Patents

Literature

35 results about "Natrolite" patented technology

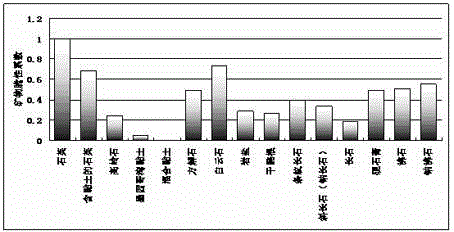

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

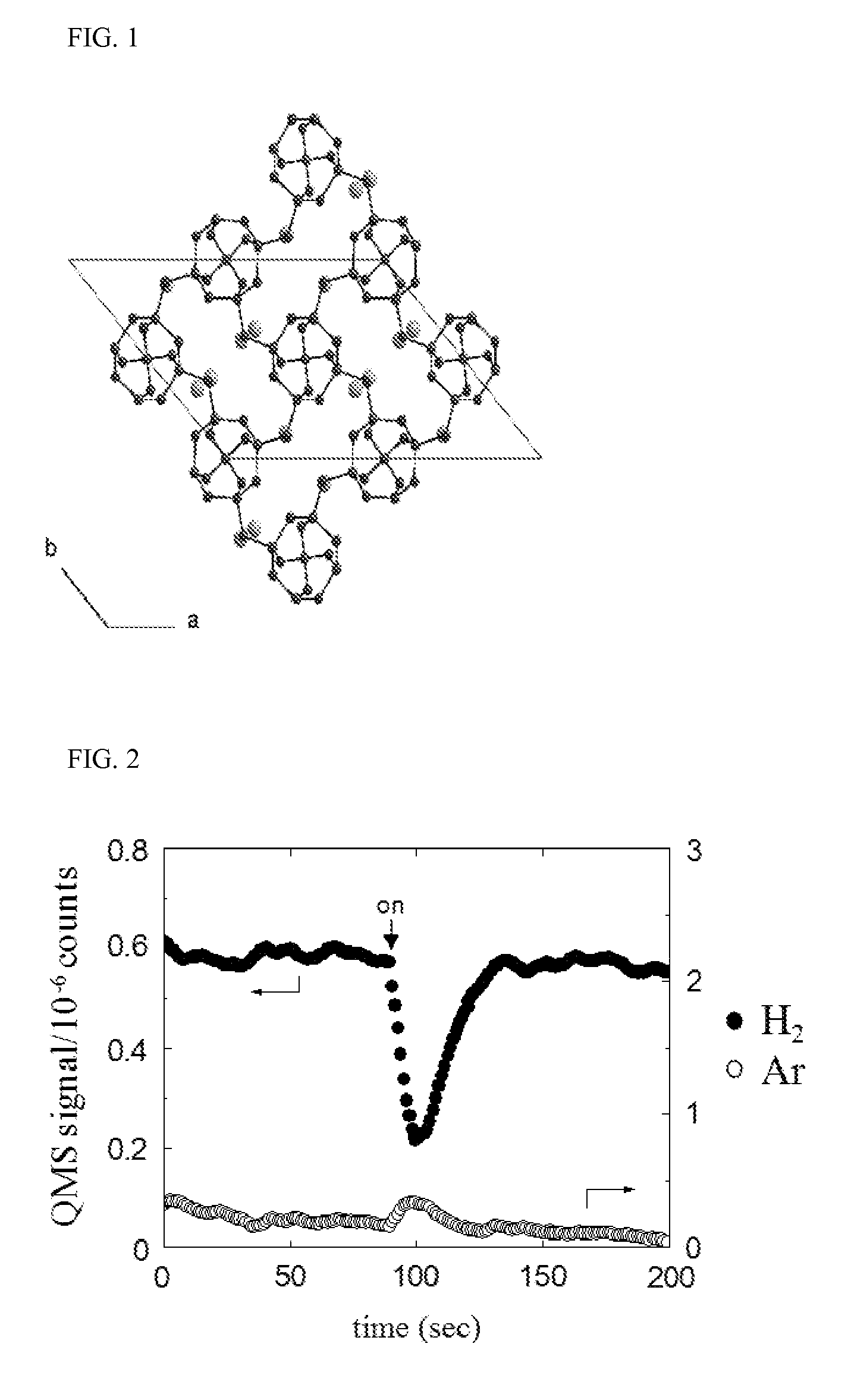

Natrolite is a tectosilicate mineral species belonging to the zeolite group. It is a hydrated sodium and aluminium silicate with the formula Na₂Al₂Si₃O₁₀ · 2H₂O. The type locality is Hohentwiel, Hegau, Germany.

Cementing compositions containing substantially spherical zeolite

ActiveUS20050133222A1Improve flexural strengthReduce brittlenessDrilling compositionSealing/packingPortland cementNatrolite

A cementitious composition for cementing an oil or gas well and which exhibits, when cured, increased flexural strength and a flexural strength to compressive strength ratio between from about 0.29 to about 0.80, contains a hydraulically-active cementitious material, such as Portland cement, and substantially spherical zeolite. Representative zeolites include natrolite, heulandite, analcime, chabazite, stilbite, and clinoptilolite. The weight percent of zeolite in the cement composition is generally less than or equal to 15 percent. In practice, a well bore may be cemented by pumping the activated slurry and pumping it within the well bore to a pre-selected location and allowing it to solidify.

Owner:BAKER HUGHES INC

Method of cementing a well using composition containing zeolite

ActiveUS7137448B2Good physical propertiesImprove flexural strengthDrilling compositionSealing/packingNatrolitePortland cement

A cementitious composition for cementing an oil or gas well and which exhibits, when cured, increased flexural strength and a flexural strength to compressive strength ratio between from about 0.29 to about 0.80, contains a hydraulically-active cementitious material, such as Portland cement, and substantially spherical zeolite. Representative zeolites include natrolite, heulandite, analcime, chabazite, stilbite, and clinoptilolite. The weight percent of zeolite in the cement composition is generally less than or equal to 15 percent. In practice, a well bore may be cemented by pumping the activated slurry and pumping it within the well bore to a pre-selected location and allowing it to solidify.

Owner:BAKER HUGHES INC

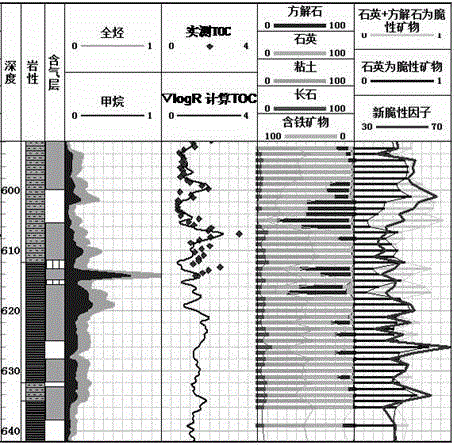

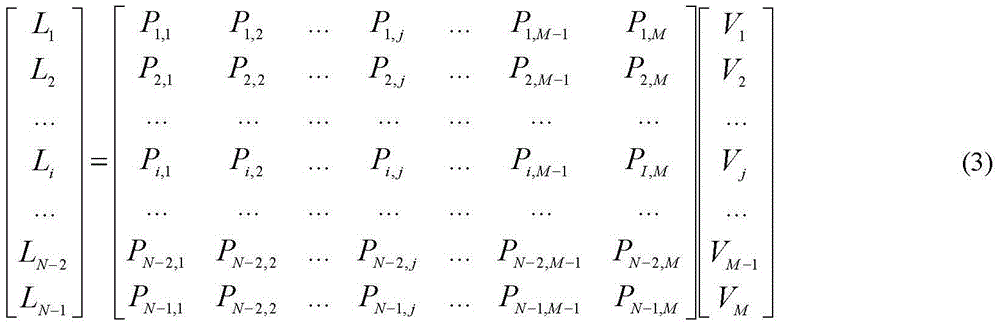

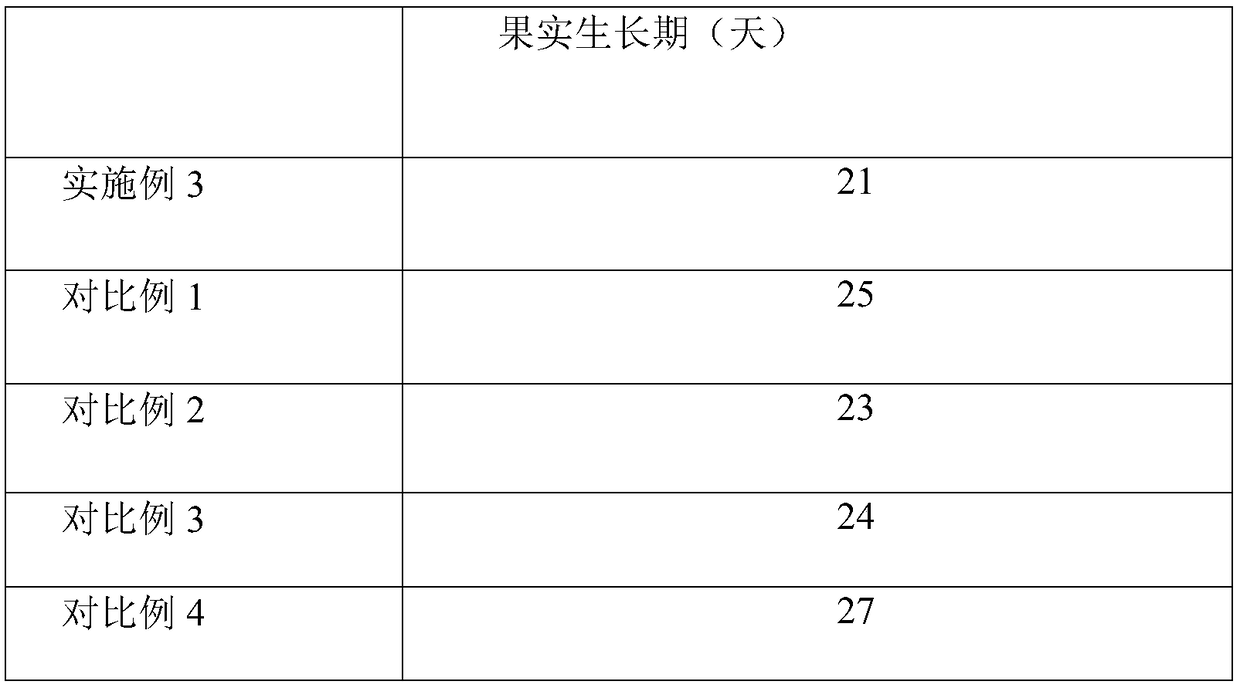

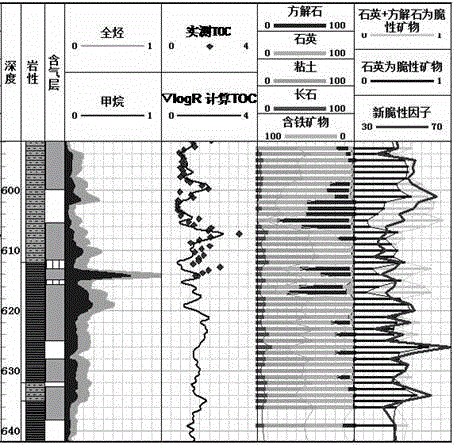

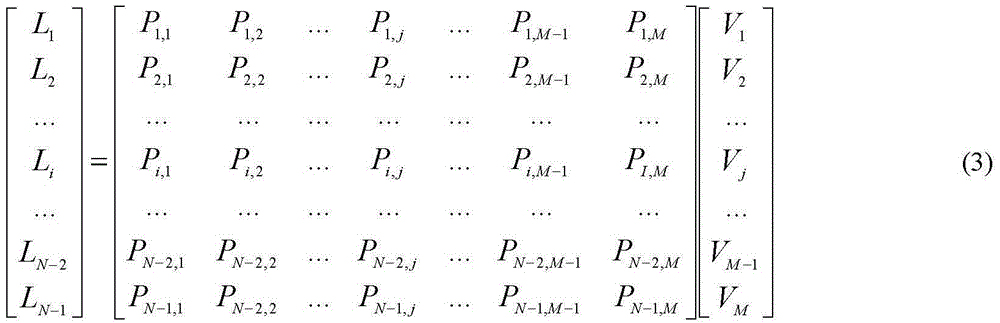

Mineral content-based brittleness evaluation method for shale gas reservoir

The invention discloses a mineral content-based brittleness evaluation method for a shale gas reservoir. By taking the brittleness of quartz as the standard, the relative brittleness degree, called as a mineral brittleness coefficient, of each essential mineral in the shale gas reservoir is determined; the essential minerals comprise the quartz, clay-contained quartz, kaolinite, Mexico clay, mixed clay, calcite, dolomite, rock salt, kerogen, perthite, anorthose, feldspar, anhydrite, zeolite and natrolite; the overall brittleness degree of reservoir rock is computed by utilizing mineral volume content and the brittleness coefficient of each mineral; the mineral volume content refers to the percentage that the volume of minerals in porous rock accounts for the total volume of the porous rock. The brittleness evaluation method is superior to a method, used in oil exploration industry at present, for evaluating brittleness by comparing the volume content of the quartz and carbonatite and the total volume of the minerals.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for increasing selective non-catalytic reduction denitration efficiency

InactiveCN102247754APromote the reaction to reduce NOxReduce OHDispersed particle separationNitrogen oxidesNatrolite

The invention relates to a method for increasing selective non-catalytic reduction (SNCR) denitration efficiency, and belongs to the field of control of nitrogen oxides. The method comprises a step of spraying natrolite powder in an SNCR system while spraying ammonia liquid, urea, ammonium hydrogen carbonate or ammonium carbonate serving as a reducing agent in the SNCR system; and thus, the utilization rate of the reducing agent of the SNCR system is increased by a sodium element and other trace elements such as nickel, titanium, vanadium, molybdenum, selenium and the like in the natrolite powder, the denitration efficiency is increased, the optimal reaction temperature range of the system is expanded, the oxidation reaction of the reducing agent and the nitrogen oxide is suppressed, the leakage of the reducing agent of the system is reduced, the consumption of the reducing agent of the SNCR system is reduced, and a basis is provided for application of the SNCR system under more working conditions.

