Patents

Literature

87results about How to "Save auxiliary materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

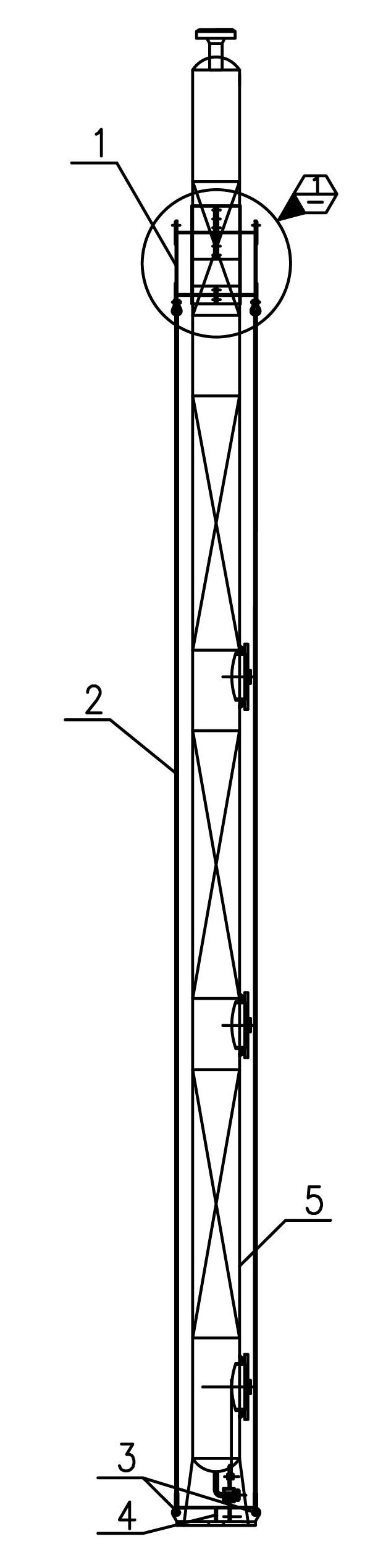

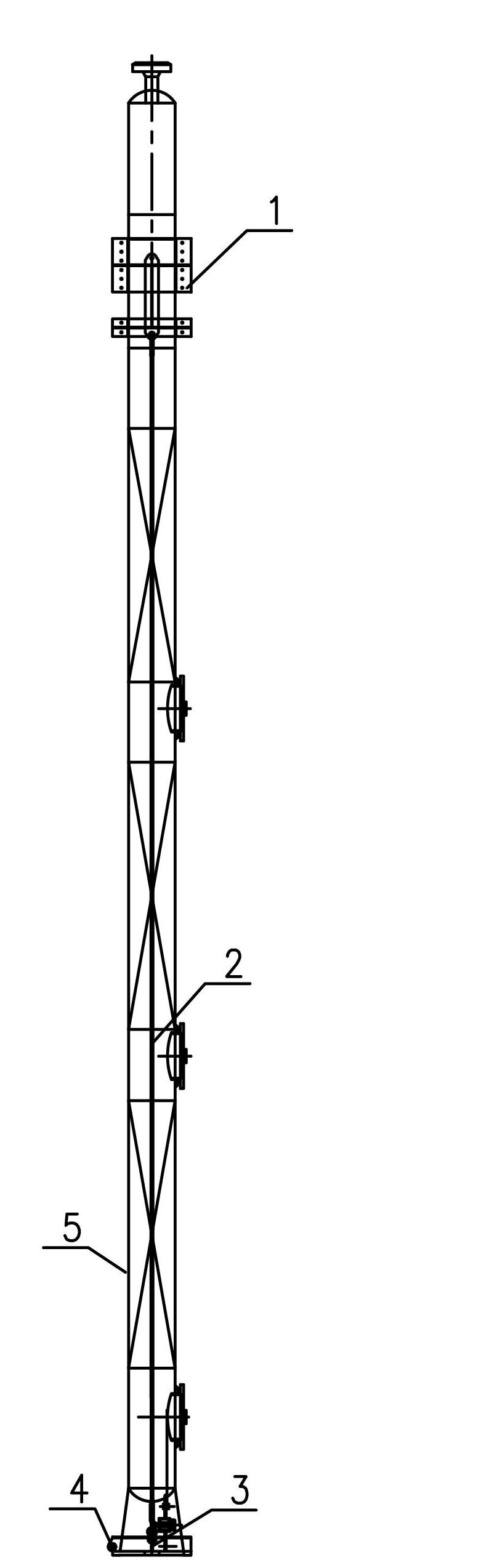

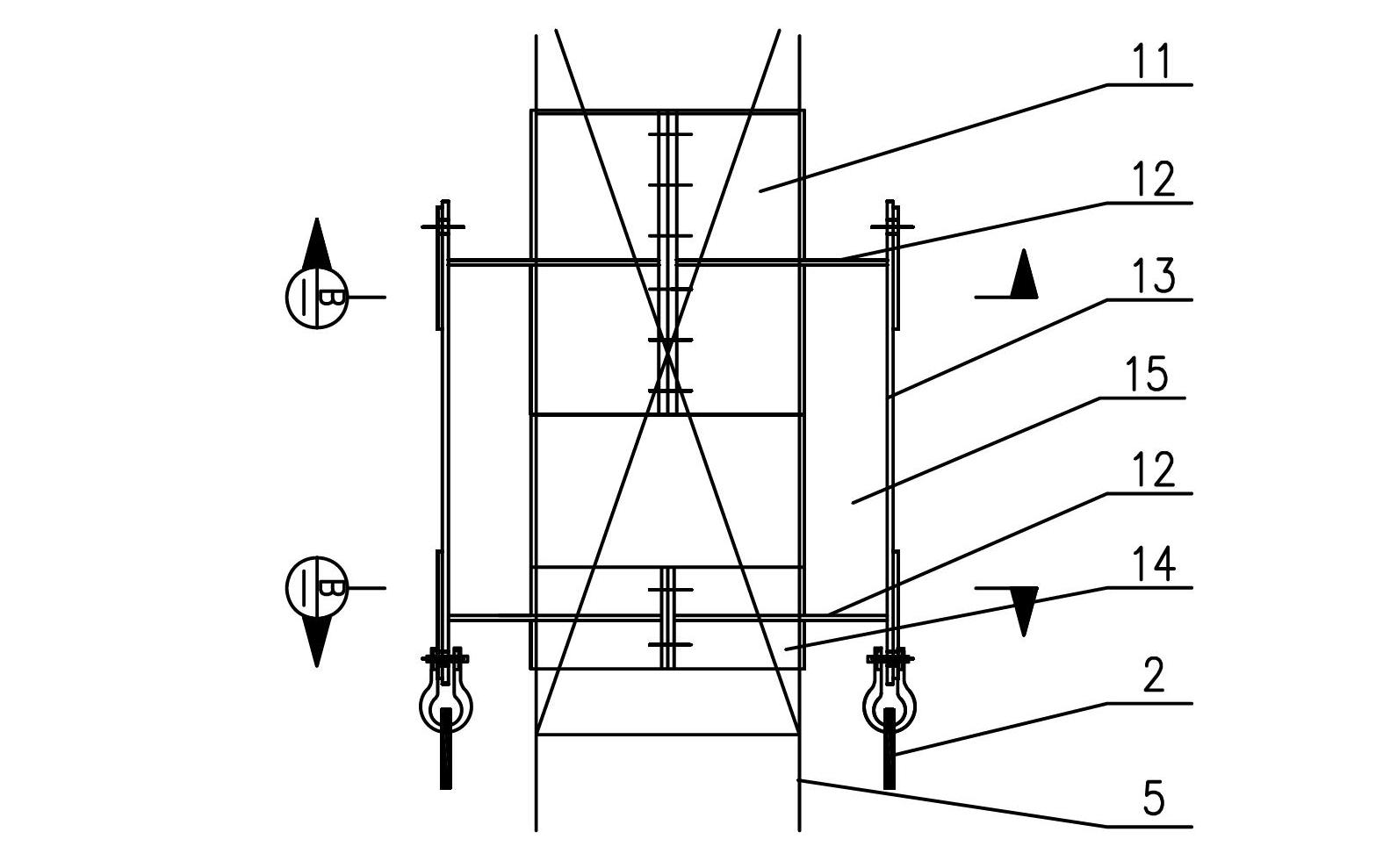

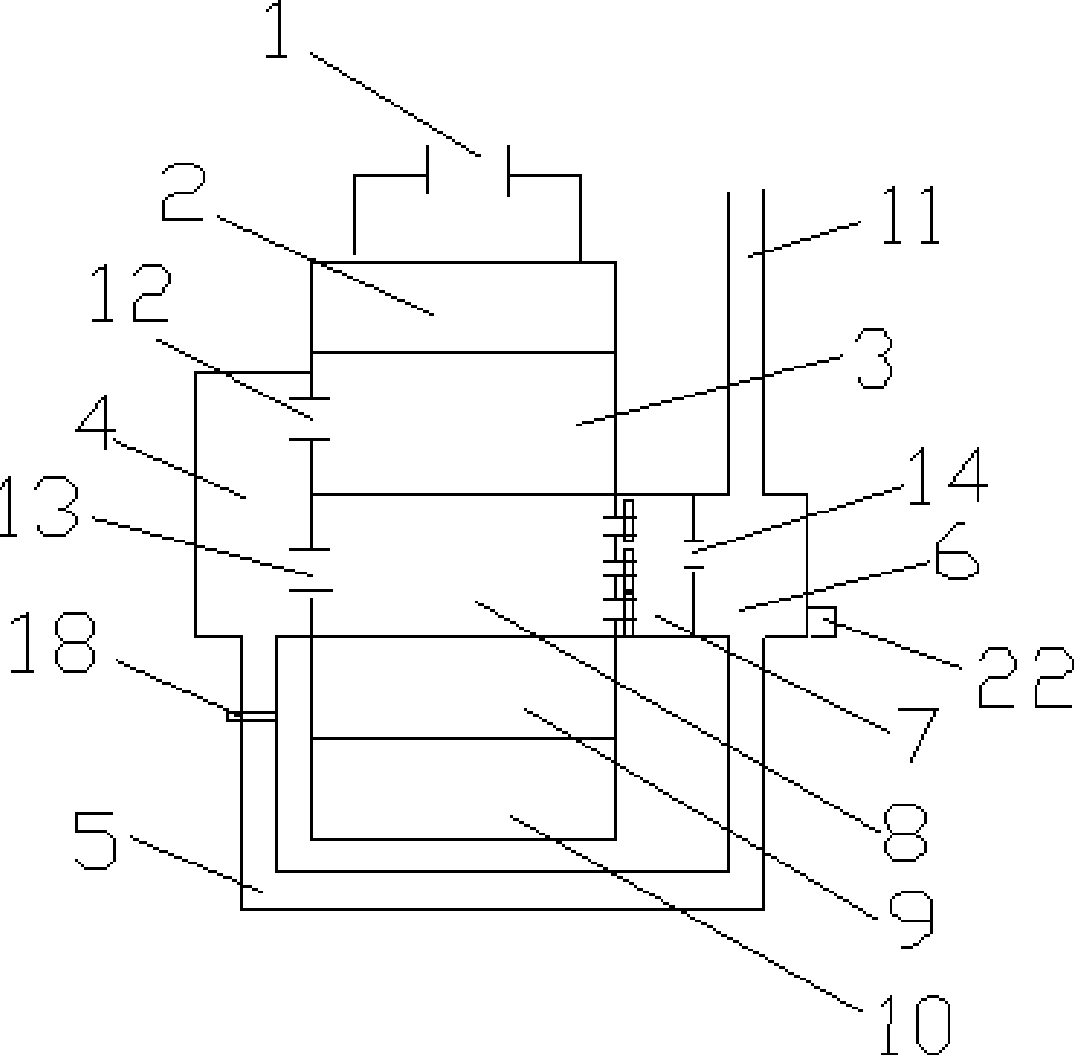

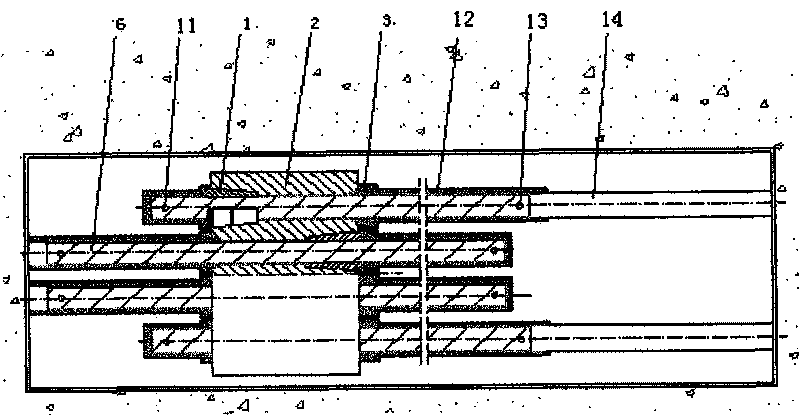

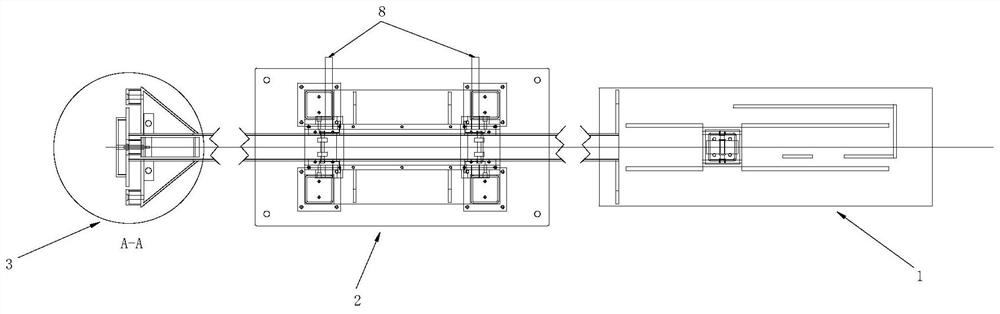

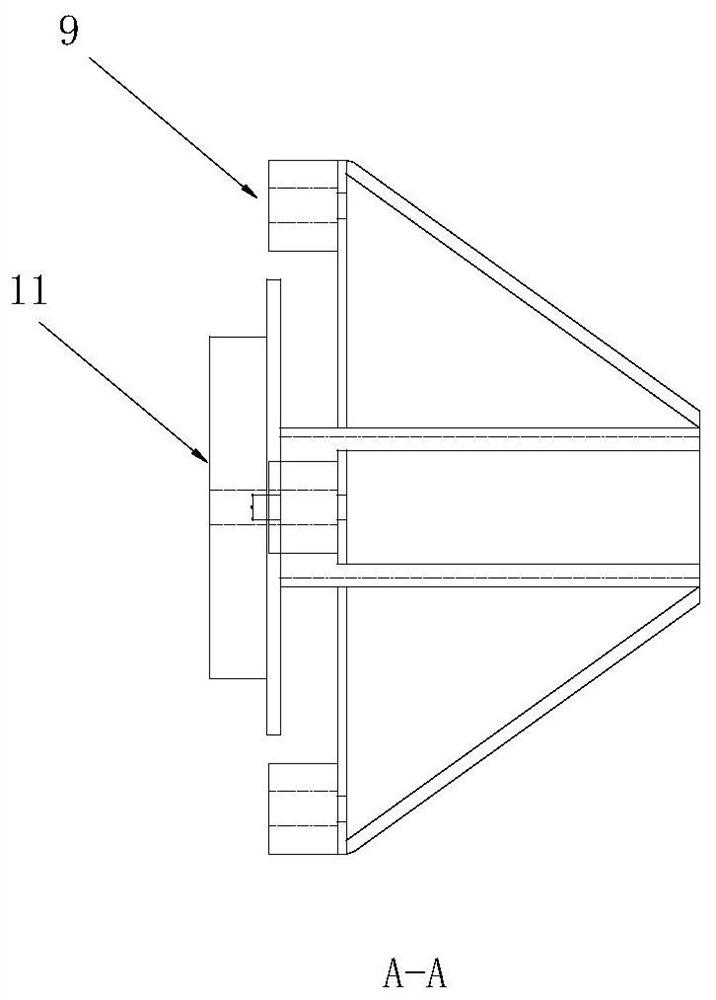

Lifting method for large-scale tower equipment

InactiveCN102674136ASimple hanging point typeEasy to assemble and disassembleLoad-engaging elementsWire ropeIndustrial engineering

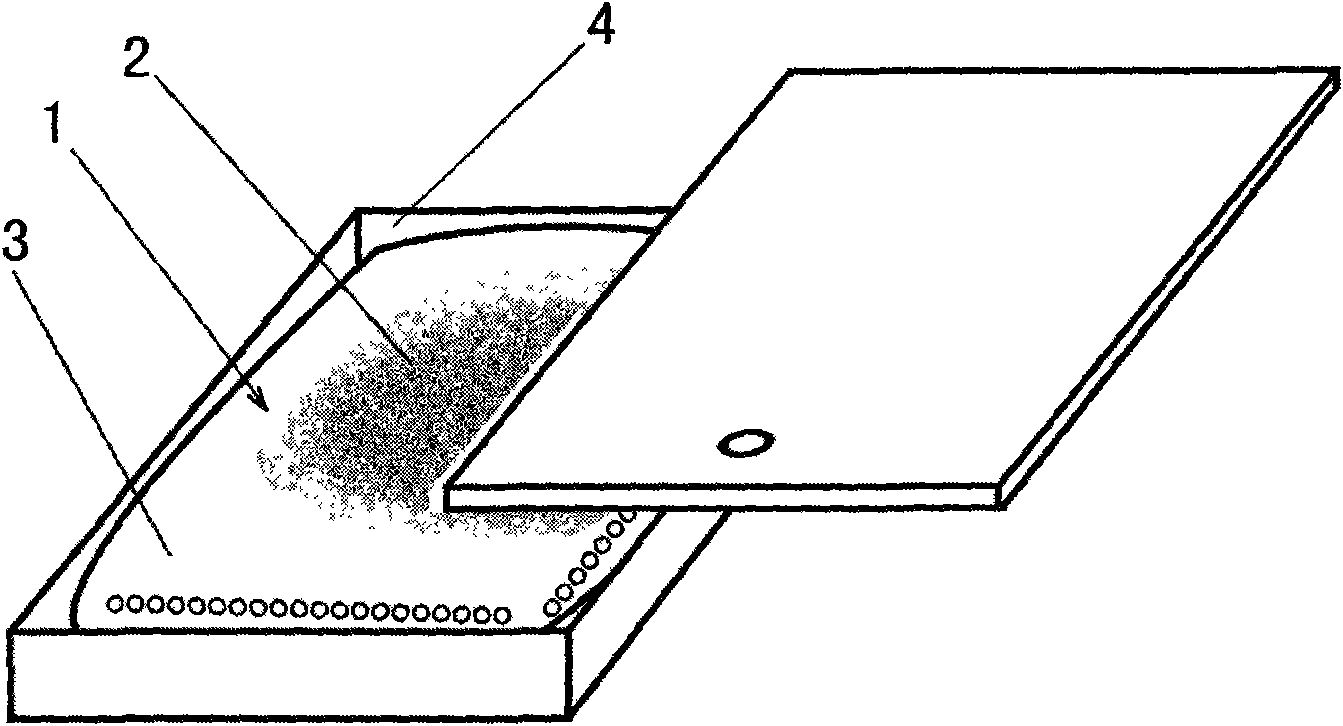

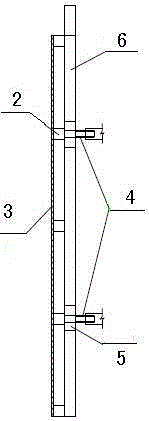

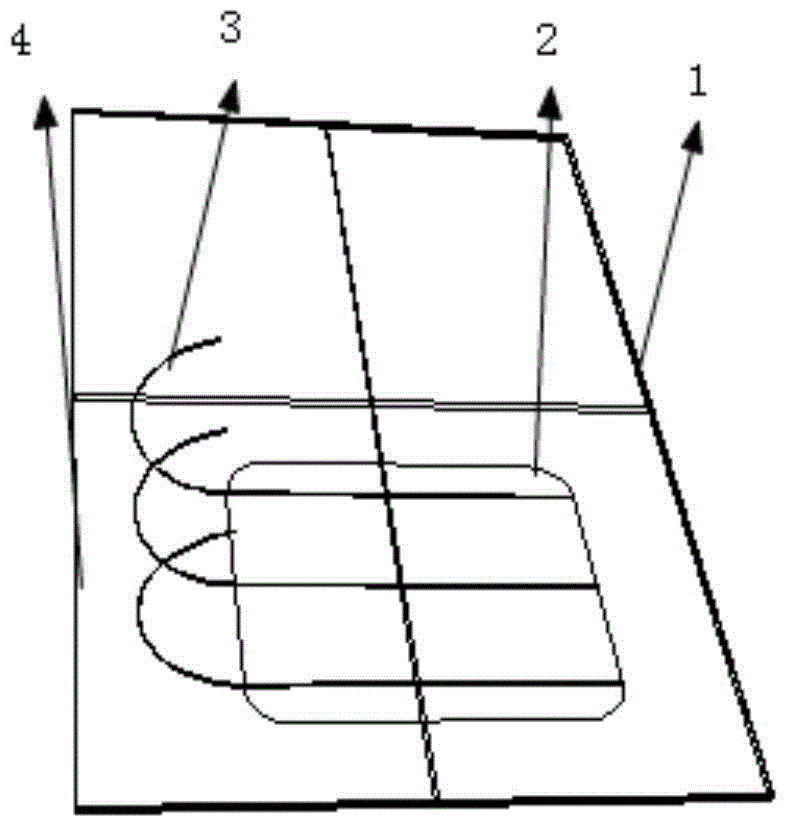

The invention discloses a lifting method for large-scale tower equipment, comprising the following steps of: 1) welding two connecting lifting lug plates and a bottom lifting lug plate on the base of the equipment, wherein the two connecting lifting lug plates are respectively arranged at two sides of the base of the equipment, and the bottom lifting lug plate is arranged between the two connecting lifting lug plates; a pipe clamp lifting structure is fixed at the top of the equipment and comprises a pipe clamp fastened on an equipment tower cylinder, and the pipe clamp is connected with two top lifting lug plates by a ring plate; the two top lifting lug plates are respectively arranged at two sides of the equipment tower cylinder, are in parallel with the equipment tower cylinder, and are respectively opposite to the two connecting lifting lug plates; and tensioning steel wire ropes are arranged between the connecting lifting lug plates and the top lifting lug plates, which are opposite to each other; 2) horizontally lifting equipment by two lifters; 3) lifting the top of the equipment by one lifter; and 4) lifting the equipment to a preset position. The method is safer, more efficient, and more convenient to operate, and the lifting auxiliary materials and the preset time and cost can be saved, so that the lifting method has high economical efficiency and practical applicability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

