Patents

Literature

59 results about "Analcime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

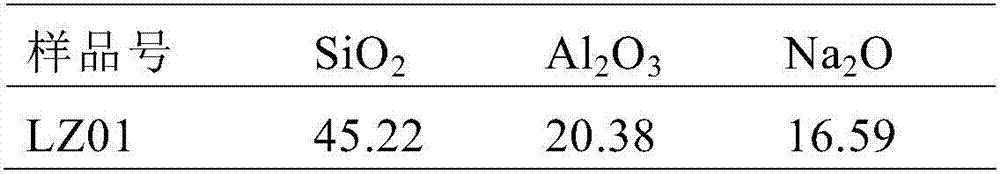

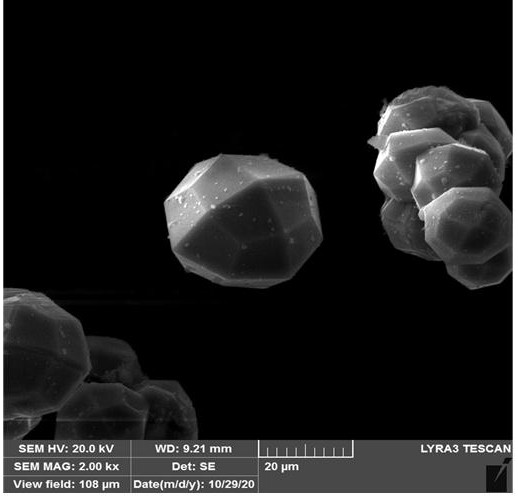

Analcime or analcite (from the Greek analkimos - "weak") is a white, gray, or colorless tectosilicate mineral. Analcime consists of hydrated sodium aluminium silicate in cubic crystalline form. Its chemical formula is NaAlSi₂O₆·H₂O. Minor amounts of potassium and calcium substitute for sodium. A silver-bearing synthetic variety also exists (Ag-analcite).

Cementing compositions containing substantially spherical zeolite

ActiveUS20050133222A1Improve flexural strengthReduce brittlenessDrilling compositionSealing/packingPortland cementNatrolite

A cementitious composition for cementing an oil or gas well and which exhibits, when cured, increased flexural strength and a flexural strength to compressive strength ratio between from about 0.29 to about 0.80, contains a hydraulically-active cementitious material, such as Portland cement, and substantially spherical zeolite. Representative zeolites include natrolite, heulandite, analcime, chabazite, stilbite, and clinoptilolite. The weight percent of zeolite in the cement composition is generally less than or equal to 15 percent. In practice, a well bore may be cemented by pumping the activated slurry and pumping it within the well bore to a pre-selected location and allowing it to solidify.

Owner:BAKER HUGHES INC

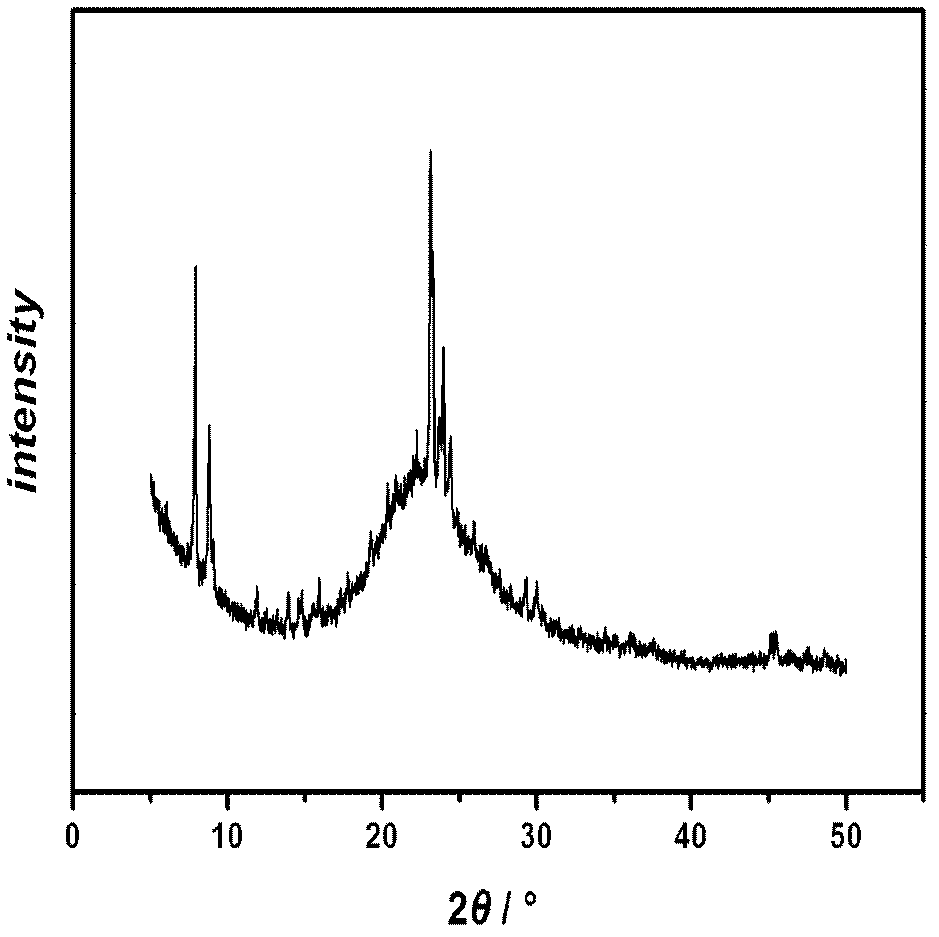

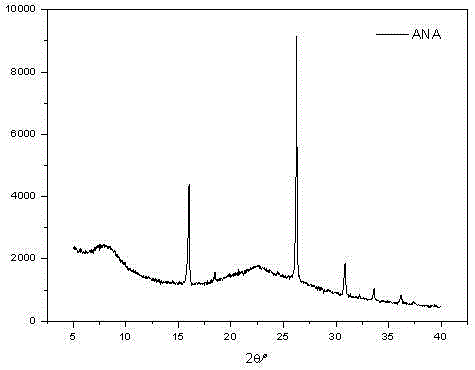

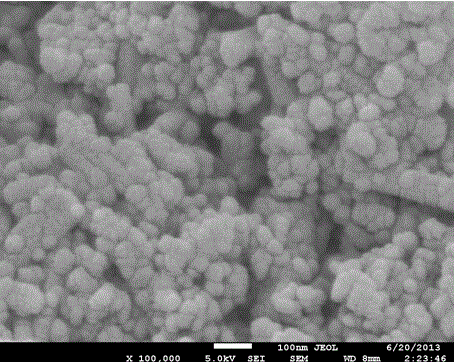

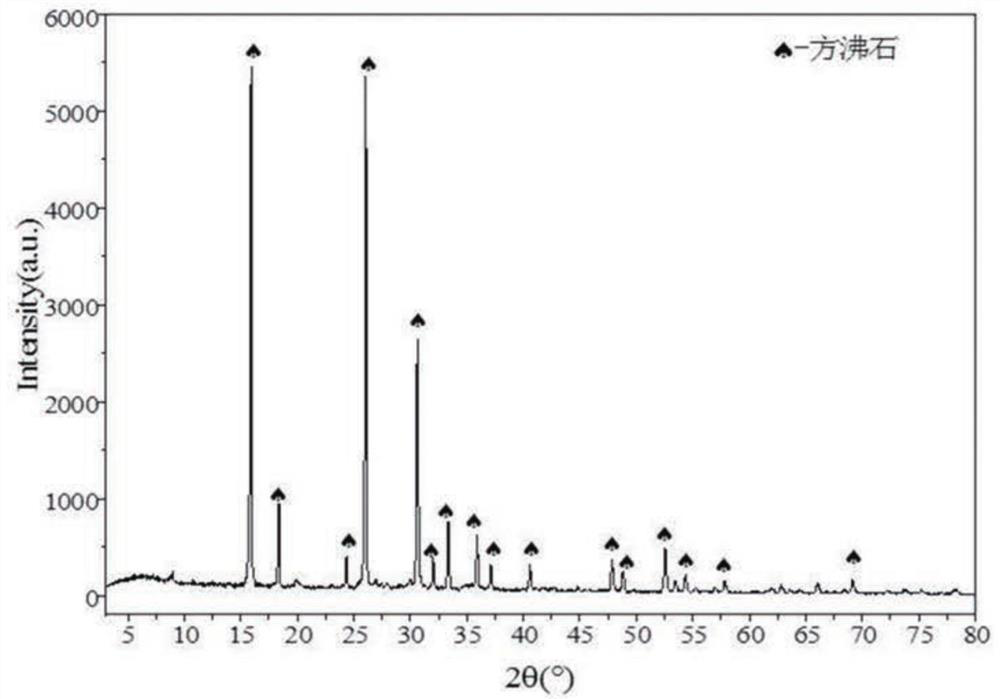

Method for preparing nano analcime with fly ash

InactiveCN103046111ALess reservesRealize resource utilizationMaterial nanotechnologyPolycrystalline material growthResource utilizationSingle crystal

The invention provides a method for preparing nano analcime with fly ash. The method comprises the steps that 1), the fly ash and alkali are mixed and roasted at a high temperature; 2), deionized water is added after cooling; heating stirring and room temperature stirring are combined; collosol is obtained; 3), the collosol is subjected to ultrasonic treatment and filtering after the stirring; 4), filtered solid is added to an alkaline solution, and hydrothermal crystallization is conducted at a lower temperature; and 5), filtering, washing and drying are conducted after the crystallization, and powdered nano analcime is obtained. Compared with the prior art, the method has the following advantages that 1, fly-ash monocrystal nano analcime with fewer reserves in nature is synthesized by taking the fly ash as a raw material; 2, other silicon and aluminium sources and template agents are not added; and 3, the nano fly ash analcime is synthesized by a simple technology through the hydrothermal crystallization at a low temperature (not exceeding 100 DEG C). The method utilizes the waste fly ash to achieve resource utilization of the fly ash, synthesizes the analcime with fewer resources, and can be applied to fluorine, cesium and heavy metal waste water treatment.

Owner:EAST CHINA UNIV OF TECH

Method of cementing a well using composition containing zeolite

ActiveUS7137448B2Good physical propertiesImprove flexural strengthDrilling compositionSealing/packingNatrolitePortland cement

A cementitious composition for cementing an oil or gas well and which exhibits, when cured, increased flexural strength and a flexural strength to compressive strength ratio between from about 0.29 to about 0.80, contains a hydraulically-active cementitious material, such as Portland cement, and substantially spherical zeolite. Representative zeolites include natrolite, heulandite, analcime, chabazite, stilbite, and clinoptilolite. The weight percent of zeolite in the cement composition is generally less than or equal to 15 percent. In practice, a well bore may be cemented by pumping the activated slurry and pumping it within the well bore to a pre-selected location and allowing it to solidify.

Owner:BAKER HUGHES INC

Method for preparing ethylene propylene by catalytic pyrolysis of light oil

ActiveCN101279880AIncrease acidityHigh acid strengthMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisMordenite

The invention relates to a method for preparing ethylene propylene by light oil through catalytic cracking, which mainly solves the problems of low catalyst activity, low ethylene propylene yield and high reaction temperature of the current ethylene propylene preparing technique by catalytic cracking. The invention properly solves the problems by adopting the technical proposals that: a ZSM-5 / mordenite / analcime intergrown molecular sieve, a ZSM-5 / mordenite / zeolite beta intergrown molecular sieve, a ZSM-5 / mordenite / zeolite Y intergrown molecular sieve, a ZSM-5 / mordenite / MCM-22intergrown molecular sieve or a mixture thereof serves as a catalyst, the light oil with the compositions of C4 to C10 hydrocarbon is adopted as a raw material, and the material is in contact reaction with a catalyst under the conditions of a reaction temperature of between 600 and 700 DEG C, a reaction pressure of between 0.001 and 0.5MPa, a reaction weight space velocity of between 0.1 and 4 / h, and water / light oil being present in a weight ratio of 0.5-6: 1, and the method of preparation can be used for the industrial production of preparing the ethylene propylene by the light oil through catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