Owner:UNIV OF SCI & TECH BEIJING

Cementing compositions containing substantially spherical zeolite

ActiveUS20070029088A1Good physical propertiesImprove flexural strengthDrilling compositionSealing/packingPortland cementNatrolite

Owner:BAKER HUGHES HLDG LLC

Aluminum-based composite heat sink material for LEDs

InactiveCN106191713AImprove sinterabilityEffective protectionHeat-exchange elementsLED lampZirconium diboride

The invention discloses an aluminum-based composite heat sink material for LEDs. The aluminum-based composite heat sink material comprises, by mass, 20-25 parts of organic silicon resin, 13-14 parts of hydantoin epoxy resin, 5-8 parts of chlorphenyl silicone oil, 3-6 parts of graphene, 3-6 parts of curing agent diethylaminopropylamine, 5-6 parts of 95% aluminum oxide ceramic fiber, 0.3-0.5 part of magnesium isooctanoate, 0.2-0.3 part of silicon nitride, 0.5-0.8 part of magnesium sulfate, 0.2-0.3 part of zirconium oxide, 0.2-0.3 part of chromium oxide, 0.5-0.8 part of vanadium boride, 0.5-0.8 part of zirconium diboride, 0.2-0.3 part of aluminum nitride, 0.5-0.8 part of natrolite, 0.1-0.2 part of organic chelated titanium, 15-18 parts of aluminum, 0.1-0.2 part of zinc oxide, 0.1-0.2 part of calcium carbonate and 0.1-0.2 part of zinc borate. The prepared heat sink material is ideal in sintering effect, smooth and compact in surface, stable in temperature variation, durable, excellent in heat conduction coefficient and capable of effectively protecting LED lamps and greatly prolonging the service life of the lamps.

Owner:ANHUI FUN OPTOELECTRONICS TECH

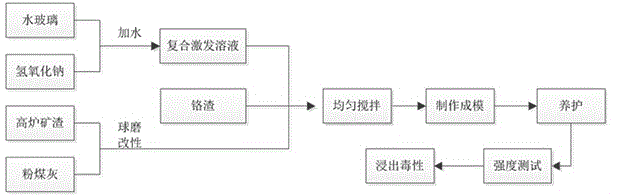

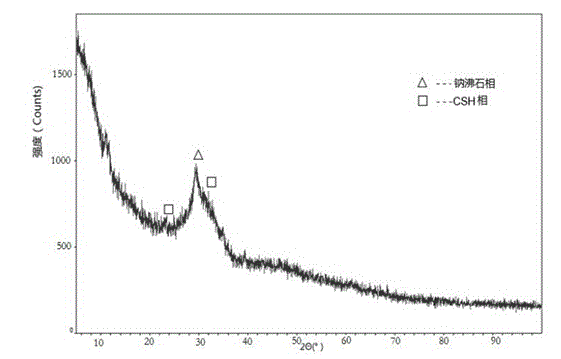

Chromium slag solidification gelling polymer

ActiveCN104961392AGood mechanical propertiesHigh compressive strengthCement productionCalcium silicateHydration reaction

The invention relates to a chromium slag solidification gelling polymer. The polymer is an inorganic polymer gel formed through mutual connection of -Si-O-Al-O- bonds via a condensation polymerization reaction of geopolymer particles. The polymer comprises a zeolite phase composed of natrolite formed through a geopolymerization reaction, and a CSH mineral phase composed of calcium silicate hydrate and calcium aluminate generated through a hydration reaction. Most hexavalent chromium ions are solidified in the zeolite phase, and a small amount of hexavalent chromium ions are solidified in the CSH mineral phase, so the gelling polymer realizes immobilization of chromium ions in a geopolymer solidified body in an amorphous form. The chromium slag solidification gelling polymer is prepared through processing chromium slag, blast furnace slag and fly ash as raw materials by using a composite exciting agent composed of sodium hydroxide and water glass. A preparation method of the chromium slag solidification gelling polymer is simple to operate, and the gelling polymer prepared in the invention has good mechanical performances, can reduce the environmental pollution problem caused by piling of the blast furnace slag and the fly ash, and also can effectively prevent the leaching behavior of chromium ions in the chromium slag.

Owner:沃德费默循环经济科技发展(北京)有限公司

Reinforced active aluminum-based composite heat dissipation material for LED (light emitting diode)

ActiveCN104087794AExcellent decontaminationReduced moisture resistanceHeat-exchange elementsRare-earth elementSlag

The invention relates to a heat dissipation material for lamps, and in particular relates to a reinforced active aluminum-based composite heat dissipation material for an LED (light emitting diode) and a production method of the material. The heat dissipation material is prepared from the following raw materials in parts by weight: 83-85 parts of aluminum, 15-18 parts of aluminum nitride, 4-5 parts of magnesium nitride, 8-10 parts of zirconia, 4-6 parts of magnesium oxide, 1-3 parts of straw powder, 1-2 parts of tourmaline powder, 0.1-0.2 part of monazite slag, 0.5-1 part of natrolite and 4-5 parts of aids. The heat dissipation material disclosed by the invention integrates the advantages of aluminum, aluminum nitride, zirconia and the like, has good heat conduction and heat dissipation capabilities; the tourmaline powder is an active matter and can endow the material with good detergency, electromagnetic radiation reducing capability and moisture resistance, the monazite slag contains multiple rare earth elements and can effectively improve the heat dissipation performance of the material and can improve the sintering effect and the compactness of the material together with the aids. The material has good mechanical properties, is simple in use and maintenance and durable and can be used for effectively protecting an LED lamp and greatly prolonging the service life of the lamp.

Owner:YANYANG LAMP SET TIANCHANG CITY

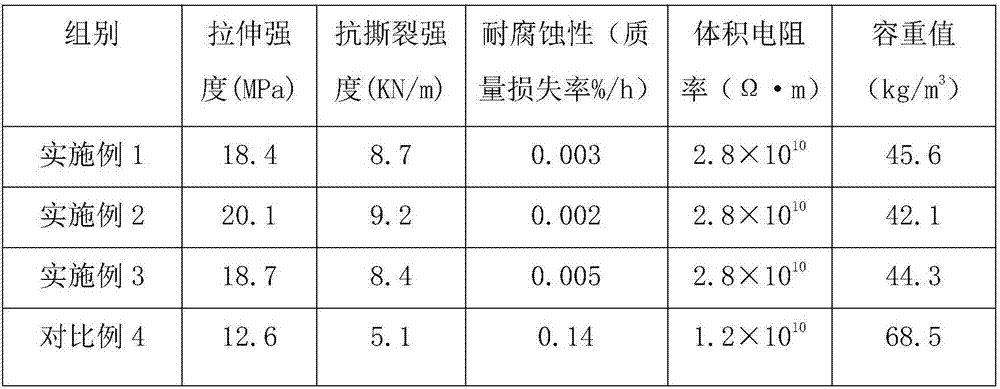

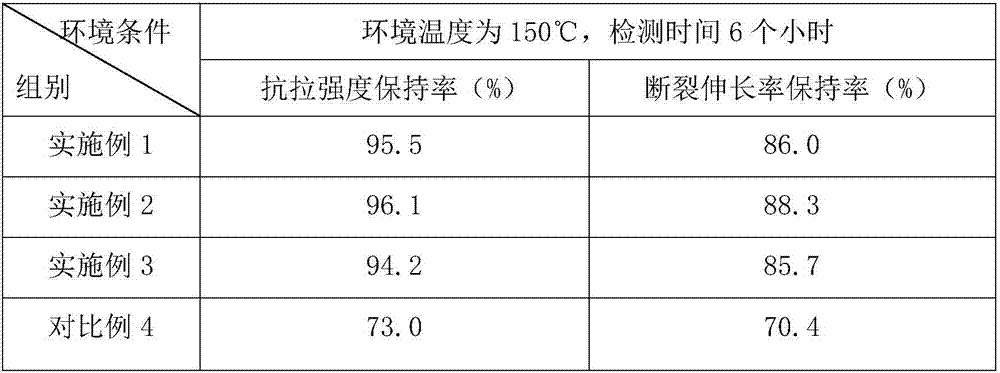

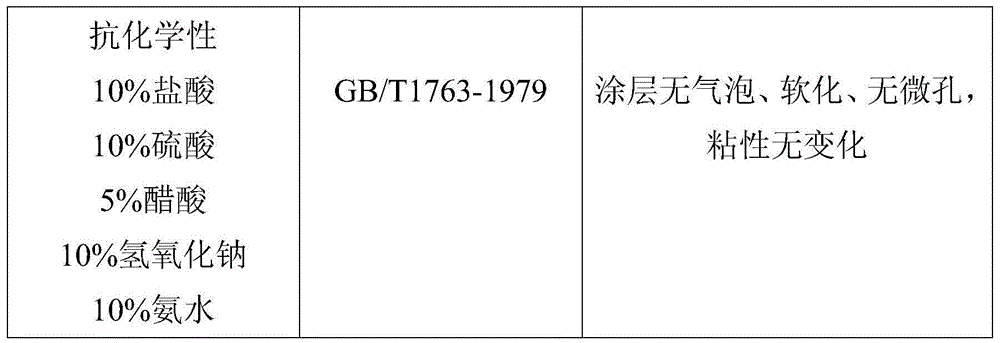

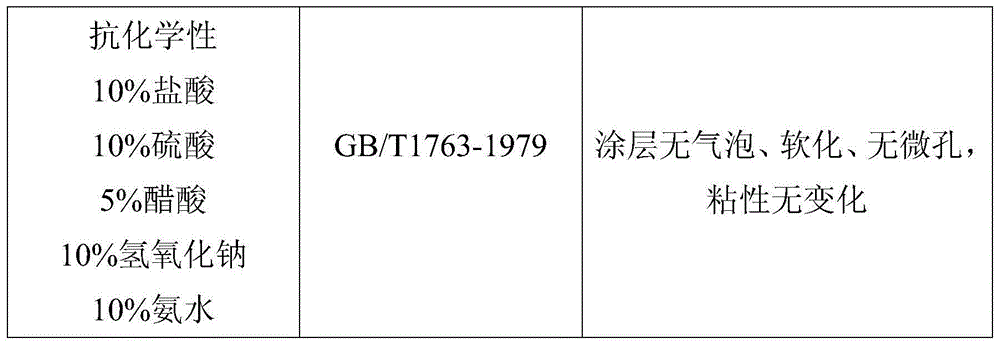

Sun-proof and anti-corrosion cable sheath material and preparation method thereof

InactiveCN107312254AExtended service lifeHigh mechanical strengthPlastic/resin/waxes insulatorsPolymer scienceSodium Bentonite

The invention discloses a sun-proof and anti-corrosion cable sheath material and a preparation method thereof, and relates to the technical field of an electric wire and a cable. The sheath material is prepared from the following raw materials including chlorinated polyethylene, thermoplastic polyurethane elastomers, polyphenylene sulfone resin, modified natrolite powder, sodium bentonite, microcrystalline wax, glass fiber, boron nitride, dioctyl phthalate, diphenyl phosphate, bonding agents, antistatic agents, antioxidants and anti-radiation agents. According to the preparation method, the sun-proof and anti-corrosion cable sheath material is obtained through performing mixing, banburying and granulation on the raw materials. The cable sheath material provided by the invention has the advantages that the preparation is simple and convenient; the production cost is low; excellent acid, alkali and chemical corrosion performance, sun-proof insulation performance, anti-aging performance and tensile strength are realized; the application field is wide; the service life is long; wide market and application prospects are realized.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

