Silk fibroin/calcium phosphate bone cement-based porous composite material and preparation method thereof

A technology of calcium phosphate bone cement and silk fibroin, applied in medical science, prosthesis, etc., can solve the problems of unfavorable bone tissue and blood vessel growth, affecting the application of silk fibroin, non-injectable, etc., and achieve good biocompatibility Sexuality, beneficial to bone tissue reconstruction, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A silk fibroin / calcium phosphate bone cement-based porous composite material and a preparation method thereof, comprising the following steps;

[0031] (1) Preparation of silk fibroin

[0032] After silk is removed from sericin, it is dissolved in a ternary solution of calcium chloride, ethanol and deionized water, and a silk fibroin solution with a concentration of 3% is obtained through dialysis and filtration, and spray-dried at an inlet air temperature of 130°C to obtain Silk fibroin particles are mainly hollow spherical and ellipsoidal.

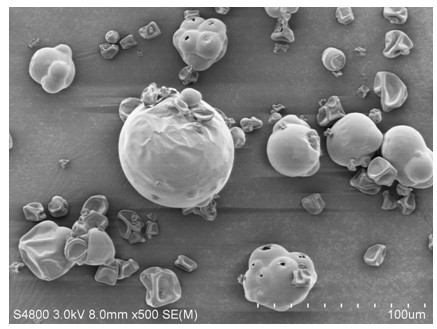

[0033] See attached figure 1 , it is the scanning electron micrograph of the silk fibroin particle that the concentration that this embodiment provides is 3%, by figure 1 It can be seen that the shape of silk fibroin particles is mainly hollow spherical and ellipsoidal;

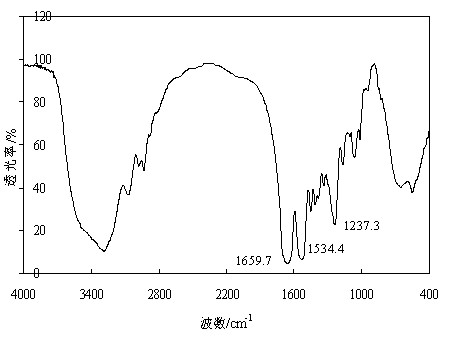

[0034] See attached figure 2 , which is the infrared spectrogram of the silk fibroin granules with a concentration of 3% provided by the embodiments of the ...

Embodiment 2

[0041] (1) Preparation of silk fibroin

[0042] The preparation method of silk fibroin solution is the same as example one. Use spray drying equipment to dry it at an inlet temperature of 140° C. to obtain silk fibroin particles mainly in hollow spherical and ellipsoidal shapes.

[0043] (2) Preparation of calcium phosphate bone cement-based composite powder

[0044] Add 2.0 g of silk fibroin granules obtained in step (1) to 18.0 g of tetracalcium phosphate, α-tricalcium phosphate, calcium hydrogen phosphate and calcium sulfate composite powder, and mix evenly to obtain a solid phase of the composite material .

[0045] (3) Preparation of solidified body of silk fibroin / calcium phosphate bone cement-based porous composite material

[0046] Add the solidified solution (same as in Example 1) to the solid phase obtained in step (2) at a liquid-solid ratio of 0.55 ml / g, and after uniform preparation, inject the bone cement paste into the mold for molding at a temperature of 37 ...

Embodiment 3

[0048] (1) Preparation of silk fibroin

[0049] The preparation method of silk fibroin solution is the same as example one. Use spray drying equipment to dry it at an inlet temperature of 130° C. to obtain silk fibroin particles mainly in hollow spherical and ellipsoidal shapes. .

[0050] (2) Preparation of calcium phosphate bone cement-based composite powder

[0051] Add 1.0 g of silk fibroin particles obtained in step (1) to 19.0 g of tetracalcium phosphate, α-tricalcium phosphate, and calcium hydrogen phosphate composite powder, and mix evenly to obtain a solid phase of the composite material.

[0052] (3) Preparation of solidified body of silk fibroin / calcium phosphate bone cement-based porous composite material

[0053] Add the solidification solution (same as in Example 1) to the solid phase obtained in step (2) according to the liquid-solid ratio of 0.45 ml / g, and after uniform preparation, inject the bone cement paste into the mold for molding. After curing for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com