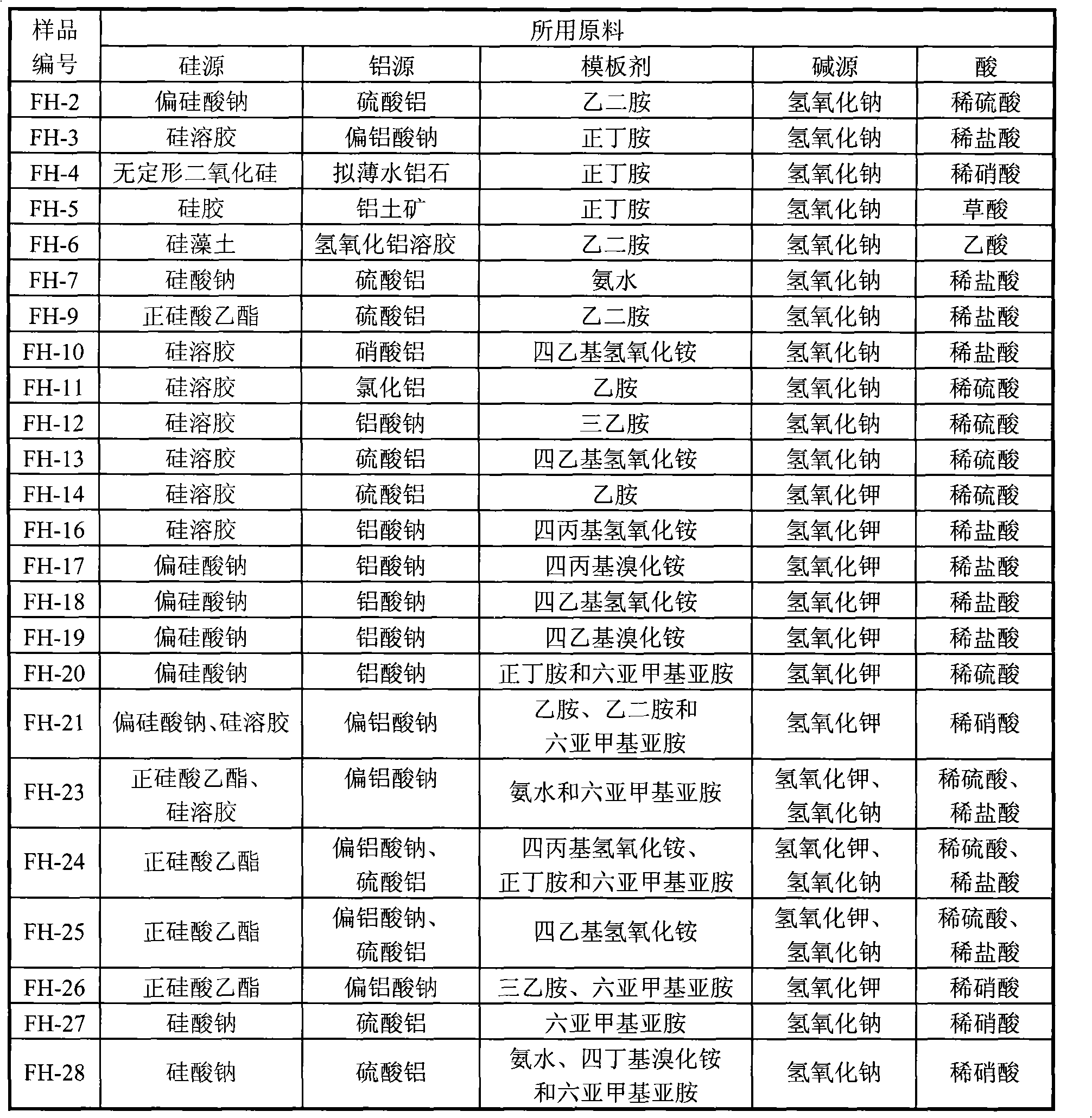

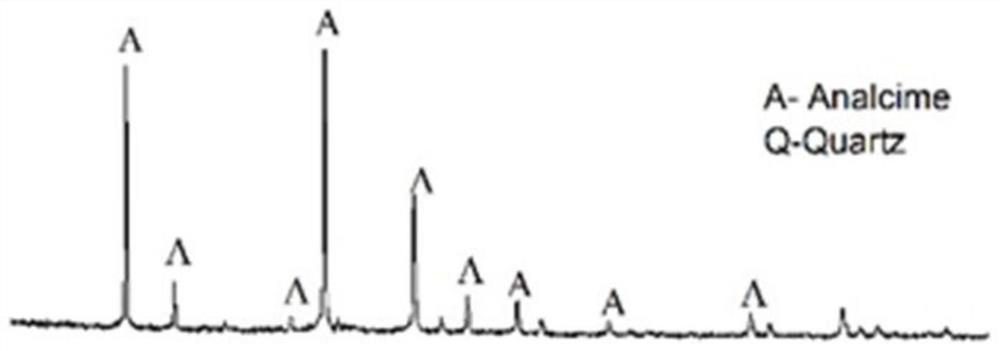

Method for synthesizing ZSM-5 molecular sieve

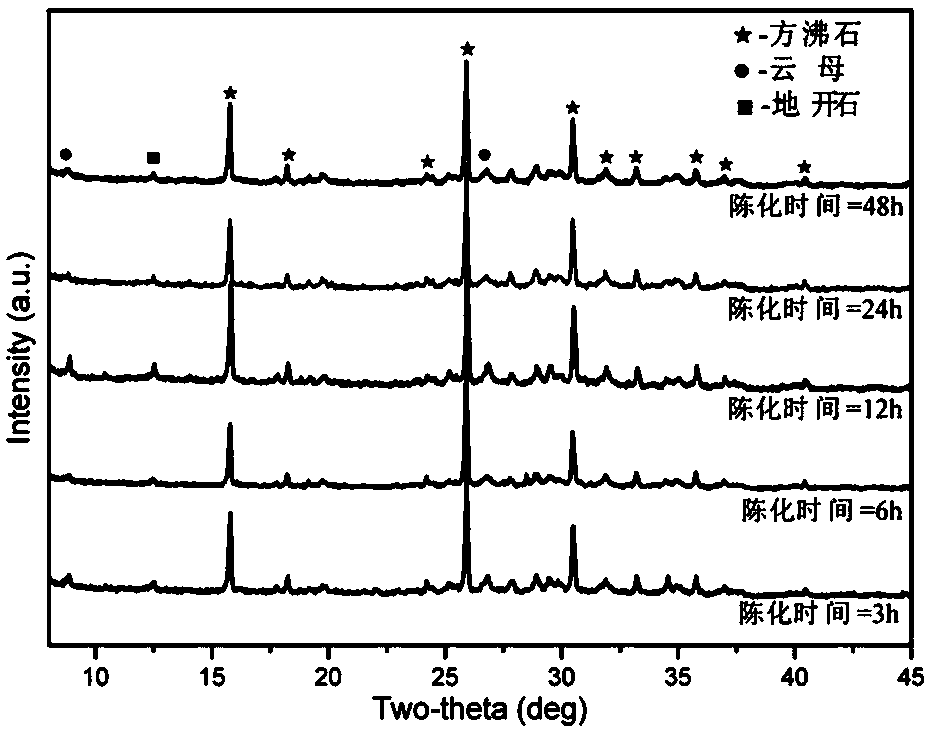

InactiveCN103936026ABroaden the range of synthesisPentasil aluminosilicate zeoliteRoom temperatureCrystallinity

The invention relates to a method for synthesizing a ZSM-5 molecular sieve. The method comprises the following specific steps: mixing a silicon source, an aluminum source, a template agent, an assistant and water according to a certain ratio, adjusting the pH value of the mixture, stirring to dissolve at room temperature, transferring into a stainless steel crystallization kettle with a polytetrafluoroethylene liner, carrying out crystallization at a certain temperature, filtering, washing, drying and roasting to obtain the ZSM-5 molecular sieve with good crystallinity. The method provided by the invention inhibits the formation of mixed crystal analcime by adding certain assistants, breaks through the conventional concept that ZSM-5 cannot be synthesized under high pH conditions, widens the synthesis range of the ZSM-5 molecular sieve, and has important research value and theoretical significance.

Owner:NANJING UNIV OF TECH

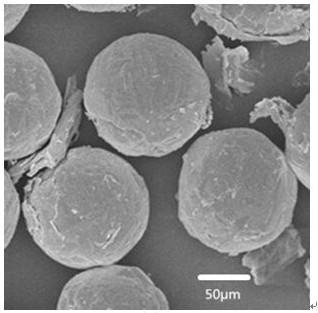

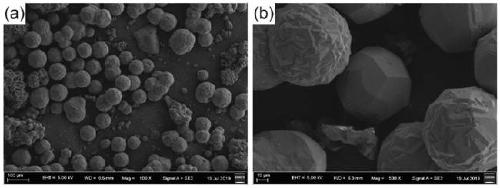

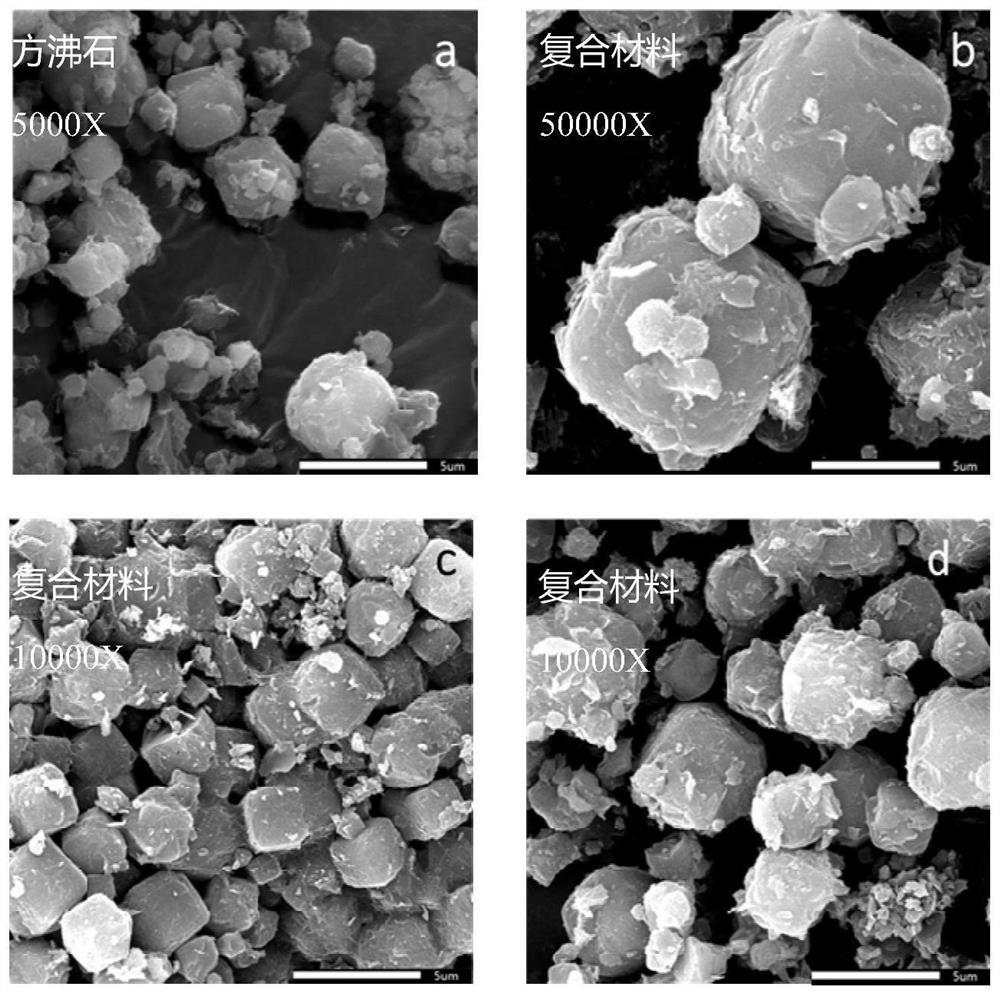

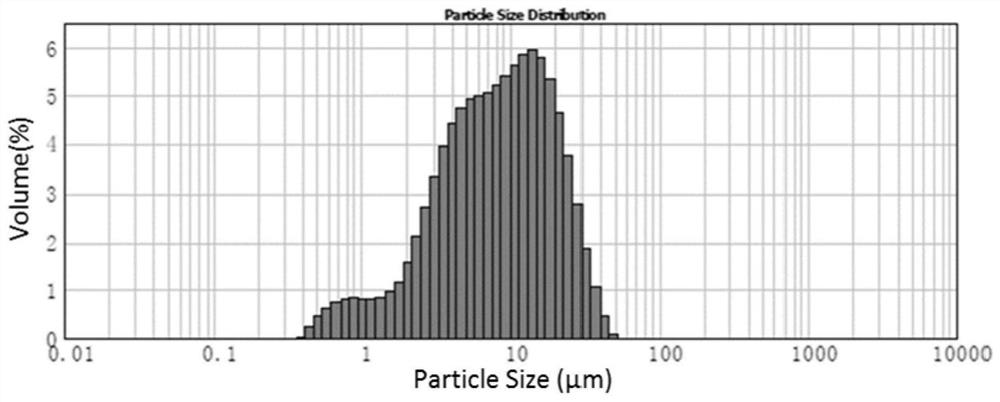

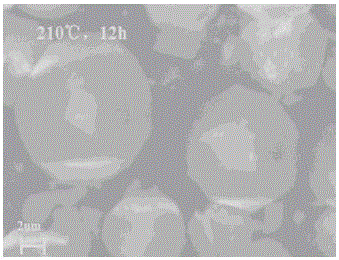

Method for preparing spherical analcite mesoporous material from low-quality attapulgite clay tailings

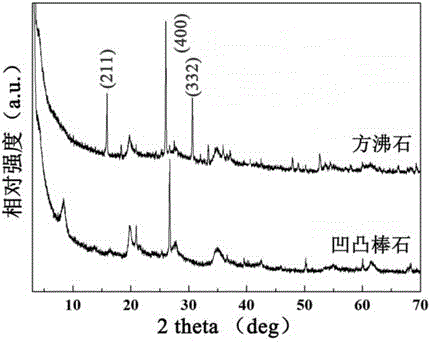

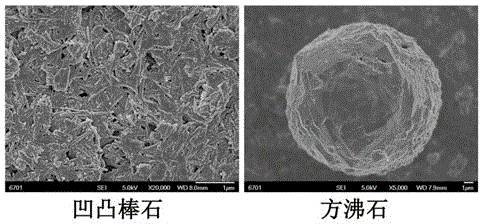

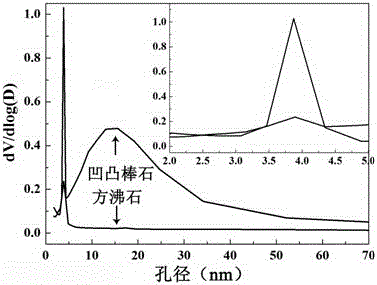

ActiveCN105731486AStable pore size distributionUniform pore size distributionCrystalline aluminosilicate zeolitesMycotoxinActive agent

The invention discloses a method for preparing a spherical analcite mesoporous material from low-quality attapulgite clay tailings. The method is characterized in that through one-step hydrothermal reaction, the attapulgite clay tailings which are low in grade, complex in component and poor in adsorption property are transformed into a micron-grade spherical mesoporous adsorption material which is uniform and controllable in aperture distribution and excellent in adsorption property. On the premise that an organic surfactant type pore-forming agent is not introduced, the crystal structure and the aggregation state of attapulgite are transferred through one-step hydrothermal reaction, at the same time associated minerals are dissolved, crysatalized and recombined so as to obtain the mesoporous analcite material of the micron-grade spherical morphology, and the product is narrow in aperture distribution, simple in process, stable in product property, controllable in aperture distribution and excellent in adsorption property, and can be used as an adsorbent which is widely used in multiple fields such as efficient adsorption of antibiotics, mycotoxin, dye and heavy metals so as to remove enrichment of precious metal ions such as rubidium and caesium.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