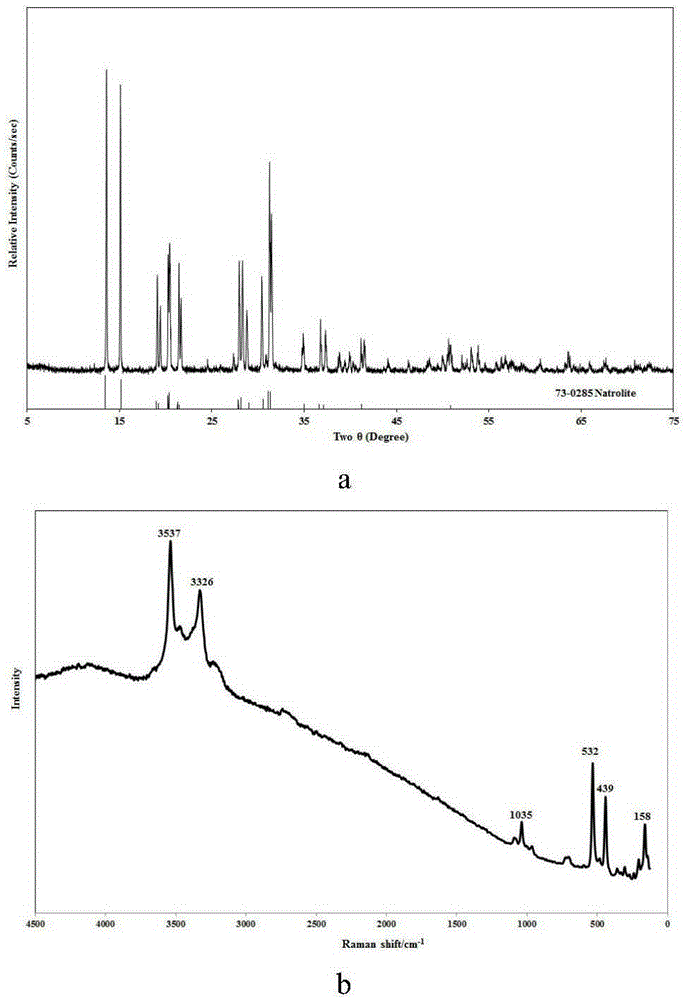

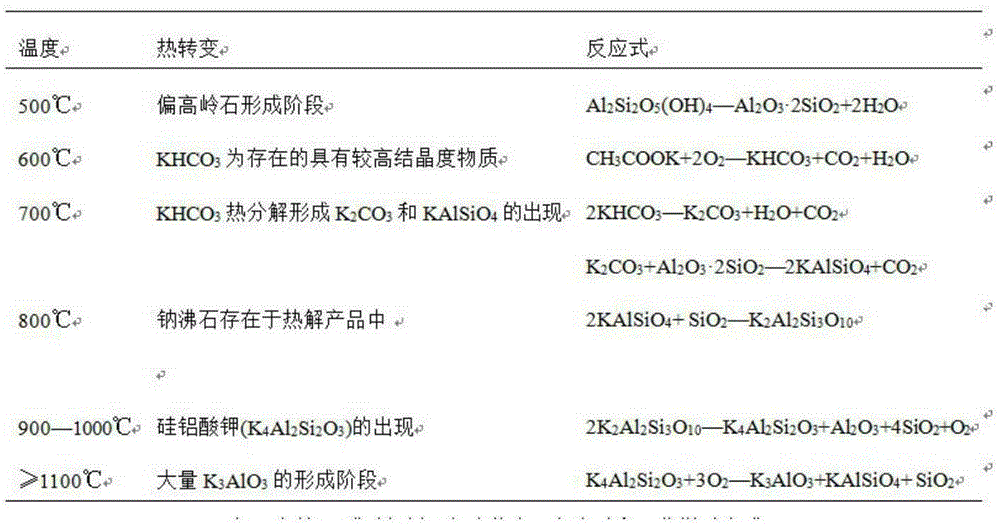

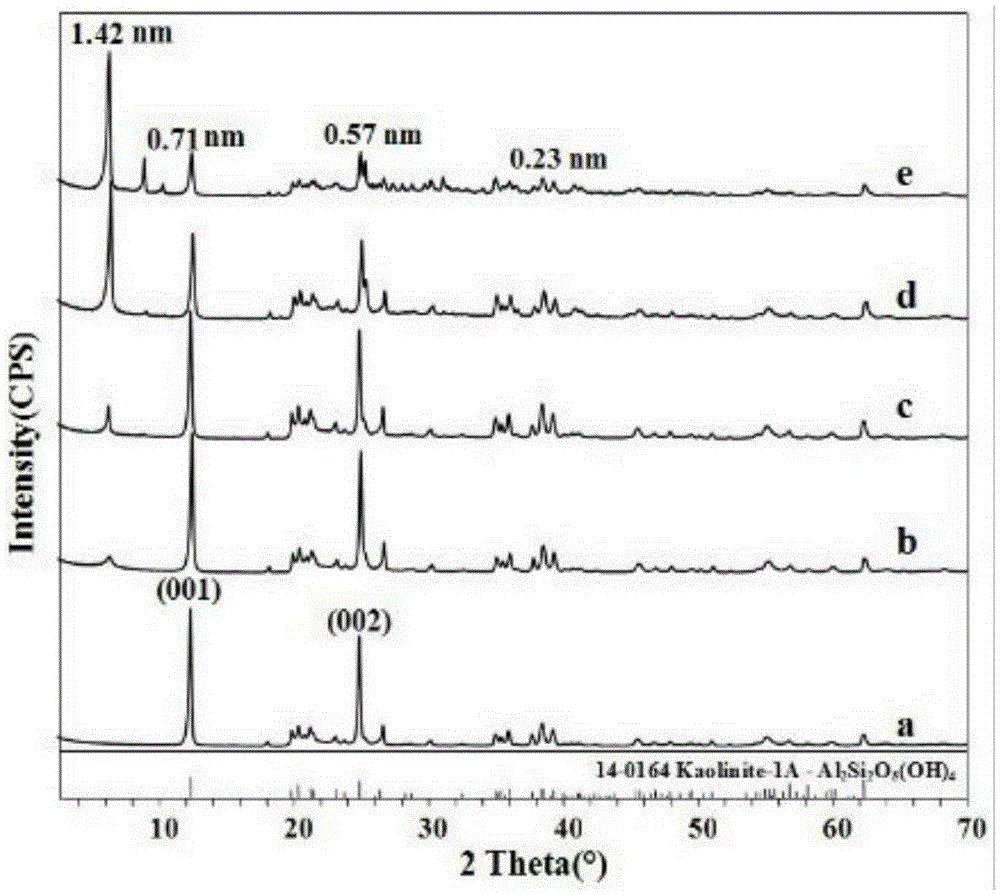

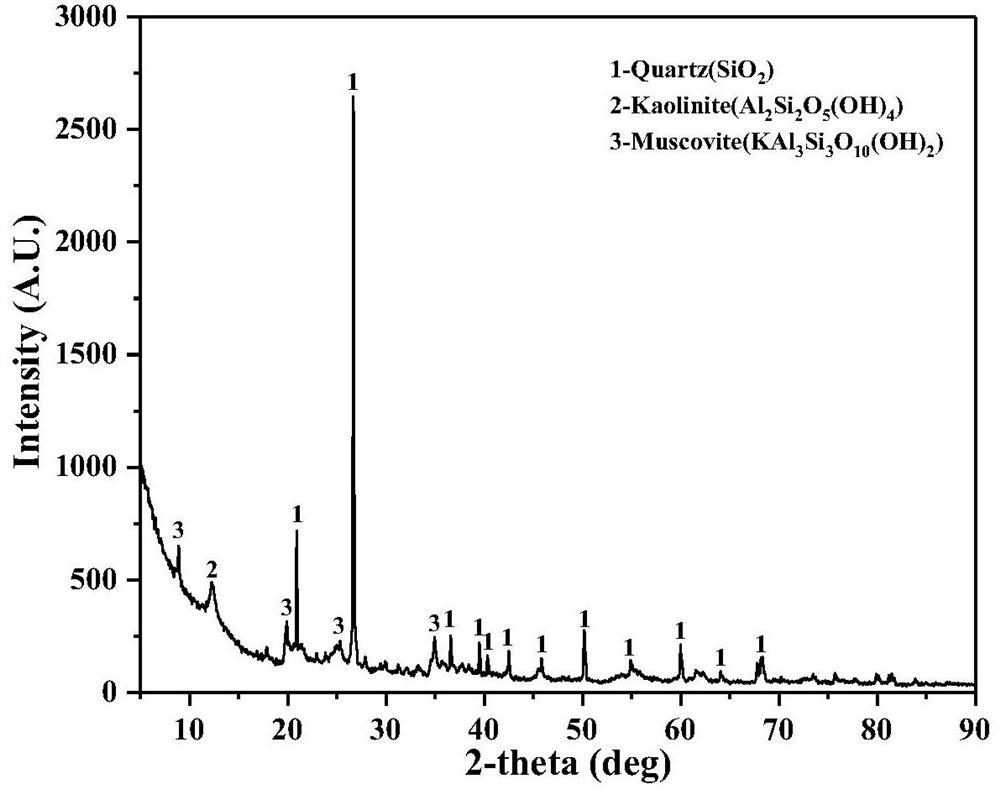

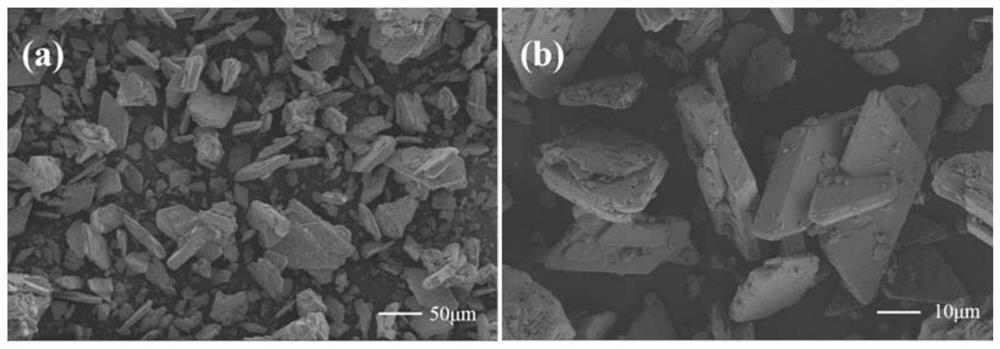

Method for preparing natrolite from coal series kaolinite intercalation composite

The invention discloses a method for preparing natrolite from a coal series kaolinite intercalation composite, and belongs to the field of coal series kaolinite. The method includes the following steps that the coal series kaolinite is smashed; a potassium acetate solution with the mass fraction of 30% and the smashed coal series kaolinite are mixed by the mass ratio of 10:1 and are stirred magnetically for 3-4 days at the room temperature; the product obtained after stirring is filtered, washed and centrifugally treated; the centrifuged product is put in an electrothermal blowing dry box to be dried for 24 h; the air-dried product is put into a muffle furnace, heated to 800 DEG C, kept at the constant temperature for 4 h and then cooled on the natural condition, and natrolite exists in the pyrolysis product. The method is simple in preparing process, convenient to operate and easy to control, and natrolite is prepared through high-temperature phase change of the potassium acetate and kaolinite composite. Compared with an existing natrolite preparing process, the preparing process of the method is relatively simple, the process flow path is obviously simplified and easy to control, and the quality of generated natrolite is much higher than that generated through the existing natrolite preparing process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

