Method for preparing analcite from loess based on loess plateau

A loess plateau and analcime technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high energy consumption and high production cost, and achieve the effect of mild reaction conditions, simple and easy process method, and great ecological environment application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

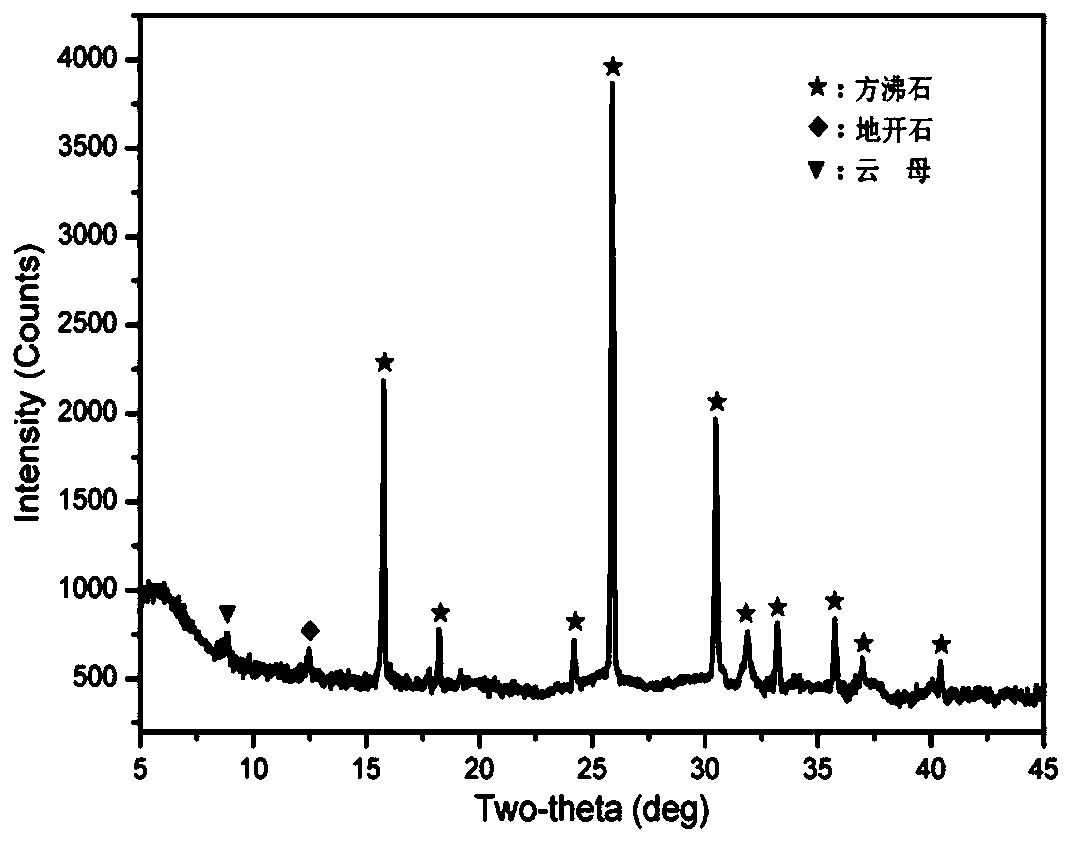

[0027] Take 10.0g of loess sample, 6.7g of sodium hydroxide, and 0.4g of quartz in 60mL of deionized water, stir for 24h to make it fully mixed; Crystallize at 180°C for 48 hours; then wash the obtained product with acidic water with pH=3 for 3 times, and then wash with deionized water until neutral; finally, wash the product repeatedly with ultrasonic waves, and extract the bottom sediment at 80°C Dry for 18h. The XRD spectrum of the obtained sample is as figure 1 As shown, its SEM photo is shown as figure 2 As shown, the crystallinity of the product is good, and the main crystal form is analcime, and contains a small amount of clay minerals.

Embodiment 2

[0029] Directly take 10g of loess sample and 6.3g of sodium hydroxide in 100mL of deionized water, without adding quartz silicon source, and stir for 12h; Crystallize for 36 hours; then wash the obtained product with acidic water with pH=3 for 3 times, and then wash with deionized water until neutral; the product is not subjected to ultrasonic treatment, and the bottom precipitate is extracted after solid-liquid separation and dried at 80°C 18h. The XRD spectrum of the obtained sample is as image 3 shown.

Embodiment 3

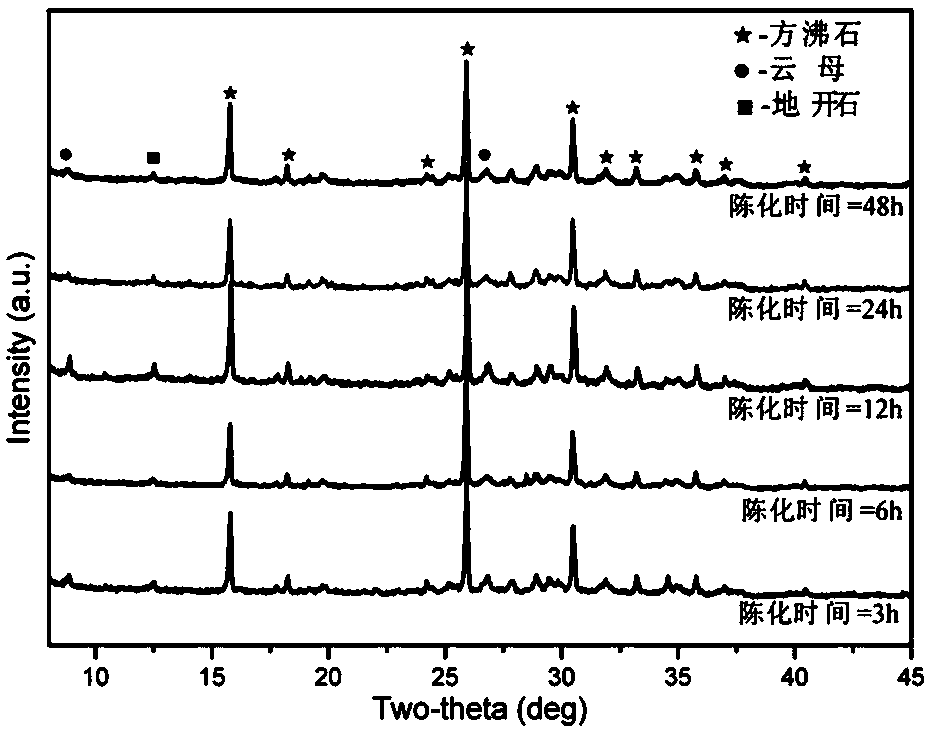

[0031] Take 10g of loess samples, 5.7g of sodium hydroxide, and 0.4g of quartz in 100mL of deionized water, and stir for 6h; then stand and age them for 3h, 6h, 12h, 24h, and 48h respectively, and then put the materials into a closed reactor crystallization at 200°C for 24 hours; then the obtained product was washed three times with acidic water with pH = 3, and then washed with deionized water until neutral; the product was not subjected to ultrasonic treatment, and the bottom layer was extracted after solid-liquid separation The material was dried at 80°C for 18h. The XRD spectrum of the obtained sample is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com