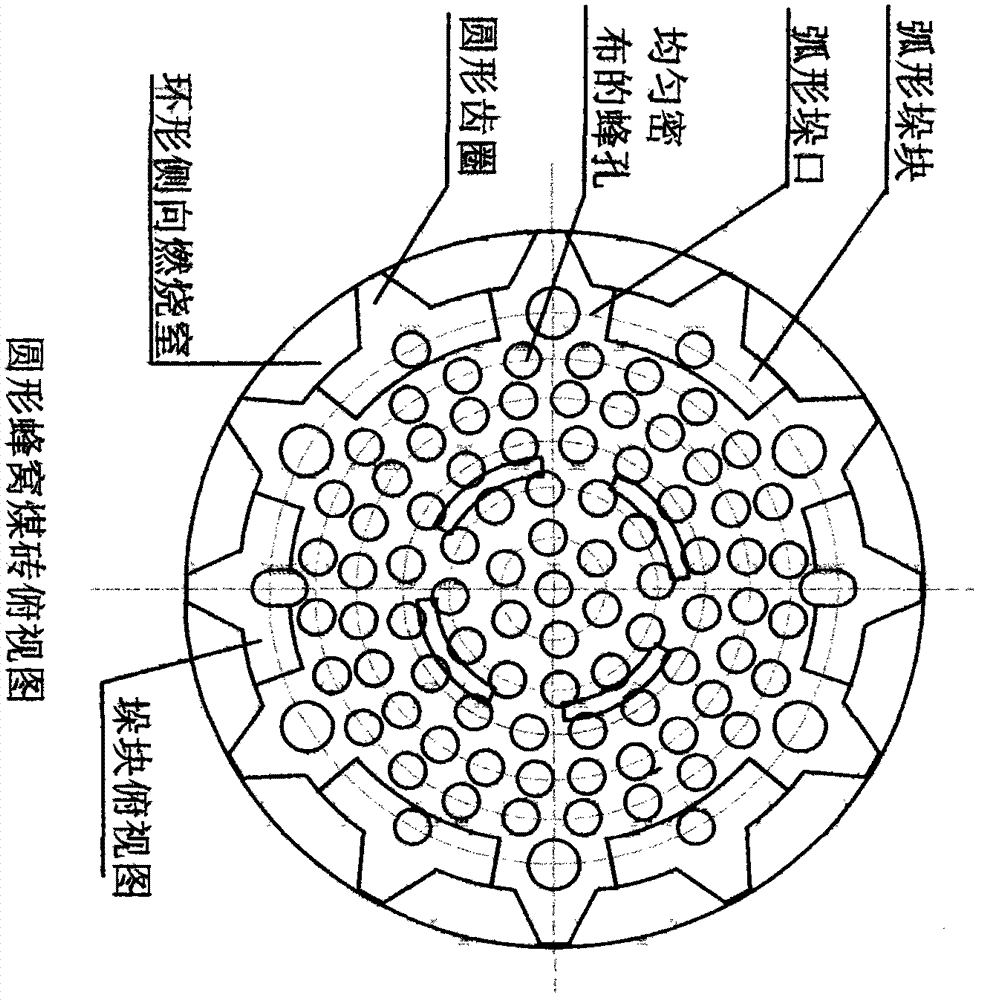

Carbonization-activation integral furnace for producing active carbon

The invention relates to a carbonization-activation integral furnace for producing active carbon, in particular to a carbonization-activation integral furnace for recycling smoke gas. The carbonization-activation integral furnace comprises a carbonization chamber, an activation chamber, a heat accumulation chamber, a preheating boiler and an exhaust pipe, wherein the heat accumulation chamber is communicated with the preheating boiler through the exhaust pipe. The carbonization-activation integral furnace makes full use of high-temperature smoke gas to avoid waste of heat source, lower the production cost and reduce heat corrosion of the smoke gas. Besides, the smoke gas is converted into harmless gas through secondary combustion in the heat accumulation chamber, thereby avoiding pollution to the environment when being discharged finally.

