A kind of composite adsorption material and preparation method thereof

A technology of composite adsorption materials and materials, which is applied in the field of ternary composite adsorption materials and its preparation, can solve the problems of limited material absorption capacity, limited effect, low specific surface area of adsorbents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

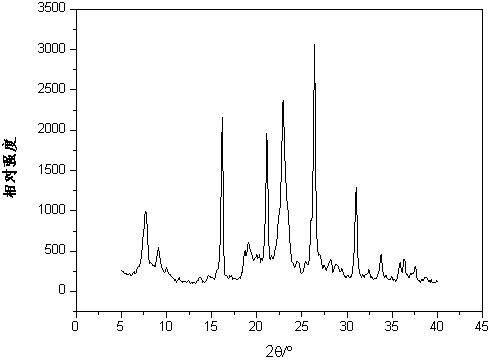

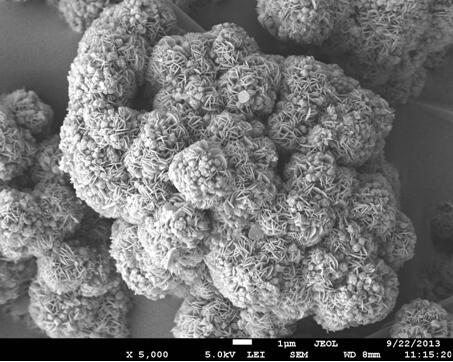

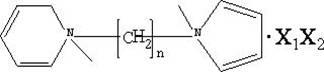

[0033] Under room temperature and under mechanical stirring, silica sol, sodium hydroxide, water, organic matter M (n is 4, X 1 for Cl, X 2 Cl) mixed according to a certain ratio, then heated in closed water at 100°C for 24 hours, and cooled to room temperature. Add the reserved sodium metaaluminate into the silicon source solution and stir evenly. The final material ratio satisfies: Al 2 o 3 / SiO 2 =35, M / SiO 2 =0.20,OH - / SiO2 =0.75,H 2 O / SiO 2 =40. Afterwards, the above mixture was ultrasonically (1.0 KW / L) and magnetically stirred at 40°C for 3 hours, and then placed in a reactor for crystallization at 175°C for 70 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 600°C for 5 hours. It is confirmed by XRD detection that it is a eutectic of mordenite and analcime, and observed by scanning electron microscope, the eutectic is nearly spherical, with an average diameter of about 4.2 μm. The two zeolites are well disper...

Embodiment 2

[0035] Under room temperature and under mechanical stirring, ethyl silicate-40, sodium hydroxide, water, organic matter M (n is 4, X 1 for Cl, X 2 For Br) mixed according to a certain ratio, then heated in closed water at 100°C for 24 hours, and cooled to room temperature. Add the reserved aluminum sec-butoxide into the silicon source solution, and stir evenly. The final material ratio satisfies: Al 2 o 3 / SiO 2 =40, M / SiO 2 =0.45,OH - / SiO 2 =0.85, H 2 O / SiO 2 =80. The total reaction system is 100mL. Afterwards, the above mixture was ultrasonically (1.0 KW / L) and magnetically stirred at 40°C for 3 hours, and then placed in a reaction kettle for crystallization at 170°C for 100 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 600°C for 5 hours. It was confirmed by XRD detection that it was a eutectic of mordenite and analcime, and observed by a scanning electron microscope, the eutectic was nearly spherical, with an ...

Embodiment 3

[0037] At room temperature and under magnetic stirring, white carbon black, sodium hydroxide, water (100% of the total water), organic matter M (n is 6, X 1 for Br, X 2 For Br) mixed according to a certain ratio, then sealed water heating at 85 ℃ for 24 hours, and cooled to room temperature. Add the aluminum isopropoxide powder into the silicon source solution in batches, and stir well and evenly. The final material ratio satisfies: Al 2 o 3 / SiO 2 =40, M / SiO 2 =0.25,OH - / SiO 2 =0.9,H 2 O / SiO 2 =80. Afterwards, the above mixture was ultrasonically (1.0 KW / L) and magnetically stirred at 50°C for 3 hours, and then placed in a reaction kettle for crystallization at 185°C for 60 hours. The obtained product was washed with distilled water, dried at 120°C, and then calcined at 550°C for 5 hours. It was confirmed by XRD detection that it was a eutectic of mordenite and analcime, and observed by a scanning electron microscope, the eutectic of mordenite and analcime was nea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com