Patents

Literature

44 results about "Methyl Catechol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

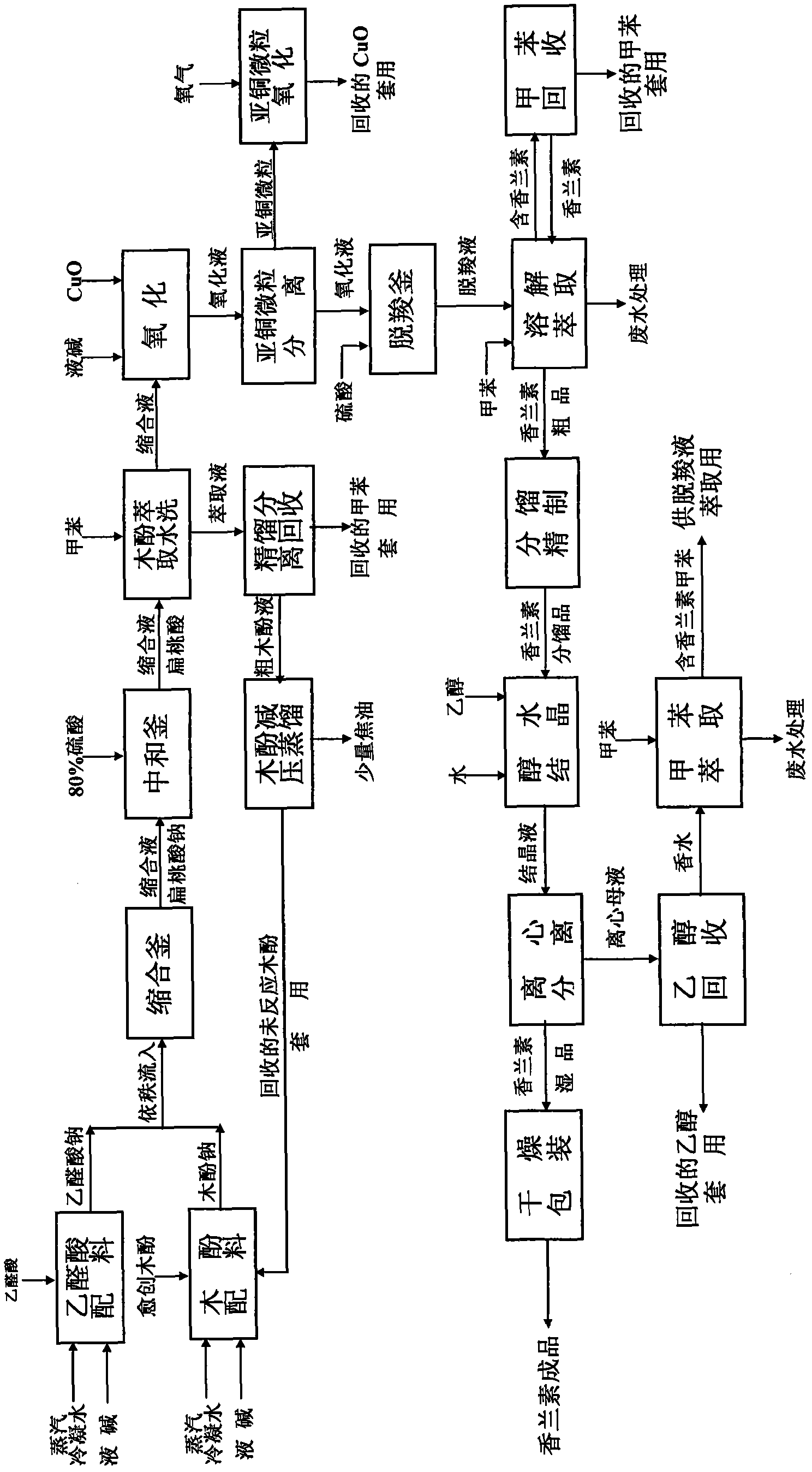

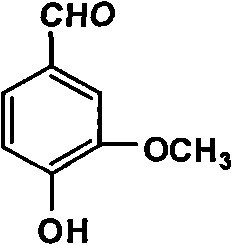

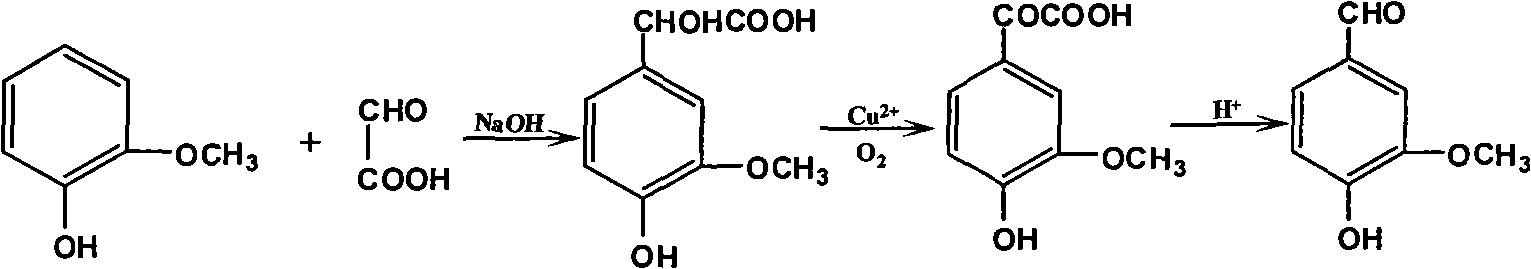

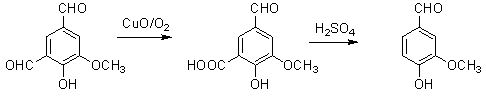

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

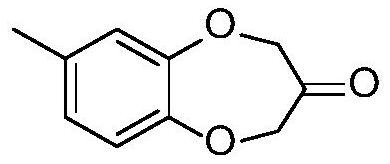

Synthesis of watermelon ketone

InactiveCN101429188AMild reaction conditionsEasy to operateOrganic chemistryThermal insulationFiltration

The invention discloses a method for synthesizing watermelon ketone. Under the protection of nitrogen, inorganic or organic base, PEG-400, potassium iodide, methanol, and 4-methyl pyrocatechol are added into a reactor and are heated to be between 65 and 70 DEG C, then 1,3-dichloroacetone is dripped into the mixture, and the mixture is subjected to reflux reaction under thermal insulation for 5 to 6 hours after the dripping is finished; a crude product is obtained through cooling and suction filtration, and the methanol is recovered; ethyl acetate is added into the crude product, a saturated saline solution is used to scrub to be neutral, and the ethyl acetate is recovered; and the reduced pressure distillation is performed, and a distillate is recrystallized by a mixed solvent of the methanol and n-hexane to obtain a white crystalline solid, namely the watermelon ketone, wherein the mass ratio of the 4-methyl pyrocatechol to the 1,3-dichloroacetone is 1 to 1, the mass ratio of the inorganic or organic base to the 4-methyl pyrocatechol is between 1 to 0.7 and 0.75, the mass ratio of the potassium iodide to the 4-methyl pyrocatechol is between 1 to 7.0 and 7.5, the mass ratio of the PEG-400 to the 4-methyl pyrocatechol is between 1 to 20 and 30, and the mass ratio of the methanol to the n-hexane in the mixed solvent is 1 to 2. The method adopts a one-pot method to synthesize a target product, and has the advantages of mild reaction conditions, convenient operation, and high product yield.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

Method for preparing and purifying watermelon ketone

The invention relates to a method for preparing and purifying watermelon ketone. According to the method, 4-methylcatechol and 1,3-dichloroacetone are used as raw materials to prepare a watermelon ketone rough product, and the watermelon ketoxime with the high purity is obtained by carrying out oximation, crystallization and purification on the watermelon ketone rough product; and then, the watermelon ketone with high purity is obtained by carrying out oxime removing on the watermelon ketone through oxidization or reduction or hydrolysis. The method disclosed by the invention has the advantages of good selectivity, high yield, wide raw material source, low price, and reasonable and feasible process design.

Owner:WUHAN UNIV OF TECH

Method for preparing o-vanillin

InactiveCN102644091AReduce pollutionRaw materials are easy to getElectrolysis componentsOrganic compound preparationChemical synthesisElectrolysis

The invention discloses a method for preparing o-vanillin and relates to a chemical synthesis method. The method comprises the following steps of: by utilizing the characteristics that a sulfonic acid group occupies a site and is removed by hydrolysis, firstly, sulfonating methyl catechol at the temperature of about 80 DEG C under the catalysis of concentrated sulfuric acid; then, performing a condensation reaction between the sulfonated methyl catechol and glyoxylic acid under the alkaling condition, and then, performing the hydrolysis at the temperature of about 110 DEG C to remove the sulfonic acid group; performing electrolytic oxidation, syneresis and filtration on a product, and then, extracting the product by using ethyl acetate when the product is hot; merging an upper extract layer; and drying, filtering and performing reduced pressure rotary distillation to obtain an o-vanillin product, and simultaneously recovering a low layer aqueous phase, and performing recrystallization to obtain a high-purity sodium sulfate crystal. The o-vanillin is derived from a byproduct generated by synthetizing vanillin at present, therefore, the yield is low, the demand is high, and the price is high. The technical problem that the o-vanillin is directly synthetized in China is solved by the method for preparing the o-vanillin, and meanwhile, lower layer extract liquor is recovered to obtain byproduct sodium sulfate with a high additional value. The method for preparing the o-vanillin is higher in economic benefit and social benefit.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

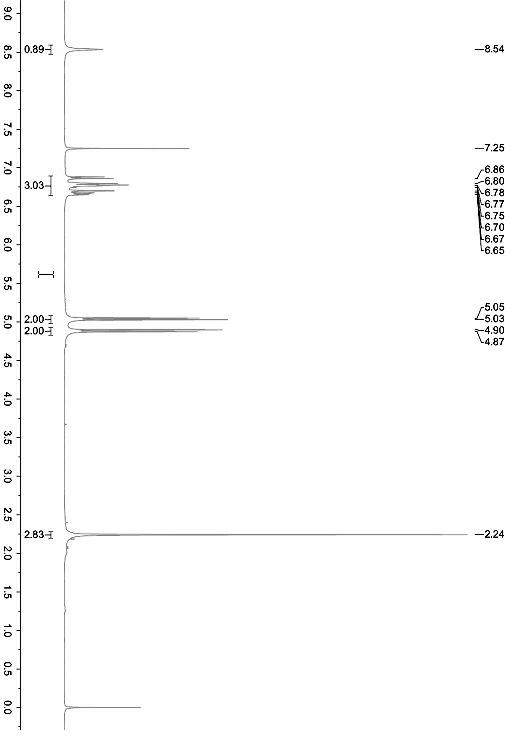

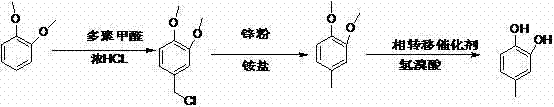

Preparation method of 4-methylcatechol

InactiveCN103570507AHigh yieldReduce manufacturing costOrganic chemistryOrganic compound preparationParaformaldehydeDemethylation

The invention discloses a preparation method of 4-methylcatechol. The method comprises the following steps: (a) adding dimethoxybenzene and paraformaldehyde to an organic solvent, dropwise adding concentrated hydrochloric acid at minus 5 to 10 DEG C, so as to obtain 4-chloromethyl dimethoxybenzene; (b) firstly, adding the 4-chloromethyl dimethoxybenzene to an alcohol solvent, adding zinc powder and ammonium salt, heating and refluxing to generate the 4-chloromethyl dimethoxybenzene in a reduction manner; (c) mixing the 4-chloromethyl dimethoxybenzene, a hydrogen bromide aqueous solution and / or added cosolvent, warming and refluxing to obtain 4-methylcatechol. By adopting the method, the dimethoxybenzene is taken as a raw material; 4-methylcatechol is synthetized by three steps of chloromethylation, reduction and demethylation. The method has the characteristics of being high in yield, simple in steps, available in raw materials, mild in reaction condition, fewer in three wastes, low in production cost, simple in post-treatment and the like, and has good industrial application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

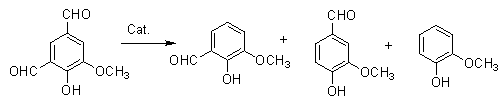

Comprehensive utilization method of byproduct 5-aldehyde vanillin in vanillin production process

InactiveCN103319320AFew synthetic stepsRaise the ratioOrganic compound preparationCarbonyl compound preparationPtru catalystBiochemical engineering

The invention discloses a comprehensive utilization method of a byproduct 5-aldehyde vanillin in a vanillin production process. The comprehensive utilization method comprises the following steps of: taking the byproduct 5-aldehyde vanillin produced in the vanillin production process as a material, carrying out high-temperature aldehyde removal under existence of dealdehyding catalysts such as Pt / C or Pd / C and the like after proper purification to generate a mixture of ortho vanillin, vanillin and methyl catechol; and respectively obtaining the ortho vanillin, the vanillin and the methyl catechol by rectification. By adopting the comprehensive utilization method of the byproduct 5-aldehyde vanillin in the vanillin production process disclosed by the invention, not only are the three wastes reduced, but also the comprehensive utilization method has good economic benefits by transforming the 5-aldehyde vanillin into the ortho vanillin, the vanillin and the methyl catechol.

