Mineral filtering material and preparation method thereof, and filtering core obtained from mineral filtering material

A mineral and filter material technology, applied in the field of water treatment, can solve problems such as heavy metal poisoning, uncoordinated ratio, and slow mineral precipitation speed, and achieve the effects of convenient operation, simple preparation method, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

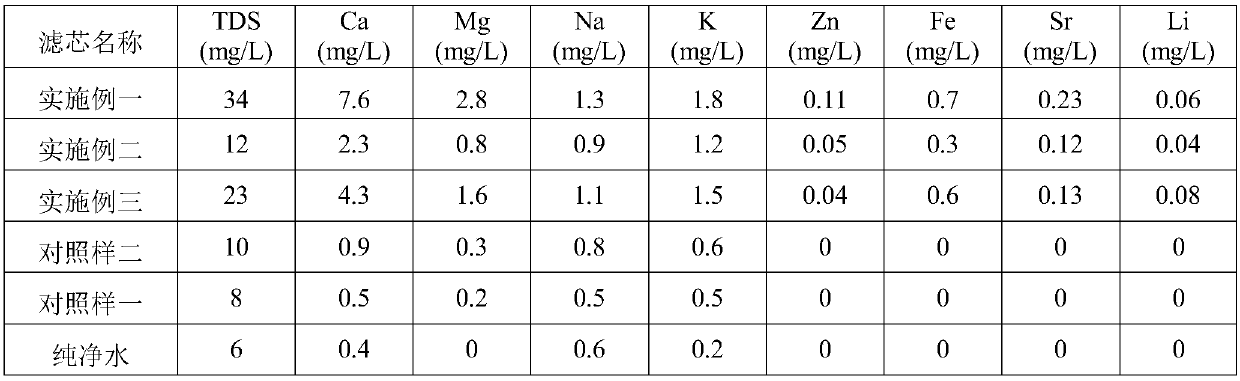

Examples

preparation example Construction

[0027] A kind of preparation method of mineral filter material of the present invention, comprises the following steps: 1) take secondary quartzite, feldspar quartz sandstone, rhodochrosite and zeolite successively, carry out modification treatment, obtain secondary quartzite particle, feldspar respectively Quartz sandstone particle, rhodochrosite particle and zeolite particle; 2) the secondary quartzite particle, feldspar quartz sandstone particle, rhodochrosite particle and zeolite particle of activated carbon particle, activated carbon fiber and binding agent and step 1) gained, mix, Stir evenly to obtain a mixture; 3) Put the mixture obtained in step 2) into a hydraulic mold at a temperature of 150-160° C. and a pressure of 12-18 MPa, and sinter for 20-60 minutes to obtain a filter material.

[0028] A mineral filter element of the present invention comprises a shell, the inside of which is provided with any one of the above mineral filter materials, and both ends of the sh...

Embodiment 1

[0031] A kind of preparation method of mineral filter material of the present invention, comprises the following steps:

[0032] 1) Take the raw materials according to the following parts by weight: 12g of secondary quartzite, 4g of feldspar quartz sandstone, 3g of rhodochrosite, 35g of zeolite, 25g of activated carbon particles, 10g of activated carbon fiber, and 35g of binding agent; wherein, rhodochrosite is iron rhodochrosite It is a mixture composed of zinc rhodochrosite in a weight ratio of 3:2, and the zeolite is a mixture of phillipsite and analcime in a weight ratio of 3:1;

[0033] 2) taking secondary quartzite, feldspar quartz sandstone, rhodochrosite and zeolite in sequence, and carrying out modification treatment to obtain secondary quartzite particles, feldspar quartz sandstone particles, rhodochrosite particles and zeolite particles respectively;

[0034] 3) The activated carbon particles, activated carbon fibers and binder and the secondary quartzite particles,...

Embodiment 2

[0038] A kind of preparation method of mineral filter material of the present invention, comprises the following steps:

[0039] 1) Take the raw material according to the following parts by weight: 36g of kaolinite tourmaline secondary quartzite, 12g of feldspar quartz sandstone, 5g of rhodochrosite, 46g of zeolite, 20g of activated carbon particles, 30g of activated carbon fiber, and 60g of binding agent; wherein, rhodochrosite is The mixture of iron rhodochrosite and zinc rhodochrosite according to the weight ratio of 1:2, and the zeolite is the mixture of phillipsite and analcime according to the weight ratio of 1:1;

[0040] 2) Take kaolinite tourmaline secondary quartzite and feldspathic quartz sandstone, pulverize, mix, add citric acid aqueous solution with a mass concentration of 5%, wash under ultrasonic conditions for 12h, use deionized water to wash, dry, and store at 400°C , roasted for 1 hour, cooled, ground, and sieved to obtain mixed particles of secondary quartz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com