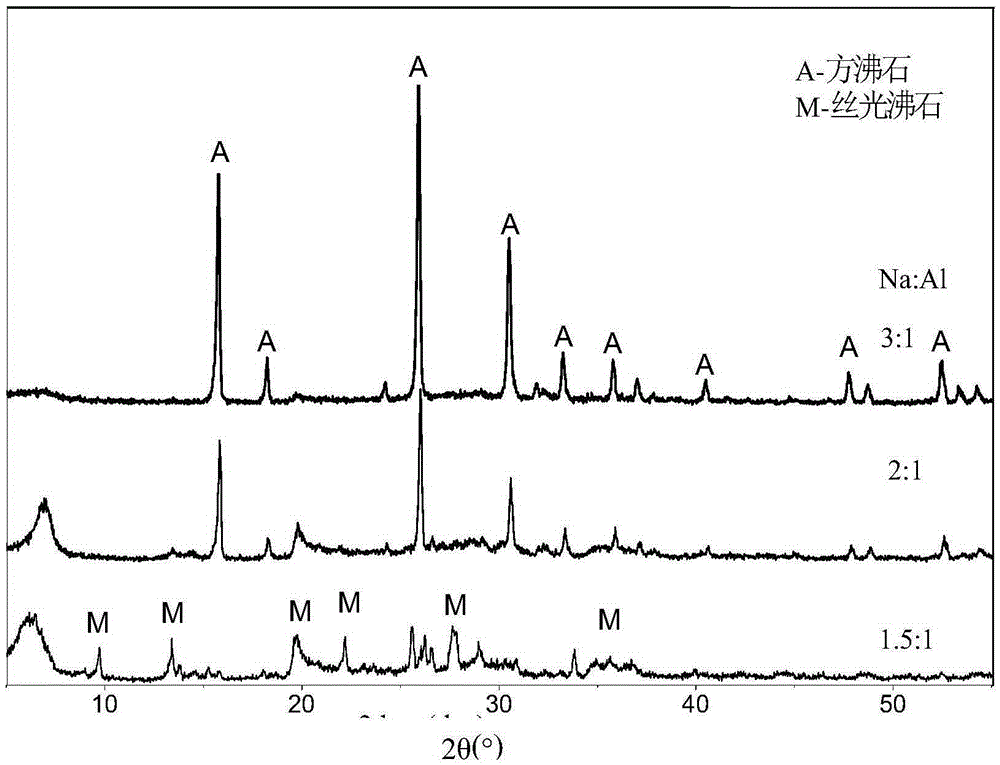

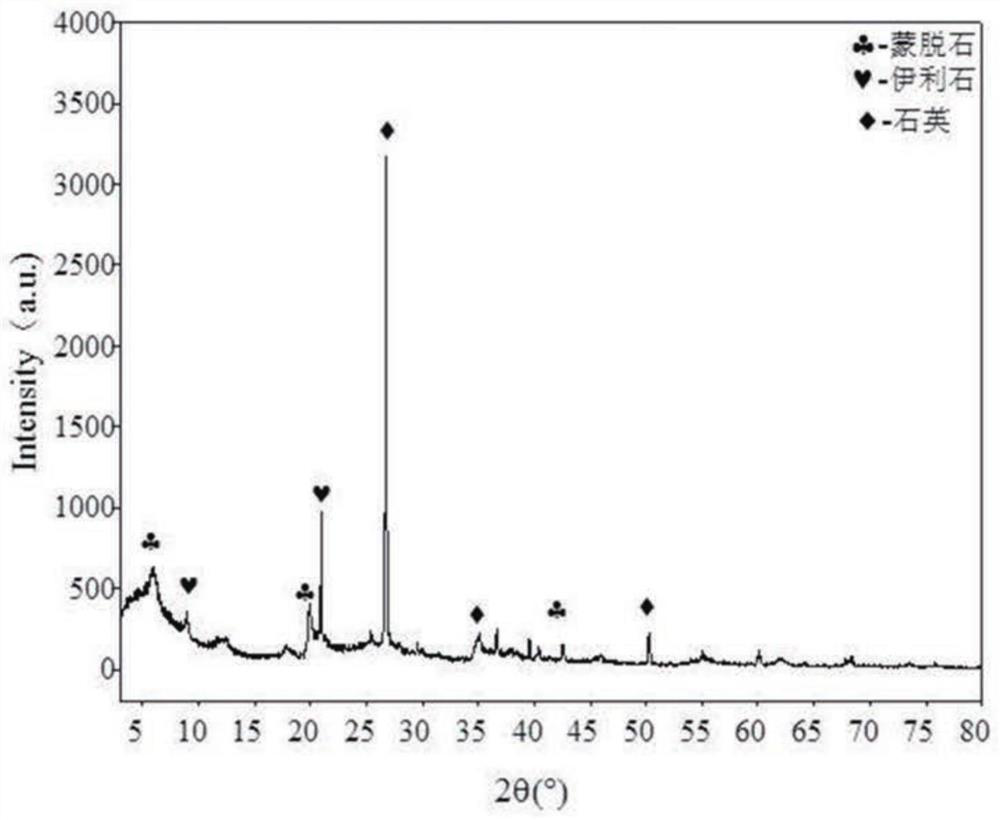

Method for producing zeolite by using soil clay minerals as raw materials

ActiveCN105417554ARich sourcesLow priceMolecular-sieve and base-exchange compoundsClay mineralsEconomic benefits

The invention relates to a method for producing zeolite by using soil clay minerals as a raw material, and belongs to the technical field of mineral synthesis. The method is characterized by using the soil clay minerals as the raw material, drying the raw material and detecting the content of elements in the soil clay mineral; using NaOH and NaCl as sodium sources, wherein an alkaline environment is provided by NaOH; weighing the soil clay minerals and the sodium sources according to a molar ratio, which is (0.7 to 3):1, of Na and Al, weighing water according to a mass ratio, which is (0.15 to 0.75):1, of the water and the soil clay minerals, and adding NaOH or NaOH and NaCl in the soil clay minerals after dissolving NaOH or NaOH and NaCl in the water; then putting the mixture in a reaction kettle, treating the mixture for 4 to 12 hours under saturated water vapor of which the temperature is 120 to 240 DEG C, and obtaining a reaction product-the zeolite after drying, wherein the soil clay minerals are commercially available montmorillonite raw materials or illite raw materials, and NaCl and NaOH of the sodium sources are weighed according to a molar ratio which is (0 to 2):1. According to the method for producing the zeolite by using the soil clay minerals as the raw material, disclosed by the invention, the process is simple and convenient, the economic benefit is high, and the obtained product-analcime is purer.

Owner:TONGJI UNIV

Method for synthesizing analcime block material by using metakaolin

ActiveCN104445249AIncrease productionLow priceCrystalline aluminosilicate zeolitesCompression moldingWater quality

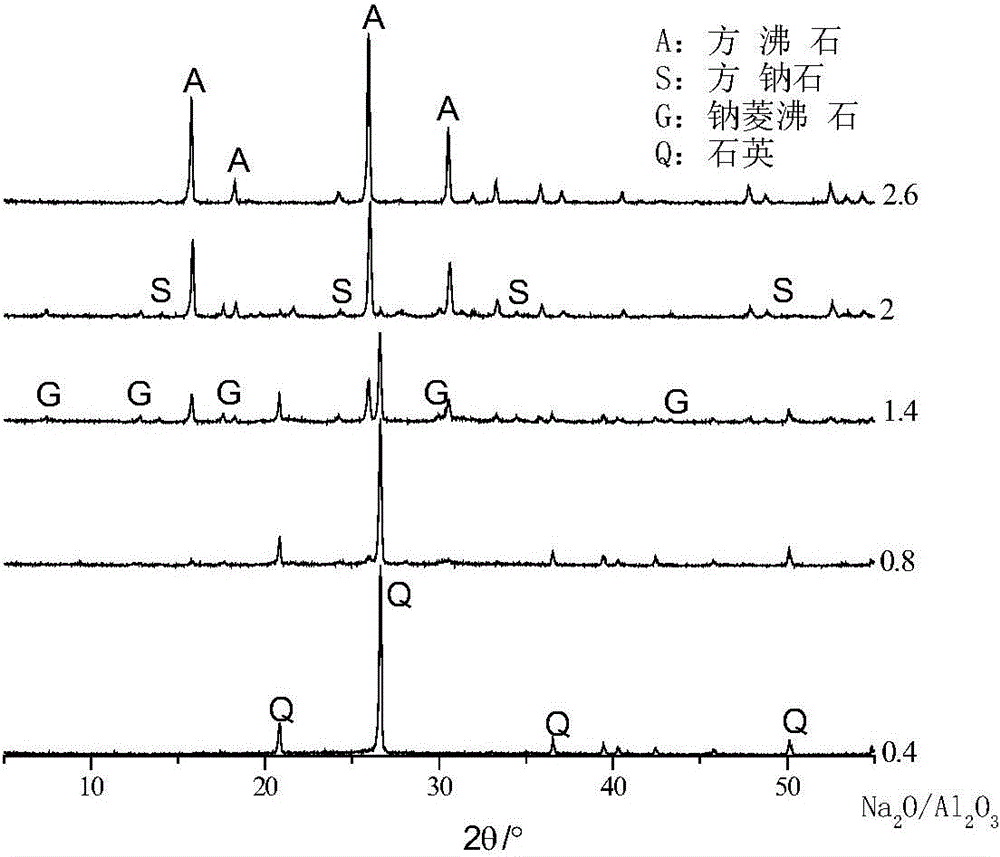

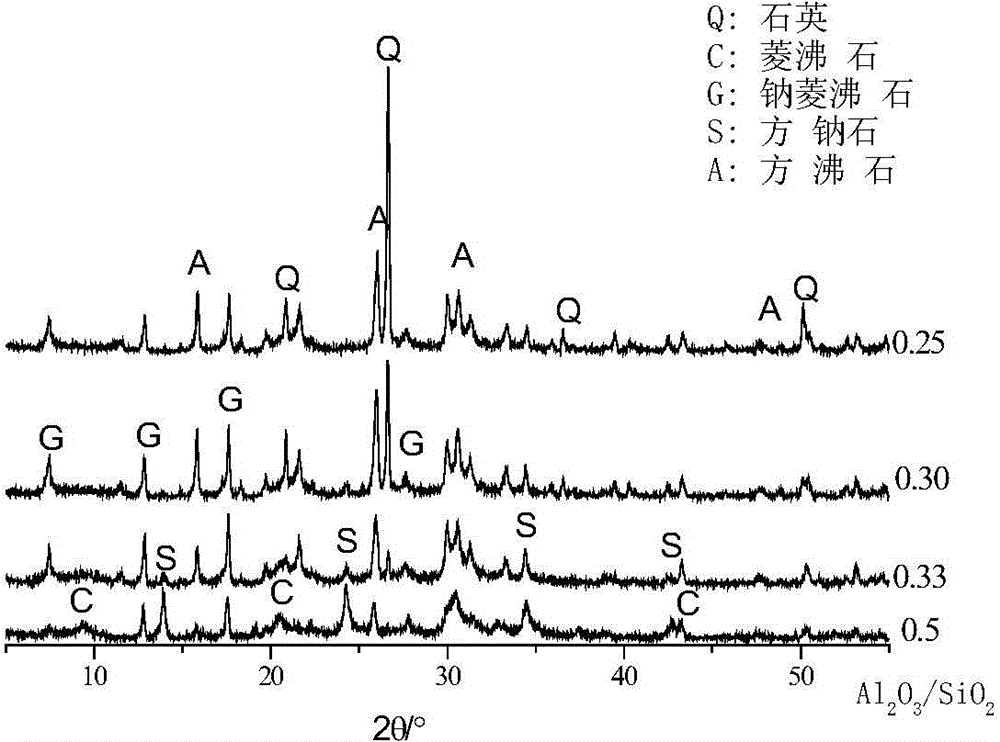

The invention relates to a method for synthesizing an analcime block material by using metakaolin. The method comprises the following steps: firstly, measuring metakaolin, quartz flour, NaOH and water to ensure that the molar ratio of Na2O to Al2O3 is 0.4-2.6, and the molar ratio of SiO2 to Al2O3 is 0.20-0.50; secondly, adding water into NaOH, and stirring to obtain a solution, wherein the added amount of water is 19.0-21.0% of the total mass of the metakaolin, quartz flour and NaOH; thirdly, uniformly mixing the metakaolin and the quartz flour, then adding the mixture into the solution, and uniformly mixing to obtain a prepared material; and finally, putting the prepared material into a pelletizer, performing compression molding at a pressure of 10-50MPa, putting the material into a still kettle, and performing hydro-thermal treatment in saturated steam at 80-220 DEG C for 2-36 hours, thereby obtaining a block material taking the metakaolin as a main product phase. The method provided by the invention is simple in process, low in cost, and easy to realize industrialization, the product can be widely used for performing water purification and contaminated soil restoration, and curing cesium-containing radioactive wastes, and no secondary waste is generated.

Owner:TONGJI UNIV

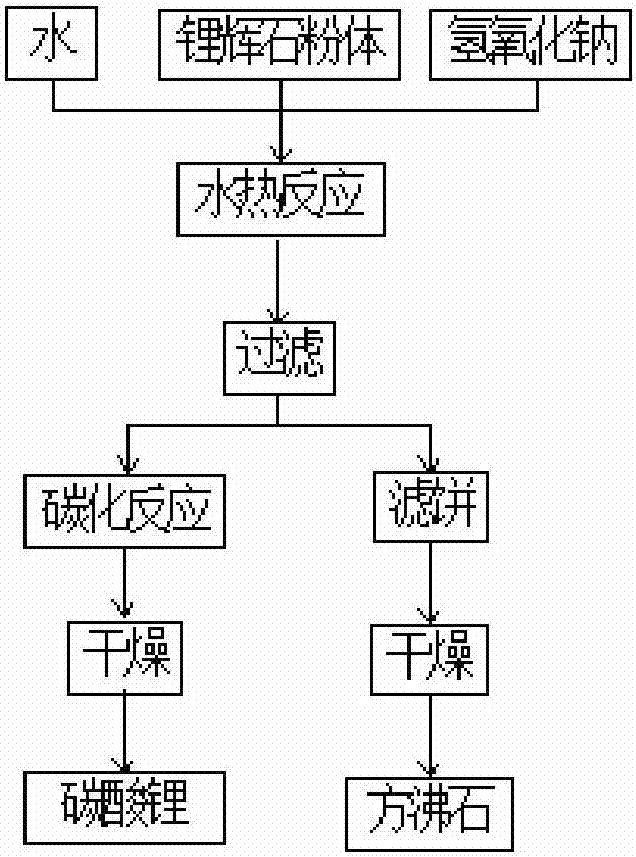

Method for preparing lithium carbonate with byproduct analcime by NaOH decomposition of spodumene

InactiveCN107381605ALow costSimple processAluminium silicatesLithium carbonates/bicarbonatesDecompositionLithium carbonate

The invention discloses a method for preparing lithium carbonate with byproduct analcime by NaOH decomposition of spodumene. The process is as follows: crushing and grinding spodumene ore to powder with a particle size of less than 74 mu m, uniformly mixing the spodumene powder with sodium hydroxide and water, then hydrothermally reacting at 240~280 DEG C for 60 min~240 min to obtain analcime and a lithium-containing solution, filtering the resulting mixture, washing and drying to obtain the analcime product, carbonating filtrate to obtain a lithium carbonate precipitate, filtering, washing and drying to obtain the lithium carbonate product. The process has no "three wastes" emissions, spodumene resources are efficiently used, lithium element in the spodumene resources is transformed into the lithium carbonate, silicon and aluminum elements in the spodumene resources are transformed into the analcime, meanwhile most of Li2O in the spodumene is dissolved out, the cost of lithium salt preparation is reduced, and the method is easy to promote and implement.