Owner:王立新

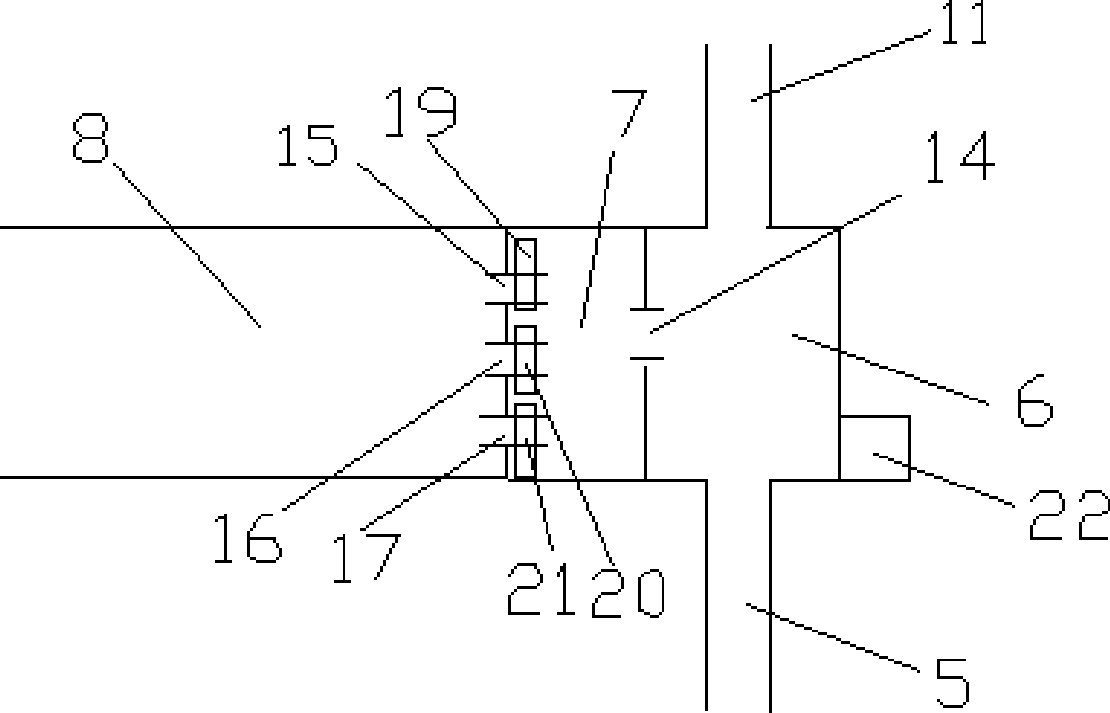

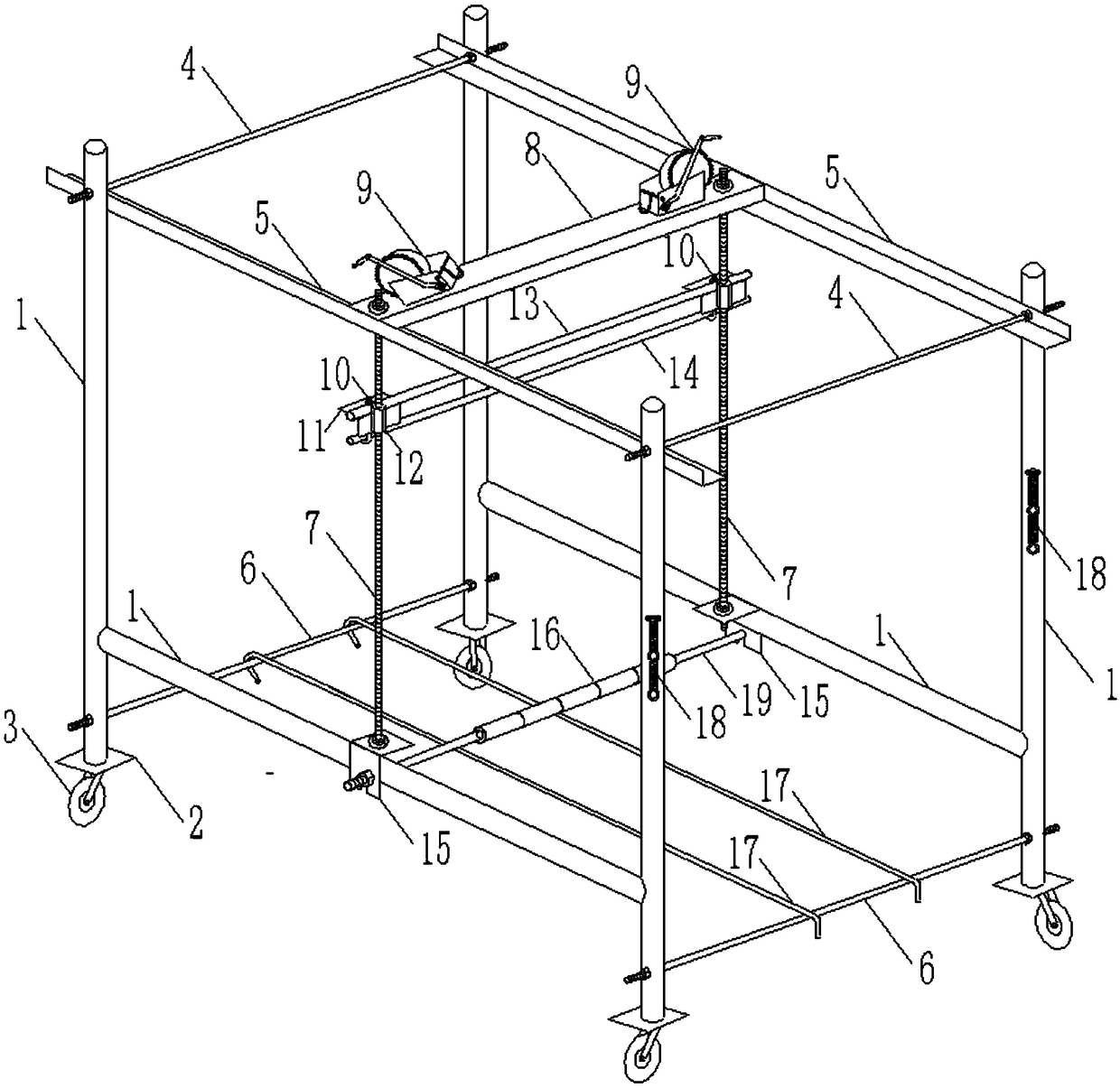

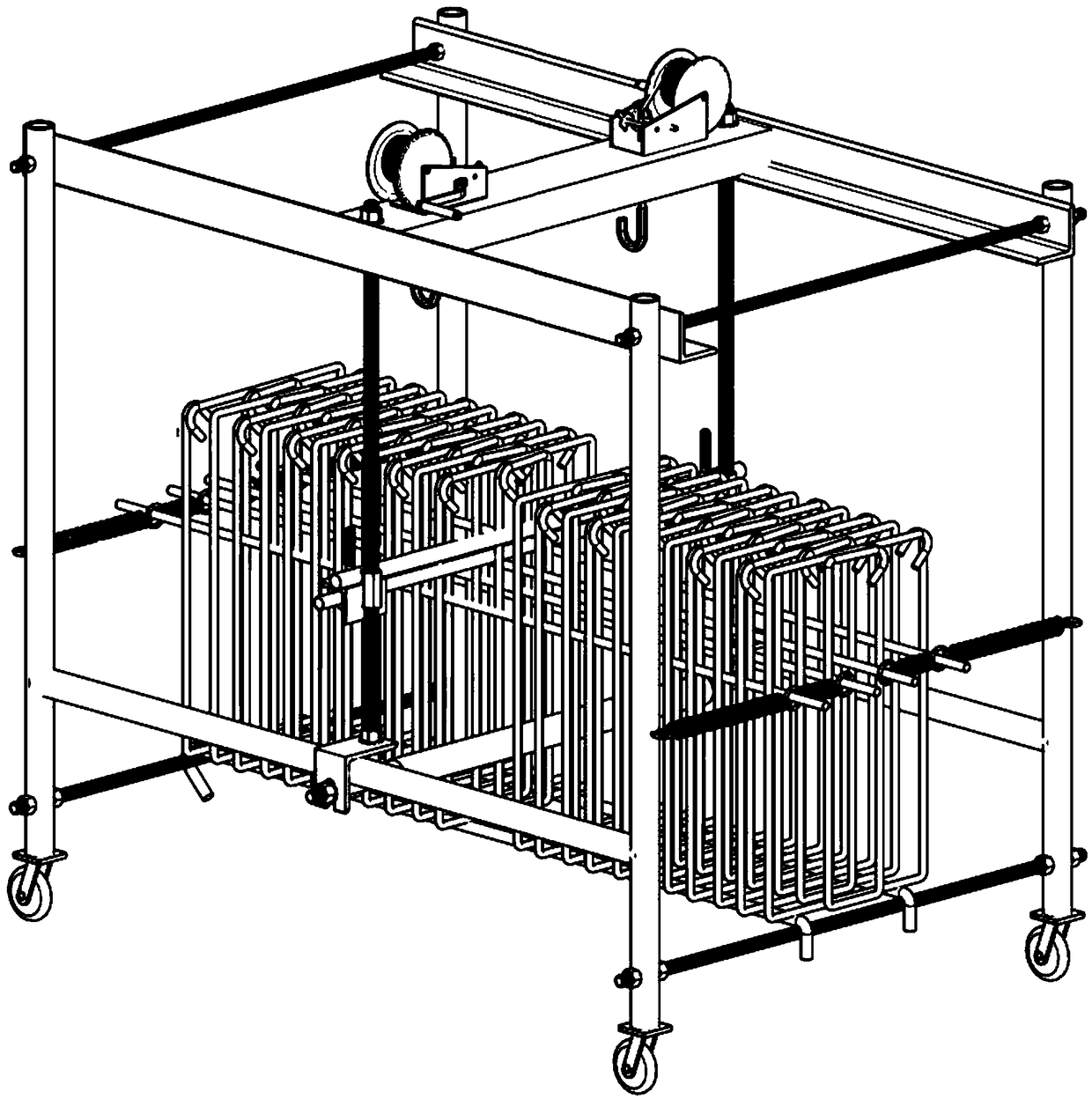

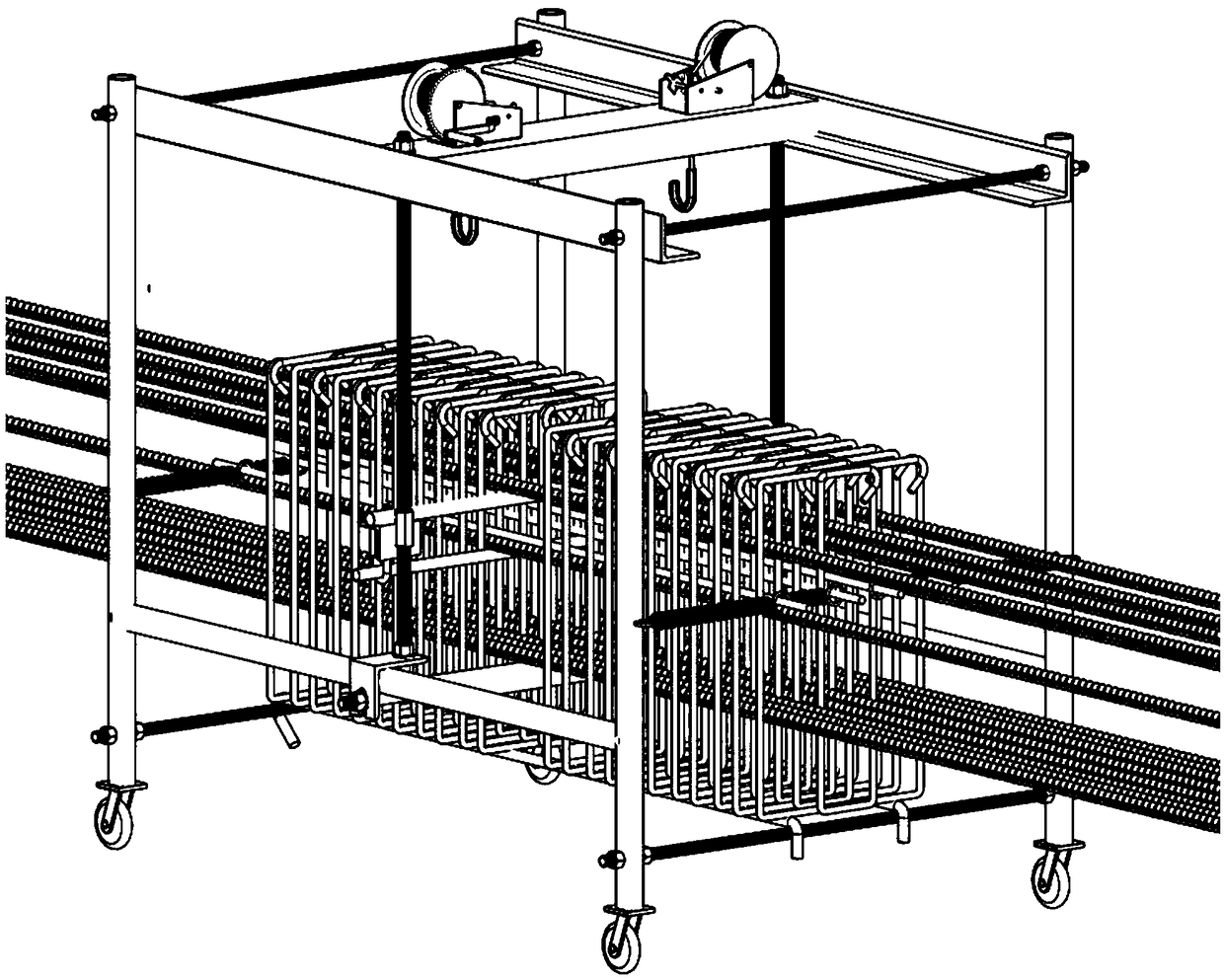

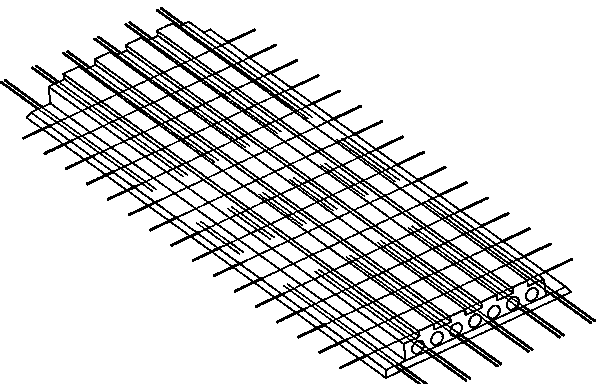

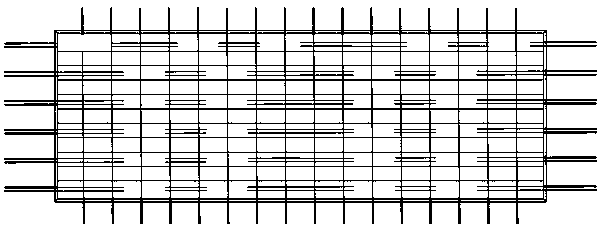

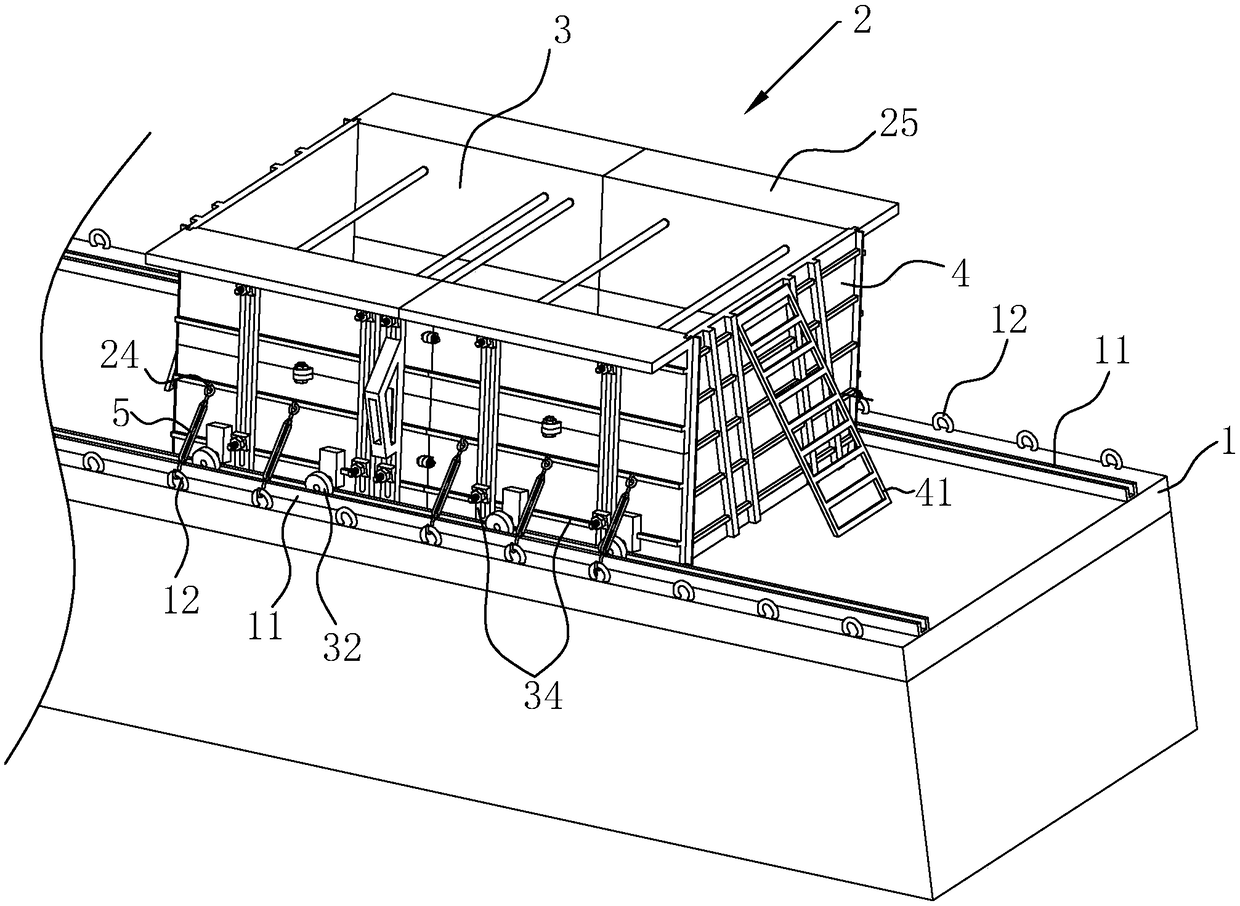

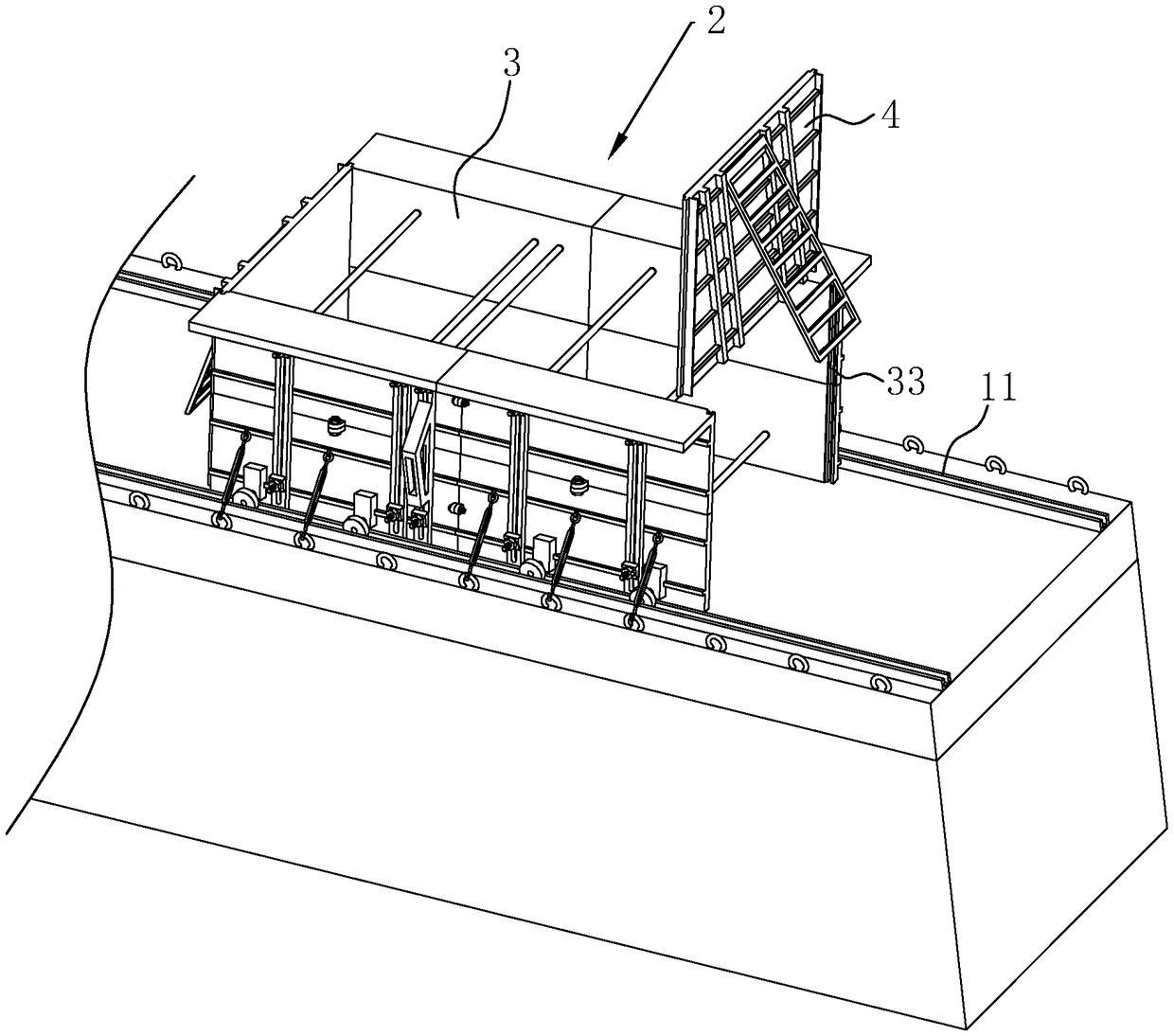

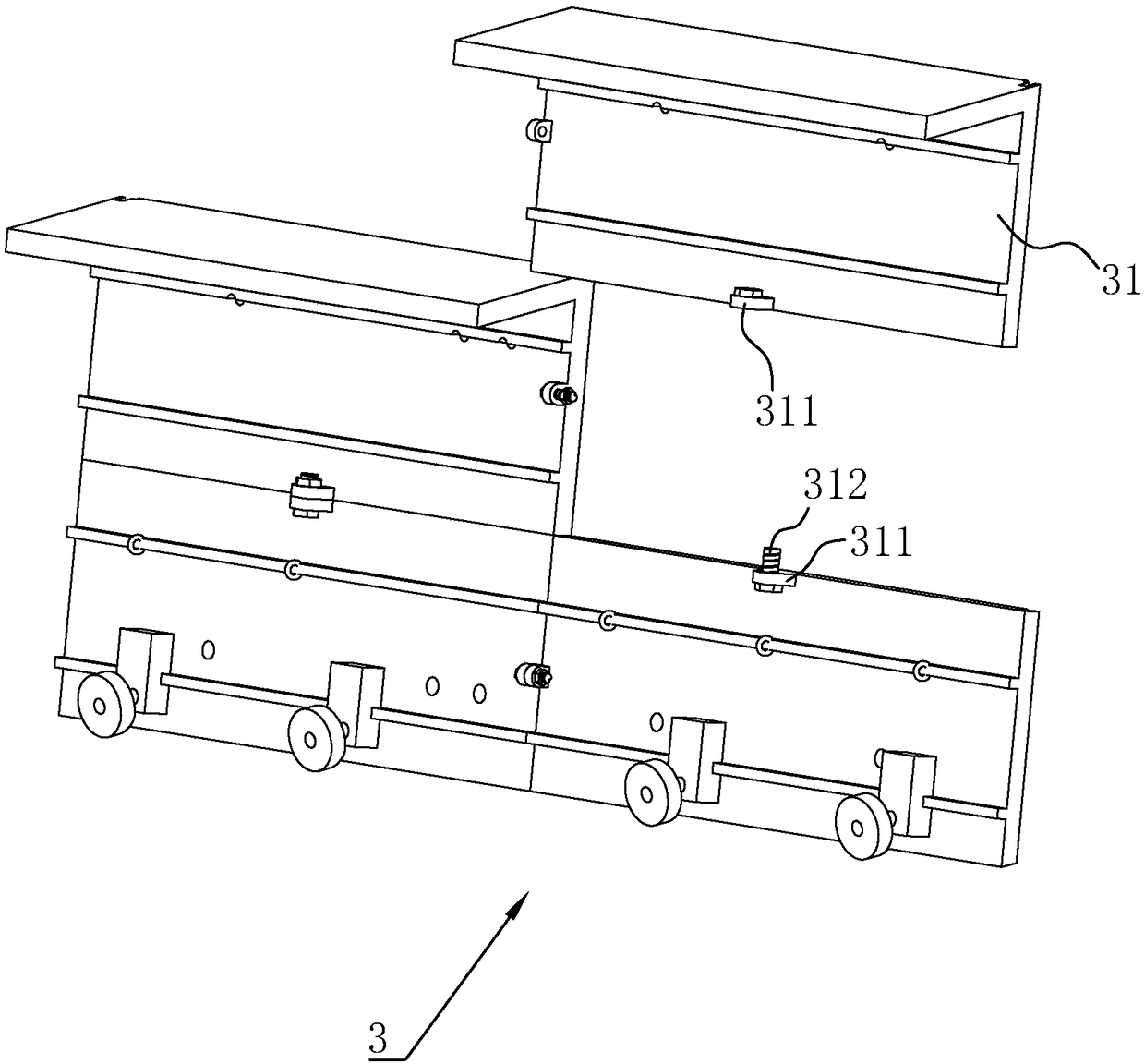

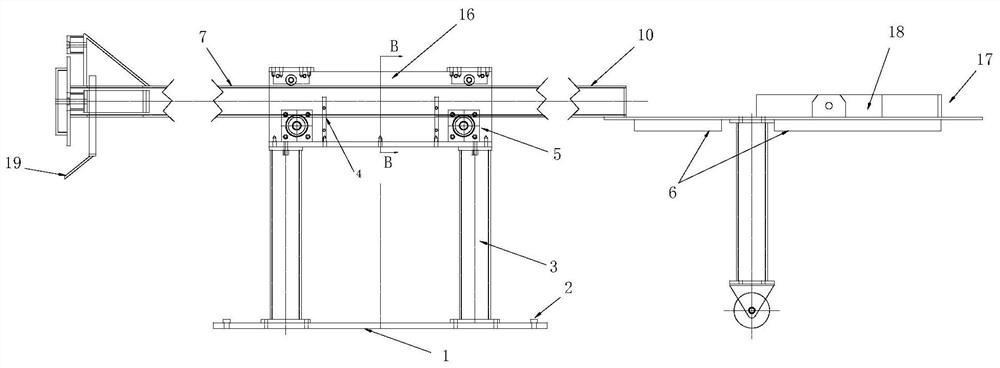

Cast-in-place beam reinforcement cage binding installation multi-function trolley

PendingCN109339458AGuaranteed installation qualityReduce labor intensityBuilding material handlingEngineeringRebar

The invention discloses a cast-in-place beam reinforcement cage binding installation multi-function trolley. The cast-in-place beam reinforcement cage binding installation multi-function trolley comprises a rectangular tubular trolley body frame extending in the front-rear direction, and openings at the front and rear ends of the trolley body frame correspond to reinforcement cage stirrups. A first transverse support, a second transverse support and a third transverse support are detachably arranged in the trolley body frame from top to bottom. The first transverse support, the second transverse support and the third transverse support separately extend in the left and right direction, and the first transverse support and the second transverse support can slide up and down synchronously. The trolley body frame is further internally provided with limiting screws corresponding to the reinforcement cage stirrups in a penetrating mode, and the limiting screws extend in the front-rear direction. A plurality of tension springs are arranged at the front and the rear ends of the trolley body frame, and the limiting screws and the tension springs are detachably connected. The cast-in-placebeam reinforcement cage binding installation multi-function trolley has the characteristics and functions of loading and transporting, stirrup pre-penetrating, skeleton binding, vertical lifting and lowering, adjustable size, flexible movement and the like and replaces traditional cumbersome processes of temporary bracket building, on-site secondary transportation, multiple times of replacing andsupporting, manual or mechanical lifting of the reinforcement cage into a mold.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

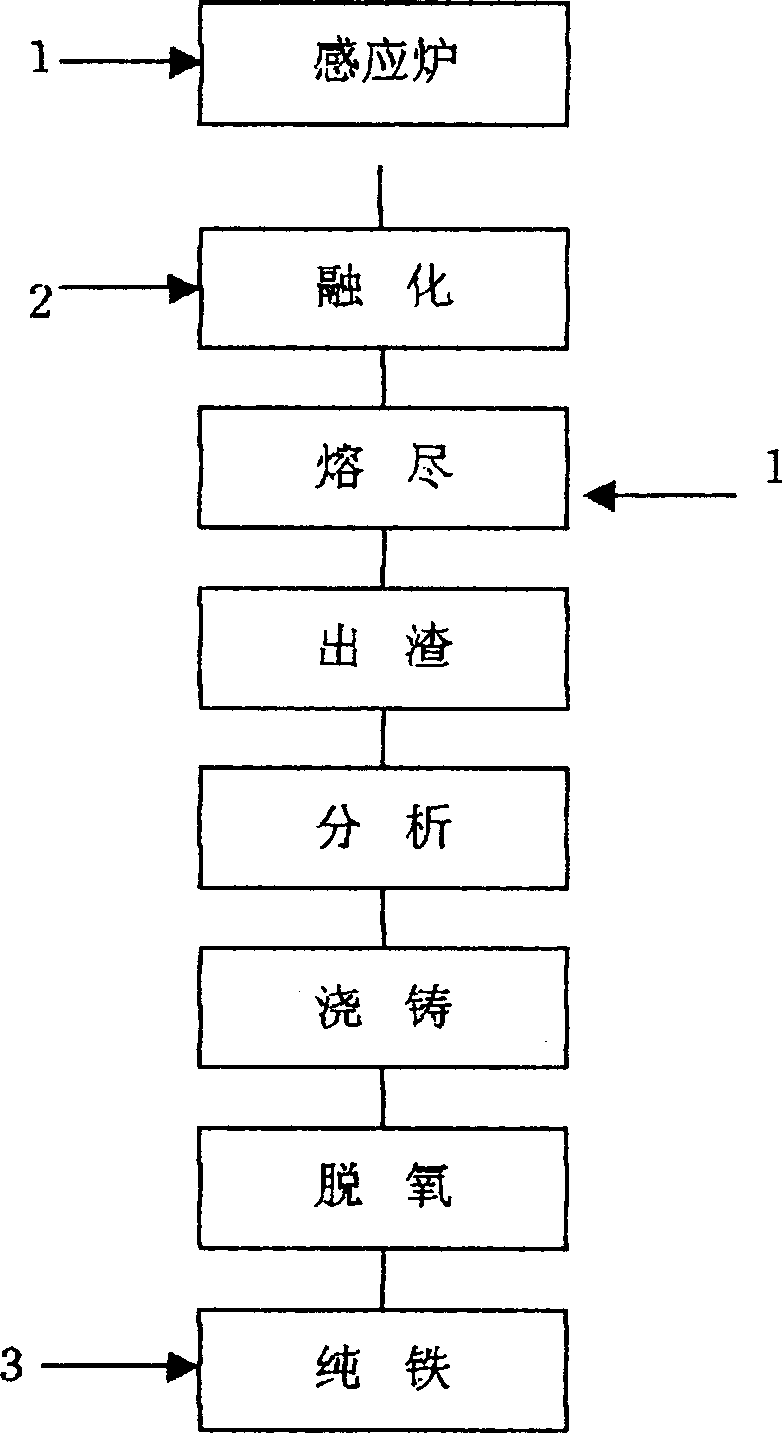

Pure iron smelting method

The present invention relates to pure iron smelting method and aims at providing one kind of iron smelting process with smoke and dust from converter steel smelting and waste steel as material and thus with low cost, simple process and stable quality. The material is first added into and heated in inducing furnace; slag forming agent NaHCO3, CaO and MgO are added when the material begins to smelt; the all materials are made to smelt and the slag is exhausted; and the components in the iron including impurity are analyzed. The said process is repeated for at least two times to produce pure iron reaching the relevant standard. The molten iron is poured into steel llade, added with deoxidizing agent aluminium and cast to obtain pure iron product.

Owner:攀枝花市永禄科技开发有限责任公司

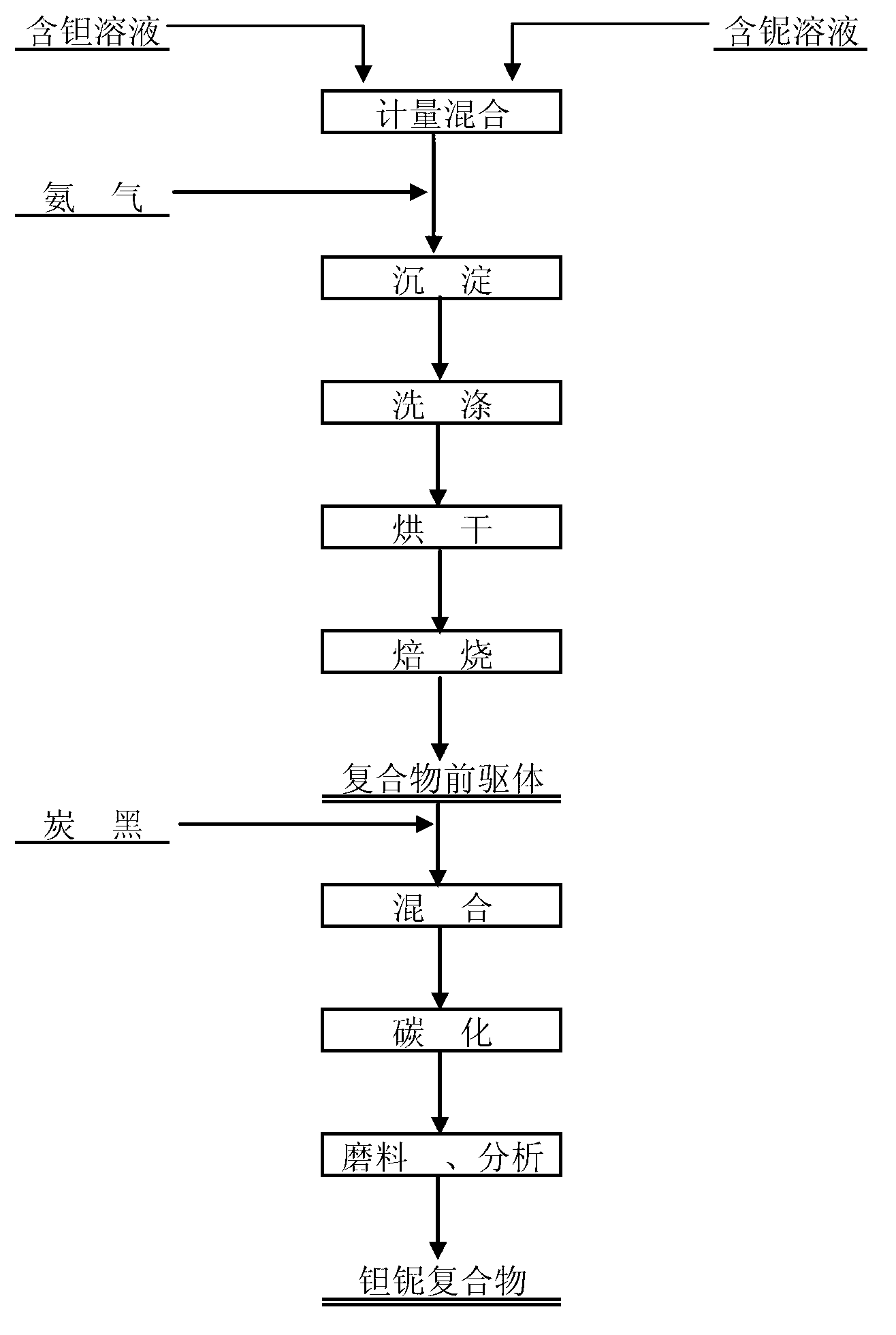

Preparation method of tantalum and niobium composite carbide

The invention relates to a preparation method of tantalum and niobium composite carbide. The preparation method of the tantalum and niobium composite carbide is characterized by comprising the following technical processes: selecting a tantalum-containing solution and a niobium-containing solution which are produced by an HF-H2SO4 system extraction technology; performing precise calculation according to a tantalum-niobium ratio of the tantalum and niobium composite carbide required to be produced, and mixing the tantalum-containing solution and the niobium-containing solution; adding a precipitant A, and performing chemical co-precipitation reaction to obtain a tantalum hydroxide and niobium hydroxide mixed slurry; eluting the tantalum hydroxide and niobium hydroxide mixed slurry with ammonia water or purified water, and drying eluent to obtain tantalum hydroxide and niobium hydroxide mixed powder; roasting the mixed powder at 800-1200 DEG C to obtain a precursor of the tantalum and niobium composite carbide; and adding carbon black, carbonating the carbon black in vacuum, performing ball milling, and sifting the carbon black to obtain a finished product, namely the tantalum and niobium composite carbide. A tantalum oxide and niobium oxide mixture is prepared by a chemical co-precipitation method, so that energy sources and auxiliary materials are saved, and raw materials are mixed more uniformly; in the co-precipitation method, the auxiliary materials are not mixed, so that a doping opportunity is reduced and precise control and calculation of components are very easy; therefore, a tantalum and niobium composite which has a relatively narrow grain distribution range and is more uniform can be prepared.

Owner:NINGXIA ORIENT TANTALUM IND

Hollow composite floor slab and construction method thereof

InactiveCN103981987AOptimize the force structureHigh strengthConstruction materialFloorsFloor slabReinforced concrete

The invention provides a hollow composite floor slab and a construction method of the hollow composite floor slab. The hollow composite floor slab is convenient to transport, low in breakage rate, small in self-weight, low in cost, large in rigidity and good in anti-seismic property. To achieve the aim, according to the scheme, the hollow composite floor slab comprises a prefabricated hollow slab body and a rear pouring reinforced concrete layer, and the prefabricated hollow slab body comprises a base board reinforced concrete layer and a porous concrete layer; a plurality of long through holes are longitudinally formed in the porous concrete layer at intervals; the two sides or the single side of the porous concrete layer are concaved in the two side faces of the base plate reinforced concrete layer, and a rear pouring portion is formed on the prefabricated hollow slab body; the rear pouring reinforced concrete layer is arranged above the prefabricated hollow slab body, and the porous concrete layer and the rear pouring reinforced concrete layer are meshed through a groove and beads. The construction method comprises the steps of manufacturing the prefabricated hollow slab body and mounting the hollow composite floor slab.