Owner:SHANGHAI INST OF TECH

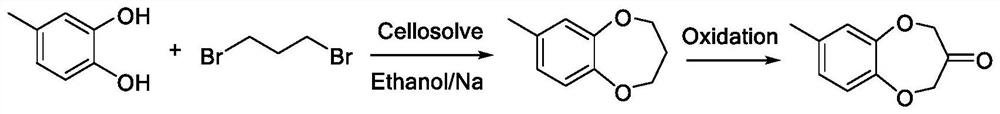

Preparation method of watermelon ketone

The invention relates to a preparation method of watermelon ketone, which comprises the following steps: by taking 4-methylcatechol and 1,3-dichloroacetone as raw materials and carbonate as a base catalyst, adding a drying agent into a Soxhlet extractor for dehydration, and under the protection of inert gas, assembling a reduced pressure reflux water removal device to prepare a watermelon ketone crude product; carrying out rotary evaporation to recover a solvent, carrying out post-treatment steps of decoloration, concentration and the like, and transferring an obtained solution into a rectification device provided with a glass vacuum rectification column to carry out segmented rectification: in first-stage rectification, evaporating off reaction solvent light components, in second-stage rectification, collecting fractions to obtain a residual raw material 4-methylcatechol and a part of crude product watermelon ketone, and in third-stage rectification, collecting a main fraction watermelon ketone crude product; and recrystallizing the watermelon ketone crude product. According to the preparation method of the watermelon ketone, the yield of the watermelon ketone is improved through the reduced pressure reflux water removal device, the watermelon ketone is purified step by step by combining segmented rectification and recrystallization, the purity of the product reaches 98% or above, the technological process is simplified, and the problem that industrial large-scale production is difficult to achieve through an existing watermelon ketone synthesis technology is solved.

Owner:CENT SOUTH UNIV

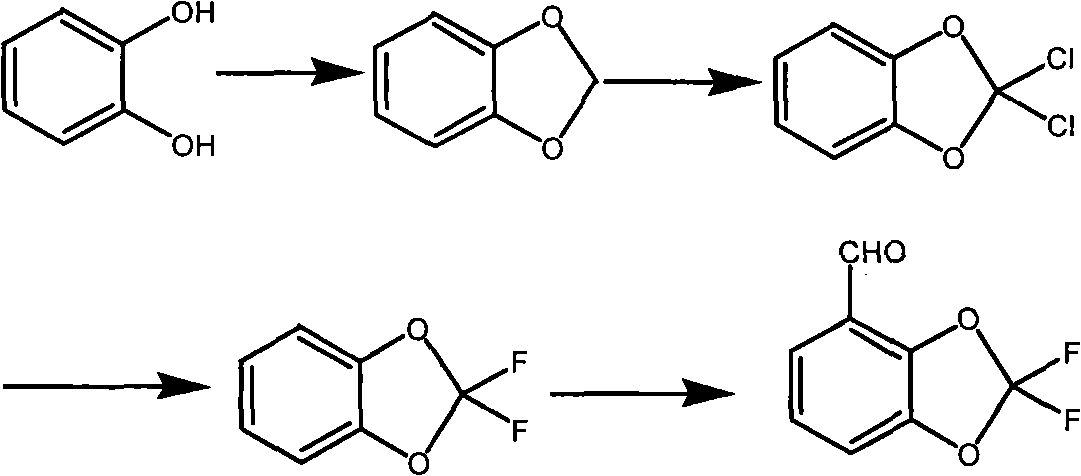

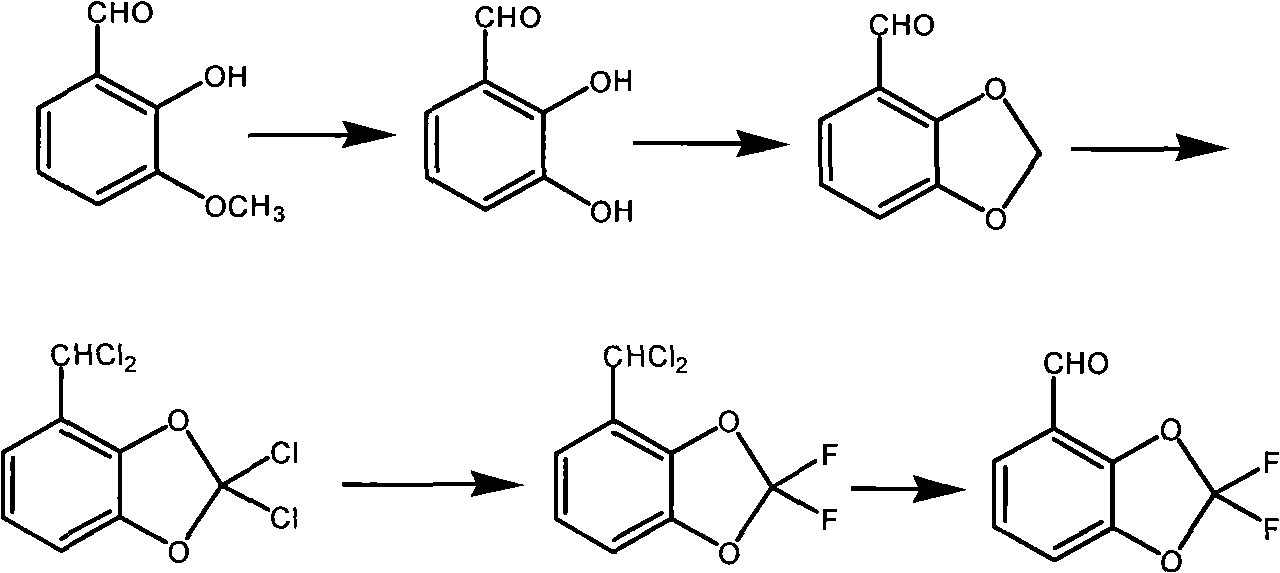

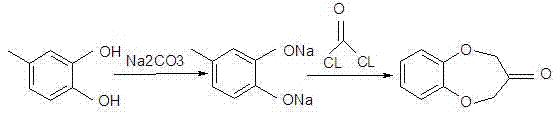

Method for synthesizing fludioxonil intermediate 4-aldehyde-2,2-difluorobenzodioxole

ActiveCN101851225AReduce usageReduce the risk of contaminationOrganic chemistryHydrolysisMethyl group

The invention discloses a method for synthesizing fludioxonil intermediate 4-aldehyde-2,2-difluorobenzodioxole. The method comprises the following steps of: performing o-orientating formylation on o-cresol serving as an initiative raw material to obtain 3-methylsalicylaldehyde, converting the 3-methylsalicylaldehyde into 3-mehtylpyrocatechol through Dakin reaction, directly reacting the 3-mehtylpyrocatechol with dichloromethane or dibromomethane to generate 4-methylbenzodioxole without separation and purification, and performing three-step reaction of chlorination, fluoro and oxidation on the 4-methylbenzodioxole to generate a product. The cheap o-cresol is used as the initiative raw material, and the obtained 3-mehtylpyrocatechol directly enters the next reaction without separation, so the production cost is greatly reduced; phosphorus pentachloride is used as a chlorination reagent in the chlorination link so as to avoid the use of chlorine and reduce the risk of causing environmental pollution; and the methyl is converted into aldehyde group through the oxidation reaction so as to avoid a route of chlorination hydrolysis, simplify the operation, reduce the environment-friendly pressure and gain higher economic value and social meaning.

Owner:SHANDONG BOYUAN PHARM CO LTD

Recovering and recycling method of excessive methyl catechol in vanillin production process

InactiveCN103319318AReduce recycling costsHigh purityEther separation/purificationOrganic compound preparationGlyoxylic acidSodium Phenolate

The invention discloses a recovering and recycling method of excessive methyl catechol in a vanillin production process. The method comprises the following steps of: carrying out condensation reaction on the methyl catechol and glyoxylic acid under an alkaline condition after the methyl catechol is prepared into a methyl catechol sodium phenolate solution in the vanillin production process; adjusting the pH to 3-5 after the condensation reaction is finished; then extracting and separating by using a non-polar organic solvent to obtain methyl catechol extract liquor; carrying out reverse extraction on the obtained methyl catechol extract liquor by using proper concentration of an aqueous solution of sodium hydroxide, so that the methyl catechol in the methyl catechol extract liquor is transformed into methyl catechol sodium phenolate and transferred into a water phase, so as to obtain a water solution of the methyl catechol sodium phenolate; and adding the methyl catechol to the obtained water solution of the methyl catechol sodium phenolate to prepare the methyl catechol sodium phenolate solution with the concentration which is required for carrying out condensation reaction with the glyoxylic acid, so as to achieve recycling. By adopting the method, separation and purification of the methyl catechol can be simultaneously achieved; and the method is simple to operate, less in steam consumption, and energy-saving. Therefore, the production cost of the vanillin is reduced.

Owner:SHANGHAI INST OF TECH

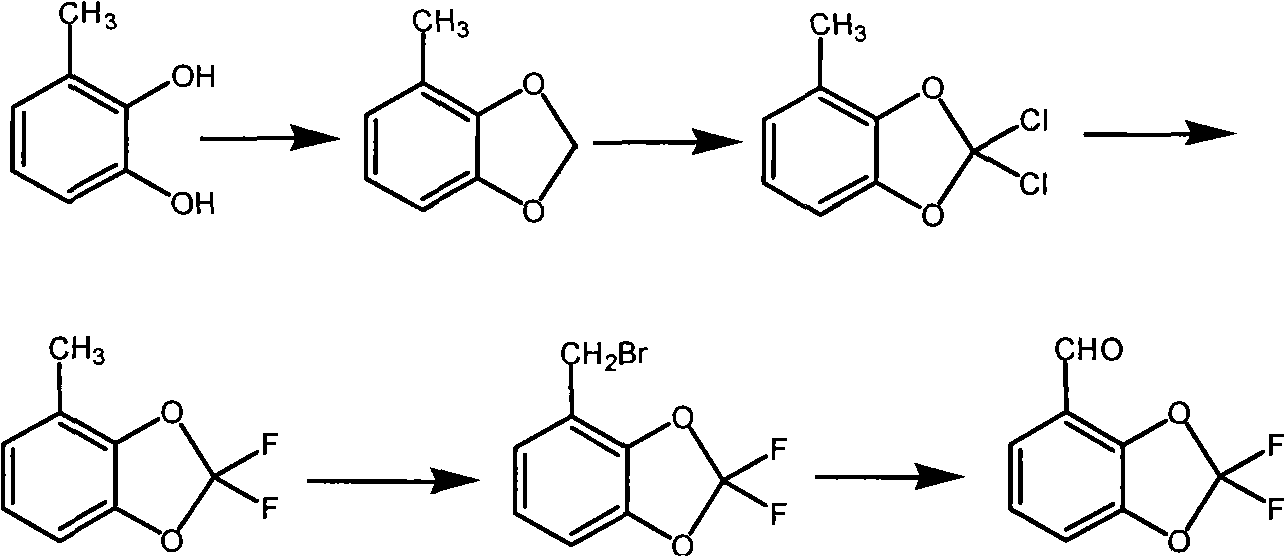

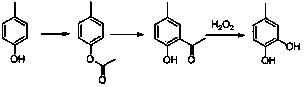

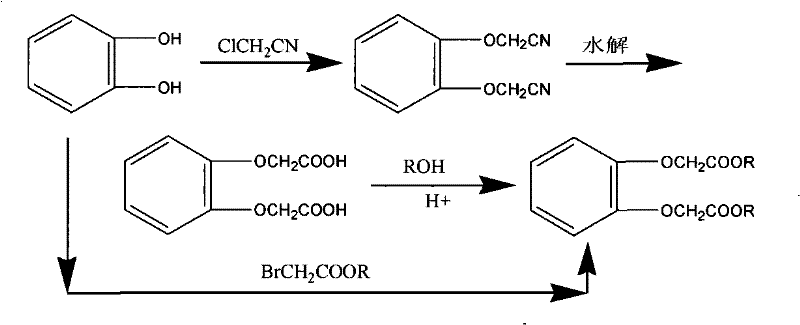

Chemical synthetic method for para-methyl catechol diacetoxyl dimethyl ester

InactiveCN101544564ARaw materials are easy to getMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationChemical synthesisAcetophenone

The invention relates to a synthetic method for para-methyl catechol diacetoxyl dimethyl ester. The method uses paracresol as an initial raw material to synthesize the para-methyl catechol diacetoxyl dimethyl ester into a target compound through acetylation reaction catalyzed by acid, Fries rearrangement reaction of phenolic ester, Dakin oxidation reaction of 2-hydroxy-5-methyl acetophenone and direct etherification reaction of para-methyl catechol. The total yield of the whole reaction is more than 70 percent, and the purity of the product is more than 98 percent. The method of the invention has the characteristics of easily-obtained raw materials, mild reaction condition, low equipment requirement, simple operation, low production cost, little side reaction, simple post treatment, and the like. Therefore, the synthetic method of the invention is a method suitable for industrialized production.