Owner:昊青薪材(北京)技术有限公司

Cementing compositions containing substantially spherical zeolite

ActiveUS20070029088A1Good physical propertiesImprove flexural strengthDrilling compositionSealing/packingPortland cementNatrolite

Owner:BAKER HUGHES HLDG LLC

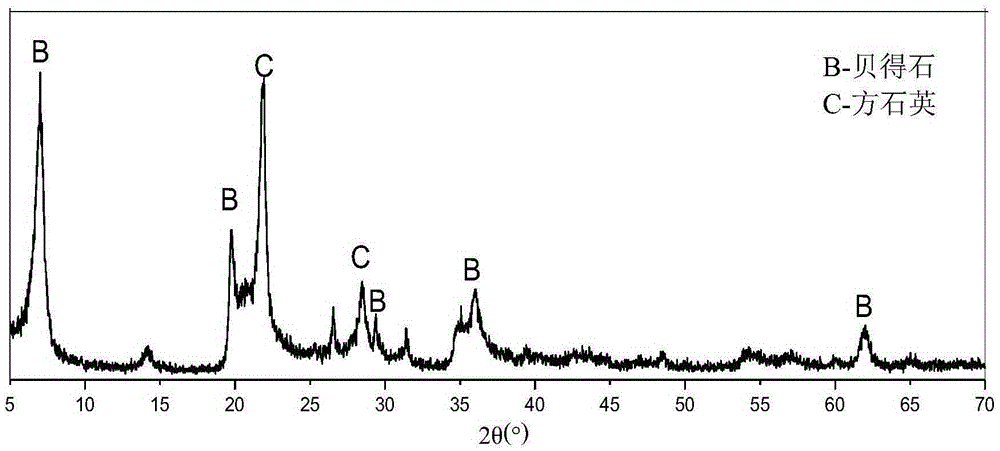

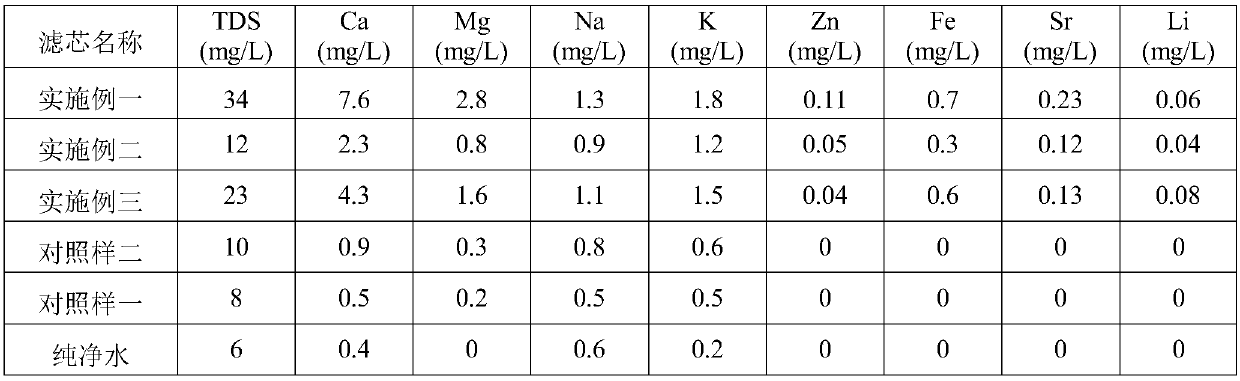

Mineral filtering material and preparation method thereof, and filtering core obtained from mineral filtering material

InactiveCN110833723ALightweightEasy to useTreatment involving filtrationWater/sewage treatment by substance additionFiberRhodochrosite

The invention discloses a mineral filtering material and a preparation method thereof, and a filtering core obtained from the mineral filtering material, wherein the mineral filtering material comprises the following raw materials by weight: 9-24 parts of secondary quartzite, 3-8 parts of feldspar quartz sandstone, 2-5 parts of rhodochrosite, 20-40 parts of zeolite, 10-30 parts of active carbon particles, 5-20 parts of active carbon fibers and 20-40 parts of a binder, wherein the rhodochrosite is a mixture of iron rhodochrosite and zinc rhodochrosite according to a weight ratio of 1-3:2, and the zeolite is a mixture of phillipsite and analcime according to a weight ratio of 1-3:1. The invention further provides a preparation method of the filtering material and a filtering core prepared from the filtering material. According to the invention, the filtering core capable of stably releasing mineral substances beneficial to growth and development of infants is obtained by utilizing natural rock materials through reasonable matching, and is environmentally friendly, free of secondary pollution and free of heavy metal exceeding the standard, wherein the TDS of the water mineralized by the filtering core is kept at 10-40 mg / L.

