Patents

Literature

191results about How to "Reduce processing loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

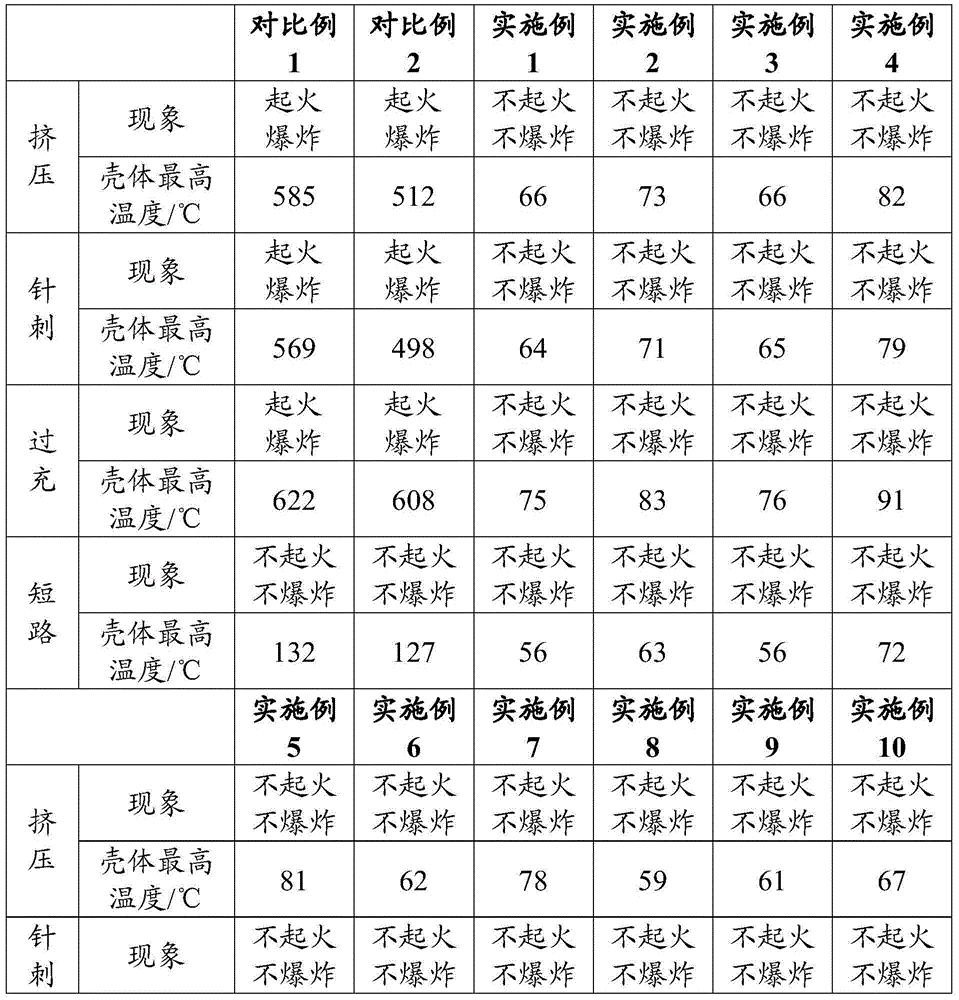

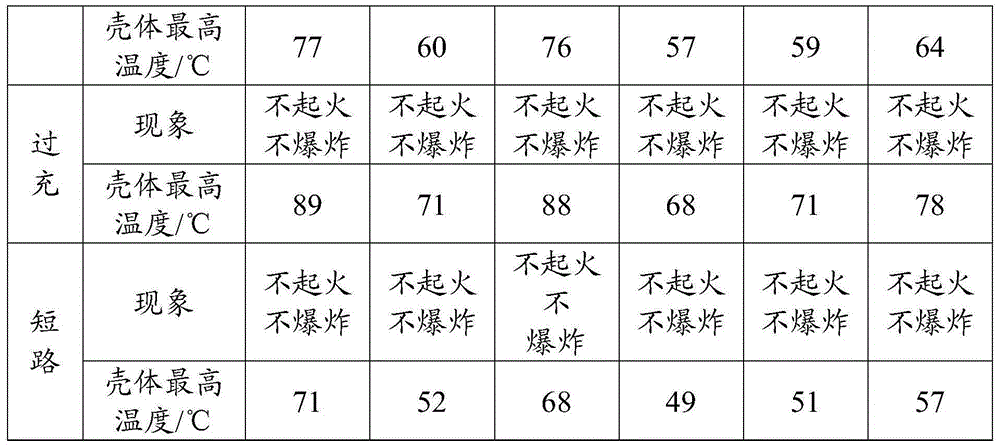

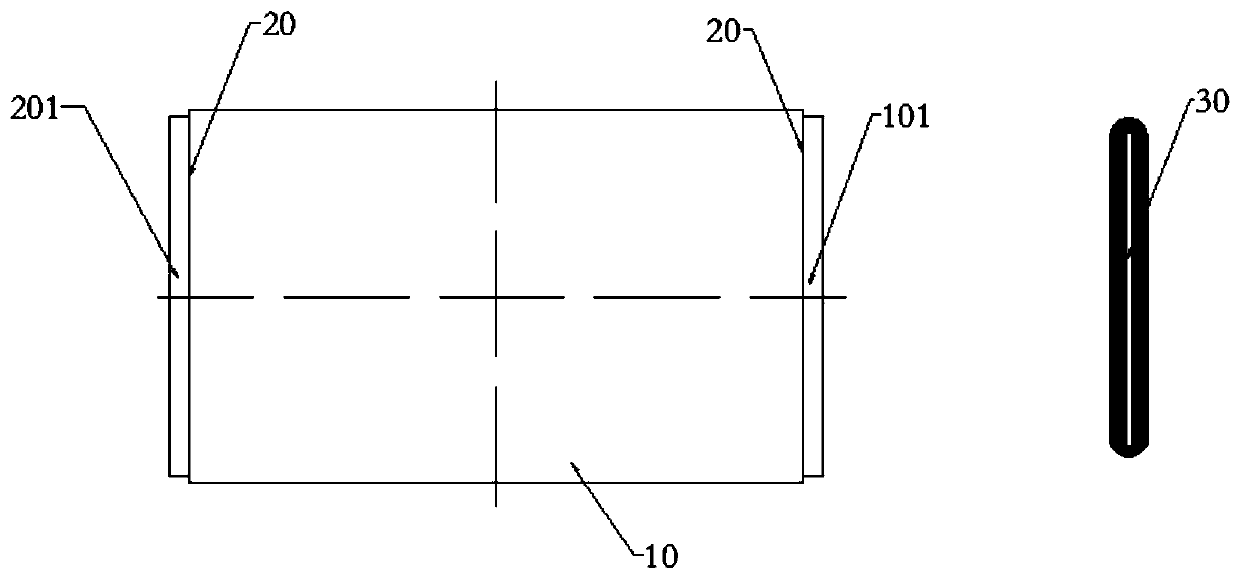

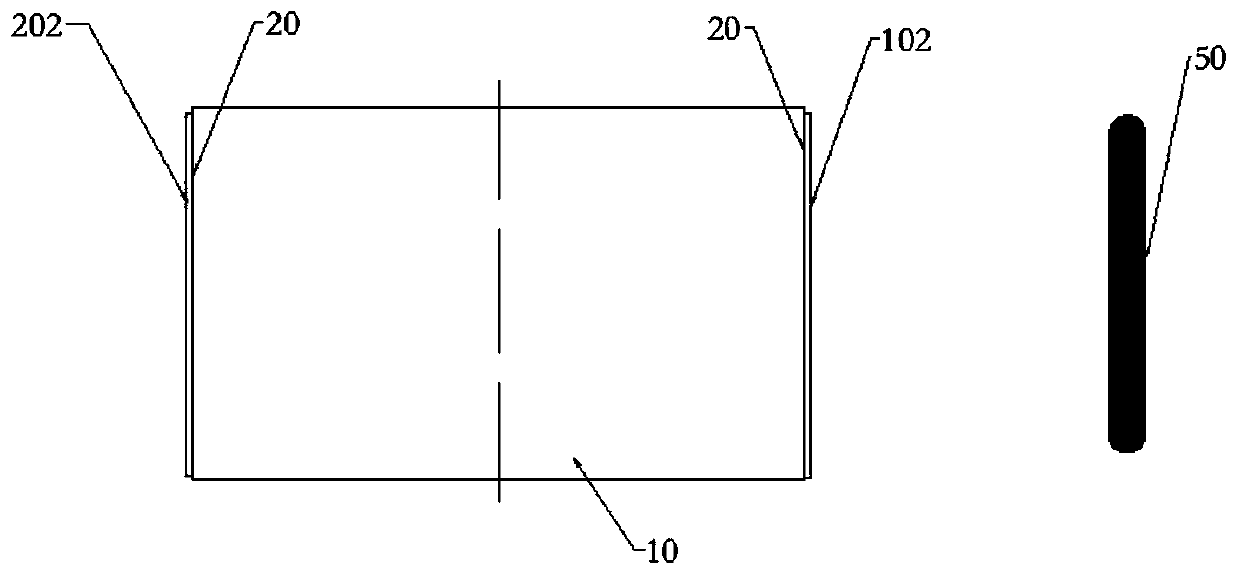

Lithium ion battery composite pole piece, preparation method thereof and lithium ion battery

ActiveCN105118970AIncrease temperatureControl security risksLi-accumulatorsNon-aqueous electrolyte accumulator electrodesChemical reactionAdhesive

The invention provides a lithium ion battery composite pole piece. The lithium battery composite pole piece comprises battery pole pieces and functional coatings composited on surfaces of the battery pole pieces, wherein the functional coatings are prepared from functional substances and adhesives, the functional substances comprise one or more of a phosphorous compound, a nitrogenous compound and inorganic silicon compounds, and the battery pole pieces are a battery positive pole and / or a battery negative pole. According to the lithium ion battery composite pole piece, the functional coating is applied to the surface of each battery pole piece, can quickly absorb excess heat of the battery when the temperature of a lithium ion battery rises and responds to a chemical reaction spontaneously as reaction entropy to form a protective coating on the surface of the corresponding battery pole piece; on one hand, the temperature of the battery can be effectively prevented from rising continuously, on the other hand, active layers on the battery positive and negative poles can be deactivated, potential safety hazards of the battery can be controlled fundamentally, and the safety of the battery is guaranteed.

Owner:CALB CO LTD

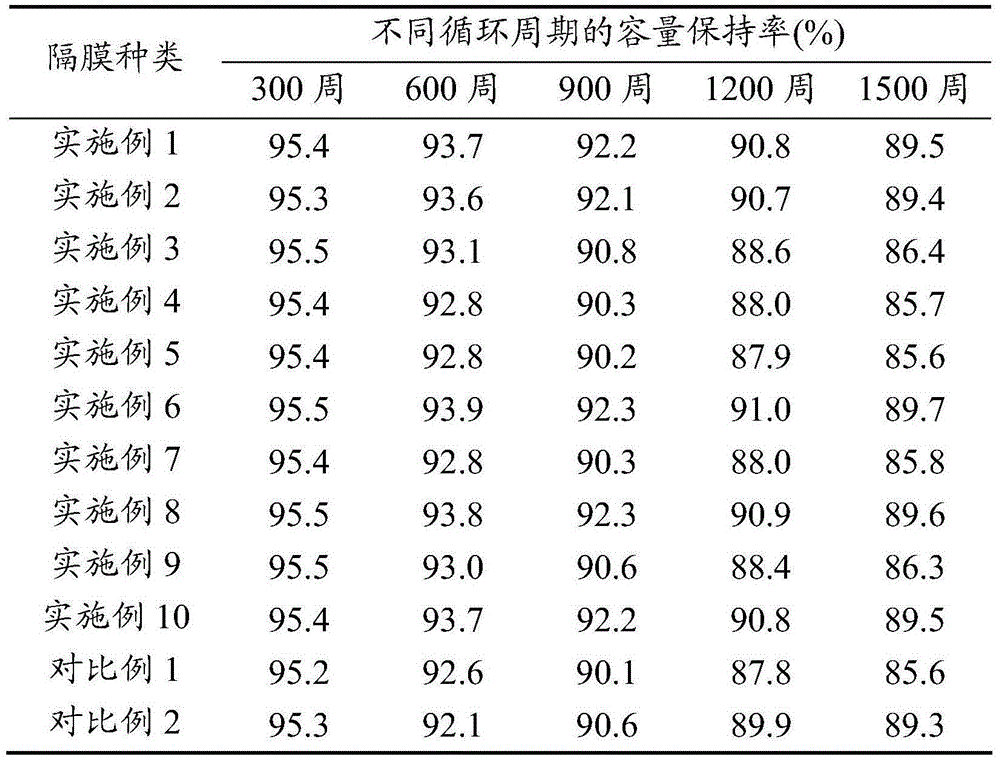

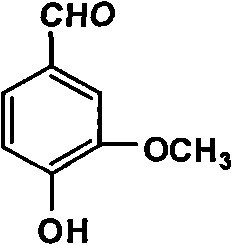

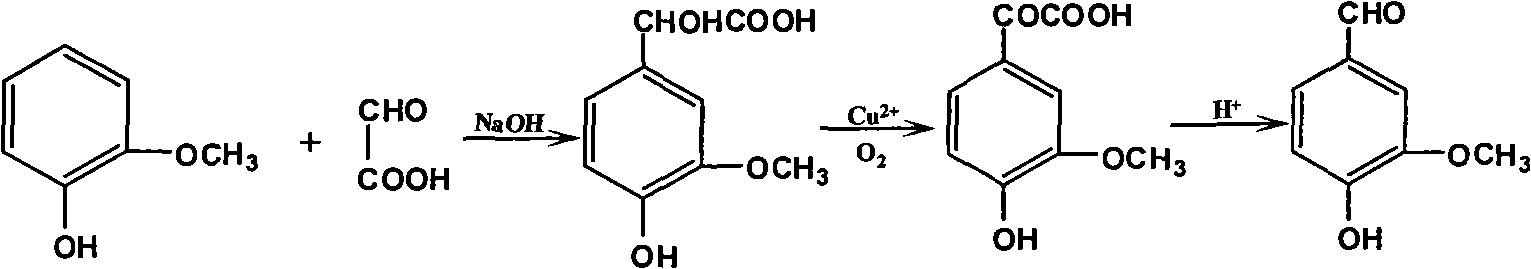

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

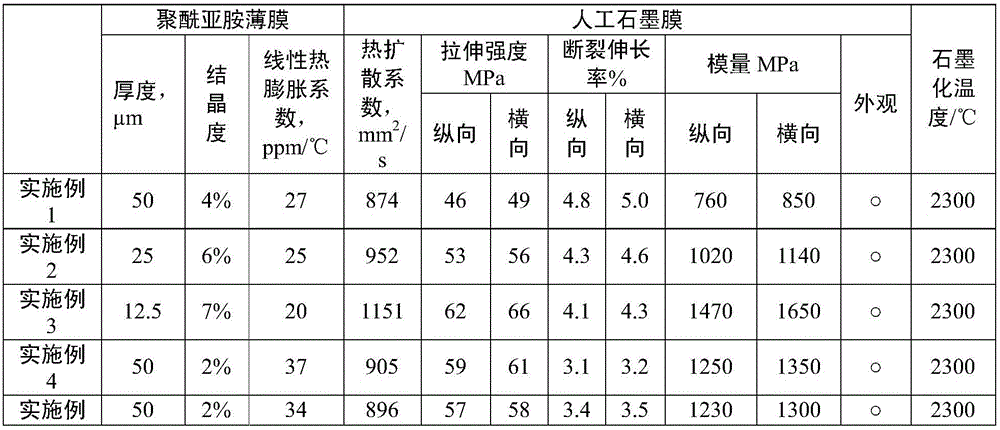

Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

The invention provides a polyimide thin film for preparing an artificial graphite film with excellent mechanical properties and a preparation method of the polyimide thin film. The polyimide thin film is prepared from a raw material diamine monomer which comprises 0 to 75 mol ratio of p-phenylenediamine; the raw material dianhydride monomer, comprises 40 percent to 100 mol ratio of of pyromellitic dianhydride; two types of inorganic fillers, including a calcium-containing compound and transition metal oxide, are uniformly dispersed in the polyimide thin film. The polyimide thin film provided by the invention is applicable to a graphitization process of single-sheet, multilayered stacking and continuous coiled materials and can be used for carrying out graphitization at temperature of 2300 DEG C; the crystallization degree is less than 10 percent. The graphite film prepared from the polyimide thin film has an excellent heat conducting property and has excellent mechanical properties in longitudinal and lateral directions of the thin film; the modulus is less than or equal to 2000MPa, the elongation at break is more than or equal to 3 percent, the tensile strength is more than or equal to 40MPa and the difference of the longitudinal and lateral directions is less than 15 percent.

Owner:RAYITEK HI TECH FILM CO LTD

Rubber-based thermal insulation layer patching method

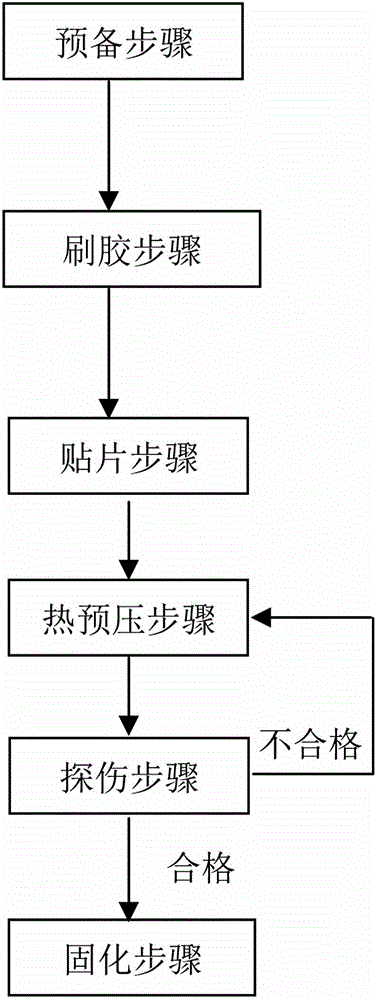

A rubber-based thermal insulation layer patching method belongs to the solid rocket motor thermal insulation layer manufacturing method, and solves the problems of long construction period, high labor intensity, inconvenient operation and the like of a solid rocket motor with the diameter Phi of Phi 100mm-1400mm, using nitrile, EPDM rubber and other materials as a thermal insulation layer material; at the same time is able to meet production requirements of a thermal insulation layer material of a charging combustion chamber of a solid rocket motor with small front and back opening sizes and large length. The method includes a preliminary step, a gluing step, a patching step, a hot prepressing step, a fault detection step and a curing step. The method is successfully applied to multiple products, the thermal insulation layer fully meets the design requirements; process cycle is reduced by 67%, labor productivity is increased by at least 1 time, lower labor cost is reduced by at least 50%, raw material cost can be reduced by 15%; the operating environment is significantly improved, and a guarantee is provided for the prevention of occupational diseases.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

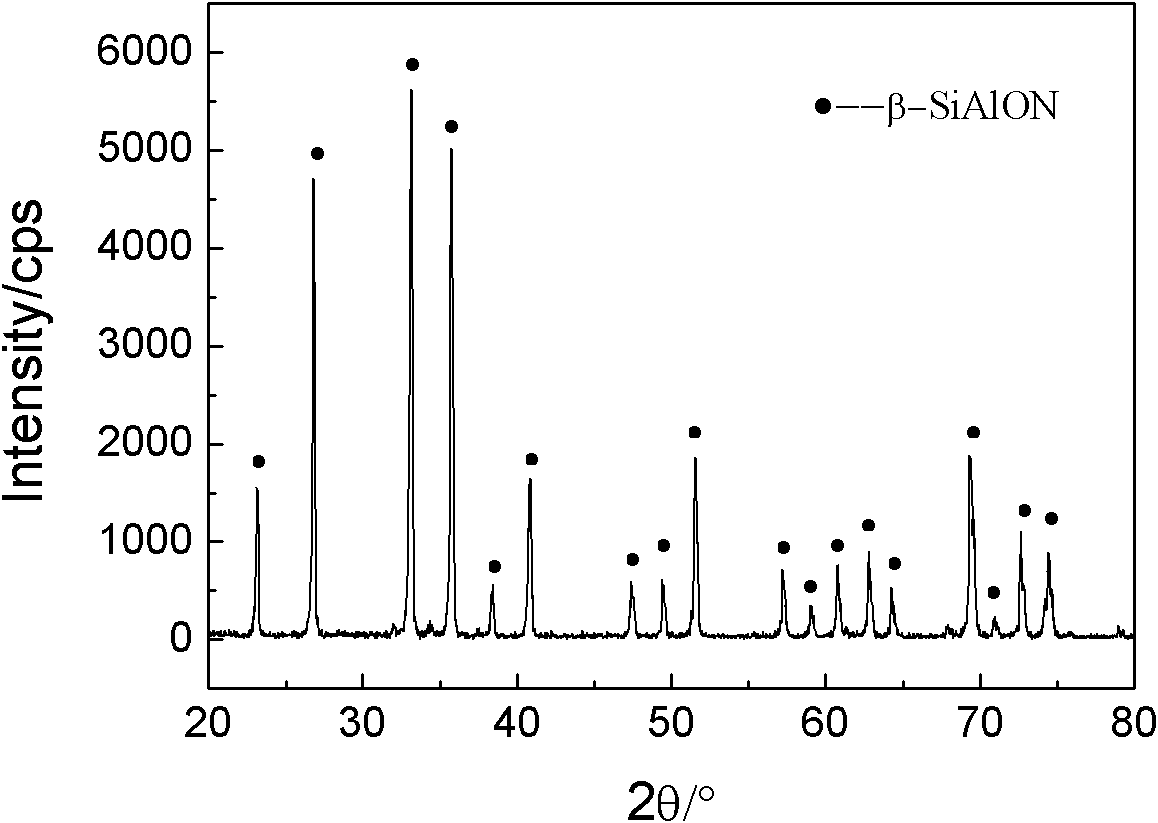

High-strength beta-SiAlON ceramic and pressureless sintering preparation method thereof