Owner:杭州浙大泛科化工有限公司

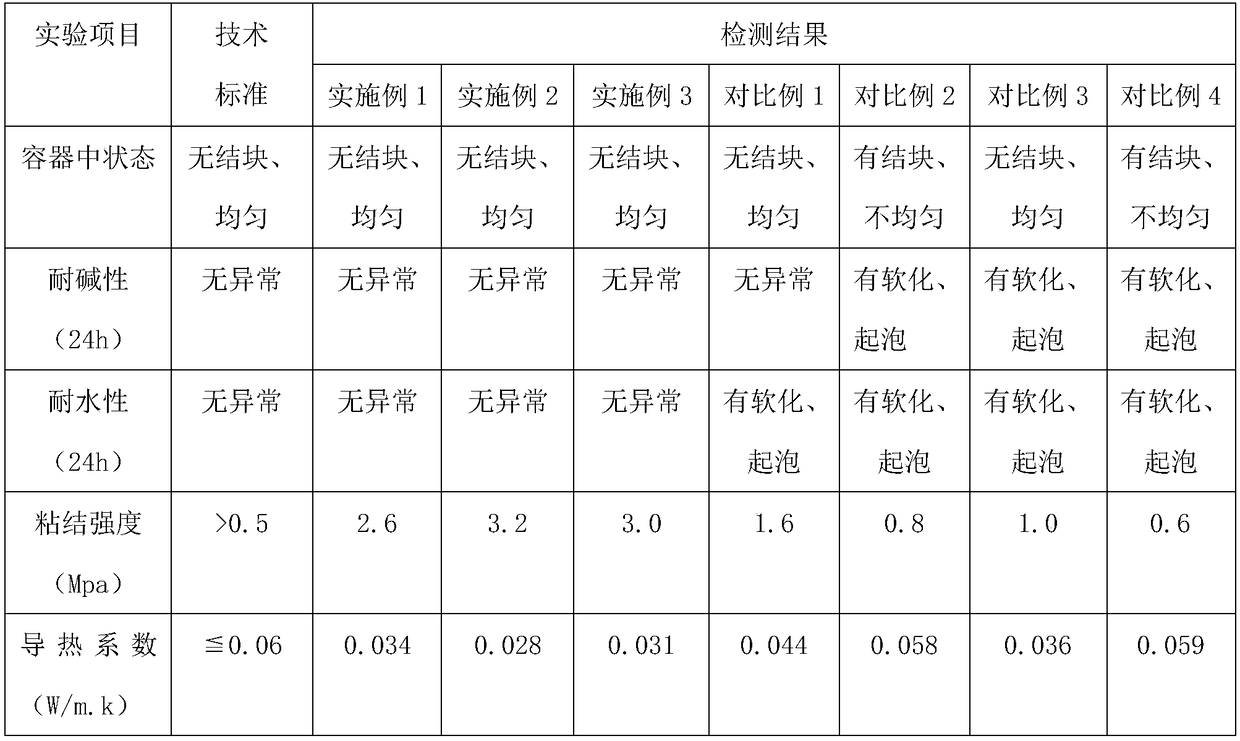

Interior wall thermal insulation putty and preparation method

InactiveCN108410245AHas a dispelling effectUnique three-dimensional space chain structureFilling pastesCelluloseAluminum magnesium silicate

The invention discloses interior wall thermal insulation putty and a preparation method. The interior wall thermal insulation putty is prepared from, by mass, 20-30% of light calcium carbonate powder,15-20% of floating beads, 10-15% of titanium dioxide, 25-30% of shell powder, 3-5% of nano thermal insulation powder, 0.2-0.3% of lignocelluloses, 0.3-0.5% of alum powder, 1-2% of bentonite, 2-4% ofpolyvinyl alcohol 2488, 1-2% of N-methyl trimethylacetamide, 1-2% of 4-methyl catechol, 0.2-0.3% of carboxymethyl cellulose, 3-5% of redispersible latex powder, 0.2-0.3% of pre-gelatinized starch and1-2% of thixotropic agent aluminum-magnesium silicate. By adoption of the raw materials and the adding sequence, the putty gives full play to advantages of the floating beads, and water resistance, alkali resistance, base material bonding strength and thermal insulation performance of the putty are remarkably improved.

Owner:常德市万福达环保节能建材有限公司

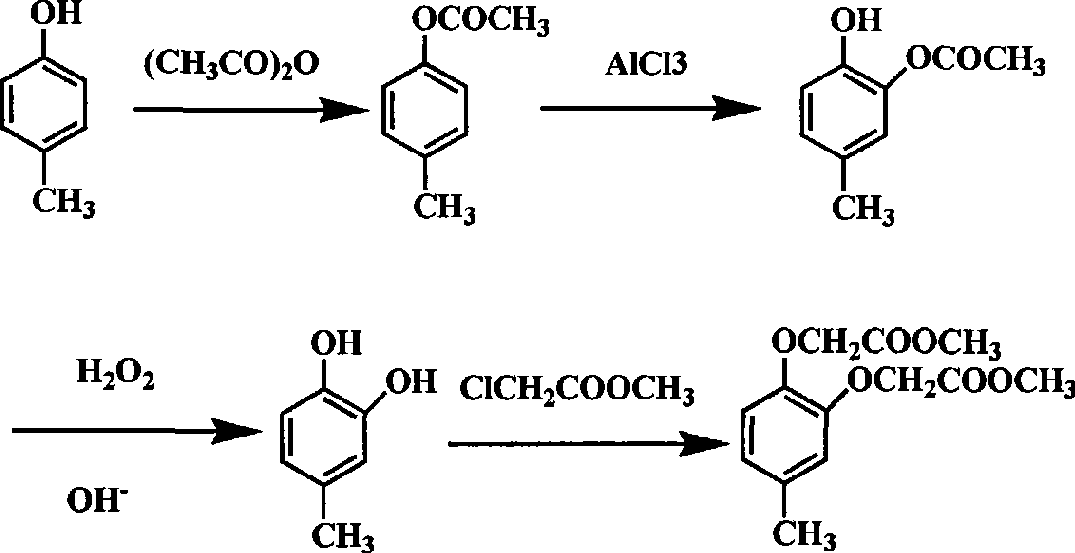

Method for preparing 4-methyl catechol

InactiveCN104030893AReduce pollutionSolving Operational Security IssuesPreparation from carboxylic acid halidesOrganic compound preparationCresolBoiling point

The invention discloses a method for synthesizing 4-methyl catechol. The method comprises the steps of carrying out acylation reaction on p-cresol as a starting materia to obtain p-cresyl acetate, carrying out Fries rearrangement reaction in a high-boiling-point inert solvent to obtained 2-hydroxy-5-methyl acetophenone, alkalifying, forming a salt, oxidizing at a low temperature, after the reaction is completed, reducing the reaction solution, acidifying, extracting and concentrating to obtain a crude product and distilling the crude product to obtain the pure 4-methyl catechol. The method disclosed by the invention is environmental friendly, available in raw materials, mild reaction conditions, low requirements on equipment, simple operation, low production cost, less side effects and high yield and is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Method for preparing and purifying watermelon ketone

Owner:WUHAN UNIV OF TECH

Inner wall emulsion paint

The invention discloses an inner wall emulsion paint, which comprises the following raw materials in part by mass: 1 to 4 parts of sodium persulfate, 2 to 4 parts of potassium citrate, 3 to 6 parts of 10-bromine diphenylethane, 4 to 9 parts of tetraethyl ammonium hydroxide methanol solution, 1 to 3 parts of trimethylamine hydrochloride, 2 to 3 parts of calcium fluoride, 2 to 5 parts of 3-methyl-2-butene aldehyde, 1 to 2 parts of zinc 3-fluoride acetyl acetone and 1 to 4 parts of 4-methyl catechol. The inner wall emulsion paint is non-toxic, tasteless, and convenient for construction, and has powerful covering capacity, good washing fastness, good alkali resistance, strong adhesive force and high antifungal and antibacterial performance, and is suitable for various conditions.

Owner:桑达化工(南通)有限公司

Extracting agent for nuclear waste liquid and preparation method for extracting agent

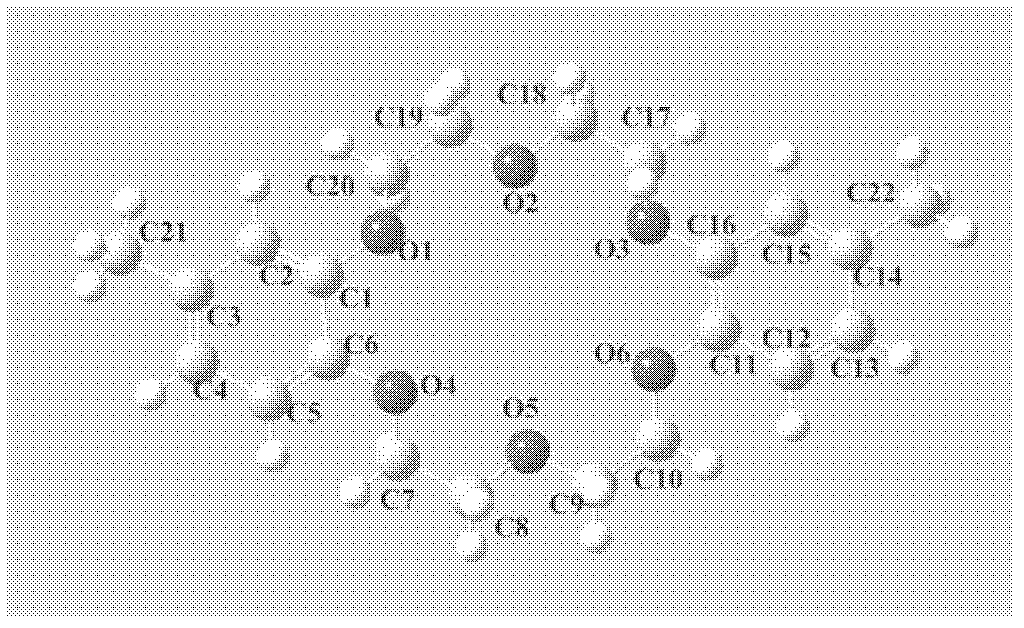

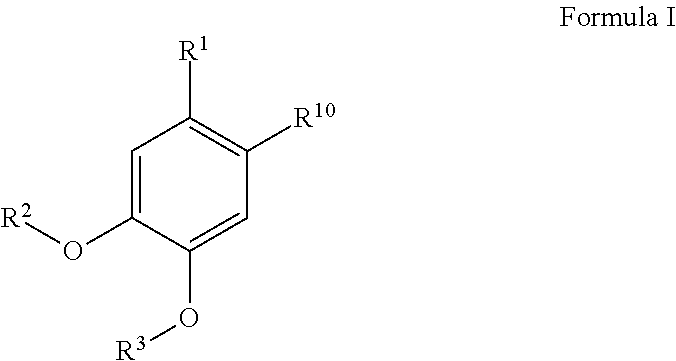

InactiveCN102424677AImprove lipophilicityImprove solubilityOrganic chemistryMethyl groupMethyl Catechol

The invention discloses an extracting agent for nuclear waste liquid. The extracting agent is a compound of 4',4''(5'')-dimethyldibenzo-18-crown-6; one methyl in dimethyl is positioned at a 4' position of a benzene ring on one side; and the other methyl is positioned at a 4'' or 5'' position of a benzene ring on the opposite side. The compound has a function of extracting 137Cs+ ions from the nuclear waste liquid. A raw material, namely para-methyl pyrocatechol, for preparing the 4',4''(5'')-dimethyldibenzo-18-crown-6 is difficultly oxidized, byproducts generated in the reaction process of the 4',4''(5'')-dimethyldibenzo-18-crown-6 are reduced, a separation flow is simplified, and the yield is improved.

