Method for preparing natrolite from coal series kaolinite intercalation composite

A technology of coal series kaolin and intercalation compound, applied in the direction of sodium zeolite, etc., can solve the problems of low quality of sodium zeolite formation and complicated process, and achieve the effects of easy control, simple manufacturing process and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: such as Figure 1 ~ Figure 3 Shown, the present invention comprises the following steps:

[0018] Step 1, pulverizing coal series kaolin;

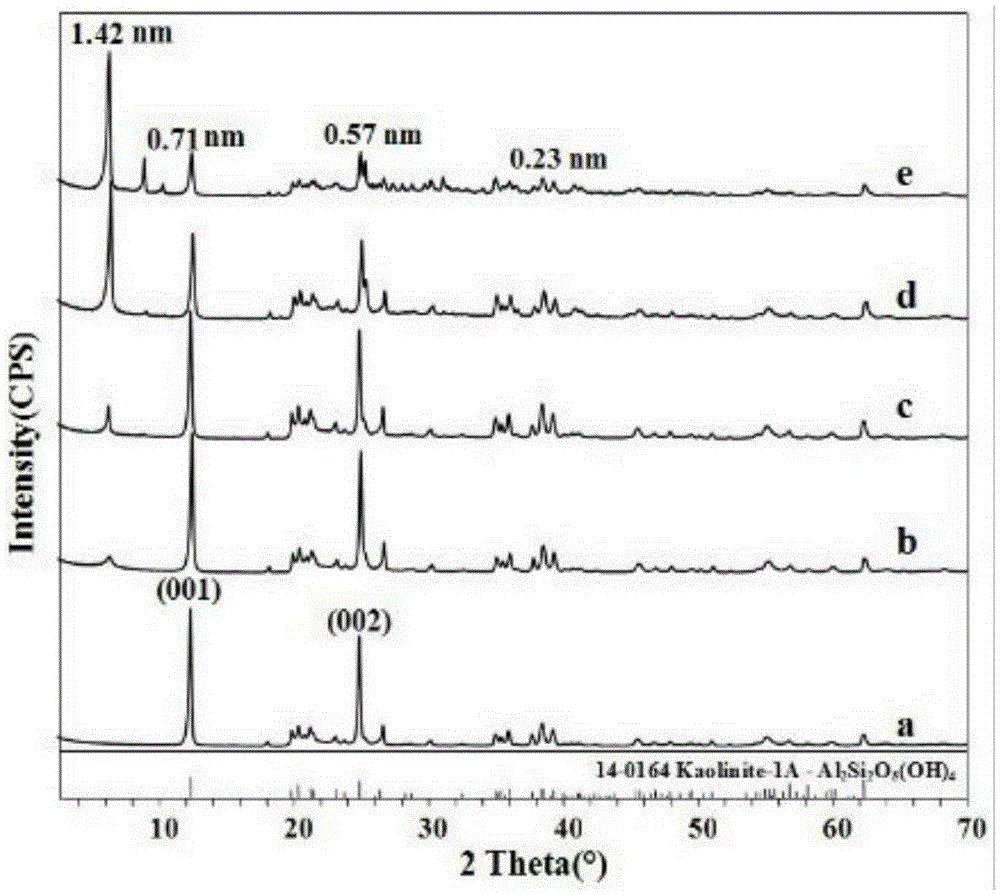

[0019] Step 2, mixing the potassium acetate solution with a mass fraction of 30% and the pulverized kaolin at a mass ratio of 10:1, and stirring magnetically at room temperature for 3 to 4 days;

[0020] Step 3, filtering, washing and centrifuging the stirred product;

[0021] Step 4. Dry the centrifuged product in an electric blast drying oven for 24 hours;

