Vertical continuous annealing furnace

A continuous annealing furnace, vertical technology, used in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of wire deviation, detachment from guide rollers, and the inability of wire to pass through the annealing zone stably, so as to reduce subsequent processing. The difficulty of the processing, the effect of small processing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

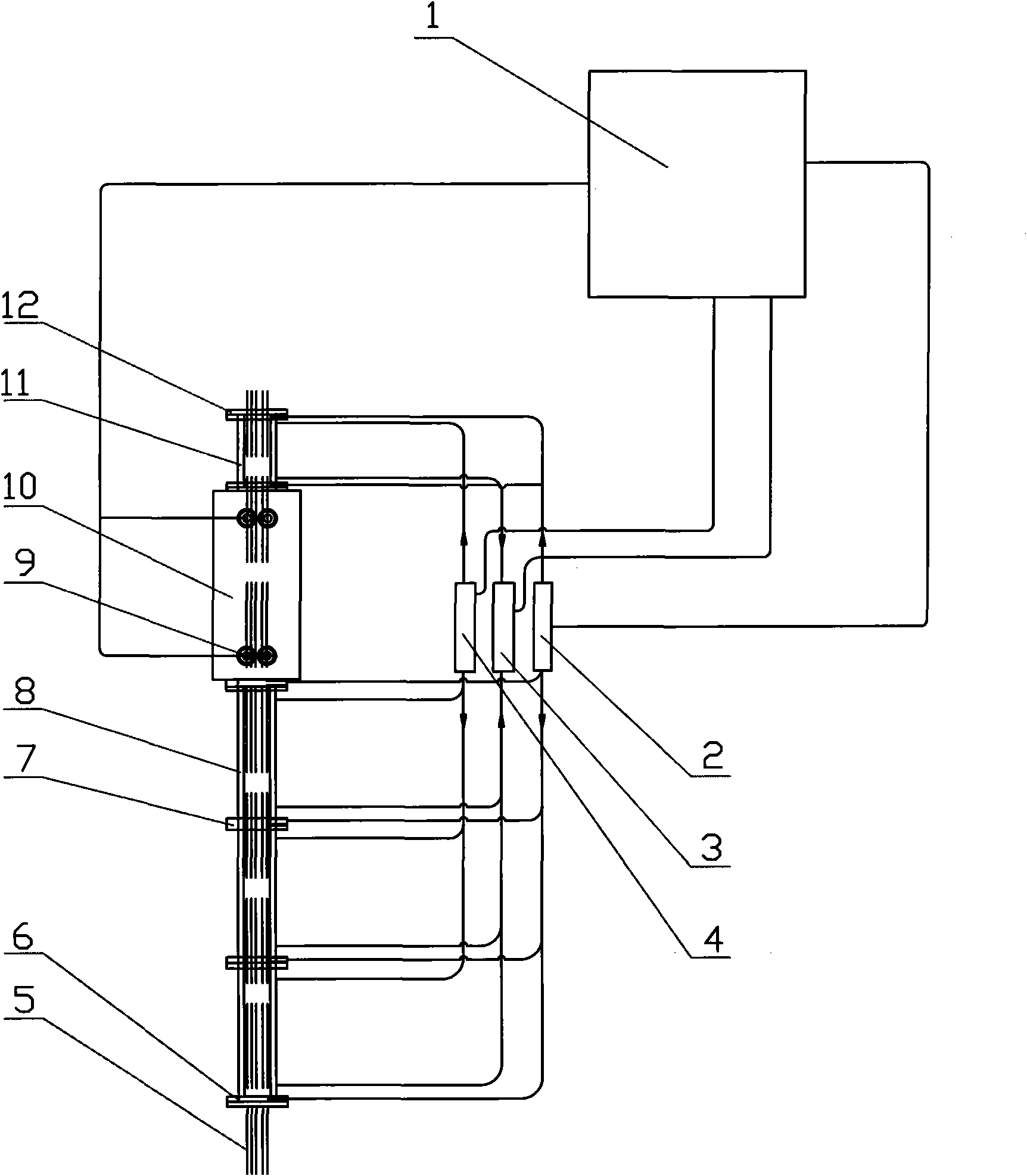

[0029] Instructions attached figure 1 The basic structure of a vertical continuous annealing furnace is shown, the annealing furnace includes:

