Patents

Literature

104results about How to "Selective stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal display

InactiveUS20040201564A1Improve image qualityPrevent degradationStatic indicating devicesNon-linear opticsData controlHysteresis

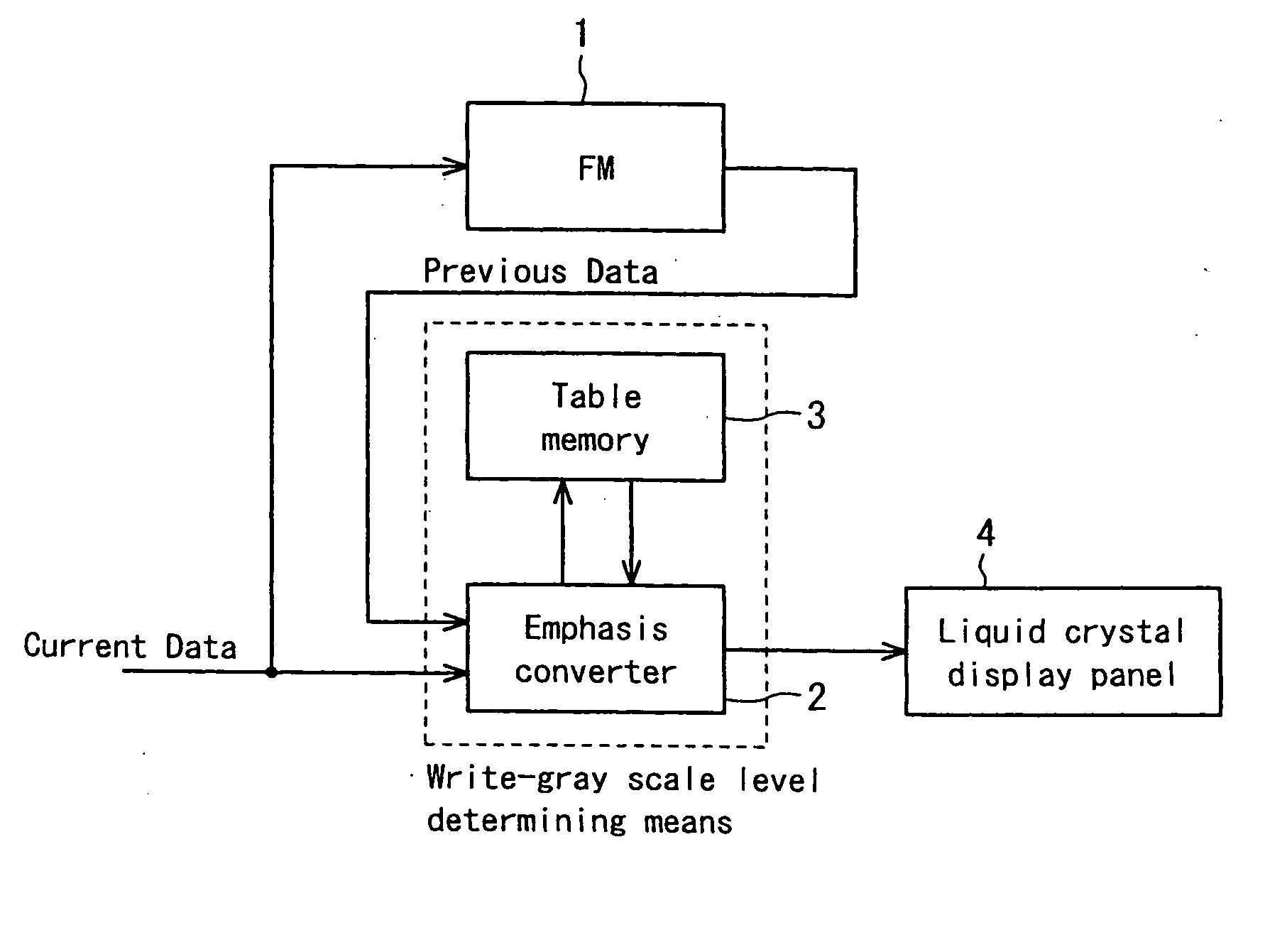

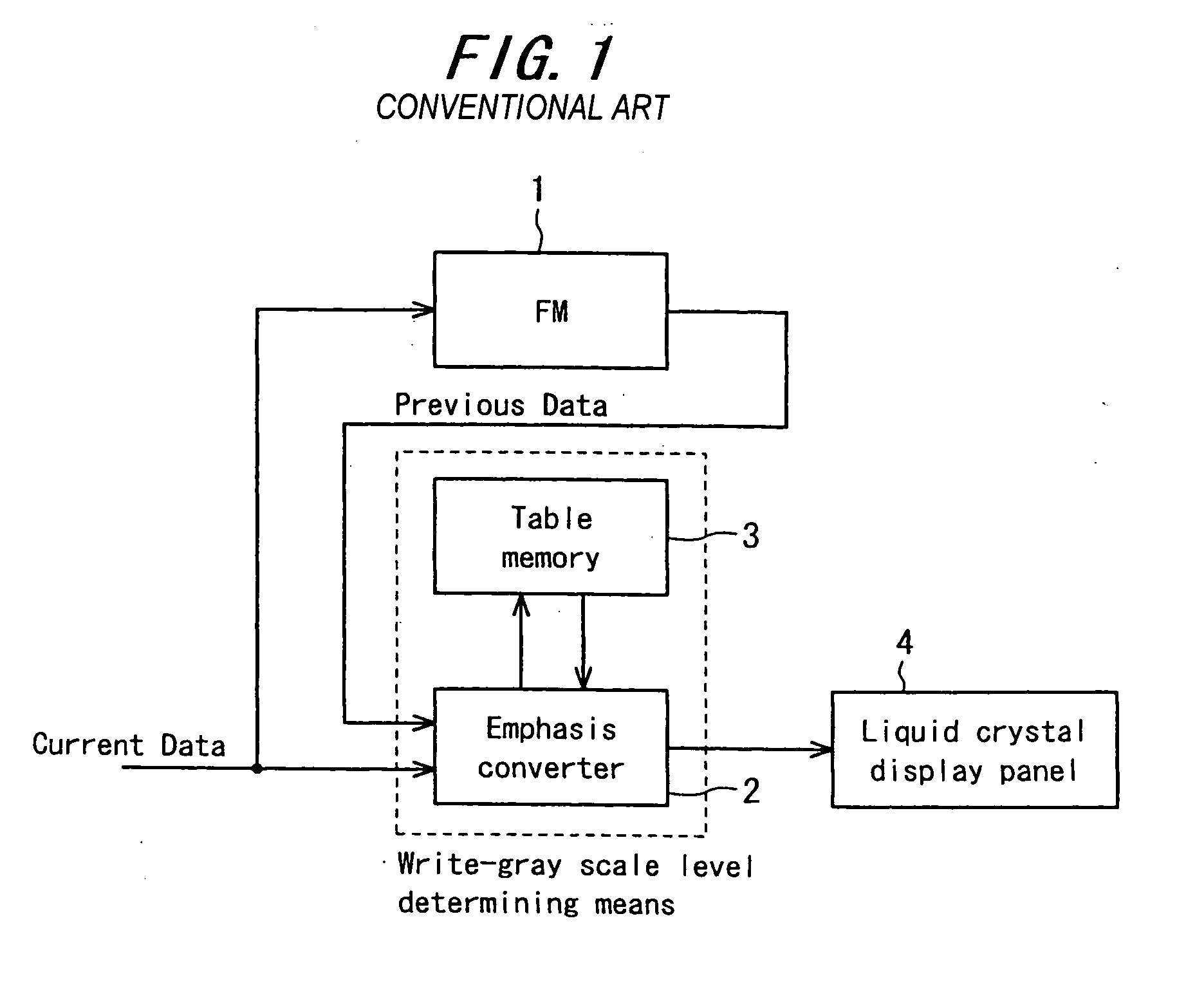

An emphasis converter 52 compares the image data of the current vertical period with the image data of the previous vertical period and controls the input image data to a liquid crystal display panel 4 based on the emphasis conversion parameters stored in tables of ROMs 3a to 3c so as to achieve accelerated drive. A microcomputer 38 is able to realize stable control of selecting emphasis conversion parameters by adding hysteresis to the detected temperature from a thermistor 37 even when the detected temperature fluctuates up and down crossing the temperature threshold.