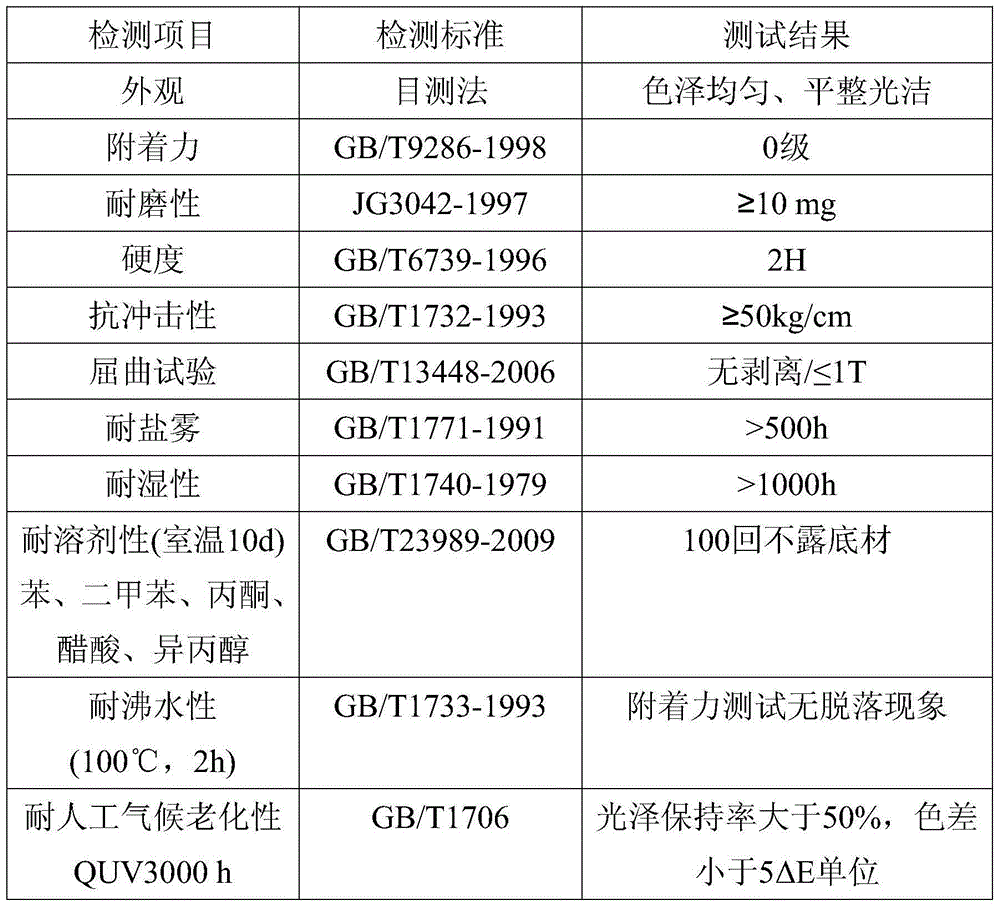

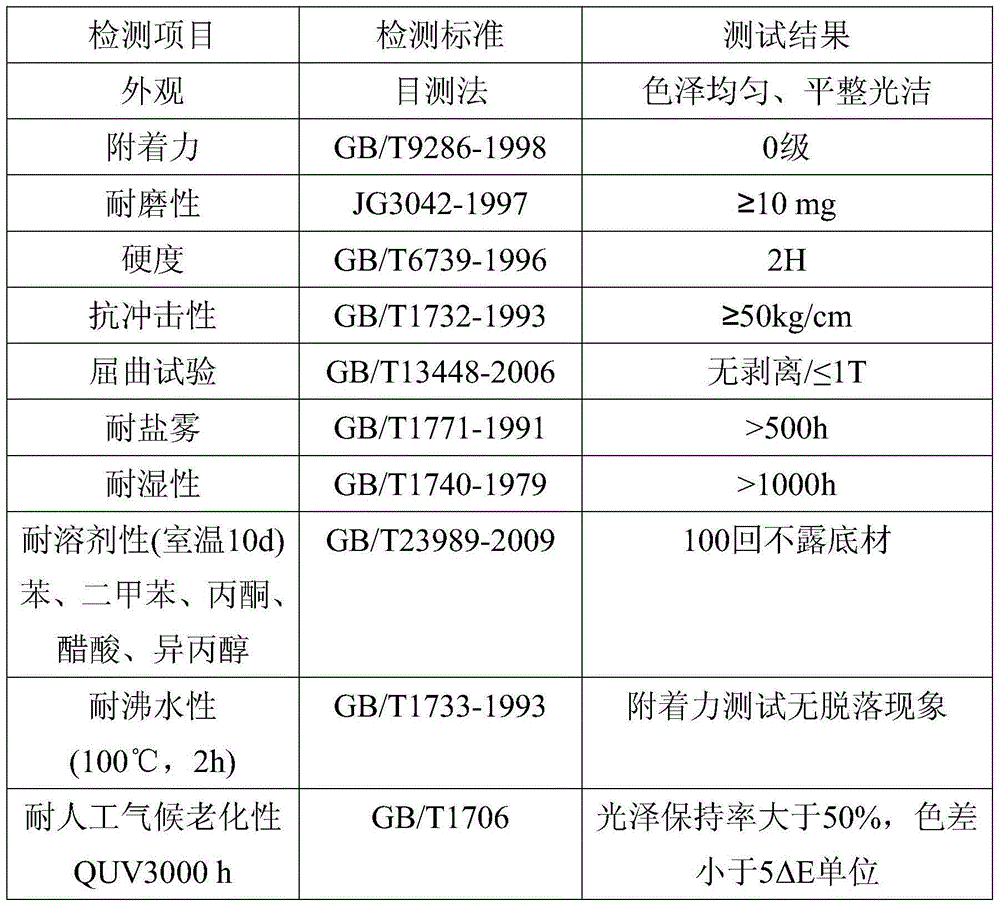

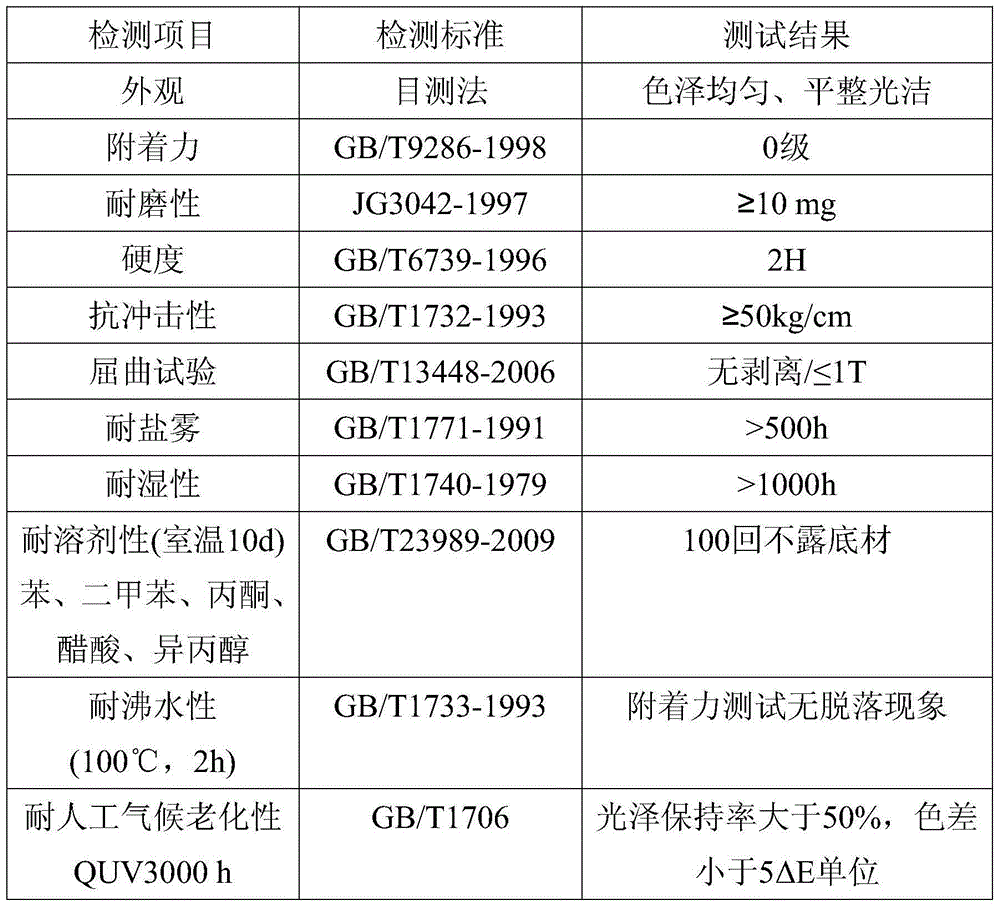

Nano calcium carbonate-modified acrylic resin type powder coating

InactiveCN104946063AMeet environmental protection requirementsIncrease profitAnti-corrosive paintsPowdery paintsGlycidyl methacrylateAcrylic resin

The invention discloses a nano calcium carbonate-modified acrylic resin type powder coating, and relates to the technical field of production of powder coatings. The powder coating is prepared from the following raw materials in parts by mass: 90-100 parts of glycidyl methacrylate, 15-20 parts of nano calcium carbonate, 10-12 parts of kieselguhr, 8-10 parts of asbestos powder, 5-8 parts of dodecanedioic acid, 4-6 parts of zirconia, 3-5 parts of natrolite, 3-4 parts of superfine transparent iron oxide yellow, 2-3 parts of dibutyl phthalate, 2-3 parts of polyether-modified organic siloxane, 1-2 parts of sodium metaborate and 100-120 parts of ethyl alcohol. The coating provided by the invention is nontoxic and free of solvents and volatile and toxic substances, and meets environmental requirements; the raw material utilization ratio can reach 99%; a compact coating layer is generated after spraying, and the coating layer is good in adhesive force and impact resistance, and excellent in weather resistance and corrosion resistance.

Owner:蚌埠市阳光粉沫涂料有限责任公司

Soil conditioner prepared from livestock dry waste

InactiveCN105732210AReduce compactionImprove physical and chemical propertiesClimate change adaptationExcrement fertilisersInsect pestPlant growth

The invention discloses a soil conditioner prepared from livestock dry waste and relates to the technical field of livestock breeding.The soil conditioner is prepared from, by weight, 70-80 parts of the livestock dry waste, 20-25 parts of illicium anisatum leaves, 15-20 parts of cassia tree leaves, 10-15 parts of camphor tree leaves, 10-15 parts of attapulgite, 8-11 parts of longhairy antenoron herbs, 6-10 parts of herba artemisiae scopariae, 6-10 parts of volcanic ash, 5-8 parts of natrolite powder, 5-8 parts of turpentine oil, 4-6 parts of silica powder, 3-5 parts of cetyl alcohol, 2-3 parts of tobacco stem ash, 2-3 parts of rice bran wax and 1-2 parts of bamboo juice.The soil conditioner has the excellent effects of conserving water and fertilizer, loosening soil and killing soil diseases and insect pests, sufficient nutrients can be provided for plant growth, soil hardening can be effectively relieved, and soil physical and chemical properties can be improved.