Owner:QINGDAO HAIER STRAUSS WATER EQUIP CO LTD

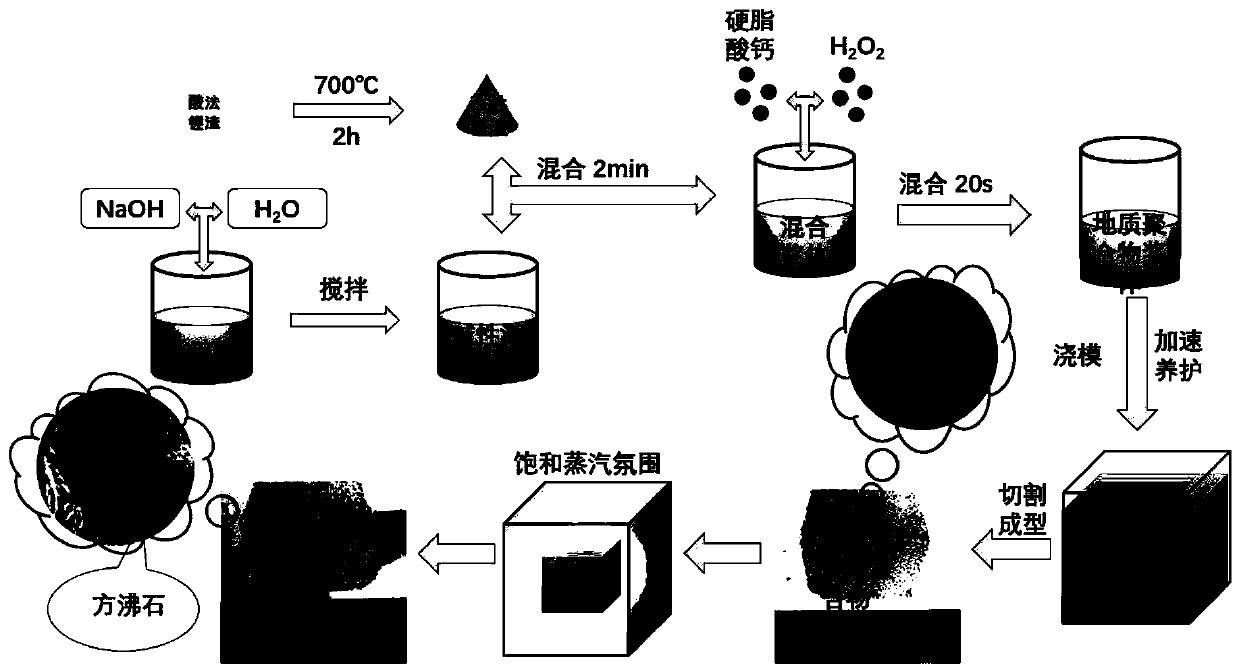

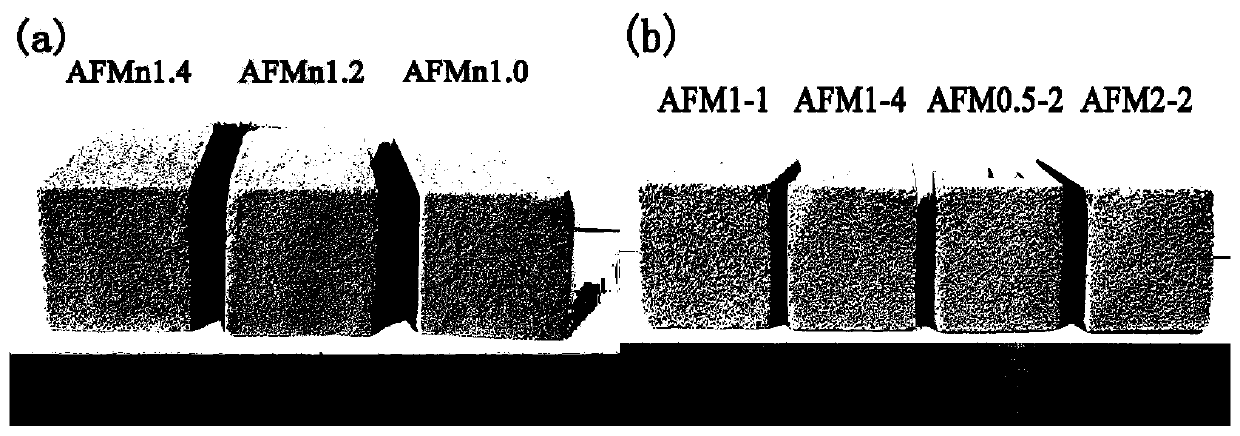

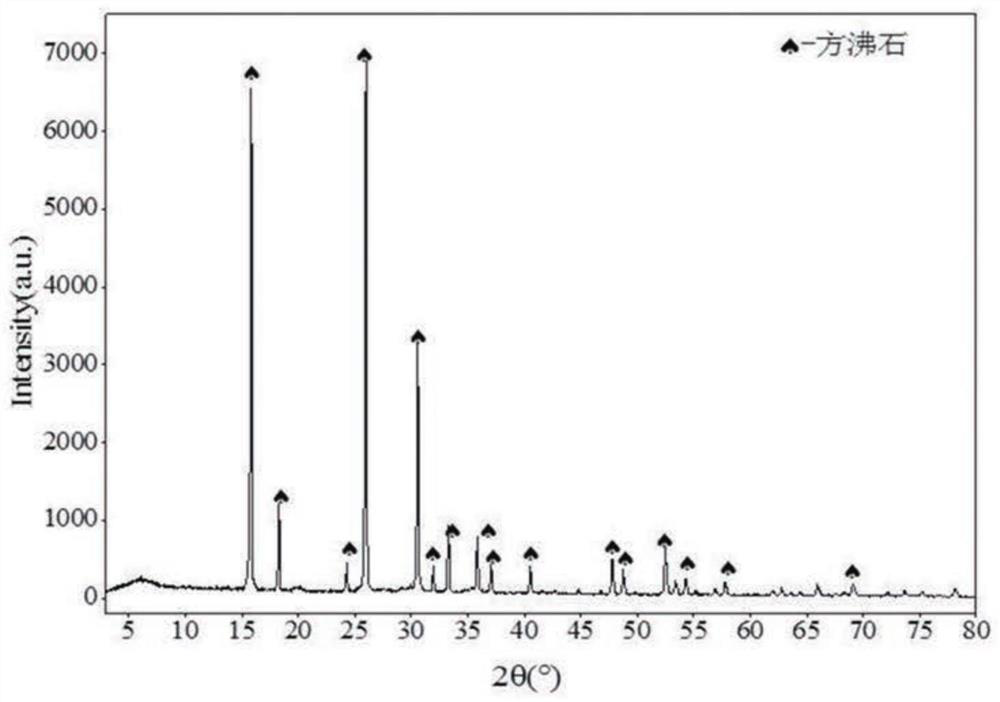

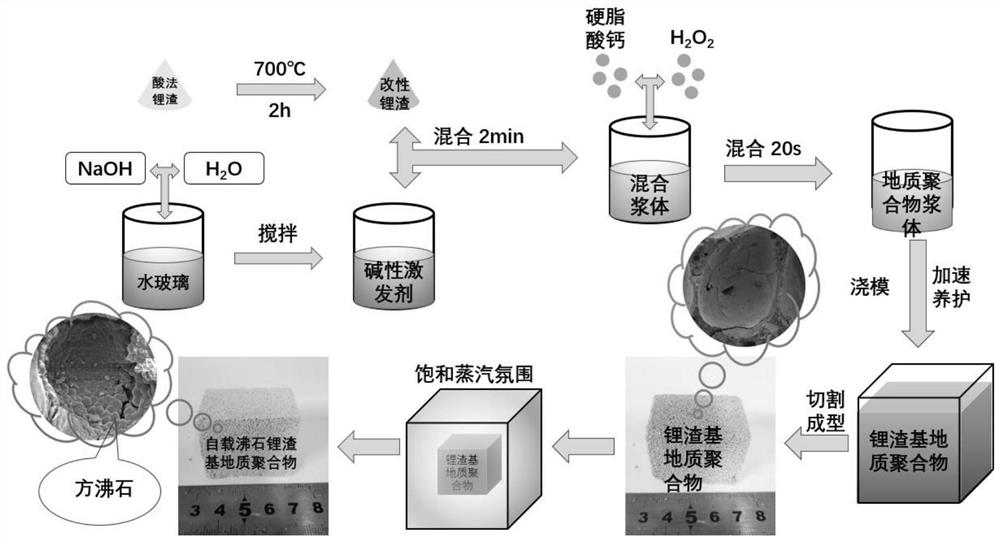

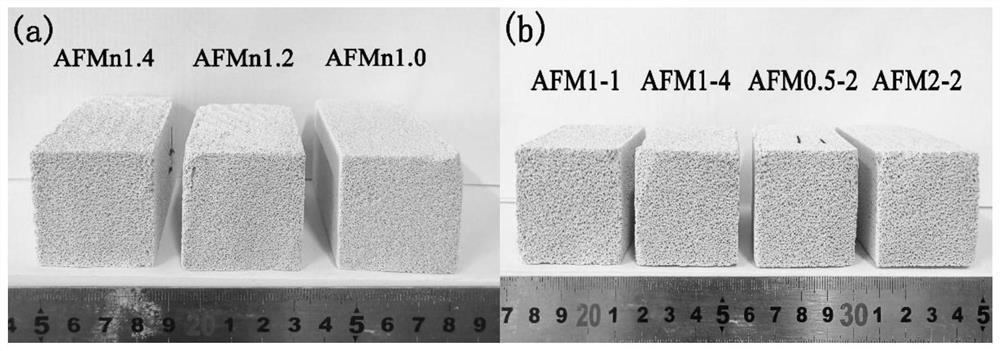

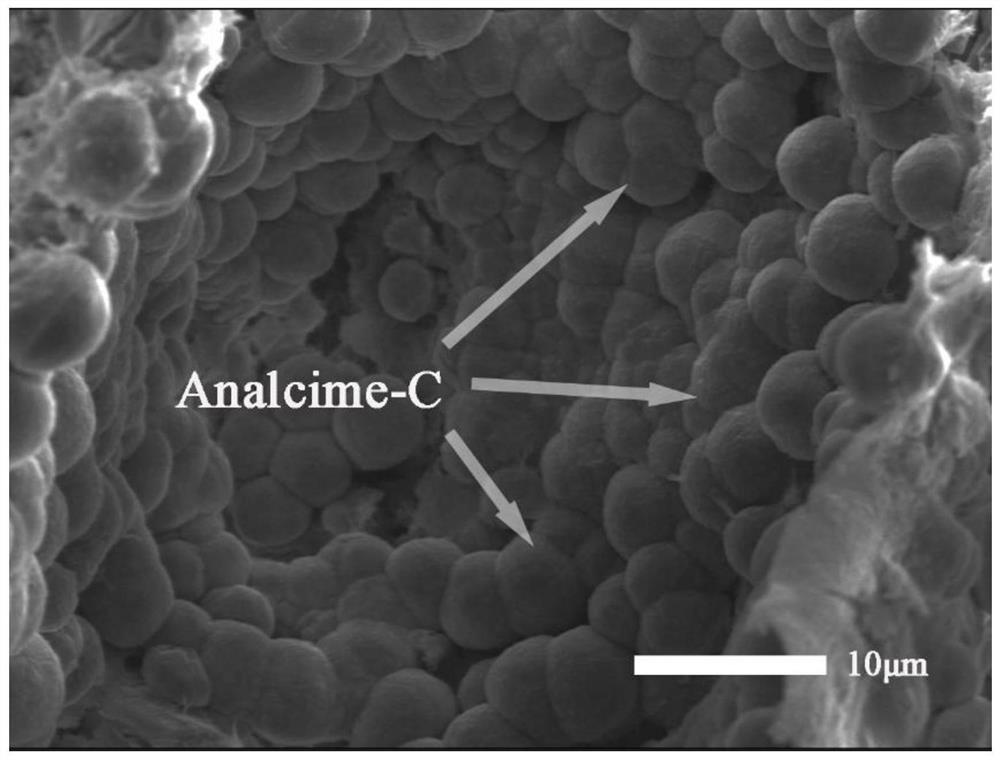

Porous self-loading zeolite material prepared from acid-process lithium slag as well as preparation method and application of porous self-loading zeolite material

ActiveCN111018422AHigh activityProtection Mechanical PropertiesOther chemical processesSolid waste managementPorosityLithium

The invention provides a porous self-loading zeolite material prepared from acid-process lithium slag as well as a preparation method and application of the porous self-loading zeolite material, and relates to the technical field of zeolite materials. The method comprises the steps: calcining the acid-process lithium slag to obtain modified lithium slag; mixing the modified lithium slag with an alkaline activator, a foaming agent and a foam stabilizer, and sequentially carrying out molding and accelerated maintenance to obtain a lithium slag-based geopolymer foaming material; and carrying outsaturated steam curing on the lithium slag based geopolymer foaming material to obtain the porous self-loaded zeolite material. The prepared porous self-loaded zeolite material is low in volume weightand high in porosity and is loaded with analcime; meanwhile, the porous self-loaded zeolite material has a solid blocky adsorbent having certain compressive strength; the porous self-loaded zeolite material has more excellent adsorption performance than fly ash-based geopolymer, kaolin-based geopolymer and lithium slag-based geopolymer materials, can be applied to adsorption of heavy metal ions,solves the problem of accumulation of lithium slag solid wastes, protects the environment and saves resources.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for measuring analcime in clastic rock

The invention discloses a method for quickly and accurately measuring analcime in clastic rock under an orthogonal polarizing microscope, and belongs to the technical field of measurement methods. The method includes the preparation of rock flake in the clastic rock, and specifically has the following steps of inserting a gypse test plate in a corresponding position of the orthogonal polarizing microscope; fixing the rock flake on an objective table of the orthogonal polarizing microscope; and measuring the content of analcime in the rock flake. Through adopting the method, the analcime can be separated from quartz, feldspath and carbonate mineral under the orthogonal polarizing microscope, and the content of analcime in the clastic rock can be further measured, therefore, the utility value is realized.