Owner:SHARP KK

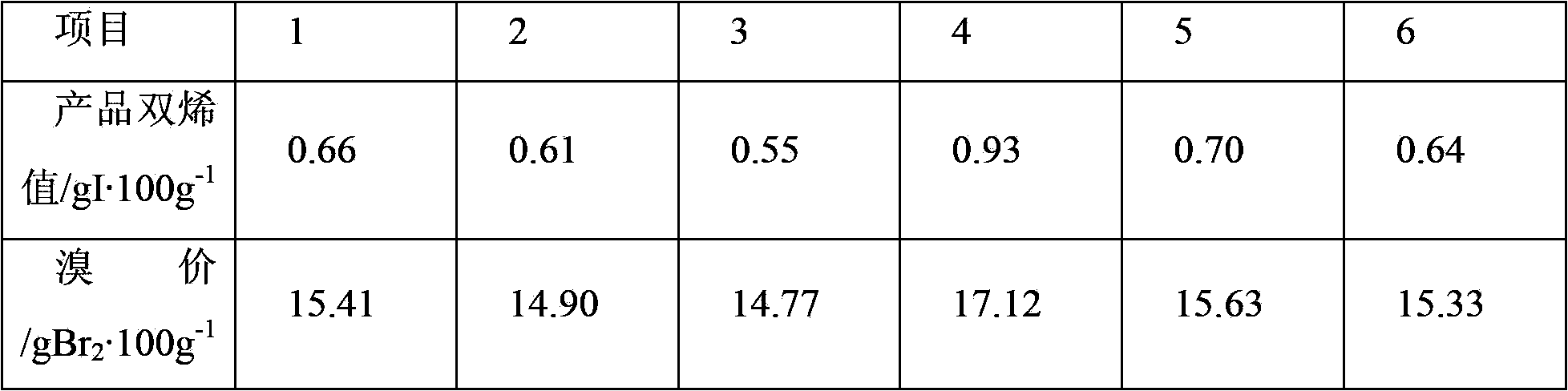

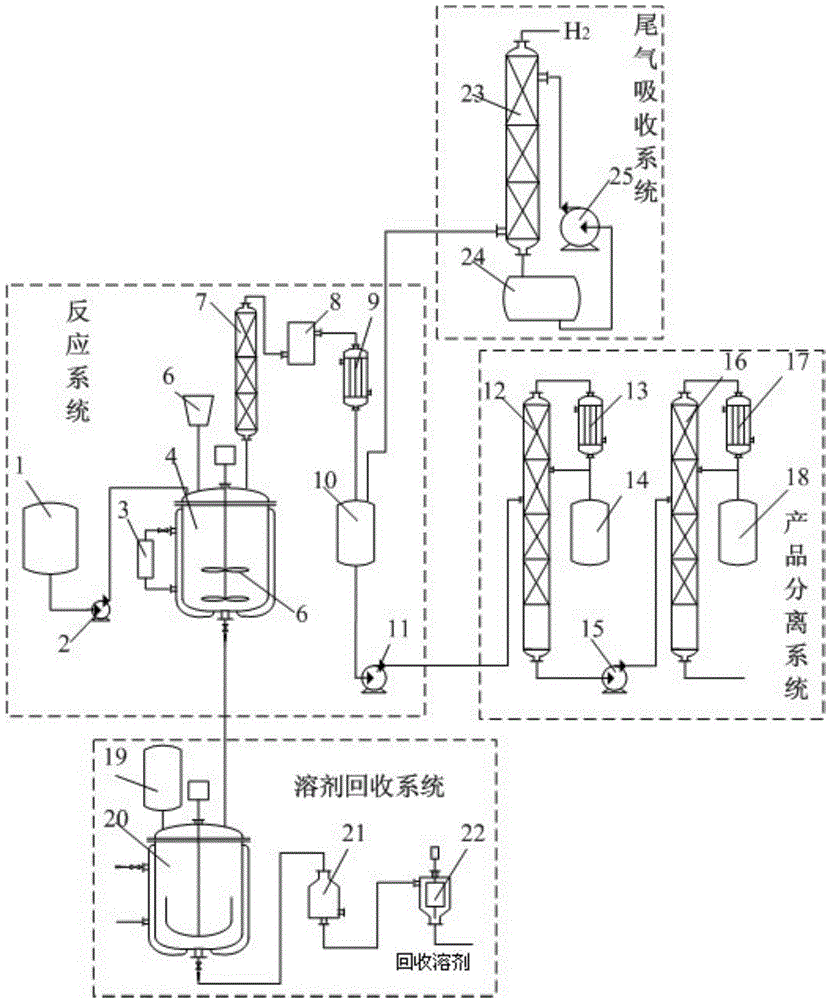

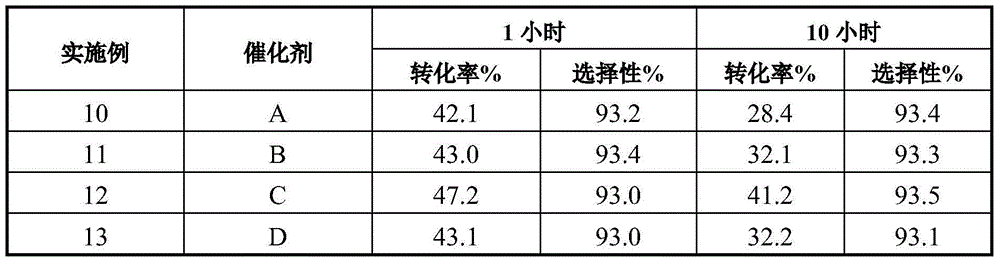

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

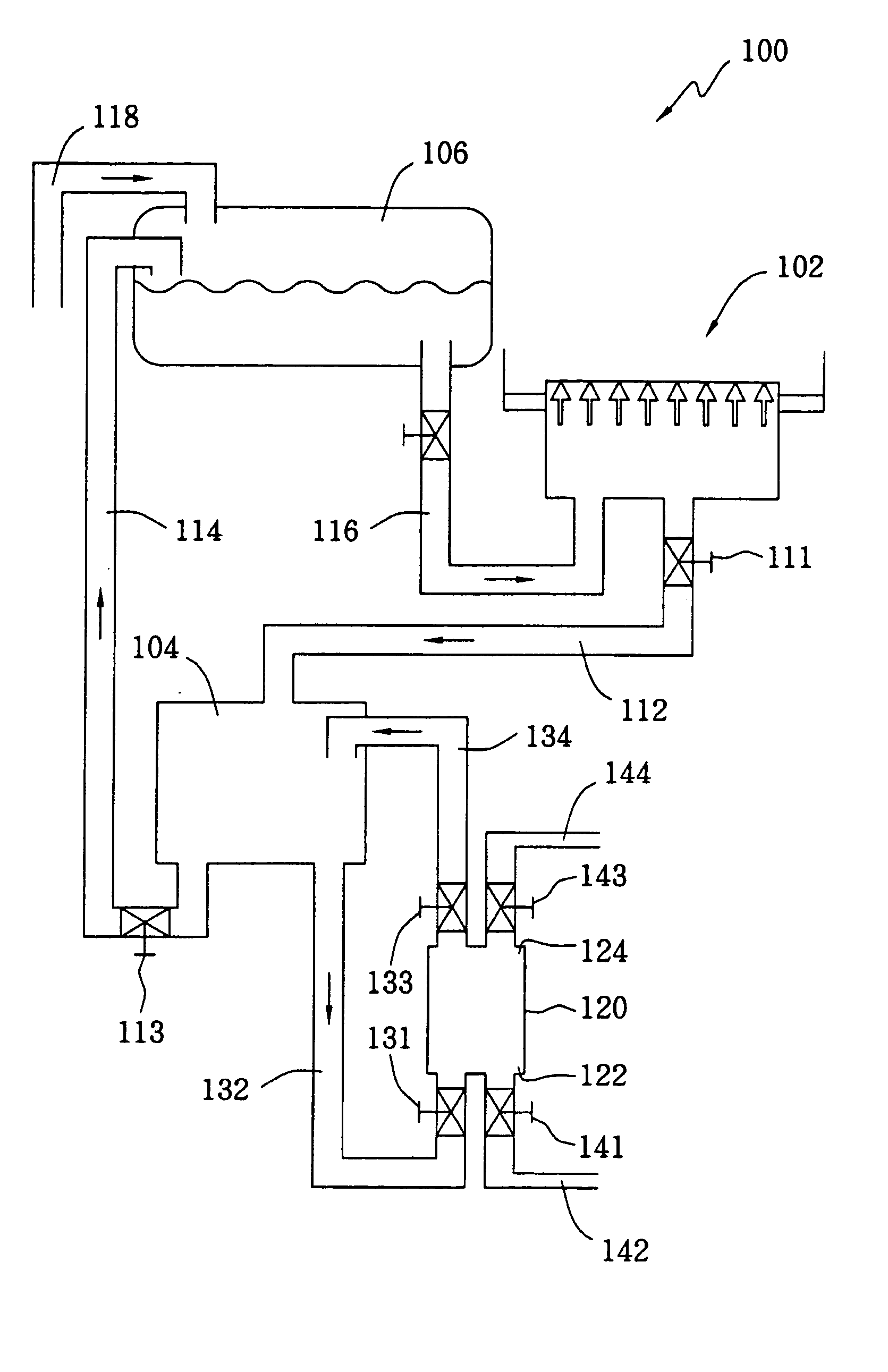

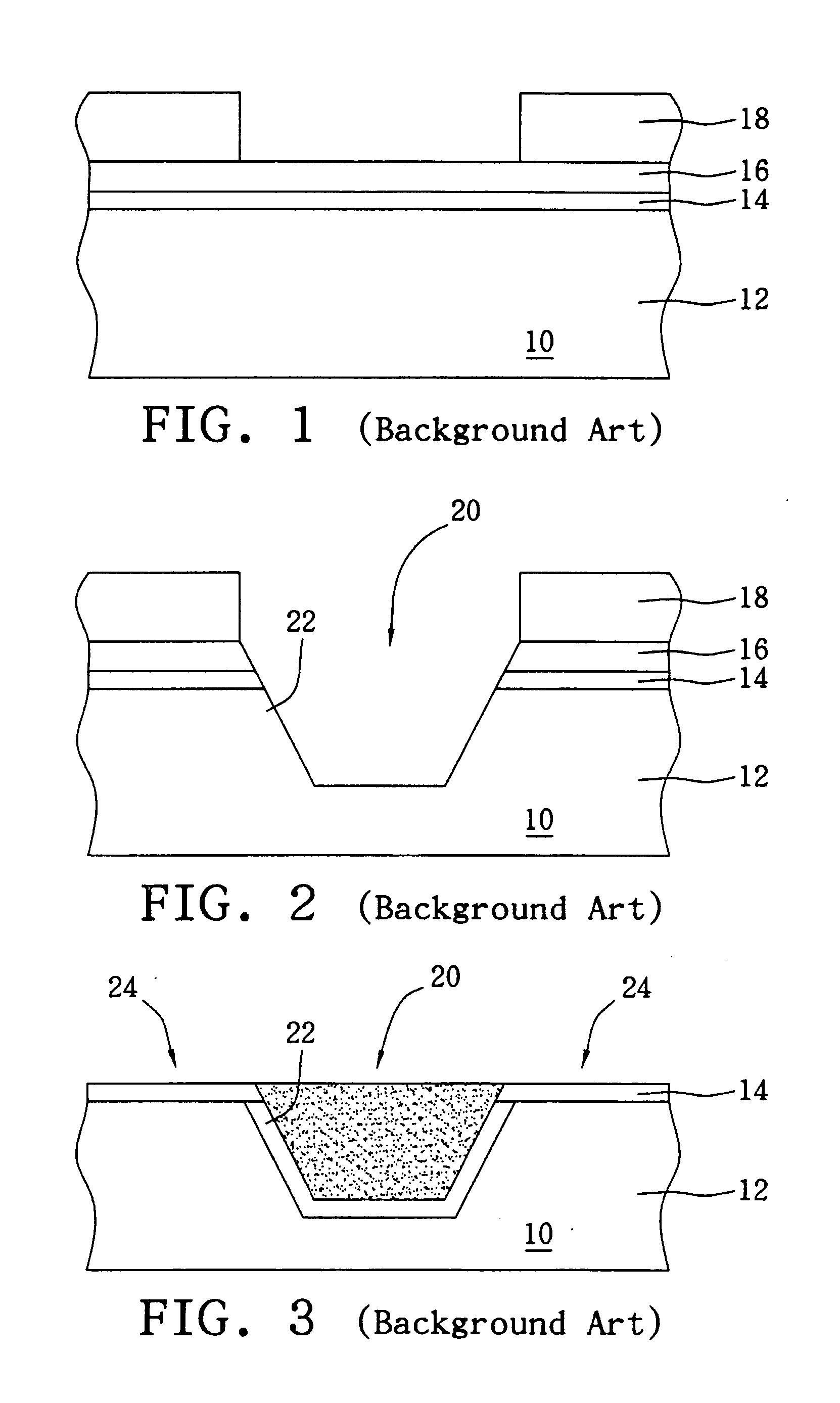

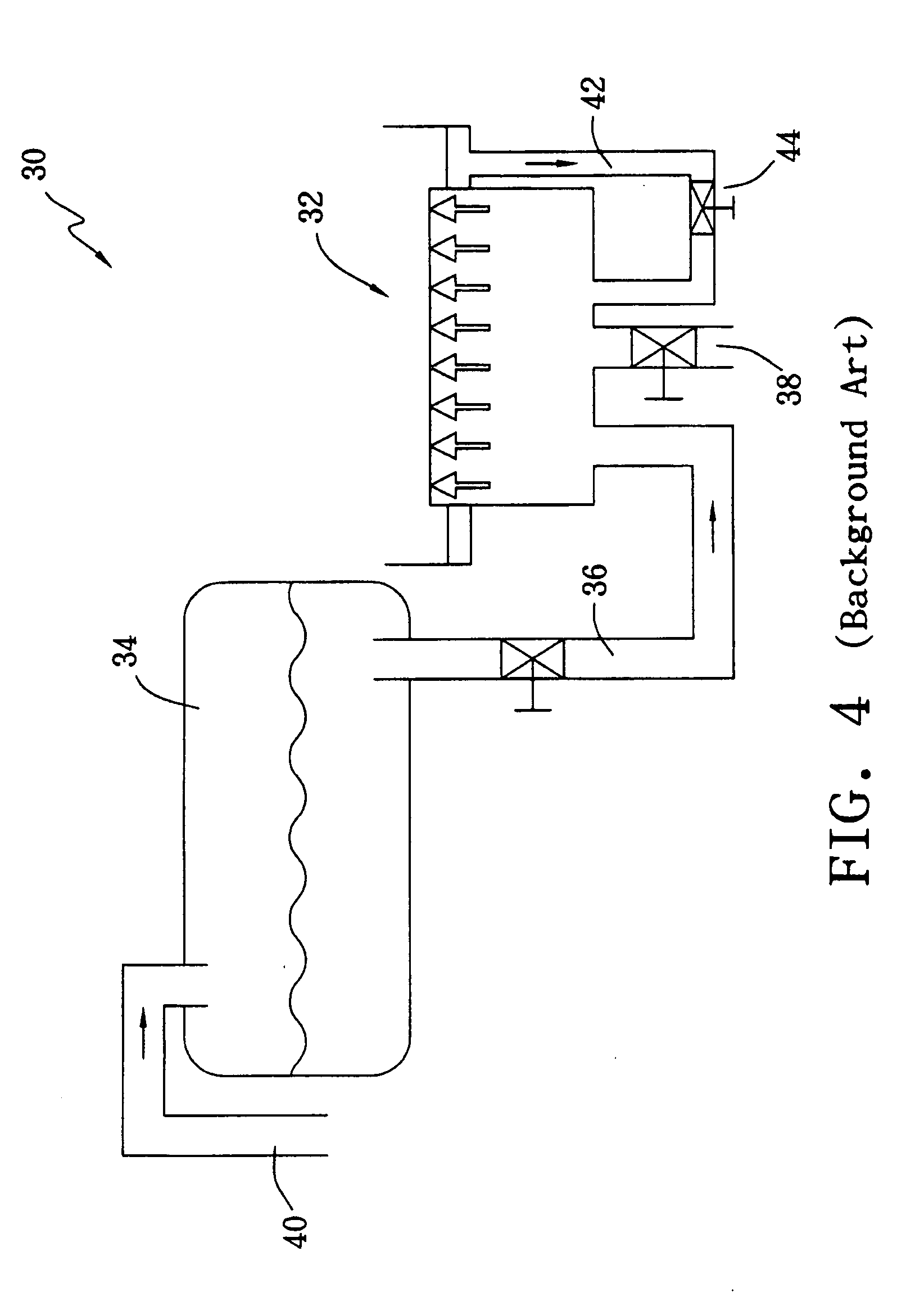

Etching system and method for treating the etching solution thereof

InactiveUS20050263488A1Improve etch selectivityReduce etching costsDecorative surface effectsSemiconductor/solid-state device manufacturingPresent methodEngineering

The present etching system includes a processing tank with an etching solution containing silicon, a cooling tank, a pre-heating tank, a first pipe for transferring the etching solution from the processing tank to the cooling tank, a second pipe for transferring the etching solution from the cooling tank to the pre-heating tank, and a third pipe for transferring the etching solution from the pre-heating tank to the processing tank. The present method for treating the etching solution first performs an etching process using the etching solution, which is then cooled to a first temperature to form a silicon-saturated etching solution. After silicon-containing particles larger than a predetermined size are filtered out, the silicon-saturated etching solution is heated to a second temperature to form a non-saturated etching solution for performing another etching process later. The second temperature is preferably at least 10° C. higher than the first temperature.

