Preparation method and purification method of watermelon ketone crude product suitable for industrial production

A purification method, watermelon ketone technology, applied in the field of synthesis of spice compounds, can solve the problems of increased material cost, complex process route, low distillate yield, etc., and achieve the effect of improving conversion rate, optimizing reaction, and simple reaction route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

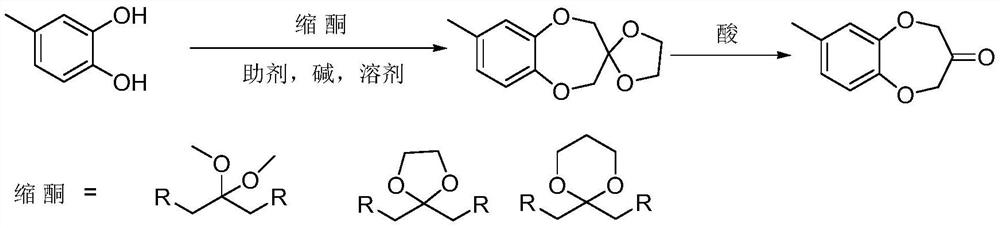

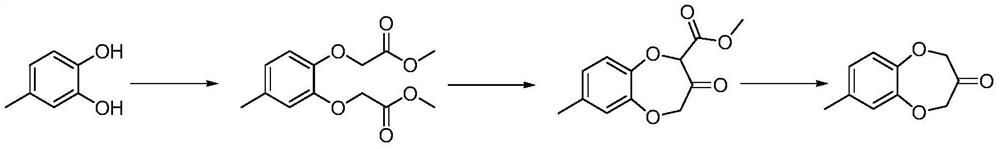

Method used

Image

Examples

Embodiment 1

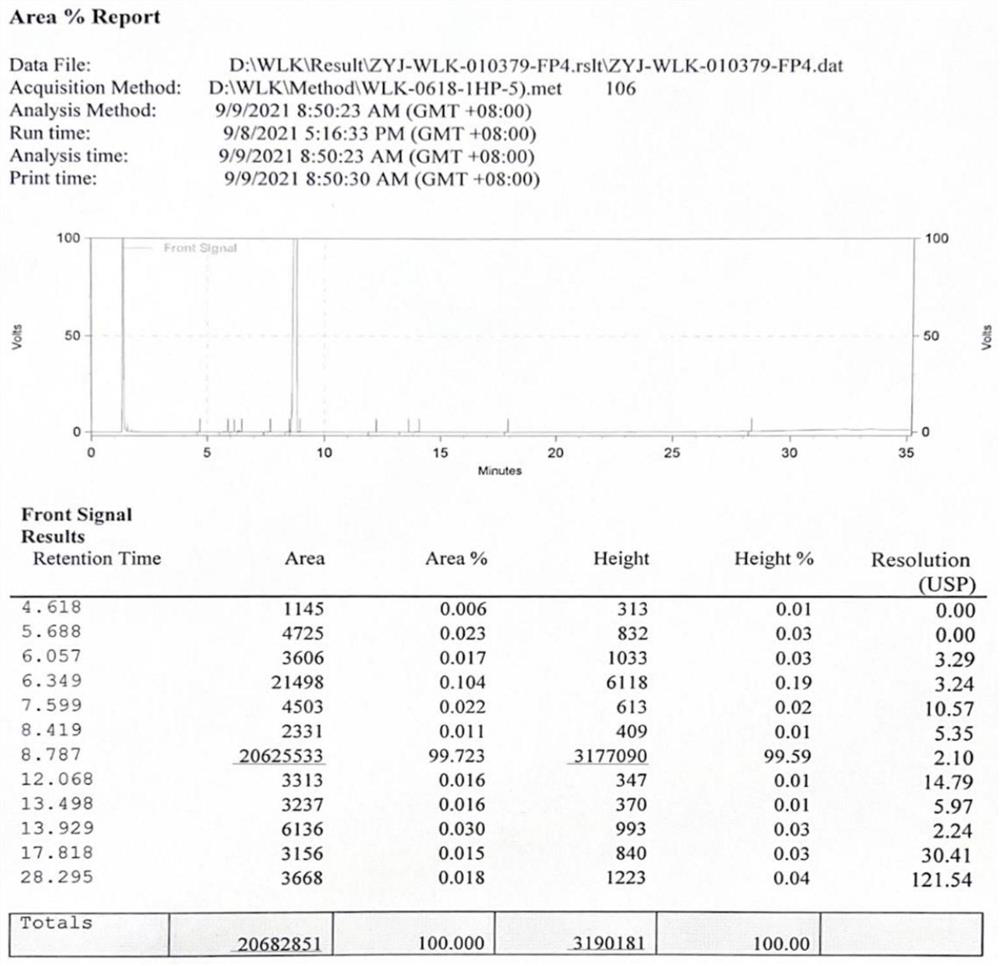

[0062]Put 30.56g of 4-methylcatechol and 300ml of 2-butanone into a 500mL four-necked bottle, stir for 0.5h to dissolve. 6.13 g potassium iodide and 52.18 g sodium carbonate were added. Heat and stir to raise the temperature to 75-80°C. At this temperature, a solution of 37.5 g of 1,3-dichloroacetone in 60 ml of 2-butanone was slowly added dropwise. After 3 hours of the reaction, gas phase detection of 4-methylcatechol was taken to be consumed below 2.0%, and the reaction was stopped. After desalting by suction filtration, the filtrate was concentrated under reduced pressure to recover the solvent. The crude watermelon ketone obtained was beaten with 300ml of n-heptane at room temperature for 0.5h, and then left to stand and layered to remove tar. Add 2.5 g of activated carbon to the beating liquid, stir at room temperature for 0.5 h, and filter with suction, the filtrate is clear and bright. Concentrate under reduced pressure to recover n-heptane. The still liquid was di...

Embodiment 2

