Non-standard Coarse Gold Powder Rapid Wet Refining Method

A non-standard, crude gold technology, applied in the field of gold refining technology, can solve the problems of poor working environment, heavy pollution, large investment, etc., and achieve the effects of low production cost, short production cycle and low processing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

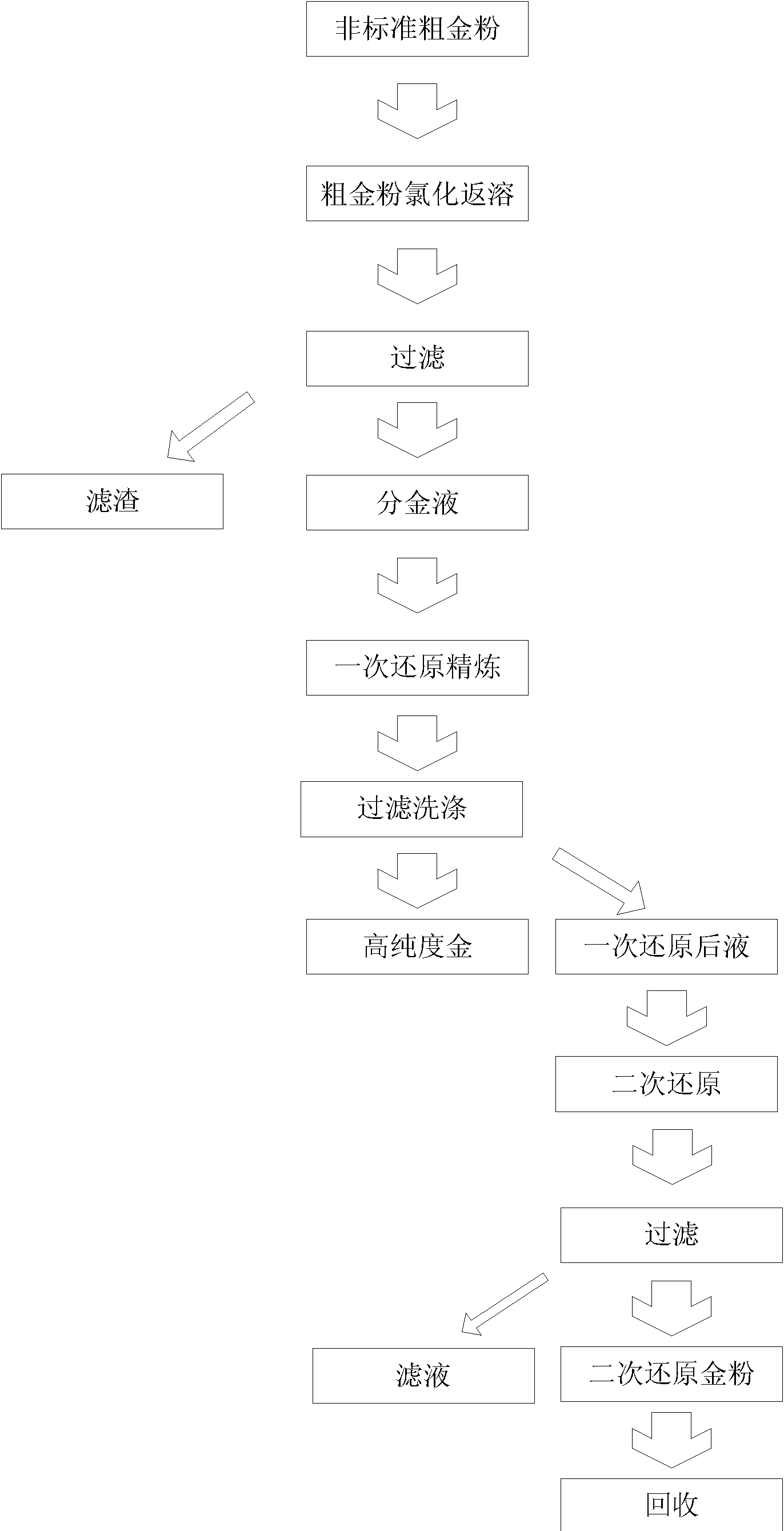

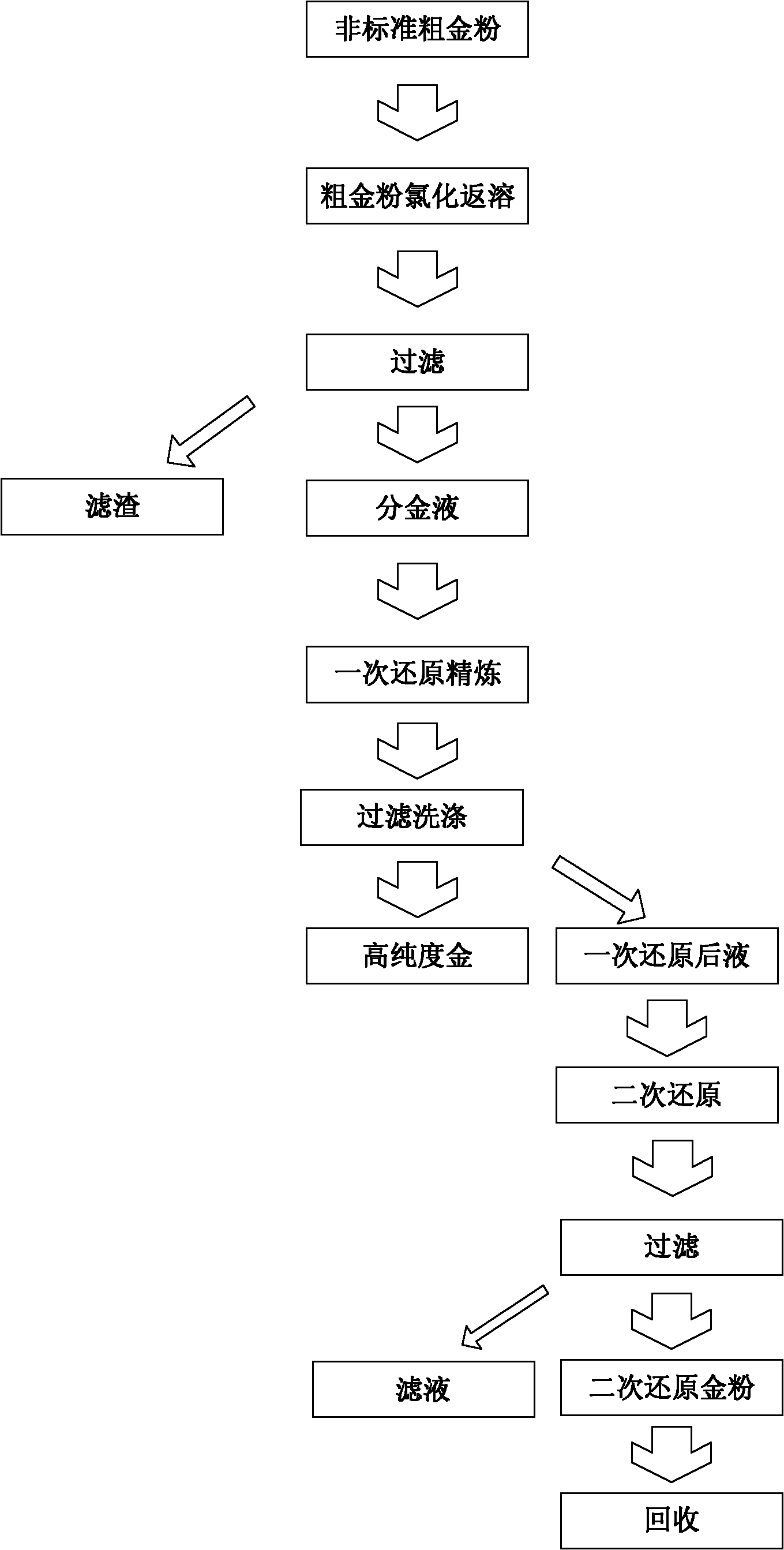

Method used

Image

Examples

Embodiment 1

[0021] A batch of non-standard coarse gold powder 80kg, its composition is as follows:

[0022] Composition (wt%)

Au

Ag

Cu

Fe

Pb

Bi

Sb

Si

PD

Mg

IC99995 standard

≥99995

≤0005

≤0002

≤0002

≤0001

≤0001

≤0001

≤0001

≤0001

≤0001

Non-standard coarse gold powder

95.319

3.975

0173

0.026

0.507

-

-

-

-

-

[0023] Refinement proceeds through the following steps:

[0024] (1) Coarse gold powder is chlorinated and redissolved; add 1600L of clear water to a 2000L reactor, put 80kg of coarse gold powder into it, add table salt, and make Cl in the clear water - The concentration is (26±2)g / L, then add H 2 SO 4 , so that H in clear water + The concentration is (2.0±0.1) M, the temperature is rapidly raised to 80°C, and the oxidant NaClO is added 3 , gradually control to the potential of 1000-1100mv, keep ...

Embodiment 2