Owner:PROMOS TECH INC

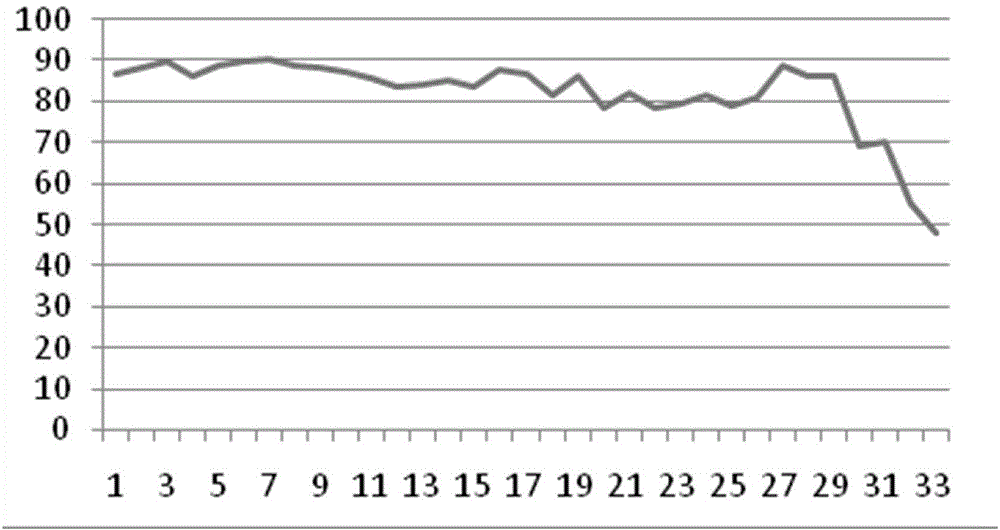

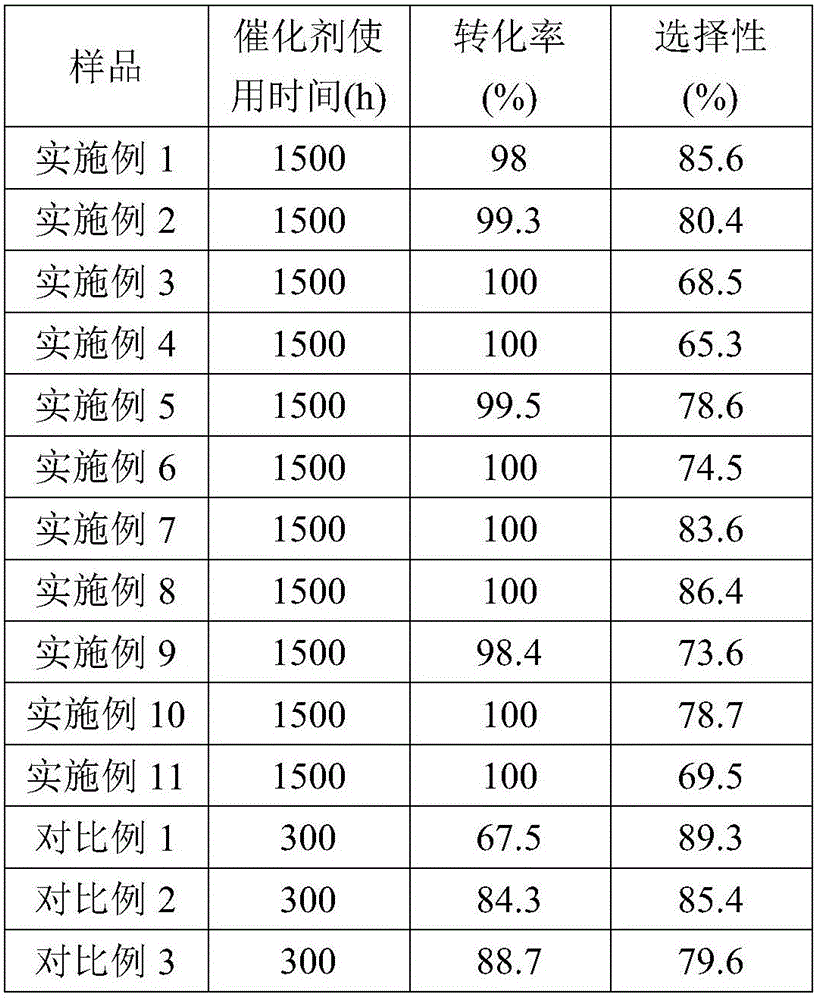

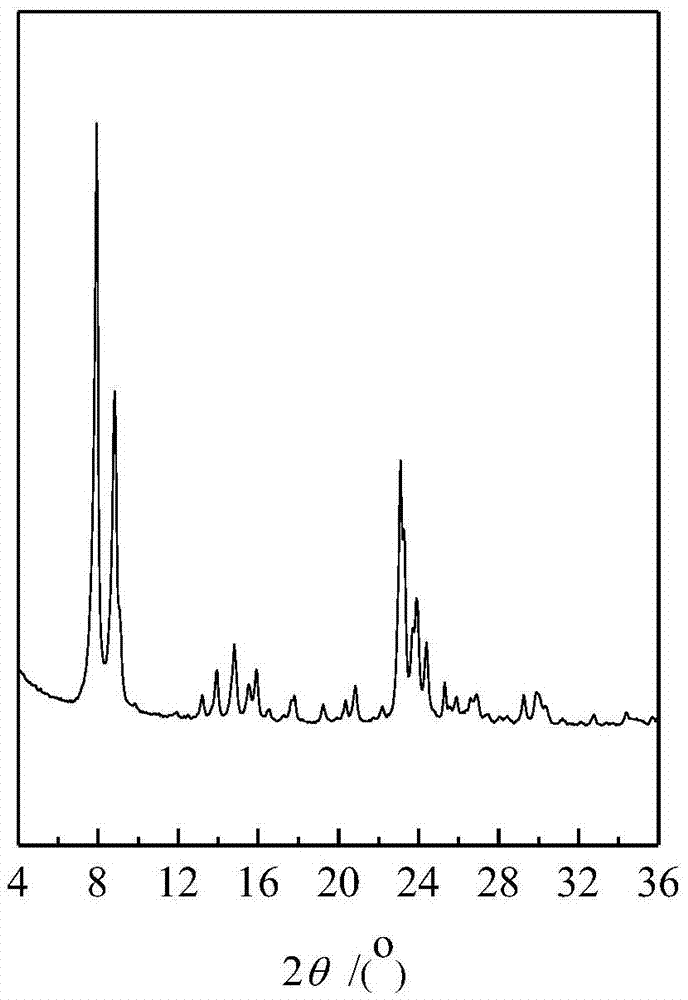

Method for preparing propylene by catalyzing methanol/dimethyl ether with composite molecular sieve with core-shell structure

InactiveCN102040448ASelective stabilityHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsChemical industryMolecular sieve

The invention belongs to the technical field of chemical industry, in particular to a method for preparing propylene by catalyzing methanol / dimethyl ether with a composite molecular sieve with a core-shell structure. In the invention, a composite molecular sieve catalyst consisting of an HZSM-5 molecular sieve and a mesoporous molecular sieve is adopted, methanol or / and dimethyl ether is / are used as raw material gas, water vapor and / or nitrogen are / is used as diluent gas to carry out a contact reaction to prepare propylene. The composite molecular sieve with the core-shell structure has the advantages that good propylene selectivity can be obtained, and better activity stability can be realized.

Owner:FUDAN UNIV +1

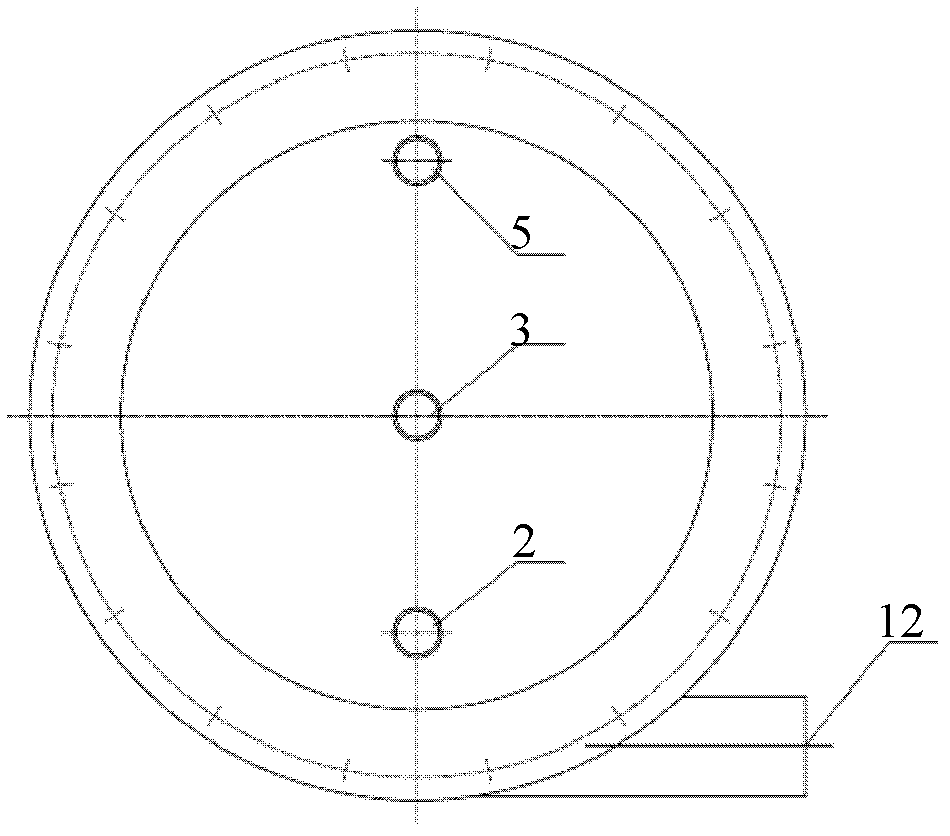

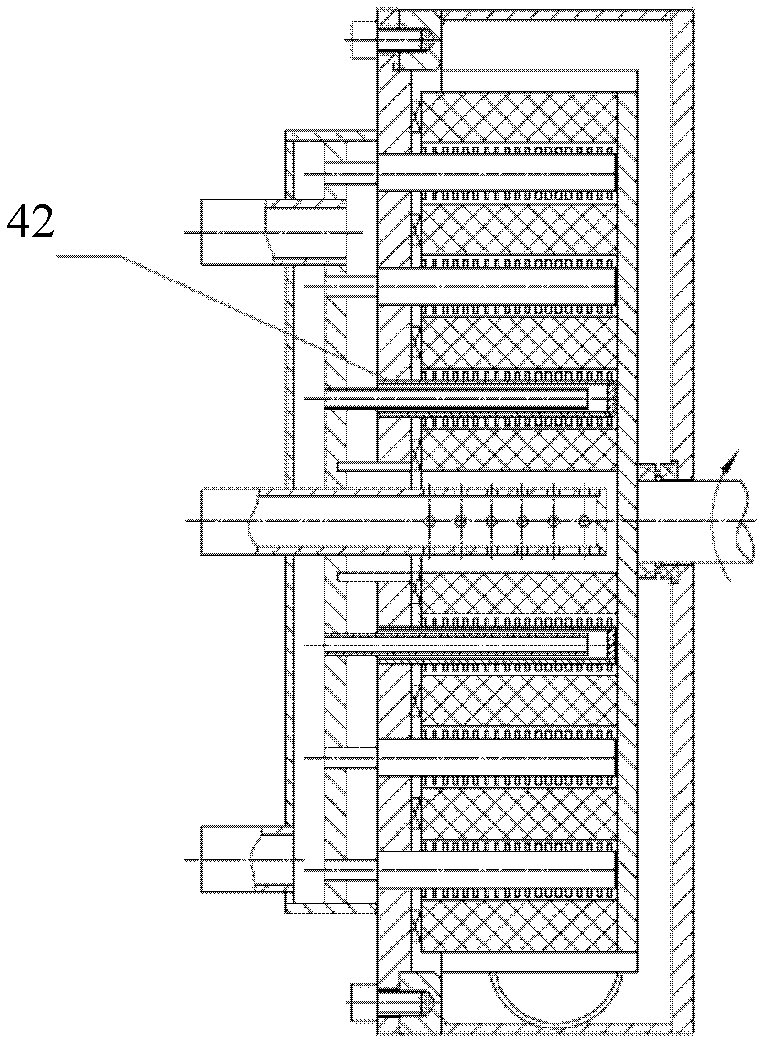

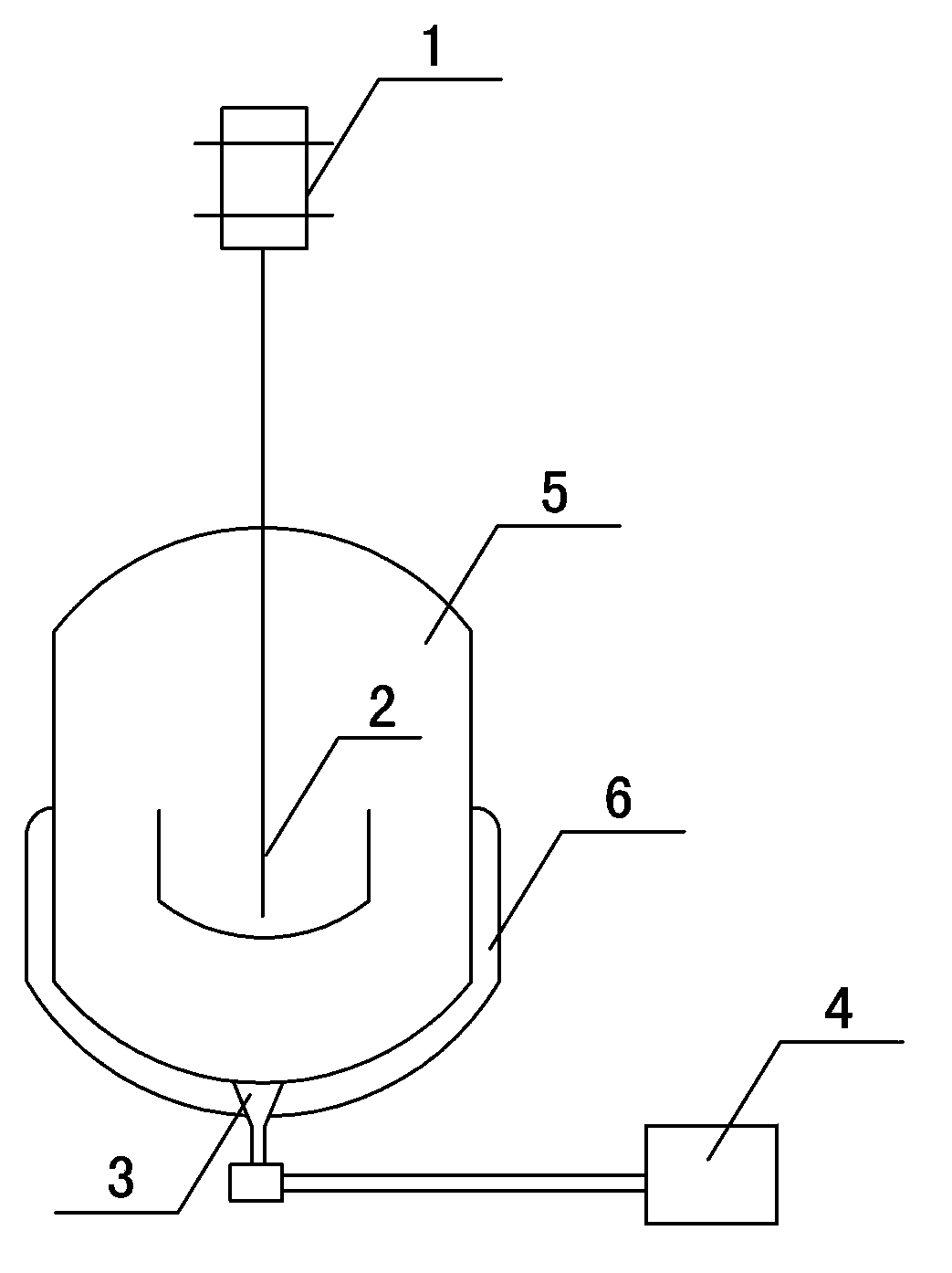

Reactor for distribution modulation of Fischer-Tropsch synthesis product and application thereof

ActiveCN102626600APrecise and controllable temperatureControl distributionLiquid hydrocarbon mixture productionChemical/physical/physico-chemical processesHypergravityProcess engineering

A reactor for distribution modulation of Fischer-Tropsch synthesis products and application thereof belong to the technical field of hypergravity reactor. The reactor comprises a sealed reactor shell, a rotor fixed with catalyst bed layers, a rotating shaft, an end cover, a reactant inlet and a reactant outlet. A rotor of a rotating packed bed catalytic reactor is provided with multiple concentric ring-type catalyst bed layers therein; an interlayer heat transfer section is arranged between every two catalyst bed layers, the interlayer heat transfer section is a concentric ring formed by multiple separated casings or heat pipes surronuding the center of the rotor; the end cover is provided with a heat transfer medium inlet and outlet devices; and the outer edge of the rotor is provided with blades. The rotating packed bed catalytic reactor changes the variety and amount of catalyst and inner structure and hypergravity level of the hypergravity reactor to synthesize products with specific component distribution with high selectivity. The hypergravity rotating packed bed catalytic reactor with a novel structure of the invention has advantages of orientated production of the target product, good heat and mass transfer performances and long service life of catalyst, etc.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for selectively hydrogenating acetylene in ethylene under normal pressure

InactiveCN102898266AStable conversion rateSelective stabilityHydrocarbon purification/separationHydrocarbonsGas phaseMixed gas

The invention discloses a method for selectively hydrogenating acetylene in ethylene under normal pressure. Ethylene mixed gas containing the acetylene is subjected to gas phase hydrogenation under normal pressure by using bimetallic A-B / TiO2 as a catalyst, the acetylene is selectively hydrogenated and reduced into ethylene, and the catalyst is an A-B / TiO2 catalyst obtained by a continuous bimetal photo-deposition method, wherein A is Pd, Pt, Au or Rh, and B is Ag, Cu or Ni. The A-B / TiO2 catalyst is used for selectively hydrogenating the acetylene under normal pressure, the ethylene can be reduced under the mild condition to form a hydrocarbon using the ethylene as a main product, and the selectivity of the catalyst is 80 to 97 percent. The method has technical feasibility, does not have secondary pollution, has a remarkable effect of selectively hydrogenating the acetylene in the ethylene, and has high economic and environmental benefits.