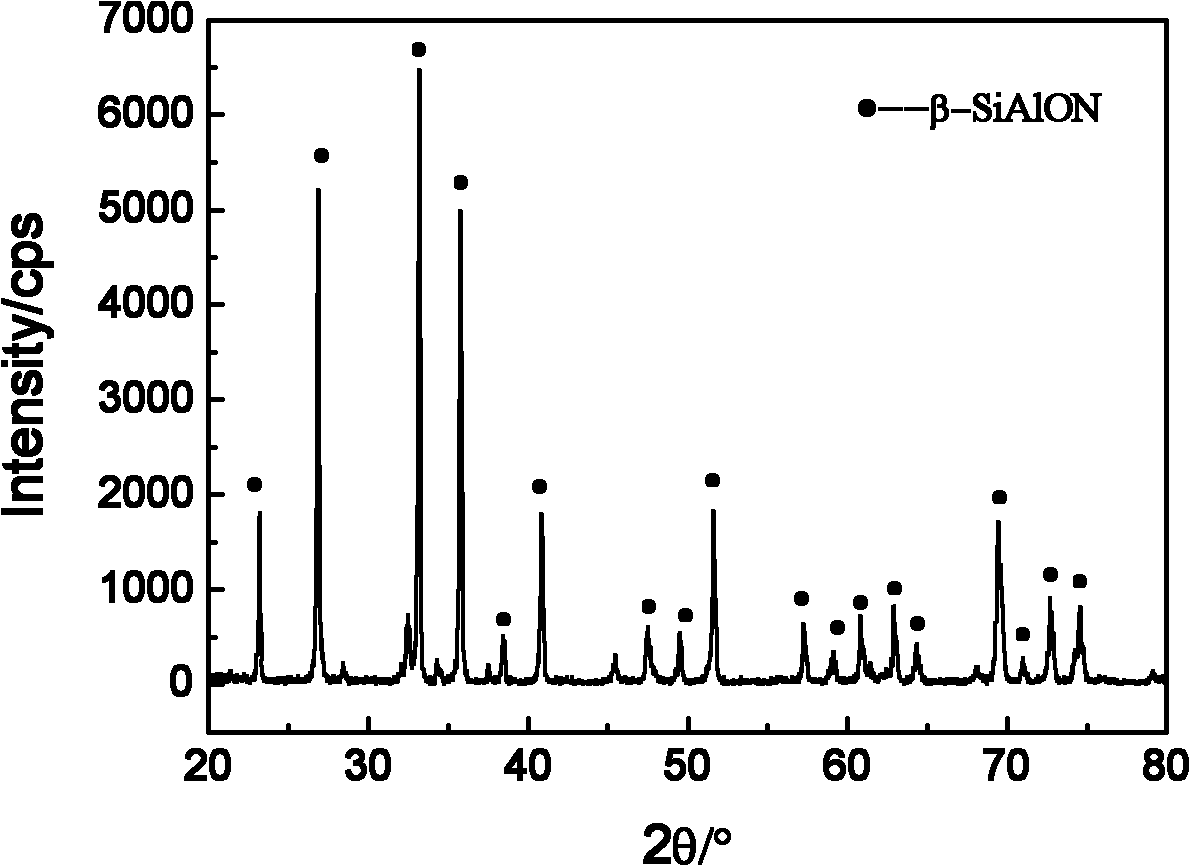

The invention belongs to the field of preparation of high-performance ceramic materials and particularly relates to a method for preparing a high-strength beta-SiAlON ceramic material by adopting the pressureless sintering technology. Silicon nitride powder, aluminum nitride powder and alumina powder are taken as raw materials, the ceramic material is designed according to the general formula Si6-zAlzOzN8-z (z is between 1 to 3.5) of eta-SiAlON, Y2O3 or one or more rare-earth oxides (such as Nd2O3, Yb2O3, etc.) are added as sintering aids, the raw material powders are mixed in absolute ethyl alcohol medium and then dried and granulated, and the sample molded by cold pressing is buried in a SiAlON filler and sintered in flow nitrogen atmosphere. No mechanical pressure is required to be applied during the ceramic sintering process, the complicated shape and the special-shaped component are easily manufactured, and the processing difficulty and the loss can be reduced, so that the methodhas a broader application prospect.

Owner:DALIAN MARITIME UNIVERSITY

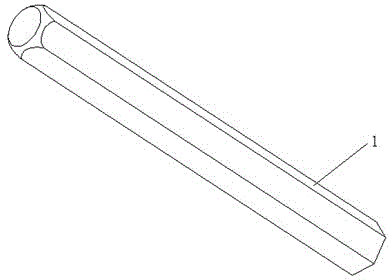

Screw and powder injection molding method thereof

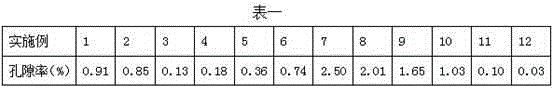

ActiveCN104308163AReduce porosityGuaranteed to be fullTurbinesOther manufacturing equipments/toolsMetallic materialsInjection molding machine

The invention discloses a screw and a powder injection molding method thereof. The method includes the steps of firstly, mixing powder metal materials and binder with the mass ratio being 100:20-200 to form homogeneous feeding materials; secondly, placing the feeding materials into an injection molding machine to perform injection molding so as to obtain injection molding blanks; thirdly, dewaxing; fourthly, pre-sintering at the temperature of 200-800 DEG C to obtain pre-sintered blanks; fifthly, rising the temperature to 1000-2500 DEG C to sinter the pre-sintered blanks for 1-10 hours under a protective atmosphere to obtain screws. The method has the advantages that the binder is added into metal materials for mixing, the metal materials can form the injection molding blanks through injection molding, the binder is completely discharged by dewaxing and pre-sintering, the screws formed by high-temperature sintering, porosity of the screws is reduced greatly, machining procedures are reduced, production efficiency is increased, and the products after injection molding are good in consistency and repeatability.

Owner:HEFEI GENIUS NEW MATERIALS

Tea of buckwheat and preparation method

ActiveCN1726794AImprove use valueAdd flavorPre-extraction tea treatmentPolygonum fagopyrumAdditive ingredient

A buckwheat tea is prepared from buckwheat flour and buckwheat bran through proportional mixing, extruding for shaping, and dewatering, fixating shape, parching or roasting and cooling. Its advantages are strong smell and less loss of nutrients.

Owner:西昌航飞苦荞科技发展有限公司 +1

Flame-retardant laminated veneer lumber wooden fireproof door and manufacturing method thereof

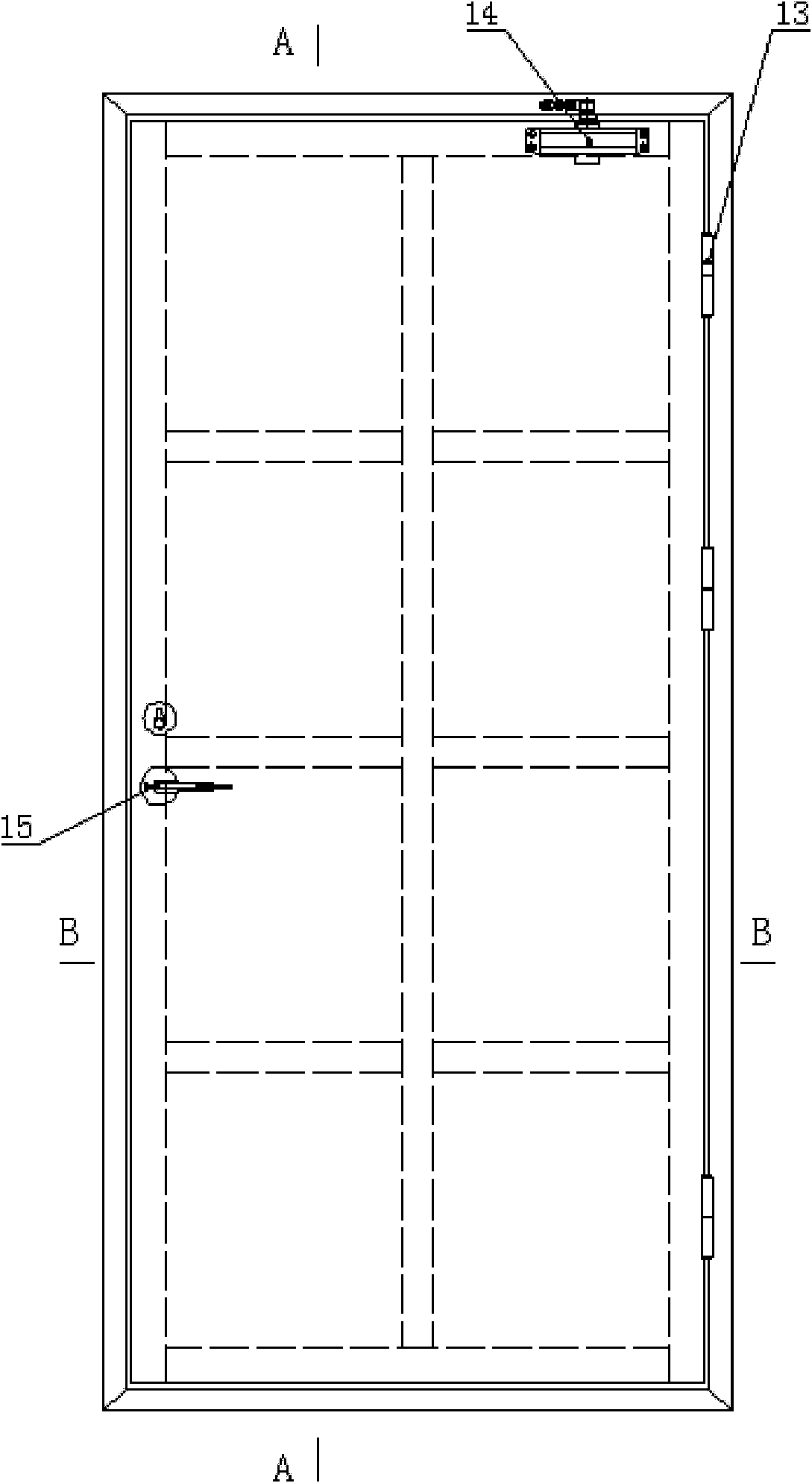

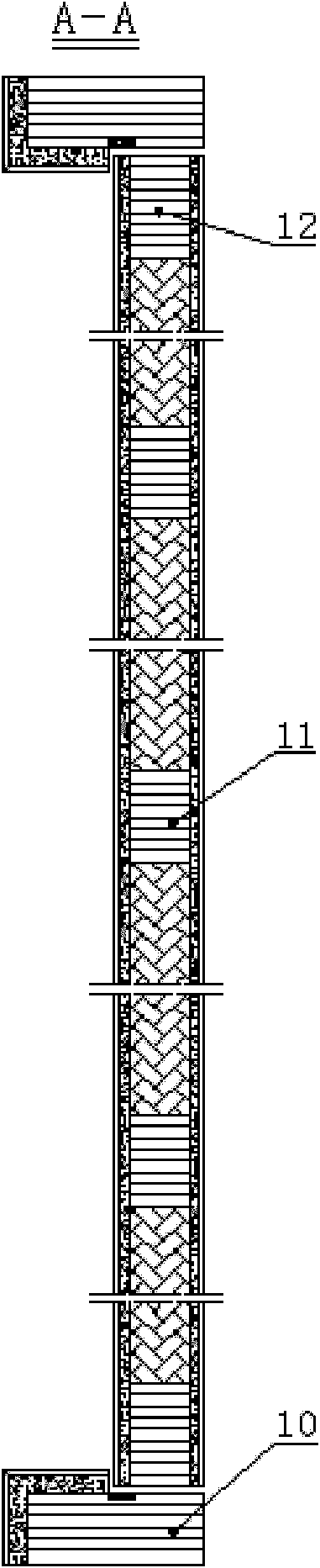

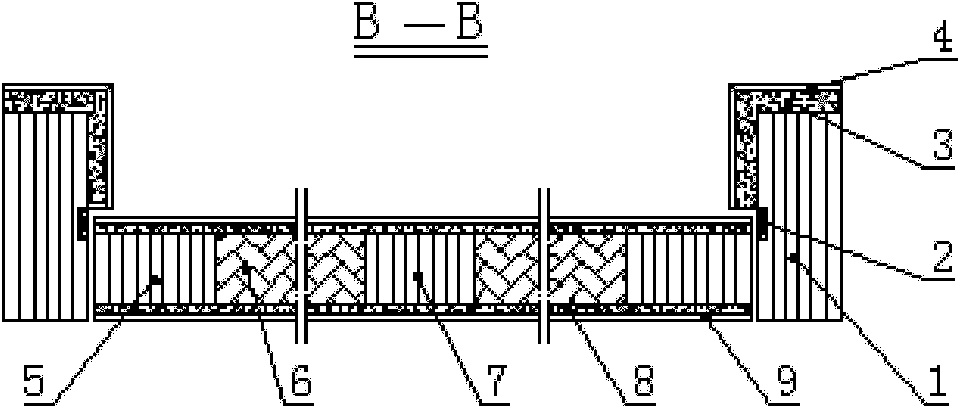

The invention discloses a flame-retardant laminated veneer lumber wooden fireproof door and a manufacturing method thereof. The manufacturing method comprises the following steps of: manufacturing flame-retardant laminated veneer lumber by using low-grade fast growing wood; and manufacturing a door frame and a door leaf framework by using the flame-retardant laminated veneer lumber, wherein the door frame consists of a vertical frame and a horizontal frame through tenon combination; the door leaf framework consists of two edge horizontal keels, two edge vertical keels, a plurality of middle vertical keels and a plurality of middle horizontal keels through tenon combination; the longitudinal textures of the wood grain of the laminated veneer lumber are parallel to the length directions of the frames of the door frame and the keels of the door leaf framework, and an adhesive layer surface is vertical to the surface of the door leaf; the width of the frames of the door frame is 90 to 110mm, and the thickness is 40 to 50mm; and the width of the edge keels of the door leaf framework is 50 to 60mm, the width of the middle keels is 40 to 50mm, and the thickness of the door leaf framework is 35 to 40mm. The flame-retardant laminated veneer lumber wooden fireproof door is made of the low-grade fast growing wood, the use value of the low-grade wood is improved and natural forest resources are protected.

Owner:宿迁新缘林木业有限公司

Preparation method of frozen prepared abalone product

ActiveCN103798848ARetain biological activityPromote absorptionFood freezingFood thermal treatmentUltrasonic assistedEngineering

The invention discloses a preparation method of a frozen prepared abalone product. The preparation method comprises the steps of selecting fresh and live big abalone, implementing pretreatment, curing, rubbing, shaping, deodorizing, carrying out vacuum flavoring, sterilizing gently, quick-freezing and refrigerating. Through gentle processing and ultrasonic wave assisted refrigeration techniques, the prepared product reserves bioactivity of fresh and live abalone, and nutrient ingredients are easy to be absorbed; the preparation method is simple, and the product taste is excellent; therefore, the preparation method has obvious economic and social benefits.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

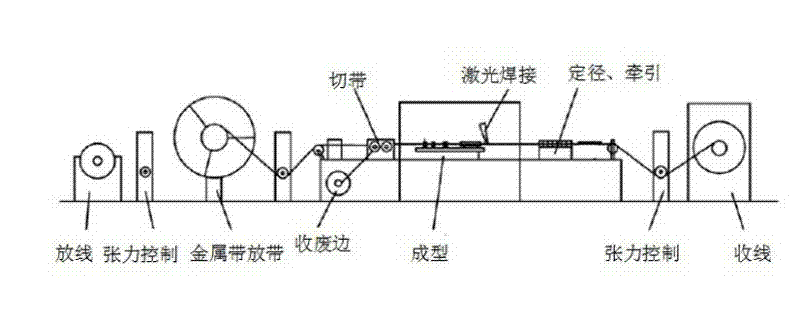

Processing process of semi-steel cable outer conductor

ActiveCN102412029ARF leakage is smallImprove performanceCable/conductor manufactureProcess lossElectrical conductor

The invention relates to a processing process of a semi-steel cable outer conductor. A semi-steel cable comprises an inner conductor, an insulating layer and the outer conductor. The processing process comprises the following specific steps: S1, firstly, putting a pushed and certificated phi 2.98 mm core wire on a pay-off stand, adjusting laying tension as 10-20 N, wherein the core wire comprisesthe inner conductor and the insulating layer; S2, putting a metal tape with the width of 12 mm-14 mm and the thickness of 0.2 mm-0.4 mm on a tap putting rack, and adjusting the tap putting tension as15-30 N; carrying out metal tape trimming, wherein the width of the trimmed metal tape is 11-12 mm, then molding through a horn model, and opening a laser welder to carry out weld debugging; and S3, penetrating the core wire with the diameter phi of 2.98 mm into the metal tape, cladding, molding, welding and coining. The semi-steel cable manufactured by the processing process provided by the invention has the advantages of small radio frequency leakage and stable property. According to the invention, the quality stability, the production length and the manufacturing process can be greatly improved, the process loss is greatly reduced, and the manufacturing cost is effectively reduced.

Owner:ZHEJIANG TIANJIE IND

Tensile RTP and manufacturing method thereof

InactiveCN103574183AWith high pressureImprove tensile propertiesCoatingsRigid pipesFiberManufacturing technology

The invention relates to a tensile RTP and a manufacturing method of the tensile RTP. The pipe comprises an inner pipe and a reinforcing layer wound on the inner pipe, the reinforcing layer is wrapped by a protective layer, the reinforcing layer is composed of two winding straps which are wound on the outer wall of the inner pipe in the opposite directions of turning at preset winding angles, a tensile layer is arranged between the reinforcing layer and the protective layer, and the tensile layer is composed of a set of fiber ropes which are evenly distributed in the circumferential direction and are pre-tensioned in the axial direction. Raw materials are placed into an inner pipe extruder to be extruded and cooled for being sized to form the inner pipe, the two high-strength winding straps are wound on the outer wall of the inner pipe in the opposite directions of turning according to the preset winding angles to form the reinforcing layer, the set of fiber ropes are evenly arranged on the outer surface of the reinforcing layer in the direction of the axis of the pipeline after being pre-tensioned to form the tensile layer, raw materials are placed into an outer pipe extruder to be extruded so as to wrap the tensile layer to form the protective layer, and then online continuous production is achieved through coiling. The tensile RTP has the advantages of being high in tensile property and in flexibility, resistant to high temperature and corrosion, safe, reliable and the like, the RTP is formed at one time according to the manufacturing technology, the production period is short, and the production efficiency is high.