Owner:MAANSHAN JINNONG ANIMAL HUSBANDRY

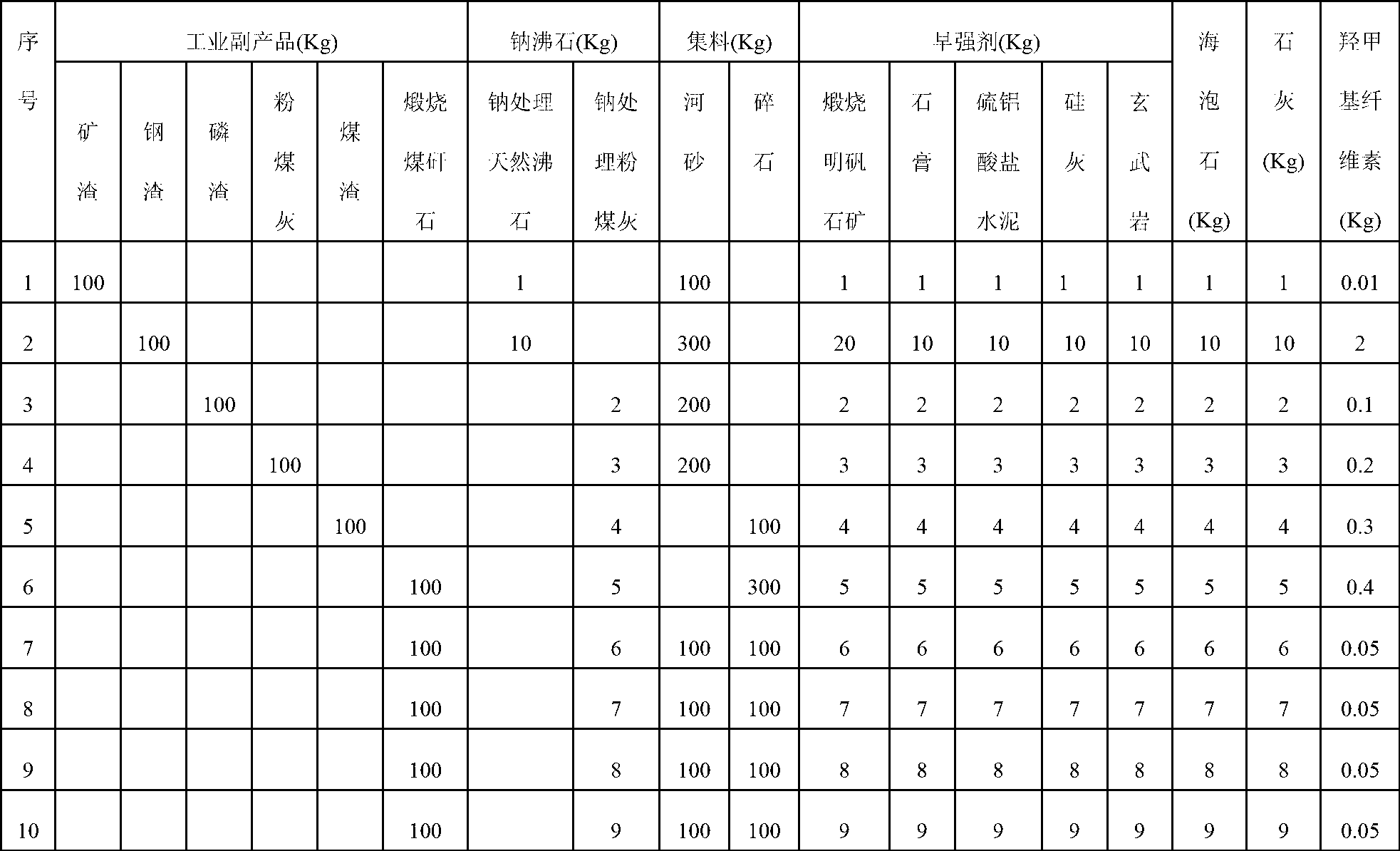

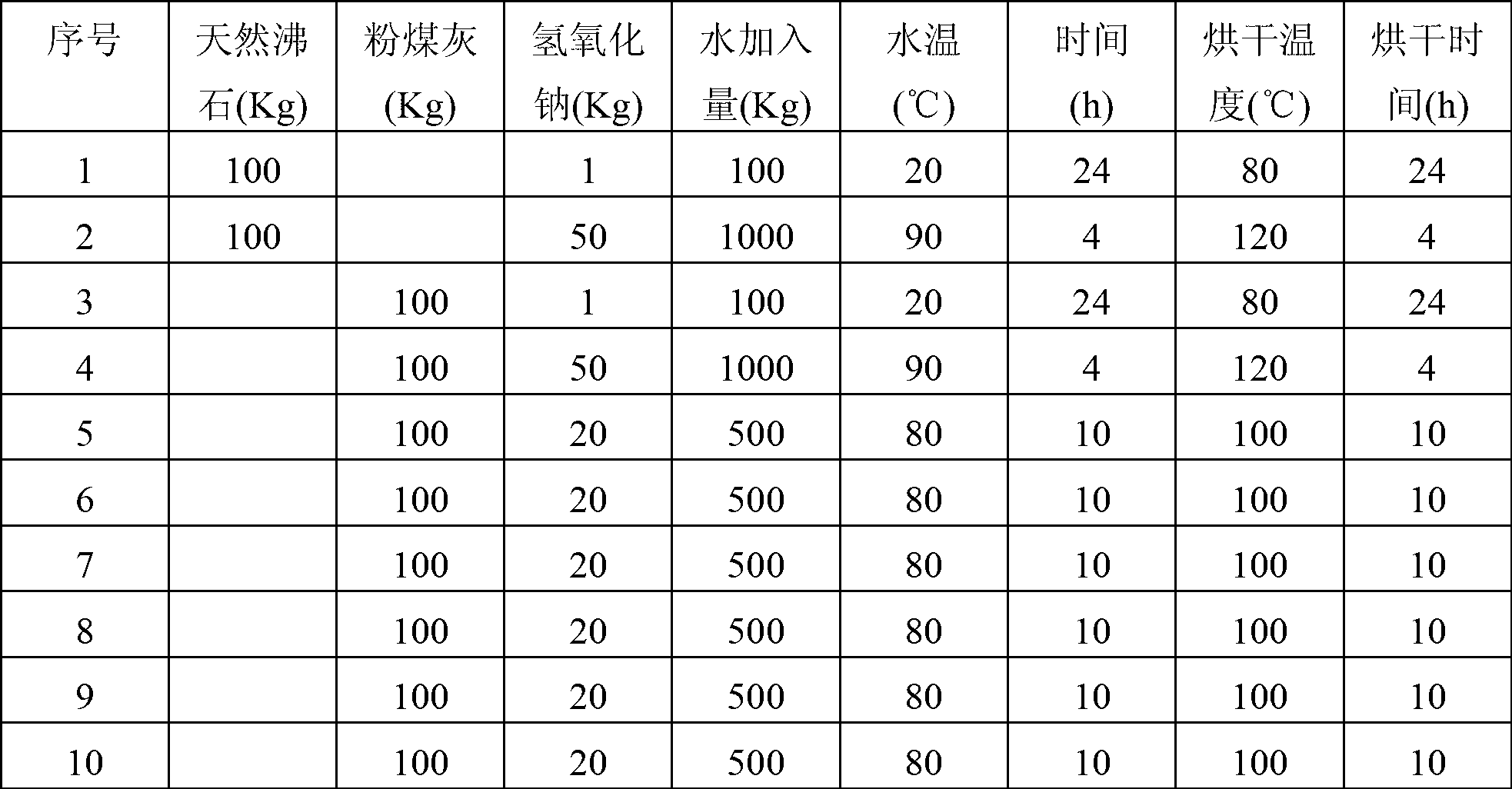

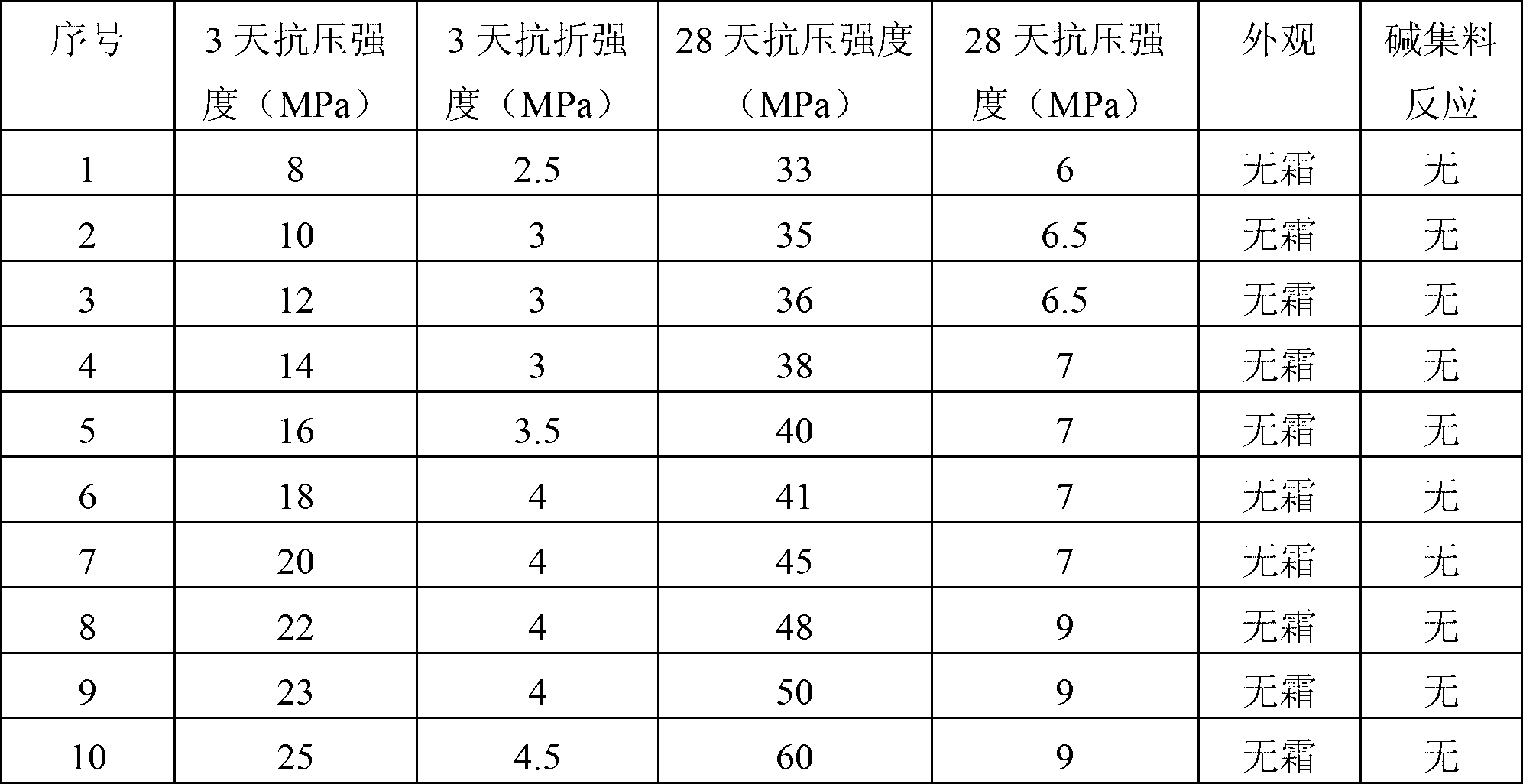

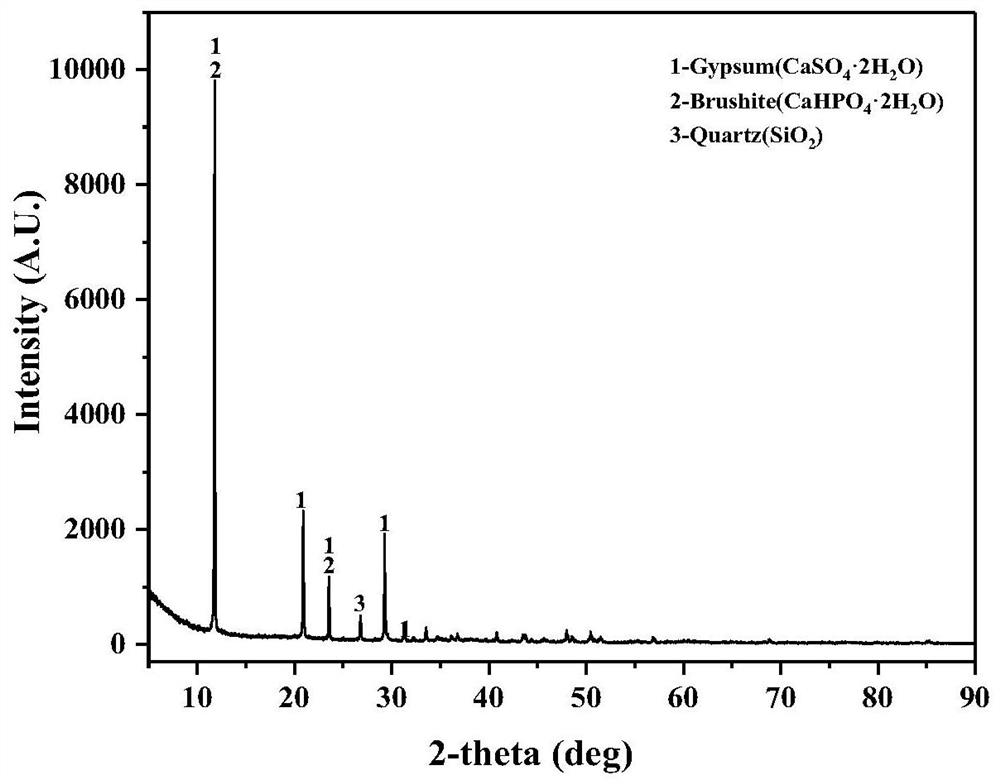

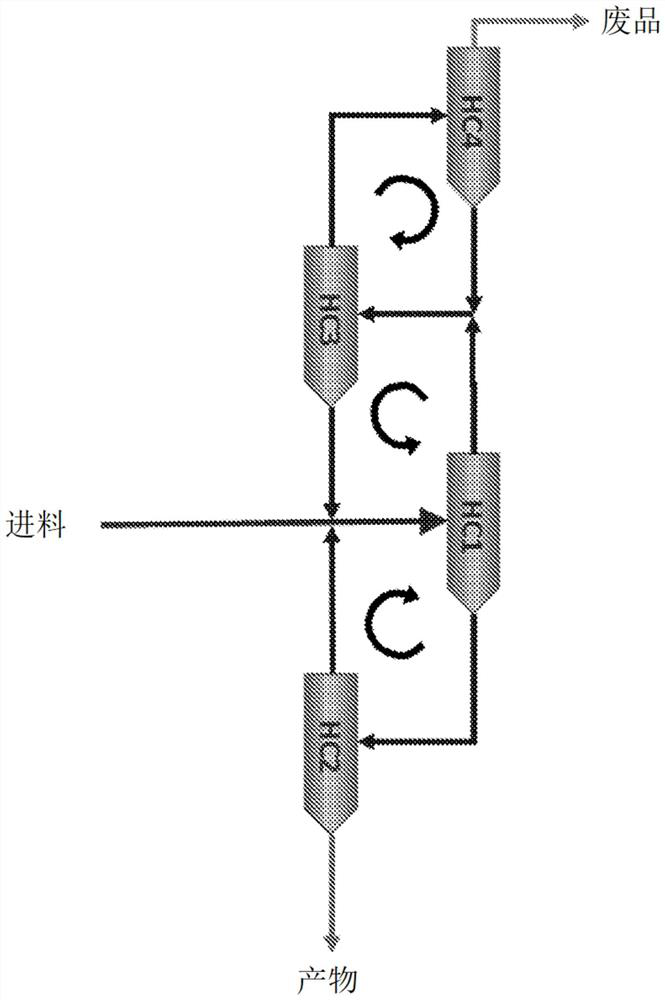

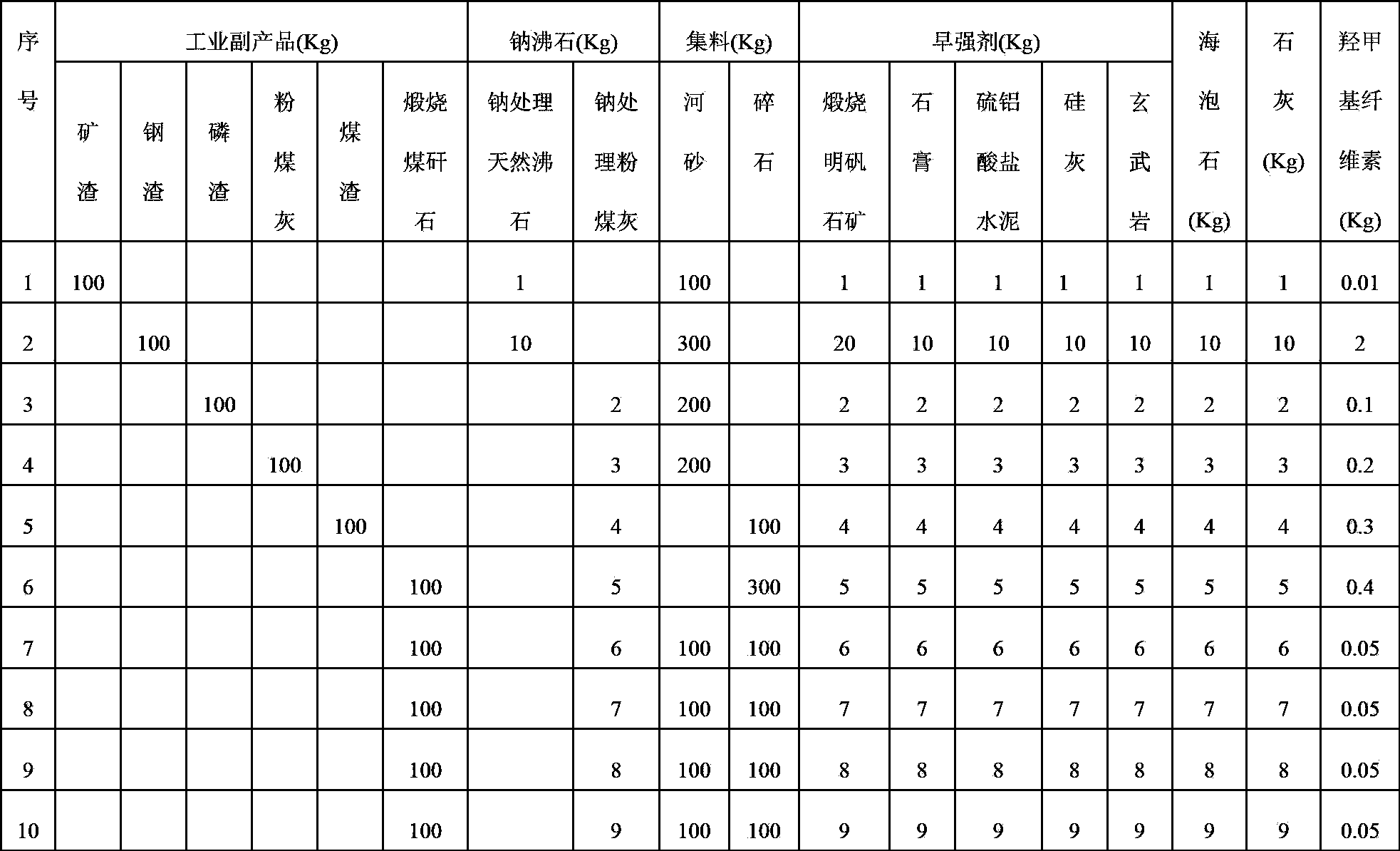

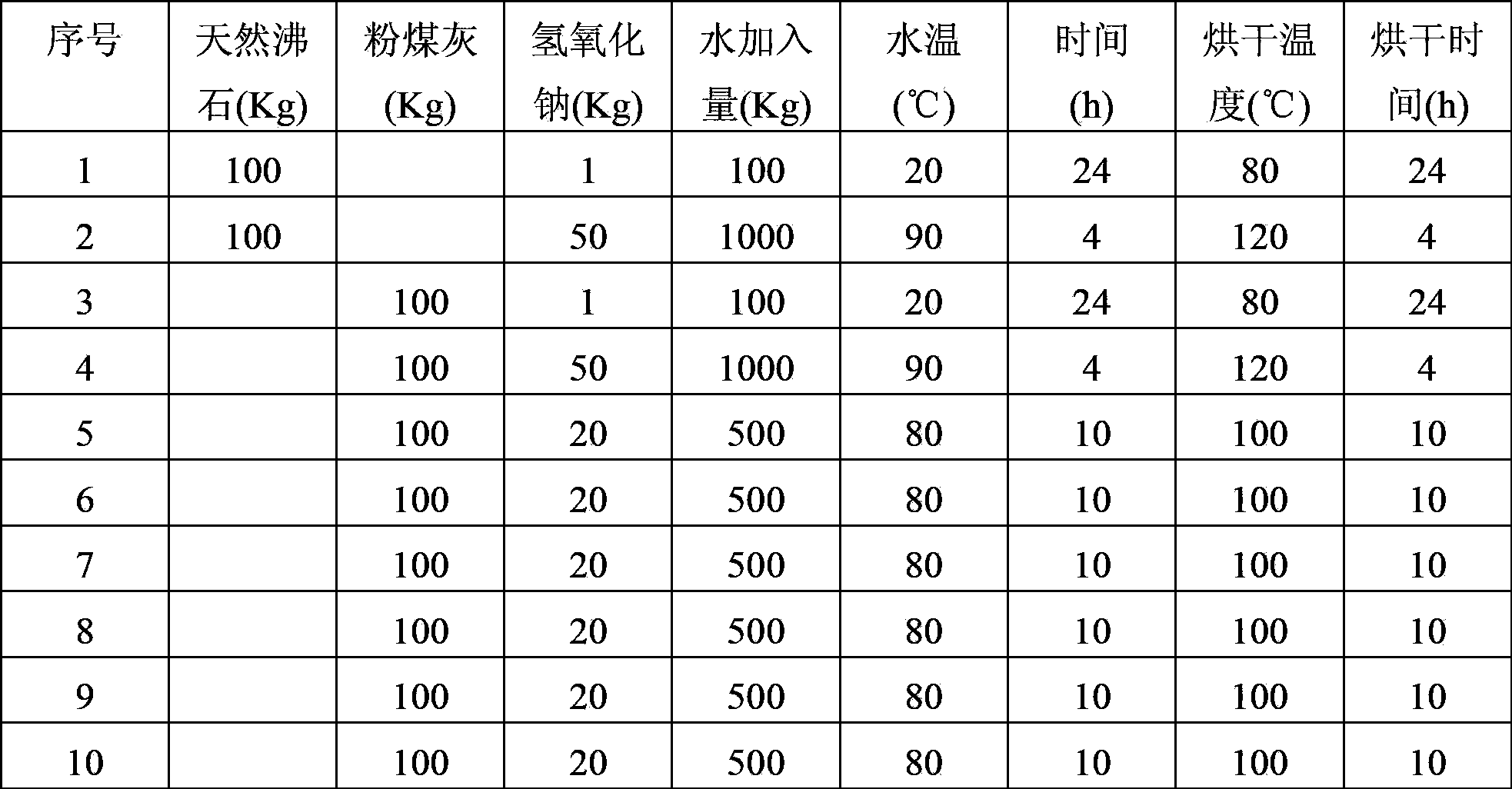

Preparation process of natrolite inorganic artificial stone

InactiveCN103011743AImprove utilization efficiencyPerformance is not affectedNatroliteArtificial stone

The invention discloses a preparation process of a natrolite inorganic artificial stone. The process is characterized by: adding natrolite, aggregate, an early strength agent, sepiolite, lime, and hydroxymethyl cellulose into an industrial by-product, and stirring them evenly to obtain natrolite inorganic artificial stone precursor powder, adding water into the natrolite inorganic artificial stone precursor powder, stirring them uniformly, pouring the mixture into a die, and performing natural curing for 28d, thus obtaining the natrolite inorganic artificial stone, which has the characteristics of high early strength, no frosting, and no alkali-aggregate reaction.

Owner:SHAANXI UNIV OF TECH

LED lamp cooling fin capable of facilitating cooling

InactiveCN106317878AImprove cooling effectExtended service lifeLighting heating/cooling arrangementsSemiconductor devices for light sourcesBorideCooling effect

The invention discloses an LED lamp cooling fin capable of facilitating cooling. The cooling fin is prepared from, by mass, 20-25 parts of silicon carbide, 20-25 parts of organic silicon resin, 13-14 parts of corn starch, 5-8 parts of itaconic acid ester, 3-6 parts of graphite, 3-6 parts of curing agent, namely diethylaminopropylamine, 5-6 parts of sodium fluosilicate, 0.3-0.5 part of magnesium isooctanoate, 0.2-0.3 part of silicon nitride, 0.5-0.8 part of magnesium sulfate, 0.2-0.3 part of zirconia, 0.2-0.3 part of chromium sesquioxide, 0.5-0.8 part of vanadium boride, 0.5-0.8 part of zirconium diboride, 0.5-0.8 part of natrolite, 0.1-0.2 part of tea leaf vinyl acetate, 15-18 parts of kaolin, 0.1-0.2 part of zinc oxide, 0.1-0.2 part of calcium carbonate and 0.1-0.2 part of lignin. The prepared LED lamp cooling fin is resistant to high temperature and ageing, good in cooling effect and long in service life.

Owner:ANHUI FUN OPTOELECTRONICS TECH

Flowering plant nutrient soil and preparation method thereof