Owner:NANJING UNIV

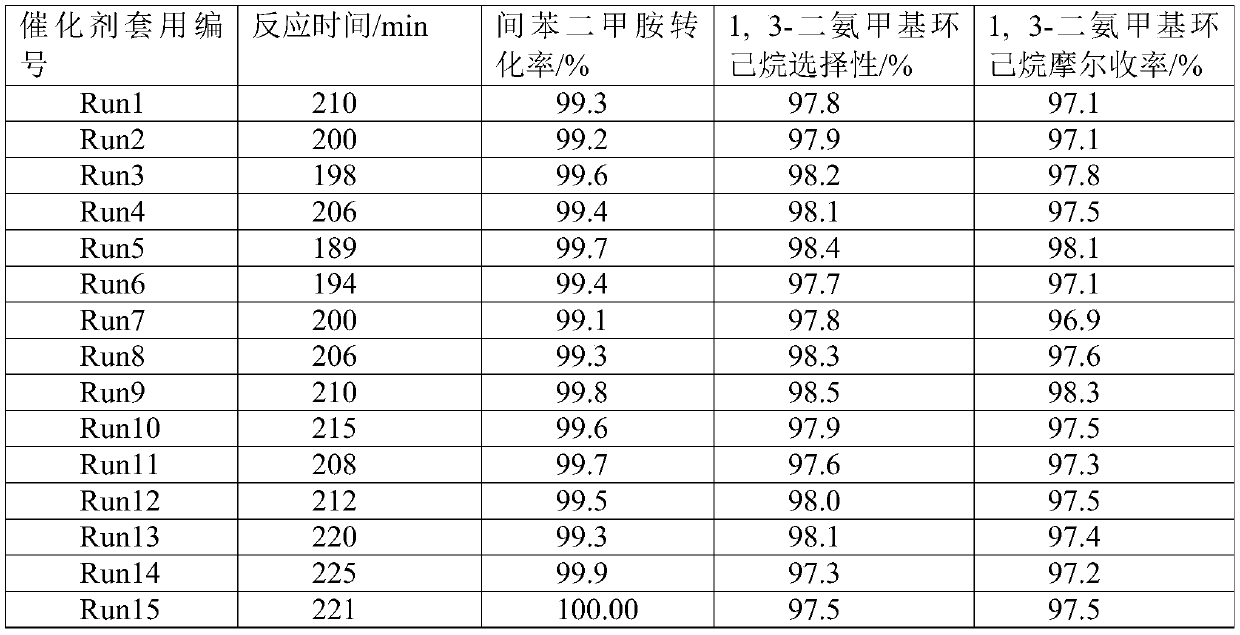

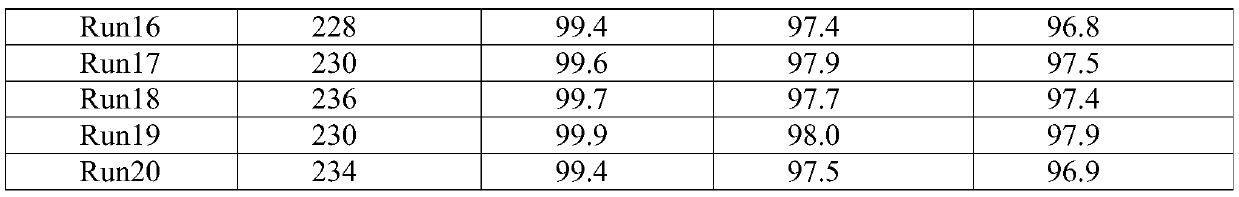

Catalyst for synthesis of bis(aminomethyl)cyclohexane and preparation method and application thereof

ActiveCN110433823AAdjust adsorptionHigh reactivityOrganic compound preparationAmino compound preparationActive componentHigh activity

The invention relates to a catalyst for synthesis of bis(aminomethyl)cyclohexane. The catalyst is prepared from a carrier, active components and additives, wherein the active components and the additives adhere to the carrier. The active components are selected from one or more of metals such as Ru, Rh, Ni, Co, Pt and Pd, and preferably, the active components are the metal Ru and are selected fromone or more of the metals such as Rh, Ni, Co, Pt and Pd; and the additives comprise a first additive and a second additive, the first additive is selected from one or more of Mn, Cr, Li and Ca, and the second additive is selected from one or more of Fe, Cu, Zn, Ag, Sn, La and Ce. Compared with the prior art, the catalyst is high in activity, good in selectivity and long in life, liquid ammonia oralkali metal hydroxides do not need to be added in a reaction system to serve as an deamination inhibitor, and thus the hydrogenation of benzene dimethylamine can be catalyzed so as to obtain bis(aminomethyl)cyclohexane in high-activity and high-selectivity modes.

Owner:WANHUA CHEM GRP CO LTD

Nickel base selective hydrogenation catalyst, preparation method and application thereof

ActiveCN103769104AAnti-glueResistant to arsenicMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationPetrochemicalPetroleum

The invention belongs to the technical field of petrochemical industry, and particularly relates to a nickel base selective hydrogenation catalyst for gasoline cracking, a preparation method and an application thereof, wherein the nickel base selective hydrogenation catalyst adopts nickel as an active component, adopts Al2O3 as a carrier, and contains (calculated as the weight of the oxide) 8-20 wt.% of Nio and the balance of Al2O3, the carrier is a theta-Al2O3 and delta-Al2O3 mixed phase carrier, the specific surface area of the catalyst is 110-130 m<2> / g, the pore volume is 0.40-0.45 mL / g, pore size distribution of the catalyst is centralized, the radius of more than 70% of the pores is 5-10 nm, and the average pore radius is 6-8 nm. According to the present invention, the catalyst adopts the metal Ni as the active component, adopts the theta and delta mixed phase alumina as the carrier, has characteristics of a certain gum resistance, a certain arsenic resistance, high hydrogenation load bearing, stable selectivity and stable activity, and is suitable for the first section selective hydrogenation in gasoline cracking; and the preparation method has characteristics of simpleness, easy performing and easy operation.

