Comprehensive utilization method of byproduct 5-aldehyde vanillin in vanillin production process

An aldehyde-based vanillin and production process technology, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problem of high comprehensive utilization cost, low proportion of ortho-vanillin, and reaction yield Low problems, to achieve the effects of good economic benefits, fewer synthesis steps, and high reaction yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

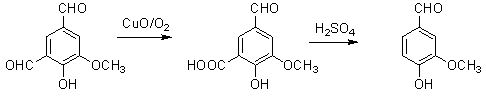

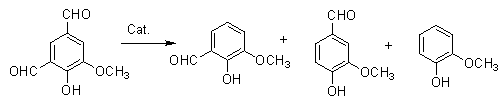

Method used

Image

Examples

Embodiment 1

[0026] A comprehensive utilization method of by-product 5-formyl vanillin in the production process of vanillin, specifically comprising the following steps:

[0027] (1) Take 800g of the distilled fraction of vanillin, and the content of 5-formyl vanillin reaches 93.1% after testing;

[0028] (2) Add 1.5 g of a dealdehyde catalyst to the 800 g of 5-formyl vanillin crude product obtained in step (1) with a purity of 93.1%, and control the temperature to 190°C for the dealdehyde reaction, while controlling the pressure to 6.0 Kpa carries out vacuum distillation, collects the distillate between boiling point 120~155 ℃ and promptly obtains the mixture 450g of guaiacol, ortho-vanillin and vanillin;

[0029] Described dealdehyde catalyst is the Pt / C that load capacity is 5%, the amount of the dealdehyde catalyst added is 0.19% of 5-formyl vanillin crude product weight;

[0030] In the mixture of ortho-vanillin, vanillin and guaiacol obtained above, the content of ortho-vanillin is...

Embodiment 2

[0036] A comprehensive utilization method of by-product 5-formyl vanillin in the production process of vanillin, specifically comprising the following steps:

[0037] (1), the production of vanillin obtained 1760g of 66% The by-product 5-formyl vanillin is obtained by vacuum distillation under the control pressure of 0.8kpa 920 grams The crude product of 5-formyl vanillin with a purity of 92%;

[0038] (2), obtained in step (1) 920 grams Add 1.2g of dealdehyde catalyst to the crude product of 5-formyl vanillin with a purity of 92%, control the temperature at 182°C for dealdehyde reaction, and control the pressure at 2.0kpa for vacuum distillation at the same time, the collected boiling point is 112-148 The distillate between ℃ promptly obtains the mixture of guaiacol, ortho-vanillin and vanillin 548g altogether;

[0039] Described dealdehyde catalyst is the Pd / C that load capacity is 10%, the amount of the dealdehyde catalyst added is 0.13% of 5-formyl vanillin crude pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com