The invention discloses flowering plant nutrient soil, and aims to provide the flowering plant nutrient soil and a preparation method thereof. The flowering plant nutrient soil is prepared from, by weight, 34-38 parts of a base material, 26-32 parts of coal gangue, 20-26 parts of porous limestone, 18-22 parts of peat, 14-18 parts of rice hull ash,12-16 parts of argillaceous sediment, 8-12 parts ofpretreated natrolite, 3-7 parts of super absorbent resin, 3-5 parts of Yunnan Tengchong volcanic mud, 2-4 parts of Faku clay, 2-4 parts of bamboo fiber and 12-18 deionized water. The flowering plantnutrient soil and the preparation method thereof have the advantages that the nutrient soil has high hygroscopic property and porosity, and the germination rate and plant height of flowering plants are improved, so that the use value is higher, and the application prospect is good.

Owner:来安县出尘茶业有限公司

Refractory insulating brick and production method thereof

InactiveCN107162625AWide variety of sourcesEasy to makeCeramic materials productionCeramicwareFiberBrick

The invention discloses a refractory insulating brick and a production method thereof and relates to the field of building materials. The refractory insulating brick comprises river channel mud, fly ash, wood fiber, modified celsian powder, sodium zeolite powder, aerated aluminum powder, sodium-based bentonite, polyacrylate copolymer emulsion, a water reducer, a foaming agent, and a foam stabilizer. The preparation method comprises: stirring and mixing the materials to obtain slurry, pressing the slurry for forming, curing naturally, drying, calcining at high temperature and the like. The refractory insulating brick has low dry density, low unit weight and high compressive strength, features good resistance to high temperature and corrosion, has long life and high reliability, and is simple and convenient to produce and suitable for popularization and application.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Modified-bauxite hollow brick and preparation method thereof

The invention discloses a modified-bauxite hollow brick and a preparation method thereof, and relates to the technical field of novel building materials. The hollow brick comprises the following raw materials: modified bauxite, coal gangue, shale pottery sand, natrolite, volcanic rock fibers, waste glass aggregate, zirconium silicate, calcium lignosulfonate, a foaming agent, a water reducing agent, an early strength agent and an exciting agent. The modified-bauxite hollow brick is prepared by uniform mixing, aging, injection molding, cutting, baking and sun drying of the above raw materials. According to the invention, the preparation method of the hollow brick is simple and convenient, production energy consumption is low, the dry density of the finished hollow brick is low, transportation and construction are convenient, compared with bricks sold in markets, the hollow brick has higher compressive strength, and the hollow brick is safe and reliable, and suitable for promotion and application.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