Owner:王睿敏

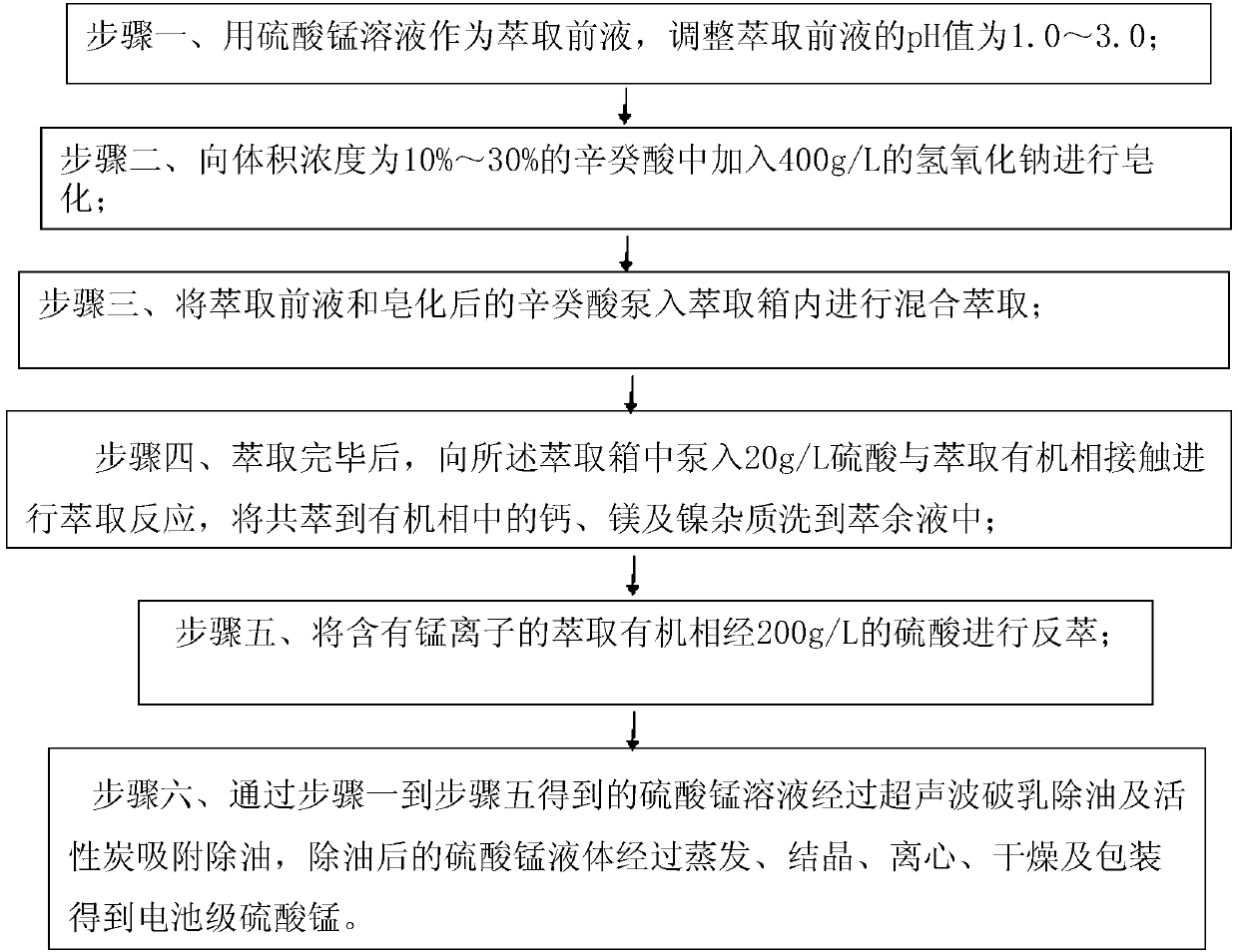

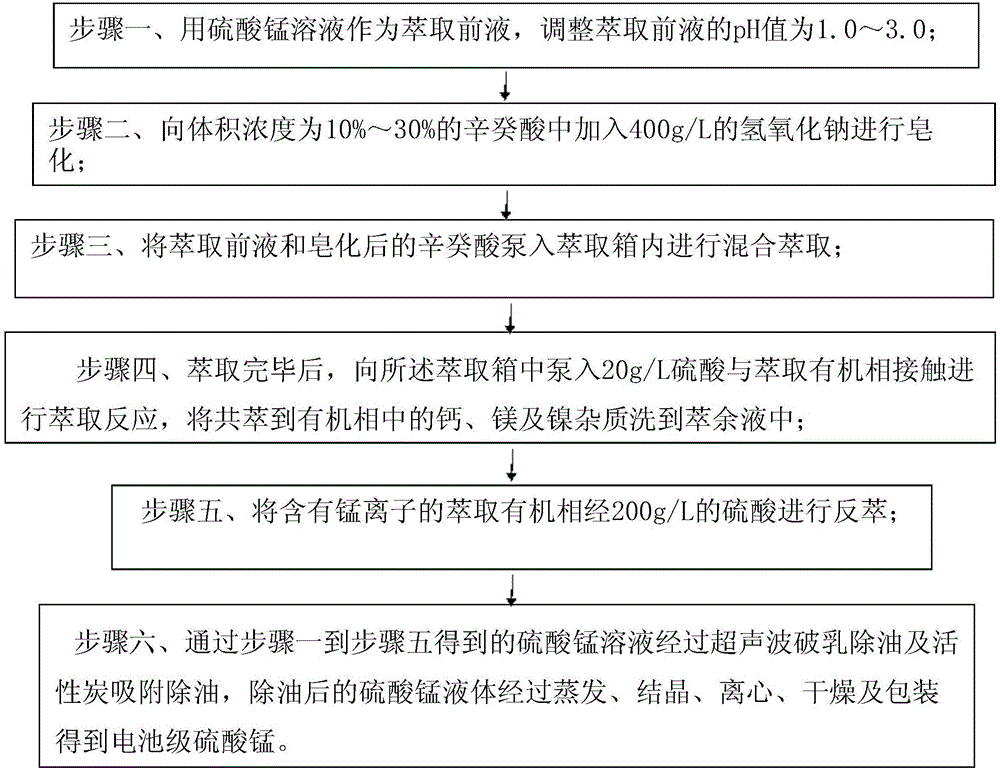

A kind of preparation method of battery grade manganese sulfate

ActiveCN106517347BSave energySave auxiliary materialsManganese compounds preparationManganese sulfatesManganeseHydrometallurgy

The invention provides a preparation method of battery-grade manganese sulfate and belongs to the technical field of hydrometallurgy. The method comprises steps as follows: step one, a manganese sulfate solution is taken as a pre-extraction solution; step two, 400 g / L of sodium hydroxide is added to octocapric acid for saponification; step three, the pre-extraction solution and octocapric acid after saponification are subjected to mixed extraction; step four, 20 g / L of sulfuric acid is pumped into an extraction box to be contacted with an extracted organic phase for the extraction reaction; step five, the extracted organic phase containing manganese ions is subjected to reverse extraction with 20 g / L of sulfuric acid; step six, battery-grade manganese sulfate is obtained. According to the method, the manganese sulfate solution with higher impurity content is enabled to enter an extraction system and the purpose of removing impurities is achieved by extraction, washing and reverse extraction of the solution; the overall technological process avoids chemical purification, chemical calcium removal and chemical magnesium removal processes, so that energy and auxiliary materials are saved, besides, no negative ions such as fluoride ions are introduced, and the requirement for equipment is reduced.

Owner:JILIN JIEN NICKEL IND

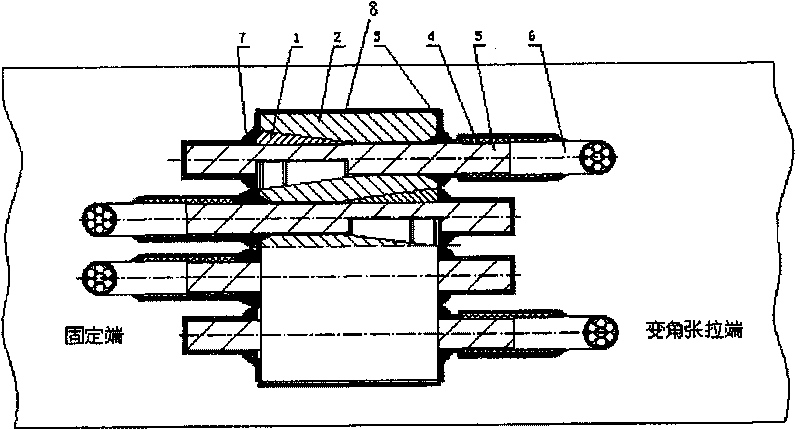

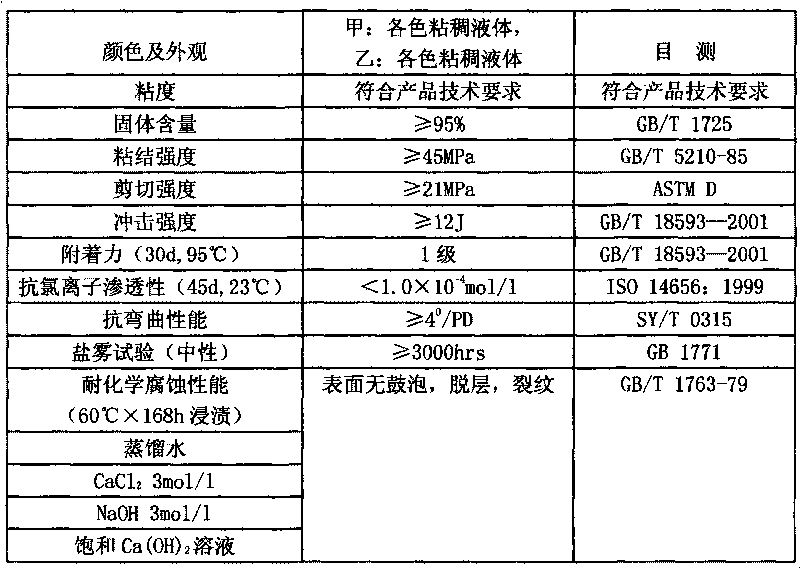

Protection method of prestressed concrete post-tensioning steel strand anchorage

InactiveCN101748414AUniform thicknessLow costLiquid surface applicatorsAnti-corrosive paintsPre stressThermosetting polymer

The invention relates to a protection method of a prestressed concrete post-tensioning steel strand anchorage, comprising the following requirements in sequence: (1) firstly, using a solvent-free thermosetting polymer liquid coating to repair a perfusion coating, concretely carrying out surface coating antiseptic maintenance treatment, and forming insoluble and infusible durable protective coatings at the outer part of the steel strand anchorage; the performance indicators of the solvent-free thermosetting polymer liquid coating should meet the requirements; (2) and selecting a perfusion plastic jacket and a clamp to carry out outer packaging protection to the prestressed concrete post-tensioning steel strand anchorage on site to connect the tensioning end with the fixing end of the anchorage into a body. The protection operating specifications of the protection method to the prestressed concrete post-tensioning steel strand anchorage are easy to comply, the protective effect is good, the service life is long, and the protection method has foreseeable huge economic and social values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

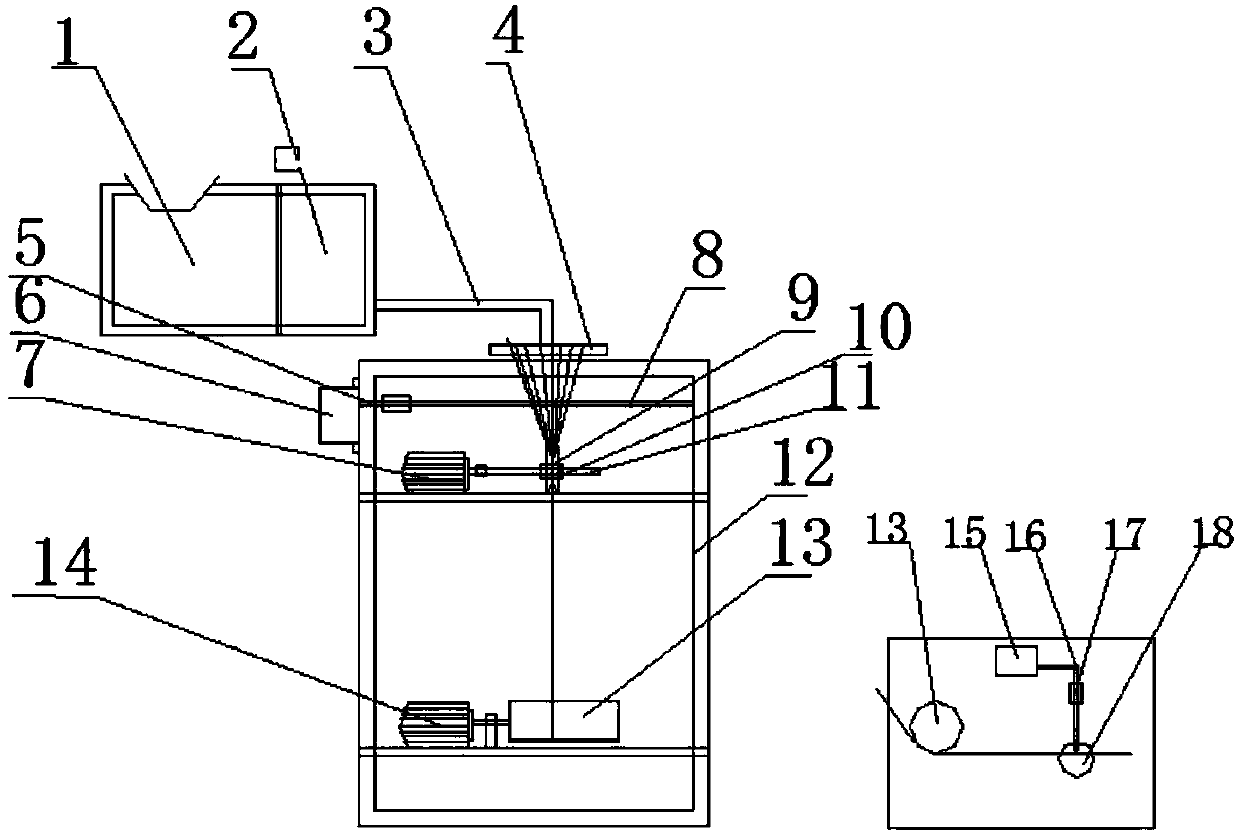

Glass fiber wire-drawing device

The invention discloses a glass fiber wire-drawing device which comprises a melting device, a wire-drawing device, an air jetting device, a bundle collection device and an oil coating device; the melting device comprises a ball-charging machine; a melting furnace is connected to one side of the ball-charging machine and is fixed above the wire-drawing device; the wire-drawing device comprises a wire-drawing rack, a bushing plate, a rotation motor, a coupler and a rotary drum; the air jetting device comprises an air pump, an air pipe, a transverse pipe and a nozzle; the air pump is arranged onthe outer side of the wire-drawing rack and is connected to the transverse pipe through the air pipe; and the transverse pipe is provided with an opening to be connected with the nozzle and is fixed to the rack and below the bushing plate. The glass fiber wire-drawing device has the beneficial effects that the temperature of wire drawing is controlled, the drawn wire is prevented from deformationdue to excessive temperature, the linear speed of the oil coating device is slowed down, and the auxiliary material is saved; and through wire drawing, the rate of produced finished products is increased, and the amount of waste wires is reduced.

Owner:SHANDONG FIBERGLASS GRP

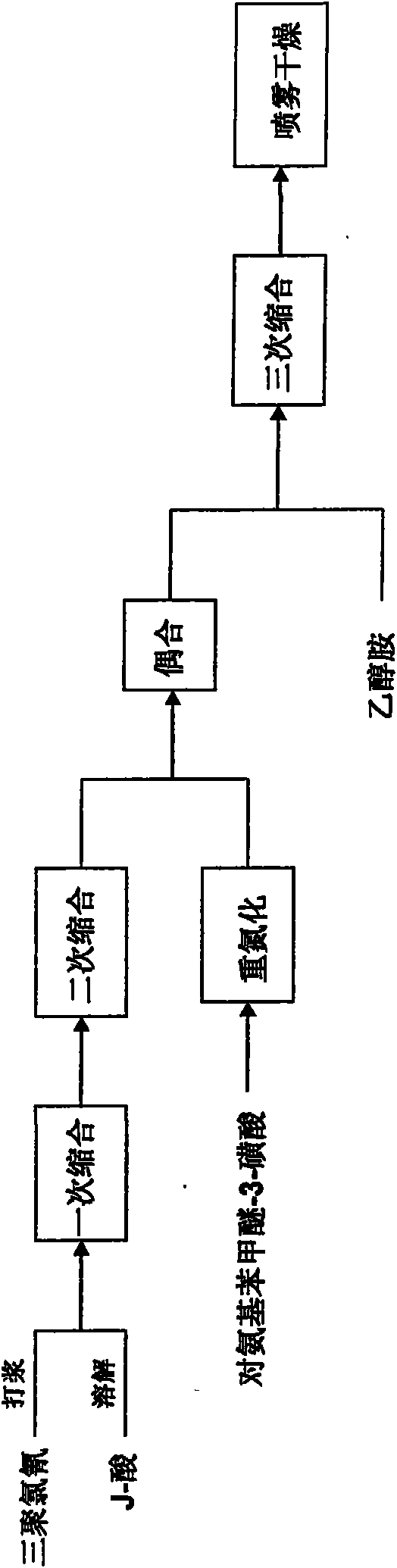

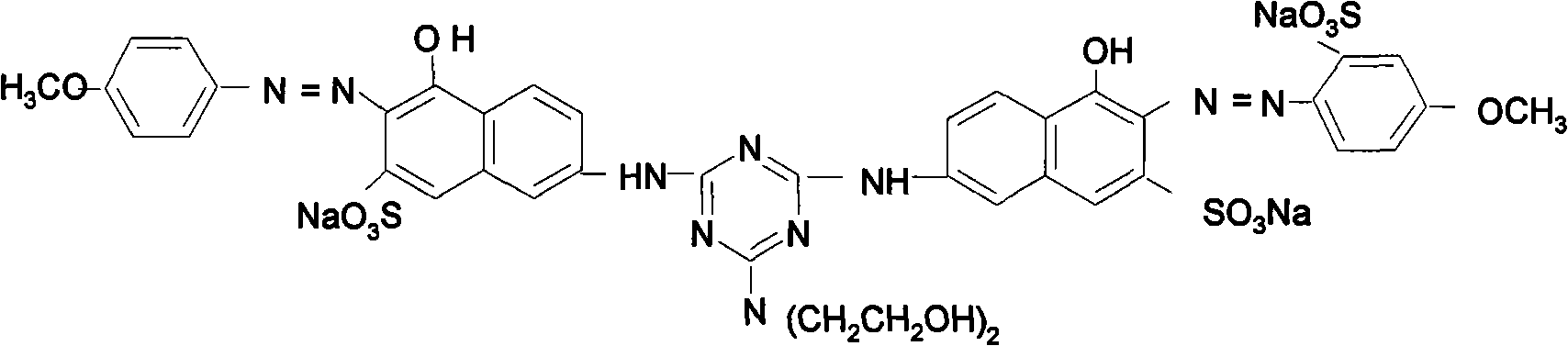

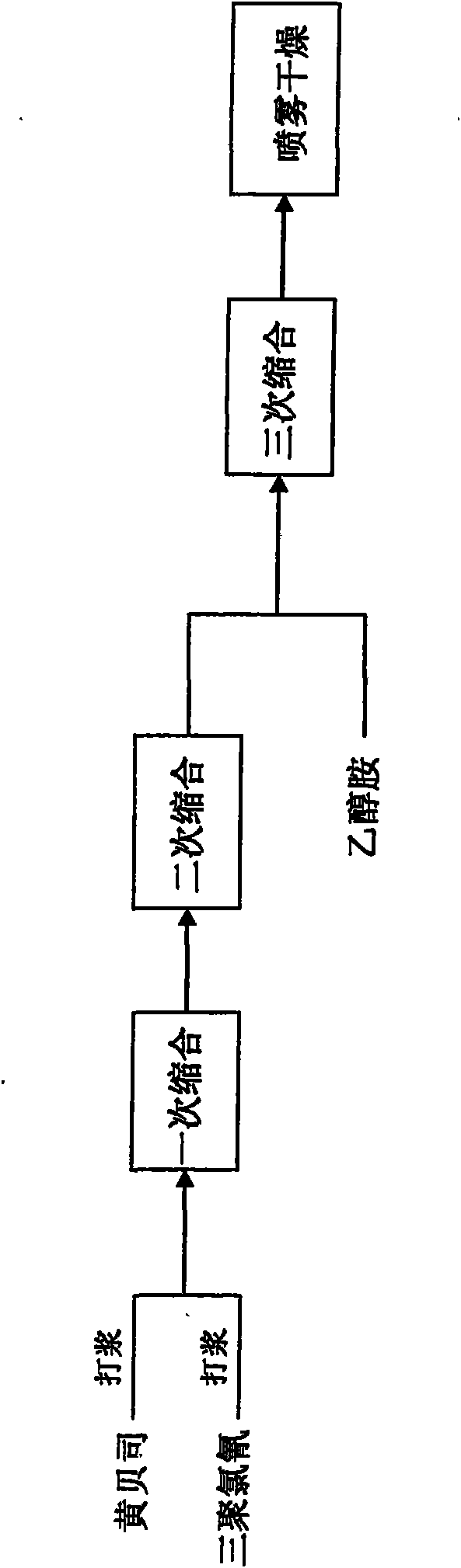

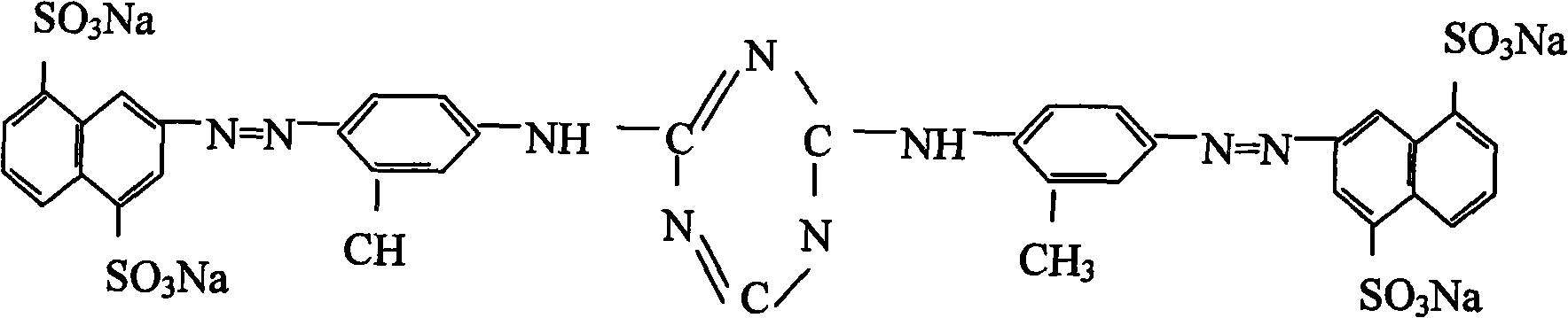

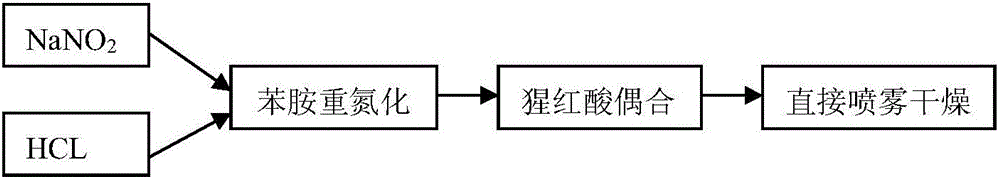

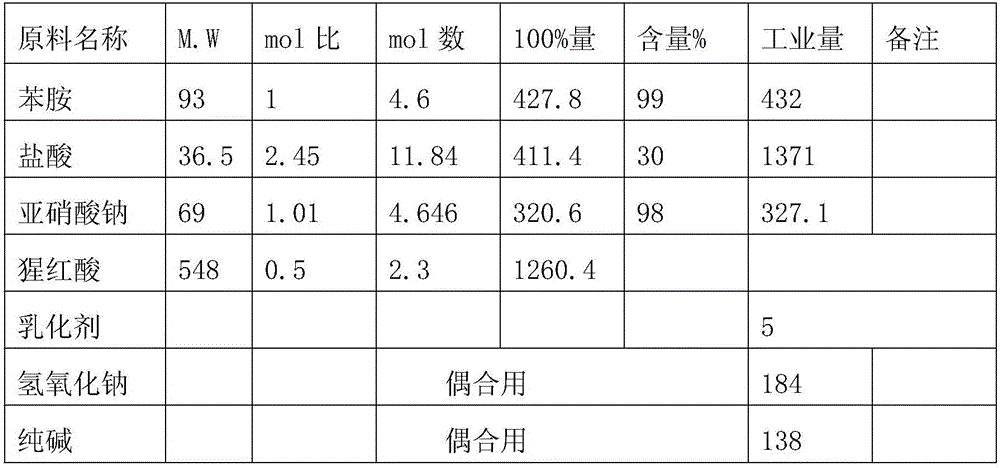

Pollution-free preparation technology of direct fast scarlet F2G

The invention relates to a pollution-free preparation technology of direct fast scarlet F2G, comprising the following implementation steps: firstly, primary condensation is carried out on pulped cyanuric chloride and J-acid under the pH of 4 to 4.5 at the temperature t of 0 DEG C to 5 DEG C; then, the pH is adjusted to 5 to 5.5, the temperature t is adjusted to 40 DEG C to 45 DEG C, and secondary condensation is carried out; and hydrochloric acid and sodium nitrite are added into anisidine-3-sulfonic acid, the mixture after diazotization is coupled with a secondary condensation product, ternary condensation is carried out on the obtained coupling product and diethanolameine to obtain the final product, and direct spray drying is carried out. The invention changes the traditional production technology condition of the direct fast scarlet F2G, omits the procedures of salting out, filter pressing and pulping and adopts a primary pulp direct spray method; zero discharge of industrial wastewater is achieved; compared with the traditional technology, the yield is greatly increased; large numbers of energy sources are saved, and environment pollution is also reduced; and the invention effectively increases the yield and the coloring intensity of dye, simplifies the technology, saves the cost and has very extensive market prospect.