[0028] Secondary reduction: heat the primary reduction solution obtained in Example 1 to 80°C, quickly add oxalic acid to make the potential reach 440-460mv, keep the potential at 440-460mv and react for 2-3 hours, filter, and the filter residue is It is the secondary reduction gold powder, and the secondary reduction gold powder is recovered, which can be used to remove impurities in the wet smelting of the raw material cyanide gold mud, and continue to be used to produce high-purity gold; the filtrate is put into the next kettle and replaced with iron powder to ensure that the waste liquid Only when the content of precious metals and miscellaneous elements in the medium reaches the standard can it be discharged.

[0029] Obtain 2.40kg of secondary reduction gold powder, the gold content is 51.875%, after two reductions, the total recovery rate of gold is 99.98%.

Embodiment 3

[0031] A batch of non-standard coarse gold powder 80kg, its composition is as follows:

[0032] Composition (wt%)

Au

Ag

Cu

Fe

Pb

Bi

Sb

Si

PD

Mg

IC99995 standard

≥99995

≤0005

≤0002

≤0002

≤0001

≤0001

≤0001

≤0001

≤0001

≤0001

Non-standard coarse gold powder

98.719

0.075

0.588

0.012

0.606

-

-

-

-

-

[0033] Refinement proceeds through the following steps:

[0034] (1) Coarse gold powder is chlorinated and redissolved; add 800L of clear water to a 2000L reactor, put 80kg of coarse gold powder into it, add table salt, and make Cl in the clear water - The concentration is (26±2)g / L, then add H 2 SO 4 , so that H in clear water + The concentration is (2.0 ± 0.1) M, the temperature is rapidly raised to 85 ° C, and the oxidant NaClO is added 3 , Gradually control to the potential of 1000-1100mv, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com