Method for smelting high-nitrogen steel by compression electroslag furnace

A pressurized electroslag and high-nitrogen steel technology, which is applied in the field of smelting high-nitrogen steel, can solve problems such as uneven distribution of nitrogen, and achieve the effects of simple process, avoiding secondary remelting, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

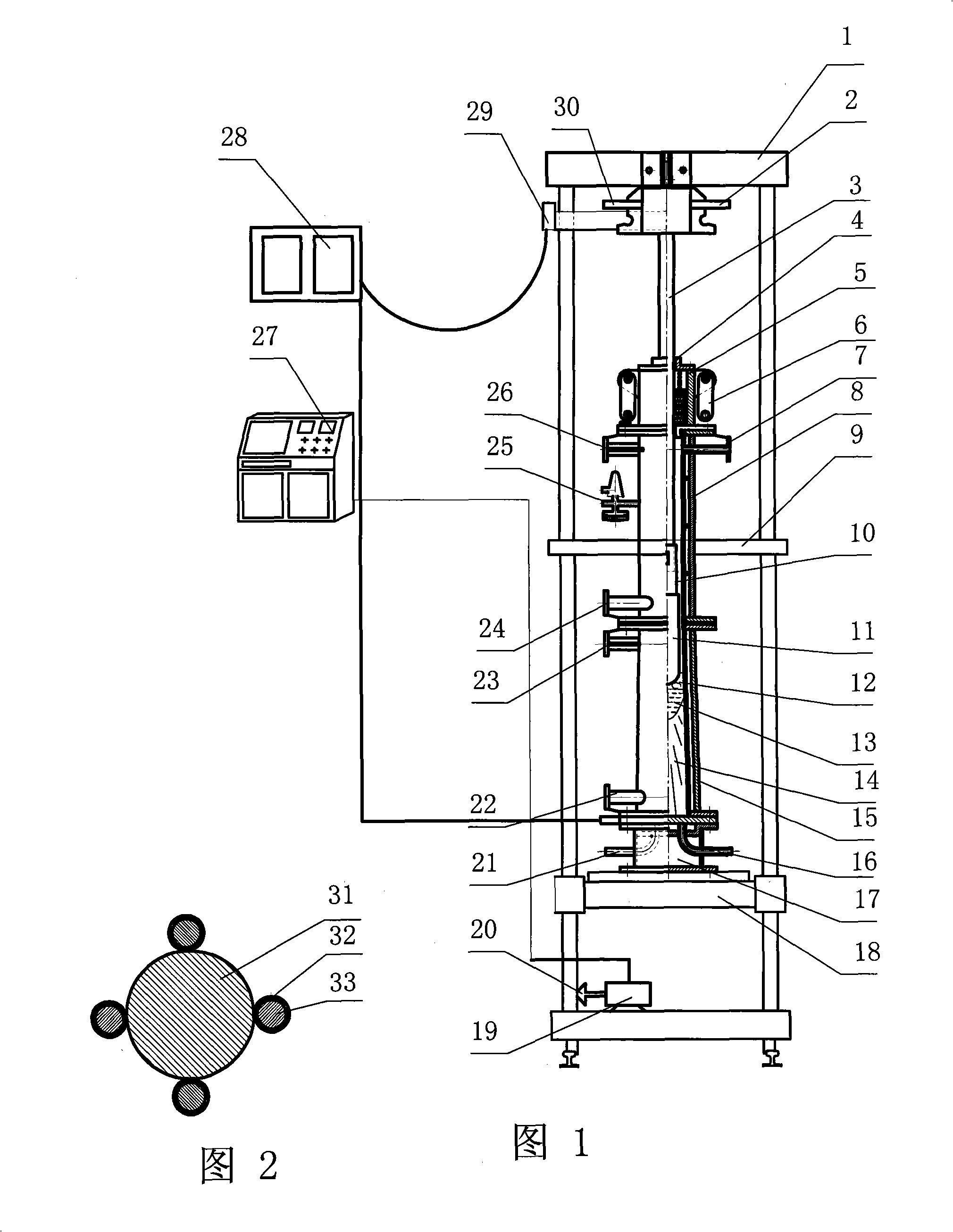

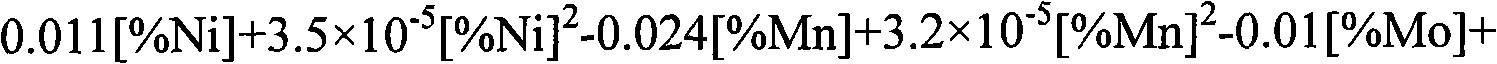

[0030] Embodiment 1: as shown in Figure 1, the present invention comprises sealing device 5, is provided with the electrode 3 that is connected with its sliding sealing in sealing device 5, is equipped with smelting chamber 8 below sealing device 5, is housed below smelting chamber 8 Crystallizer 15, bottom water tank 17 is housed below crystallizer 15, is contained on the trolley lifting platform 18 below bottom water tank 17. The upper end of the electrode 3 is welded on the cross-arm beam 1, and a conductive connector 29 is welded on the electrode 3. The conductive connector 29 is connected to one end of the water-cooled cable, and the other end of the water-cooled cable is connected to the AC power supply 28. The electrode cooling water inlet 2 and the electrode cooling water outlet 30 are welded on the side, and the lower end of the electrode 3 is a dummy electrode 10 , and the consumable composite electrode 11 is welded at the lower end of the dummy electrode 10 . A safe...

Embodiment 2

[0060] Example 2: Target steel for smelting 0Cr17.5Mn14.5Mo3.2N1

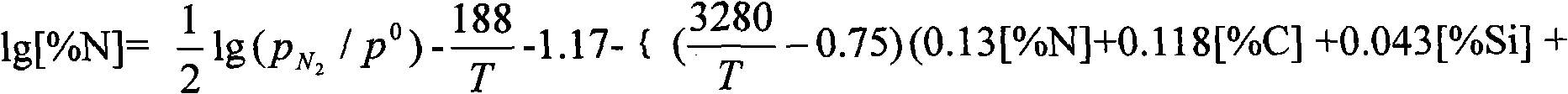

[0061] 1. Through the calculation formula

[0062] lg [ % N ] = 1 2 lg ( p N 2 / p 0 ) - 188 T - 1.17 - { ( 3280 T - 0.75 ) ( 0.13 [ % N ] + 0.118 [ % C ] + 0.043 [ % Si ] +

[0063] 0.011 [ % Ni ] + ...

Embodiment 3

[0071] Example 3: Target steel for smelting 0Cr23Mo2Ni1N1

[0072] 1. Through the calculation formula

[0073] lg [ % N ] = 1 2 lg ( p N 2 / p 0 ) - 188 T - 1.17 - { ( 3280 T - 0.75 ) ( 0.13 [ % N ] + 0.118 [ % C ] + 0.043 [ % Si ] +

[0074] 0.011 [ % Ni ] + 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com