Owner:NANJING CHENGUANG COMPOSITE PIPE ENG CO LTD

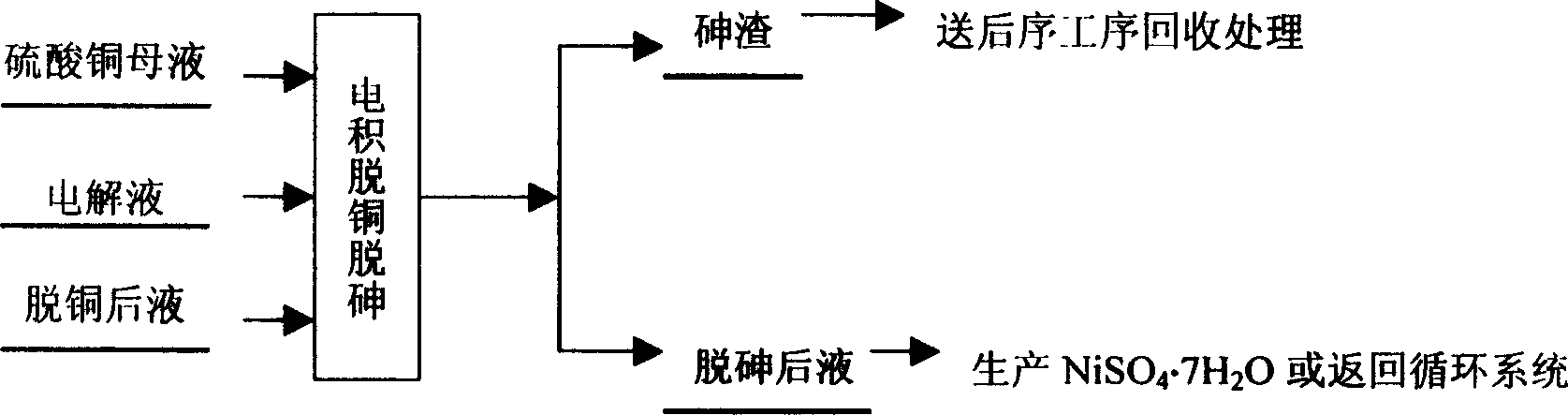

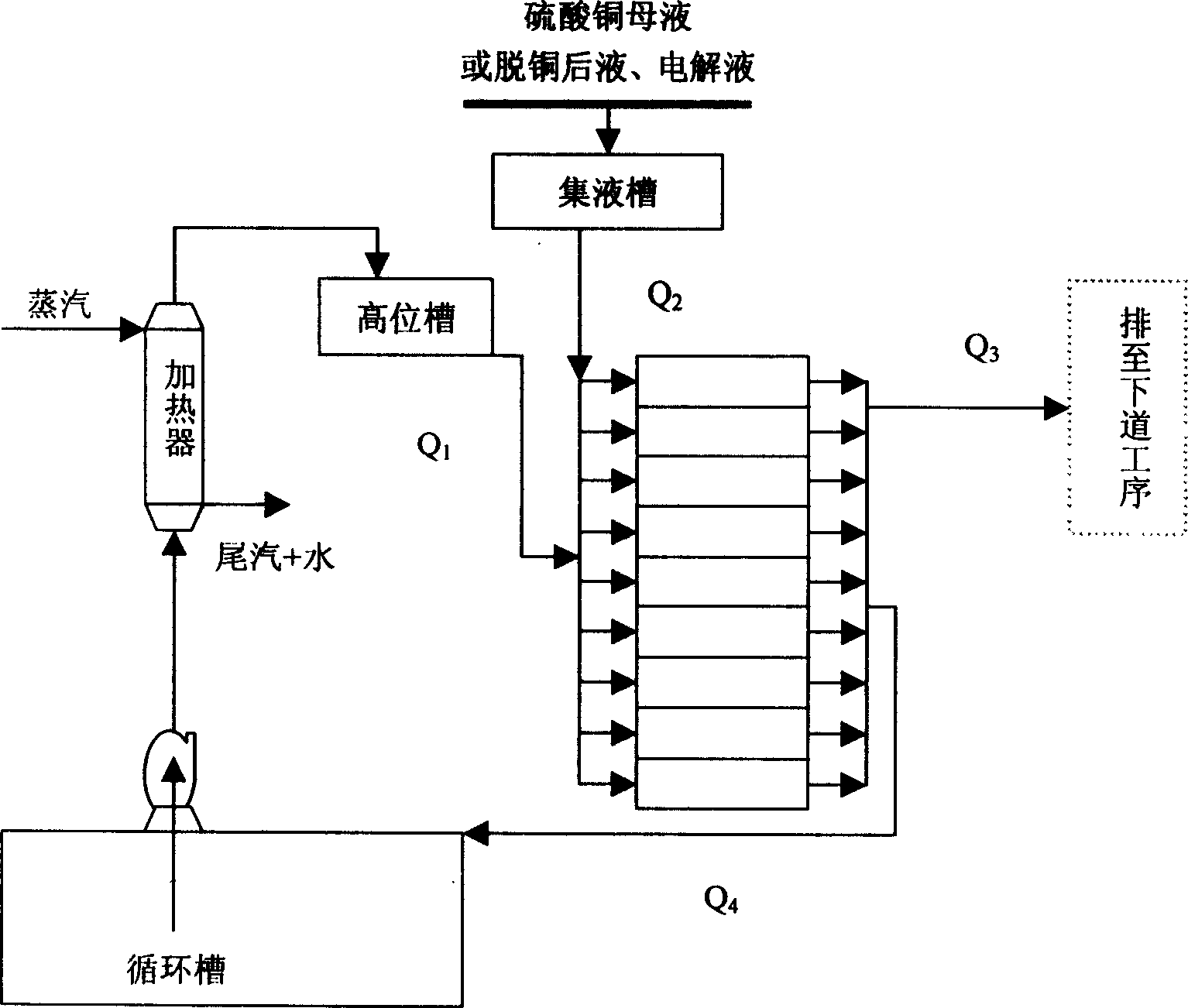

Method of dearsenic by parallel circulating continuous electric formation

ActiveCN1560289AIncrease production capacityReduce investmentPhotography auxillary processesProcess efficiency improvementEngineeringCopper

The invention is a parallel circulating continuous electrodeposition arsenic-removing method, where the electrolyte flows between electrowinning arsenic-removing tanks in parallel circulating form, heating circulating liquor, controlling the temperature at 60-66 deg.C, and completely supplying liquor in the electrodeposition arsenic-removing course, where the flow rate of supply liquor is equal to that of discharge liquor and controlled at 1-20 cu m / h, and the ratio of Cu to As in the supply liquor = 1.5-3 : 1-1.5; and partial electrobaths act as terminal tank, the Cu-ion concentration in the discharge liquor of the terminal tank is controlled at Cu2+ = 0.5-2.5g / L, and it controls the supply liquor, circulating liquor and terminal discharge liquor to make As and Cu form As-Cu alloys Cu2As and Cu3As in the arsenic-removing course, and it produces Cu2As as far as possible.

Owner:YUNNAN COPPER CO LTD

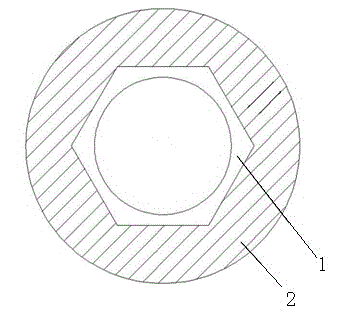

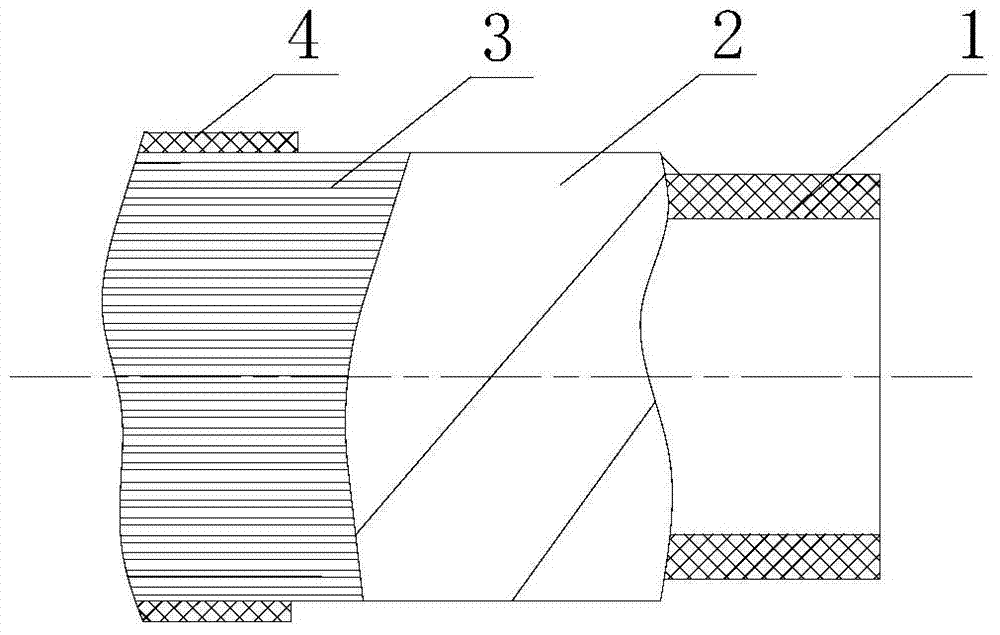

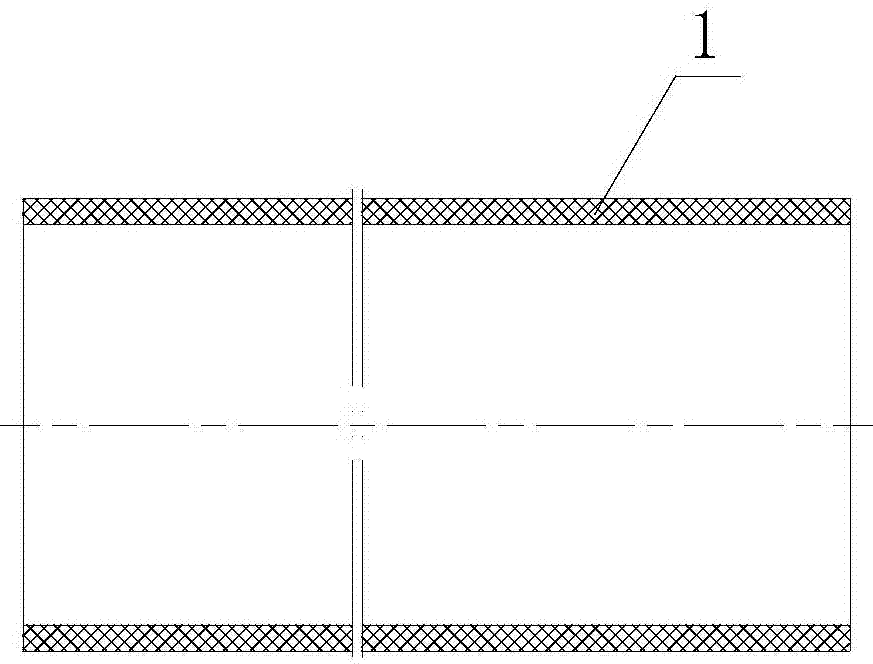

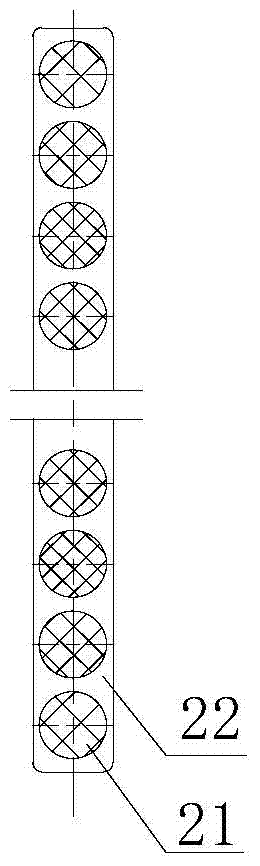

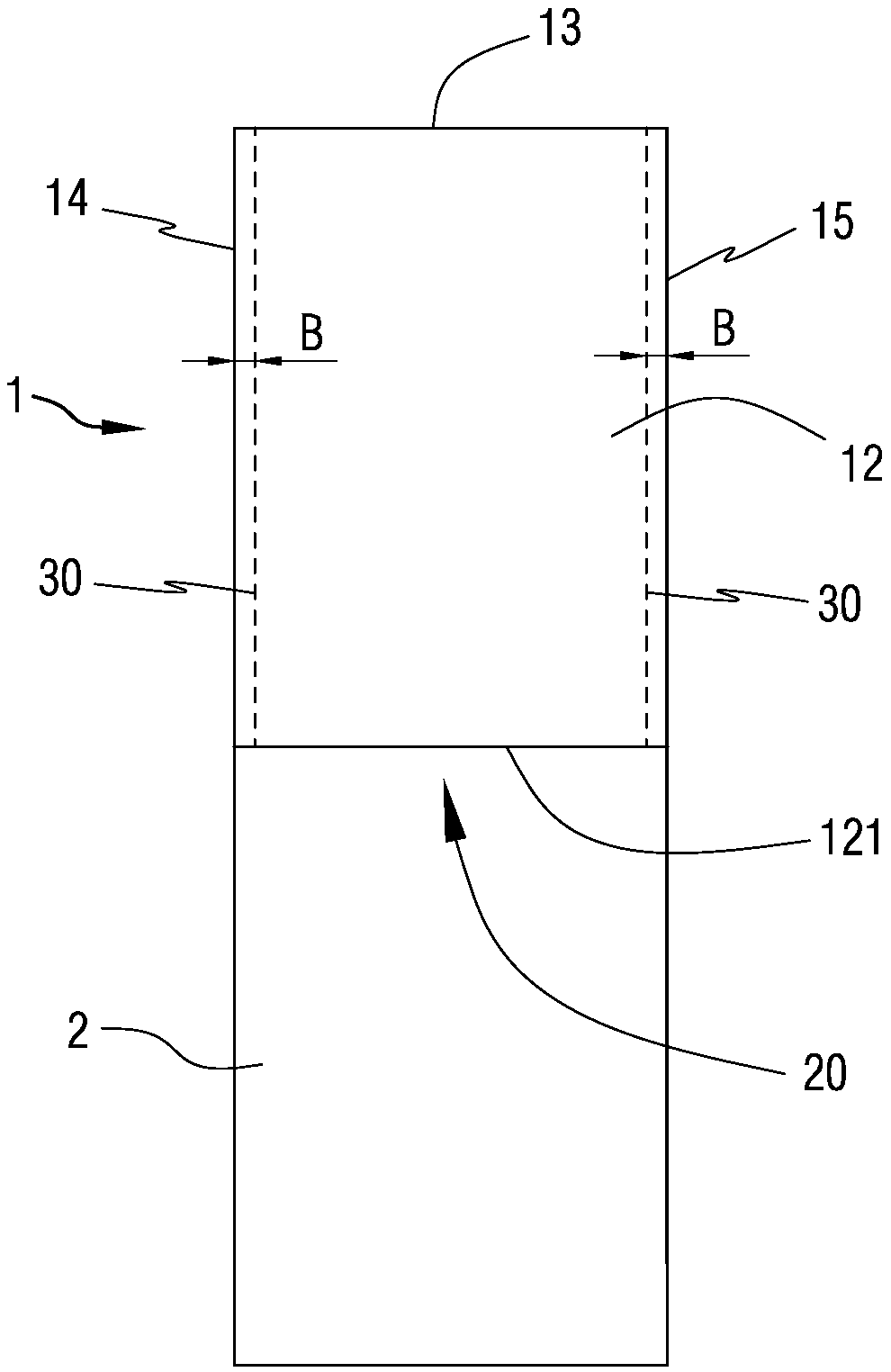

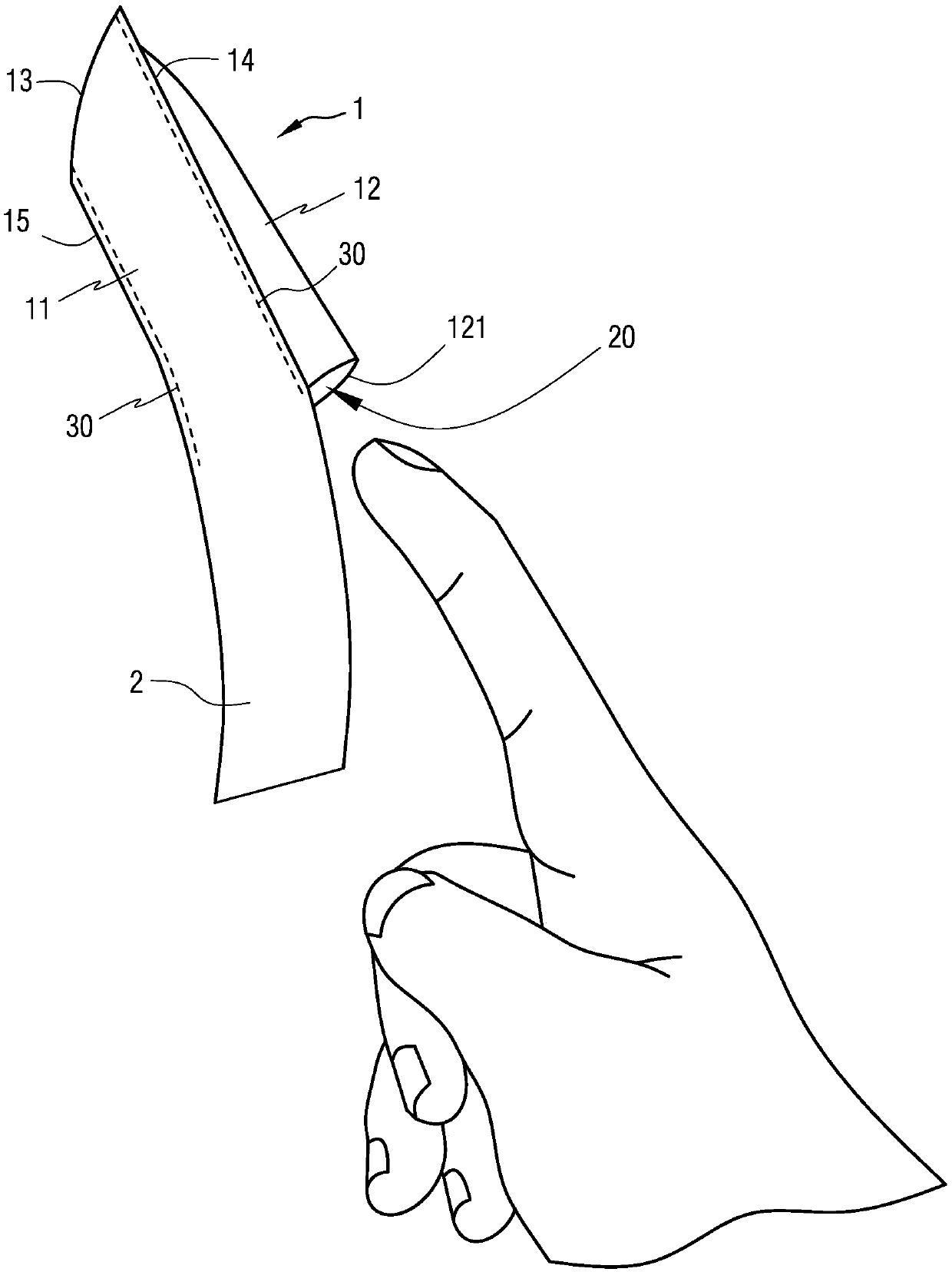

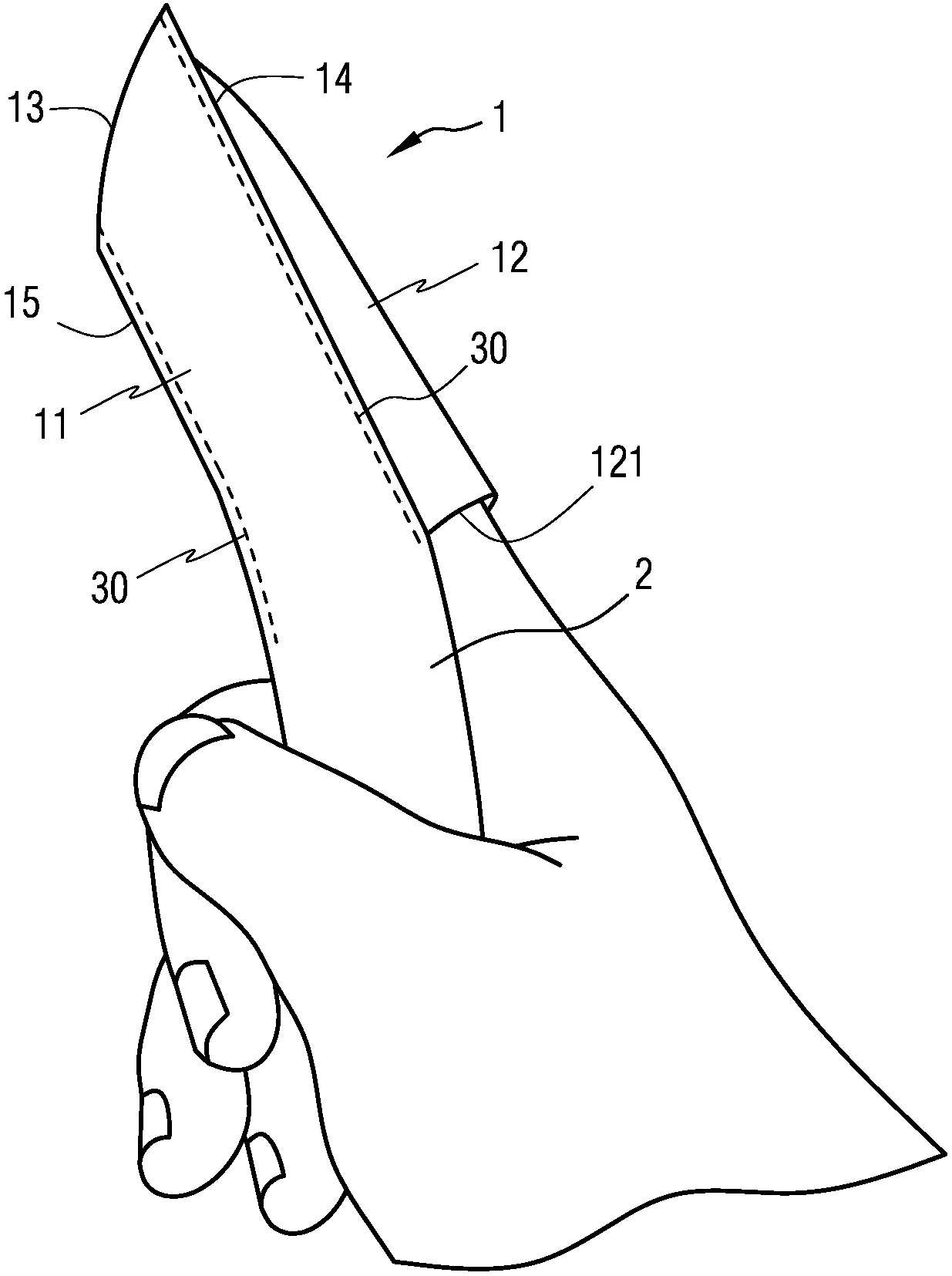

Cleaning sleeve for cleaning oral cavity

InactiveCN107693143AEasy to manufacture in batchesLow costBrush bodiesSurgeryEngineeringNonwoven fabric

The invention provides a cleaning sleeve for cleaning oral cavity. The cleaning sleeve sleeves a finger or the outside of a tool to clean the inside of the oral cavity. The cleaning sleeve is of a flat layer-shaped structure and comprises a sleeving part (1) which is formed through overlapped-piece woven fabrics, and a holding part (2) which is formed through a single-piece woven fabric; the sleeving part (1) which is formed through the overlapped-piece woven fabrics comprises a working layer (11) and a sleeve layer (12) which form a head part (13) on the top end of the cleaning sleeve; the holding part (2) integrally extends from the working layer (11). The cleaning is formed by ultrasonically adhering two rear sides of a complete degradable nonwoven fabric after the complete degradable nonwoven fabric is folded, and additional processes such as the process of sewing and the process of connecting are saved, so that the massive processing and manufacturing can be easily carried out, and the cost is low; the cleaning sleeve is disposable and suitably bought by people with low price in daily life; in addition, the thermal adhering effect and the locking property of the degradable nonwoven fabric are perfectly balanced.