Owner:CHINA PETROLEUM & CHEM CORP

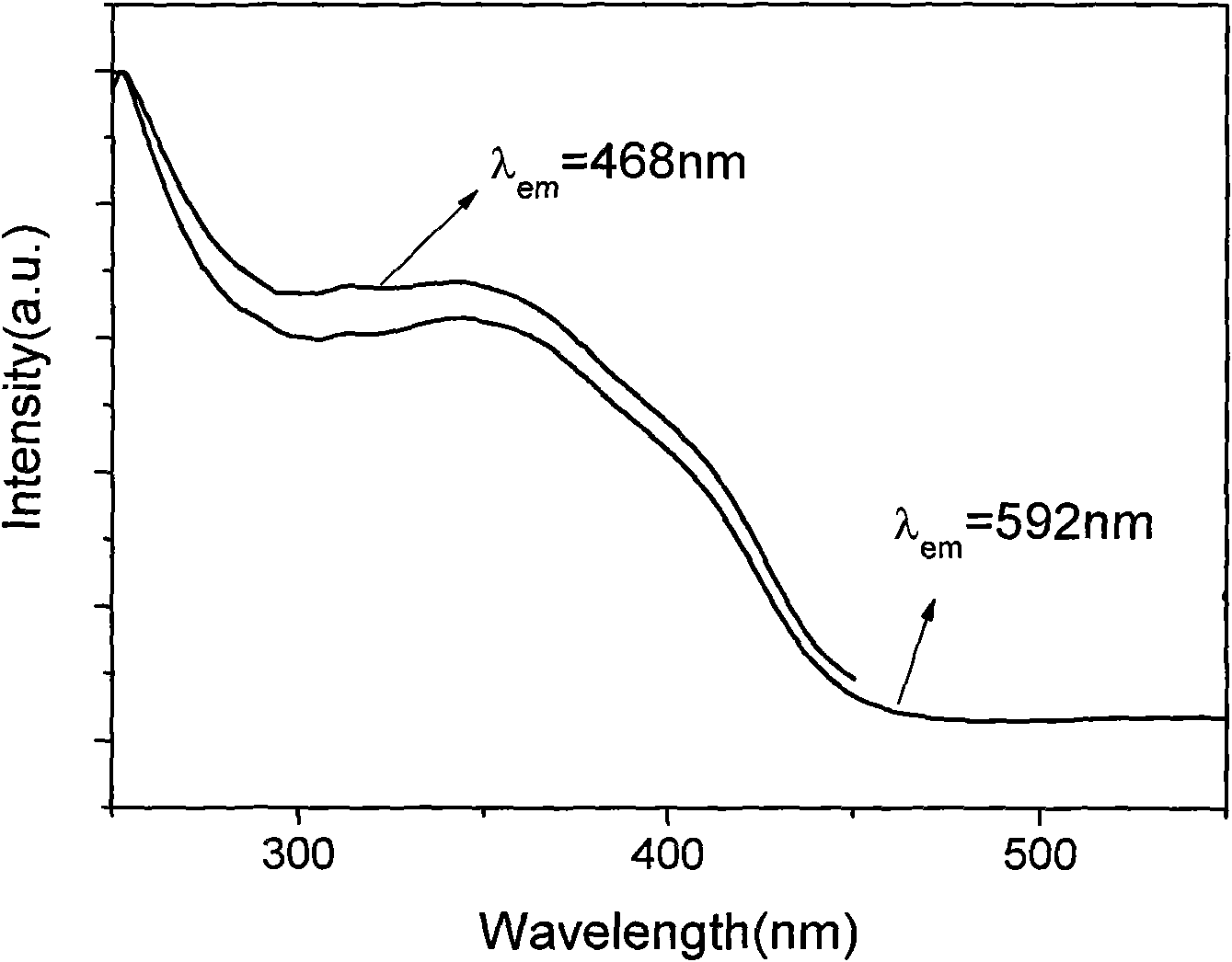

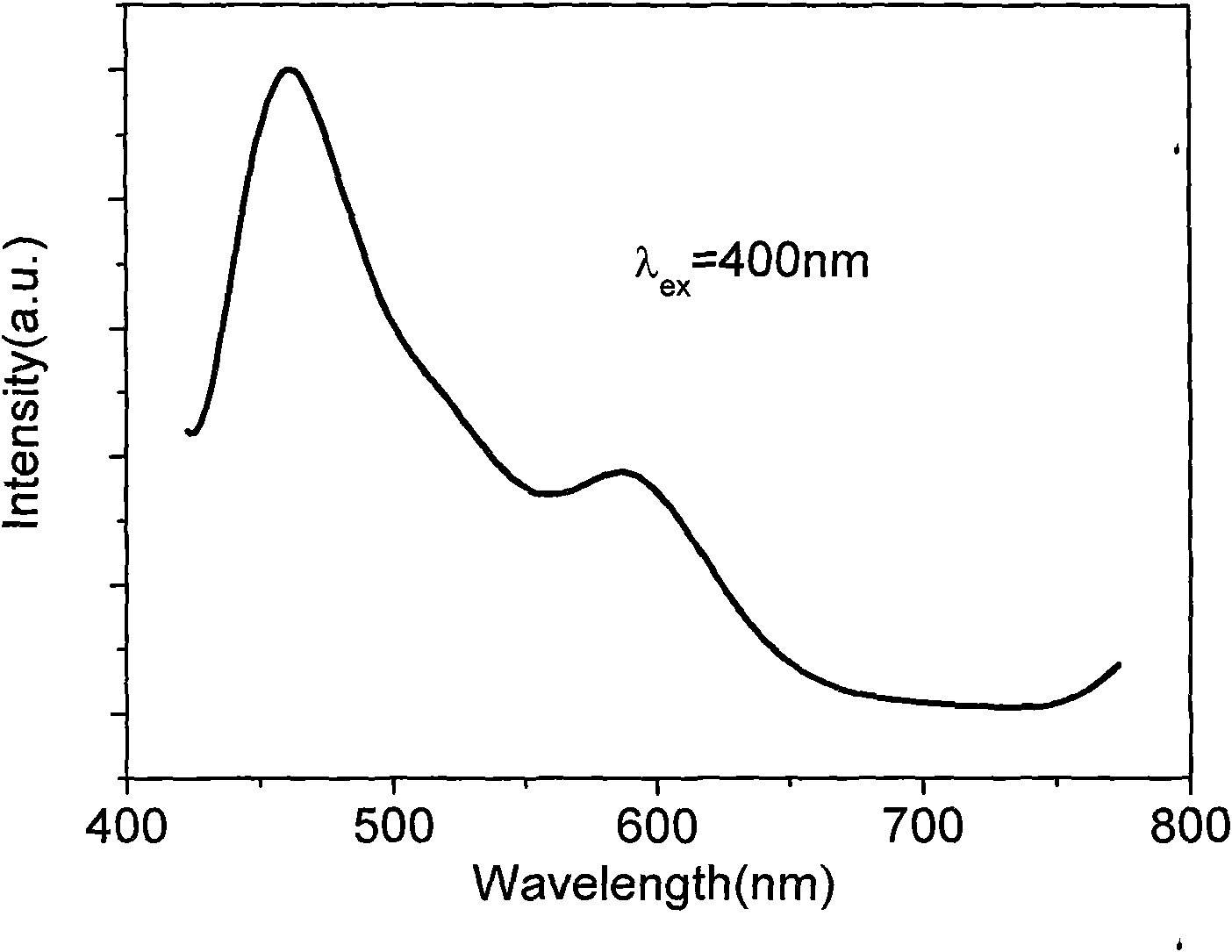

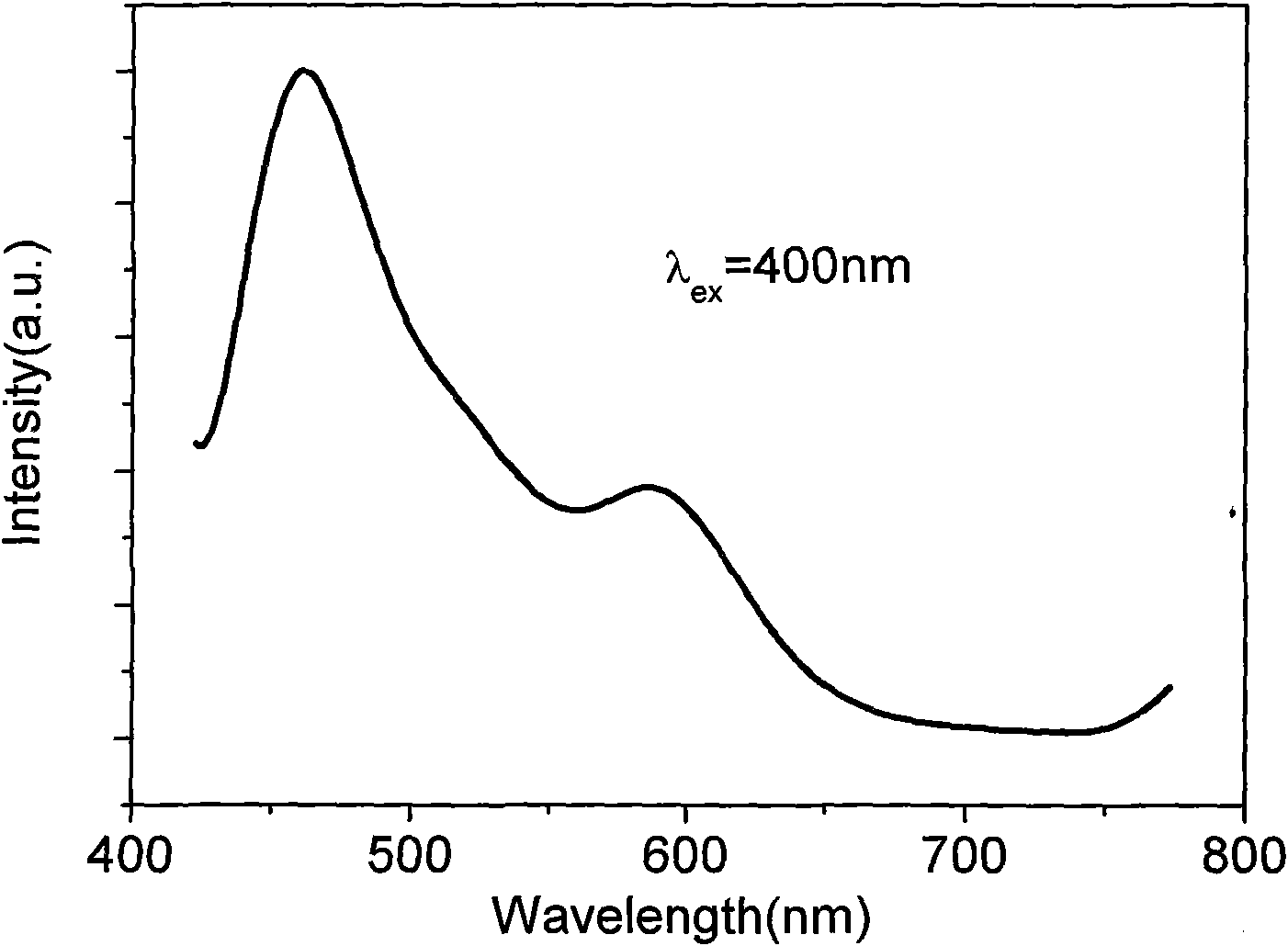

Single-matrix white fluorescent powder, manufacturing method thereof and light emitting device manufactured thereby

InactiveCN101880528AWide excitation spectrumHigh emission intensityGas discharge lamp usageLuminescent compositionsLuminous intensityUltraviolet lights

The invention relates to a single-matrix white fluorescent powder, a manufacturing method thereof and a light emitting device manufactured thereby. The chemical formula of the involved fluorescent powder is Ba(3-m-n-a)AaLu2-bRbSi3O12:mEu2+,nMn2+. The method comprises the following steps of: mixing and uniformly grinding all raw materials; roasting the mixture in reducing atmosphere at a high temperature; and performing post-processing to obtain the fluorescent powder. The fluorescent power has the characteristics of high chemical stability, super-wide excitation waveband, adjustable emission wavelength as required, high luminous intensity and the like and has the advantages of simple method, no pollution and low cost. A white LED and a warm tone light source can be manufactured by using ultraviolet light or a ultraviolet LED chip and the fluorescent powder of the invention.