Owner:TIANJIN YADONG CHEM & DYESTUFF FACTORY

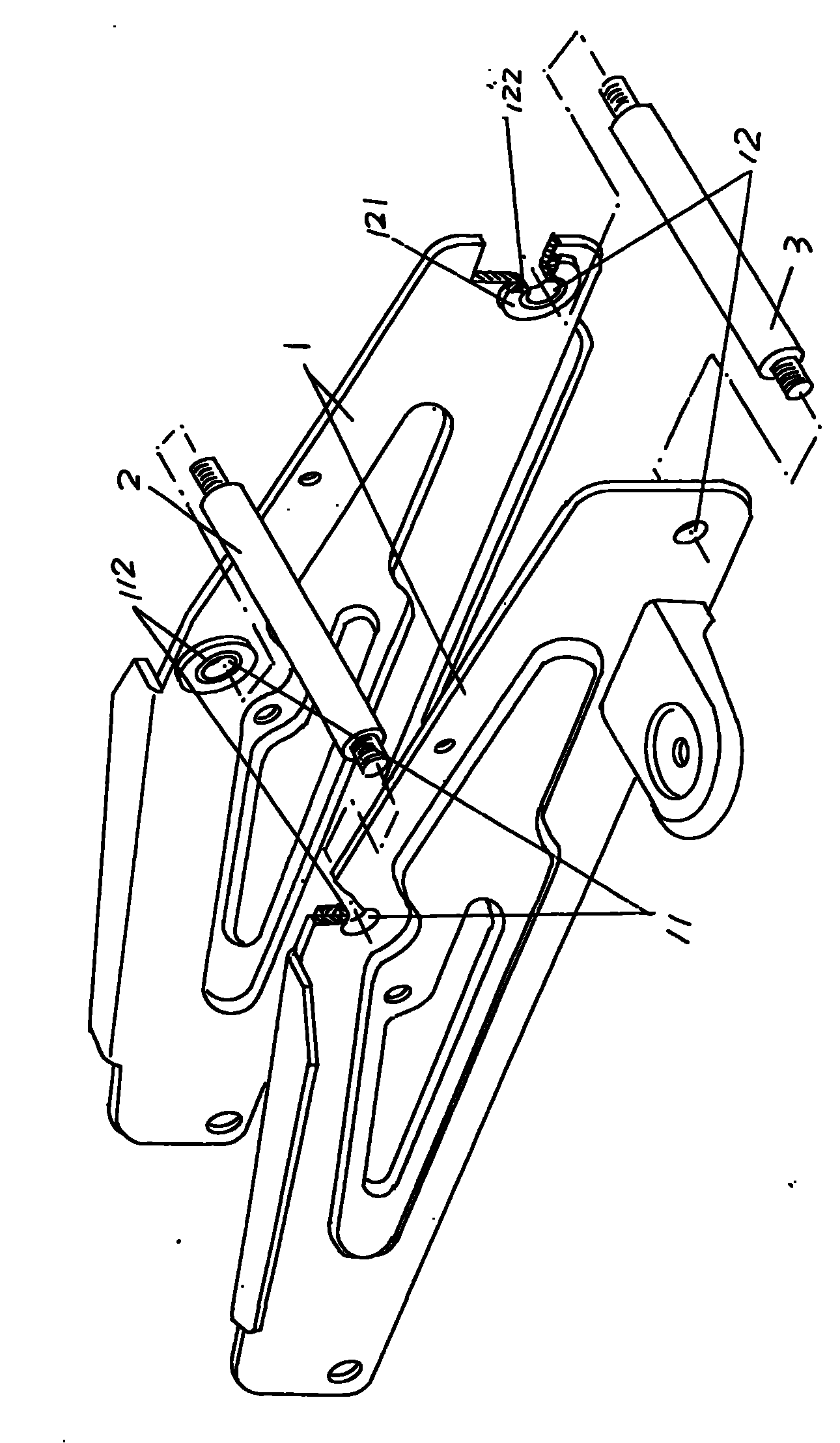

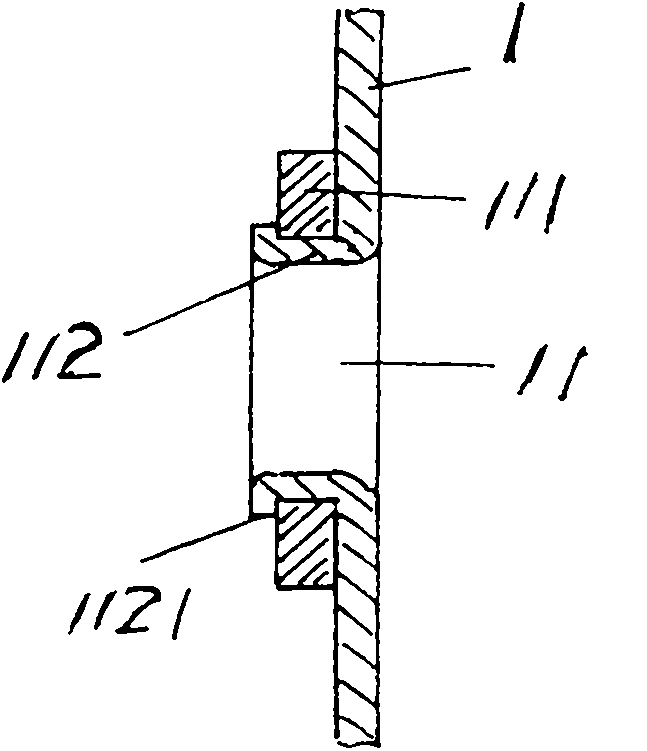

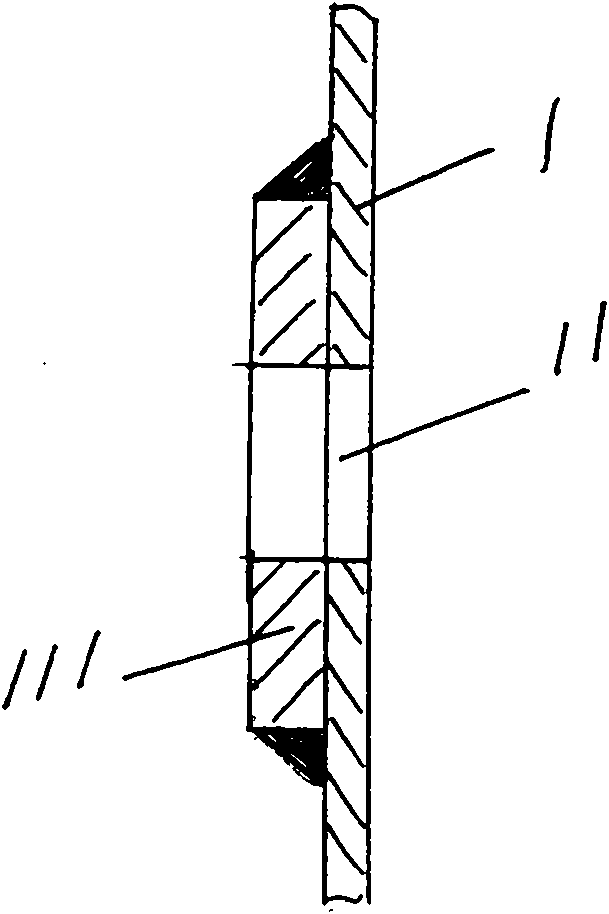

Method for processing horizontal type jack wallboard

InactiveCN102020219ASimple processingReduce processing stepsLifting devicesPulp and paper industrySoldering

The invention discloses a method for processing a horizontal type jack wallboard, and belongs to the technical field of processing of lifting tools. The method comprises the following steps of: simultaneously stamping an upper arm axle hole and a cylinder axle hole on a wallboard when the wallboard is molded with a stamping device, extending the material at the upper arm axle hole and the cylinder axle hole towards the back side of the wallboard so as to form an upper arm axle hole stacking ring and a cylinder axle hole stacking ring for enhancing the strength of the upper arm axle hole and the cylinder axle hole, and then covering an upper arm axle hole enhancing ring on the upper arm axle hole stacking ring and a cylinder axle hole enhancing ring on the cylinder axle hole stacking ring. According to the technical scheme of the invention, the upper arm axle hole enhancing ring and the cylinder axle hole enhancing ring are respectively positioned on the upper arm axle hole stacking ring and the cylinder axle hole stacking ring without welding so as to simplify the processing, reduce the processing steps, efficiently shorten the processing time, increase the processing efficiency and save the auxiliary materials which are used as soldering flux.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

Preparation method of battery-grade manganese sulfate

ActiveCN106517347ASave energySave auxiliary materialsManganese compounds preparationManganese sulfatesManganeseHydrometallurgy

The invention provides a preparation method of battery-grade manganese sulfate and belongs to the technical field of hydrometallurgy. The method comprises steps as follows: step one, a manganese sulfate solution is taken as a pre-extraction solution; step two, 400 g / L of sodium hydroxide is added to octocapric acid for saponification; step three, the pre-extraction solution and octocapric acid after saponification are subjected to mixed extraction; step four, 20 g / L of sulfuric acid is pumped into an extraction box to be contacted with an extracted organic phase for the extraction reaction; step five, the extracted organic phase containing manganese ions is subjected to reverse extraction with 20 g / L of sulfuric acid; step six, battery-grade manganese sulfate is obtained. According to the method, the manganese sulfate solution with higher impurity content is enabled to enter an extraction system and the purpose of removing impurities is achieved by extraction, washing and reverse extraction of the solution; the overall technological process avoids chemical purification, chemical calcium removal and chemical magnesium removal processes, so that energy and auxiliary materials are saved, besides, no negative ions such as fluoride ions are introduced, and the requirement for equipment is reduced.

Owner:JILIN JIEN NICKEL IND

Composite felt-type fabric manufacture process

InactiveCN102166875ASave auxiliary materialsHigh precisionSynthetic resin layered productsLaminationBatch productionManufacturing engineering

The invention relates to a composite felt-type fabric manufacture process. The composite felt-type fabric manufacture process comprises the following steps: (1) preparing a die; (2) carrying out gel coat construction on the surface of the die; (3) laying a reinforcing material; (4) laying vacuum bag materials according to the laying sequence of an upper demoulding cloth, a guide cloth and a vacuum bag; (5) evacuating the system constructed by the step (4) after the materials of the step (4) are laid; (6) preparing resin after the evacuation operation meets a certain requirement; (7) feeding the resin prepared in the step (6) to the system processed by the step (5); and (8) demoulding. The manufacture process can be used for manufacturing products with lighter weight and higher strength at a higher accuracy and a higher speed. In addition, the manufacture process ensures that the technique cost and the material cost during batch production are lowered.

Owner:SKYFORCE COMPOSITES KUSN

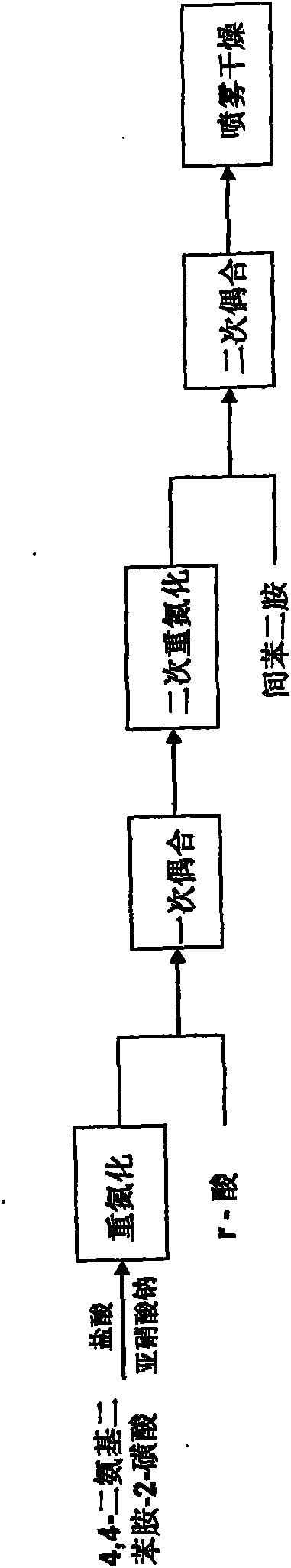

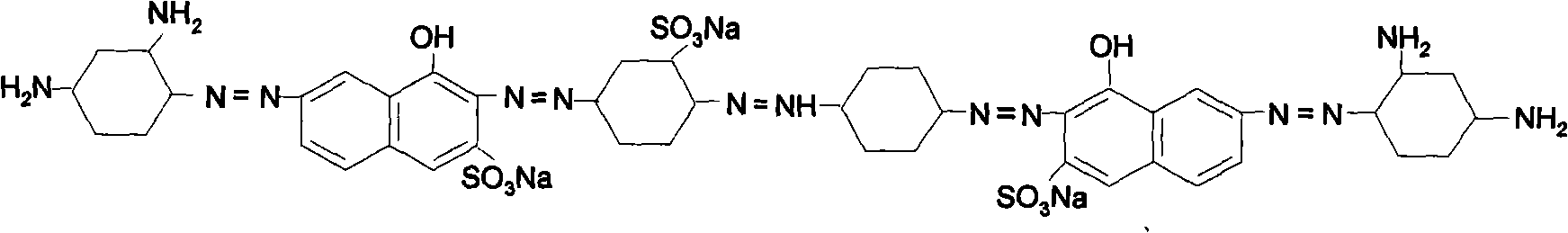

Direct spray drying preparation technology of direct fast black 22

The invention relates to a direct spray drying preparation technology of direct fast black 22. The technology is characterized in that the technology comprises the following implementation steps: firstly, diazotization is carried out on 4, 4-diamino-diphenylamine-2-sulfonic acid, and then the 4, 4-diamino-diphenylamine-2-sulfonic acid is coupled with dissolved r acid under an alkaline condition; after hydrochloric acid and sodium nitrite are added into the primary coupling product for carrying out secondary diazotization, secondary coupling is carried out on the mixture with the pH of 9 to 9.5 and lentine, and the coupling temperature is controlled at t of 10 DEG C to 15 DEG C; and after the reaction is completed, the mixture is delivered to a drying tower for direct spray drying, and then the final product is obtained. In the invention, the traditional production technology condition is changed, the procedures of salting out, filter pressing and pulping are omitted, and the optimized technology directly transfers primary pulp after secondary coupling to the drying tower for spray drying. Zero discharge of industrial wastewater is achieved. Compared with a traditional technology, the yield is greatly increased. The invention effectively increases the yield and the coloring intensity of dye, reduces energy consumption and simplifies the technology; and with steady quality, pollution reduction effect and cheap price, the invention has very strong competitive strength and very extensive market prospect.