Owner:HANGZHOU JADE CLOVE SCI & TECH CO LTD

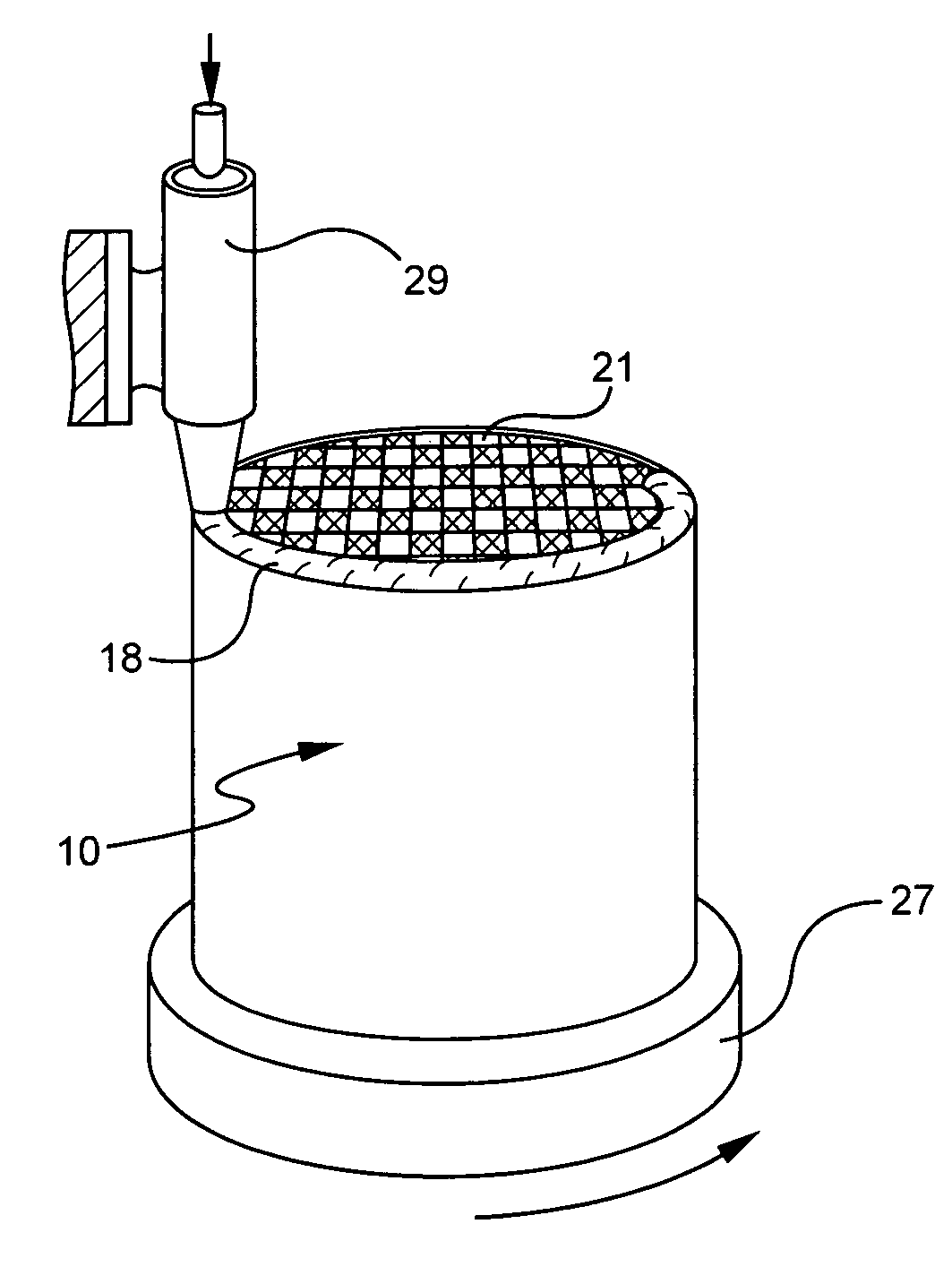

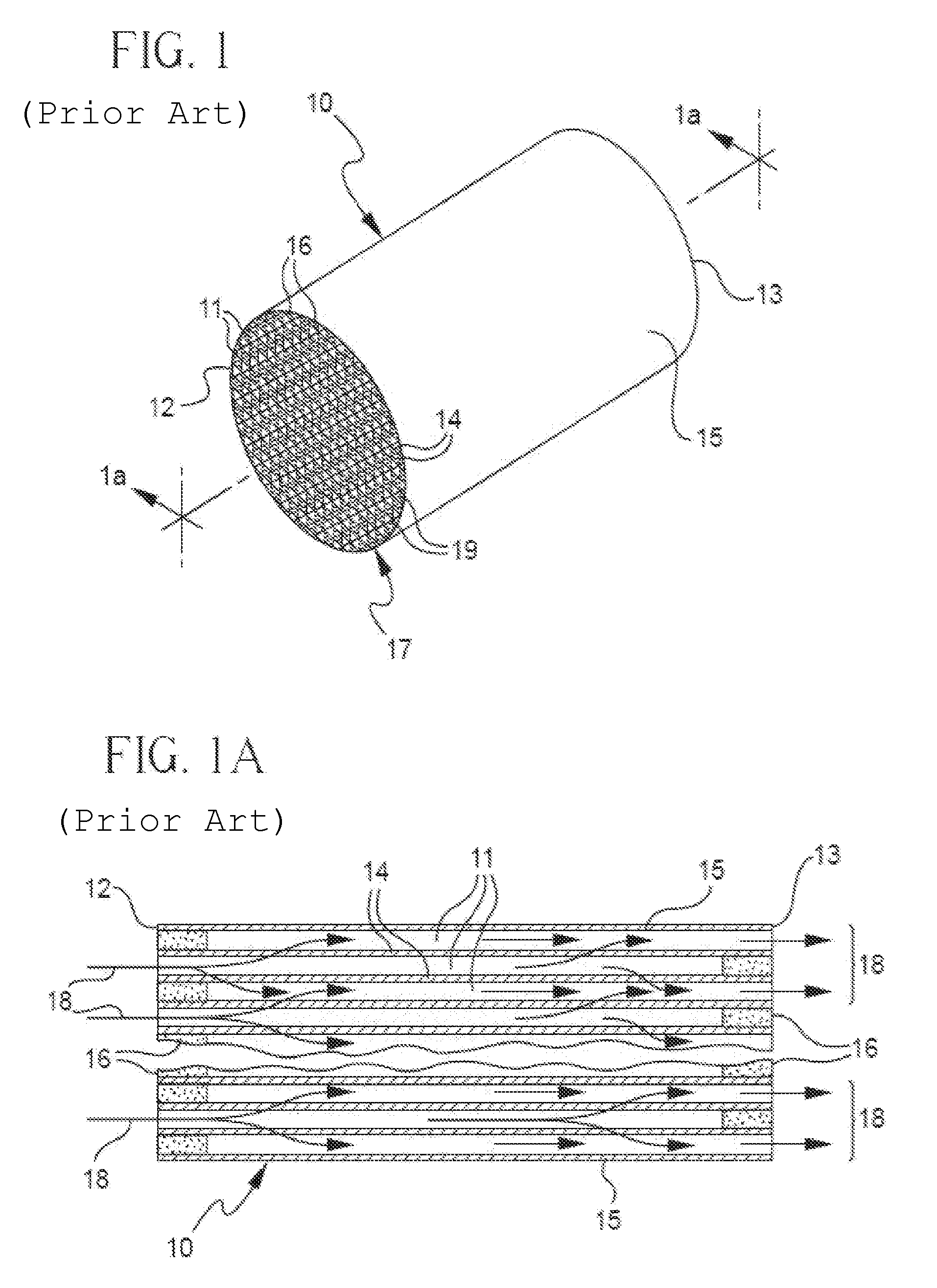

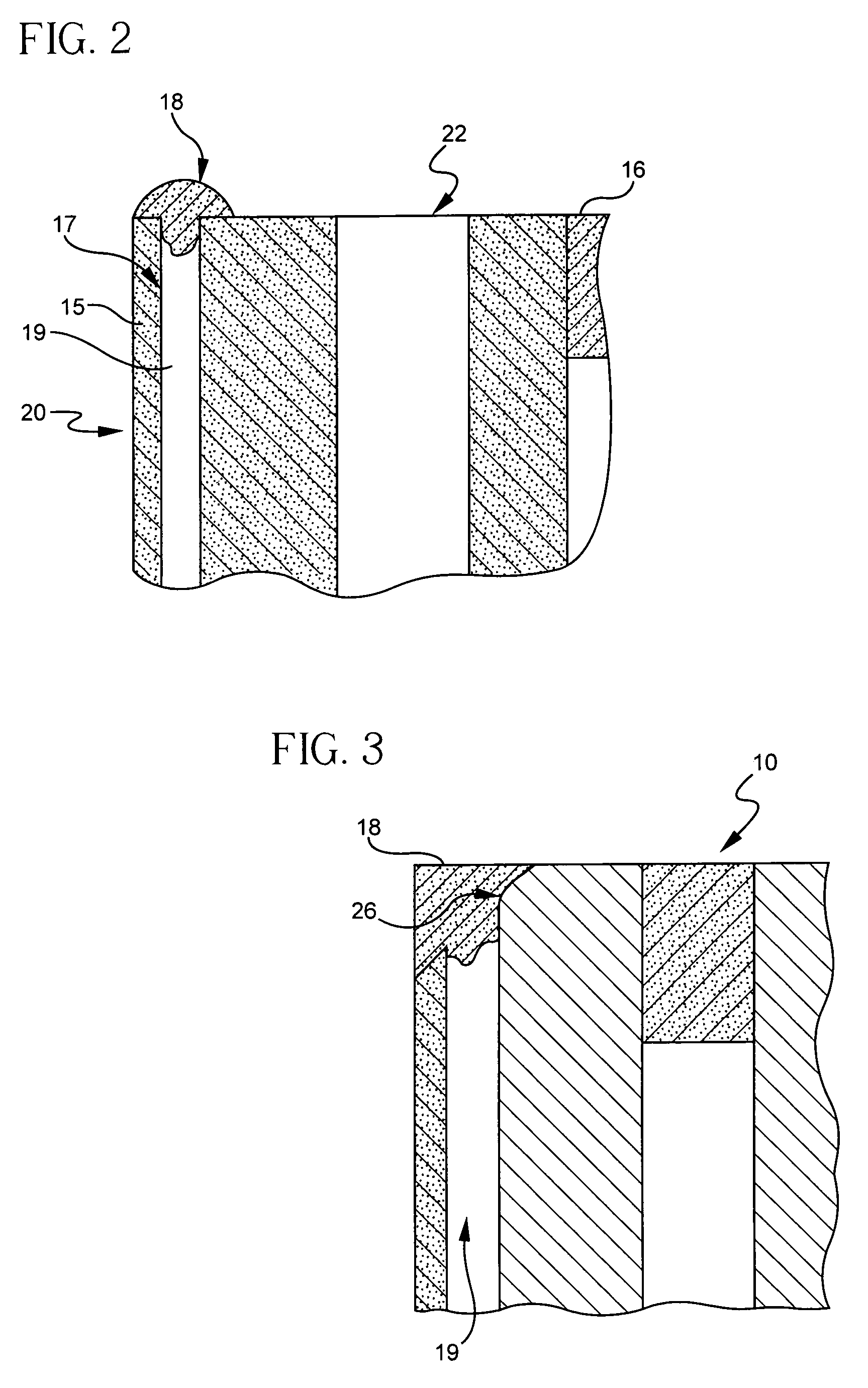

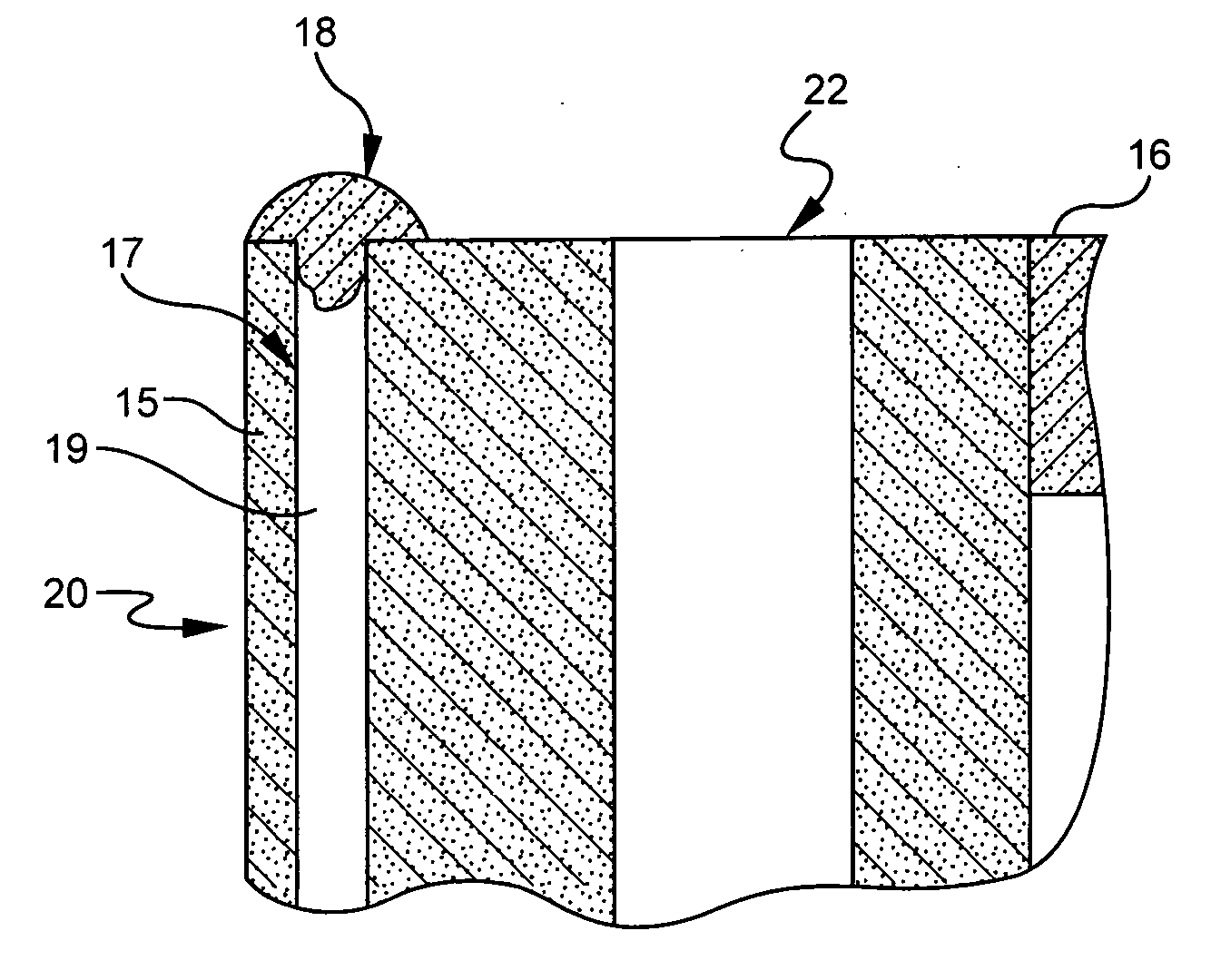

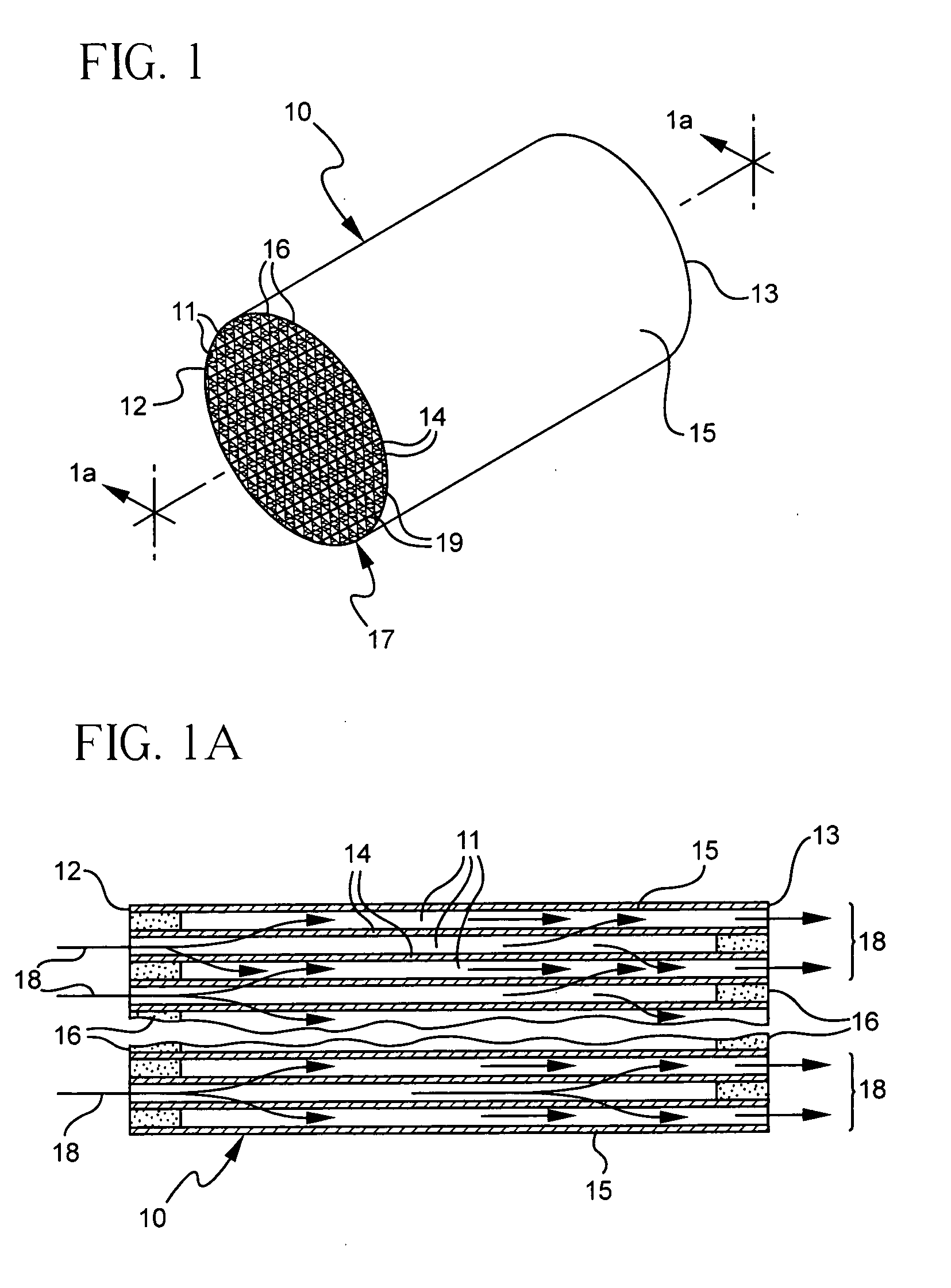

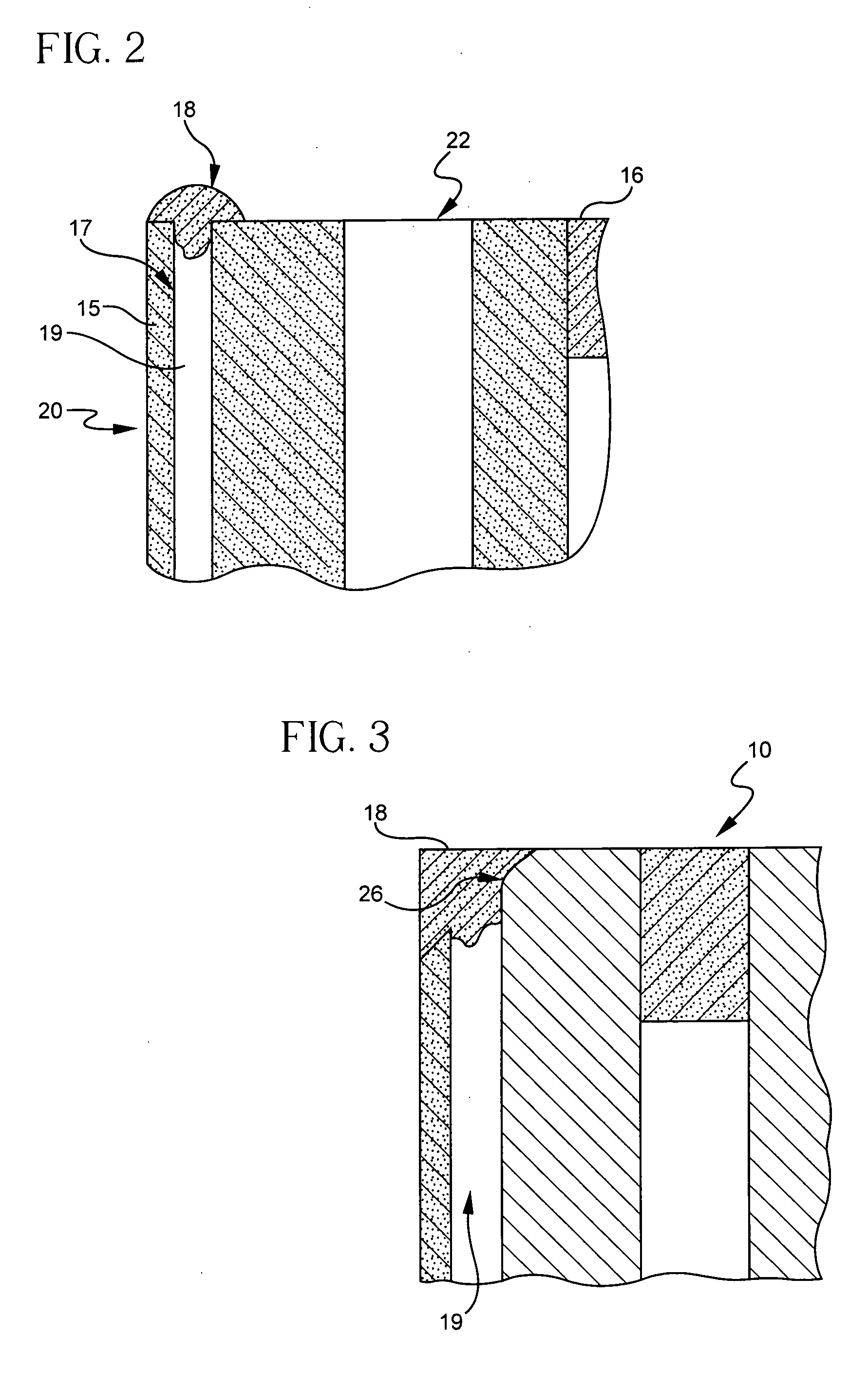

Honeycomb filters with reduced number of unplugged partial peripheral cells and methods of manufacturing same