Owner:JIANGXI UNIV OF SCI & TECH

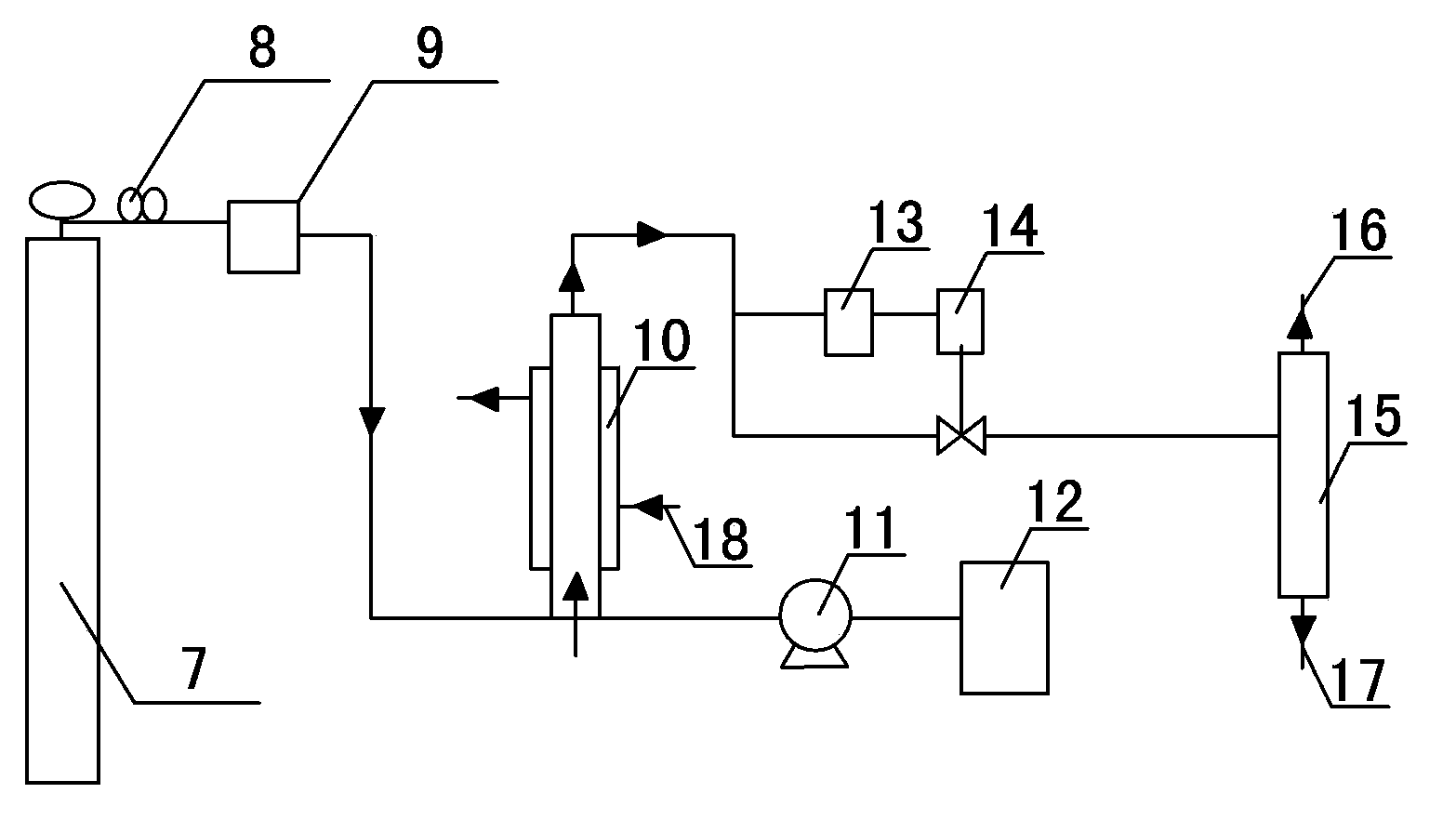

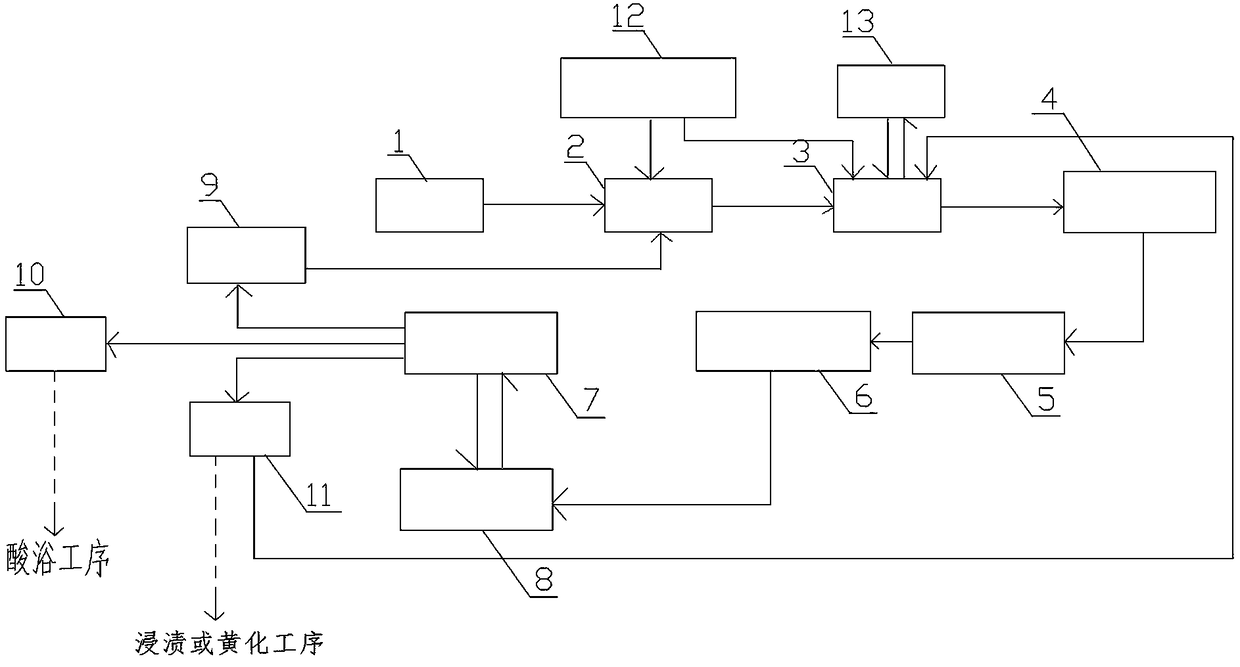

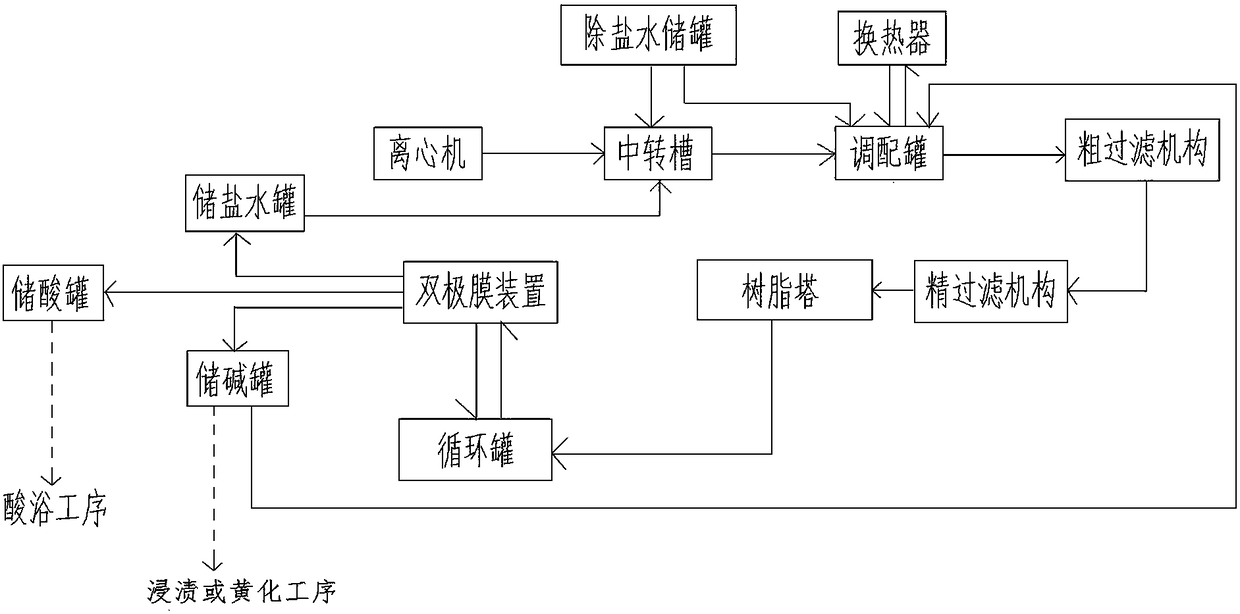

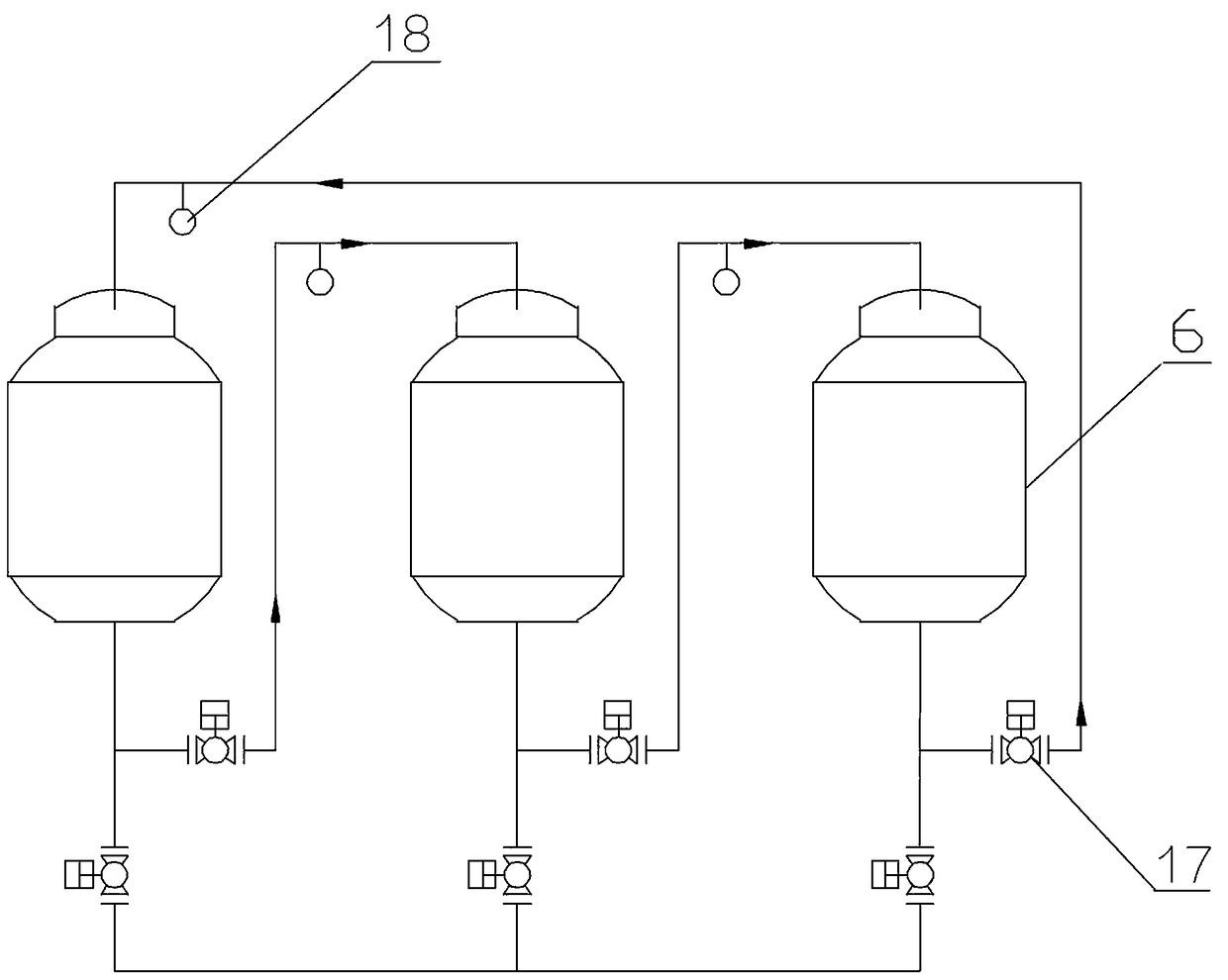

Circulating environment-friendly treatment process and circulating environment-friendly treatment system for waste viscose liquid

PendingCN109133448AGuaranteed purityGuaranteed concentrationWater/sewage treatment by centrifugal separationGeneral water supply conservationLiquid wasteFiltration

Owner:YIBIN HIEST FIBER +2

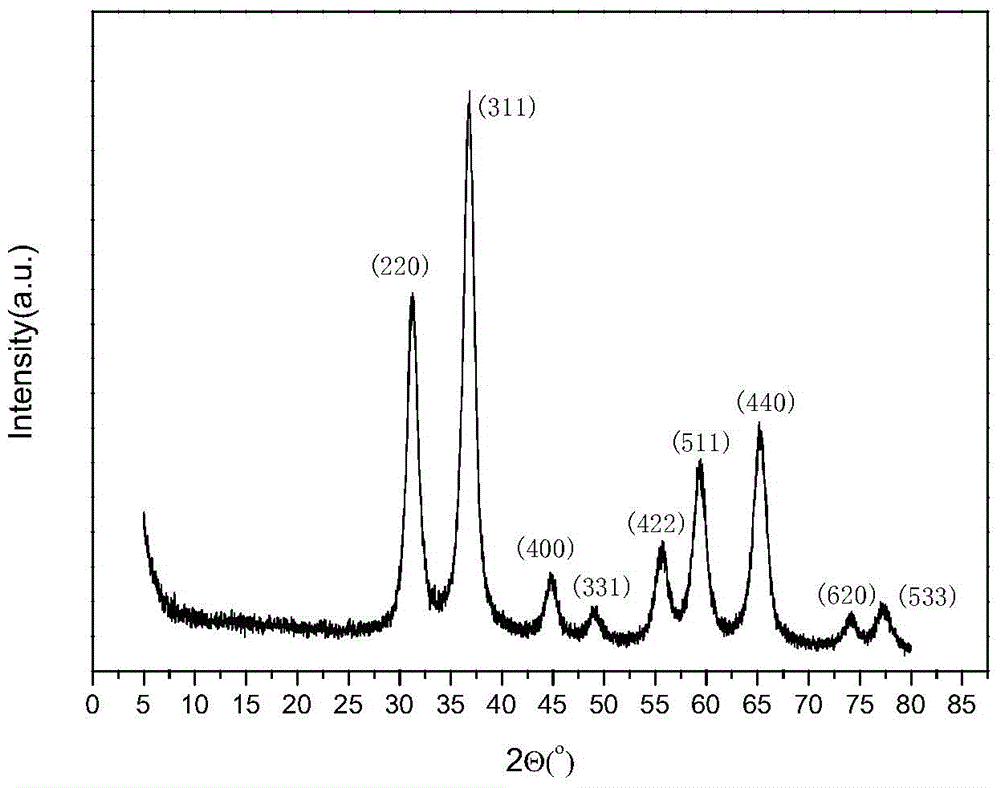

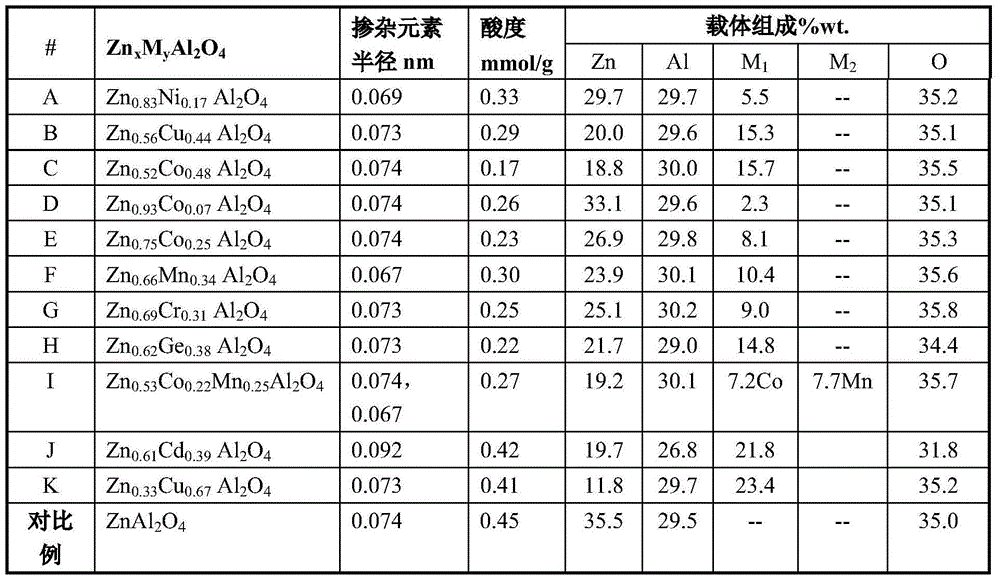

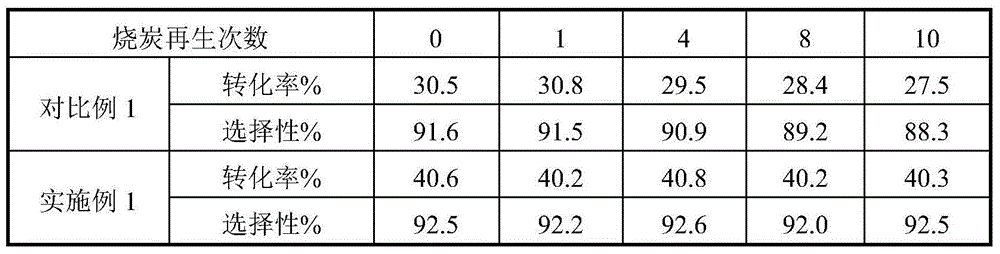

Low-carbon olefin catalyst made through dehydrogenation of low-carbon alkane and use method of low-carbon olefin catalyst

ActiveCN105363472AReduce acidityGood dispersionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneCooking & baking

The invention relates to a low-carbon alkane dehydrogenation platinum catalyst and a use method thereof and mainly solves the problems that in an existing preparation method, the catalyst conversion rate is low, and the selectivity is lowered in the use process. According to the low-carbon alkane dehydrogenation platinum catalyst and the use method thereof, firstly, a coprecipitation method is adopted for introducing copper, nickel, manganese, cobalt and other transition metal elements into a zinc aluminate carrier, and a composite metal oxide carrier is obtained; then an impregnation method is adopted, platinum components are loaded, in other words, a water solution of soluble salt of platinum is dipped, and the platinum catalyst is obtained after drying, baking and stream treatment. Propane / iso-butane serve as raw materials, the raw materials are in contact with the catalyst in the conditions that the reaction temperature is 520-620 DEG C, the reaction pressure is 0-0.4 MPa, the alkane mass airspeed is 0.1-8.0 h<-1>, the H<2>O / C<n>H<2n+2> volume ratio is 1-18, a reaction is condnucted, and propane / iso-butane are generated, by means of the technical scheme, the problem is well solved, and the low-carbon alkane dehydrogenation platinum catalyst and the use method thereof can be used for industrial application of low-carbon olefin catalysts made through dehydrogenation of low-carbon alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of coating catalyst and coating catalyst prepared by using method

ActiveCN104801351AHigh strengthIncrease profitOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidSlurry

The invention relates to a preparation method of a coating catalyst and the coating catalyst prepared by using the method. The coating catalyst comprises a spherical inert carrier and polyvinylpyrrolidone-loading outer active components of heteropolyacid, wherein heteropolyacid uses phosphorus, molybdenum, vanadium, copper and arsenic as essential elements. In the catalyst preparation process, the slurry obtained by dispersing heteropoly acid catalyst powder into ethyl alcohol and an ethanol solution of polyvinylpyrrolidone are sprayed on the spherical inert carrier at the same time to obtain the coating catalyst. The coating catalyst forms specifically distributed holes after calcining, has high intensity and is high in conversion rate and selectivity when used to catalyze (methyl) acraldehyde to prepare (methyl) acroleic acid with vapour-phase oxidation.