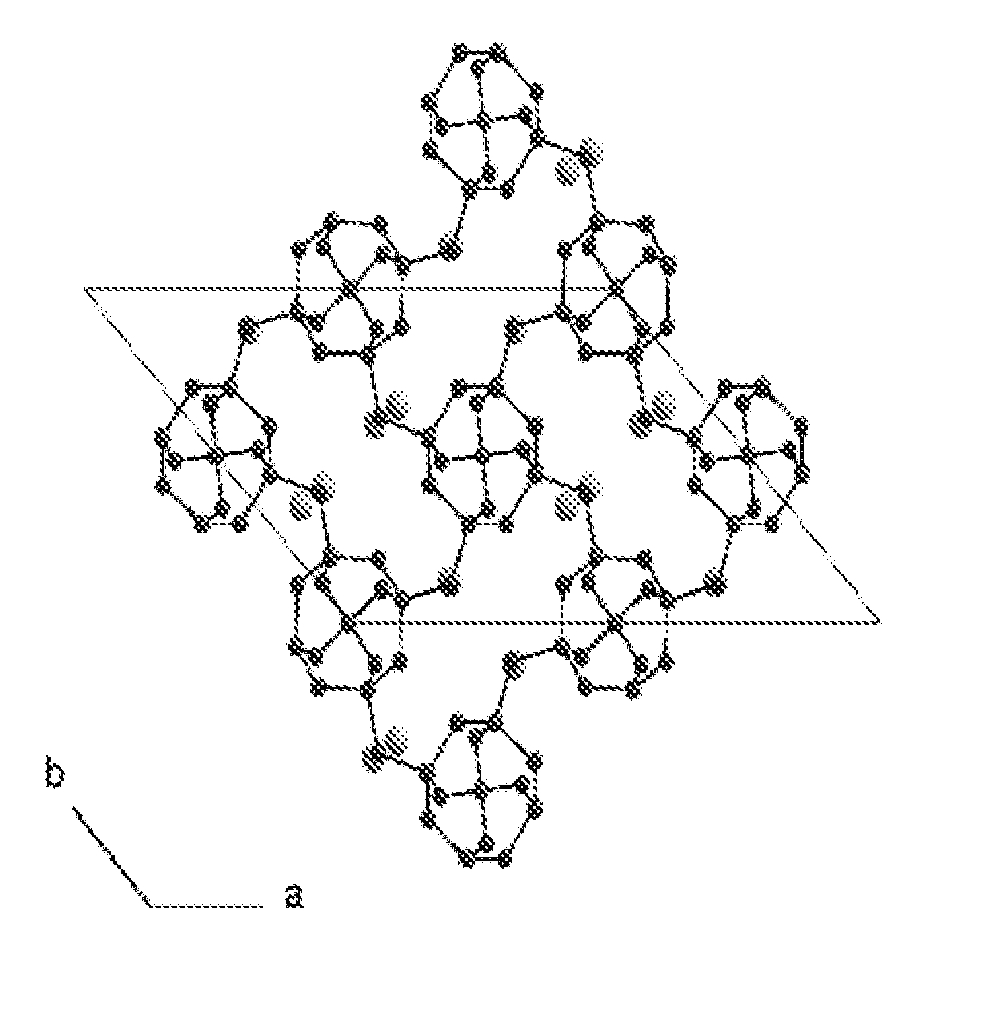

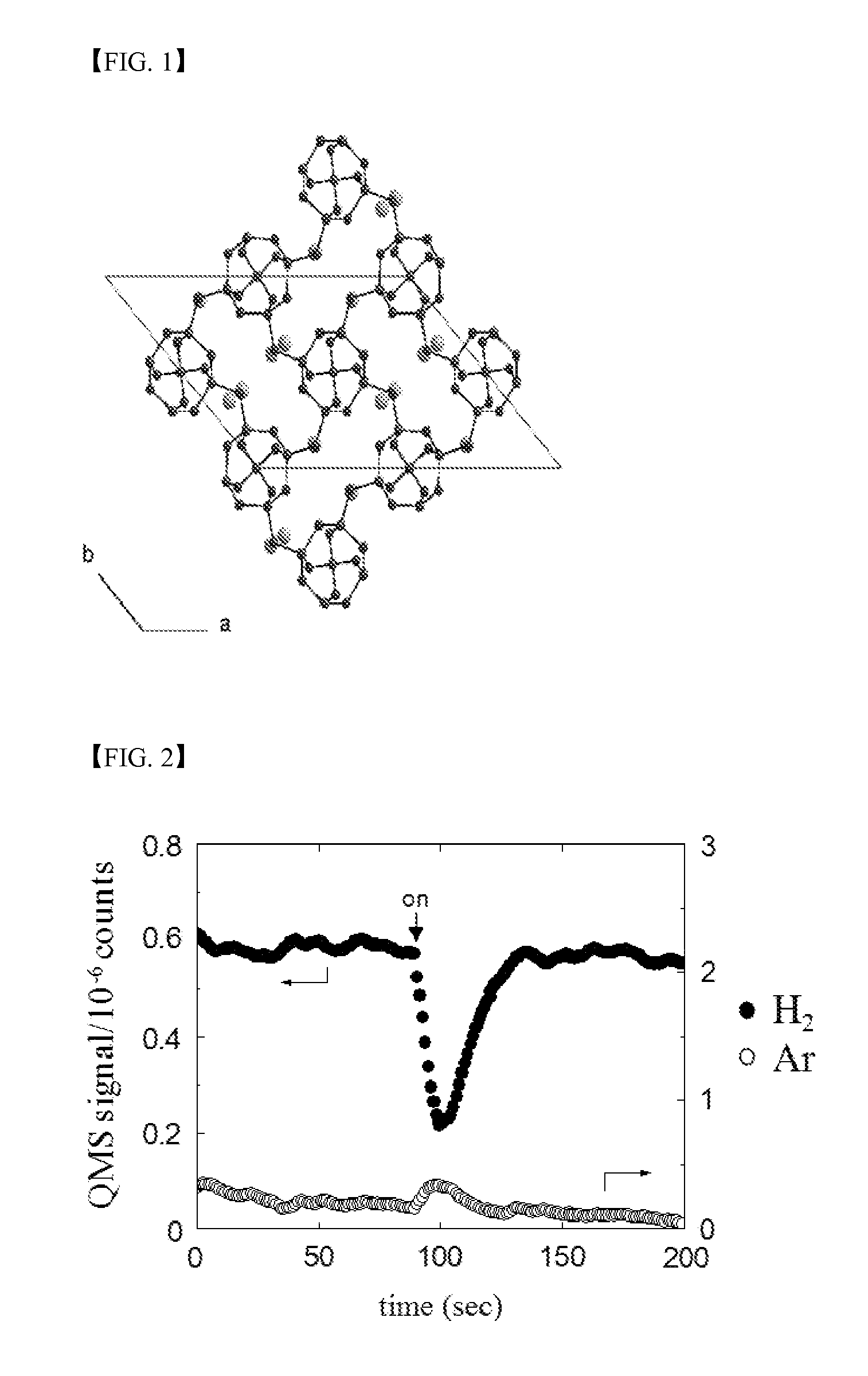

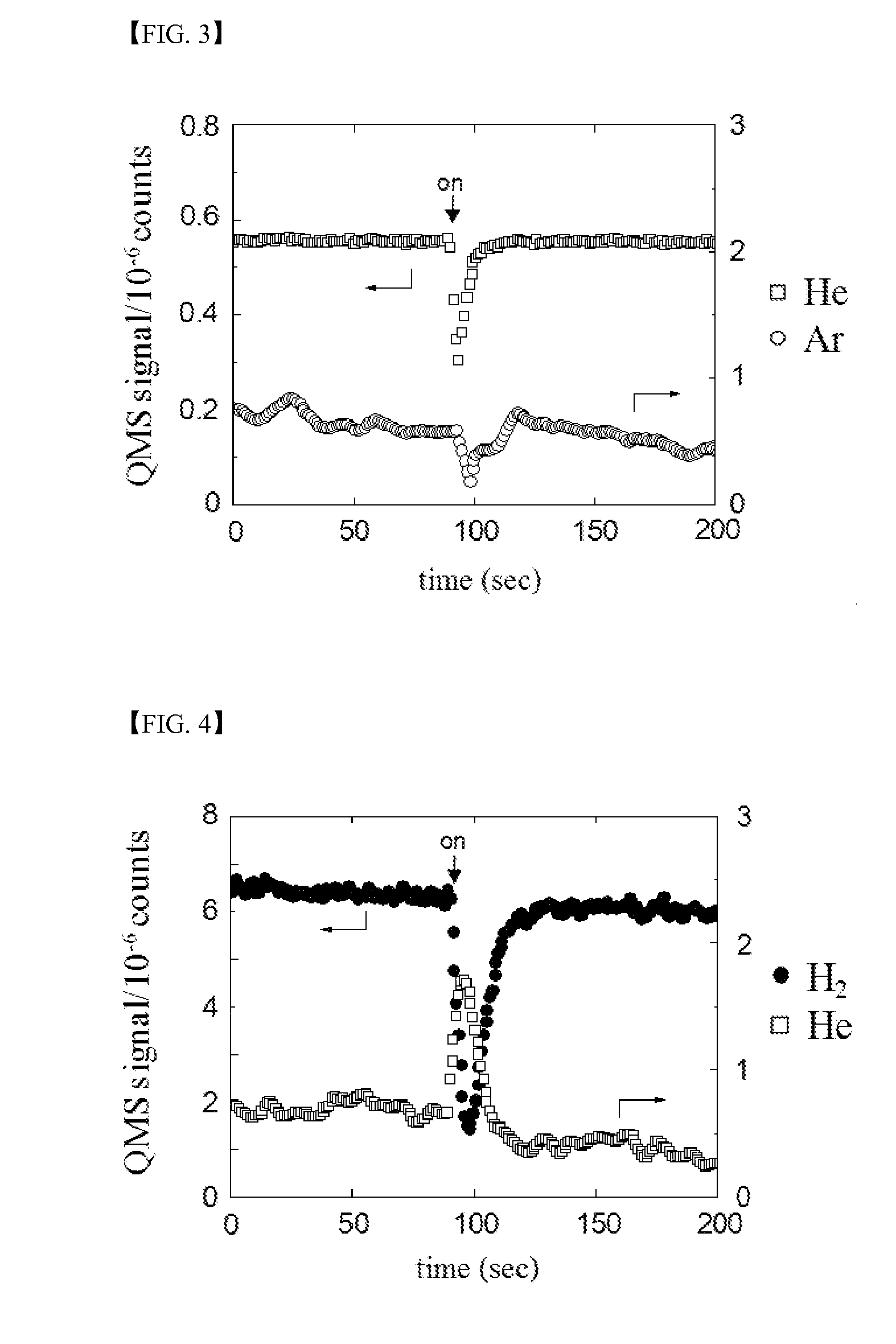

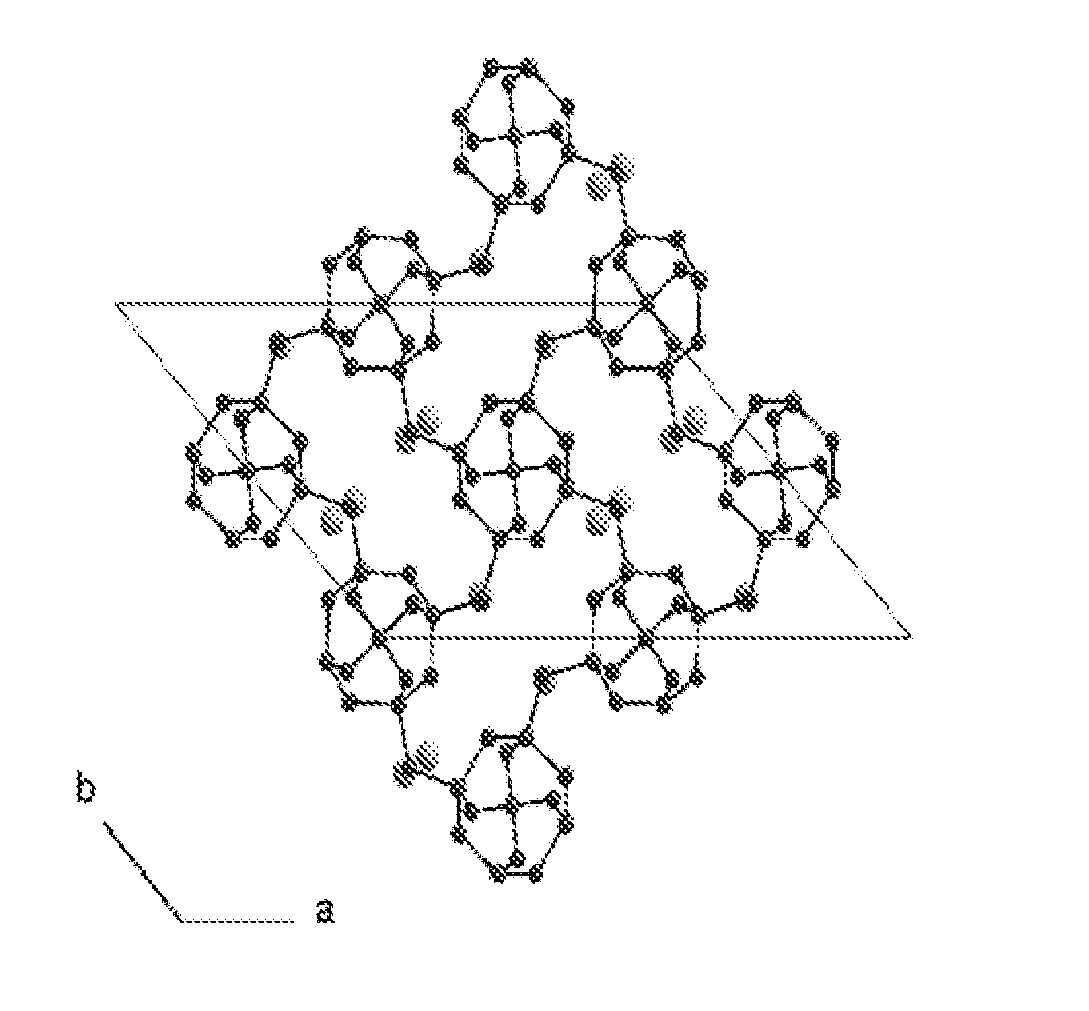

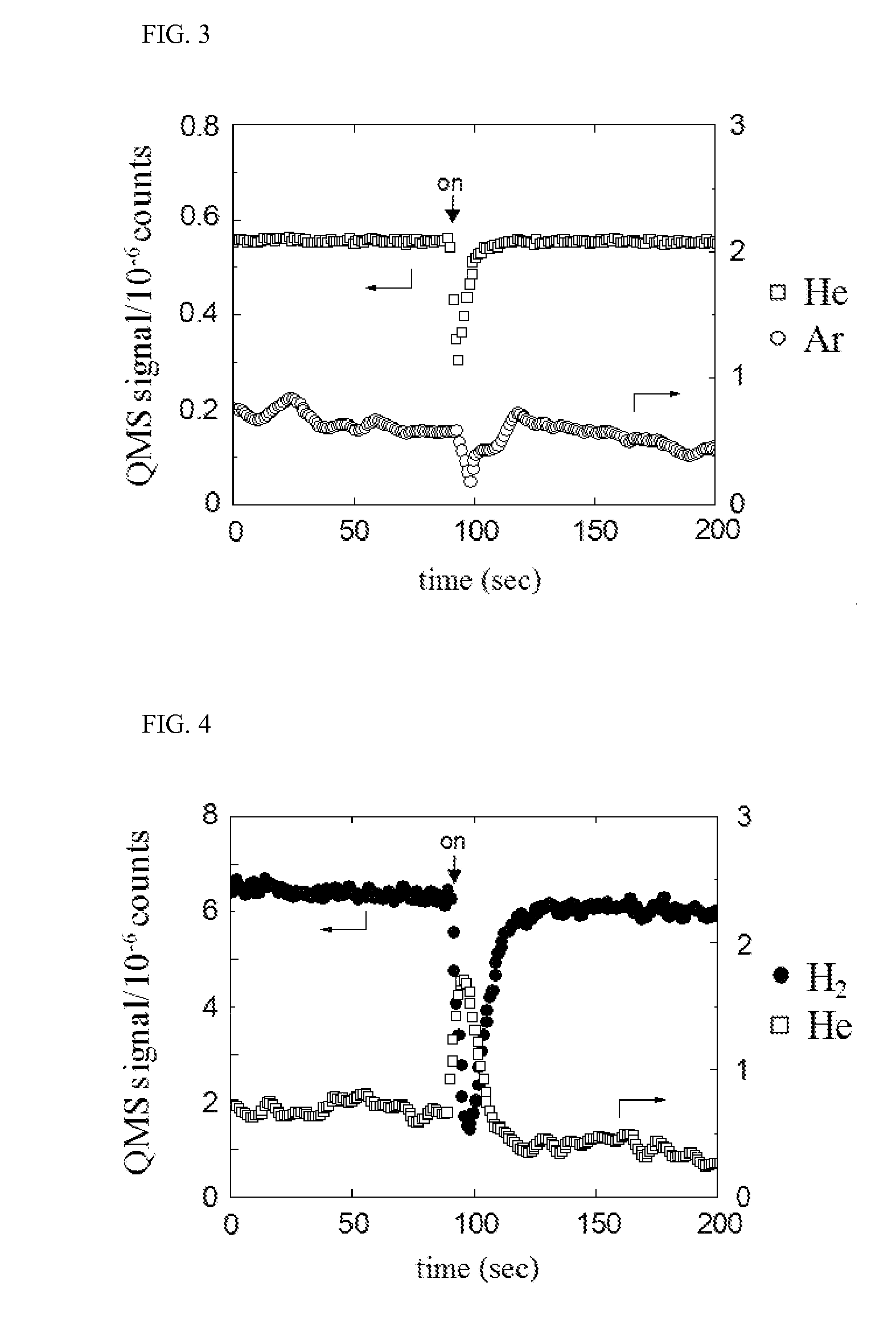

Method for selectively isolating hydrogen or helium using a natrolite-based zeolite, and novel natrolite-based zeolite

InactiveUS20110308385A1Process economyLow-temperature performanceHydrogen separation by selective and reversible uptakeGas treatmentHydrogenNatrolite

The present invention relates to selectively isolating gases using a natrolite-based zeolite, and more particularly, to a novel natrolite-based zeolite and to selectively isolating hydrogen and / or helium gas using a natrolite-based zeolite. The present invention is characterized in that gas containing hydrogen is brought into contact with a natrolite-based zeolite to selectively isolate the hydrogen. The present invention provides a sorbent which can selectively isolate hydrogen and / or helium, and provides a method for isolating the hydrogen and / or helium at room temperature or at a high temperature.

Owner:POSTECH ACAD IND FOUND

Production process of quartz ceramic crucible material

The invention discloses a production process of a quartz ceramic crucible material, wherein the production process comprises the following steps: step 1, preparation of a base body: mixing quartz sandand ceramic according to a weight ratio of 2:1, then sending the mixture into a ball mill, carrying out ball milling at a ball milling rotation speed of 1000-1500 r / min. The quartz ceramic crucible disclosed by the invention is prepared from quartz sand and ceramic as a base body; the base body raw material treated by a treatment liquid can be more easily matched with a corrosion-resistant auxiliary agent and an auxiliary material; therefore, the compatibility among the raw materials is improved; natrolite in the corrosion-resistant auxiliary agent is one of main mineral components of zeoliteore, and the natrolite is more easily mixed with quartz sand and ceramic through dispersing in bentonite; the diamond powder in the auxiliary material has quite high corrosion resistance, the corrosion resistance of the material can be remarkably improved by adding the diamond powder into the material, and the corrosion resistance of the material can be improved by matching the raw materials.