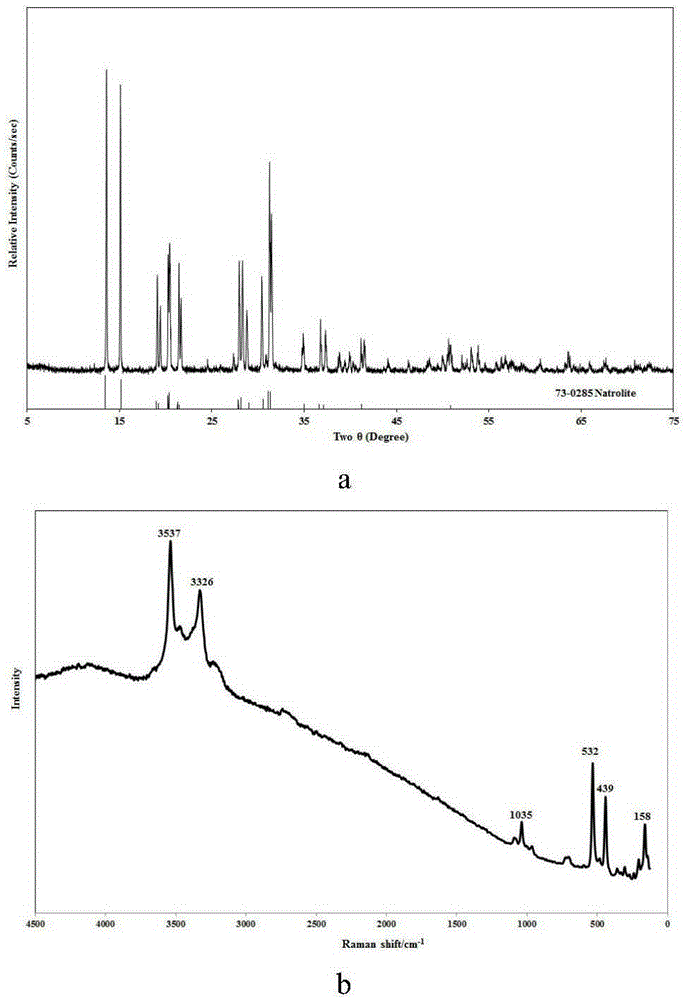

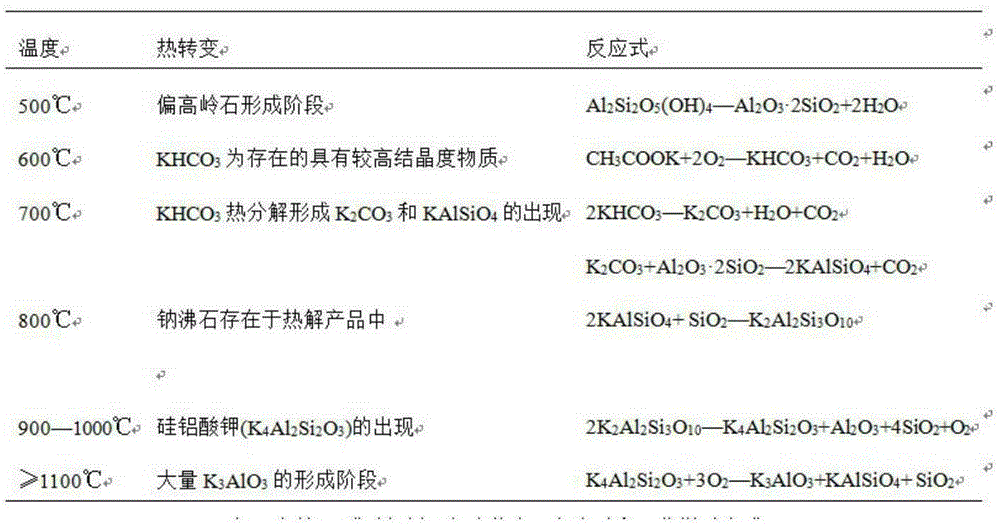

[0022] Step 5. Put the air-dried product into a muffle furnace and raise the temperature to 800°C for 4 hours, then cool it under natural conditions. The sodium zeolite exists in the pyrolysis product. During the entire process of calcining the compound, the X-ray of the synthetic sodium zeolite Diffraction (XRD) pattern and Raman spectrum pattern such as figure 1 shown. The basic principle of the present invention is the high-temperature phase transition of kaol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com