Owner:XI AN JIAOTONG UNIV

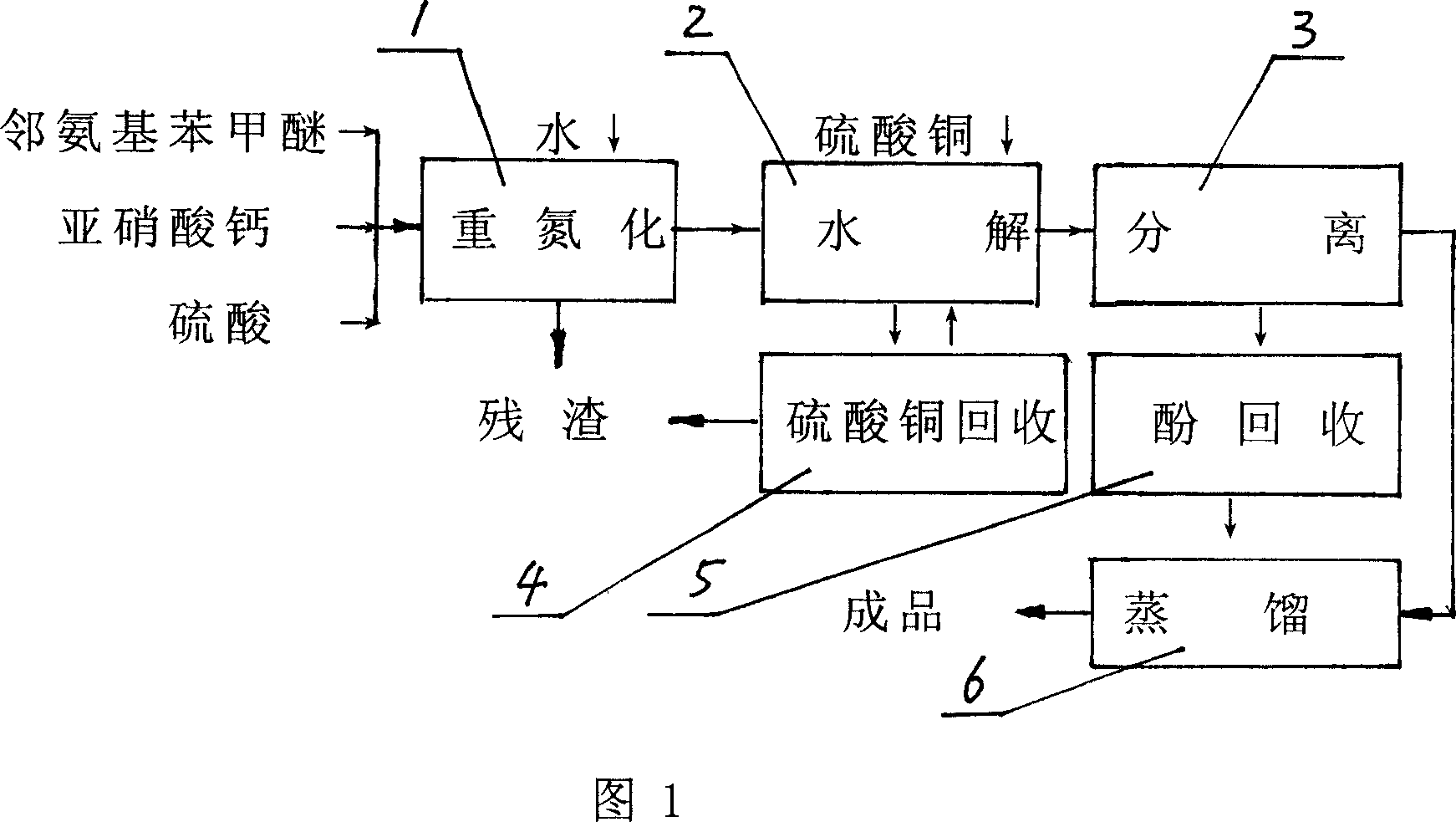

Method of preparing methyl catechol using calcium nitrite as raw material

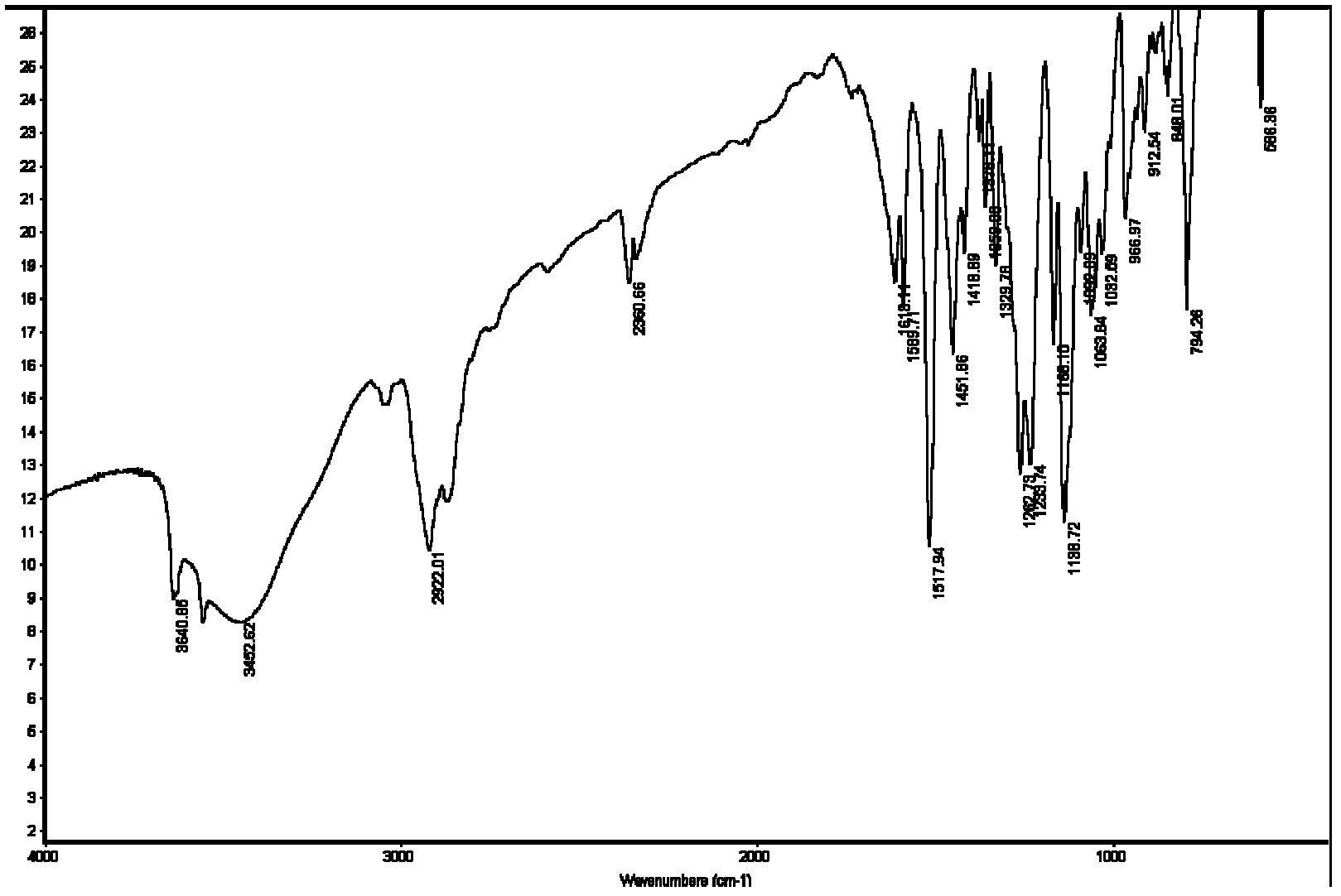

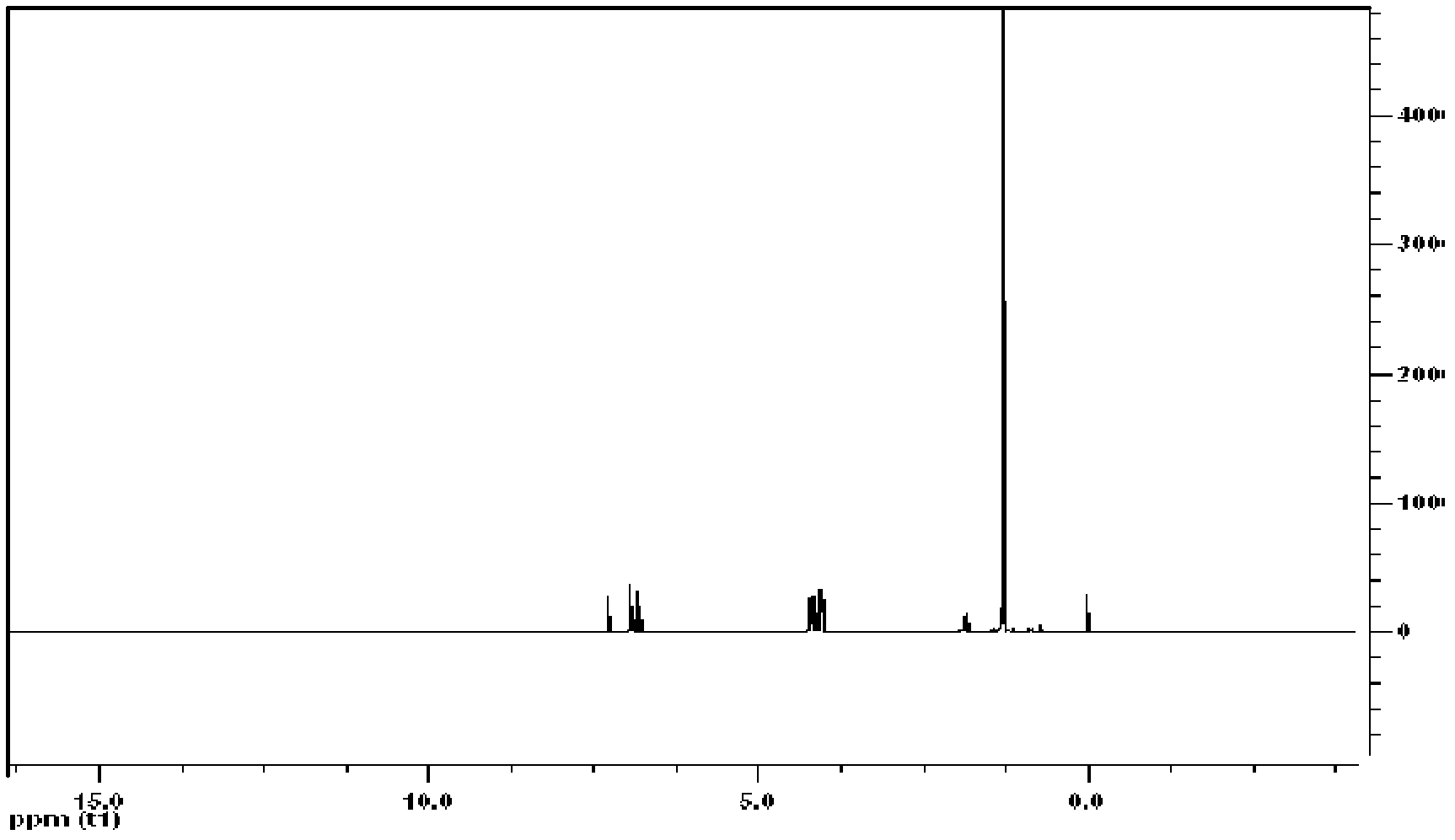

InactiveCN1948252AHigh yieldImprove hydrolysis conditionsOrganic chemistryOrganic compound preparationDistillationGuaiacol

The present invention relates to a method for preparing guaiacol by using calcium nitrite as raw material. Said method is characterized by that it includes the following steps: in a diazotization still adding o-aminoanisole into dilute sulfuric acid to make neutralization to obtain methyl ether sulfate, then drop-adding calcium nitrite solution to make diazotization reaction, separating out solid residue, feeding the diazotization solution into hydrolysis procedure to make hydrolysis reaction so as to obtain crude guaiacol, then feeding the obtained crude guaiacol into separation procedure; making the waste liquor be fed into copper sulfate recovery procedure and making the phenol water containing crude guaiacol be fed into phenol recovery procedure, making the phenol water be continuously adsorbed in adsorption tower with macroporous adsorbing resin, using sodium hydroxide solution to make elution, using sulfuric acid to acidify eluent to separate out crude guaiacol; mixing above-mentioned two crude guaiacols in a distillation still, making reduced pressure distillation to remove water content and impurity from crude guaiacol so as to obtain the invented guaiacol finished product.

Owner:刘仁杰

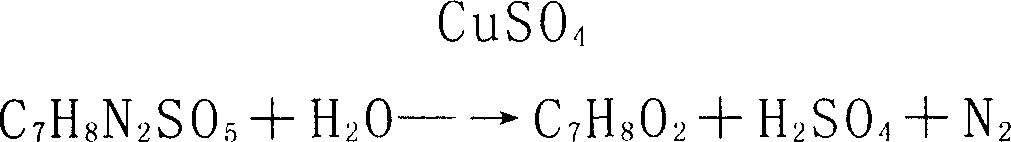

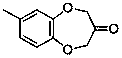

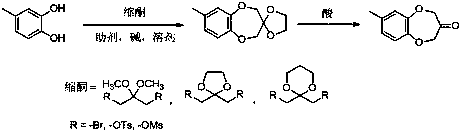

Watermelon ketone preparation method

InactiveCN108164499AAvoid interferenceAvoid it happening againOrganic chemistrySodium bicarbonateKetone

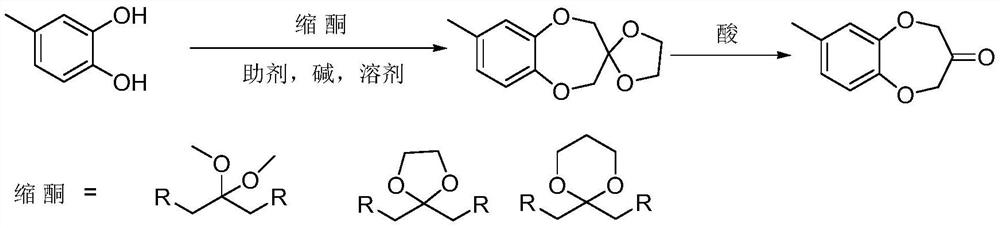

The invention discloses a watermelon ketone preparation method which comprises the following steps: (1) under an alkali condition and in the presence of aids, heating 4-methyl-orthodioxybenzene and alcohol-protected ketalized 1,3-bisubstited acetone to 30-120 DEG C in a solvent, and performing a Williamson ether synthesis reaction so as to generate a corresponding ketal intermittent, wherein reaction materials are fed in the following sequence: firstly, adding the solvent, an alkali and aids, uniformly stirring, heating to a set temperature, slowly dropping 4-methyl-orthodioxybenzene and alcohol-protected ketalized 1,3-bisubstited acetone, and performing a reaction for 2-12 hours after dropping is competed; (2) performing a backflow reaction on the ketal intermittent obtained in the step (1) for a certain time under an acid condition, pouring into water to implement hydrolysis, extracting with ethyl ether, washing an organic phase with a sodium bicarbonate solution, drying sodium sulfate, evaporating off the solvent, and performing recrystallization, thereby obtaining watermelon ketone. The method disclosed by the invention is easy to control, simple to operate, good in environmentprotection, relatively high in yield and beneficial to industrialization.

