Process for synthesis of analcime from red mud by hydrothermal alkaline method

An analcime and synthesis method technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large stockpiles of red mud, and achieve cheap and easy-to-obtain materials, convenient operation, and simple procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

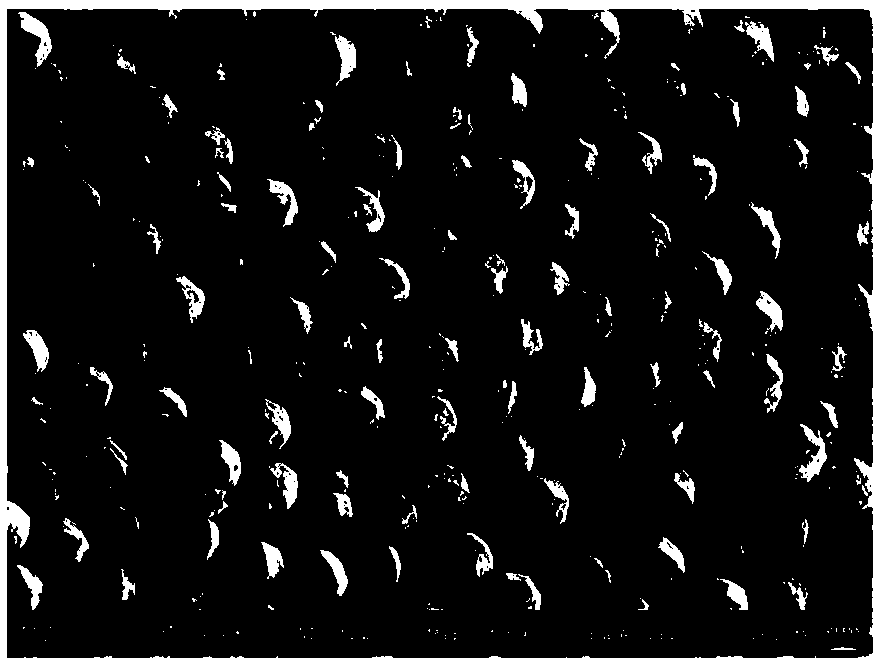

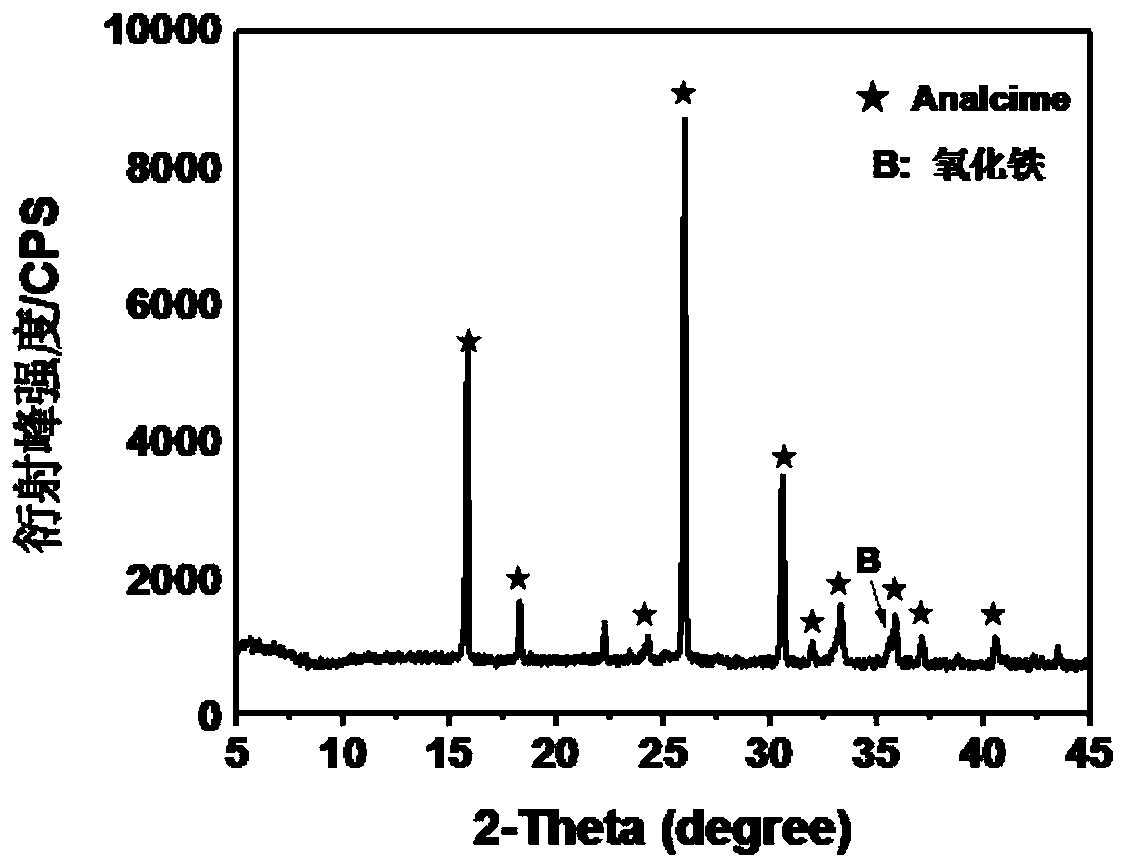

[0029] Take 10.0g of red mud powder, 5.2g of sodium hydroxide, and 6.4g of quartz in 100mL of distilled water, and stir for 12h. After standing still for 12 hours, the materials were put into a closed reaction kettle and crystallized at 180°C for 24 hours. The obtained product was washed twice with acidic water having a pH of 2, and then washed four times with deionized water until neutral. Clean the product with ultrasonic waves, extract the bottom sediment and dry it at 70°C for 15 hours, and its XRD spectrum is as follows figure 1 As shown, its SEM spectrum is shown as figure 2 As shown, the crystallinity of the product is good, and the main crystal form is analcime, containing a small amount of iron oxide impurities.