Owner:TIANJIN YADONG CHEM & DYESTUFF FACTORY

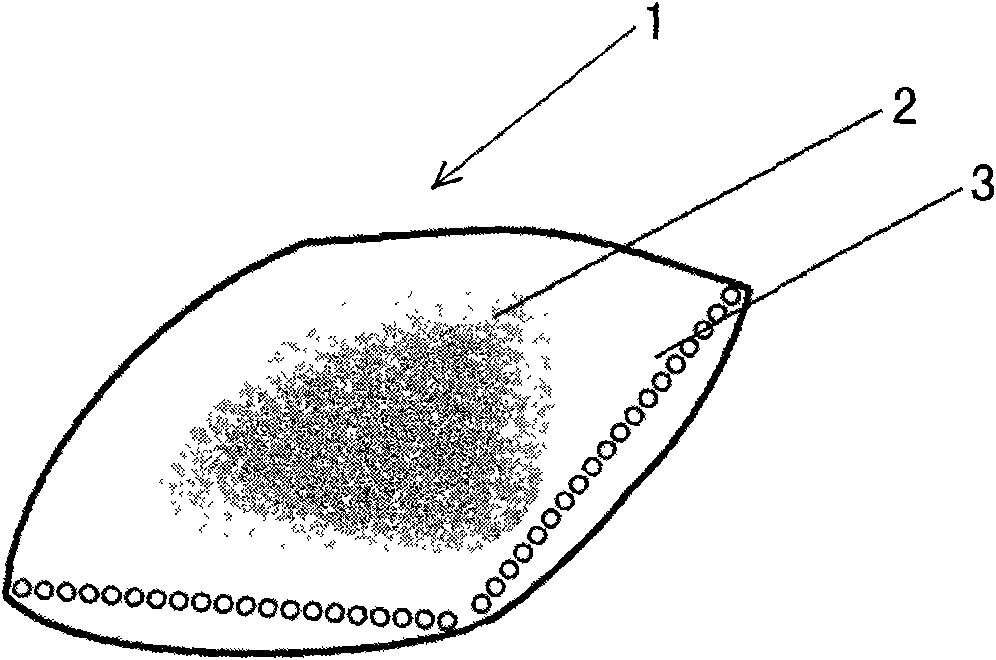

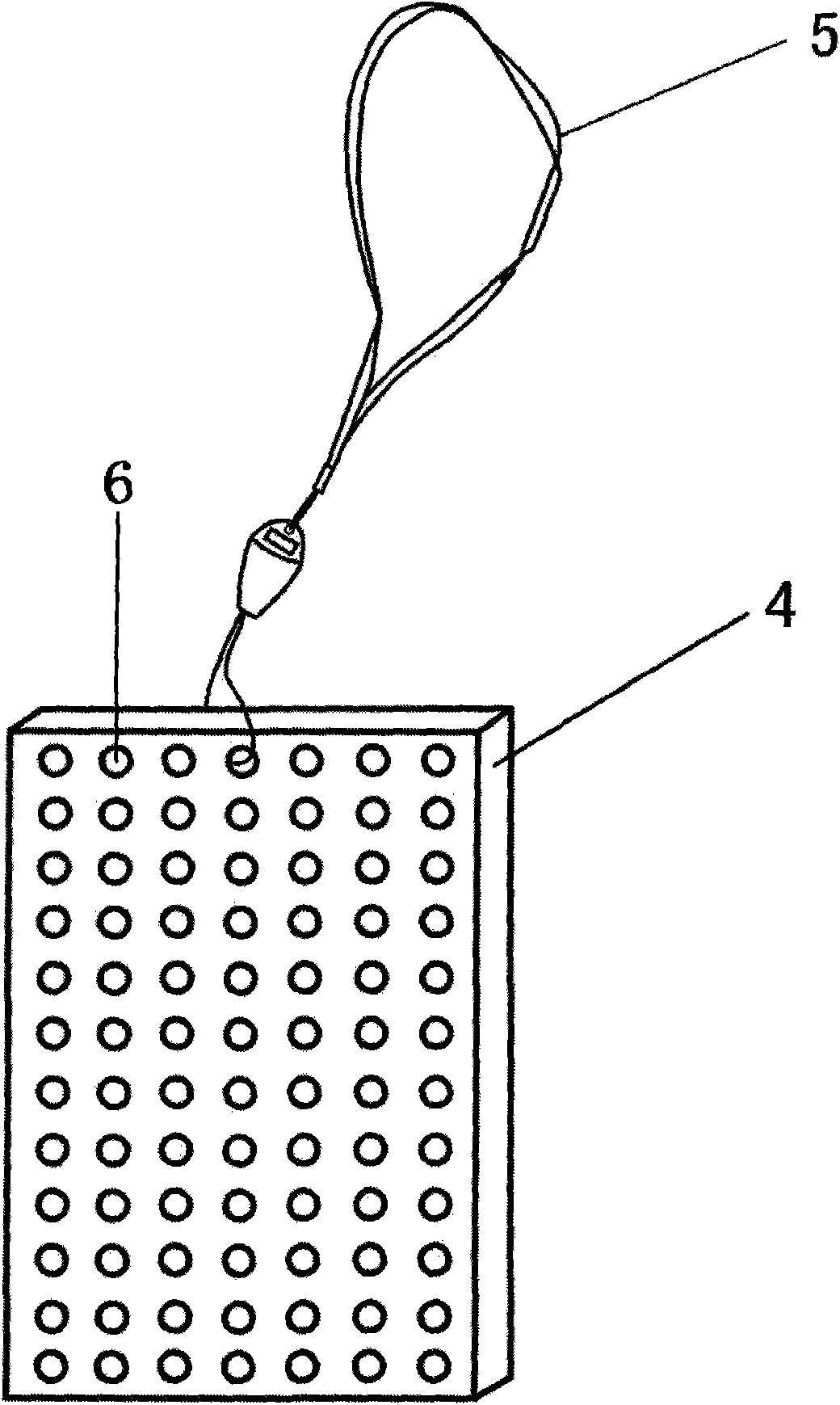

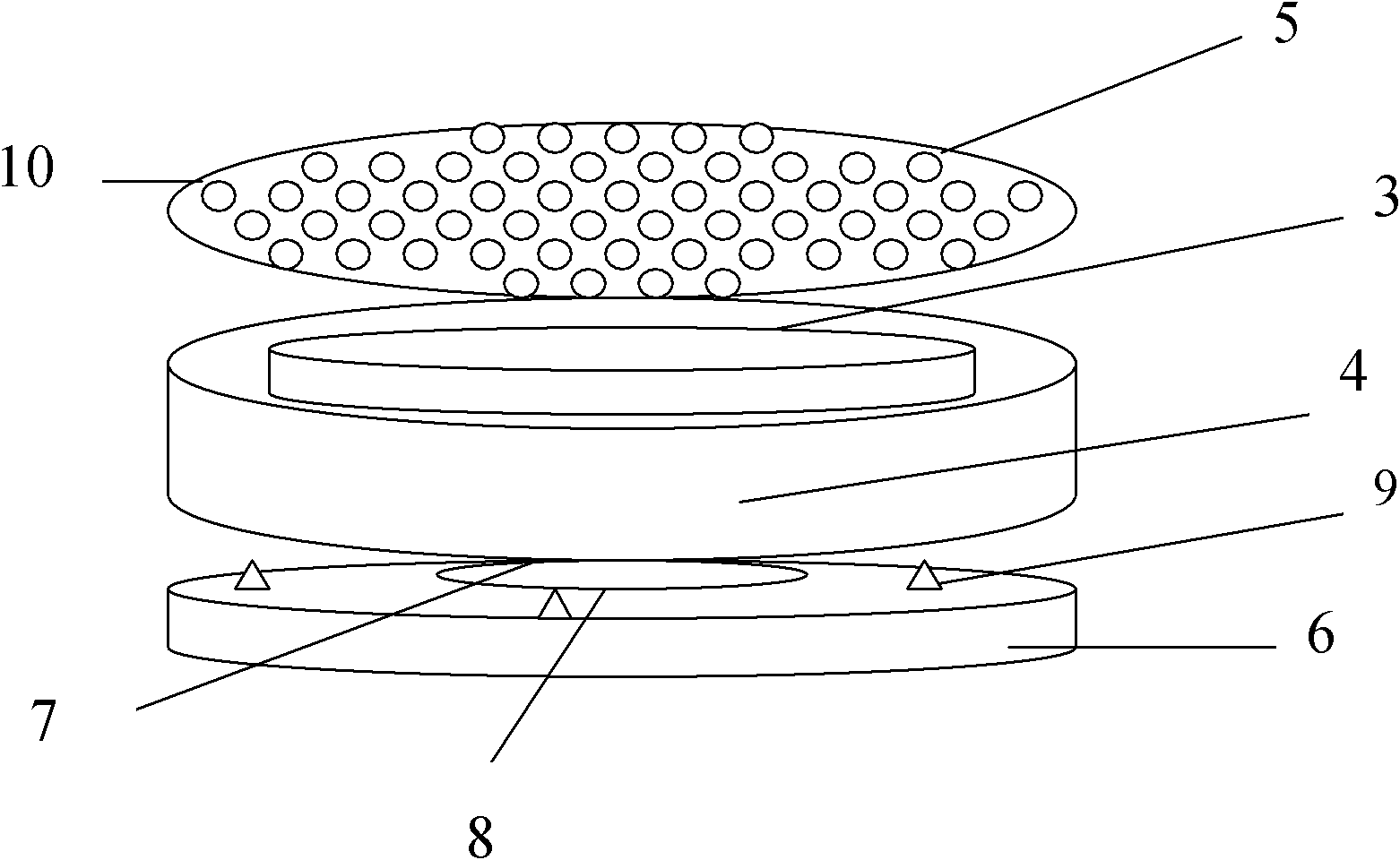

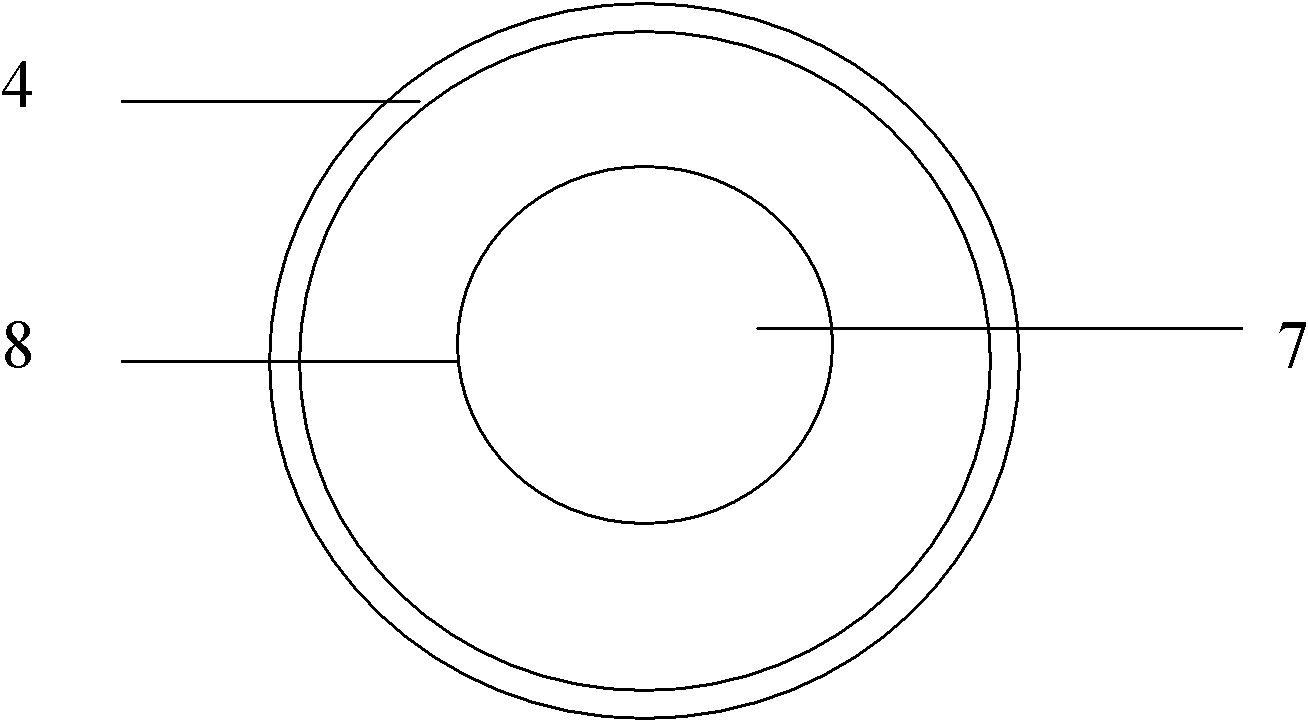

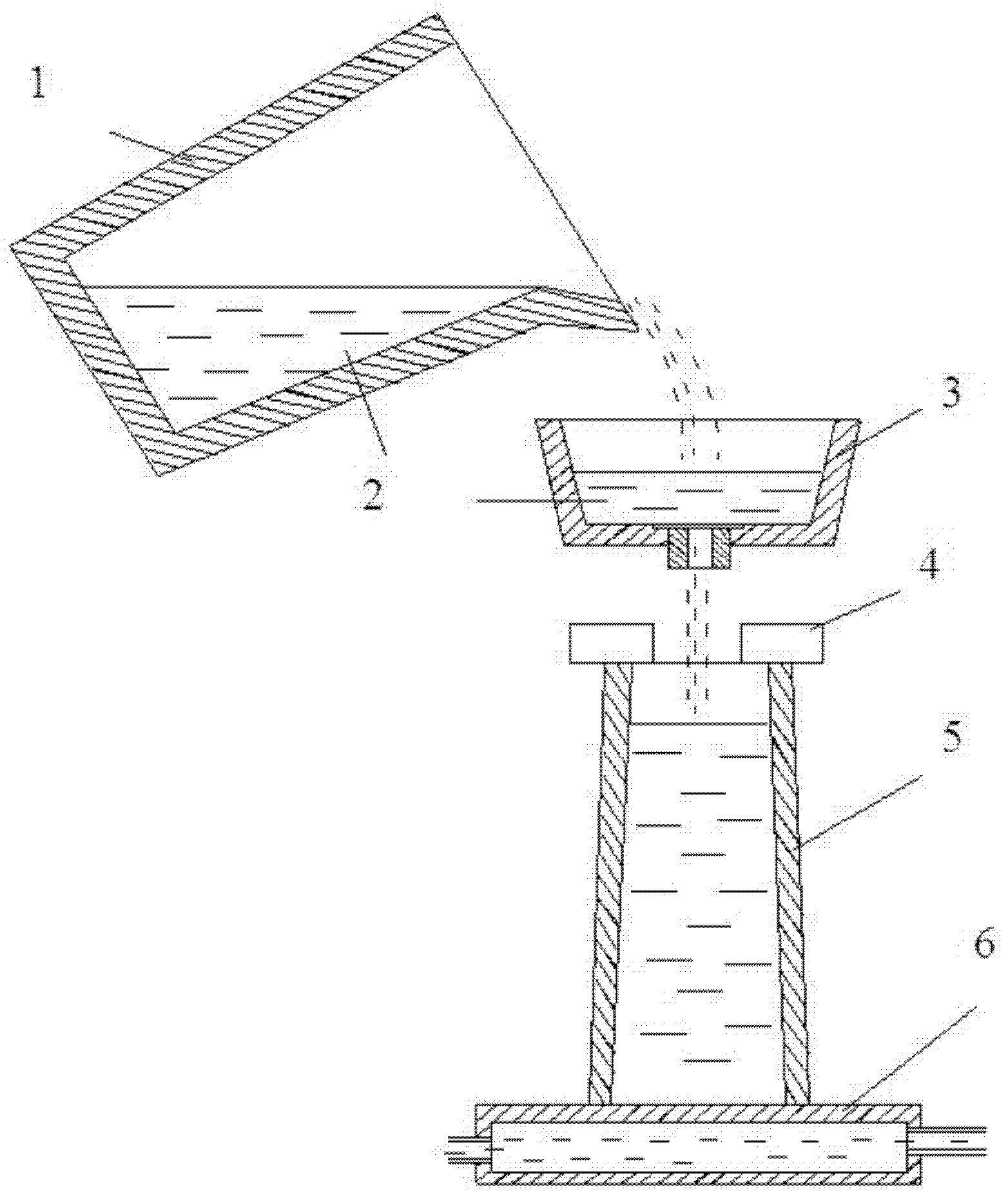

Medical suspended preparation and preparation method thereof

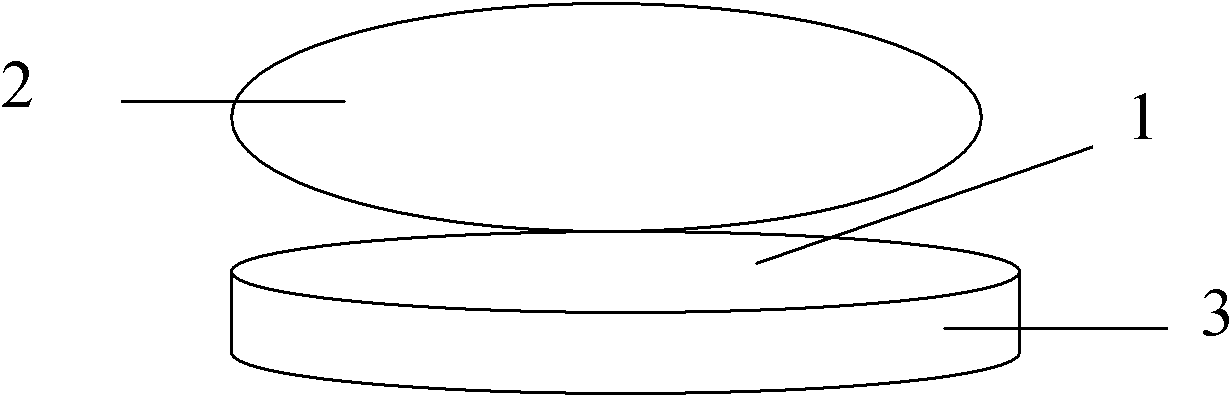

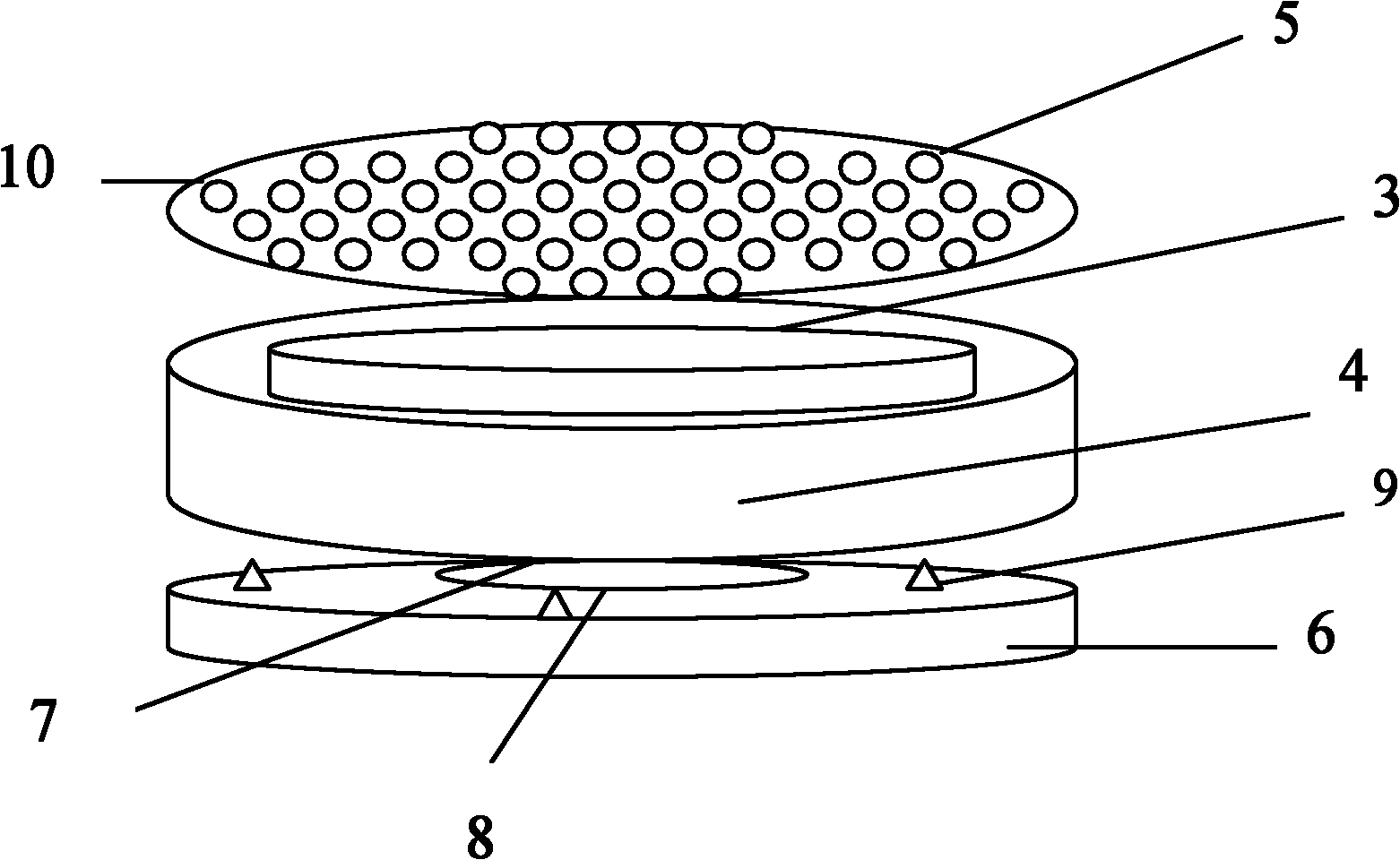

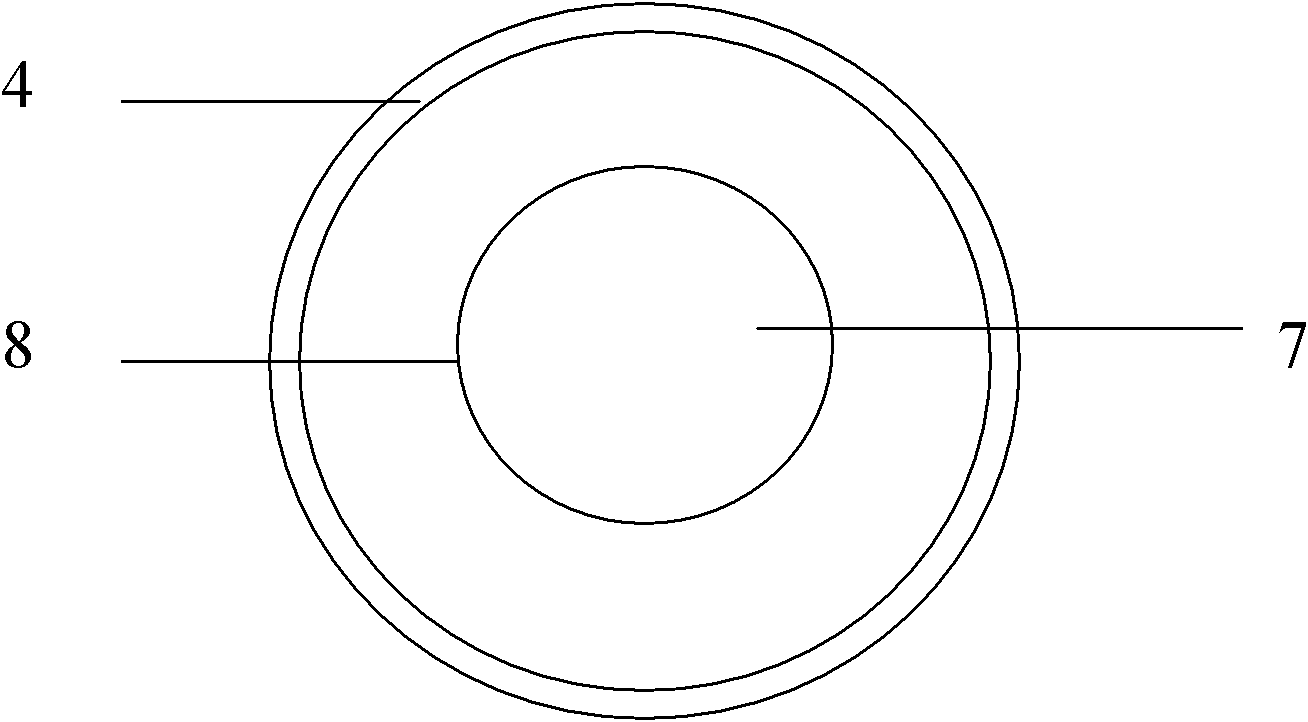

ActiveCN101849886ALow costSave auxiliary materialsTravelling carriersHoldersTransdermal patchAdhesive

The invention discloses a medical suspended preparation and a preparation method thereof. The medical suspended preparation is used for treating and preventing diseases or regulating physiological functions through medical information without contacting human or animal body skins. The basic structure of the medical suspended preparation is composed of a medicament bank (1), a container (4) and a connecting piece (5). Contents (2) are medicaments having pharmacological activities. When the preparation is used in treatment, no medicinal material matters enter a human or animal body, so safety problem as well as the simulation of oral preparations to the gastrointestinal tract, the first-pass effect of the gastrointestinal tract, the drawbacks of pains, cross-infection risks and injection and infusion reactions of injections, the simulation and damage of transdermal patchs to skin, the damage of adhesive to skin, and the like are avoided. The product can be used repeatedly, so the consumption of medicaments is reduced greatly, medicament resources are saved, environmental pollution caused by pharmaceutical industry is reduced greatly, and ecological is protected. The preparation is simple, convenient and safe to use and is particularly suitable for treating the aged and weak, children, people with mental retardation and animals.