Owner:王成宇

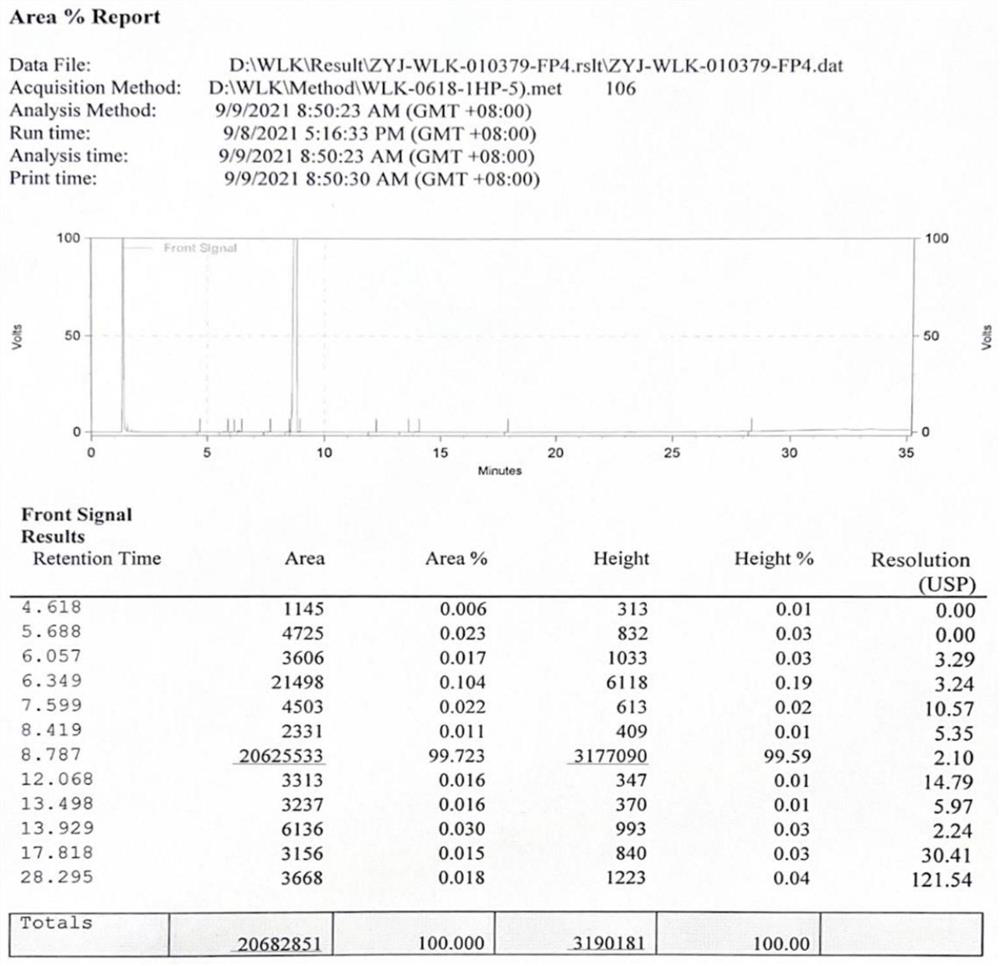

Preparation method and purification method of watermelon ketone crude product suitable for industrial production

ActiveCN114292256AThe reaction route is simpleImprove responseOrganic chemistryChemical industryBiotechnologyDistillation

The invention discloses a preparation method of a crude watermelon ketone product suitable for industrial production, and the crude watermelon ketone product is produced by reacting a 2-butanone solution of 4-methylcatechol with 1, 3-dichloroacetone. The reaction route is simple, and the conversion rate is improved. The invention also provides a purification method of the watermelon ketone crude product suitable for industrial production. The purification method comprises the following steps: (1) removing tar in the watermelon ketone crude product; (2) distilling the decoked crude product for primary purification; and (3) recrystallizing the distilled watermelon ketone crude product to obtain a solid watermelon ketone pure product. The method has the advantages of high purity and few impurities. And tar is removed from the crude watermelon ketone product, so that tar accumulation in the distillation process can be prevented from damaging the product and influencing crystallization of the product. The distillation yield is greatly improved. And a high-yield and high-purity pure watermelon ketone product can be obtained through recrystallization treatment.

Owner:江苏恒沛药物科技有限公司

Microbial composition

A synergistic microbicidal composition containing a phenolic compound selected from the class consisting of chlorinated phenols, monosubstituted phenols, fused bicyclic phenols, isopropyl methyl catechols, and monosubstituted catechols and an antimicrobial alcohol selected from the class of menthadiene alcohols and other antimicrobial alcohols.

Owner:DOW GLOBAL TECH LLC

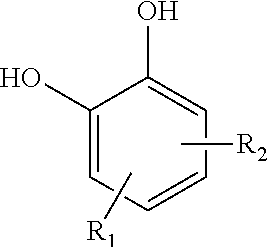

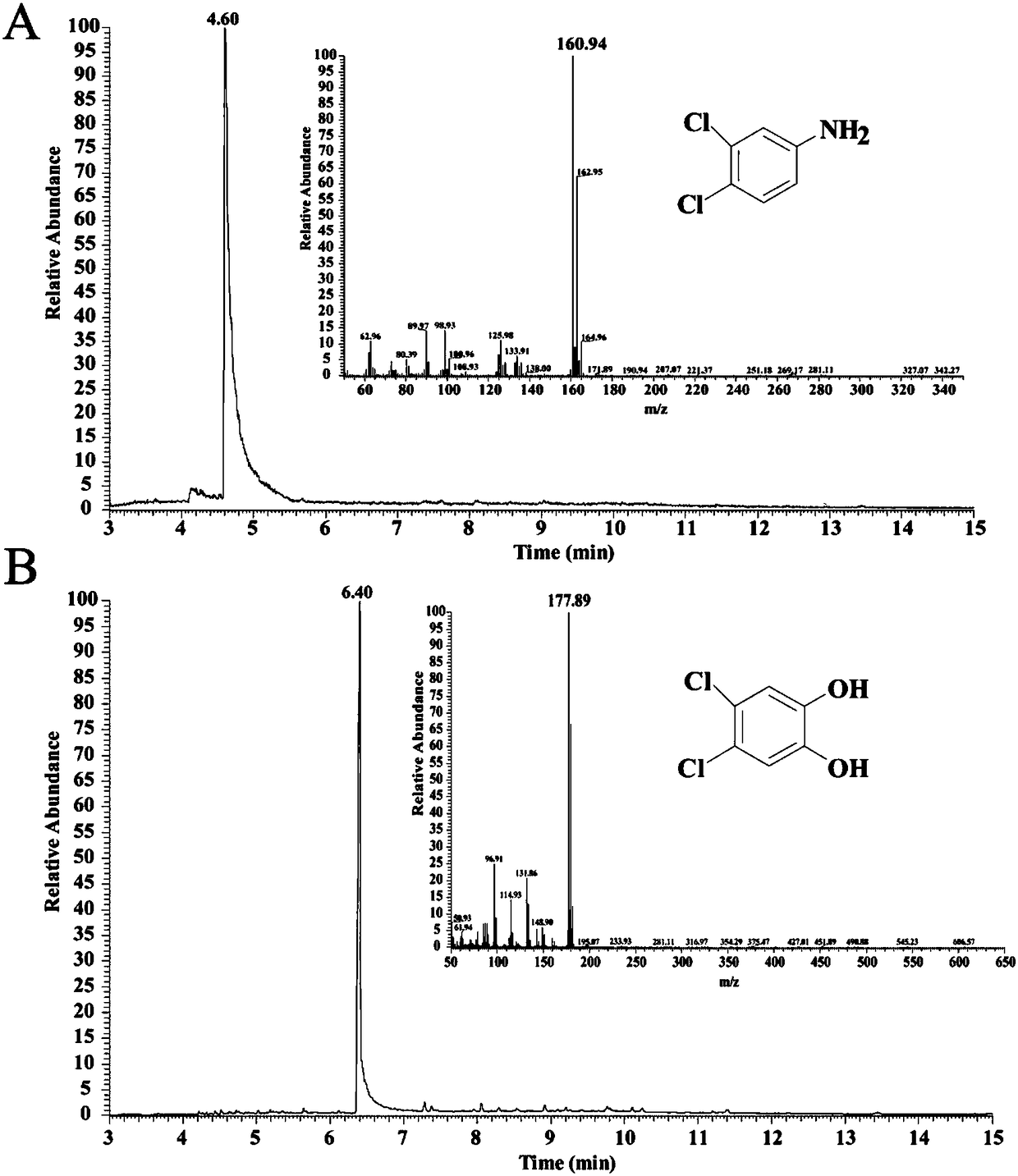

Method for preparing catechol compounds by biotransformation

InactiveCN108486141AWide applicabilityNo environmental burdenFermentationVector-based foreign material introductionEscherichia coliTert-butylcatechol

The invention belongs to the field of biological high technology, and discloses a method for preparing catechol compounds by biotransformation. The method comprises the steps that two kinds of anilineoxidase ATD and ADO are efficiently synthesized by escherichia coli; under normal circumstances, escherichia coli cells containing the ATD and ADO can efficiently convert aniline compounds to producea plurality of catechol compounds which include catechol, 3-methylcatechol, 4-methylcatechol, 3-chlorocatechol, 4-chlorocatechol, 4,5-dichlorocatechol, p-tert-butylcatechol and isopropyl catechol, and the conversion rate is greater than 95%. The waste produced in the scheme is mainly bacterial cells, the bacterial cells can be killed by high temperature, and the environmental burden is almost notproduced.

