Nickel base alloy cast ingot and preparation method thereof

A nickel-based alloy and ingot casting technology is applied in the field of nickel-based alloy ingots and their preparation, which can solve the problems of unstable chemical composition of alloy ingots, low ingot yield and uneven internal structure, and avoid air pollution. And the effect of burning loss of alloying elements, alloy purity and ingot yield, shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Production of nickel-based alloy Inconel718 ingot

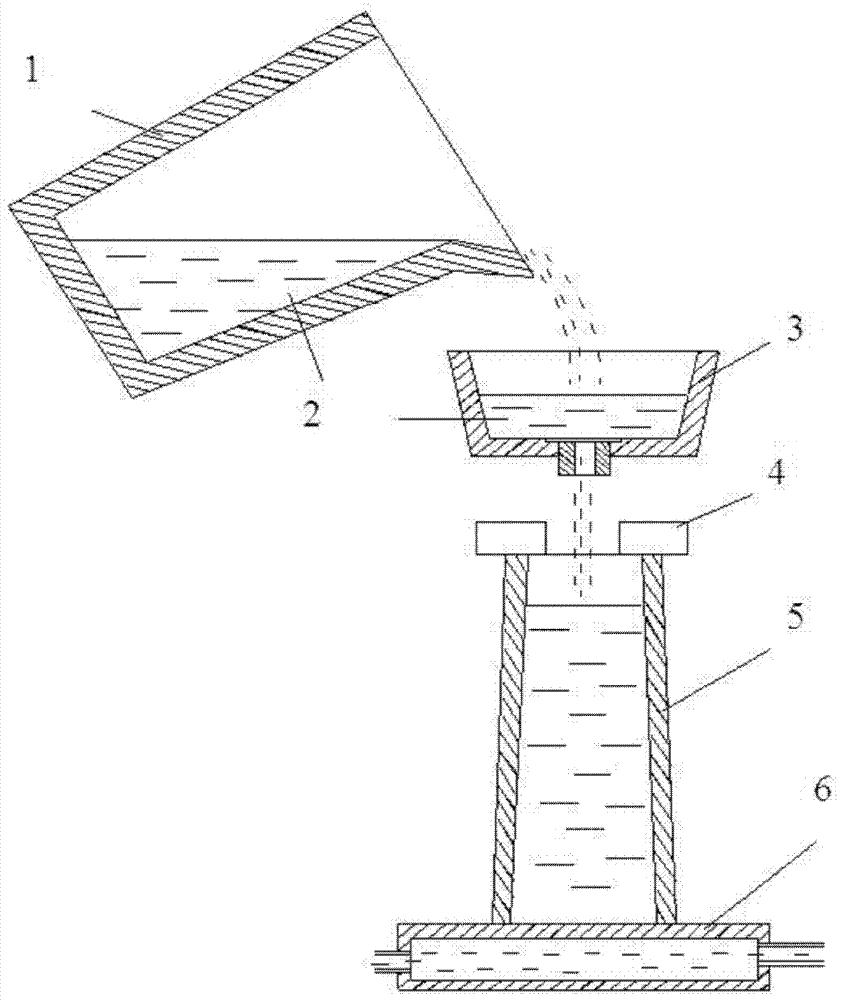

[0036] Pour Inconel718 molten steel 2 refined in 1 ton vacuum induction furnace 1 into tundish 3, and its temperature is controlled at 1580°C. Connect the circulating cooling water tank 6 on the bottom plate of the casting mold. The molten steel 2 is poured from the bottom nozzle of the tundish 3 into the casting mold 5 made of 00Cr25Ni20 with a specification of Φ360*1600mm. After the casting is completed, the arc device is turned on and the power is kept at 300KW. The electric arc between the two ends of the non-consumable electrode 4 heats the molten steel 2 in the mold, and the molten steel 2 is directional solidified from bottom to top to form an ingot, and the ingot is fully fed. The arc heating time was 55 minutes. Close the arc device, and after the ingot is cooled, the mold is demoulded to obtain a nickel-based alloy Inconel718 ingot without surface structure defects, see figure 1 .

Embodiment 2

[0037] Embodiment 2 Production of GH3128 nickel-based alloy ingot

[0038] Pour 1.5 tons of GH3128 molten steel 2 refined in the vacuum induction furnace 1 into the tundish 3 and control the temperature at 1600°C. Connect the circulating cooling water tank 6 on the bottom plate of the casting mold. The molten steel 2 is poured from the bottom nozzle of the tundish 3 into the casting mold 5 with a specification of Φ320*1300mm made of 00Cr25Ni20. The electric arc between the two ends of the non-consumable electrode 4 on the top heats the molten steel 2 in the mold, and the molten steel 2 solidifies directionally from bottom to top to form an ingot, and fully feeds the ingot. The arc heating time is 40 minutes. Turn off the arc device, and demould after the ingot is cooled, so as to obtain a GH3128 high-temperature alloy ingot without surface structure defects. figure 1 .

Embodiment 3

[0039] Example 3 Production of nickel-based alloy NC30Fe (Inconel690) ingot

[0040] Pour NC30Fe (Inconel690) molten steel 2 refined in 1 ton vacuum induction furnace 1 into tundish 3, and its temperature is controlled at 1700°C. Connect the circulating cooling water tank 6 of the bottom plate of the casting mold. The molten steel 2 is poured from the bottom nozzle of the tundish 3 into the casting mold 5 with a specification of Φ360*1600mm made of 00Cr25Ni20. After the pouring is completed, the arc device is turned on and the power is kept at 280KW. The electric arc between the two ends of the non-consumable electrode 4 on the top of the casting mold heats the molten steel in the casting mold, and the molten steel 2 solidifies directionally from bottom to top to form an ingot and fully feeds the ingot. The arc heating time is 70 minutes. Close the arc device, and after the ingot is cooled, it is demoulded to obtain a nickel-based alloy NC30Fe (Inconel690) ingot without surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com