Owner:杨孟君

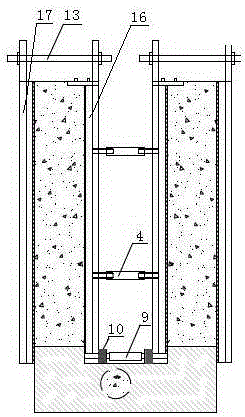

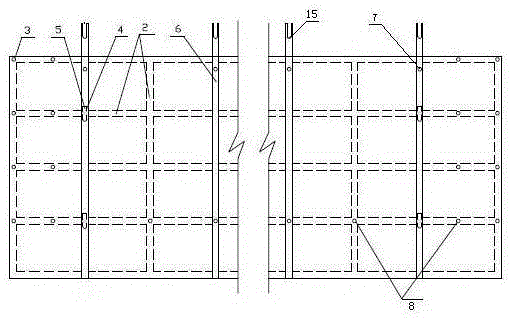

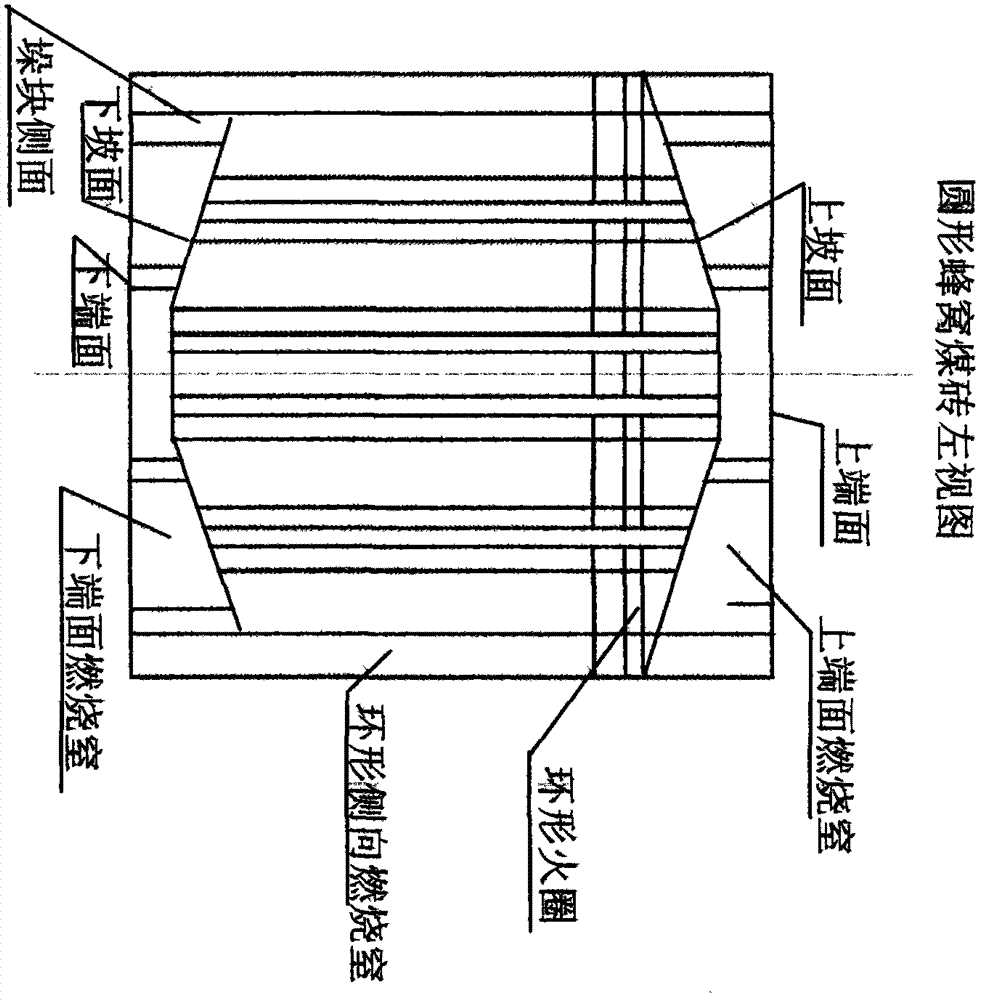

Wall continuous pouring nonmetal horizontal slip form system for deep and narrow drainage ditch

ActiveCN105178256AIncreased shear strengthReduce deflection deformationSewerage structuresArtificial water canalsRear quarterEngineering

A wall continuous pouring nonmetal horizontal slip form system for a deep and narrow drainage ditch comprises a unit slip form. A unit slip form body is composed of inside plates and outside plates. The inside plates are manufactured and located through adjusting type fixed supporting rods, and bottom rolling wheel shaft sleeves and bottom rolling wheels are arranged at the bottoms of the inside plates. The tops of the inside plates and the tops of the outside plates are fixed through top opposite-pull lead screws, and the surfaces of the tops of the inside plates and the surfaces of the tops of the outside plates are closed by cover plate pressing plates. The system has the beneficial effects that a novel form board is high in bending resisting and shear resisting strength and small in flexibility deformation, and the mechanical property is great superior to that of a common wood form board; plant prefabrication machining standardization and serialization are achieved, machining losses are small, and the cyclic use frequency is large; and mounting and dismounting are convenient, the workloads of form erecting and dismounting are greatly reduced, and the form board use efficiency is improved.

Owner:江苏海宏智能科技有限公司

Centrifugal casting method of chromium-containing high silicon cast iron anode tube

The invention relates to a centrifugal casting method of a chromium-containing high silicon cast iron anode tube. The centrifugal casting method is characterized by comprising the steps: preparing, smelting, refining, pouring, mold stripping, insulating and fire returning, specifically, preparing raw materials in percentage by weight: 14.2-14.75% of silicon, 3.25-5% of chromium, 0.7-1.1% of carbon, 0.1-0.5% of copper, and 78.65-81.75% of iron according to the proportion; smelting the raw materials for 50-60 minutes, refining after the temperature of the melt achieves 1400 DEG C, adding 0.3% of rare earth-silicon alloy when the interior of a refining furnace achieves 1420 DEG C, and pouring when the temperature achieves 1450 DEG C; controlling a centrifugal machine at 1800-2500 turns / minute; conducting cast cooling at 1000-1050 DEG C for stripping a mold; filling a cast into a holding furnace, controlling the furnace temperature to be 1000-1020 DEG C, holding the temperature for 60 minutes, conducting natural cooling for baking along with the furnace. The problems that sand type and metal type cast chromium-containing high silicon cast iron anode tubes are uneven in wall thickness and poor in product property, and the centrifugal casting method is best technology for producing the chromium-containing high silicon cast iron anode tubes.

Owner:QINGDAO YOUCHANG ANTI CORROSION LIGHTNING PROTECTION MATERIAL

Solar cell module electrode tension test device

InactiveCN105703709AQuick testEasy to installPhotovoltaic monitoringPhotovoltaic energy generationEngineeringBattery cell

The invention relates to a solar cell module electrode tension test device. A solar cell module comprises a silicon cell and a solder strip welded to the silicon cell. The test device comprises glass used for installing and fixing the silicon cell, and a tensile machine of which one end is connected with the glass and the other end clamps the welding head of the solder strip. After the tensile machine is started, the separation force between the solder strip and the silicon cell can be tested. Compared with the prior art, the test device can effectively increase the speed of cell electrode tension test, ensure the accuracy of electrode tension data, and the like.

Owner:CEEG SHANGHAI SOLAR SCI & TECH

Sealing performance detection method for single-frame protection air-tight door

InactiveCN109443656AAchieve independent detectionImproving the efficiency of detecting the sealing performance of protective airtight doorsMeasurement of fluid loss/gain rateAir tightnessIndustrial engineering

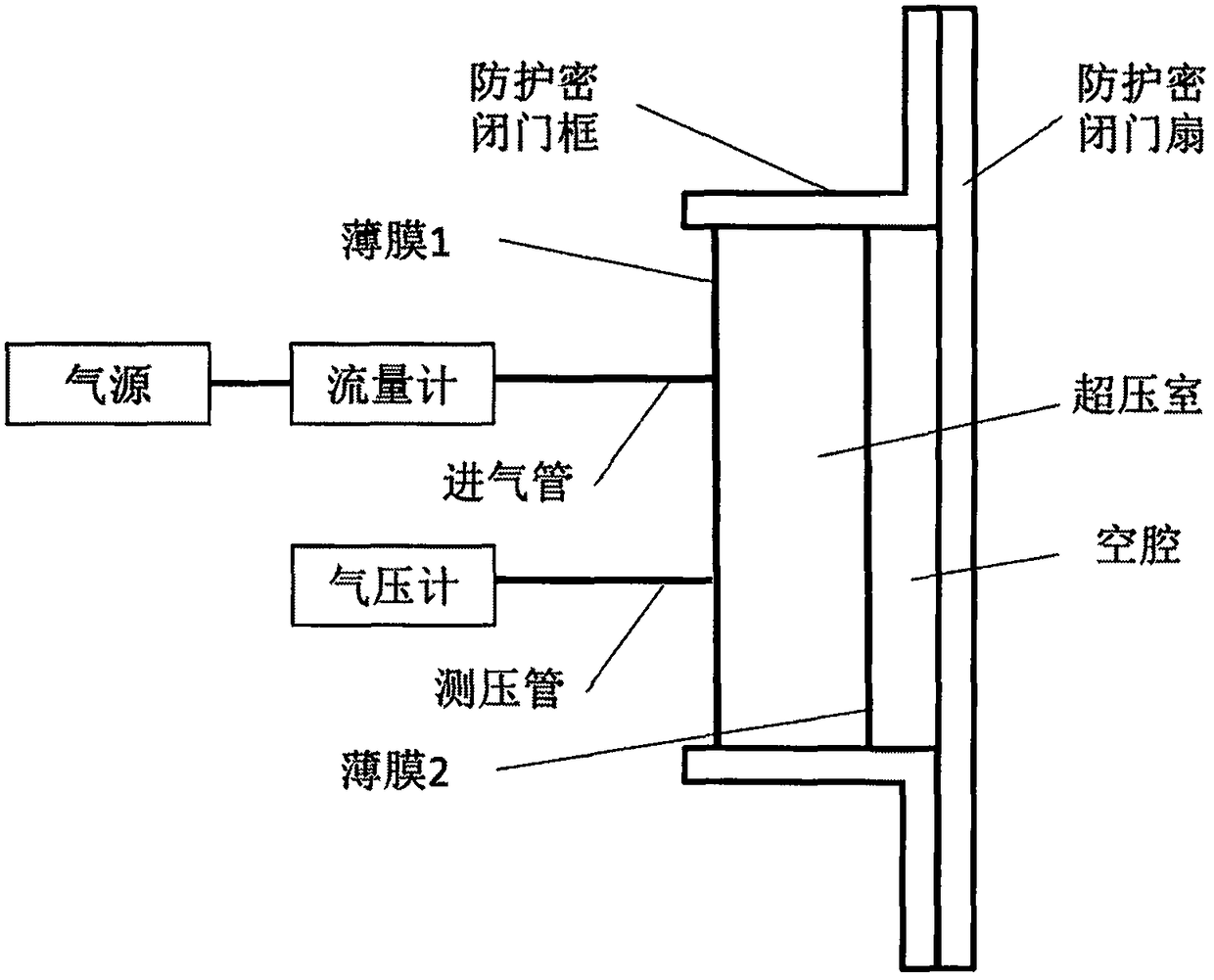

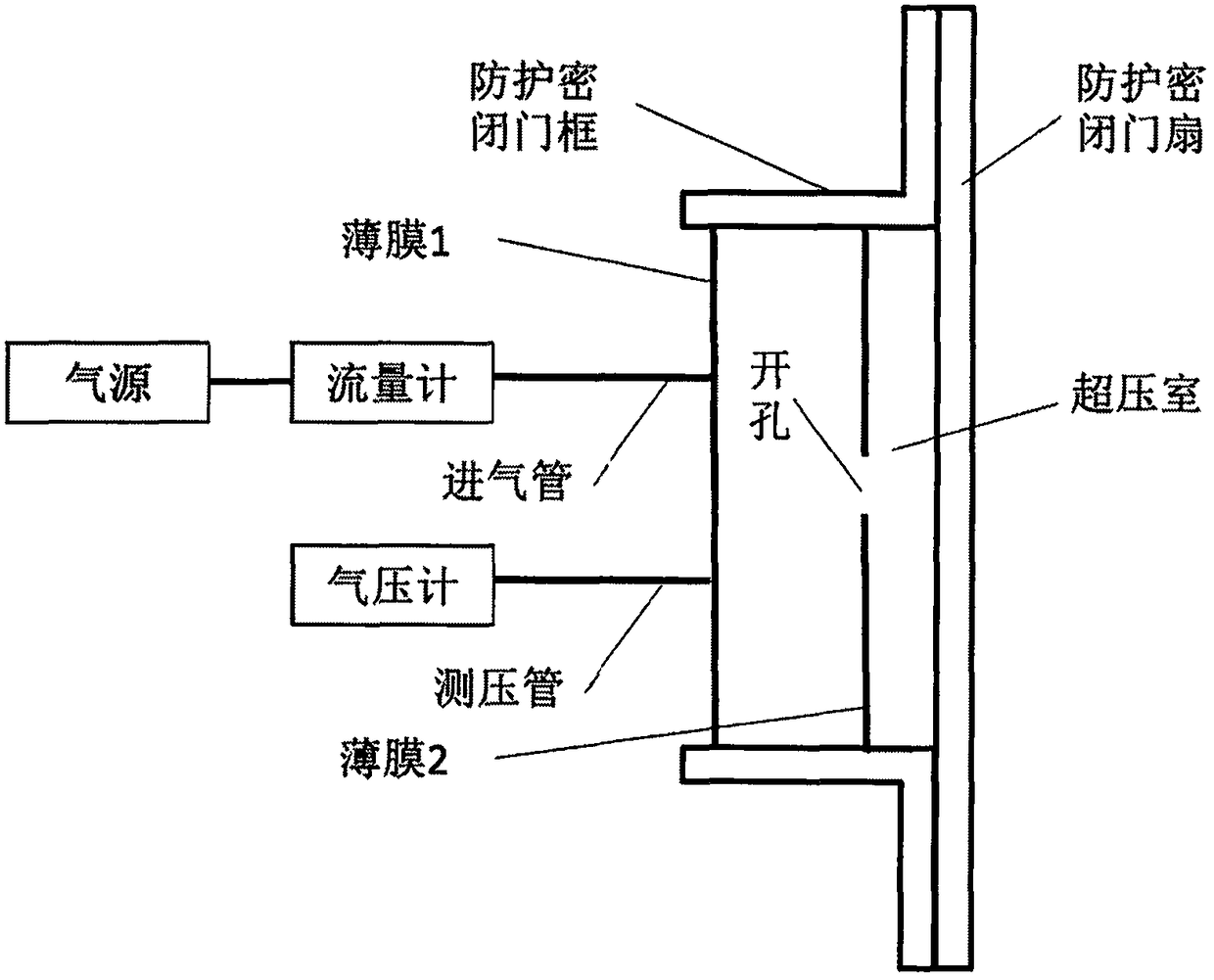

The invention relates to a sealing performance detection method for a single-frame protection air-tight door. According to the method, two layers of films which are made of a PE material are used to form an air-tight overpressure chamber; after the air leakage amount of the air-tight overpressure chamber is measured and confirmed, a reserved opening in the film 2 is opened, process operation to test the air leakage amount is performed. With the detection method adopted, the efficiency of detecting the sealing performance of the protection air-tight closed door can be improved, and the difficulty that the airtightness detection of the air-tight door cannot be performed at an engineering site at present can be eliminated. The method can be widely applied to the independent and rapid detection of the airtight performance of protective devices.

Owner:北京海岸灰狐智能科技有限公司

Pollution-free preparation technology of direct fast yellow D-RL

ActiveCN101580644AReduce saltHigh tinting strengthDisazo dyesIn situ polymerizationReaction temperature

The invention discloses a polyurea formaldehyde coated with organic tin compound microcapsule and a preparation method thereof. The invention adopts an in-situ polymerization method, takes urea and formaldehyde as main wall material raw materials, takes a catalyst organic tin compound as a main capsule core raw material, takes water as a reaction medium, selects surface active agents of different varieties and adjusts the pH value of a reaction solution system to 4 to 5 by controlling a certain rotating speed, the reaction temperature is 30 DEG C to 50 DEG C, and the polyurea formaldehyde coated with organic tin compound microcapsule is obtained by synthesis after the reaction is carried out for 2 to 4 hours; and white microcapsule particles are obtained by carrying out water / acetone washing, leaching and drying on the reaction product. The polyurea formaldehyde coated with organic tin compound microcapsule synthesized by adopting the in-situ polymerization method has simple technology operation and easy control, the yield of synthesized microcapsule products is 85% to 95%, and the polyurea formaldehyde coated with organic tin compound microcapsule can be used for the control of the solidification reaction of thermosetting resin and the toughening and modification of correlative materials simultaneously.

Owner:TIANJIN YADONG CHEM & DYESTUFF FACTORY

A honeycomb briquette brick

The invention relates to a honeycomb briquette brick and belongs to solid fuel. Compared with honeycomb briquette, the honeycomb briquette brick has innovative combustion chambers so as to generate an epoch-making combustion method that is an internal combustion method. By the internal combustion method, the heat efficiency generated by the honeycomb briquette brick is extremely high, the combustion strength is high, and fault coal even coal gangue can be adopted as a combustion material. The honeycomb briquette brick can be combusted continuously, no black smoke generates when a new honeycomb briquette brick is added, and the flame combustion is not influenced. Coal gas is combusted when the honeycomb briquette brick is combusted, thus achieving zero emission. A brick which is a building material is discharged after the honeycomb briquette brick is combusted. The honeycomb briquette brick is free of dust discharge and coal cinder discharge. The honeycomb briquette brick fundamentally improves the environment. The honeycomb briquette brick allows a tube furnace to be compact in structure and simplified and to have characteristics of small size, light weight, small floor space, easy manufacturing and low total cost. The upper and lower parts of the honeycomb briquette brick are provided with end-surface combustion chambers. The external side surface of the honeycomb briquette brick is an annular side combustion chamber. The honeycomb briquette brick is covered by the combustion chambers, namely, the honeycomb briquette brick is combusted while being covered by flame. The honeycomb briquette brick is widely used for various coal furnace appliances.

