Composite adsorption material and preparation method thereof

A technology of composite adsorption materials and materials, applied in the field of organic-inorganic mineral water treatment and purification materials and their preparation, can solve the problems of limited material absorption capacity, limited effect, low specific surface area of adsorbents, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

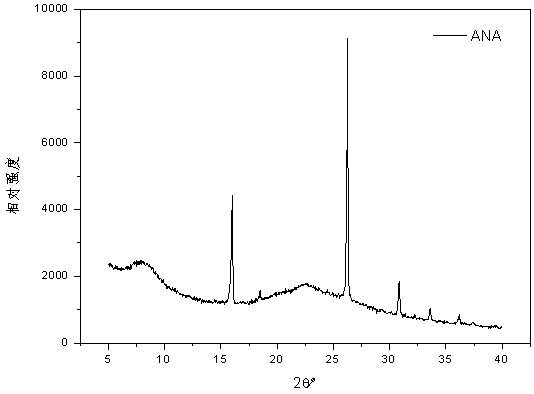

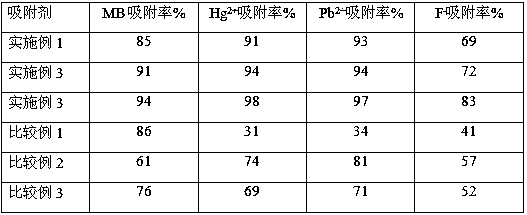

Embodiment 1

[0034] At room temperature, mix water, sodium hydroxide, silica sol, and N-methylpyrrolidine according to a certain ratio, then heat in sealed water at 90°C for 24 hours, cool to room temperature, and then add the spare sodium metaaluminate powder to the above solution in, and stir well. The final material ratio satisfies: Al 2 o 3 / SiO 2 =30, N-Methylpyrrolidine / SiO 2 =0.15,OH - / SiO 2 =0.75,H 2 O / SiO 2 =40. Afterwards, the above mixture was ultrasonically (1.0 KW / L) and magnetically stirred at 40°C for 3 hours, and then placed in a reactor for crystallization at 175°C for 120 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 550°C for 5 hours. It is confirmed to be analcime by XRD detection, observed by scanning electron microscope, it is spherical shape, the grain size is about 30nm, it belongs to ultrafine nanoscale range, and the specific surface area is 270m 2 / g. Mix 200-mesh coal fly ash (with 10-100μm macropor...

Embodiment 2

[0036] At room temperature, mix water, sodium hydroxide, silica sol, and N-methylpyrrolidine according to a certain ratio, then heat in sealed water at 100°C for 24 hours, cool to room temperature, and then add the spare sodium metaaluminate powder to the above solution in, and stir well. The final material ratio satisfies: Al 2 o 3 / SiO 2 =40, N-Methylpyrrolidine / SiO2 =0.20,OH - / SiO 2 =0.8,H 2 O / SiO 2 =60. Afterwards, the above mixture was ultrasonically stirred (0.5 KW / L) at 60°C for 3 hours, and then placed in a reaction kettle for crystallization at 180°C for 140 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 550°C for 5 hours. The product was confirmed to be analcime by XRD detection, observed by scanning electron microscope, it was spherical shape, the grain size was about 35nm, belonging to the nanoscale range, and the specific surface area was 212m 2 / g. Mix 500-mesh coal fly ash (with large and super-large ...

Embodiment 3

[0038] At room temperature, mix water, sodium hydroxide, silica sol, and N-methylpyrrolidine according to a certain ratio, then heat in sealed water at 120°C for 6 hours, cool to room temperature, and then add aluminum isopropoxide powder to the above solution, and stir well. The final material ratio satisfies: Al 2 o 3 / SiO 2 =60, N-Methylpyrrolidine / SiO 2 =0.25,OH - / SiO 2 =0.9,H 2 O / SiO 2 =80. Afterwards, the above mixture was ultrasonically (2.0 KW / L) and magnetically stirred at 50°C for 3 hours, and then placed in a reactor for crystallization at 180°C for 140 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 550°C for 5 hours. The product was confirmed to be analcime by XRD detection, observed by scanning electron microscope, it was in spherical shape, the grain size was about 18nm, it belonged to the ultrafine nanometer range, and the specific surface area was 380m 2 / g. Mix 500-mesh coal fly ash (with 10-100μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com