Owner:南京乐夫朗生物科技有限公司

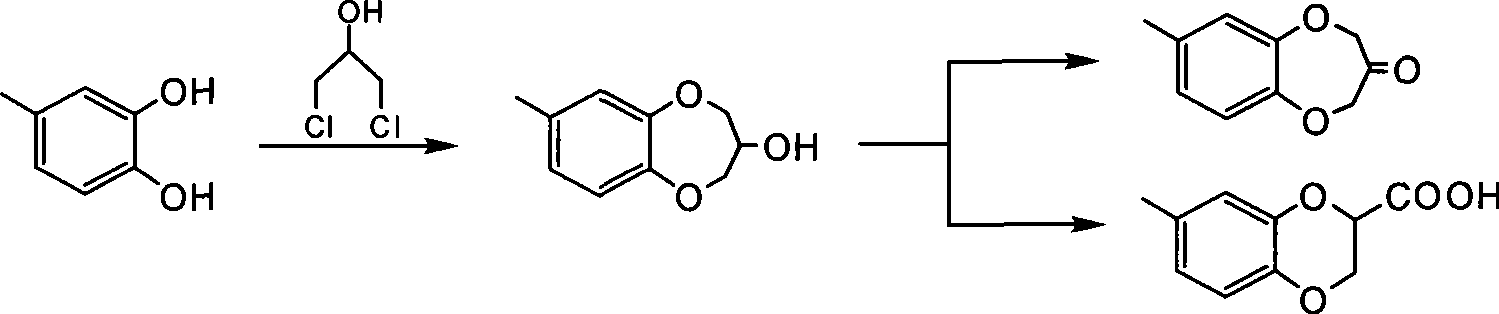

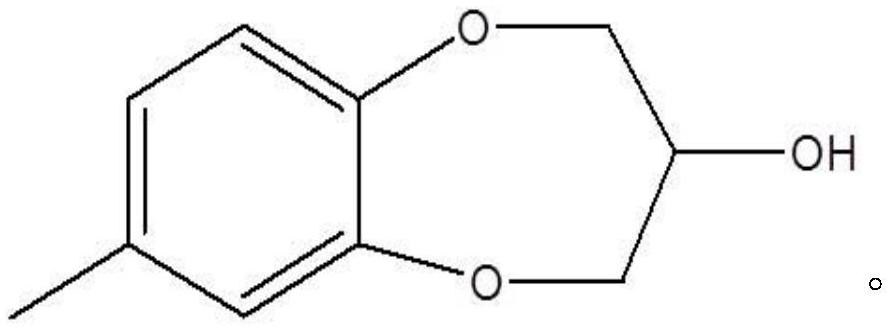

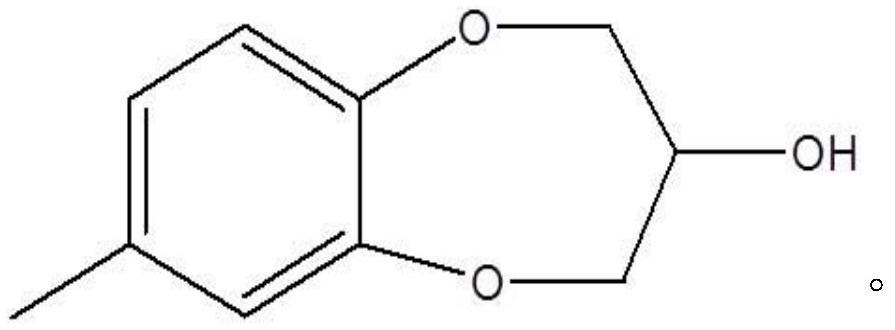

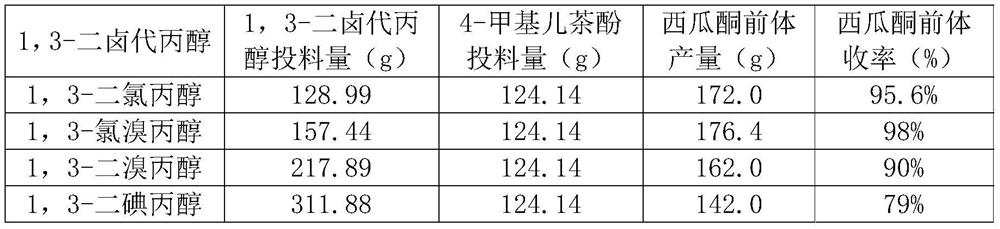

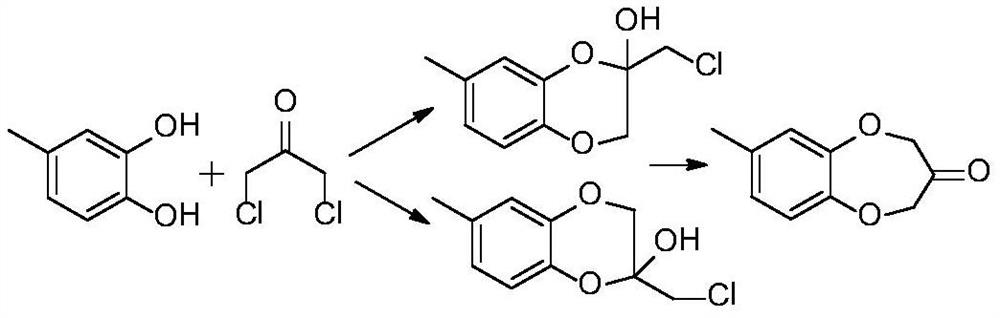

Synthesis process of watermelon ketone precursor

The invention provides a synthesis process of a watermelon ketone precursor. According to the invention, cheap 1,3-dihalopropanol and 4-methyl catechol are subjected to a condensation reaction under an alkaline condition to synthesize a watermelon ketone precursor 3,4-dihydro-7-methyl-2H-1,5-benzoxazole-3-ol. According to the method, the use of highly toxic 1,3-dichloroacetone is avoided, the yield of the watermelon ketone precursor is greatly increased, the production cost of the watermelon ketone spice is reduced, and the quality of watermelon ketone is improved; and the synthesis process issimple to operate and environment-friendly.