ActiveUS7517379B2More resistant to edge chippingReduce processing lossCombination devicesAuxillary pretreatmentEngineeringHoneycomb structure

Owner:CORNING INC

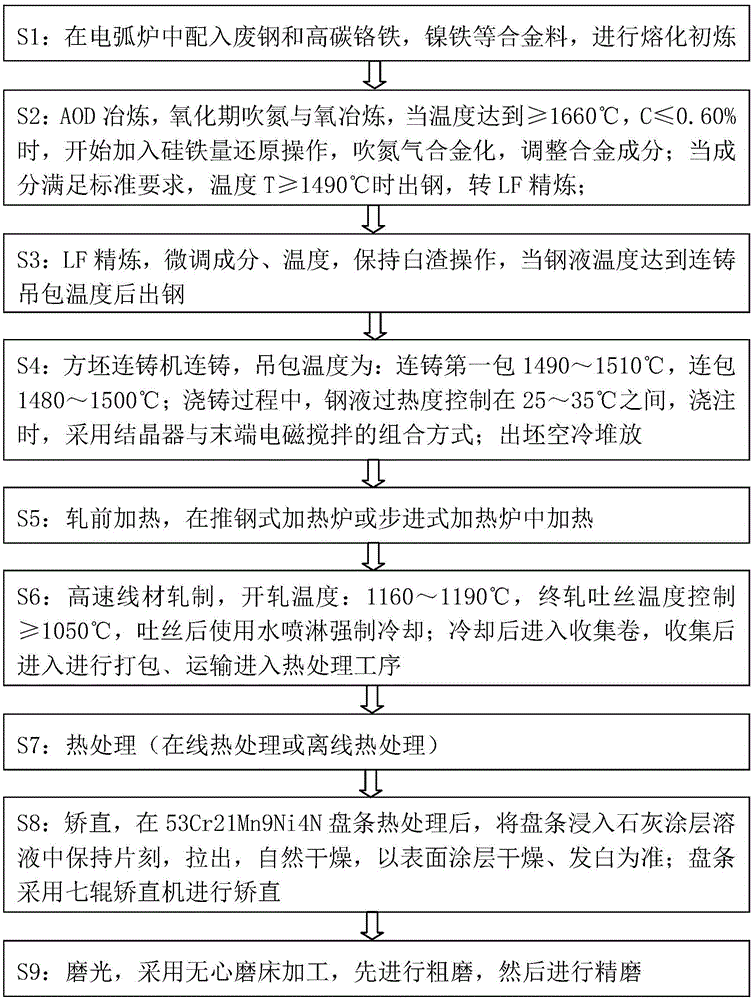

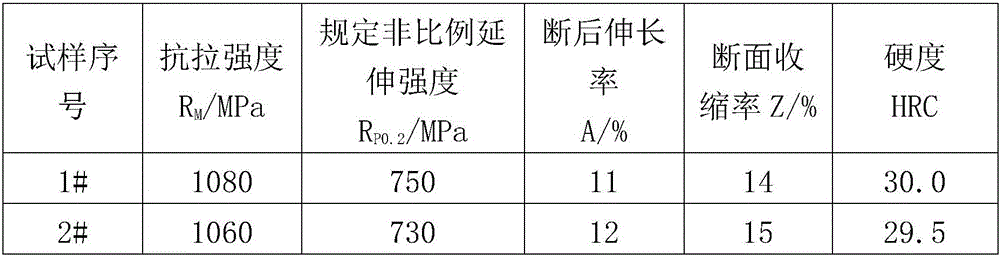

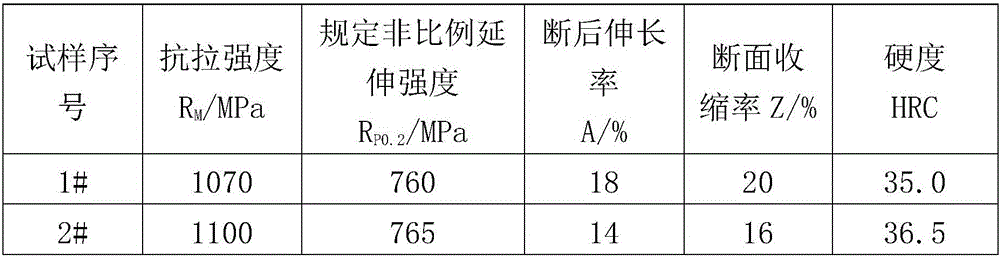

Production method of valve steel 53Cr21Mn9Ni4N polishing bar

InactiveCN106269869AReduce processing lossReduce processing energy consumptionFurnace typesMetal rolling arrangementsWire rodOnline and offline

The invention provides a production method of a valve steel 53Cr21Mn9Ni4N polishing bar. The method comprises the steps of valve steel melting, continuous casting, high speed wire rolling, thermal treatment to obtain finished products. The method comprises the technological processes of electric furnace smelting, external refining, continuous casting, heating, high speed wire rolling, (offline / online type) thermal treatment, straightening, polishing, inspection and storage. The production method adopts the continuous casting mode, overcomes the defects that 53Cr21Mn9Ni4N high temperature plasticity is poor, deformation resistance is large, and continuous casting is hard, performs rolling directly through a continuous casting slab, greatly lowers material processing losses and energy consumption in links, and increases the yield of the slab; the continuous casting slab direct high speed wire precision rolling technology is adopted, the production efficiency is improved, the rolled finished wire rod size precision control is greatly improved, and 53Cr21Mn9Ni4N steel continuous casting slab direct rolling to steel wire rod one heating forming is achieved; online and offline types of thermal treatment are achieved, and free choosing can be performed according to client quality requirements.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

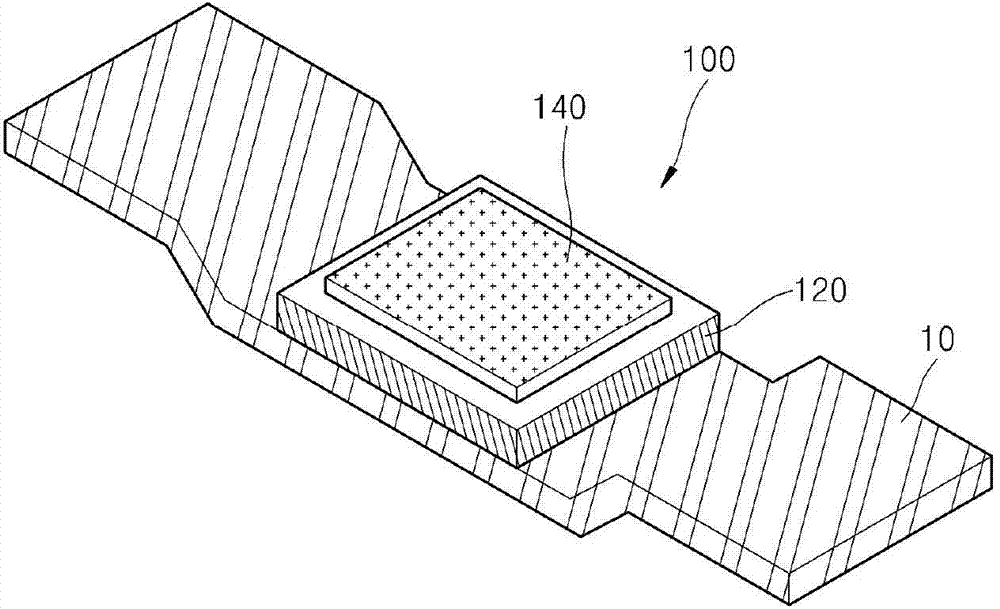

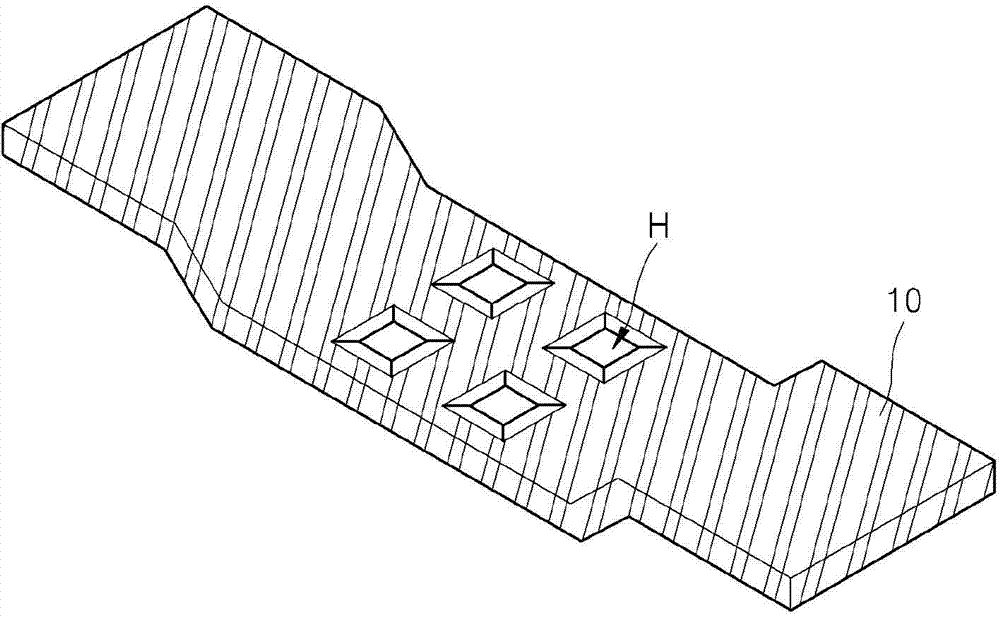

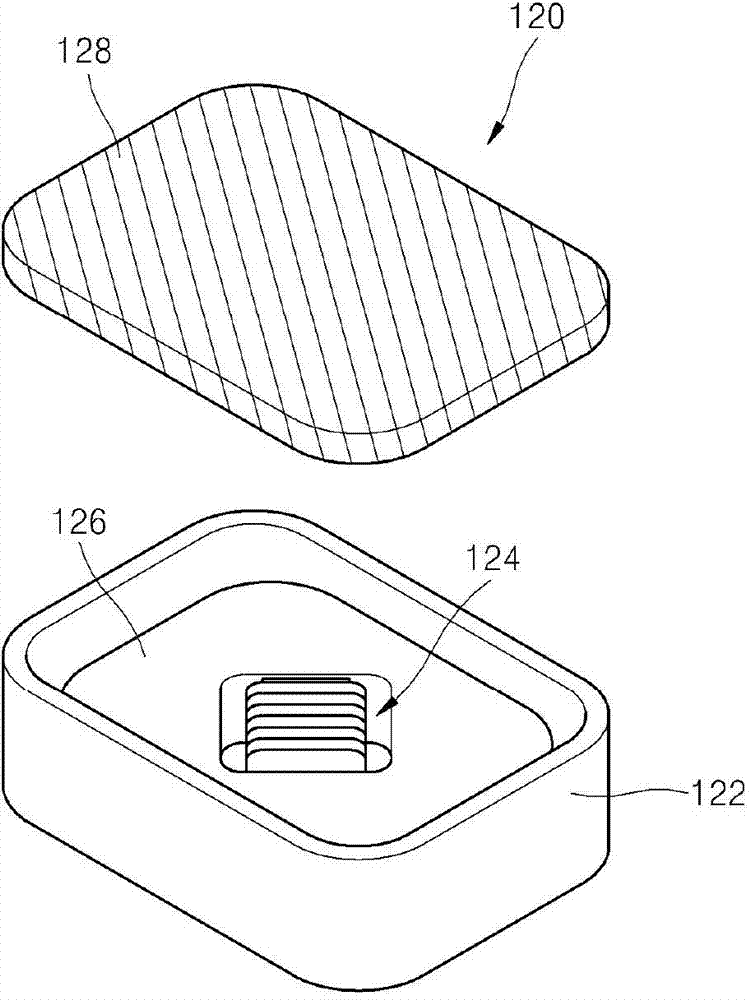

Window cleaning kit for wire bonding apparatus, wire bonding apparatus including the same and cleaning method of capillary using the same

InactiveCN103831676AExtended replacement cycleLower replacement costsSolid-state devicesSemiconductor/solid-state device manufacturingForeign matterCleaning methods

The invention relates to a window cleaning kit for a wire bonding apparatus, a wire bonding apparatus including the same and a cleaning method of capillary using the same; the apparatus can effectively clean foreign matters attached on end portions of the capillaries in a long term process using the wire bonding; the cleaning kit for wire bonding apparatus can fix a wire bonding object, can be arranged on a window clamp plate having a hole in a fixed manner for usage, and can be used as the cleaning kit in a dismounting state; the cleaning kit comprises a vibration generation plate and a grinding sheet; the vibration generation plate is placed on the window clamp plate; the grinding sheet is attached on the vibration generation plate and linked with the vibration generation plate.