Owner:WANHUA CHEM GRP CO LTD

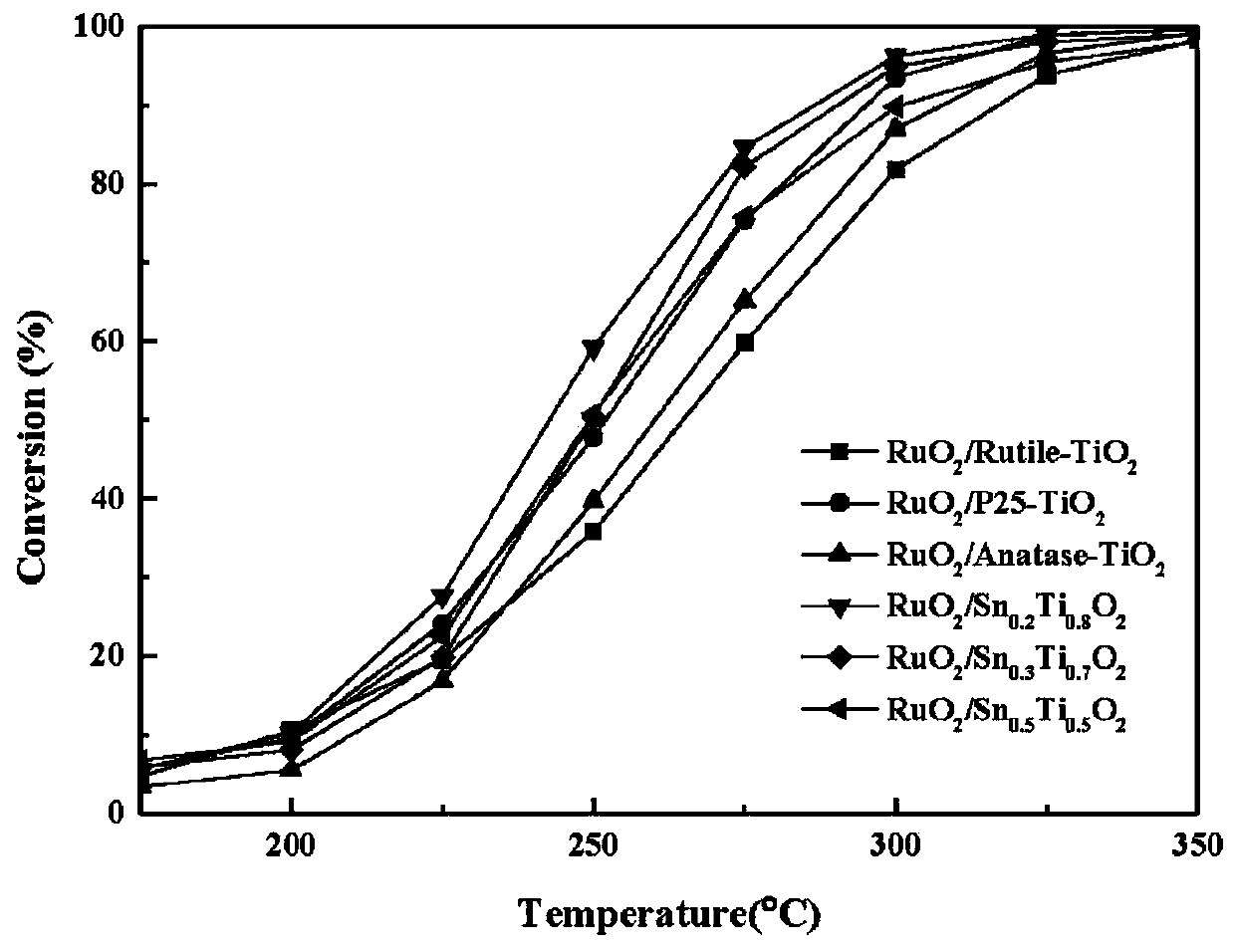

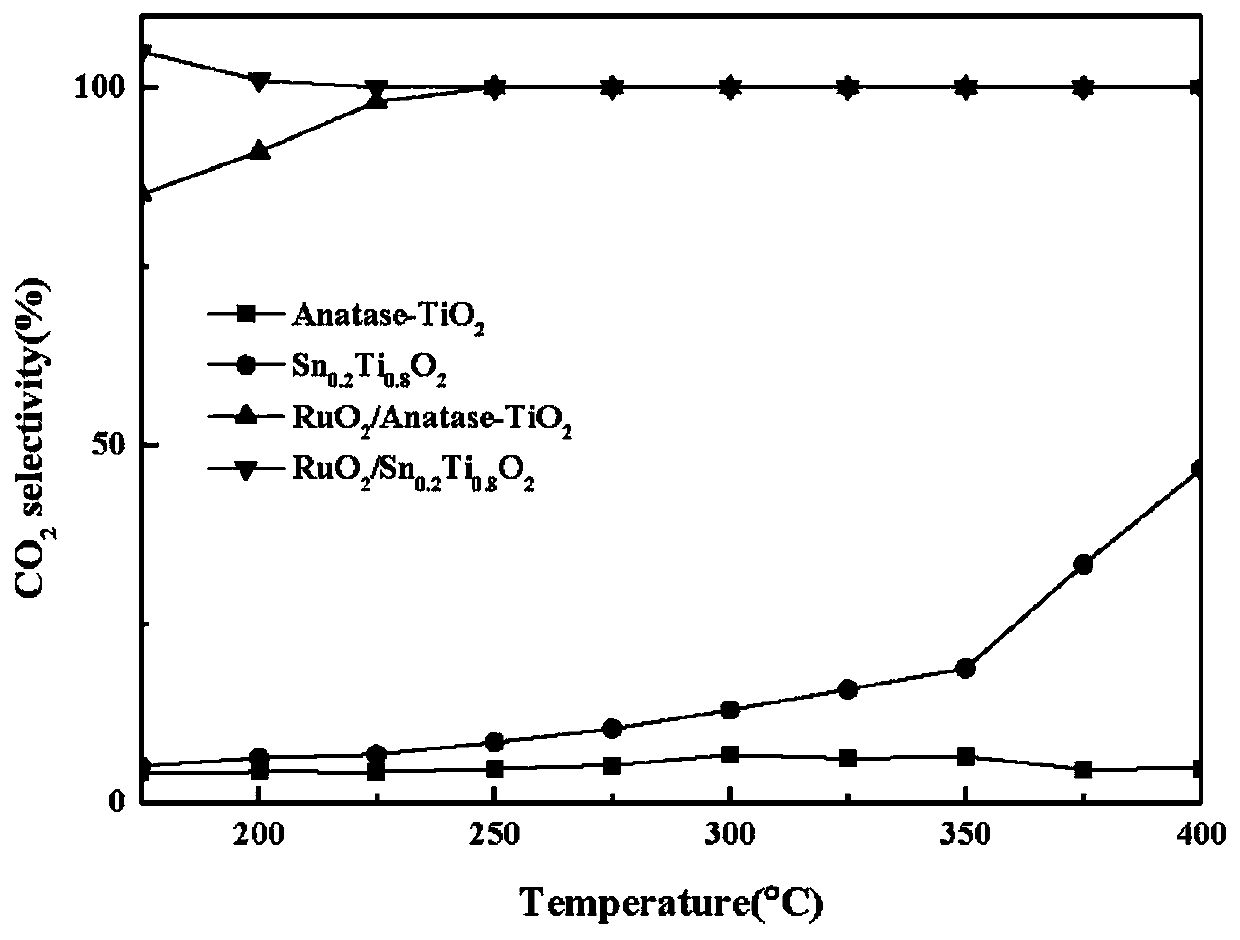

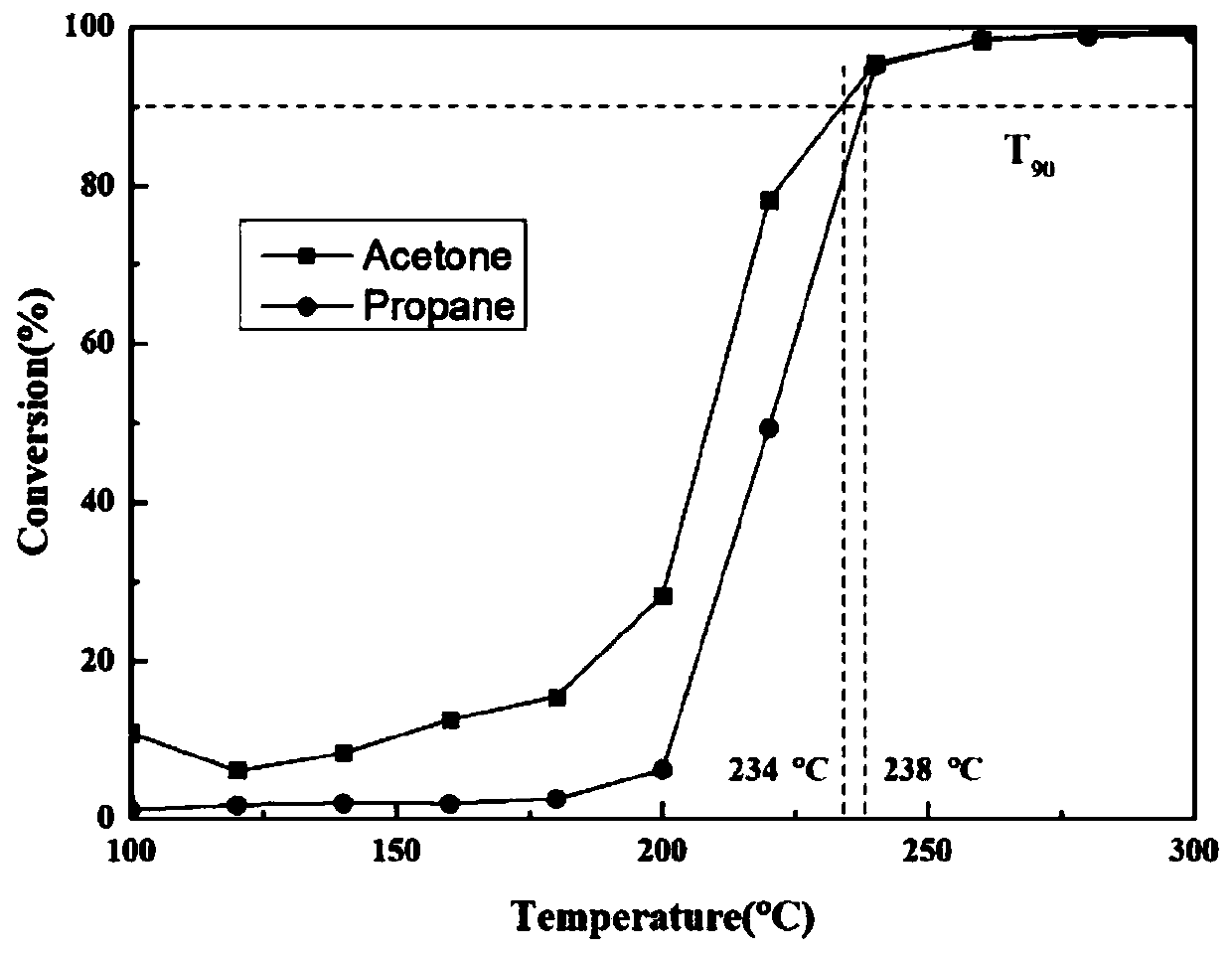

Volatile organic compound catalytic oxidation catalyst with high chlorine poisoning resisting efficiency, and preparation method thereof

ActiveCN110404534AGood dispersionRealize regulationGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHigh activationOrganic synthesis

The invention relates to a volatile organic compound catalytic oxidation catalyst with a high chlorine poisoning resisting efficiency, and a preparation method thereof. The catalyst adopts RuO2 as anactive component, and adopts a SnyTi1-yO2 or MOx-SnyTi1-yO2 mixed metal oxide as a carrier. TiO2 is doped with Sn to realize the regulation of the crystal form of the carrier oxide, so the dispersiondegree of RuO2 on the surface of the carrier is greatly improved while constructing the tin-titanium-based catalyst carrier with a high activation performance; and the catalyst has the characteristicsof high catalytic activity to chlorine-containing volatile organic compounds, strong chlorine poisoning resistance, and high selectivity of the product to CO2, has a good removal effect on common volatile organic compounds, and can be widely used in treatment of chlorine-containing organic waste gases in the fields of pharmaceutical, organic synthesis and paint spraying.

Owner:ZHEJIANG UNIV

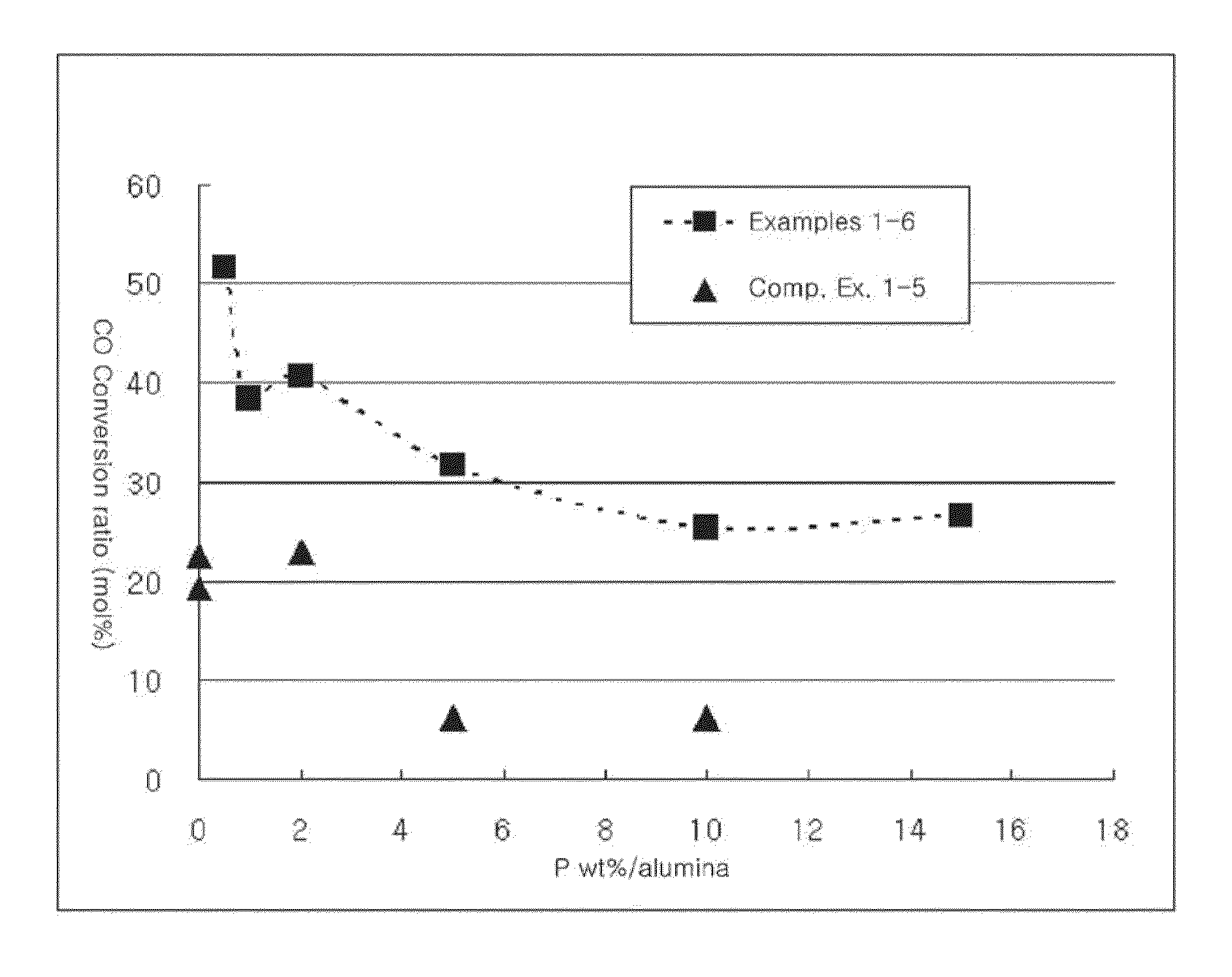

Preparing phosphorus containing alumina support by sol-gel method for fischer-tropsch synthesis and catalyst preparation thereof