Owner:江西开源香料有限公司

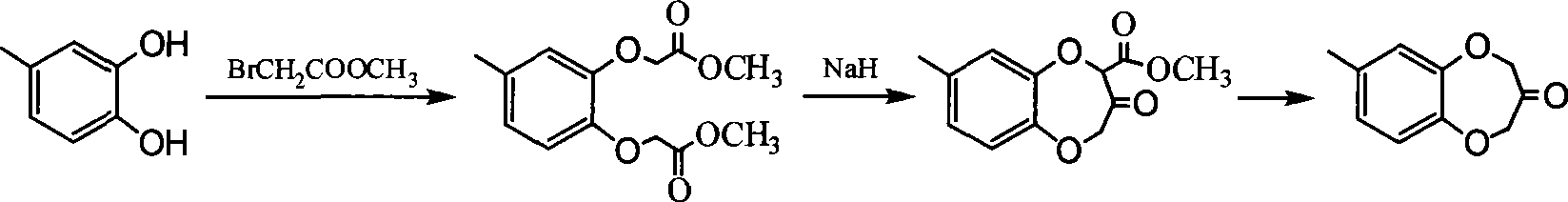

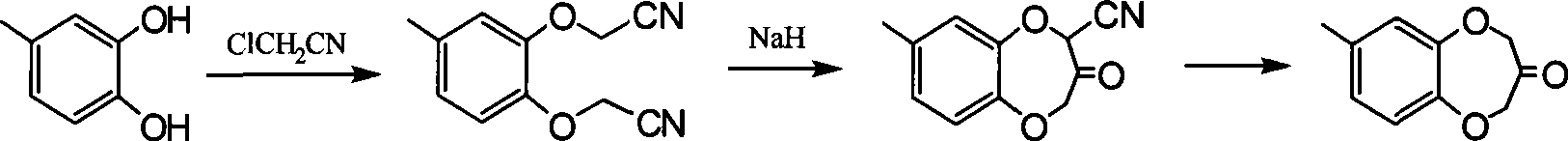

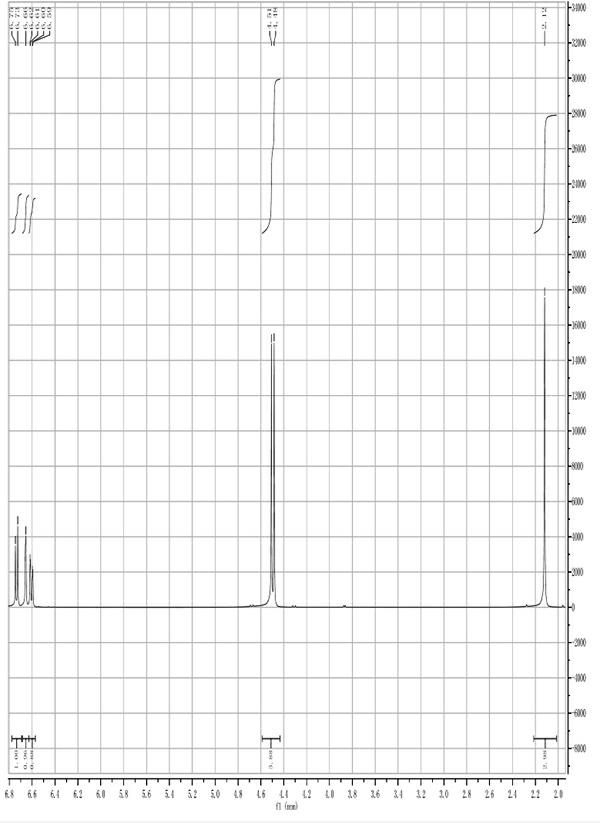

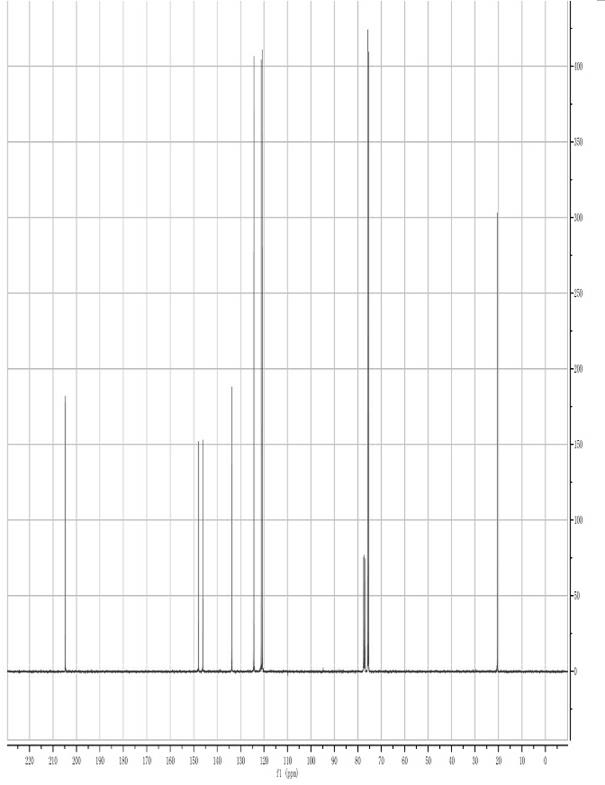

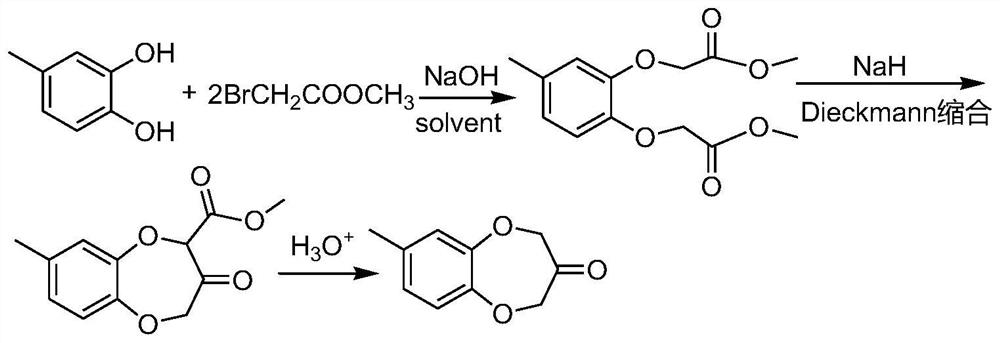

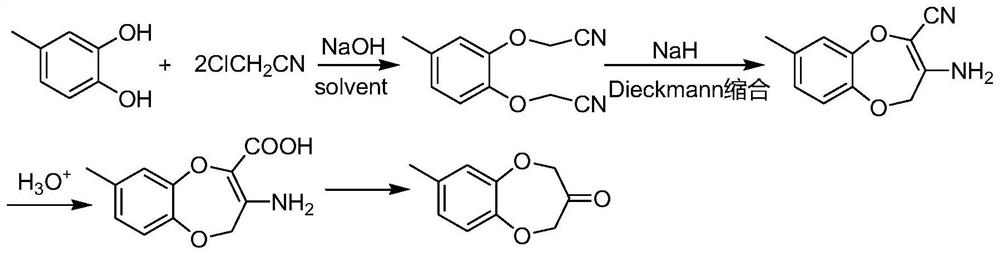

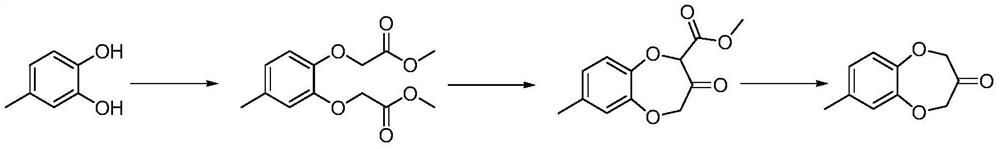

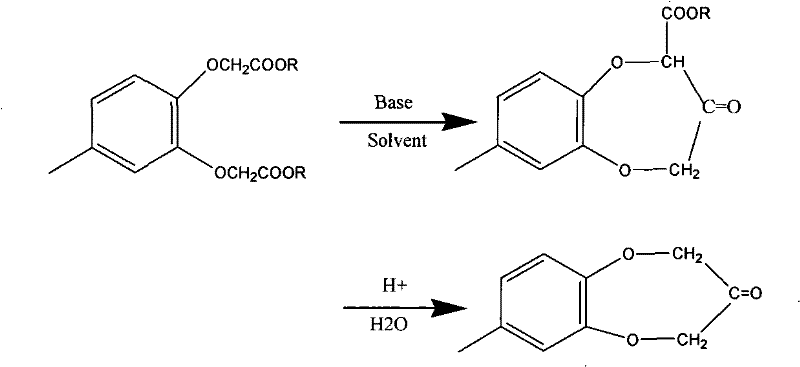

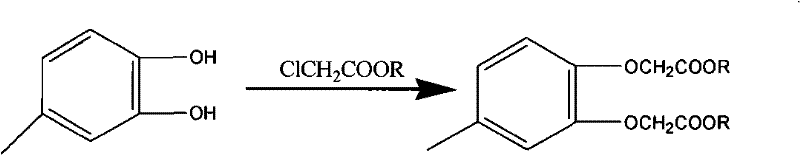

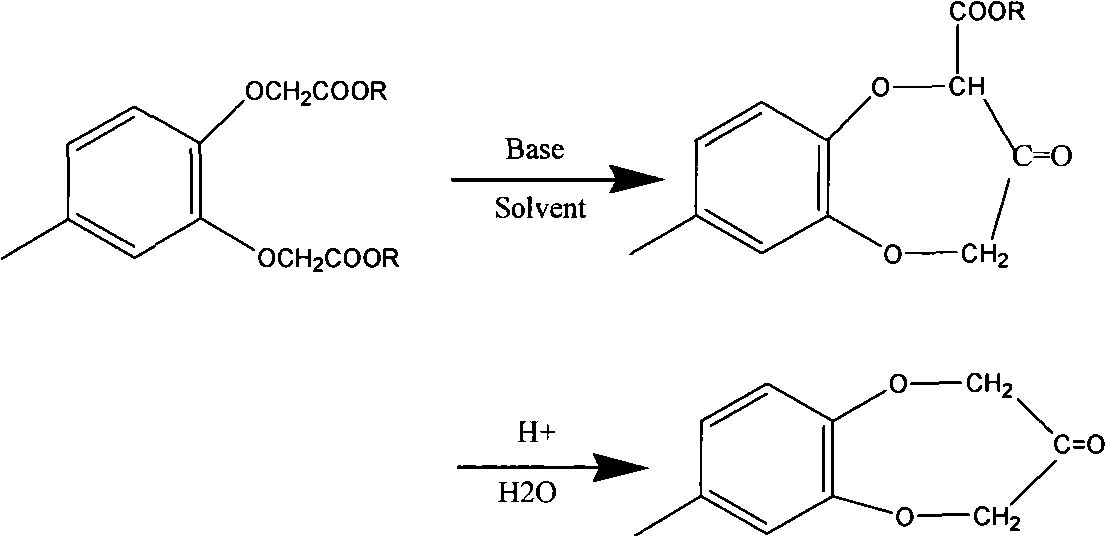

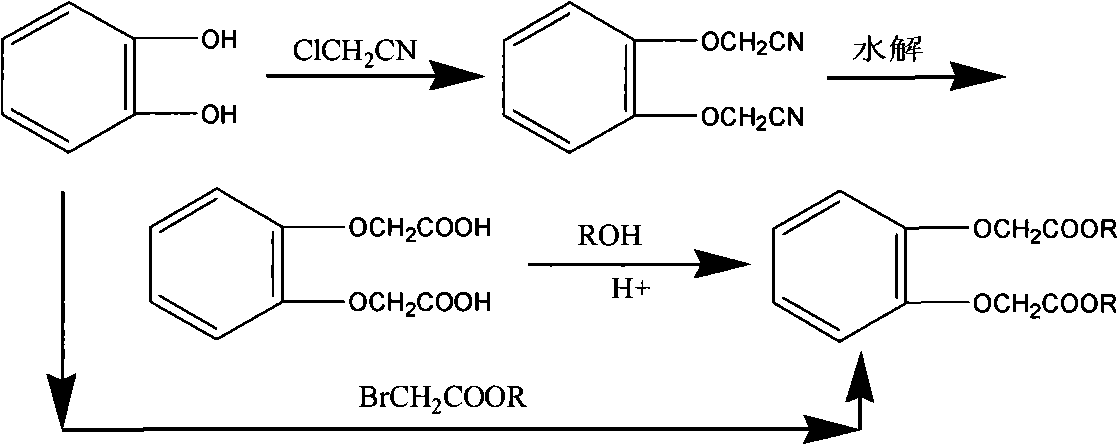

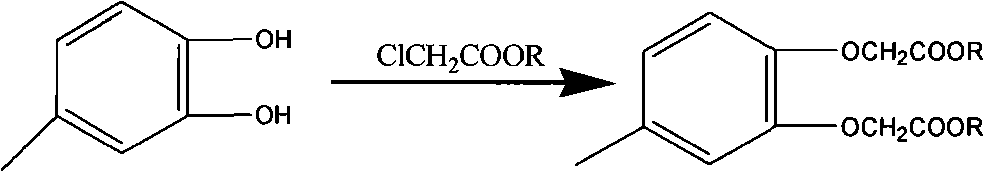

Method for synthesizing 4-methyl-1, 2-phenylenedioxyacetic ester

ActiveCN101580470BRealize one-step etherificationHigh yieldOrganic compound preparationCarboxylic acid esters preparationBenzeneKetone

The invention discloses a method for synthesizing 4-methyl-1, 2-phenylenedioxyacetic ester, which comprises the following steps: taking 4-methylpyrocatechol and chloracetate as basic raw materials; taking aliphatic ketone or cyclic ketone as a solvent; performing heating reflux reaction for 6 to 10 hours in the presence of a phase transfer catalyst and anhydrous alkali metal carbonate; filtering after the cooling of the reaction; distilling a filtrate under reduced pressure after the solvent of the filtrate is recovered; and intercepting fractions of a product with the yield of between 85 and98 percent. The method uses the chloracetate to realize the one-step etherification of the 4-methylpyrocatechol, has high yield and low cost, is particularly an environment-friendly method, and is easy to realize industrialized production.

Owner:DALIAN LAIKE FINE CHEM CO LTD

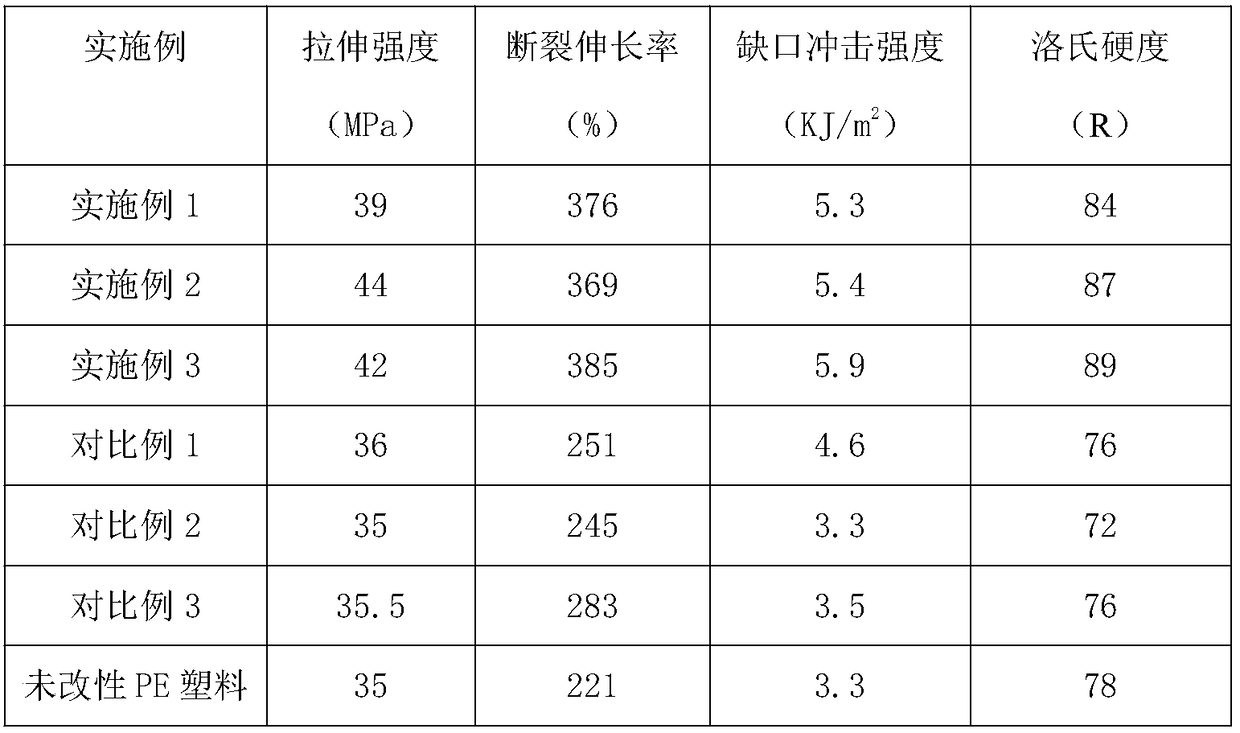

Recycled plastic and preparation method thereof

The invention discloses a recycled plastic. The recycled plastic comprises the following components in percentages by mass: 60-75% of waste plastics, 10-15% of waste ceramic powder, 0.5-2% of a coupling agent, 0.1-0.5% of monostearin, 5-10% of floating beads, 2-4% of SBS, 3-5% of a maleic anhydride grafted ethylene-propylene copolymer, 1-2% of 4-methylcatechol, 2-3% of ammonium ferric sulfate, and1-3% of phthalate. According to the recycled plastic disclosed by the invention, the 4-methylcatechol, the ammonium ferric sulfate, the floating beads are added and mixed with other raw materials, sothat full modification can be performed on the surface of the ceramic powder, and the difference between the polyolefin plastics and the ceramic powder can be reduced; and the ceramic powder and theplastics have good compatibility and strong interfacial adhesion, and the obtained recycled plastic has improved rigidity and toughness compared with a pure plastic substrate, and significantly-improved wear resistance, durability, corrosion resistance and heat resistance.

Owner:HUNAN YINGHONG SCI & TECH

Synthesis method of watermelon ketone

The invention discloses a synthesis method of watermelon ketone. Under protection of nitrogen, a sodium carbonate solution and 4-methylcatechol are added into a reactor, temperature is controlled at 60-80 DEG C for 1-2 hours, methylbenzene is added to completely bring out water at normal pressure, organic alkali and iodinated amine are added, then a mixed solution of 1- dichloroacetone, 3-dichloroacetone and butanone is dropwise added at the temperature of 60-80 DEG C, heat preservation reaction is carried out for 3-5 hours after dripping, crude products are obtained after cooling and suction filtration, methylbenzene is recycled, a sodium sulfate solution is used for washing until the crude products are neutral, decompression distillation is carried out, distillate is recrystallized through a mixed solvent of acetone and normal hexane, and white crystal solid watermelon ketone is obtained. The synthesis method is adopted for synthesizing target products, reaction conditions are easy to control, operation is simple, yield coefficient is high, production cost is low, and reaction is safe and environment-friendly.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

Method for synthesizing 4-methyl-1, 2-phenylenedioxyacetic ester

ActiveCN101580470ARealize one-step etherificationHigh yieldOrganic compound preparationCarboxylic acid esters preparationBenzeneKetone

The invention discloses a method for synthesizing 4-methyl-1, 2-phenylenedioxyacetic ester, which comprises the following steps: taking 4-methylpyrocatechol and chloracetate as basic raw materials; taking aliphatic ketone or cyclic ketone as a solvent; performing heating reflux reaction for 6 to 10 hours in the presence of a phase transfer catalyst and anhydrous alkali metal carbonate; filtering after the cooling of the reaction; distilling a filtrate under reduced pressure after the solvent of the filtrate is recovered; and intercepting fractions of a product with the yield of between 85 and 98 percent. The method uses the chloracetate to realize the one-step etherification of the 4-methylpyrocatechol, has high yield and low cost, is particularly an environment-friendly method, and is easy to realize industrialized production.