Owner:PETROCHINA CO LTD

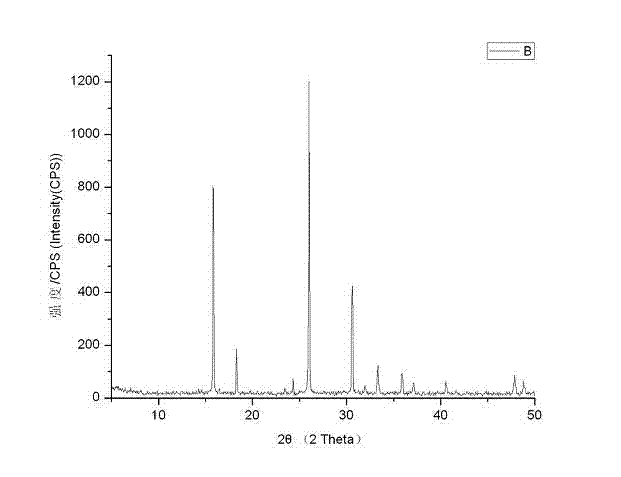

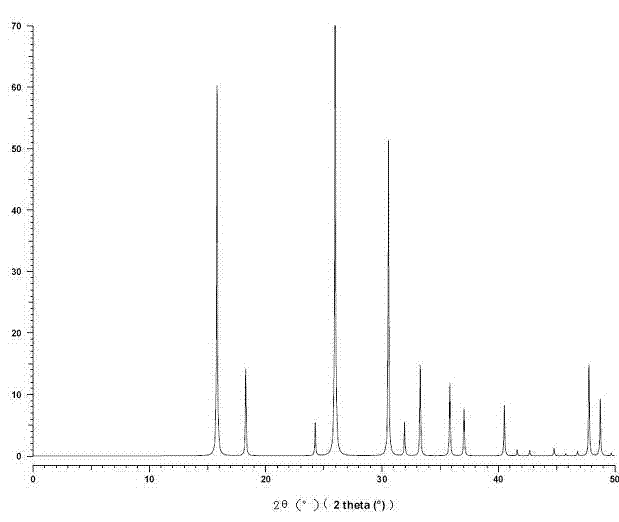

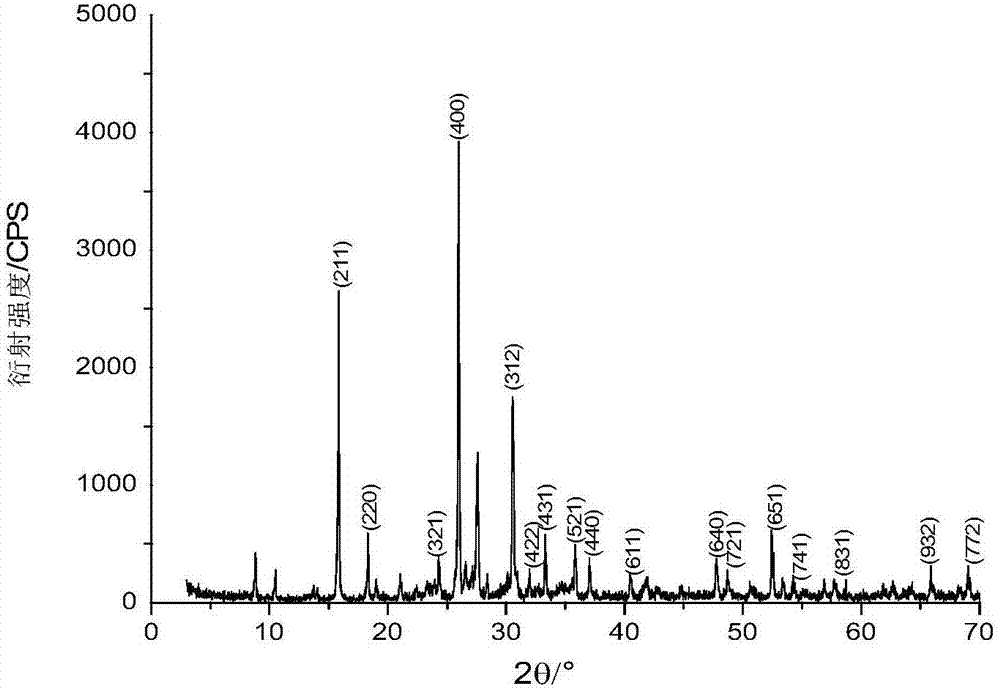

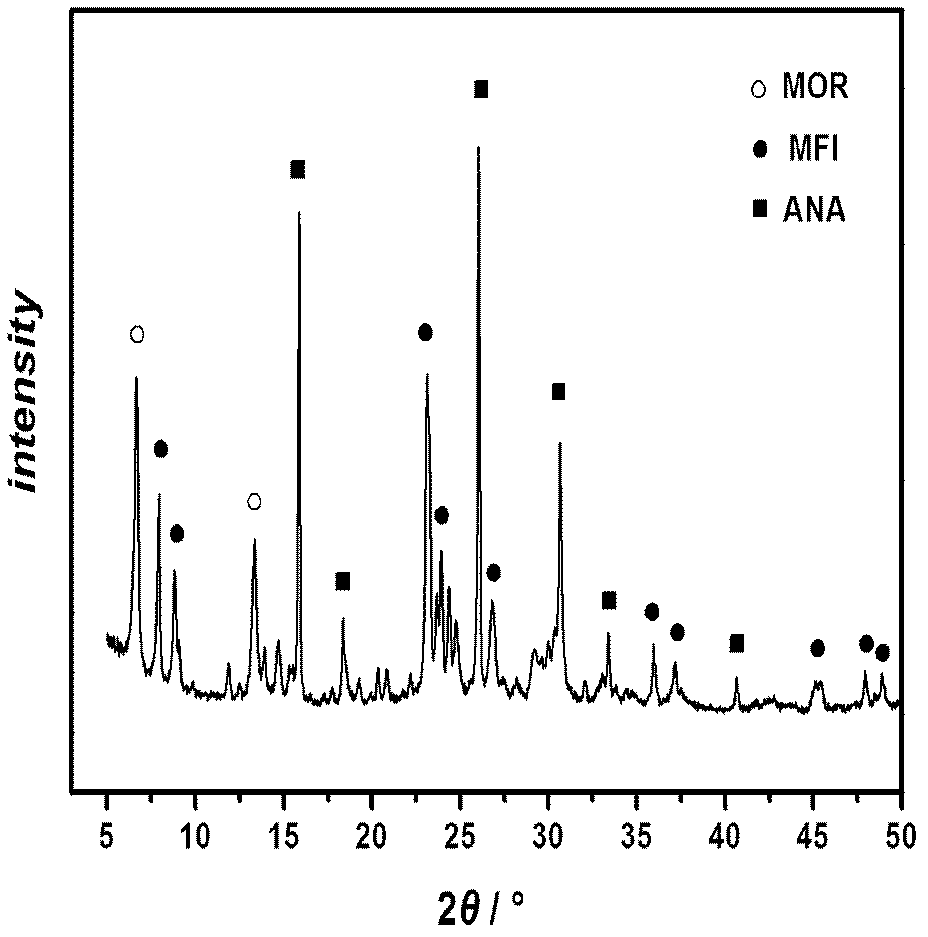

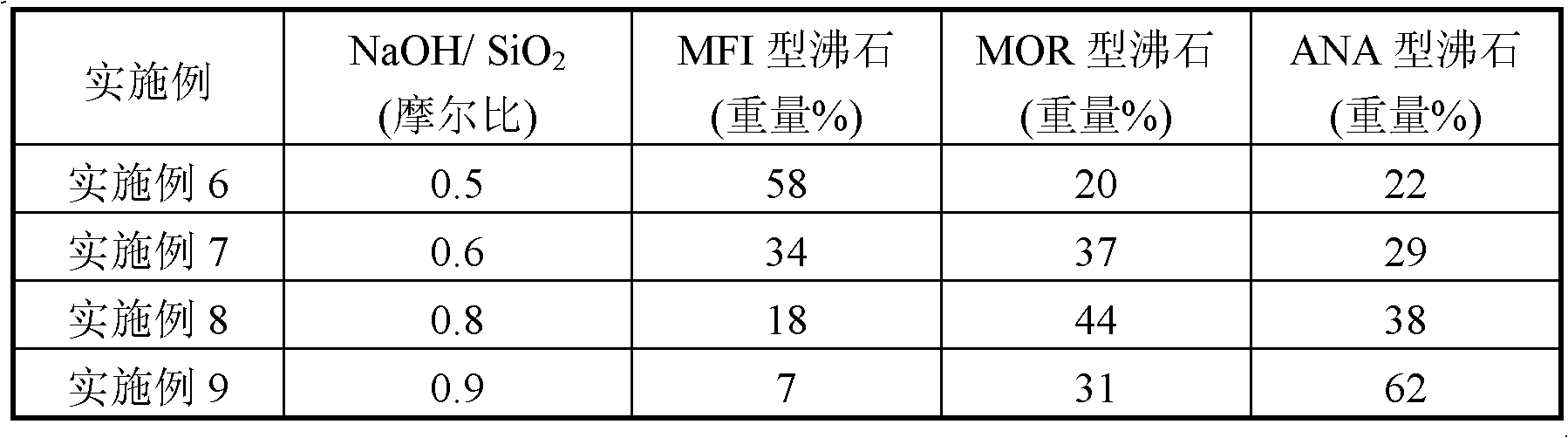

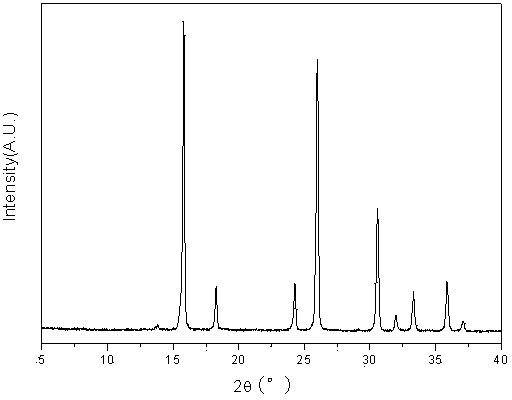

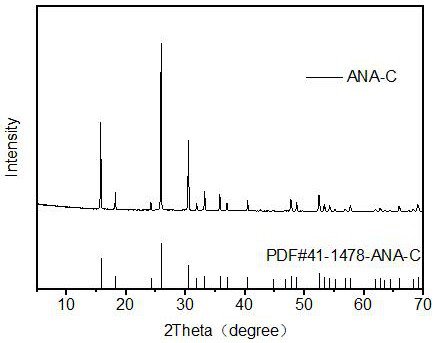

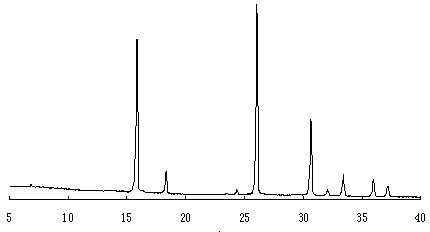

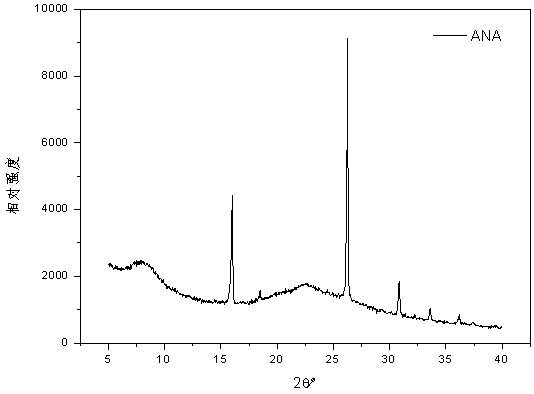

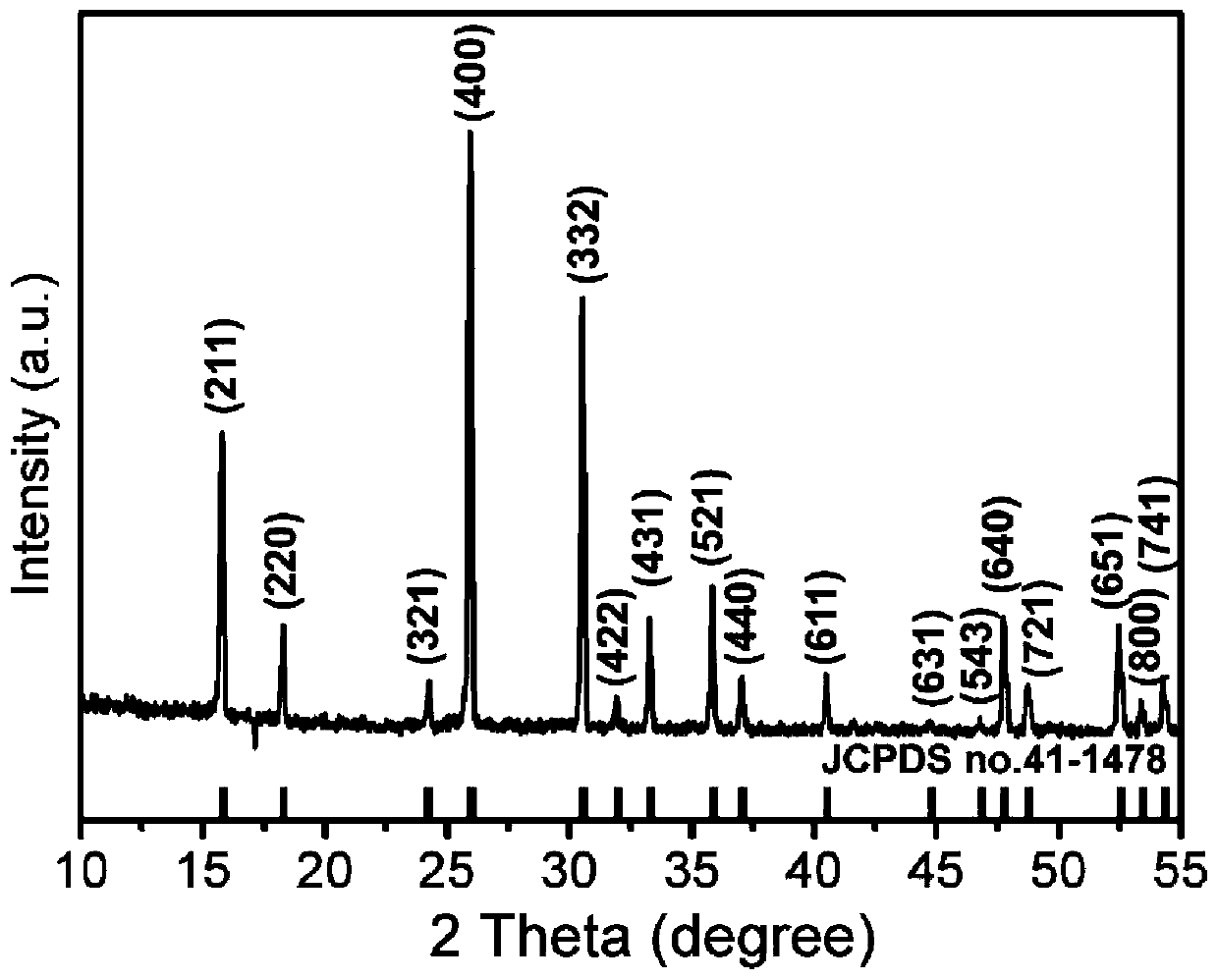

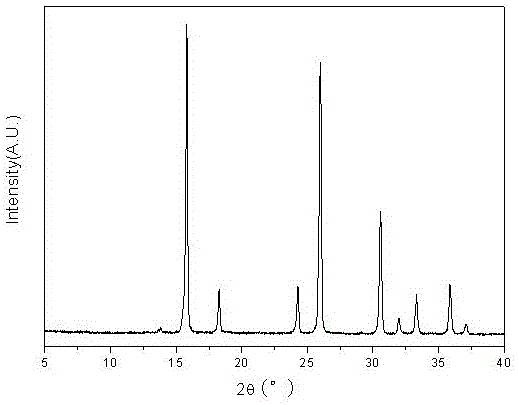

MFI (ZSM-5 zeolites)/MOR (Mordenite)/ANA (Analcime) type porous zeolite intergrowth material and preparation method thereof

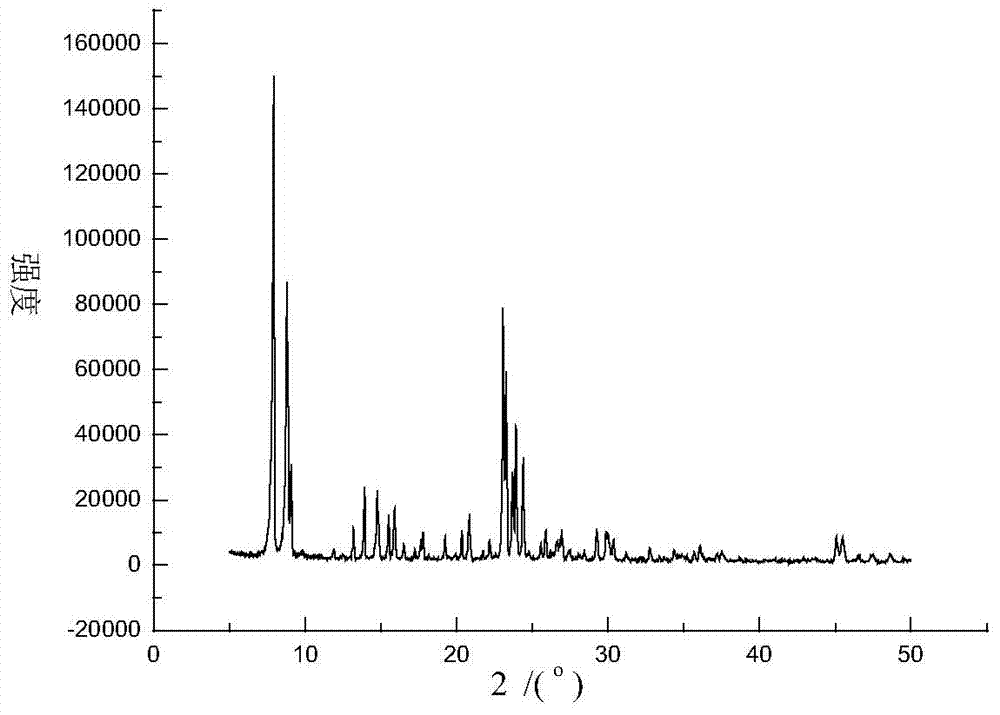

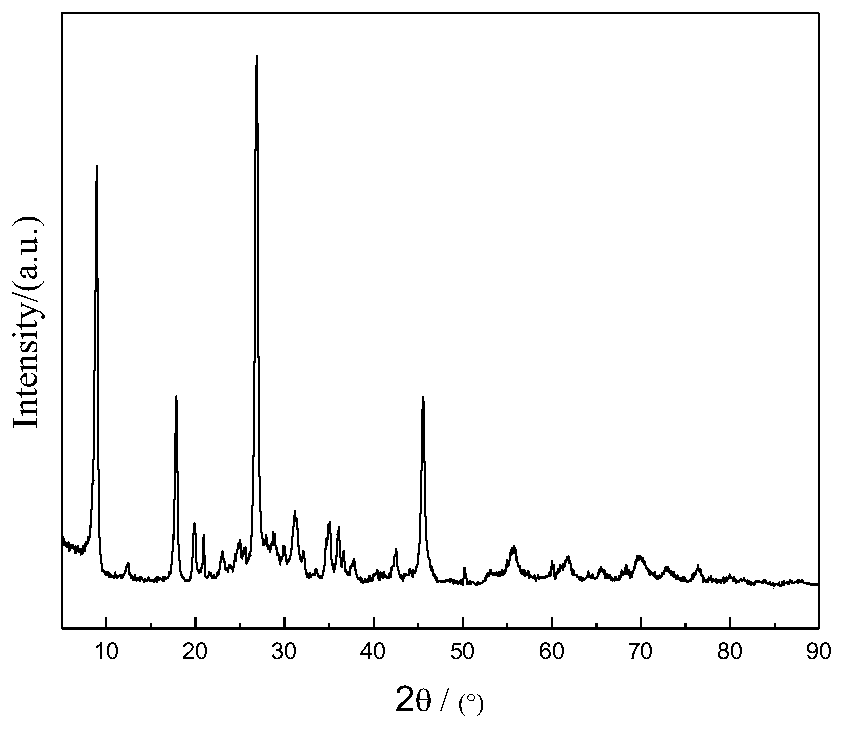

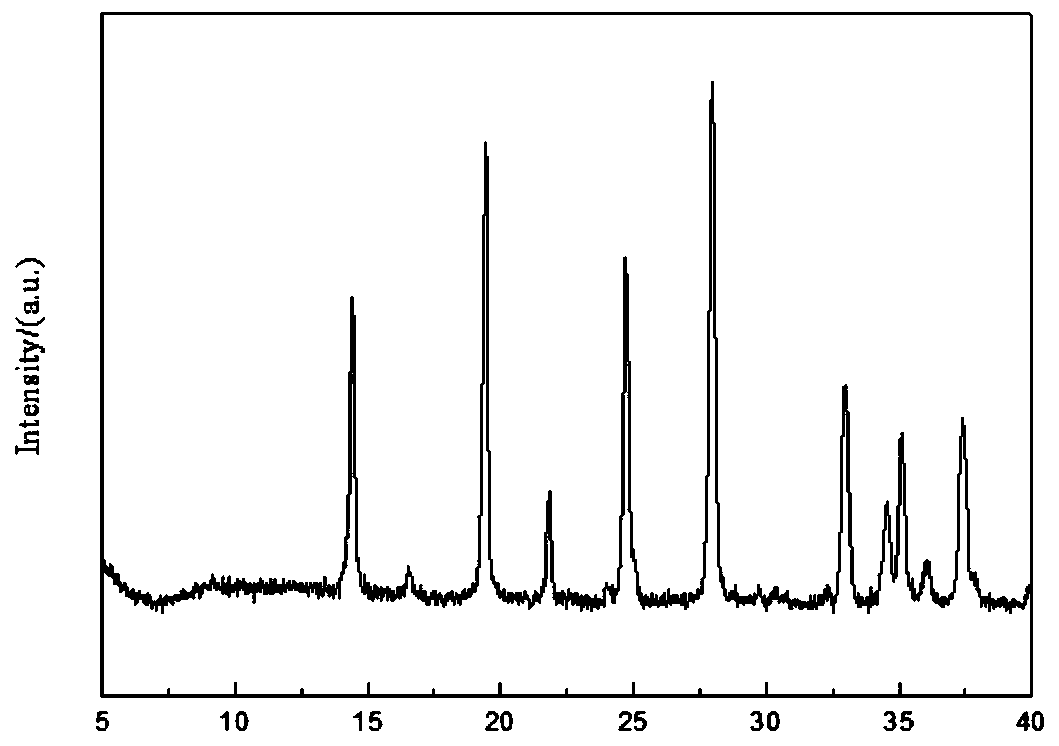

ActiveCN103121692AEmission reductionWidely distributedCrystalline aluminosilicate zeolitesX-rayMordenite

The invention relates to an MFI (ZSM-5 zeolites) / MOR (Mordenite) / ANA (Analcime) type porous zeolite intergrowth material and a preparation method thereof and mainly aims to solve the problems of single aperture and higher cost of a porous material synthesized by using the prior art. The problems are better solved by using the technical scheme as follows: the porous zeolite intergrowth material is prepared by using a method for realizing whole crystal transformation by utilizing seed crystal induction, wherein the intergrowth biophase is adjustable in proportion, and the synthesized porous intergrowth material comprises the following components in molar relation: nSiO2:Al2O3, wherein n ranges from 4 to infinity, and an XRD (X-Ray Diffraction) pattern 2 theta has characteristic diffraction peaks at the following positions: 6.51+ / -0.02, 7.95+ / -0.03, 8.84+ / -0.02, 13.45+ / -0.03, 15.81+ / -0.03, 18.28+ / -0.03, 23.18+ / -0.02, 23.32+ / -0.01, 25.96+ / -0.03, 30.54+ / -0.02, 33.27+ / -0.03 and 35.82+ / -0.02. The MFI / MOR / ANA type porous zeolite intergrowth material and the preparation method thereof can be used for industrial production of analysis and adsorption separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

