MFI (ZSM-5 zeolites)/MOR (Mordenite)/ANA (Analcime) type porous zeolite intergrowth material and preparation method thereof

A porous zeolite and zeolite technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high cost, single pore size of porous materials, etc., and achieve the effects of reducing emissions, good repeatability, and achieving wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

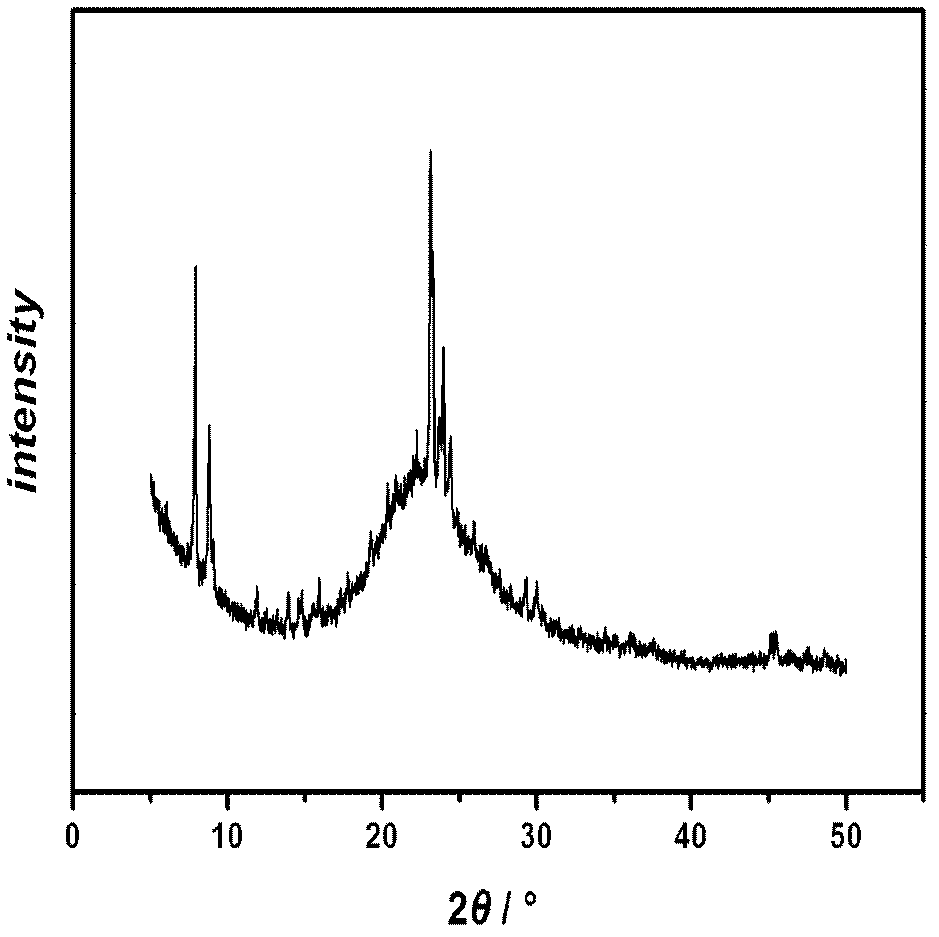

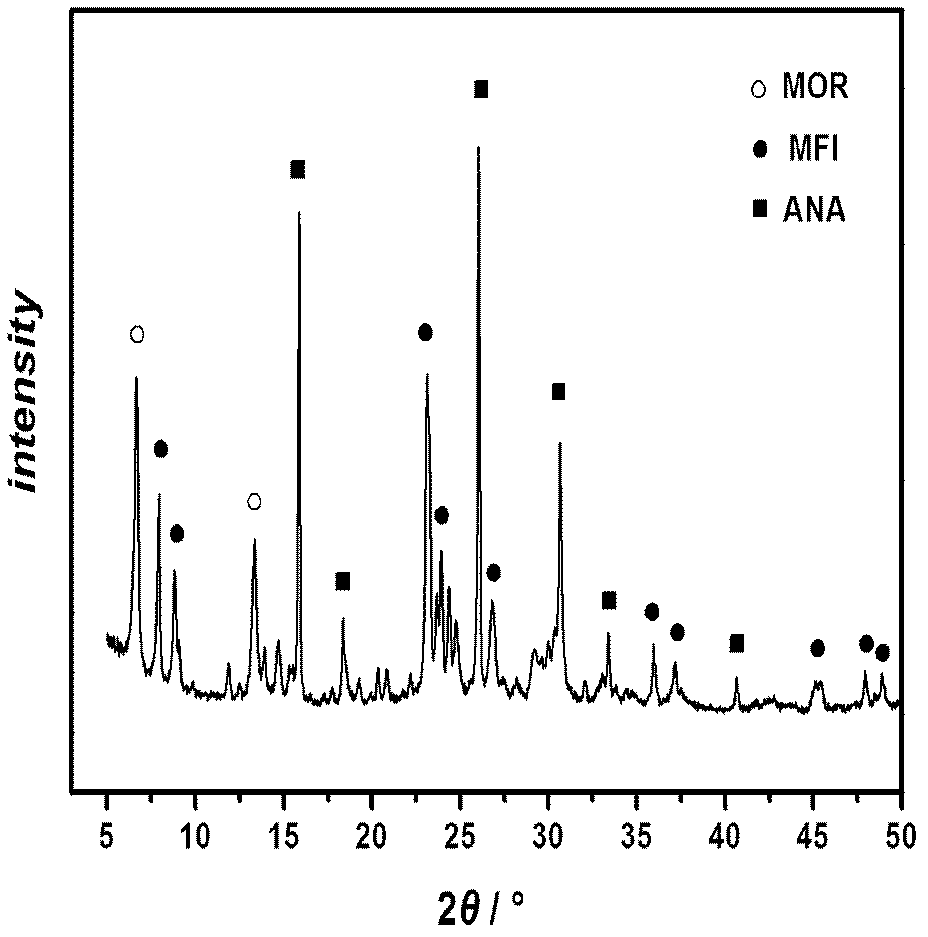

[0021] Dissolve 2.13g of NaOH and 7.1g of tetrapropylammonium bromide in 60g of deionized water, stir at 30°C until clear, then slowly add 20g of silica sol (SiO 2 40wt%) and 0.89g aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O), after continuing to stir for 18 hours, put it into a crystallization kettle and cool it after hydrothermal treatment at 100 ° C for 24 hours, so that the molar composition is SiO 2 : 0.01Al 2 o 3 : 0.2TPABr : 0.4NaOH : 30H 2 The white seed solution of O, denoted as S1, its XRD diffraction pattern is figure 1 ; Add 4.67g NaOH and 3g seed crystal solution to 27g deionized water and stir evenly, then take 10g silica gel powder and 1.11g aluminum sulfate and add them to the mixed solution. 