[0064] Put 30.56g of 4-methylcatechol and 300ml of 2-butanone into a 500mL four-necked bottle, stir for 0.5h to dissolve. 6.13 g potassium iodide and 52.18 g sodium carbonate were added. Heat and stir to raise the temperature to 75-80°C. At this temperature, a solution of 34.5 g of 1,3-dichloroacetone in 60 ml of 2-butanone was slowly added dropwise. After 3 hours of the reaction, gas phase detection of 4-methylcatechol was taken to be consumed below 2.0%, and the reaction was stopped. After desalting by suction filtration, the filtrate was concentrated under reduced pressure to recover the solvent. The crude watermelon ketone obtained was beaten with 280 ml of n-heptane at room temperature for 0.5 h, and then left to stand for layering to remove tar. Add 2.0 g of activated carbon to the beating liquid, stir at room temperature for 0.5 h, and filter with suction, the filtrate is clear and bright. Concentrate under reduced pressure to recover n-heptane. The still liquid wa...

Embodiment 3

[0066] Put 30.56g of 4-methylcatechol and 300ml of 2-butanone into a 500mL four-necked bottle, stir for 0.5h to dissolve. 6.13 g potassium iodide and 68.03 g potassium carbonate were added. Heat and stir to raise the temperature to 75-80°C. At this temperature, a solution of 37.5 g of 1,3-dichloroacetone in 60 ml of 2-butanone was slowly added dropwise. After 2 hours of reaction, gas phase detection of 4-methyl catechol consumption was taken to be below 2.0%, and the reaction was stopped. After desalting by suction filtration, the filtrate was concentrated under reduced pressure to recover the solvent. The crude watermelon ketone obtained was beaten with 300ml of n-heptane at room temperature for 0.5h, and then left to stand and layered to remove tar. Add 2.5 g of activated carbon to the beating liquid, stir at room temperature for 0.5 h, and filter with suction, the filtrate is clear and bright. Concentrate under reduced pressure to recover n-heptane. The still liquid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com