Owner:江苏康姆罗拉特种陶瓷有限公司

Zirconia-doped rare earth-modified acrylic resin type powder coating

The invention discloses a zirconia-doped rare earth-modified acrylic resin type powder coating, and relates to the technical field of powder coating production. The powder coating is prepared from the following raw materials in parts by mass: 90-100 parts of glycidyl methacrylate, 15-20 parts of zirconia, 5-8 parts of rare earth, 10-12 parts of diatomite, 8-10 parts of asbestos powder, 5-8 parts of dodecanedioic acid, 4-6 parts of white carbon black, 3-5 parts of natrolite, 3-4 parts of ultra-fine transparent yellow iron oxide, 2-3 parts of dibutyl phthalate, 2-3 parts of polyester-modified organosiloxane, 1-2 parts of sodium metaborate and 100-120 parts of ethanol. The coating provided by the invention is non-toxic and free of solvents and volatile toxic substances, and complies with environmental requirements; the raw material utilization rate reaches 99%; a dense coating is formed after spraying, and high adhesion, good impact resistance, and excellent weather resistance and corrosion resistance are realized.

Owner:蚌埠市阳光粉沫涂料有限责任公司

Composite heat dissipating material for base of LED lamp

The invention discloses a composite heat dissipating material for a base of an LED lamp. The composite heat dissipating material comprises the following raw materials of, by mass, 63-65 parts of aluminum, 5-8 parts of vanadium boride, 4-5 parts of ferrochrome slag, 1-3 parts of glycerin, 1-2 parts of triethanolamine, 6-8 parts of calcite, 10-12 parts of talc, 3-5 parts of medical stone, 1-2 partsof manganese sulfide, 0.3-0.5 part of magnesium isooctanoate, 0.2-0.3 part of silicon nitride, 0.2-0.3 part of zirconium oxide, 0.2-0.3 part of chromic oxide, 0.5-0.8 part of zirconium diboride, 0.2-0.3 part of aluminium nitride, 0.5-0.8 part of natrolite, 0.1-0.2 part of organic chelated titanium, 0.1-0.2 part of zinc oxide, 0.1-0.2 part of calcium carbonate and 0.1-0.2 part of zinc borate. The prepared heat dissipating material is ideal in sintering effect, bright and clean and compact in material surface, stable in temperature change, durable in use and excellent in heat conductivity coefficient, and the LED lamp can be effectively protected, and the service life of the lamp is prolonged greatly.

Owner:安徽新欧电子科技有限公司

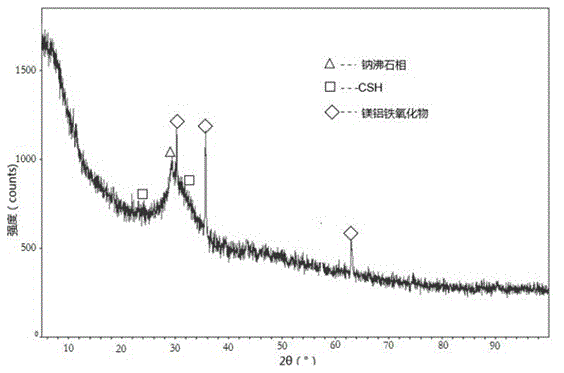

Geopolymer curing material based on manganese tailings and preparation method of geopolymer curing material

The invention discloses a geopolymer curing material based on manganese tailings and a preparation method of the geopolymer curing material. The raw materials comprise a solid-state raw material and a liquid-state raw material, wherein the solid-state raw material comprises the following components in percentage by mass: 4.5-5.5% of cement, 4.5-5.5% of manganese tailings and 89-91% of multi-metal polluted soil, the liquid-state raw material is an aqueous solution containing an alkali activator and a water reducing agent, the mass concentration of the alkali activator is 1-2%, the mass concentration of the water reducing agent is 0.8-1.0%, and the solid-state raw material and the liquid-state raw material are mixed according to a water-cement ratio of 0.30-0.40. According to the invention, soluble SiO2, Al2O3 and Ca(OH)2 in manganese tailings are subjected to hydration reaction, so that kaolin, C-S-H, C-A-H and natrolite gel materials are continuously increased, and the compressive strength of a manganese tailing-based geopolymer solidified body is continuously improved; acidic oxides in manganese tailings can also promote dissolution of active glass bodies SiO2 and Al2O3, and hydration reaction is guaranteed; and the hydroxide of Mn has strong obligate adsorption capacity on Pb<2+> and Zn<2+>, and has a good physical wrapping effect on heavy metals such as Pb, Zn and the like.

Owner:CENT SOUTH UNIV

Nanometer aluminium oxide-modified acrylic resin type powder coating

InactiveCN104945972AMeet environmental protection requirementsIncrease profitAnti-corrosive paintsPowdery paintsGlycidyl methacrylateAcrylic resin

The invention discloses a nanometer aluminium oxide-modified acrylic resin type powder coating, and relates to the technical field of production of powder coatings. The powder coating is prepared from the following raw materials in parts by mass: 90-100 parts of glycidyl methacrylate, 15-20 parts of nanometer aluminium oxide, 10-12 parts of kieselguhr, 8-10 parts of asbestos powder, 6-9 parts of carboxymethyl chitosan, 5-8 parts of dodecanedioic acid, 4-6 parts of zirconium oxide, 3-5 parts of natrolite, 3-4 parts of superfine transparent iron oxide yellow, 2-3 parts of dibutyl phthalate, 2-3 parts of polyether-modified organic siloxane and 100-120 parts of ethyl alcohol. The coating provided by the invention is nontoxic and free of solvents and volatile and toxic substances, and meets environmental requirements; the raw material utilization ratio can reach 99%; a compact coating layer is generated after spraying, and the coating layer is good in adhesive force and impact resistance, and excellent in weather resistance and corrosion resistance.

Owner:蚌埠市阳光粉沫涂料有限责任公司

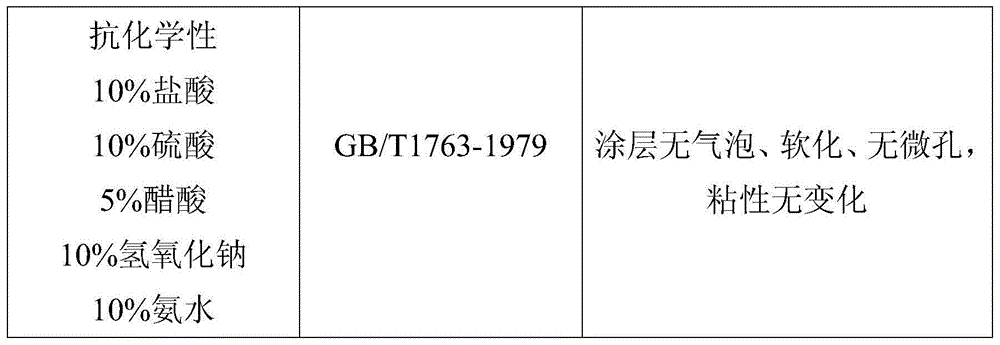

Preparation method for soil conditioner for reducing growth period of watermelon fruit

InactiveCN108911912ARich in nutrientsImprove growth performanceBio-organic fraction processingAgriculture tools and machinesNatroliteSoil conditioner

The invention discloses a preparation method for a soil conditioner for reducing a growth period of watermelon fruit. The preparation method comprises the following steps: 1) weighting the following raw materials in parts by weight for standby application: 26-32 parts of compound fertilizer mixed with dry branches and fallen leaves, 8-14 parts of carbonized pine cone shell, 12-18 parts of natrolite, 4-8 parts of active vesuvianite powder, 2-6 parts of an organic material decomposing agent, 5-9 parts of muddy sediment, 2-5 parts of sodium hexametaphosphate and 32-38 parts of water. The invention aims to provide the preparation method for the soil conditioner for reducing the growth period of the watermelon fruit. The soil conditioner is capable of supplying abundant nutrition and shorteningthe growth period of the fruit and has higher use value and good application prospect.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Heat dissipation material used for producing LED lamp shells

ActiveCN109724053AReduce heat dissipationExtended service lifeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyDiboride

The invention discloses a heat dissipation material used for producing LED lamp shells. The heat dissipation material comprises a heat dissipation layer and an adhesive layer. The adhesive layer is composed of, by weight, 27-36 parts of polyethylene glycol isophthalate, 11-17 parts of polybutylene terephthalate, 31-37 parts of epoxy resin, 11-17 parts of graphene powder, and 9-13 parts of methacryloxy silane. The heat dissipation layer is composed of, by weight, 15-17 parts of ceramic powder, 5-12 parts of polyethylene glycol, 7-13 parts of graphene powder, 9-13 parts of epoxy resin, 9-14 parts of polyimide, 3-7 parts of triethoxy chlorosilane, 11-17 parts of polyethylene glycol, 1-3 parts of magnesium isooctanoate, 2-4 parts of zinc borate, 1-3 parts of vanadium diboride, 2-5 parts of sodium borohydride, 0.1-0.3 part of natrolite, and 0.1-0.4 part of medical stone powder. By means of the heat dissipation material, the heat dissipation capacity of LED lamps under the working conditioncan be improved, thus the service life of the LED lamps is prolonged, and the working stability of the LED lamps is improved. In addition, the heat dissipation material is provided with the adhesive layer, the function of improving adsorption capacity of the heat dissipation layer is achieved, and heat can be transferred efficiently.

Owner:重庆秉为科技有限公司

A brittleness evaluation method for shale gas reservoirs based on mineral content

The invention discloses a mineral content-based brittleness evaluation method for a shale gas reservoir. By taking the brittleness of quartz as the standard, the relative brittleness degree, called as a mineral brittleness coefficient, of each essential mineral in the shale gas reservoir is determined; the essential minerals comprise the quartz, clay-contained quartz, kaolinite, Mexico clay, mixed clay, calcite, dolomite, rock salt, kerogen, perthite, anorthose, feldspar, anhydrite, zeolite and natrolite; the overall brittleness degree of reservoir rock is computed by utilizing mineral volume content and the brittleness coefficient of each mineral; the mineral volume content refers to the percentage that the volume of minerals in porous rock accounts for the total volume of the porous rock. The brittleness evaluation method is superior to a method, used in oil exploration industry at present, for evaluating brittleness by comparing the volume content of the quartz and carbonatite and the total volume of the minerals.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for producing purified precipitated calcium carbonate from lime sludge

PendingCN114599609ACalcium/strontium/barium carbonatesLime productionCalcium hydroxidePrecipitated calcium carbonate

A method of making purified precipitated calcium carbonate from lime mud can include mixing a lime mud cake with water and sodium carbonate to form a first slurry; heating the first slurry under conditions to age the slurry and form one or more of calcium hydroxide, sodium calcium carbonate, and monoclinic natrolite; separating a solid fraction from the aged slurry; washing the solids fraction under conditions sufficient to decompose one or more of the calcareite, the sodium calcium carbonate, and the monoclinic natrolite into a CaCO3 solid fraction and a Na2CO3 solid fraction and remove the sodium salt; and mixing the CaCO3 solid fraction with water and a dispersant to disperse the CaCO3 solid fraction in water and form a dispersed slurry having a Brookfield viscosity of less than about 1000 cps at 100 rpm, thereby producing a dispersed slurry containing the purified precipitated calcium carbonate.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

Preparation process of natrolite inorganic artificial stone

InactiveCN103011743BImprove utilization efficiencyPerformance is not affectedNatroliteArtificial stone

Owner:SHAANXI UNIV OF TECH

Method for selectively isolating hydrogen or helium using a natrolite-based zeolite, and novel natrolite-based zeolite

InactiveUS8906139B2Process economyLow-temperature performanceHydrogen separation by selective and reversible uptakeAluminium compoundsHydrogenNatrolite

The present invention relates to selectively isolating gases using a natrolite-based zeolite, and more particularly, to a novel natrolite-based zeolite and to selectively isolating hydrogen and / or helium gas using a natrolite-based zeolite. The present invention is characterized in that gas containing hydrogen is brought into contact with a natrolite-based zeolite to selectively isolate the hydrogen. The present invention provides a sorbent which can selectively isolate hydrogen and / or helium, and provides a method for isolating the hydrogen and / or helium at room temperature or at a high temperature.

Owner:POSTECH ACAD IND FOUND

A kind of light-transmitting ceramic brick and its preparation method

The invention discloses a translucent ceramic tile. The tile body blank of the tile comprises, by weight, 52-62% of SiO2, 20-26% of Al2O3, 0-0.1% of Fe2O3, 0-0.2% of TiO2, 5-10% of CaO, 0-1% of MgO, 0.8-2.6% of K2O, 4-7% of Na2O, 0-2% of BaO, 0.3-0.8% of ZnO and 5-10% of ignition loss. According to the translucent ceramic tile and the preparation method thereof, natrolite is used as a main body row material of the ceramic tile body blank and matched with part of fused quartz, frit and feldspar are used as a solvent, and high ball clay and bentonite are used as a binder to achieve the excellent forming property and to solve the problems that current translucent ceramic tiles are poor in plasticity and difficult to form. The prepared translucent ceramic tile is high in light transmittance, volume density can reach 2.15 gram / cubic centimeter in minimum, whiteness is larger than 66 degrees, the usage requirements are met, at the same time, the application range of translucent ceramic tiles is wide, and the translucent ceramic tiles can be separately applied to porcelain glazed tiles and full-body tiles.

Owner:FOSHAN OCEANO CERAMICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com