2 The weight is based on 30% seed crystals, and the rest of the molar composition is SiO 2 : 0.01Al 2 o 3 :0.7NaOH:10H 2 The precursor solution of O was put into a crystallization kettle and crystallized at 170°C for 48 hours, cooled, washed and dried, and then roa...

Embodiment 2~5

[0023] According to the method and content provided in Example 1, the amount of aluminum sulfate added in the process of preparing seed crystals and crystal transformation was changed to 3.56 and 4.44g, 1.78 and 2.22g, 0.44 and 0.55g, 0 and 0g respectively, and synthesized respectively changed the molar composition to SiO 2 : Al 2 o 3 =25, 50, 200, ∞ MFI / MOR / ANA type porous zeolite intergrowth materials. The XRD pattern is similar to Example 1.

Embodiment 6~9

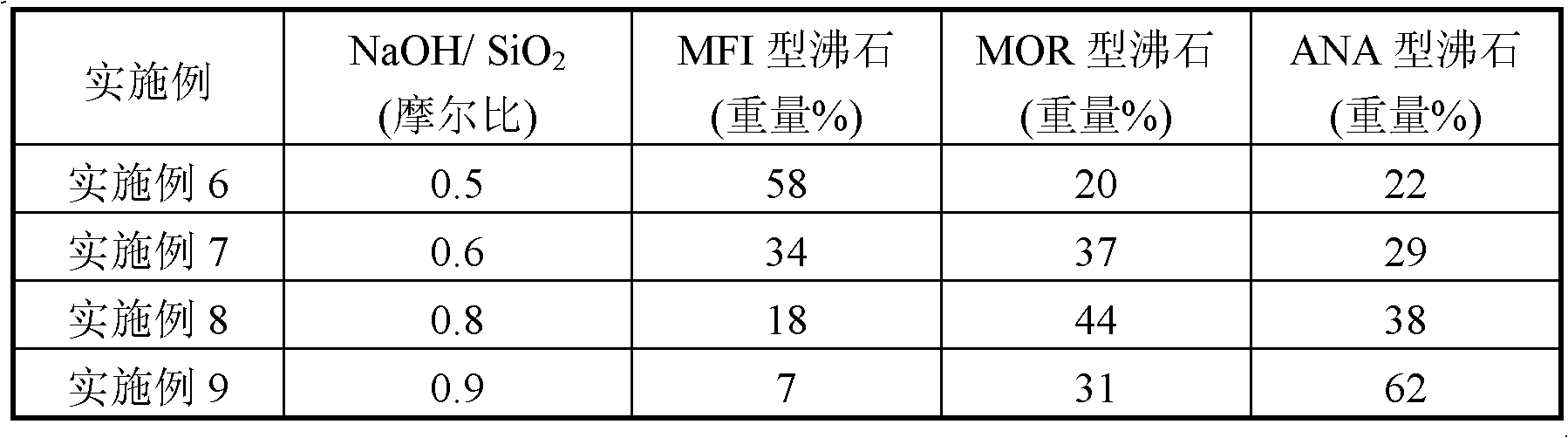

[0025] According to the method and content provided in Example 1, using the S1 seed crystal, by adjusting the NaOH / SiO 2 MFI / MOR / ANA type porous zeolite intergrowth materials with different intergrowth phase ratios were synthesized, as shown in Table 1. The XRD pattern is similar to Example 1.

[0026] Table 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com