Preparation method of watermelon ketone

A technology of watermelon ketone and dichloroacetone, which is applied in the direction of organic chemistry, can solve the problems of high price of watermelon ketone and complicated synthetic route, and achieve the effect of low cost, high product purity and low possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

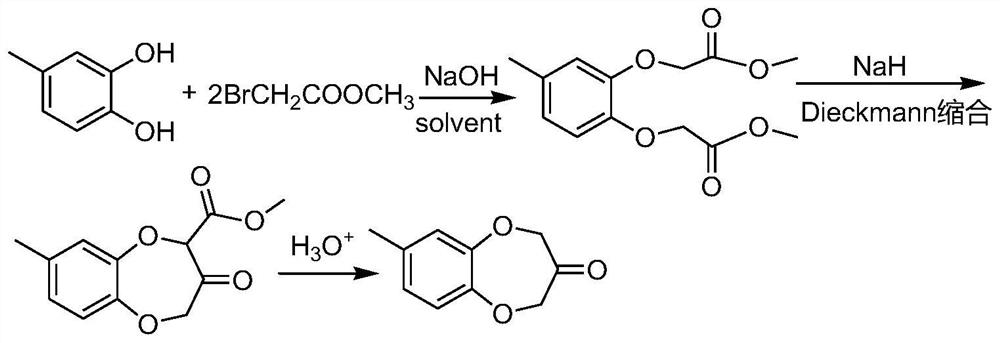

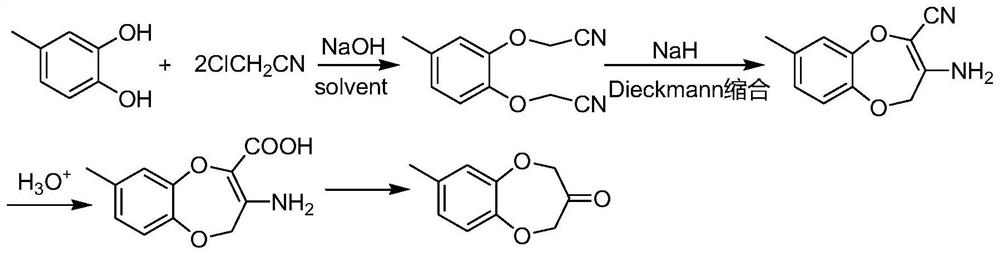

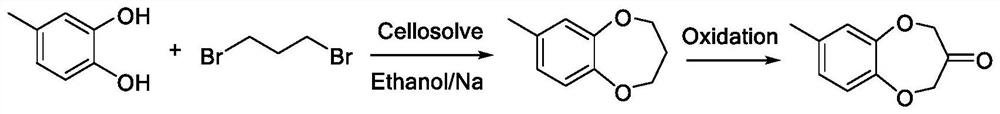

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A kind of preparation method of watermelon ketone of the present embodiment, comprises the following steps:

[0074] 1) Assemble the decompression reflux water removal device

[0075] refer to figure 1, Assemble the decompression reflux water removal device according to the figure, and add anhydrous calcium chloride wrapped in filter paper into the Soxhlet extractor.

[0076] The key of the decompression reflux water removal device is to reduce the boiling point of water through decompression, distill the water out of the reaction system, and absorb it through the desiccant;

[0077] 2) Preparation of watermelon ketone reaction solution

[0078] Add 400.0mL of acetone to the 1000.0mL four-necked flask of the decompression reflux dewatering device, then add sodium carbonate (36.0g, 340.0mmol), add catalyst potassium iodide (4.0g, 24.0mmol); start mechanical stirring, and heat up to 45 ℃; Prepare 100.0 g (mass content of 29.8%) of 4-methylcatechol (29.8 g, 240.0 mmol) ...

Embodiment 2

[0094] A kind of preparation method of watermelon ketone of the present embodiment, comprises the following steps:

[0095] 1) Assemble the decompression reflux water removal device

[0096] refer to figure 1 , Assemble the decompression reflux water removal device according to the figure, and add anhydrous magnesium sulfate desiccant wrapped in filter paper into the Soxhlet extractor.

[0097] The key of the decompression reflux water removal device is to reduce the boiling point of water through decompression, distill the water out of the reaction system, and absorb it through the desiccant;

[0098] 2) Preparation of watermelon ketone reaction solution

[0099] Drop into 400mL of acetone in the 1000mL four-necked flask of the decompression reflux dewatering device, then add potassium carbonate (47g, 340.0mmol), add the catalyst potassium iodide (4.0g, 24.0mmol), start the mechanical stirring, heat up to 45°C, use Acetone is solvent preparation 4-methylcatechol (29.8g, 24...

Embodiment 3

[0110] A kind of preparation method of watermelon ketone of the present embodiment, comprises the following steps:

[0111] 1) Assemble the decompression reflux water removal device

[0112] refer to figure 1 , Assemble the decompression reflux water removal device according to the figure, and add anhydrous calcium chloride wrapped in filter paper into the Soxhlet extractor.

[0113] The key of the decompression reflux water removal device is to reduce the boiling point of water through decompression, distill the water out of the reaction system, and absorb it through the desiccant;

[0114] 2) Preparation of watermelon ketone reaction solution

[0115]Put 400 mL of acetone into a 1000 mL four-necked flask of a decompression reflux water removal device, then add sodium carbonate (36.0 g, 340.0 mmol), and add catalyst potassium iodide (4.0 g, 24.0 mmol). Turn on the mechanical stirring and raise the temperature to 45°C. Prepare 4-methylcatechol (29.8g, 240.0mmol) solution 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com