge, and the alum sludge is used together with the phosphorus slag powder to ensure that the masonry mortar provided by the invention has an appropriate coagulation time. The environmental protection pressure and the waste discharge burden of a waste discharge enterprise can be significantly reduced, and the ecological environment can be improved.

Owner:泛城设计股份有限公司

Anti-collapsible injectable magnesium phosphate-based bone cement

ActiveCN108635624AAppropriate setting timeHigh strengthPharmaceutical delivery mechanismTissue regenerationMagnesium phosphateInjectable bone

The invention relates to anti-collapsible injectable magnesium phosphate-based bone cement. The anti-collapsible injectable magnesium phosphate-based bone cement is composed of a powder phase and a liquid phase, and the powder phase comprises magnesium oxide, potassium dihydrogen phosphate, calcium phosphate salt, citric acid (or sodium citrate) and polysaccharide (or a polysaccharide derivative),wherein the magnesium oxide is 26-28 parts by mass, the potassium dihydrogen phosphate is 52 to 55 parts by mass, the calcium phosphate salt is 16 to 18 parts by mass, the citric acid (or sodium citrate) is 0 to 4 parts by mass, and the polysaccharide (or polysaccharide derivative) is 0 to 1 part by mass. The liquid phase is an aqueous solution of glycerin. The powder phase and the liquid phase are uniformly mixed at a ratio of 1.8 to 2.4 g / mL, a mixture is conditioned for 4 to 6 minutes to form viscous slurry, and the mixture can be injected by a syringe. The injectable magnesium phosphate-based bone cement has good anti-collapsing performance, suitable coagulation time and high strength, is degradable, has good cell compatibility, and is suitable for injection filling of orthopedic anddental cavity defects in ordinary or minimally invasive surgery.

Owner:WUHAN UNIV OF TECH

Slag cement modification strengthening agent

The invention relates to a steel slag cement active enhancer. The steel slag cement active enhancer is composed of potassium aluminum sulfate, ammonium aluminum sulfate, sodium metesilicate, ferrous sulfate and melamine resin, thereby leading the early stage hydration process to timely generate appropriate amount of ettringite, calcium silicate hydrate, xonotlite, gyrolite, thomsonite, natrolite, analcime, calcium iron sulfide hydrate, calcium sulphoaluminate hydrate and others to form a cross-linked frame structure and allowing the later stage to be continuously strengthened and meet the comprehensive requirements of the use. The steel slag cement active enhancer is characterized in that: the reflected strength, the coagulation time and other performances of the early stage frame structure can achieve or be higher than the performances of the same-stage general portland cement; multi-center substances which are formed by the secondary reaction and the continuous hydration and are penetrated and connected can ensure the calcium complex salt structure to be continuously thickened and strengthened; the early stage strength is high, the coagulation time is moderate, hardened cement paste and the prepared concrete have better workability, compactibility, durability, impermeability, anti-shrinkage property, corrosion resistance, anti-freeze-thaw property, anti-carbonization property and the like; the mixing amount is less, the performance to price ratio is low, the steel slag cement active enhancer has low alkali, no chlorine, no toxicity and no side effects; and the application range is wide.

Owner:李长有

High-S silicate cement and its preparing process

A high sulfur silicate cement contains SO3 (1.5-3.0%), CaO (63-68%) and CaSO4 (2.6-5.1%), and is prepared through calcining at 1350-1400 deg.C while controlling such parameters: KH=0.92-1.0, n=1.90-2.50, p=1.0-1.8 and SR=0.18-0.32, where SR=SO3 / Al2O3+Fe2O3. Its advantages are less exhaustion of toxic waste gas, high strength and performance, and low cost.

Owner:GUANGXI UNIV

Modified repair mortar

The invention discloses modified repair mortar. The modified repair mortar is prepared by mixing sulphoaluminate cement, ordinary silicate cement, quartz sand, a complex early strength agent, a water-retaining agent, anti-crack fibers, a water reducing agent and water. According to the modified repair mortar, a sulphoaluminate cement and ordinary silicate cement mixed cementing material is adopted, the optimal mix and match proportion is selected, the early strength of the mortar is high, the setting time is proper, and construction is convenient. In addition, the complex early strength agent, the water-retaining agent, the water reducing agent and the like are added, and therefore better strength of the mortar in early stage and later stage is effectively guaranteed. The anti-crack fibers are added in the components, shrinkage deformation of the mortar is greatly reduced, when the mortar is under stress, the anti-crack fibers play an active prevention role in generation and development of cracks, the shrinkage deformation is obviously reduced, and cracks generated in the repair mortar setting and hardening processes and under stress are reduced.

Owner:张耀忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com