One-step synthesis method for B-EU-1/ZSM-5 composite molecular sieve

A technology of B-EU-1 and ZSM-5, which is applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high synthesis cost and long synthesis cycle, and achieve stable selectivity and low synthesis cost. Reduce, reduce the effect of the compositing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

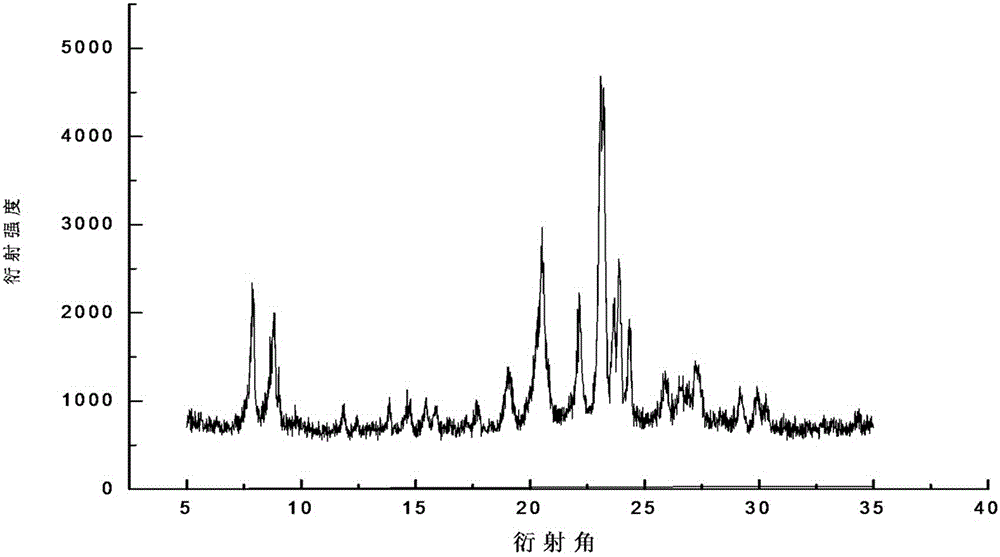

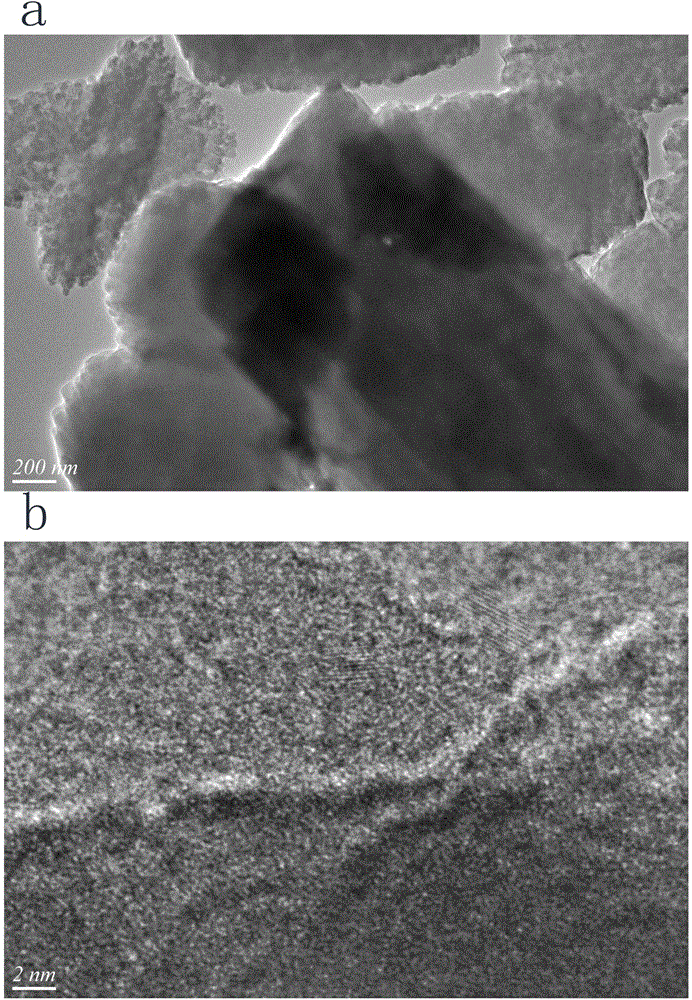

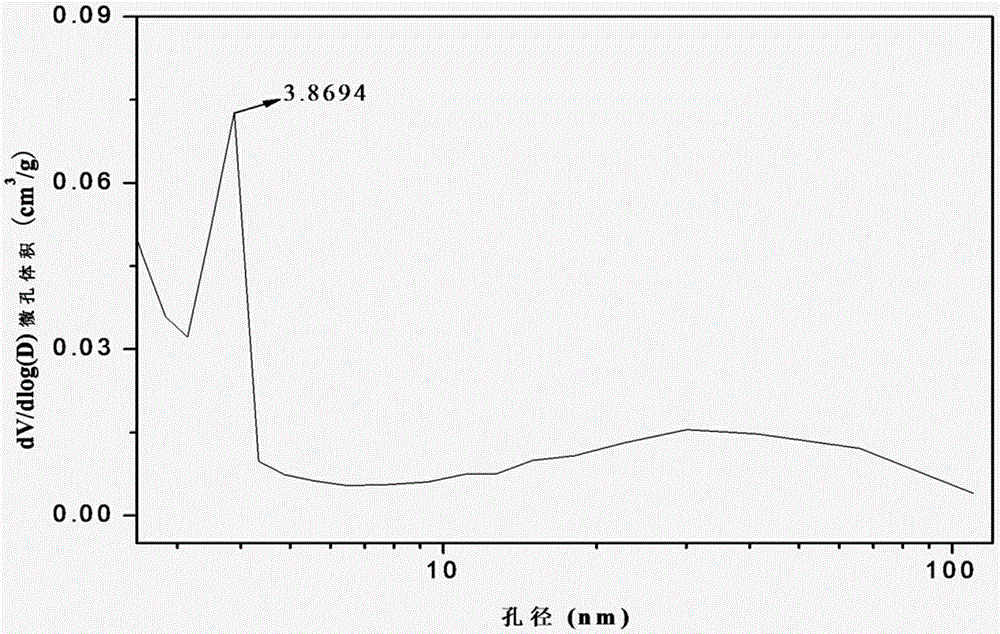

[0024] Weigh 0.5g of tetrapropylammonium bromide and 3g of hexapotassium bisammonium bromide, add it to 10ml of 10mol / L NaOH solution, fully dissolve, add 1g of aluminum sulfate octadecahydrate, 2g of boric acid, stir well, add dropwise 30ml of 5.465mol / L L silica sol, stirred for 40 minutes, and after it was in gel state, put it into a reaction kettle with a polytetrafluoroethylene liner, stood it at 200°C for 2 days, took it out to cool, washed, filtered, and dried at 500°C Calcining at the bottom to obtain sodium compound molecular sieve.

[0025] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, and filtered. Dry it in an oven at 100°C, and place it in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0026] A continuous flow fixed-be...

Embodiment 2

[0033] Add 1g of aluminum isopropoxide and 2g of boric acid into 10ml of 10mol / L NaOH solution, add dropwise 30ml of 5.465mol / L silica sol after clarification, stir evenly, take 0.5g of tetrapropylammonium bromide and 2g of hexapotassium bromide