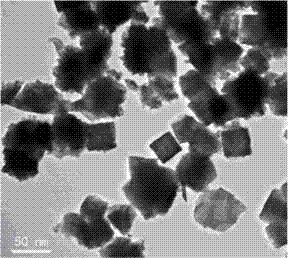

Nano-scale ultra-fine analcime preparation method

ActiveCN106672991APrevent crystallizationReduce dosageMaterial nanotechnologyCrystalline aluminosilicate zeolitesUltra fineCrystallinity

The present invention discloses a nano-scale ultra-fine analcime preparation method, wherein an alkali source, a silicon source, an aluminum source, water and N-methylpyrrolidine are adopted as reaction raw materials and crystallization is performed for 5-200 h under autogenous pressure and 140-200 DEG C hydrothermal condition to obtain the small grain nanometer analcime. According to the present invention, the obtained nano-scale ultra-fine analcime has characteristics of simple process, pure crystal phase, high crystallinity, large specific surface, low cost and the like, and has wide application prospects in ion adsorption and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nanometer negative ion functional material for board and preparation method of material

InactiveCN106007658AImprove adsorption capacityEfficient decompositionGas treatmentDispersed particle separationHigh concentrationHazardous substance

The invention discloses a nanometer negative ion functional material for a board and a preparation method of the material. The material is prepared from, by weight, 18-27 parts of opal, 12-19 parts of fly ash, 23-31 parts of Guilin stone, 10-15 parts of illite, 15-20 parts of high-temperature activated bamboo carbon powder, 16-22 parts of basalt, 20-30 parts of medical stone, 17-26 parts of analcime, 11-17 parts of pumice and 6-12 parts of light calcined powder. According to the prepared nanometer negative ion functional material, opal, Guilin stone, high-temperature activated bamboo carbon powder, basalt, medical stone, analcime and pumice serve as the main materials, the material can emit high-concentration negative ions, has excellent adsorption performance and bioactivity and can efficiently adsorb and decompose formaldehyde, benzene, VOC and other harmful matter in air, the elimination rate is as high as 95% or above, and accordingly the aims of purifying air and improving the living environment are achieved.

Owner:沈平

Method for preparing novel analcite by adding spatial steric hindering agent

ActiveCN104291348AChange direction of growthExtended Crystalline Framework TypesSolid waste disposalCrystalline aluminosilicate zeolitesAluminium hydroxideAmmonium hydroxide

The invention relates to a method for preparing novel analcite by adding a spatial steric hindering agent. The method comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and aluminum hydroxide by using activated coal ash; and III, synthesizing novel analcite: uniformly mixing an aluminum hydroxide and sodium silicate solution which is treated by coal ash, water and the spatial steric hindering agent M, stirring the mixed materials, carrying out hydro-thermal synthesis for 8-24 hours, and washing, drying and roasting products in a reaction kettle to obtain the novel analcite, wherein the molar ratios of the reaction mixture are as follows: Na2SiO3 / Al(OH)3=40-300, Na2SiO3 / M=2.5-5.0, and Na2SiO3 / H2O=0.01-0.025; the spatial steric hindering agent M is a mixed solution of one of ethanol amine, diethanol amine and triethanolamine with tetrapropylammonium hydroxide and the molar ratio of the two components in the solution is 1 to (5-50). The method provided by the invention is used for synthesizing high-purity novel analcite based on four-membered rings and five-membered rings by adding the spatial steric hindering agent to change the growing directions of crystals.

Owner:哈尔滨市金博达机电有限公司

Method for preparing analcite from loess based on loess plateau

InactiveCN110980757ASimple processing methodGood for industrializationCrystalline aluminosilicate zeolitesPhysical chemistryLoess plateau

The intention discloses a method for preparing analcite by using loess, the crystal type is analcite, and the morphology is a sphere-like polyhedron structure. The method comprises the following steps: uniformly mixing the loess, inorganic alkali, a silicon source and water according to a certain material ratio to obtain silica-alumina gel, aging to obtain an activated precursor, transferring theprecursor to a closed reactor, carrying out hydrothermal crystallization treatment, carrying out solid-liquid separation, washing, and drying to obtain the analcite product. The analcite preparation method provided by the invention is simple and feasible, mild in condition and low in cost, and resource utilization of the loess is realized by taking the loess as a preparation raw material.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Method for synthesizing analcime by microwave hydrothermal crystallization of coal gangue

ActiveCN112811435ASolve the pollution of the environmentWide variety of sourcesCrystalline aluminosilicate zeolitesEnergy based chemical/physical/physico-chemical processesMolecular sievePhysical chemistry

The invention discloses a method for synthesizing analcime from coal gangue through microwave hydrothermal crystallization, which comprises the following steps: firstly, activating the coal gangue through CaO ball milling, then digesting, activating and dissolving out aluminosilicate by utilizing a microwave synthesizer, and further synthesizing an analcime molecular sieve by adopting a hydrothermal method. Material selection is economical, cost is low, and high-added-value utilization of solid waste is achieved; the synthesis method is simple, synthesis is achieved through a microwave-assisted hydrothermal synthesis method, analcime is prepared through washing, centrifuging and drying, data is detailed and accurate, and the synthesis process does not pollute the environment.

Owner:TAIYUAN UNIV OF TECH

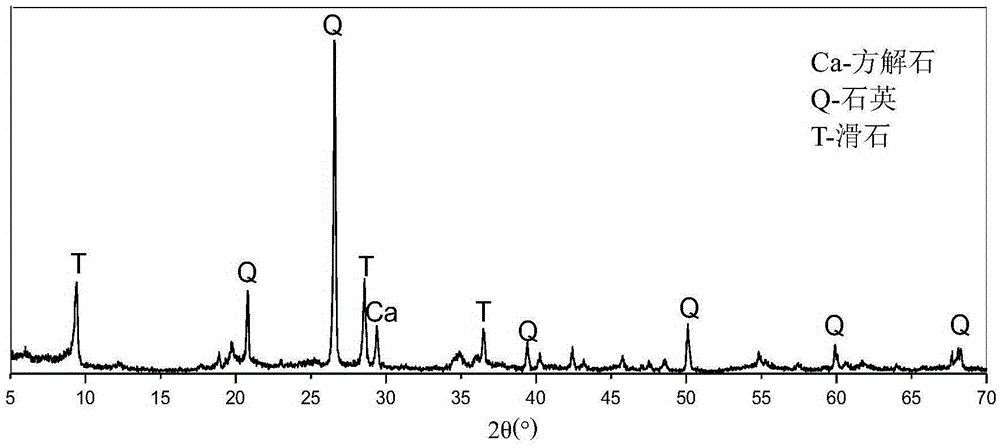

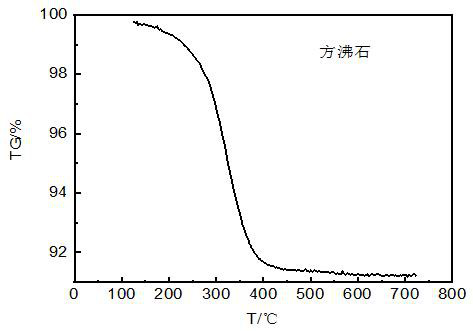

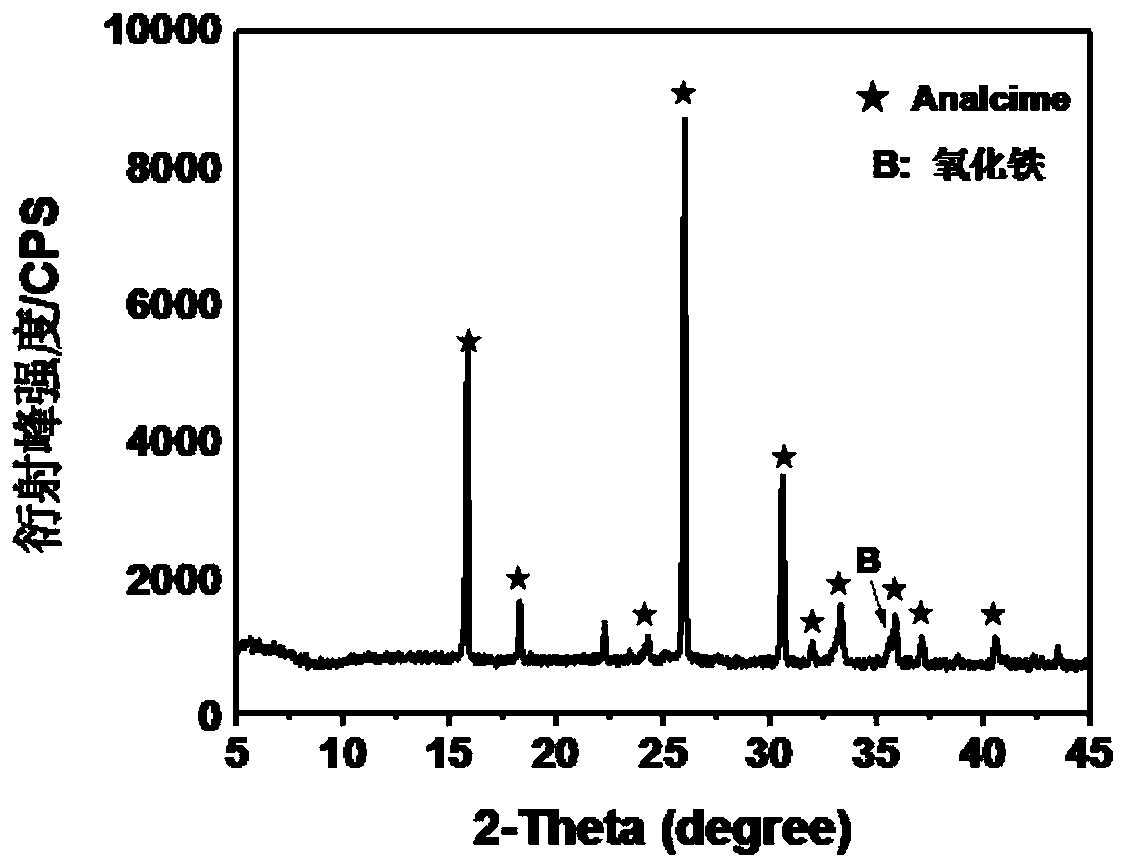

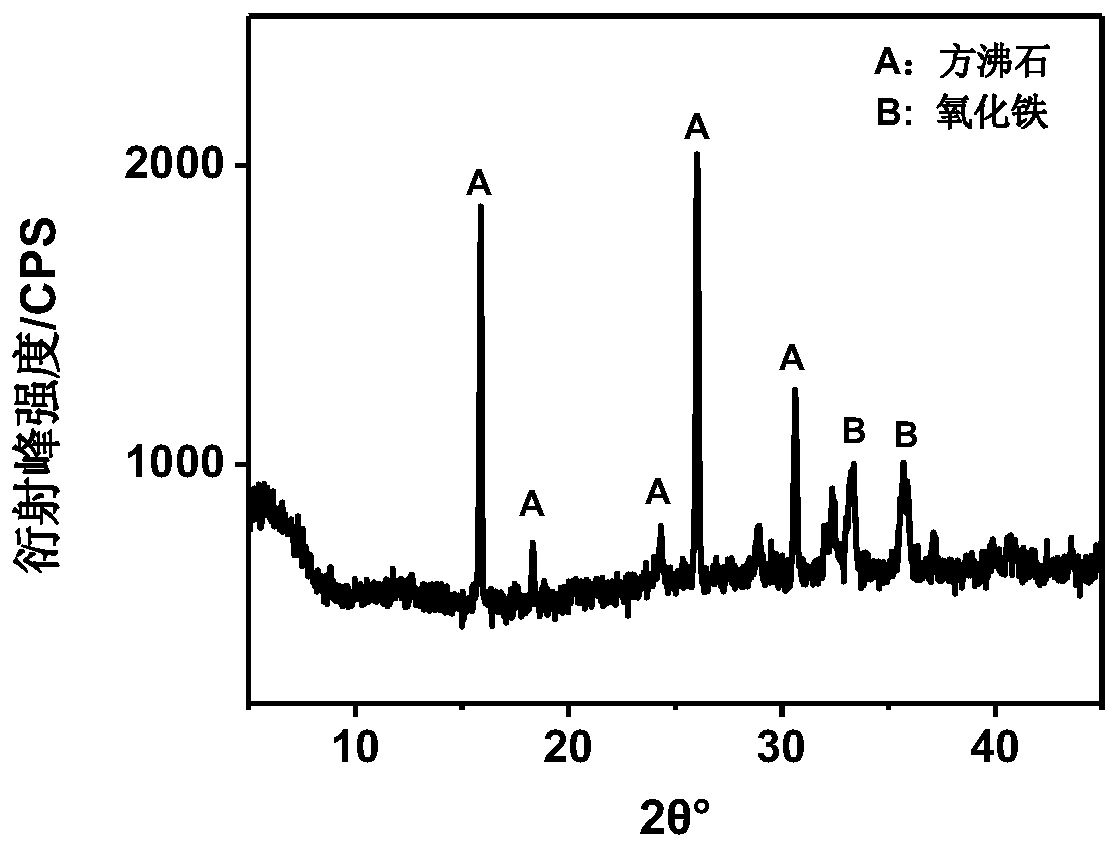

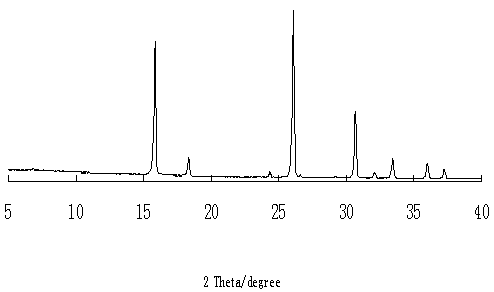

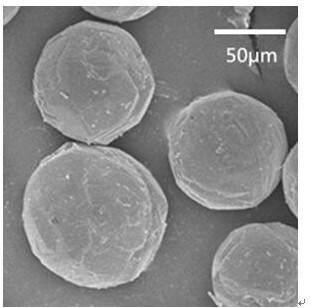

Process for synthesis of analcime from red mud by hydrothermal alkaline method

InactiveCN110775985ASimple processMaterials are cheap and easy to getMolecular-sieve and base-exchange compoundsRed mudIron oxide