Owner:ILJIN LED

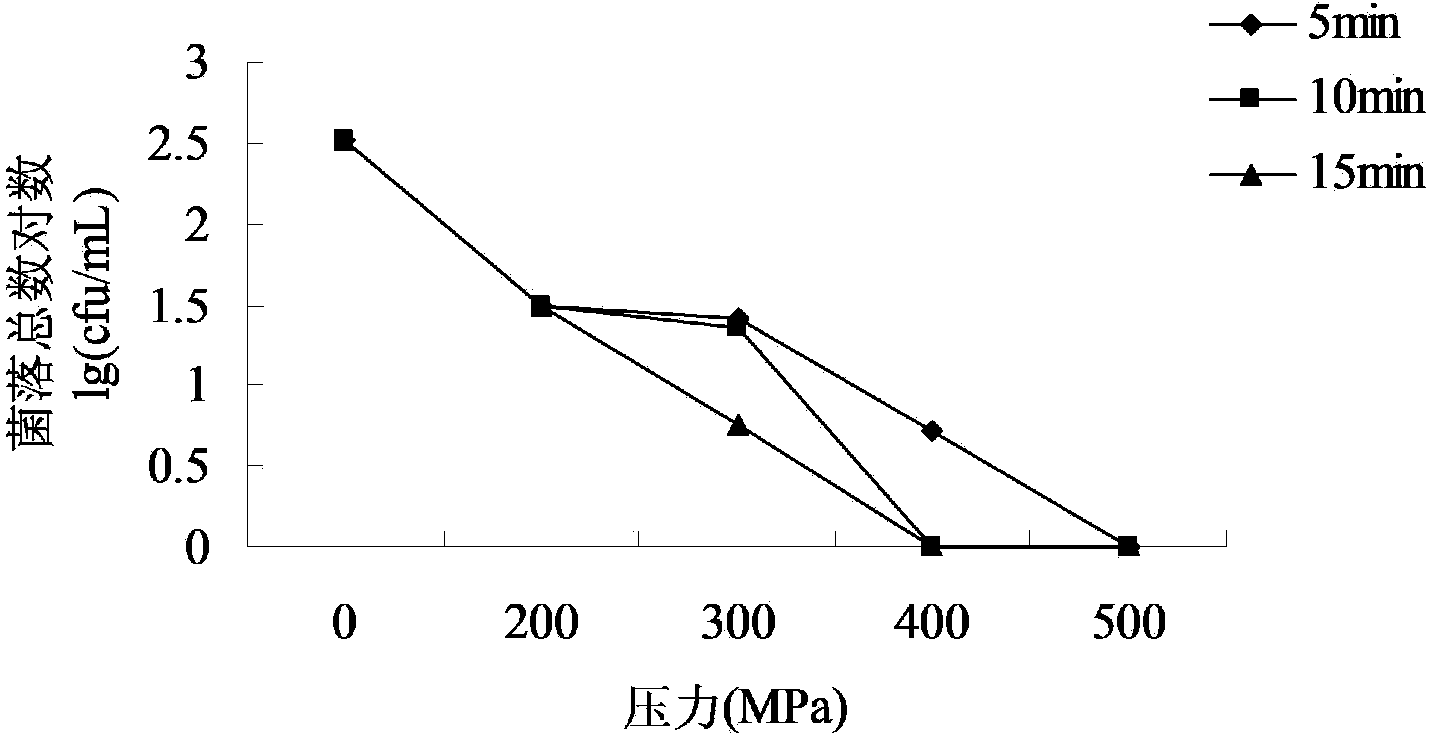

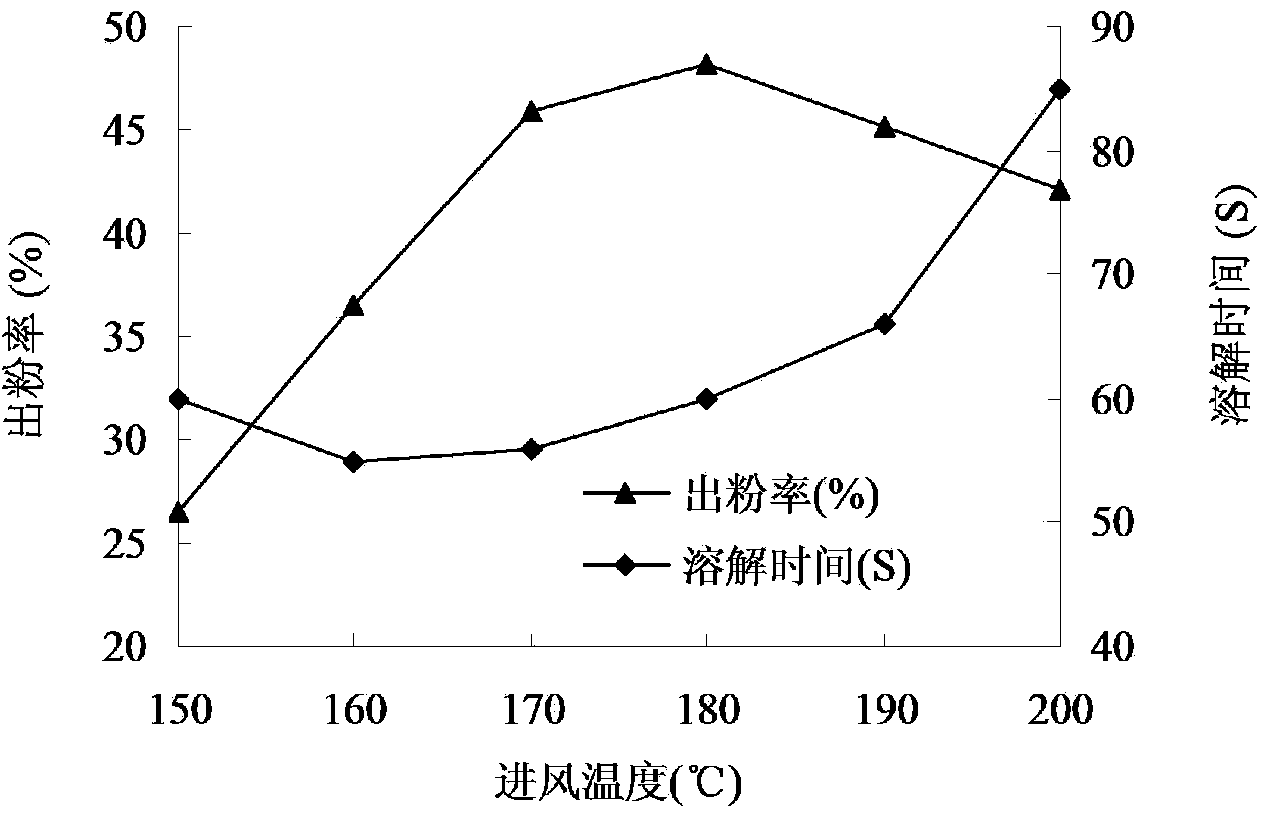

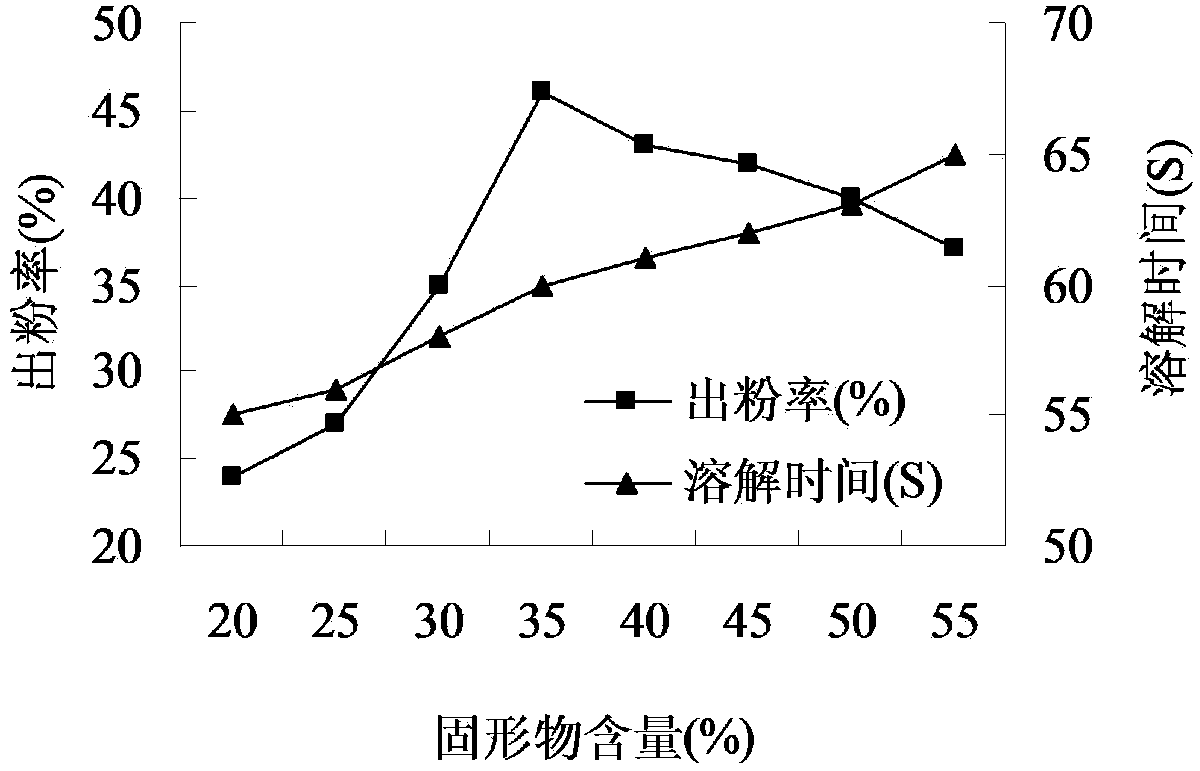

Method for preparing lucid ganoderma solid drink

ActiveCN103892256AAchieve losslessAchieve in vitro pre-degradationFood mechanical treatmentFood dryingFlavorDispersity

The invention relates to a method for preparing a lucid ganoderma solid drink. The method comprises the following steps: pretreating lucid ganoderma, performing superfine grinding, pulping, performing ultrahigh pressure treatment and performing spray drying. The lucid ganoderma solid drink product is fine and smooth in color and high in dispersity and has a particular medical material flavor of lucid ganoderma, the eating method is simple and convenient, the integrity of functional components of the lucid ganoderma is basically kept, processing loss of the raw materials is effectively reduced, and the solid drink is easy to brew. According to the lucid ganoderma solid drink, the polysaccharide leaching efficiency is 11.21-19.89mg / g, the powder extraction rate is 20.67-44.78 percent, and the dissolution time is 93-54 seconds.

Owner:长沙能峰生物科技有限公司

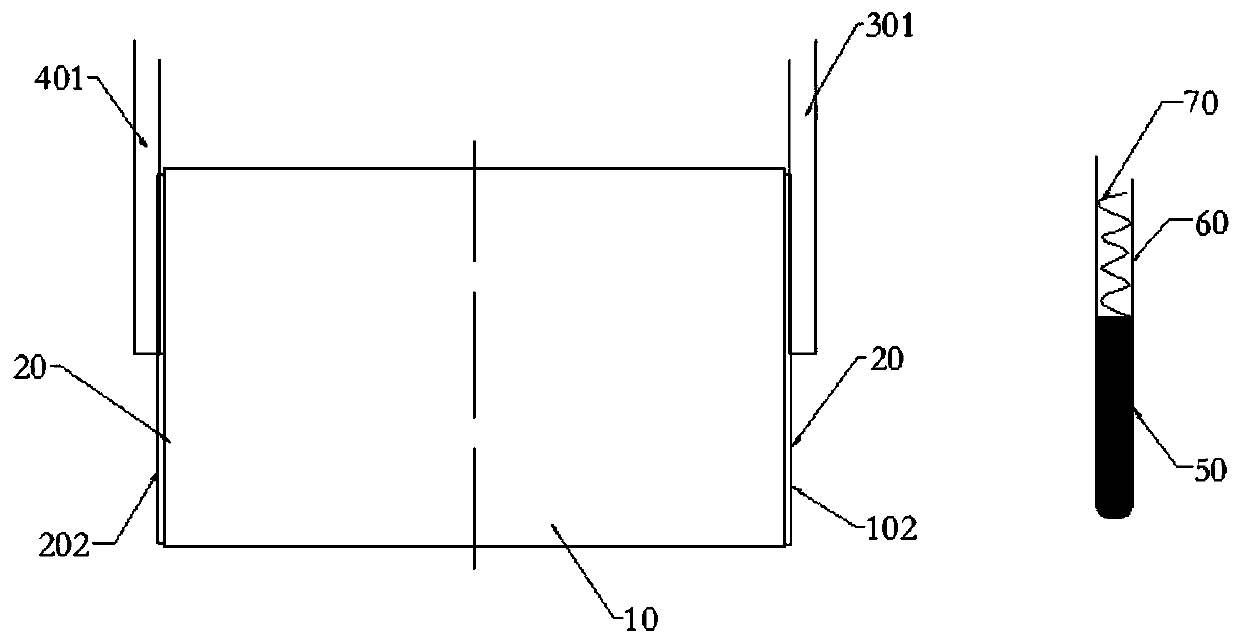

Assembling method of square winding type lithium ion battery and lithium ion battery

InactiveCN109818082AIncrease energy densityReduce invalid widthFinal product manufactureSecondary cells manufactureProcess lossBusbar

The invention belongs to the technical field of battery assembly, and relates to an assembling method of a square winding type lithium ion battery and the lithium ion battery. The assembling method ofthe lithium ion battery comprises the following steps of: shaping a roll core in at least one hot pressing and / or cold pressing manner; making a positive electrode blank area and a negative electrodeblank area at the two ends of the roll core respectively; flattening at least one part of the positive electrode blank area and the negative electrode blank area of the shaped roll core to respectively form a positive electrode flattening area and a negative electrode flattening area; respectively welding the positive electrode flattening region and the negative electrode flattening region with the positive electrode busbar and the negative electrode busbar in a laser welding manner; and putting into a shell to obtain the square winding type lithium ion battery. The battery energy density ofthe square winding full-tab design is improved, the problems of small effective volume proportion of the winding cores, low battery energy density, difficulty in parallel assembly of multiple windingcores and the like in the traditional assembly process are solved, and the process is simple, feasible, efficient, controllable and low in process loss.

Owner:SHANDONG FOREVER NEW ENERGY

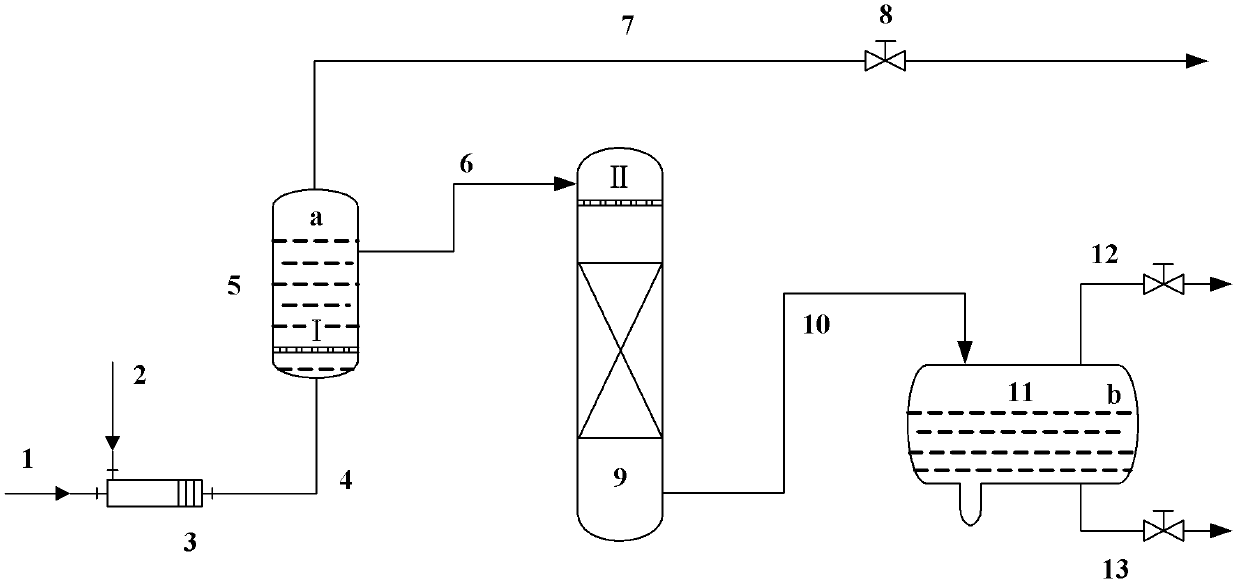

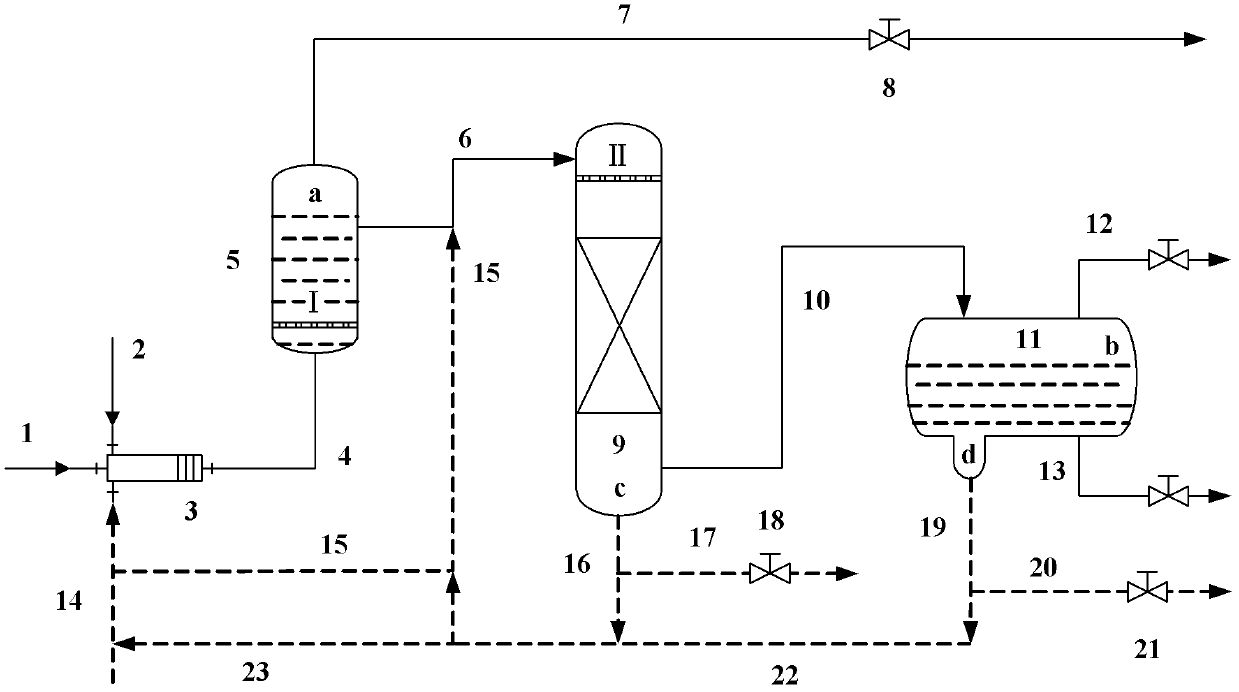

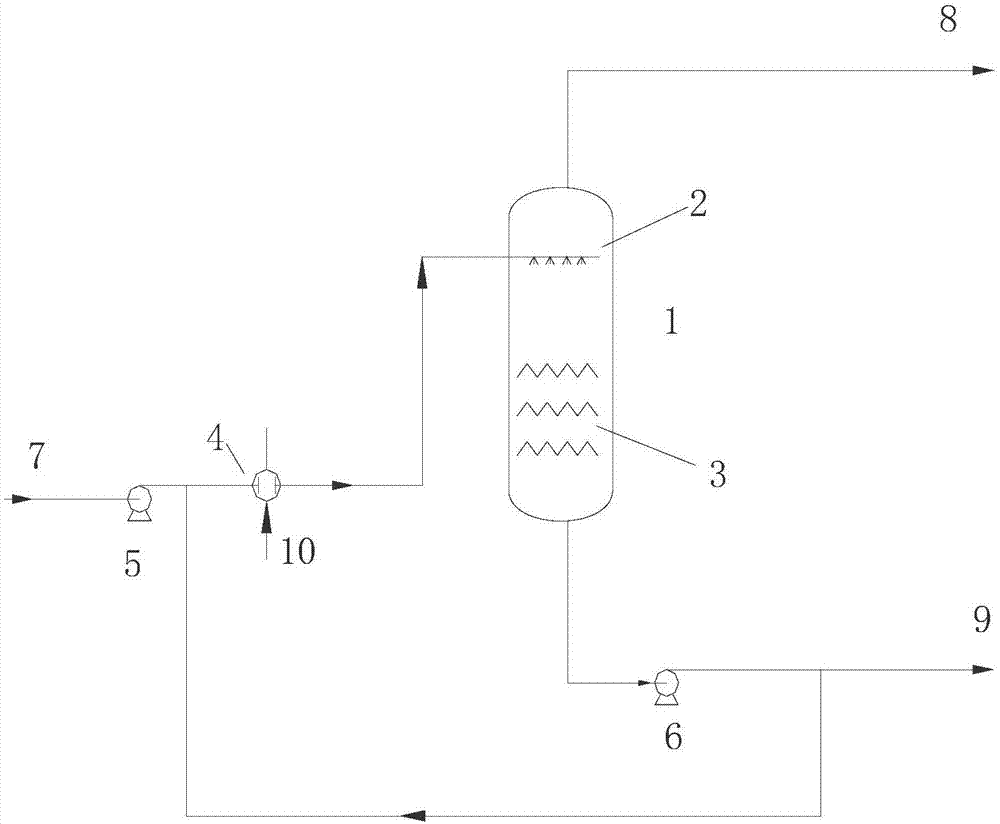

Method and device for deodorizing light oil product through dissolved oxygen

ActiveCN103374383AHigh yieldExtended service lifeRefining with oxygen compoundsAir liquid interfaceControl system

The invention provides a method and a device for deodorizing a light oil product through dissolved oxygen. The method comprises the following steps of: mixing the light oil product and air in a mixer, and then adding the light oil product into a dissolved oxygen container, wherein excess air is exhausted through an air-liquid interface control system in the dissolved oxygen container; adding the light oil product into a fixed bed reactor, and contacting the light oil product with a fixed bed oxidation catalyst; collecting the fixed bed oxidation catalyst subjected to a deodorizing reaction. According to the method and the device, on one hand, the pressure of a reaction system can be well kept in a balanced state to enable liquid-stage fluid to uniformly flow in the reactor, and on the other hand, by the reaction of mercaptan and the dissolved oxygen in the light oil product in a homogeneous state, the deodorizing efficiency can be effectively improved, and an unnecessary oxidization side reaction is avoided or slowed, so that phenomena of color deepening and colloid over-generation caused by over-oxidization of the oil product are avoided, the service life of the catalyst is prolonged, the processing loss is reduced, and the yield of the light oil product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

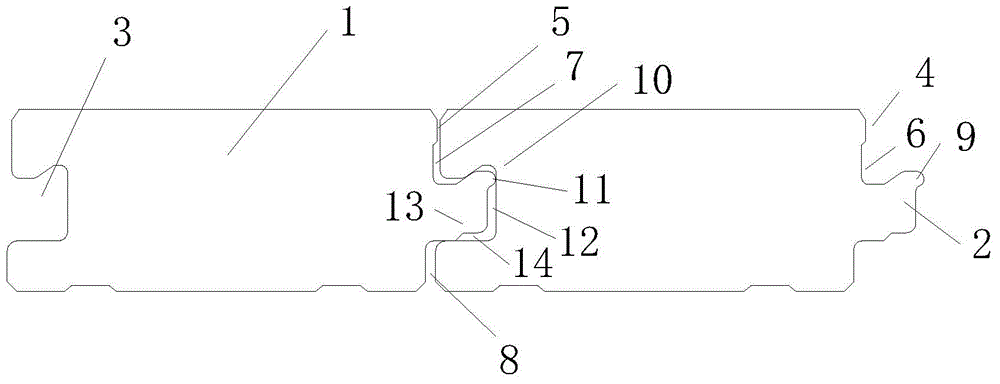

Steplike lock catch wood floor

ActiveCN104481114AEasy and stable installationPrevent archingFlooringEngineeringStructural engineering

Owner:JIUSHENG WOOD

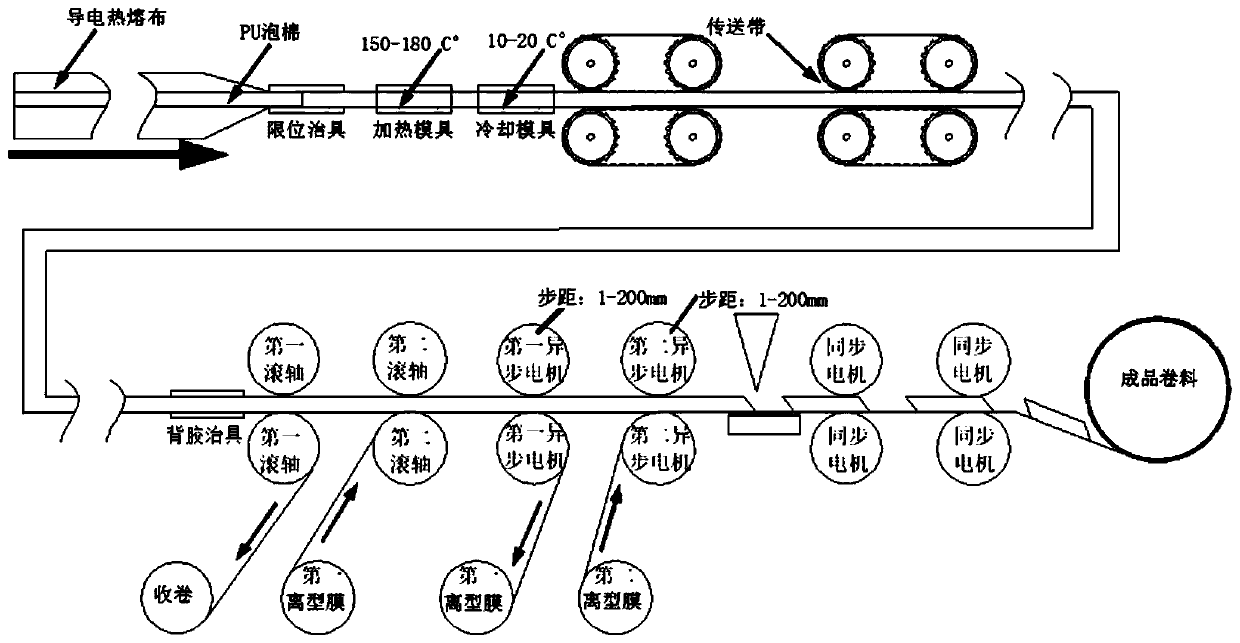

Asynchronous punching process for coated conductive foam

InactiveCN110139545AReduce lossReduce processing lossShielding materialsSynchronous motorProcess loss

The invention discloses an asynchronous punching process for coated conductive foam, which includes the steps as follows: forming is carried out: conductive hot melt cloth and PU foam are passed through a limiting fixture, a heating mold and a cooling mold of a conductive foam forming machine in turn; the coated conductive foam is pulled out by a conveyor belt; the conductive foam passes through aback glue fixture, a first roller rolls up to remove a piece of release paper thereof, and a second roller drives a first release film to fit the conductive foam; a first asynchronous motor rolls upthe first release film; a second asynchronous motor drives a second release film to fit the conductive foam; a punching machine punches the conductive foam according to the product characteristic demand; and a synchronous motor coils the finished conductive foam after punching. The original step-by-step coating forming replaced by the online integrated forming, and through conveying, punching andasynchronous winding, the difficulty that coated conductive foam cannot be wound in a traceless way and cannot be batch-grasped and pasted for SMT use is solved. The process loss, raw material loss and leftover material loss are greatly reduced, and the efficiency of production and assembly is improved.