diammonium Add it into the above solution, stir for 40 minutes, add the reaction kettle after the solution is in a gel state, crystallize at 170°C for 3 days, cool, wash, suction filter, dry, and roast at 500°C to obtain a sodium-type composite molecular sieve.

[0034] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, and filtered. Dry it in an oven at 100°C, and place it in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0035] A continuous flow fixed-bed reactor (inner diameter 10 mm, length 3...

Embodiment 3

[0038] Add 1g NaAlO to 10ml 10mol / L NaOH solution 2 , add 20ml of 4.36mol / L water glass dropwise, stir evenly, add 2g of diboron trioxide, 0.5g of tetrapropylammonium bromide and 2.5g of hexapotassium bisammonium bromide at one time, stir for 40min, until the solution is in a gel state Afterwards, it was added to a reaction kettle, crystallized at 150°C for 3 days, cooled, washed, filtered with suction, dried, and roasted at 500°C to obtain a sodium-type composite molecular sieve.

[0039] The sodium-type composite molecular sieve was ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, then ion-exchanged with 0.1mol / L ammonium nitrate solution at 90°C for 2h, washed with deionized water, and filtered. Dry it in an oven at 100°C, and place it in a muffle furnace at 500°C for 4 hours to obtain a hydrogen-type composite molecular sieve.

[0040] A continuous flow fixed-bed reactor (inner diameter 10 mm, length 30 cm) was used to eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com