Wall continuous pouring nonmetal horizontal slip form system for deep and narrow drainage ditch

A drainage ditch and non-metallic technology, which is applied to drainage structures, waterway systems, buildings, etc., can solve the problems of small operating space, long construction period, and reduced work efficiency, so as to increase the overall rigidity and strength, facilitate installation and disassembly, and improve The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

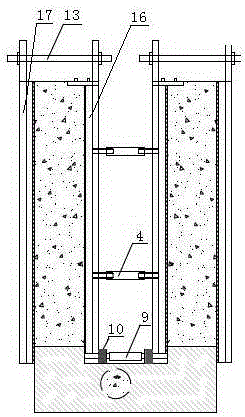

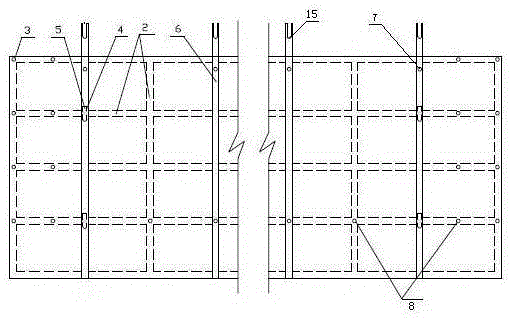

[0045] Such as Figure 1-12 As shown, a non-metallic horizontal sliding form system for continuous casting of deep and narrow drainage ditch walls includes a unit sliding form. The main body of the unit sliding form is composed of an inner plate 16 and an outer plate 17. The fixed strut 4 is made into position, and the bottom of the inner plate 16 is provided with a bottom roller bushing 9 and a bottom roller 10; The cover platen 12 is closed.

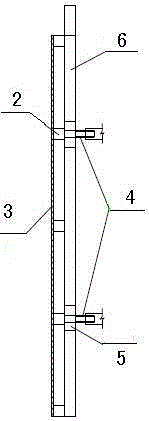

[0046] The inner formwork includes a hidden stiffening frame 2, the surface of the hidden stiffening frame 2 is provided with HDPE double-layer panels 1 and exposed longitudinal stiffeners 6, and the exposed longitudinal stiffeners 6 are provided with adjustable fixed braces 4 and adjustable fixed braces. Rod groove 5, the top of the adjustable fixed support rod groove 5 is provided with a top-to-drawing rod groove 15; both sides of the inner hidden stiffening frame 2 are provided with reserved holes 3 for the plug of the head plate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com