Owner:江苏雷兹盾材料科技有限公司

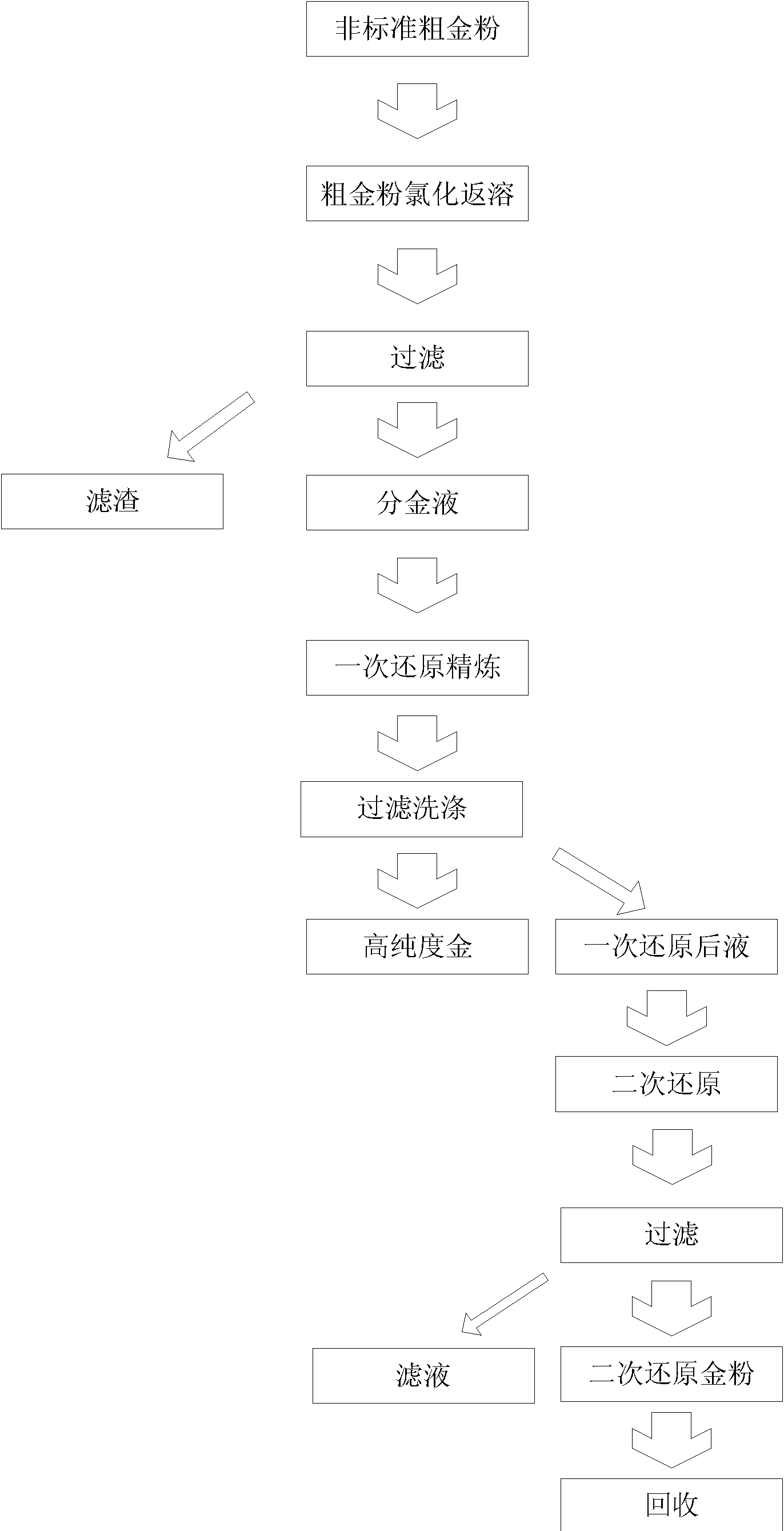

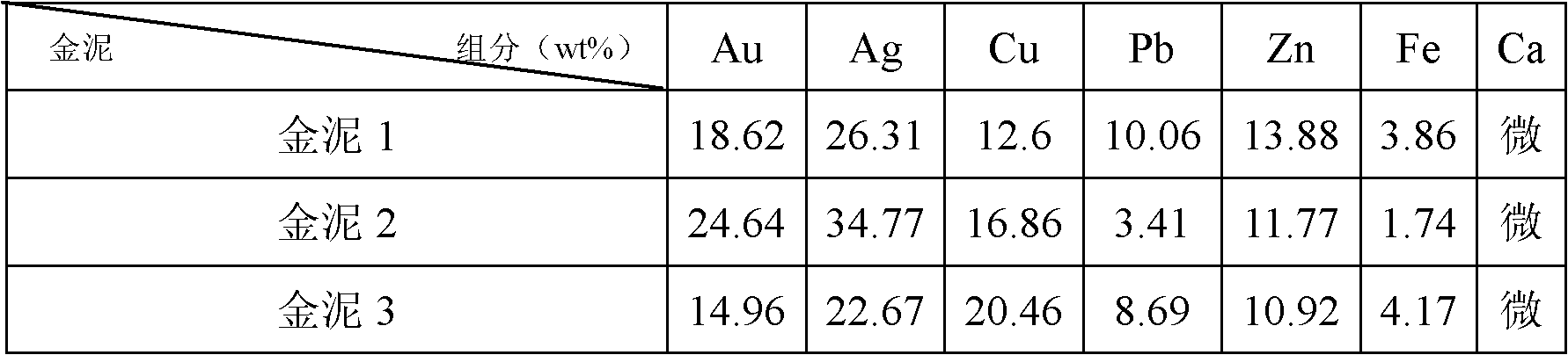

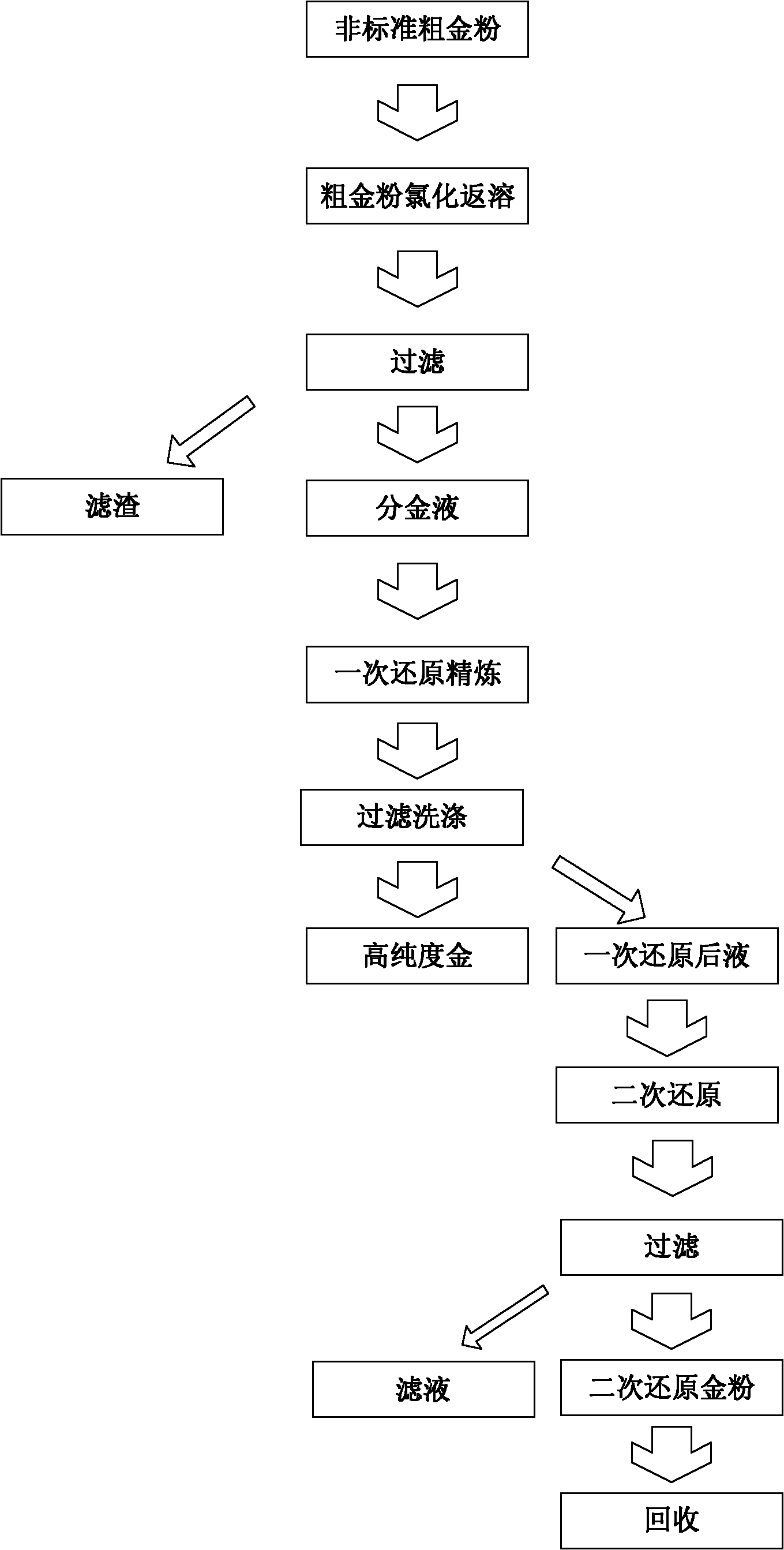

Non-standard Coarse Gold Powder Rapid Wet Refining Method

The invention relates to a method for quickly wet-process refining non-standard coarse gold powder. In the method, the quality of a product is guaranteed, the production cost is low, the product processing loss is low and the production period is short due to optimization of an oxidization-reduction potential. The method comprises the following steps of: 1) adding pure water and feeding the coarse gold powder into a reaction kettle, adding salt and H2SO4 sequentially, quickly raising the temperature to be 80 to 85 DEG C, starting to add NaClO3 serving as an oxidizing agent to make the potential reach 1,000 to 1,100 mv, keeping the potential reacting for 4.5 to 5.5 hours, raising the temperature to be 90 to 95 DEG C, keeping the temperature for 1.5 to 2.5 hours and filtering to obtain filtrate which is called gold separation solution; and 2) injecting the gold separation solution obtained by chloridizing and dissolving the coarse gold powder into the reaction kettle, raising the temperature to remove chlorine, adding oxalic acid to adjust the potential to be 880 to 920 mv, adding anhydrous sodium sulfite to make the potential reach 710 to 750 mv, filtering, and washing filter residues to be neutral by using distilled water.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

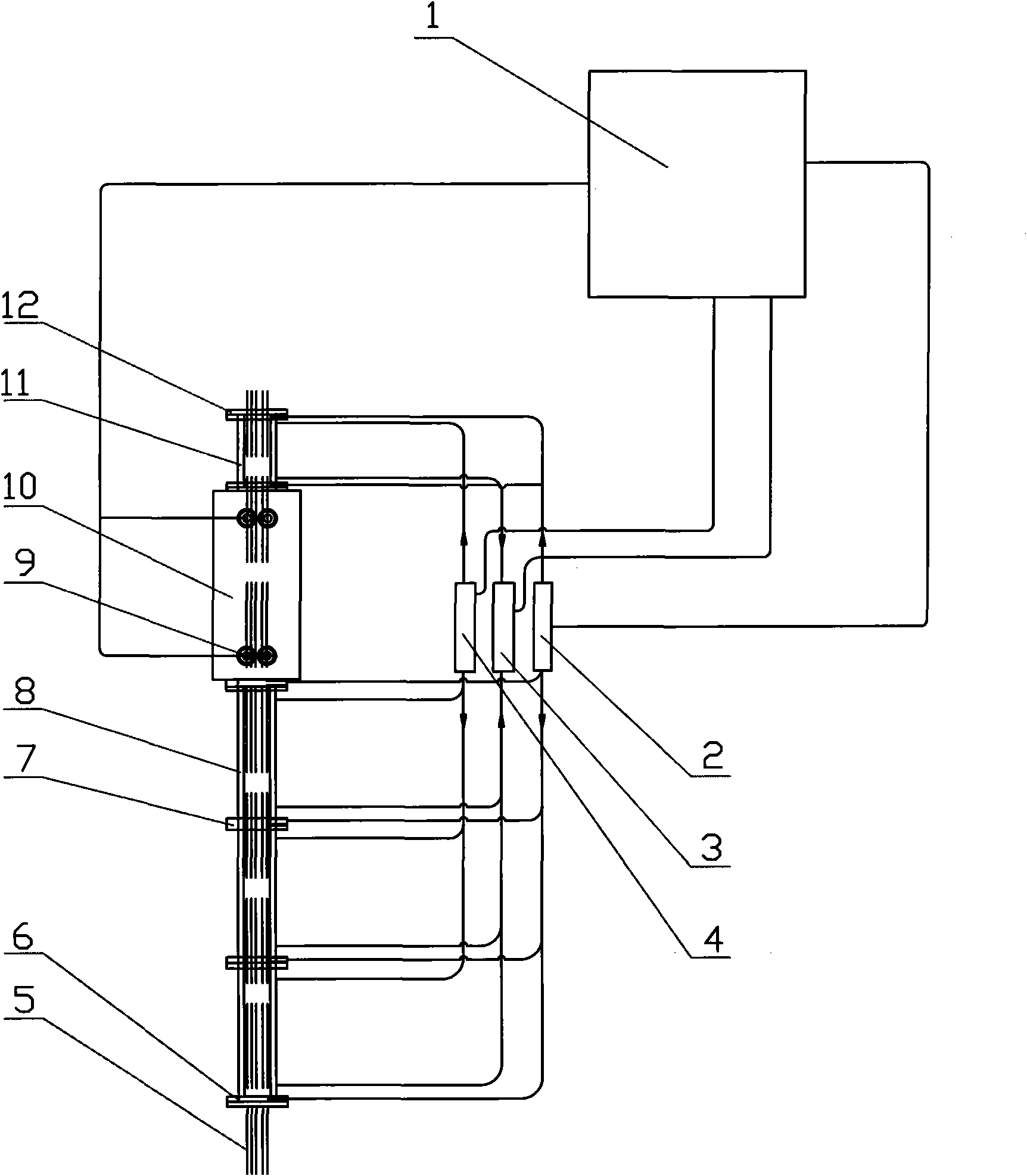

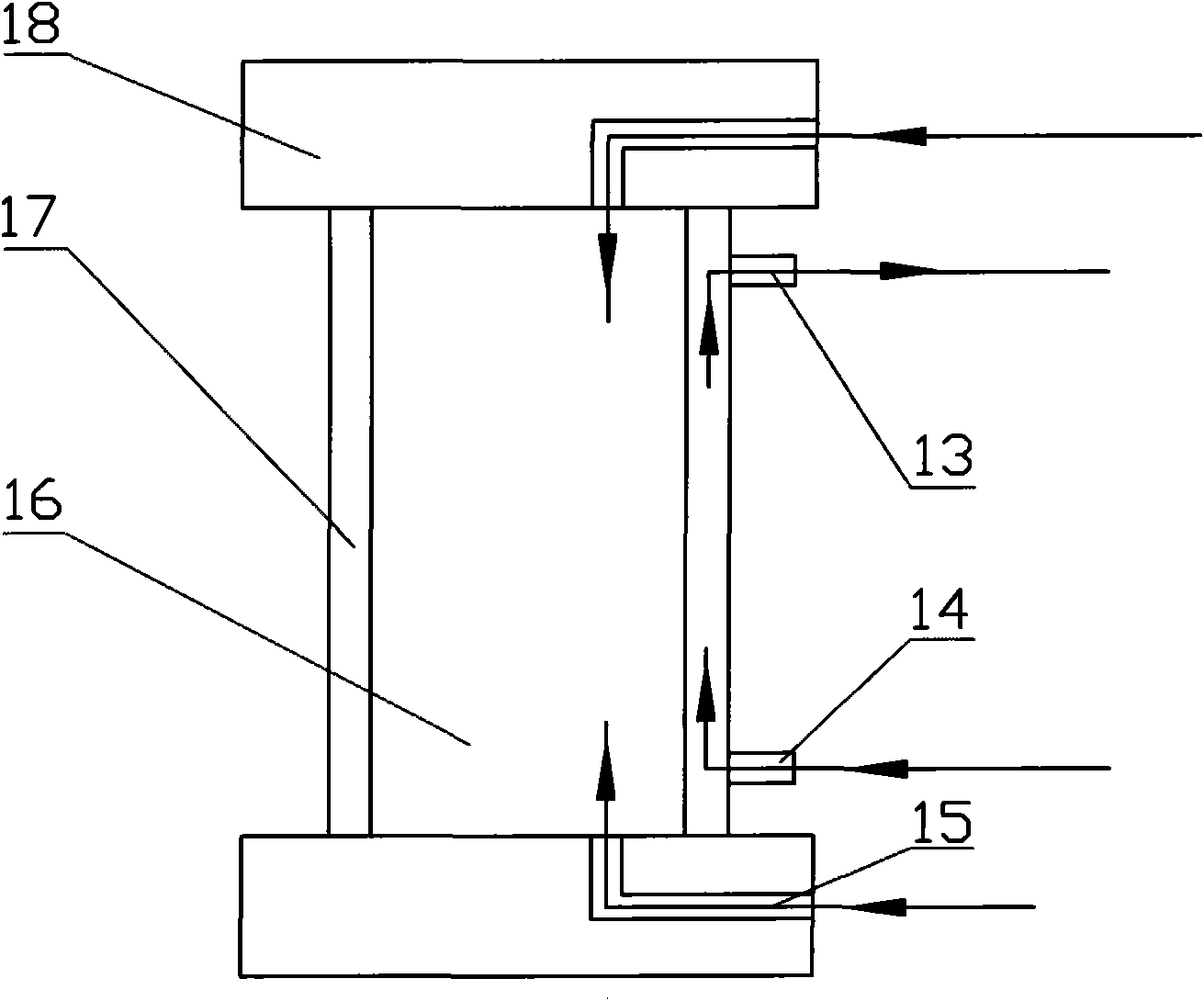

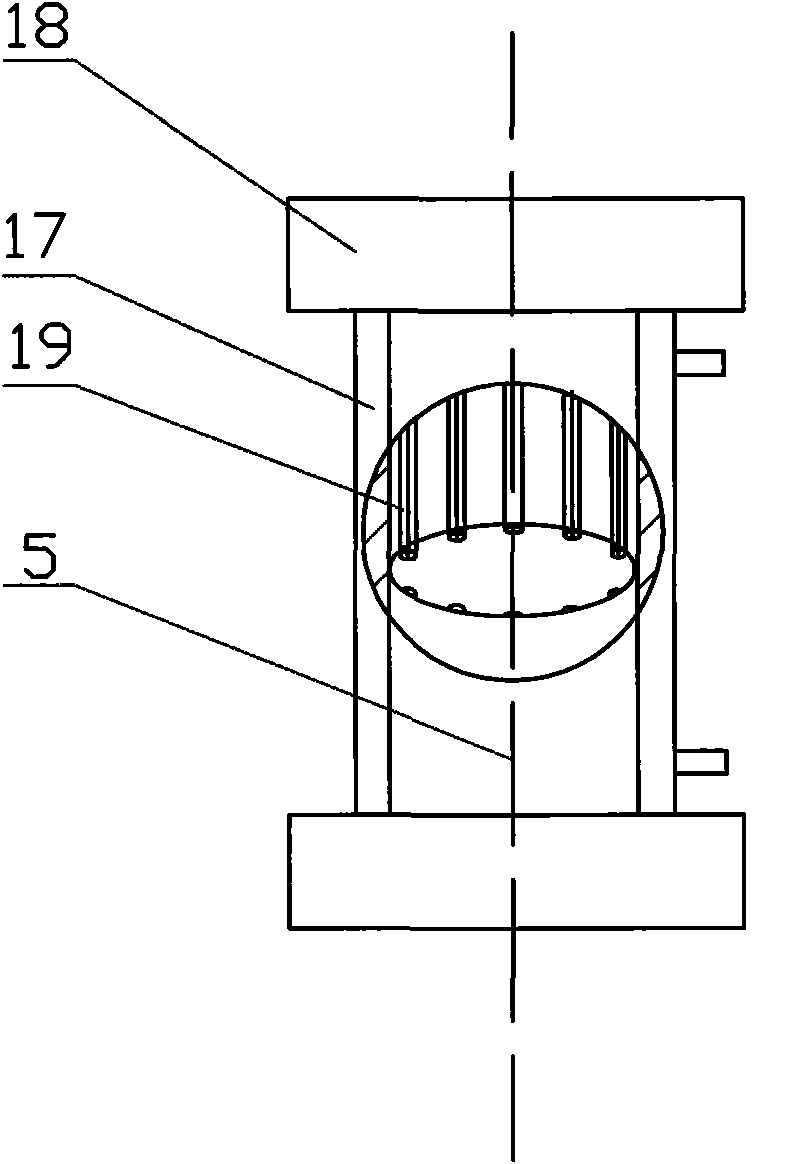

Vertical continuous annealing furnace

InactiveCN101792849AReduce difficultyReduce processing lossFurnace typesProcess efficiency improvementCooling fluidMetallurgy

The invention discloses a vertical continuous annealing furnace, which comprises an annealing tube, a lower cooling tube, a cooling system, a wire leading-in device, a wire leading-out device and an upper cooling tube, wherein a heating device for providing a predetermined annealing temperature environment for wires is arranged in the annealing tube; the lower cooling tube is connected in series with the lower end of the annealing tube and used for cooling the annealed wires; the cooling system provides cooling protection for the annealing furnace and the wires; the wire leading-in device is used for leading the wires into a furnace body; the wire leading-out device is used for leading the wires out of the furnace body; the upper cooling tube is connected in series with the upper end of the annealing tube, a cooling protection gas is introduced into a wire passage inside the upper cooling tube just like the lower cooling tube, and the outer part of the upper cooling tube is provided with a water-cooled wall; and correspondingly, the cooling system comprises a cooling liquid circulating system and a protection gas cooling device. The scheme can ensure the annealing quality of the wires.

