High-S silicate cement and its preparing process

A technology of sulfur portland cement and portland cement, which is applied in the field of cement, can solve problems such as polluting the environment, failing to meet expected requirements, and unstable calcium sulfate content, and achieves the effects of environmental protection and reduction of cement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

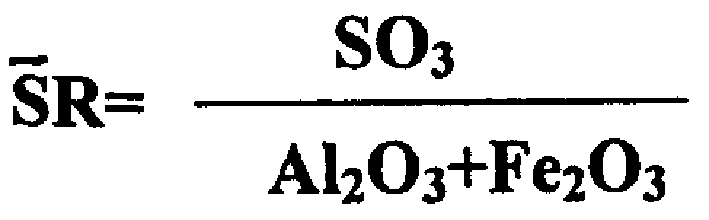

[0012] In the high-sulfur Portland cement of the present invention, the main oxide content ranges in the clinker are: CaO 63-68%; SiO 2 20-24%; Al 2 o 3 3~6%; Fe 2 o 3 2.6~5.0%; SO 3 1.5~3.0%; the corresponding main mineral component is tricalcium silicate (3CaO SiO 2 ), dicalcium silicate (2CaO SiO 2 ), tricalcium aluminate (3CaO·Al 2 o 3 ) Tetracalcium aluminoferrite (4CaO·Al 2 o 3 · Fe 2 o 3 ) and calcium sulfate (CaSO 4 ). Its physical properties and uses are the same as ordinary Portland cement.

[0013] High-sulfur Portland cement production method of the present invention is:

[0014] Grind and mix the proportioned raw materials:

[0015] Limestone 78~80% (mass percentage, the same below)

[0016] Clay 8~14%

[0017] Iron ore 4~7%

[0018] The grinding fineness of citric acid slag 4-6% is controlled at 7-10% (residual sieve), and then calcined into cement clinker in a cement kiln. The energy consumption is mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com