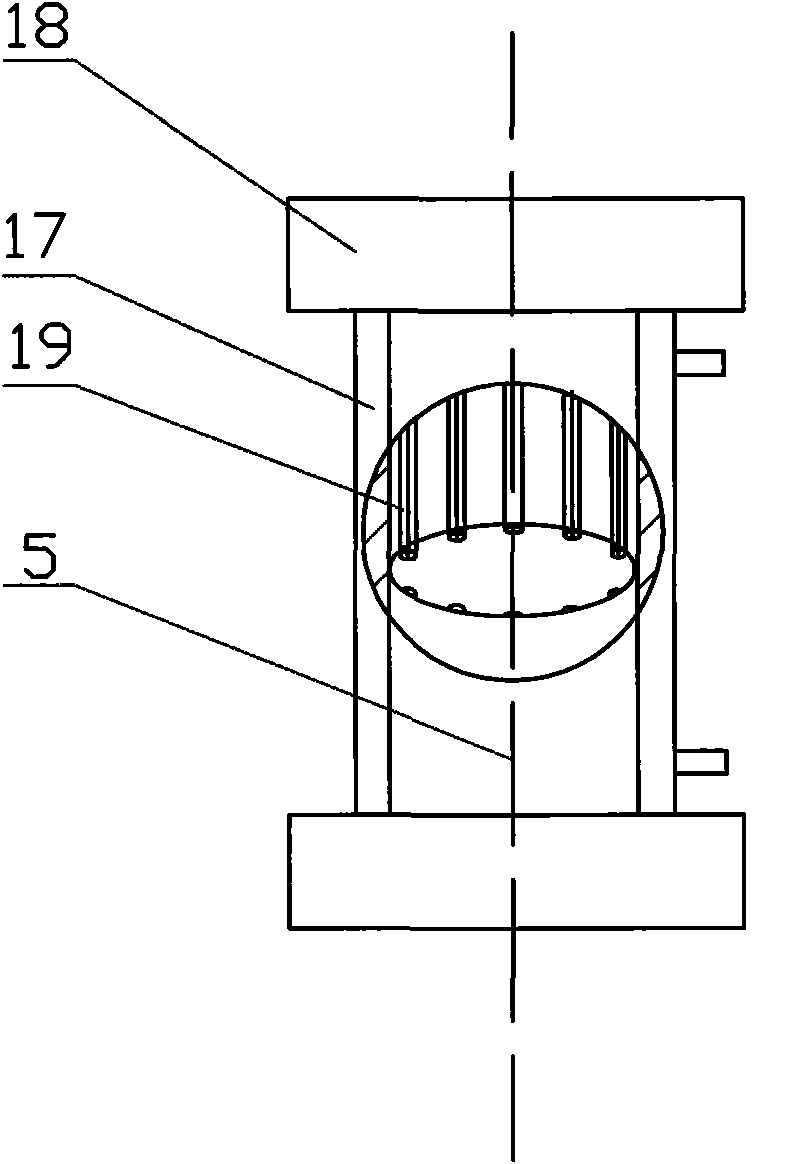

[0030] The annealing tube 10 is provided with a heating device 9 inside, which is used to provide a predetermined annealing temperature environment for the wire 5;

[0031] The lower cooling pipe 8 is connected in series with the lower end of the annealing pipe for cooling the annealed wire;

[0032] Cooling system to provide cooling protection for annealing furnace and wire;

[0033] The wire introduction device 12 is used for the introduction of the wire into the furnace body;

[0034] Wire lead-out device 6, used for the lead-out of the wire from the furnace body;