Owner:张启凤

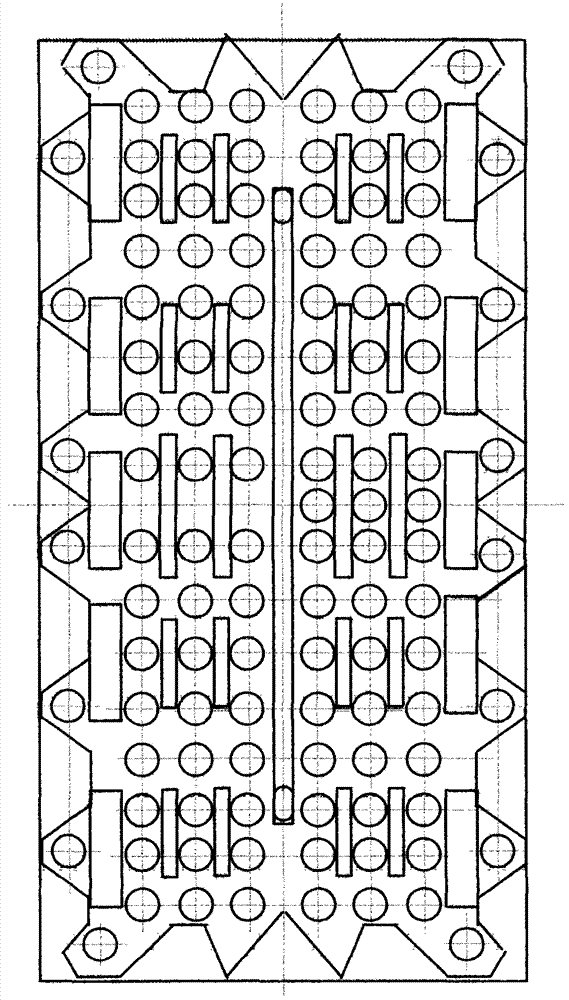

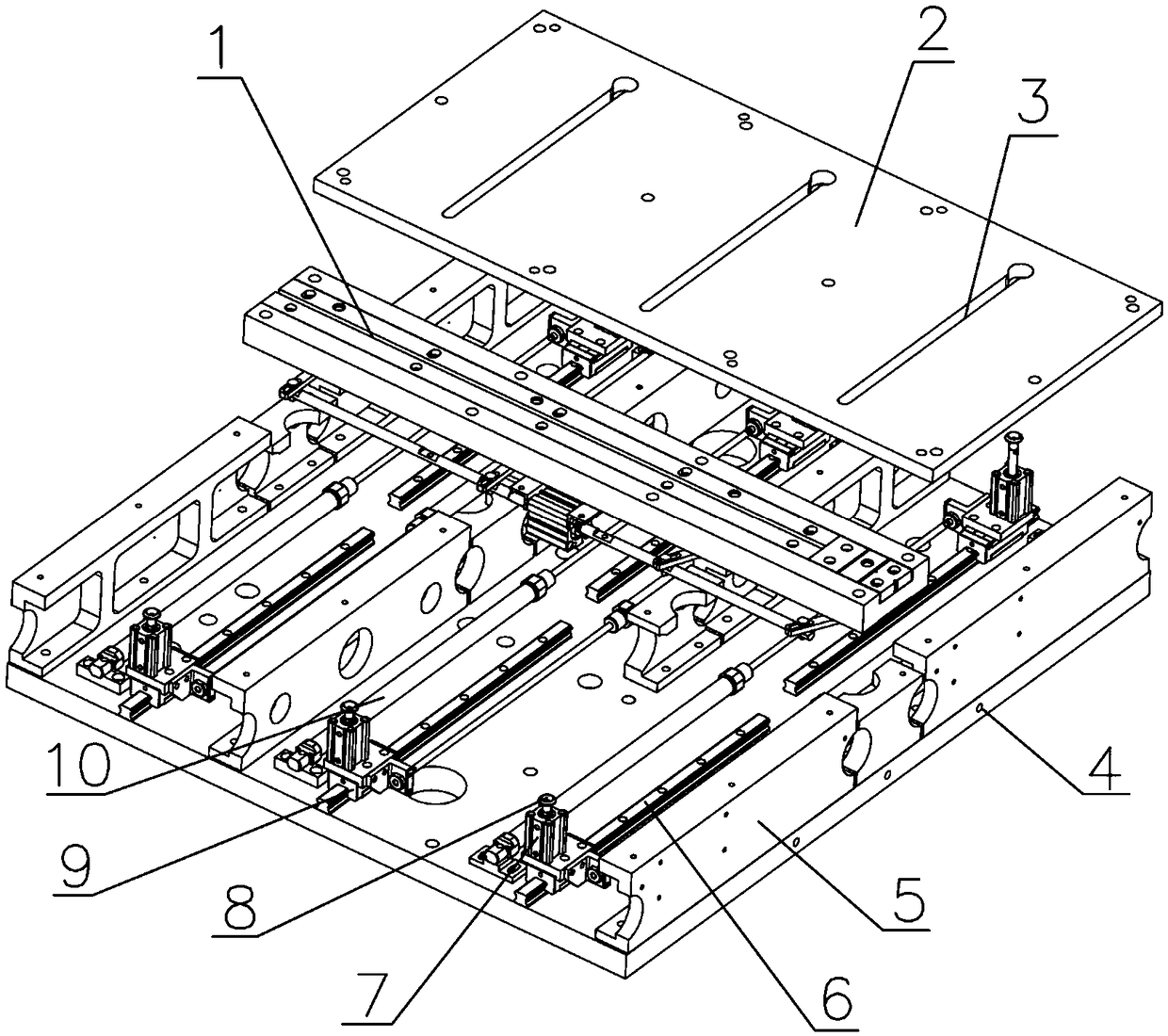

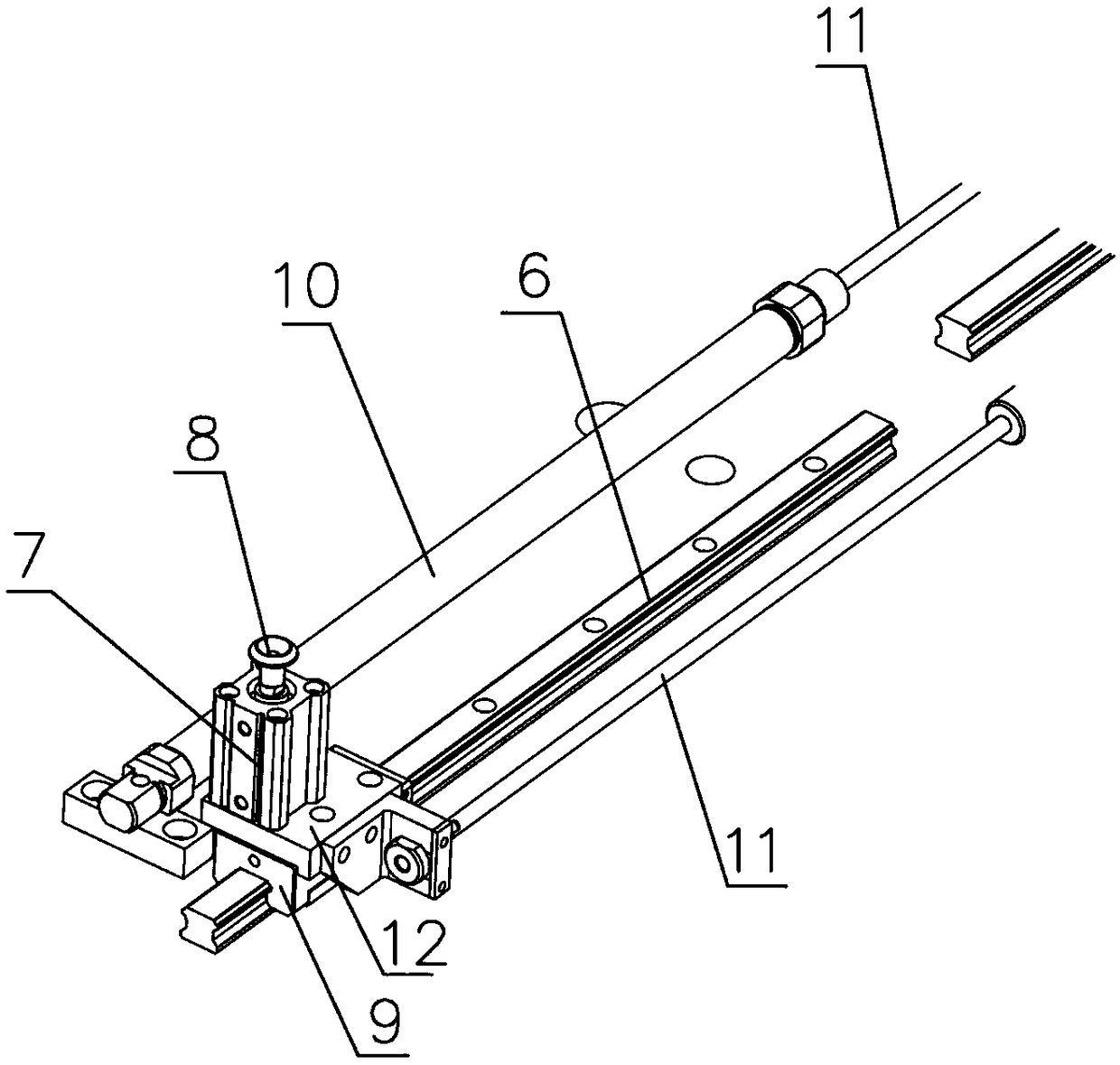

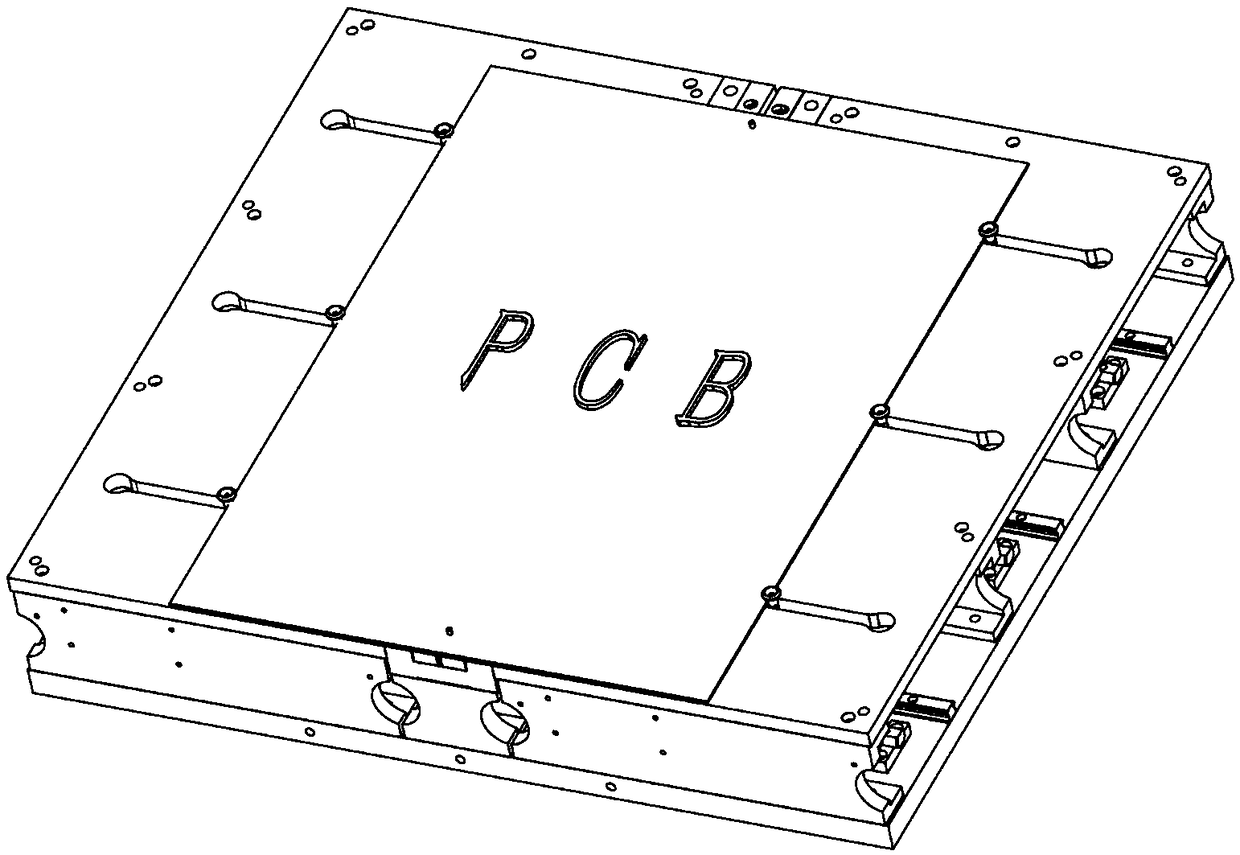

Double positioning mechanism for PCB numerical-control machine tool

ActiveCN109262320AAvoid position shiftReduce workloadWork clamping meansPositioning apparatusNumerical controlPaper adhesive tape

The invention discloses a double positioning mechanism for a PCB numerical-control machine tool. The double positioning mechanism is structurally characterized in that assistant supporting members parallel to each other are fixed on left and right sides of a workbench bottom plate, two ends of a clamping mechanism are arranged in grooves in the middles of the assistant supporting members, two workbench faceplates are fixed on two sides of the clamping mechanism and positioned above the assistant supporting member, and each workbench faceplate is at least provided with a sliding groove for cooperating with a compressing ring to move back and forth; a fastening unit is arranged in a space formed by the workbench faceplates and the workbench bottom plate and is structurally characterized in that an oriented guide rail is arranged right below a sliding groove, the oriented guide rail, an oriented slider, a compression cylinder and a compression ring are arranged sequentially, and the oriented slider is connected to a distance adjusting cylinder. The double positioning mechanism can process PCBs with various size specifications without using a paper adhesive tape to bond and compress each PCB and is flexible and multipurpose, so that time consumed by working personnel at this stage is reduced, and assistant materials are saved.

Owner:CHENGDU JINDALI TECH

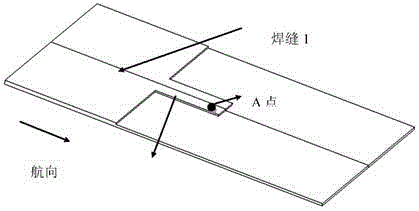

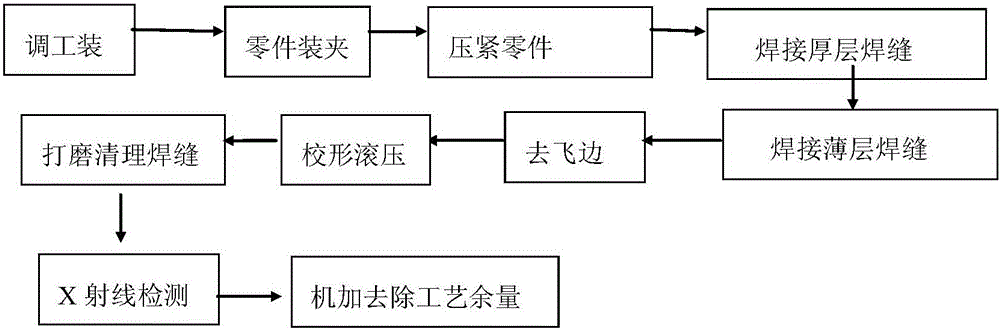

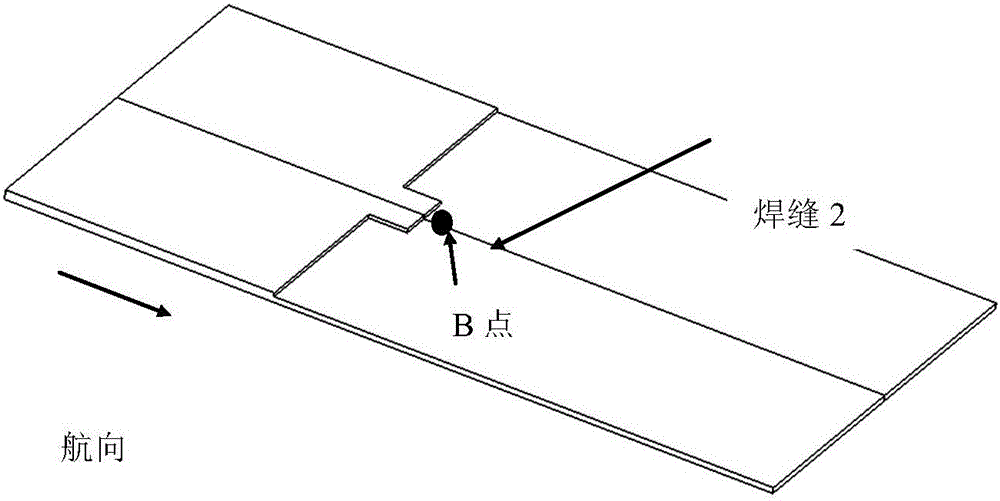

Friction stirring welding method of weld joint in step structure

ActiveCN106001906AImprove versatilityReduce manufacturing costNon-electric welding apparatusThin layerInvestment material

The invention belongs to the field of metal welding and particularly relates to a friction stirring welding method of a weld joint in a step structure. The friction stirring welding method of the weld joint in the step structure provided by the invention comprises the following steps: reserving process allowance at the step structure; during welding, firstly welding a thick layer in the step structure and welding a thick weld joint; then milling the process allowance, wherein the thick layer is aligned to a thin layer in the step structure; and then welding a thin weld joint from the milled weld joint. According to the method provided by the invention, a process test block is cancelled, the auxiliary materials are reduced, and the time of repairing and matching the process test block is shortened, and meanwhile, the risk of splashing when the process test block is milled is eliminated, and the stability of the welding quality of the weld joint is ensured and the percent of pass of the part and the production efficiency are improved at the same time. Secondarily, the welding step is optimized, the universality of a tool is realized, and the manufacturing cost of the tool is lowered. Compared with the existing welding technology, the method provided by the invention has remarkable technical progress and has relatively huge practical application value.

Owner:SHAANXI AIRCRAFT CORPORATION

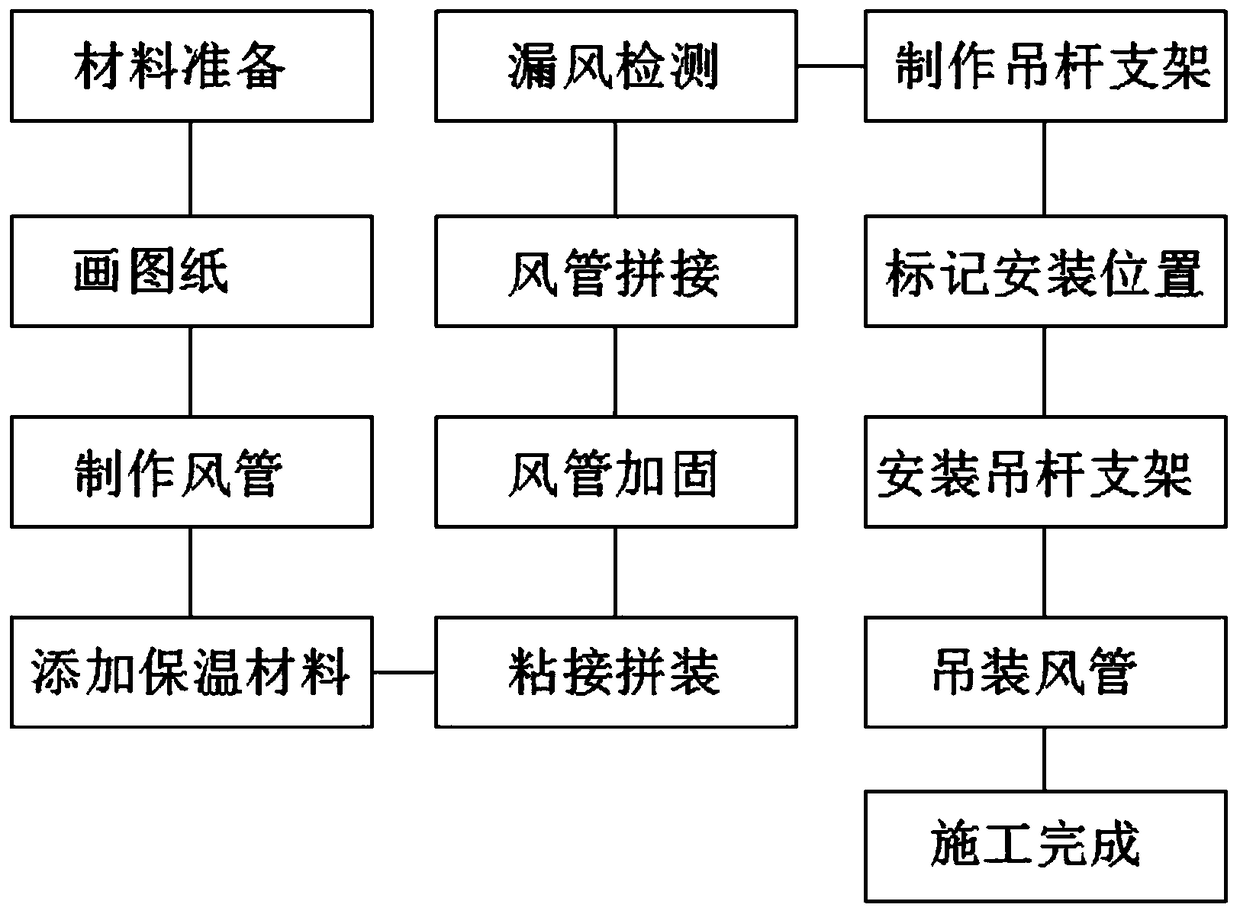

Construction technology of internal thermal insulation metal air pipe

InactiveCN109140066AImprove airtightnessEasy constructionPipe laying and repairThermal insulationMaterials preparationThermal insulation

The invention discloses a construction technology of an internal thermal insulation metal air pipe, and belongs to the field of air pipe construction technologies. The construction technology of the internal thermal insulation metal air pipe comprises the steps of S1, material preparation before construction; S2, drawing; S3, manufacturing of the air pipe; S4, addition of a thermal insulation material; S5, bonding splicing of splicing plates; S6, reinforcement of the formed air pipe; S7, splicing of the formed air pipe; S8, detection of air leakage; S9, manufacturing of a hanging rod and a bracket; S10, marking of a mounting position; S11, mounting of the hanging rod and the bracket; S12, hoisting of the air pipe; and S13, construction completion. According to the construction technology,a processing method is more scientific and reasonable, the engineering construction period is greatly shortened during manufacturing and mounting of the air pipe, besides, manufacturing and mounting of nonmetal composite air pipes are convenient, fewer auxiliary materials are required, maintenance is easy, construction is convenient, construction cost is low, comprehensive economic benefits are good, leakproofness of the air pipe is greatly improved, air leakage of connectors and flanges is reduced, and besides, strength is high, corrosion resistance is achieved, and manufacturing and mountingquality is reliable.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

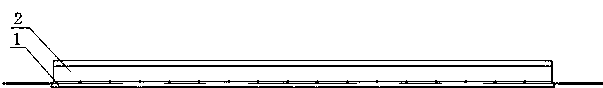

Construction method for bank protection engineering construction through integral steel sliding formwork structure

ActiveCN108612049AAvoid deformationHigh strengthCoastlines protectionEngineeringUltimate tensile strength

The invention relates to a construction method for bank protection engineering construction through an integral steel sliding formwork structure. The construction method comprises the following stepsthat S1, the position of a retaining wall is planned according to the bank situation, surveying and setting out are carried out, and a foundation pad is pre-laid; S2, a sliding rail is laid on the ground along the foundation pad, a steel sliding formwork is installed, and the installed steel sliding formwork is put on the sliding rail; S3, concrete is poured into the steel sliding formwork, 24 hours later, the steel sliding formwork is tested to slide for the first time, and debugging is carried out; S4, after debugging is completed, the steel sliding formwork forwards moves along the slidingrail by a distance smaller than the length of the steel sliding formwork every time, rock block concrete is poured, 24 hours later after the rock block concrete is poured, the steel sliding formwork can be slid and moved again, rock block concrete is poured until pouring of the retaining wall is completed; and S5, after the retaining wall is completely poured, the steel sliding formwork is dismounted. The retaining wall body is poured in situ through the integral steel sliding formwork, the operation process is simple, few auxiliary materials are used, the cost is low, the working efficiency is high, and the poured retaining wall body is high in strength and good in flatness.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

Application of compound omeprazole in preparation of information treatment drug, preparation method of compound omeprazole, and prepared novel drug

InactiveCN102600147AGood treatment effectEliminate side effectsAntibacterial agentsOrganic active ingredientsChemical treatmentSide effect

The invention discloses an application of compound omeprazole in the preparation of information treatment drug, a preparation method of the compound omeprazole, and a prepared novel drug. The information treatment drug is characterized in that the drug is not contacted with a human body directly in the treatment, the substance ingredient of the drug cannot be consumed, only the drug information is used for physical treatment, and the chemical treatment effect can be achieved, a treatment window is enlarged by more than 1000 times, and the side effects of the chemical treatment are avoided. After the omeprazole is used as the information treatment drug, the contents of active ingredients are not changed, and the omeprazole can be used as the conventional preparation of the chemical treatment for secondary effective use.

Owner:北京中卫神农慢性病医学研究院有限公司

Direct orange S dye preparation process

InactiveCN106590015AImprove solubilityImprove the coupling effectDisazo dyesChemistryEnvironmental resistance

The invention relates to a direct orange S dye preparation process. Compared with an old process, the process is mainly characterized in that salting-out, filtration and crushing procedures are removed, raw stock is directly used for spray-drying, raw auxiliary materials are omitted, 20% of sodium chloride added in proportion in a traditional method is omitted, products treated by a spray drying tower are good in consistency, and time, coal, power, steam and the like are saved. The direct orange S dye preparation process has the advantages that clean production without wastewater discharge is achieved, energy resources are saved, traditional production process conditions of direct orange S dyes are changed, the production process is simplified, production cost is reduced, product quality is effectively improved, production yield is improved, production capacity is improved, the problem of environmental pollution caused by wastewater is fundamentally solved, and the preparation process has high commercial values and meets environment-friendly sustainable development.

Owner:TIANJIN YADONG CHEM & DYESTUFF FACTORY

Application of glibenclamide compound in preparation of information therapy medicament, method for preparing information therapy medicament, and novel drug prepared with method

InactiveCN102579463AGood treatment effectEliminate side effectsMetabolism disorderSulfonylurea active ingredientsChemical treatmentSide effect

The invention discloses an application of a glibenclamide compound in preparation of an information therapy medicament, a method for preparing the information therapy medicament, and a novel drug prepared with the method. The information therapy medicament is not in direct contact with a human body during treatment, the components of the medicament is not consumed, only medicament information is utilized for physical therapy, so that the chemical treatment effect can be achieved, the therapeutic window is enlarged by more than a thousand times, and the side effect of chemical treatment is avoided. After the glibenclamide is used as the information therapy medicament, the content of effective components of the glibenclamide is not changed, so that the glibenclamide can be used as a conventional preparation in chemical treatment for secondary effective use.

Owner:北京中卫神农慢性病医学研究院有限公司

Cantilever type semi-automatic inner separating plate welding device and method

InactiveCN111992915AImprove working environmentReduce intensityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringCantilever

The invention discloses a cantilever type semi-automatic inner separating plate welding device and method. The cantilever type semi-automatic inner separating plate welding device comprises a conveying device, a welding device, a rolling device and the like. The conveying device comprises a conveying platform, a square pipe cantilever and a cantilever supporting platform. A conveying box is weldedon the conveying platform, and conveying threaded rods and compaction rolling wheels are arranged in the conveying box from bottom to top. The square pipe cantilever passes through the conveying boxand is placed above the conveying threaded rods, and the upper portion of the square pipe cantilever is closely attached to the compaction rolling wheel. The cantilever supporting platform is welded to the tail end of the square pipe cantilever in the horizontal direction. A separating plate fixing device is welded to an end opening of the square pipe cantilever, and magnets are arranged on the separating plate fixing device. The welding device comprises a welding machine head and an electromagnetic relay. The welding machine head and the electromagnetic relay are placed on the cantilever supporting platform. A wire feeding pipe of the welding machine head passes through the interior of the square pipe cantilever, comes out of the front end of the square pipe cantilever and is fixed belowthe square pipe cantilever. The electromagnetic relay is connected with the magnets in a switch mode. The cantilever type semi-automatic inner separating plate welding method solves the problems thatcontinuous welding cannot be conducted on different pipe diameters due to the environment factor, and locating is difficult.

Owner:陕西建工泾渭钢结构有限公司

Nickel base alloy cast ingot and preparation method thereof

The invention discloses a preparation method of a nickel base alloy cast ingot. The preparation method comprises the following steps of: pouring nickel base alloy molten steel into a casting mould; and heating the molten steel in the casting mould by an electric arc device, and after that, cooling to obtain the cast ingot, wherein a pair of electrodes in the electric arc device are nonconsumable electrodes, and a bottom plate of the casting mould is a cooling water tank. The method greatly shortens the production period, saves the auxiliary material and saves a great deal of energy. The invention also discloses the nickel base alloy cast ingot prepared by the method, and the nickel base alloy cast ingot is good in crystalline state and high in alloy purity.

Owner:上海丰渠特种合金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com