Preparation method of 4-methylcatechol

A technology of methyl catechol and methyl phthalate is applied in the field of preparation of 4-methyl catechol, and achieves the effects of high yield, saving time and cost, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

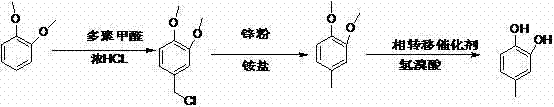

Method used

Image

Examples

Embodiment 1

[0028] Add o-phthalylene dimethyl ether (69g, 0.5mol), paraformaldehyde (15.75g, 0.525mol) and 100ml dichloroethane into the reaction flask, drop the temperature to -5~10°C, and slowly add concentrated hydrochloric acid ( 50ml, 0.6mol), then reacted at this temperature for 5 hours, filtered after the reaction, and the filtrate was separated into the water layer, and the dichloroethane layer was washed once with water, then washed once with saturated aqueous sodium bicarbonate solution, and finally washed once again with water , dried over sodium sulfate, and concentrated to obtain a crude product, which was then distilled under reduced pressure to obtain 69.9 g of 4-chloromethyl-phthalene dimethyl ether, with a yield of 75%.

Embodiment 2

[0030] Add o-phthalylene dimethyl ether (69g, 0.5mol), paraformaldehyde (30g, 1mol) and 100ml of dichloromethane into the reaction flask, drop the temperature to -5~10°C, and slowly add concentrated hydrochloric acid (100ml, 1.2 mol), and then reacted at this temperature for 3-4 hours, filtered after the reaction, and the filtrate was separated into the water layer. After the sodium was dried, it was concentrated to obtain a crude product, which was then distilled under reduced pressure to obtain 65.3 g of 4-chloromethyl-phthalamide, with a yield of 70%.

Embodiment 3

[0032] Add o-phthalylene dimethyl ether (69g, 0.5mol), paraformaldehyde (75g, 0.525mol) and 100ml chloroform into the reaction flask, drop the temperature to -5~10°C, slowly add concentrated hydrochloric acid (208ml, 2.5mol ), then reacted at this temperature for 3 hours, filtered after the reaction, and the filtrate was separated into the water layer. The chloroform layer was washed once with water, then washed once with saturated aqueous sodium bicarbonate solution, and finally washed once with water, dried over sodium sulfate, and concentrated The crude product was obtained, and then 17 g of 4-chloromethyl-phthalyl ether was obtained by distillation under reduced pressure, with a yield of 18.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com