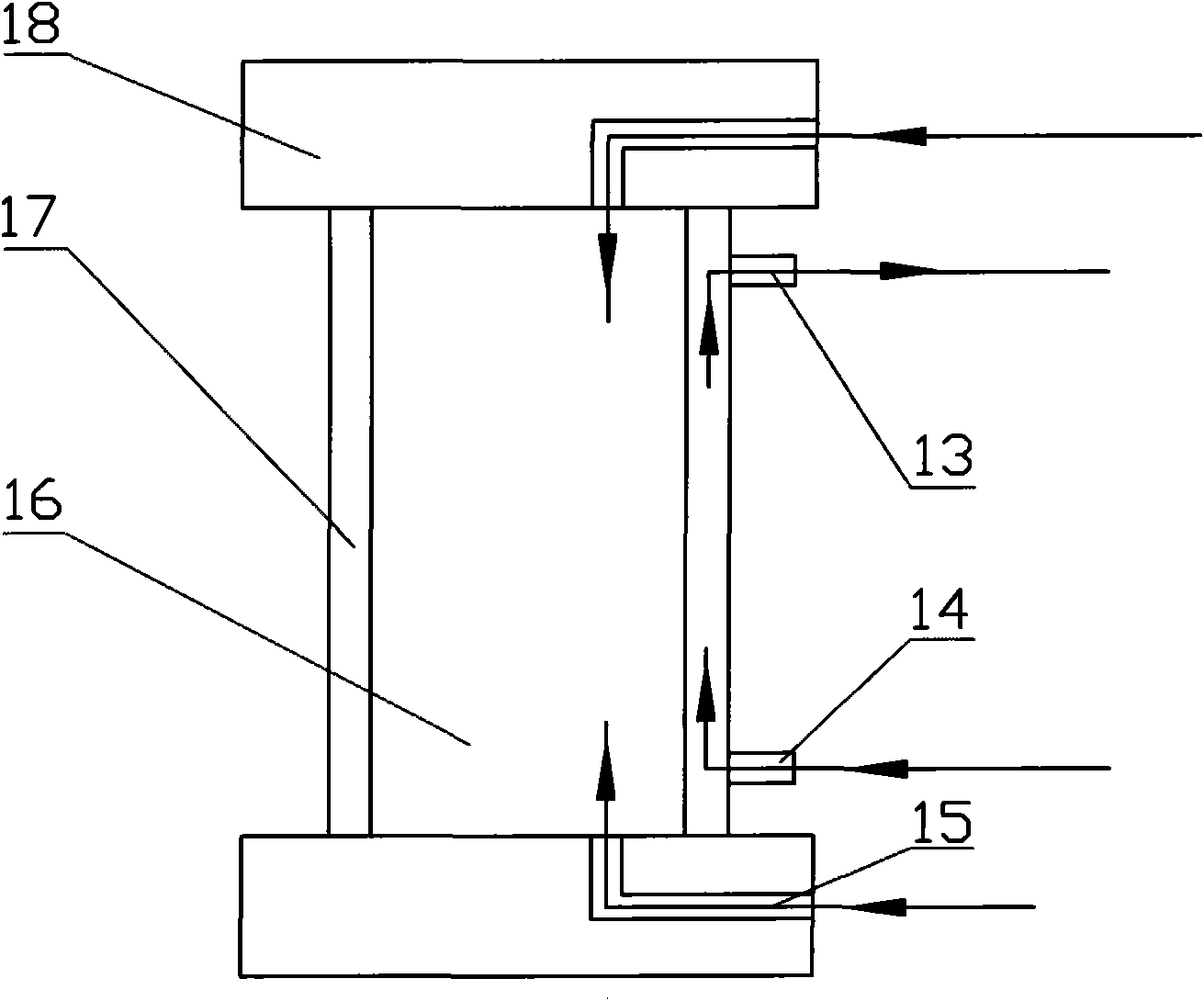

[0035] The upper cooling pipe 11 is connected in series with the upper end of the annealing pipe, and like the lower cooling pipe, the inner wire channel is passed with cooling and protective gas, and the outside is provided with a water cooling wall 17; correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com