Embodiment 2

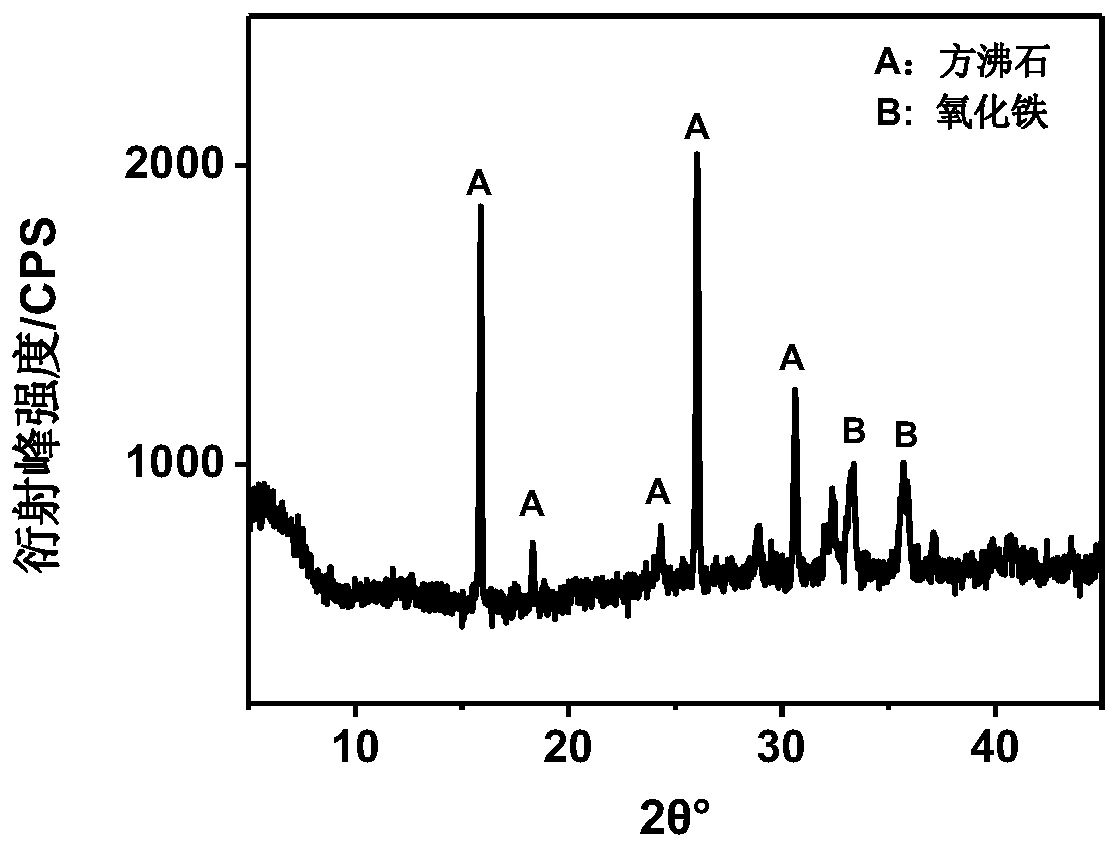

[0031] Take 10.0g of red mud powder, 8.1g of sodium hydroxide, and 6.4g of quartz in 100mL of distilled water, and stir for 24h. After standing still for 9 hours, the materials were put into a closed reaction kettle and crystallized at 180°C for 15 hours. The obtained product was washed twice with acidic water having a pH of 2, and then washed four times with deionized water until neutral. The product was dried at 70°C for 15 hours without ultrasonic treatment, and its XRD pattern was as follows: image 3 shown.

Embodiment 3

[0033] Take 10.0g of red mud powder, 5.2g of sodium hydroxide, and 6.4g of quartz in 100mL of distilled water, and stir for 12h. After standing still for 12 hours, the material was put into a closed reaction kettle and crystallized at 180°C for 9 hours. The obtained product was washed twice with acidic water having a pH of 2, and then washed four times with deionized water until neutral. The product was dried at 70°C for 15 hours without ultrasonic treatment, and its XRD pattern was as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com