Owner:JINAN LEIAOTE MACHINERY MFG

Roxburgh rose solid drink and preparation method thereof

The invention discloses a roxburgh rose solid drink and a preparation method thereof. The roxburgh rose solid drink is prepared from the following raw materials in proportion: 10L to 20L of roxburgh rose normal juice, 0g to 20g of acesulfame, 0kg to 6kg of white granulated sugar, 0kg to 6kg of xylitol, 0kg to 6kg of isomaltitol, 0kg to 4kg of maltodextrin, 0kg to 4kg of tragantine and 0kg to 4kg of water-soluble dietary fiber. The preparation method of the drink comprises the following steps of: freezing and unfreezing roxburgh rose fresh fruits and centrifuging to obtain roxburgh rose normal juice; and preparing, filtering and performing spray drying to prepare powder or granules. The drink and the preparation method have the advantages of increased juice yield of the roxburgh rose and Vc (Vitamin C) transfer rate, good mouthfeel, convenience for carrying, long quality guarantee period, stable Vc and SOD (Superoxide Dismutase) content, simple process and equipment, high efficiency and low energy consumption and are suitable for industrial production.

Owner:上海新天智药生物技术有限公司

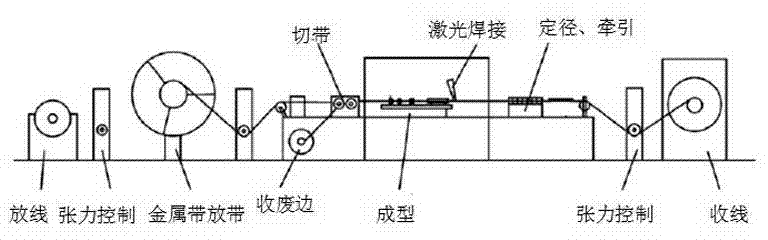

Machining process for outer conductor of semi-rigid cable

InactiveCN104078163ARF leakage is smallImprove performanceCable/conductor manufactureElectrical conductorProcess loss

The invention discloses a machining process for an outer conductor of a semi-rigid cable. The semi-rigid cable comprises an inner conductor, an insulating layer and the outer conductor. The machining process comprises the following steps of firstly, mounting a pressed and qualified cable core of phi 2.53 mm on a pay-off rack, secondly, mounting a metal band on a band pay-off rack, adjusting band pay-off tension to be 15-30 N, carrying out side cutting on the metal band, then carrying out forming through a horn die, starting a laser welding machine for welding and debugging, threading the cable core of phi 2.53 mm into the metal band for wrapping, forming, welding and sizing after the welding and the debugging. The semi-rigid cable produced thought the machining process is small in radio frequency leakage and stable in performance, quality stability, production length and the manufacturing process are improved greatly, process losses are reduced greatly, and production cost is lowered effectively.

Owner:安徽顺驰电缆股份有限公司

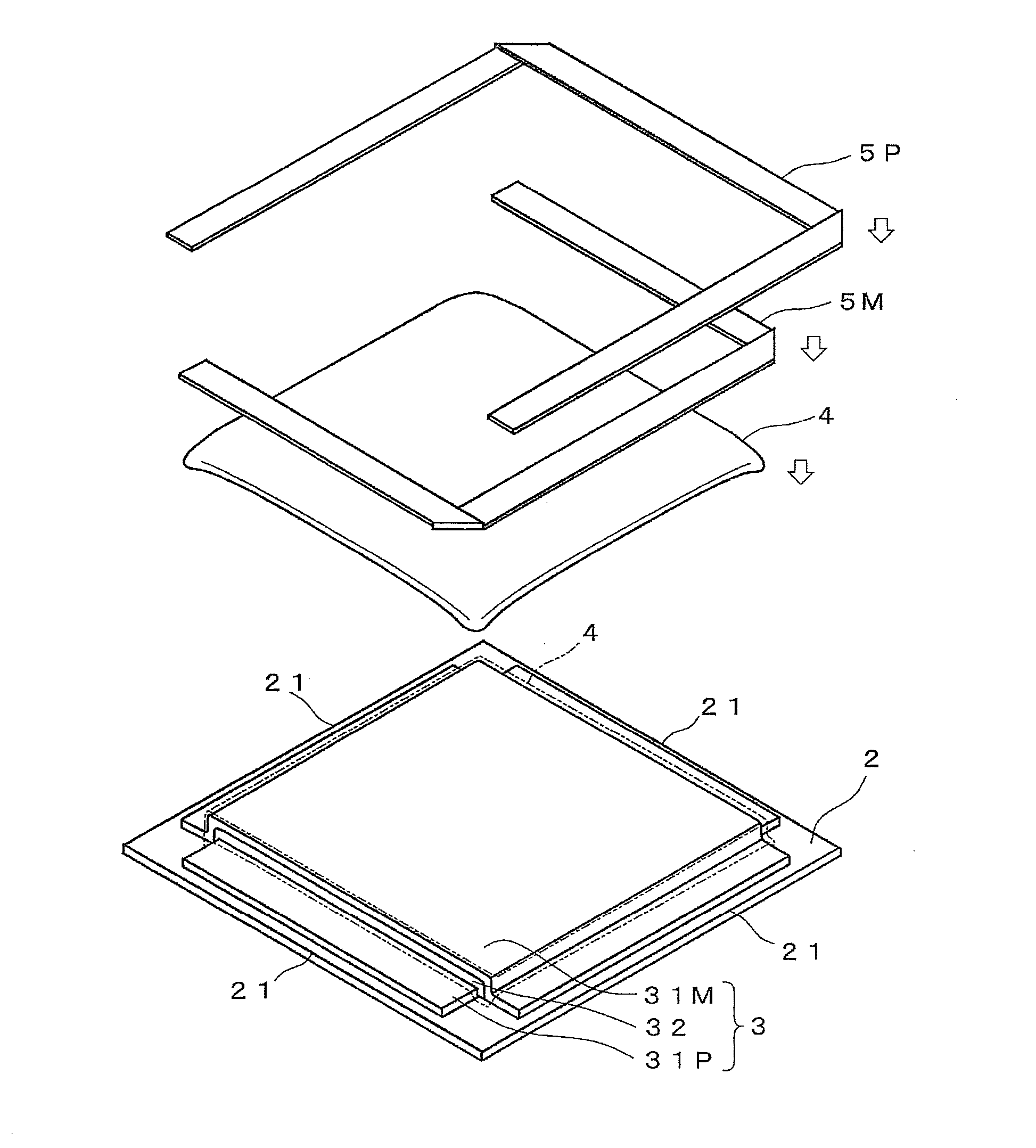

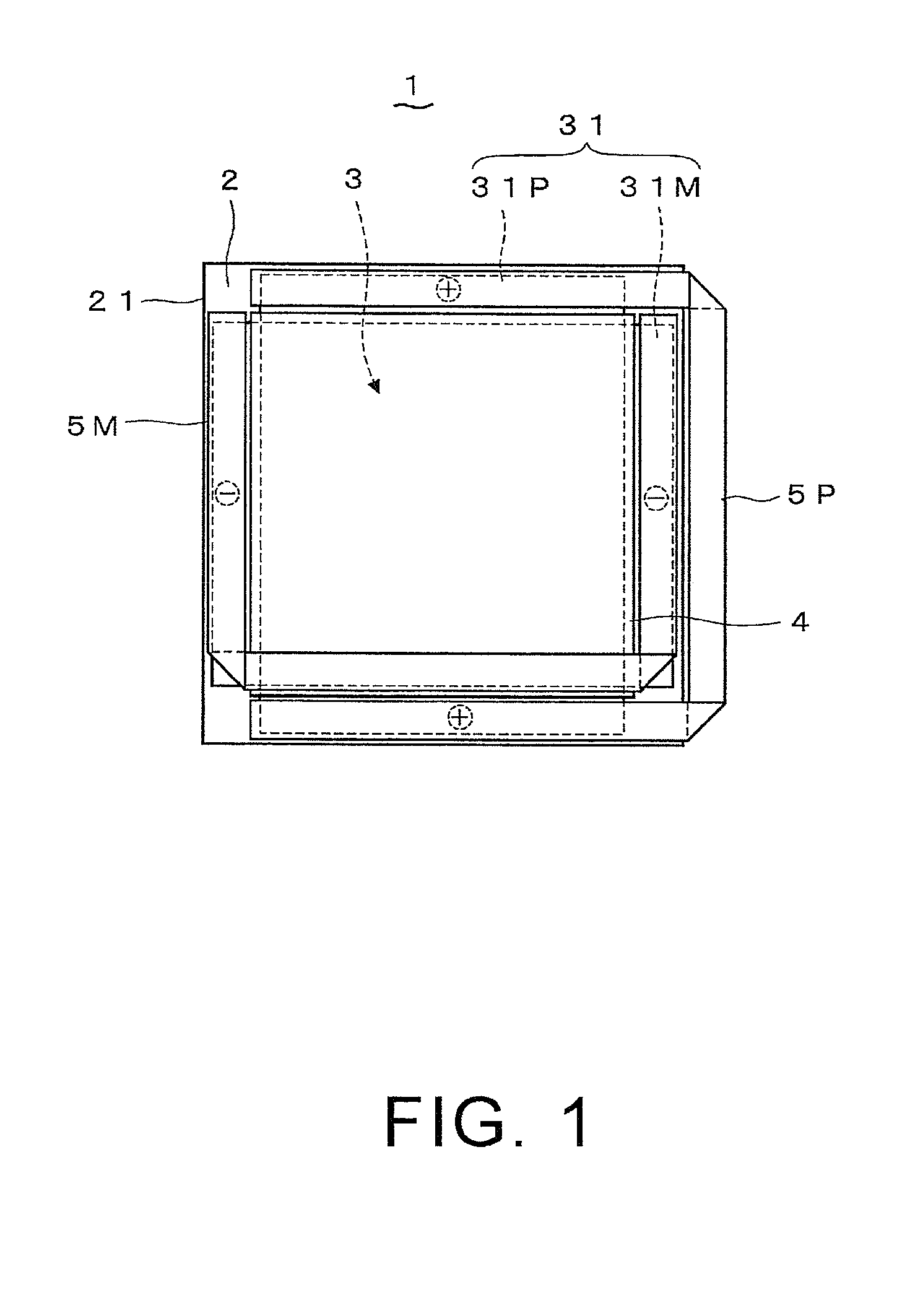

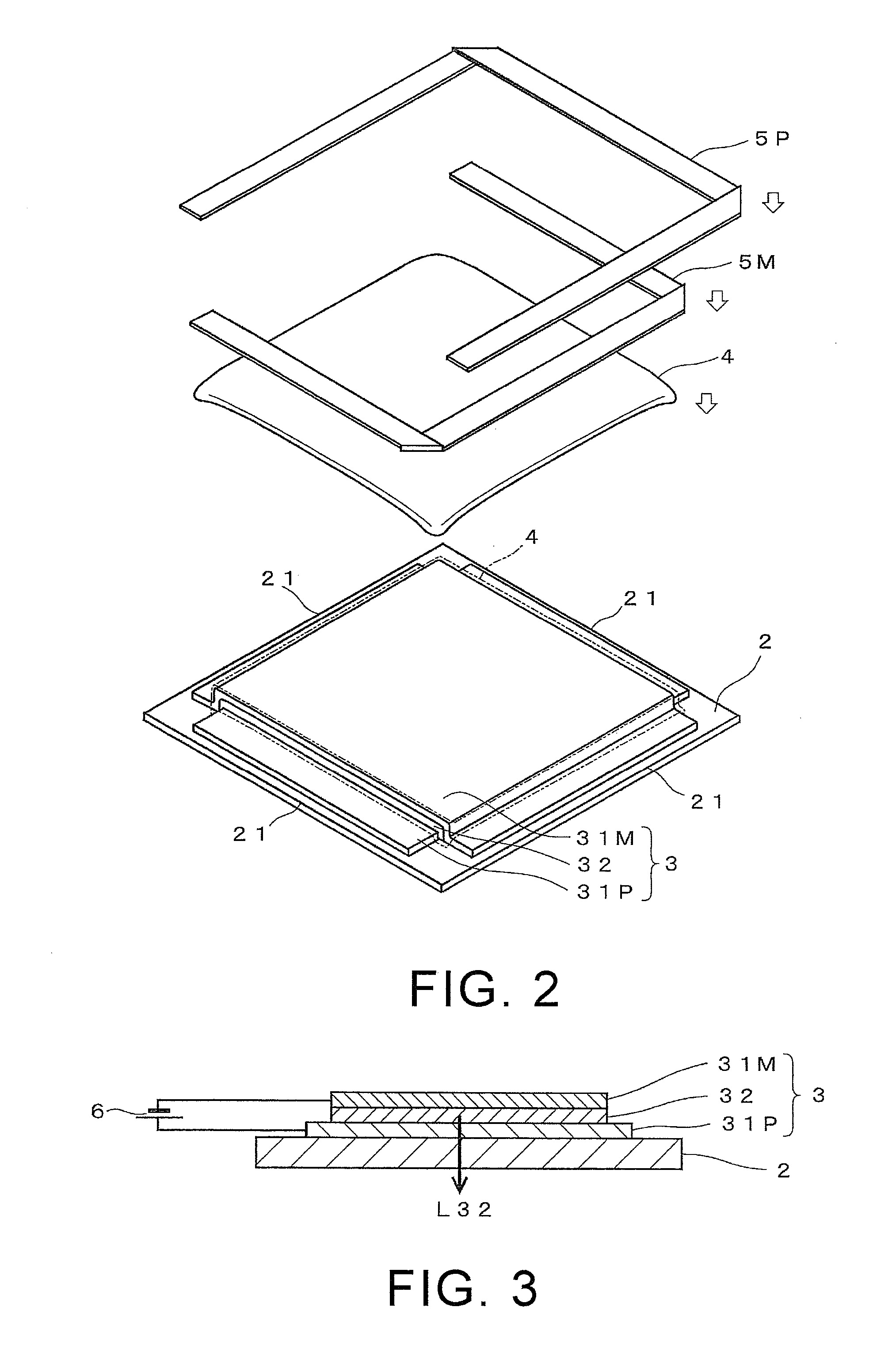

Organic electroluminescence module having a bent strip conductor

InactiveUS8207664B2Reduce processing lossReduce manufacturing costDischarge tube luminescnet screensPrinted circuit aspectsElectrical conductorOrganic electroluminescence

An organic electroluminescence (EL) module capable of reducing a processing loss of wiring boards for supplying power to an anode and a cathode is provided. Each wiring board (5) is formed by bending a strip conductor in a manner that parts of the strip in the same surface contacting each other, and is arranged on the outer periphery of the element substrate (2) in a manner of connecting the extended anode (31P) with the same pole and connecting the extended cathode (31M) with the same pole. In this manner, the wiring boards (5) having a width satisfying a shape of the electrodes without cutting a conductive plate into a U shape.

Owner:PANASONIC CORP

Energy-saving sump oil dehydration device and treatment method thereof

ActiveCN107880930AAchieve deep dehydrationLess waterTreatment with plural serial refining stagesEvaporationOil water

The invention provides an energy-saving sump oil dehydration device and a treatment method thereof. The energy-saving sump oil dehydration device comprises a sump oil dehydration tower, a sump oil atomizer, a Venturi rod layer, a circulating heater, a pump for sump oil to be dehydrated and a circulating sump oil pump. A circulating heating and atomizing technologies are used; low-temperature afterheat of an oil refining device is fully utilized; heated sump oil is atomized into fine fogdrop, so that the oil-water boundary tension is reduced; the oil-water evaporation area is increased; the deep dehydration of the sump oil is realized. The energy-saving sump oil dehydration device has the advantages that the flow process is simple; the operation is simple and convenient; the energy consumption is low; the dehydration effect is good; the applicability is wide. The energy-saving sump oil dehydration device can be used for light sump oil dehydration, can also be used for heavy sump oil dehydration and is particularly applicable to deep dehydration of seriously emulsified sump oil; the water content in the sump oil can be lowered to 2 percent or less; the requirement of sump oil refining on the water content is met.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

Honeycomb filters with reduced number of unplugged partial peripheral cells and methods of manufacturing same

ActiveUS20070137158A1More resistant to edge chippingReduce processing lossCombination devicesAuxillary pretreatmentEngineeringHoneycomb structure

A method of blocking partial cells at the periphery of diesel filters is disclosed. The method comprises plugging the partial cells with a suitable plugging material. In one embodiment, a line of plugging material is applied to either or both of the end faces of the diesel filter along an outermost row of partial cells to block same. In another embodiment, the outermost wall the diesel filter is first beveled to form a beveled edge and uniquely off-set the partial cells. Then the beveled edge has applied thereto a plugging material, such as a line or bead. A honeycomb structure having reduced number of unplugged partial cells at the periphery is also disclosed.

Owner:CORNING INC

Technology for preparing superfine pawpaw with high anti-oxidation function

The invention discloses a technology for preparing superfine pawpaw with a high anti-oxidation function. The technology comprises the following steps of: directly removing nuclei from pawpaw, crushing the pawpaw, performing flash evaporation drying, dehydrating till the water content is less than 8 percent, and crushing the dried pawpaw powder at the temperature lower than 140 DEG C through an airflow crusher of which airflow speed is more than 3.08 Mach till the superfine powder with the granularity less than 3 microns is obtained. By using the technology of combining the flash evaporation and the airflow crusher of multi-times sound velocity (exceeding 3.08 Mach), the original nutritional components and functional components of the pawpaw are kept, the nutritional effect components are easily freely released in human digestive tract, and minimum processing loss of all dietary fibers and anti-oxidation components of the fruits is ensured; the technology can greatly reduce the particle diameter of the superfine pawpaw powder; and compared with the conventional technology for extracting and spray-drying the powder, the technology has the advantages that the link is seldom, the heat loss of the anti-oxidation components is low, all dry substance components of the pawpaw are kept, the effect activity is high and any processing aid is not required to be added.

Owner:ARMY MEDICAL UNIV +1

Cigarette processing method through papermaking-method reconstituted tobacco based on fine cigarettes

ActiveCN108244687AImprove the pass rate of shreddedReasonable structureTobacco preparationTobacco treatmentEngineeringTobacco product

The invention provides a cigarette processing method through papermaking-method reconstituted tobacco based on fine cigarettes. The method comprises the following steps that (1) the papermaking-methodreconstituted tobacco is loosed and dampened, the moisture content of the reconstituted tobacco is adjusted to be 14.0-16.0%, and shredding is conducted; (2), after the physical characters of reconstituted tobacco shreds are changed through temperature and humidity increase, and then the moisture content of the reconstituted tobacco shreds turns to be 12.5-13.5% after roller drying; (3) long shreds are cut into short shreds through a shred cutting device, and the structures of the reconstituted tobacco shreds meet the requirement of the fine cigarettes; (4) the smoking quality of papermaking-method reconstituted tobacco products is improved through roller feeding; (5) flexible winnowing, feeding, measurement and binning are conducted, and residual substances with a large proportion are removed; (6) finally the reconstituted tobacco shreds are grouped and blended with rolling bags according to cigarette composition demands. According to the cigarette processing method, the blending uniformity and effective utilization rate of the papermaking-method reconstituted tobacco in the fine cigarettes are improved, and the aims of improving the quality of the fine cigarette products and lowering the processing loss are achieved.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com