The invention discloses a process for synthesis of analcime from red mud by hydrothermal alkaline method. The crystal form is analcime, and the morphology is spherical. The synthesis method of analcime includes: mixing red mud containing an aluminum source and part of a silicon source, inorganic alkali, an additional silicon source and water uniformly according to a certain material ratio to obtain mixed gel, then carrying out aging and crystallization treatment, and finally conducting washing and drying to obtain a product containing analcime and a small amount of ferric oxide. The analcime provided by the invention is good in crystal form, and the preparation method is simple and feasible.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

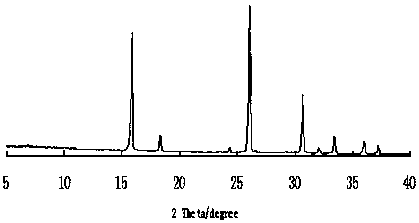

Large-size analcite and synthesis method thereof

ActiveCN109928403APromote growthSolve problems that are difficult to synthesizeCrystalline aluminosilicate zeolitesSynthesis methodsSpherical shaped

The invention discloses large-size analcite and a synthesis method thereof, wherein the type of the crystal is analcite, the morphology comprises a bulk shape and a spherical shape, and the large-sizeanalcite has a large particle size. The synthesis method comprises: uniformly mixing an inorganic alkali, a silicon source, an aluminum source and water according to a certain ratio to obtain a silicon-aluminum gel, carrying out aging treatment on part of the obtained silicon-aluminum gel, mixing the aged silicon-aluminum gel and the remaining part, carrying out crystallization treatment, separating, washing, and drying to obtain analcime. According o the present invention, the prepared analcite has large particle size, and the preparation method is simple and easy to perform.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method used for illite microwave heating solid-like-phase steam conversion method synthesis of analcime

ActiveCN110395743AImprove efficiencyOvercome technical difficulties in potassium extractionCrystalline aluminosilicate zeolitesMass ratioPotassium

The invention discloses a method used for illite microwave heating solid-like-phase steam conversion method synthesis of analcime, and belongs to the technical field of illite synthesis of zeolite andsylvine extraction. The method comprises following steps: natural illite is crushed, and is subjected to ball milling to obtain illite powder with particle size of 80 to 200 meshes; the illite powderand solid sodium hydroxide are mixed to be uniform at a certain mass ratio, and are introduced into a microwave digestion tank for processing, wherein in the microwave digestion tank, the solid / liquid ratio of solvent (water) to an obtained mixed material is controlled to be 2 to 5g / ml; after reaction, an obtained solid mixture is subjected to filtering, washing until pH value is 7, and drying soas to obtain solid analcime, and an obtained filtrate is a sodium potassium silicate solution, and can be used for preparation of sylvite products. The method is capable of realizing high extractionof potassium without high temperature roasting in high added value development of illite resource, and cheap raw materials and technology suitable for large scale industrialized production are provided for analcime synthesis.

Owner:YANBIAN UNIV

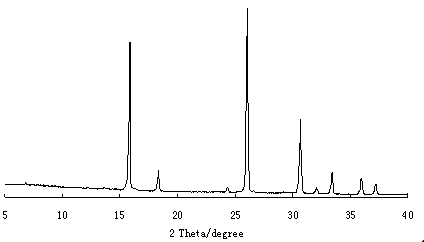

Analcite and synthesis method thereof

ActiveCN109928406AWith large particle sizeSimple manufacturing methodMolecular-sieve and base-exchange compoundsSynthesis methodsSpherical shaped

The invention discloses analcite and a synthesis method thereof, wherein the type of the crystal is analcite, the morphology comprises a bulk shape and a spherical shape, and the analcite has a largeparticle size. The synthesis method comprises: uniformly mixing an inorganic alkali, a silicon source, an aluminum source and water according to a certain ratio to obtain a silicon-aluminum gel, carrying out aging treatment on part of the obtained silicon-aluminum gel, mixing the aged silicon-aluminum gel and the remaining part, preparing a dry gel, carrying out crystallization treatment, separating, washing, and drying to obtain analcime. According o the present invention, the prepared analcite has large particle size, and the preparation method is simple and easy to perform.

Owner:CHINA PETROLEUM & CHEM CORP +1

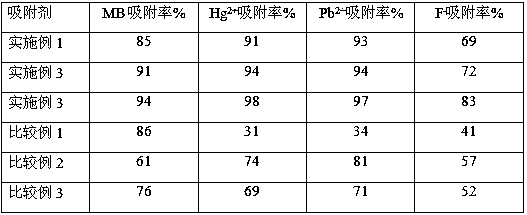

Composite adsorption material and preparation method thereof

ActiveCN108786722AEffective adsorption and removalSimple methodOther chemical processesWater/sewage treatment by sorptionIonAnalcime

The invention discloses a composite adsorption material and a preparation method thereof. The composite adsorption material comprises 5-50% of fly ash, 10-50% of activated carbon and 5-60% of nano analcime, wherein the fly ash and the analcime are integrally connected through the activated carbon. The specific surface area of the composite adsorption material is 300-1500m<2> / g, the pore volume ofthe composite adsorption material 0.3-1.5cm<3> / g, and the mechanical strength of the composite adsorption material is 5-25N / mm. The preparation method includes: mixing the fly ash, the superfine analcime and water-soluble phenolic resin, forming and performing high-temperature curing. The composite adsorption material can adsorb various organic pollutants and heavy metal ions in wastewater in a broad spectrum manner.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature green synthesis method of zeolite molecular sieve material by taking southern red soil as raw material

InactiveCN111099608AHigh crystallinitySingle crystal phaseChemical industryCrystalline aluminosilicate zeolitesMolecular sieveEnvironmental engineering

The invention relates to a low-temperature green synthesis method for preparing analcime from red soil, and belongs to the technical field of chemical preparation of environmental ecological materials. The preparation method of the zeolite material comprises the following steps: by taking red soil as a reaction raw material, directly preparing a high-crystallinity single-crystalline-phase analcimeproduct by adopting a hydrothermal method. By using southern natural soil as the raw material, the cost is low; the technological process is simple and easy to industrialize; the synthesis steps do not involve a high-temperature process, and the process path is energy-saving and environment-friendly; the prepared zeolite product has a single analcime crystal phase, and the grain size is about 80-90 microns.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Analcime/chitosan composite material and preparation method thereof and application of composite material as heavy metal adsorption material

InactiveCN111715193ASolve pollutionSynthesis conditions are simpleOther chemical processesWater contaminantsSlagComposite material

The invention discloses an analcime / chitosan composite material and a preparation method thereof, and application of the analcime / chitosan composite material as a heavy metal adsorption material. Thepreparation method of the analcime / chitosan composite material comprises the following steps: firstly, preparing analcime by taking electrolytic manganese slag as a raw material; then, modifying the surface of analcime with chitosan so as to obtain the analcime / chitosan composite material which has uniform particles and is rich in micropores and mesopores. By adding the analcime / chitosan compositematerial into heavy metal wastewater, the purpose of quickly and efficiently adsorbing and enriching heavy metals can be achieved, the synthesis condition of the analcime / chitosan composite materialis simple, operation is convenient, and a new thought is provided for a resource utilization technology of solid wastes while the problem of electrolytic manganese residue pollution is solved.

Owner:WUHAN UNIV

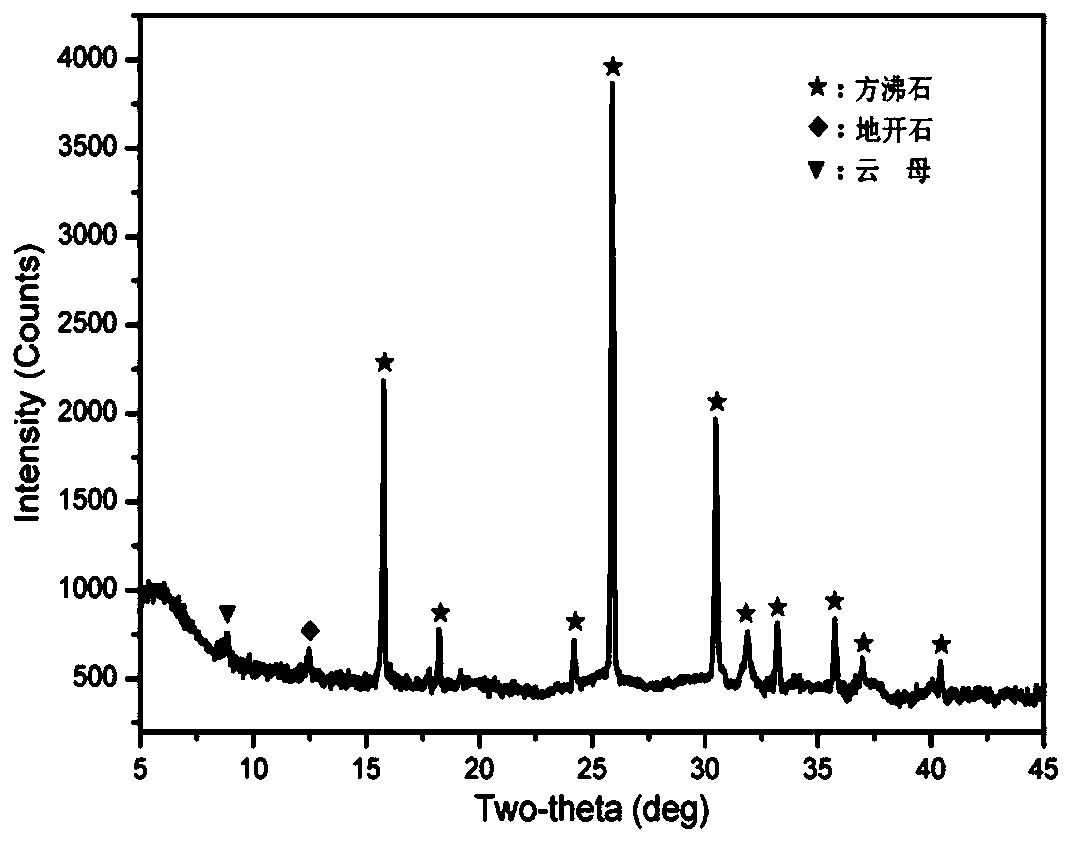

Method for synthesizing analcime from illite clay by hydrothermal alkali method and analcime

ActiveCN113479902AHas economic valueLow costWater contaminantsCrystalline aluminosilicate zeolitesMineralogyReagent

The invention provides a method for synthesizing analcime from illite clay by a hydrothermal alkali method and analcime. The method for synthesizing analcime from illite clay by a hydrothermal alkali method comprises the following steps of: mixing illite powder with inorganic alkali, a silicon-containing auxiliary agent and a solvent, and aging to obtain a suspension of the reaction materials; performing hydro-thermal synthesis on the suspension of the reaction materials to obtain analcime suspension; and filtering the analcime suspension to obtain a filter cake and a filtrate, and washing and drying the filter cake to obtain analcime powder, the solvent being water or the filtrate. The method has the advantages that the technical conditions of the synthesis process are easy to realize, the synthesis method is simple in process and convenient to operate, the synthesized product is relatively high in purity and excellent in performance, the synthesis process is green and environment-friendly, and the generated filtrate can be recycled.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Porous self-supporting zeolite material prepared by acid lithium slag and its preparation method and application

ActiveCN111018422BHigh activityProtection Mechanical PropertiesOther chemical processesSolid waste managementLithiumFoaming agent

The invention provides a porous self-carrying zeolite material prepared by an acid method lithium slag, a preparation method and application thereof, and relates to the technical field of zeolite materials. In the present invention, acid-process lithium slag is calcined to obtain modified lithium slag; the modified lithium slag is mixed with an alkaline activator, a foaming agent and a foam stabilizer, and sequentially formed and accelerated maintenance is performed to obtain a lithium slag-based substrate Polymer foaming material; the lithium slag-based geopolymer foaming material is cured with saturated steam to obtain a porous self-carrying zeolite material. The porous self-carrying zeolite material prepared by the present invention is a solid block adsorbent with low bulk density, high porosity and loading analcime, and has a certain compressive strength at the same time. Geopolymers, kaolin-based geopolymers, and lithium slag-based geopolymer materials have better adsorption properties, which can be applied to the adsorption of heavy metal ions, and solve the problem of lithium slag solid waste accumulation, protect the environment and save resources.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of method that adds steric hindrance agent to prepare novel analcime

ActiveCN104291348BChange direction of growthExtended Crystalline Framework TypesSolid waste disposalCrystalline aluminosilicate zeolitesMixed materialsSODIUM SILICATE SOLN

Owner:哈尔滨市金博达机电有限公司

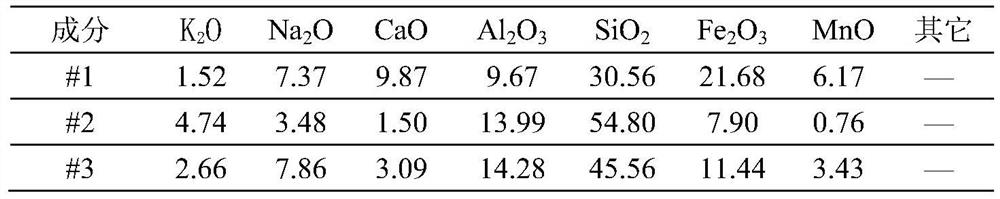

Catalytic and adsorption material prepared from deep-sea clay and method

ActiveCN113797890ALarge amount of resourcesExcellent Fenton catalytic performanceGas treatmentWater/sewage treatment by irradiationPtru catalystManganese

The invention relates to a catalysis and adsorption material prepared from deep-sea clay and a method thereof, and designs a catalysis or adsorption type material taking clay as a main body for different types of deep-sea clay according to the characteristics of chemical composition, structure and the like of the deep-sea clay. The three kinds of deep-sea clay used in the method are collected from different sea areas. The deep-sea clay is divided into iron-manganese-rich deep-sea clay, structural active deep-sea clay and silicon-aluminum-rich deep-sea clay according to the composition and structural characteristics of the deep-sea clay. The deep-sea clay with higher iron and manganese content can be directly used as a Fenton catalyst for water purification; the deep-sea clay with structural activity can be symbiotically compounded with molybdenum disulfide to serve as a photocatalyst for water disinfection; the deep-sea clay rich in silicon and aluminum can be used as a raw material for preparing zeolite molecular sieve adsorbents such as analcime, faujasite and cancrinite. The deep-sea clay with huge resource reserve in the world ocean is used as a raw material to prepare the catalysis and adsorption material for environmental restoration, and the method has innovative significance.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com