Owner:DALIAN LAIKE FINE CHEM CO LTD

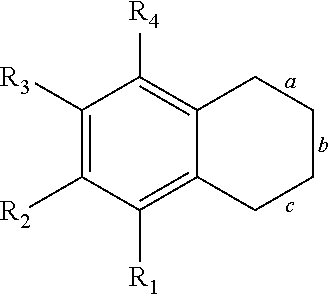

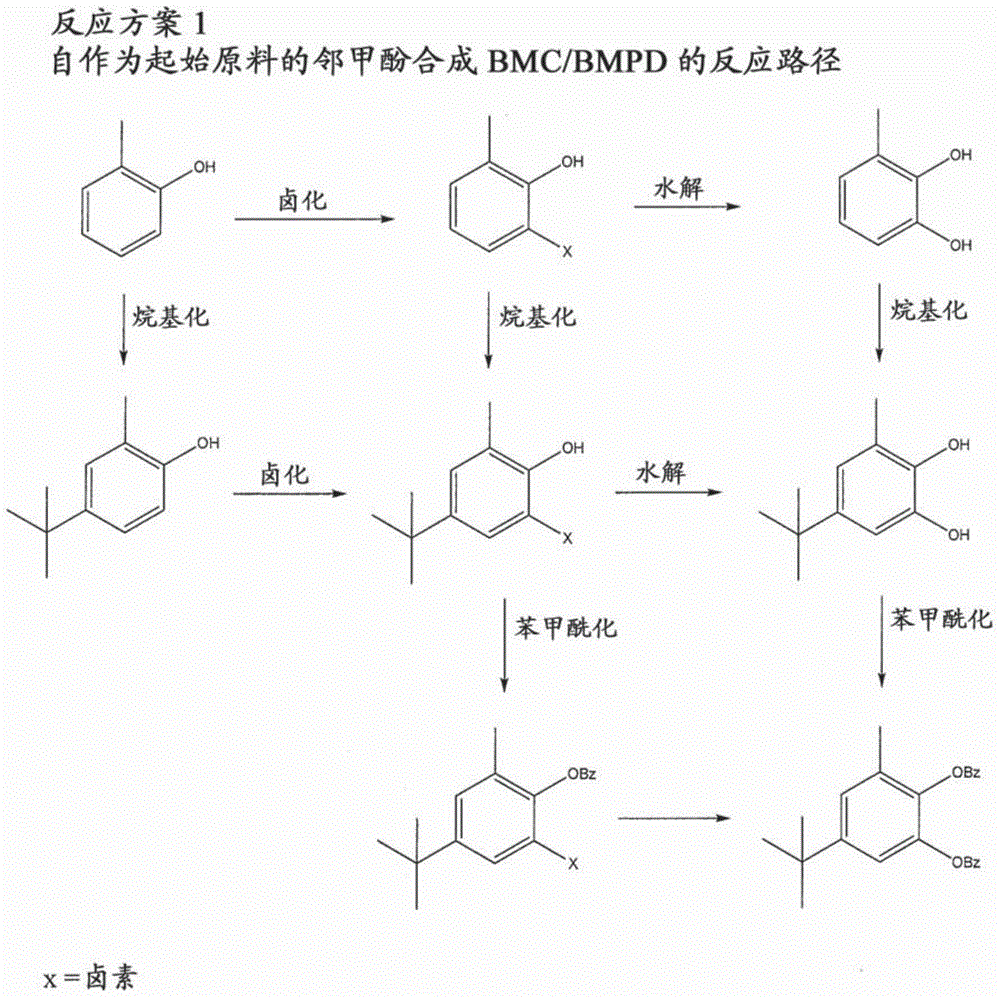

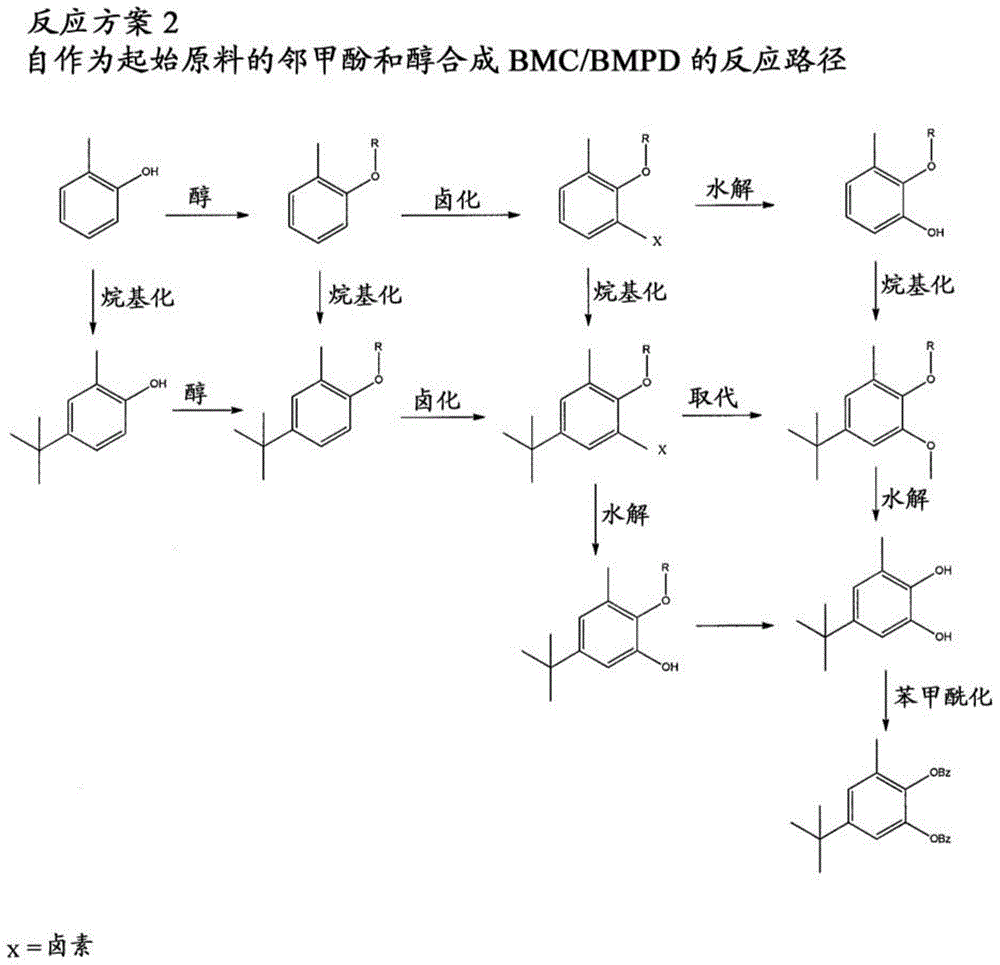

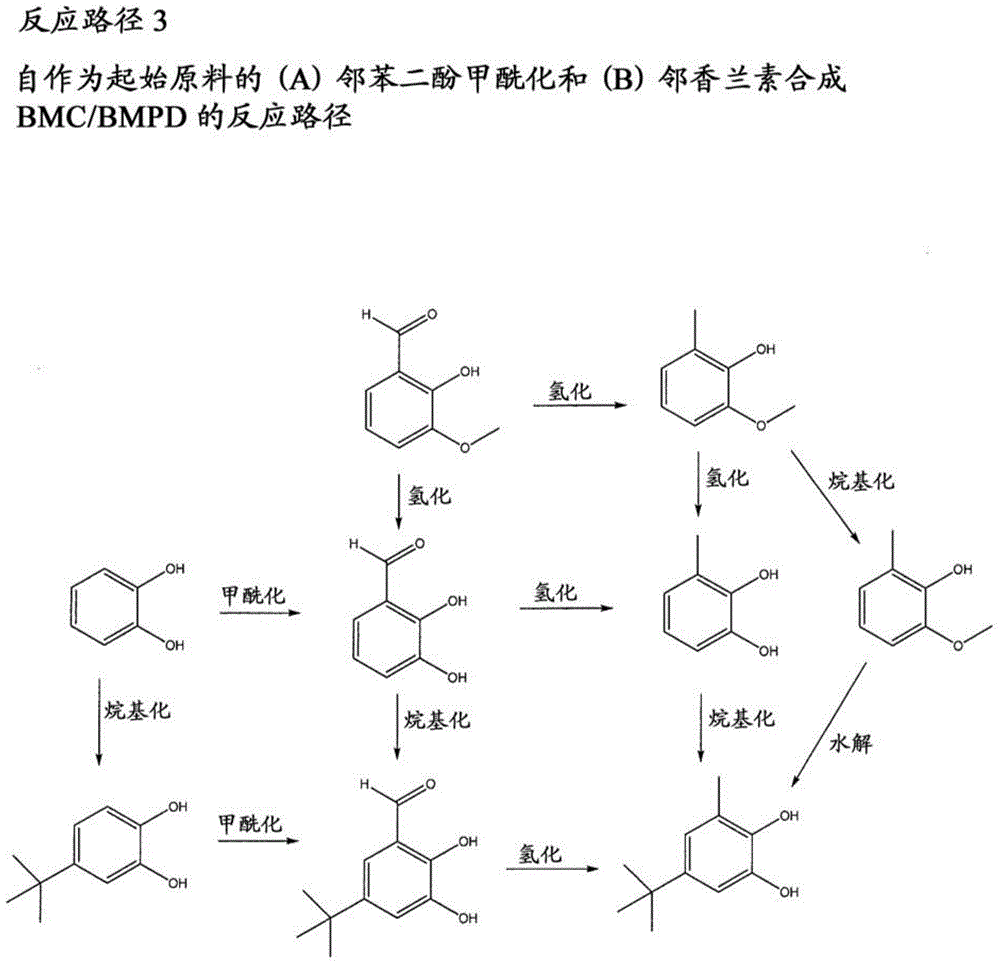

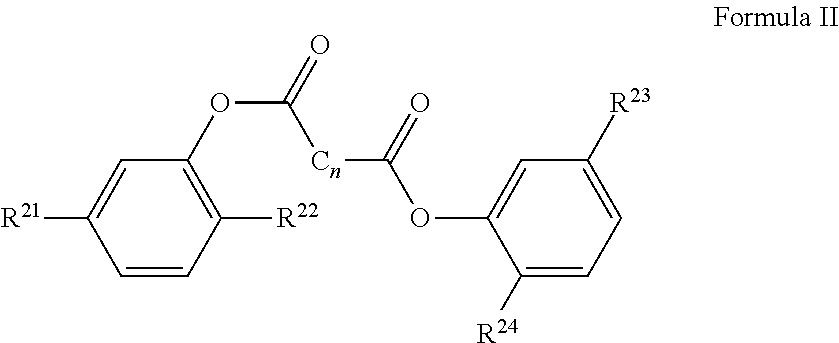

Production of substituted phenylene aromatic diesters

InactiveCN103562172AEasy to manufactureGood for commercial preparationPreparation from carboxylic acid halidesOrganic compound preparationCombinatorial chemistryMethyl group

Synthesis pathways for a precursor to 5-tert-butyl-3-methyl-1, 2-phenylene dibenzoate are provided. The precursor is methylcatechol and / or 5-tert-butyl-3-methylcatechol.

Owner:WR GRACE & CO CONN

Anti-corrosion paint for insect pest dispelling machine

InactiveCN104789018AImprove wettabilityImprove water resistanceAnti-corrosive paintsSilanesBoron nitride

The invention discloses anti-corrosion paint for an insect pest dispelling machine. The anti-corrosion paint for the insect pest dispelling machine is prepared from the following components in parts by weight: 16-25 parts of allyl heptanoate, 12-24 parts of methyl catechol, 3-8 parts of selenium acetylacetone, 2-6 parts of amino silane, 2-5 parts of zirconium silicate, 1-8 parts of perchloroethylene, 3-10 parts of tetrabutylammonium bromide, 1-2 parts of yttrium oxide, 2-5 parts of silicon dioxide, 3-7 parts of titanium dioxide, 4-6 parts of boron nitride and 8-18 parts of a solvent. The anti-corrosion paint for the insect pest dispelling machine is easy to use, easy to prepare and good in brushing property, wettability on article surface is good, and a paint film can be rapidly dried, mechanical property of the paint film is good, corrosion resistance is excellent, water resistance and weather resistance are good, and service life is long.

Owner:GUANGXI GAONONG MACHINERY

Inner wall latex paint

The invention discloses an inner wall latex paint prepared from the following raw materials in parts by weight: 1-4 parts of sodium persulfate, 2-4 parts of potassium citrate, 3-6 parts of 1,2-bis(pentabromophenyl) ethane, 4-9 parts of a tetraethyl ammonium hydroxide methanol solution, 1-3 parts of trimethylamine hydrochloride, 2-3 parts of calcium fluoride, 2-5 parts of 3-methyl-2-butenal, 1-2 parts of zinc trifluoroacetylacetone, 1-4 parts of 4-methyl catechol, 10-15 parts of deionized water, 8-10 parts of an acrylic emulsion, and 1-3 parts of zinc oxide. The invention provides the inner wall latex paint, and the inner wall latex paint can effectively remove formaldehyde and harmful volatile organic compounds in air, so as to reduce the harm to human health.

Owner:QINGDAO CHENQING INFORMATION TECH

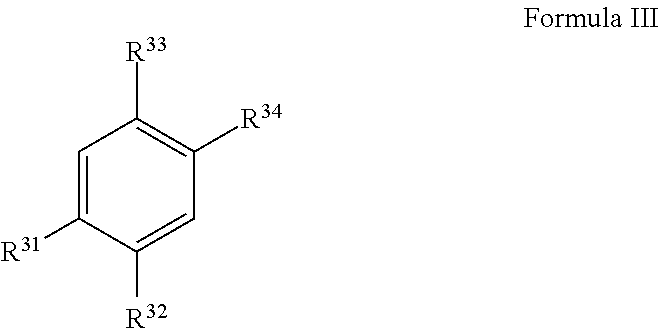

4-methylcatechol Derivatives and Uses Thereof

The invention relates to phenoxy derivatives with glycosidically bound sugar moieties, pharmaceutical compositions containing such compounds, uses of such compounds and compositions, and methods of making such compounds and pharmaceutical compositions.

Owner:THANARES

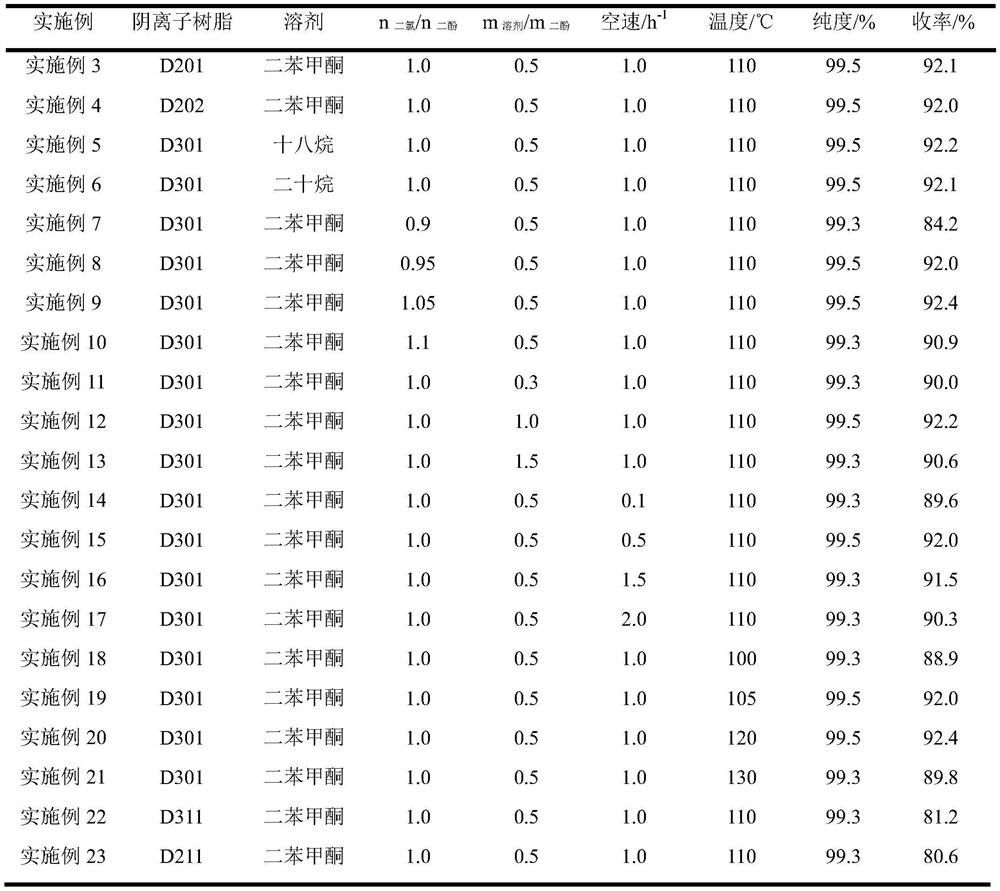

Method for synthesizing watermelon ketone

ActiveCN114456146AGood reaction selectivityLess side effectsOrganic chemistryChemical recyclingOrganic solventPtru catalyst

The invention discloses a method for synthesizing watermelon ketone. 4-methylcatechol and 1, 3-dichloroacetone are used as raw materials to react in an organic solvent to obtain the watermelon ketone, the reaction is carried out in the presence of a catalyst, and the catalyst is anion exchange resin. The boiling point of the organic solvent is 300-350 DEG C. The method further comprises recrystallization post-treatment combining dynamic recrystallization and traditional static recrystallization under stirring. The method is a one-step reaction, the used catalyst is high in reaction selectivity, the product yield and purity are high, and the fragrance of the product is not influenced.

Owner:SHANDONG NHU PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com