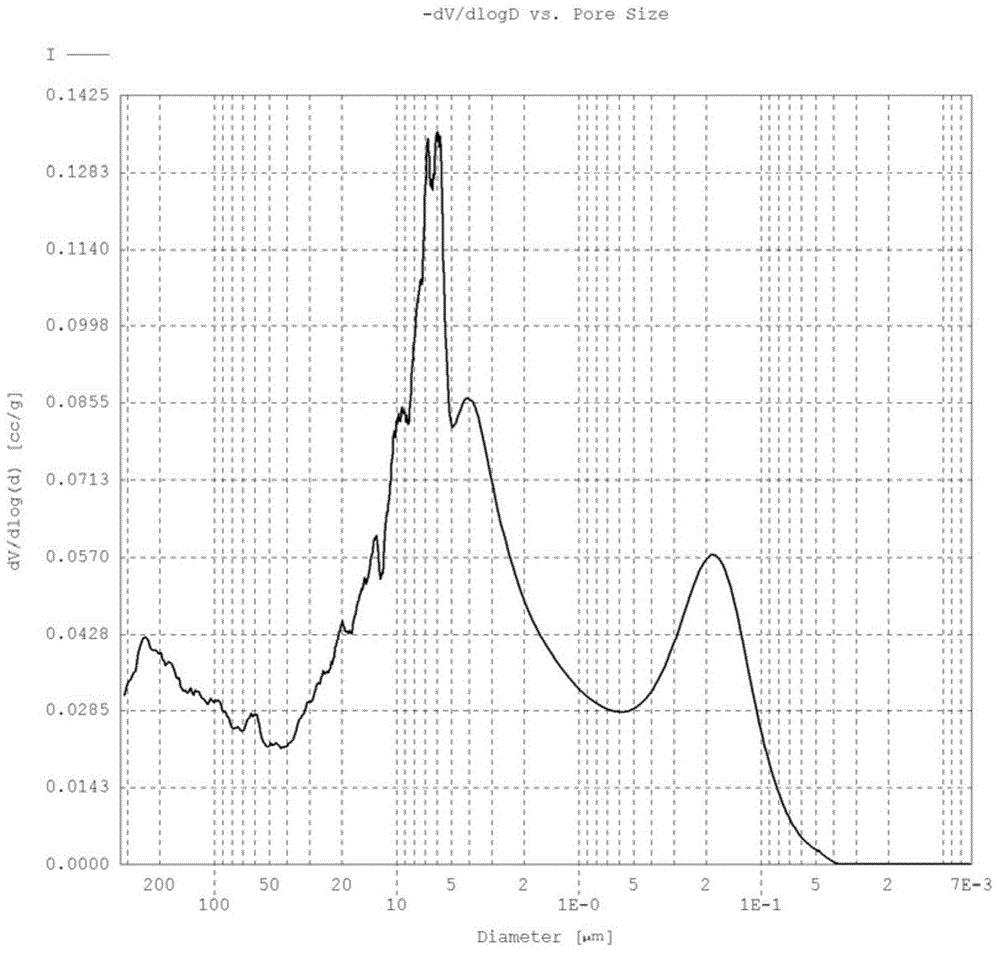

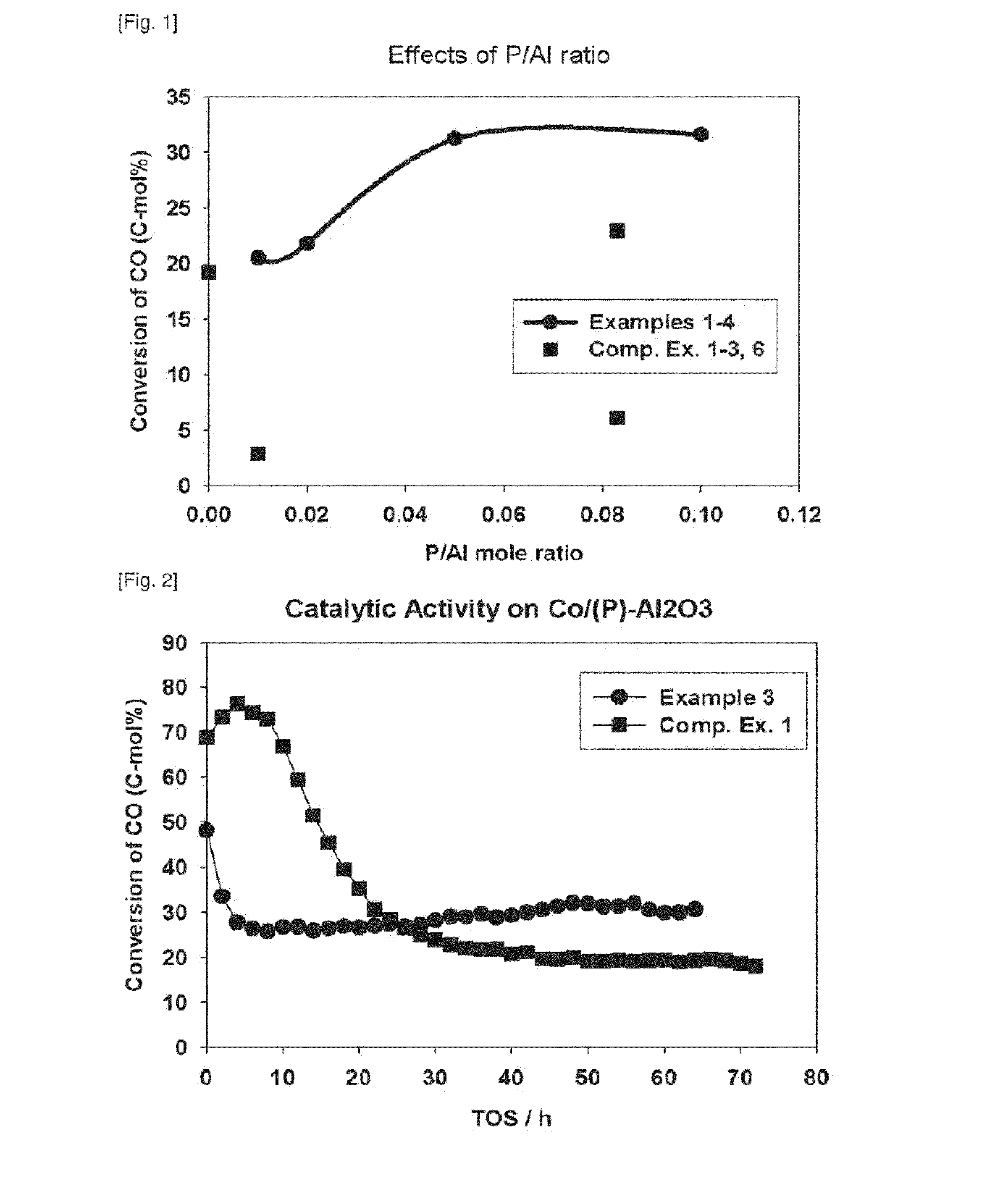

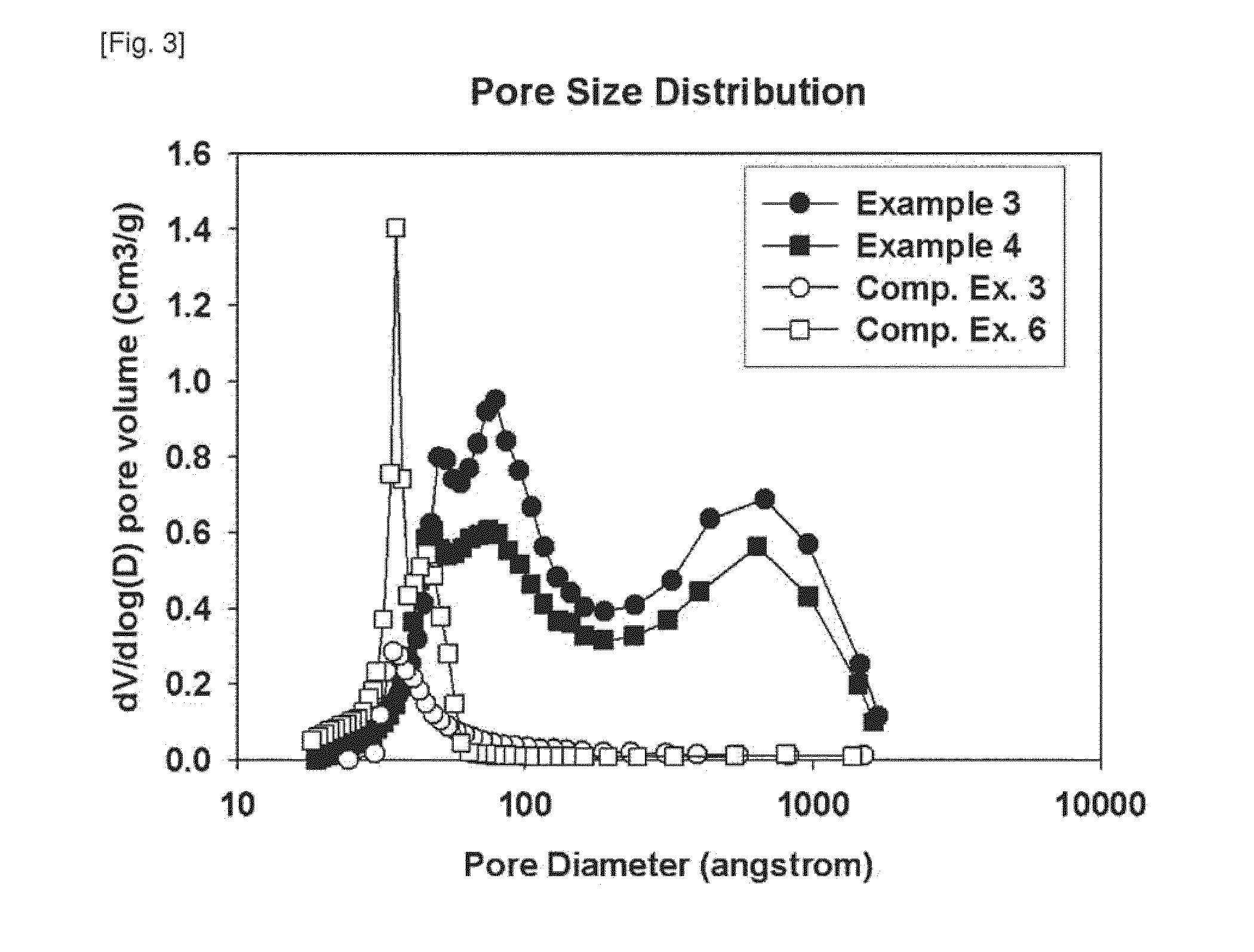

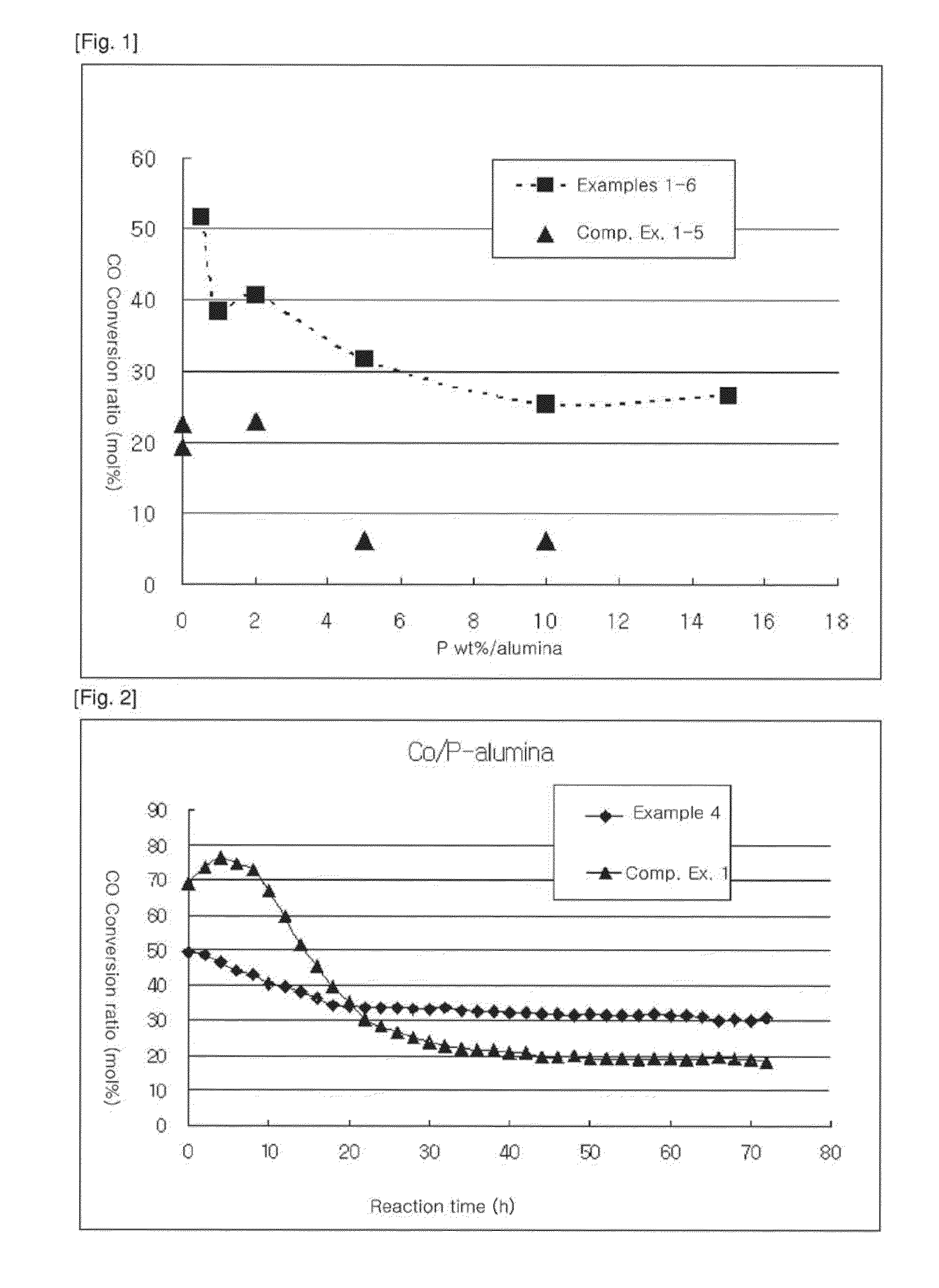

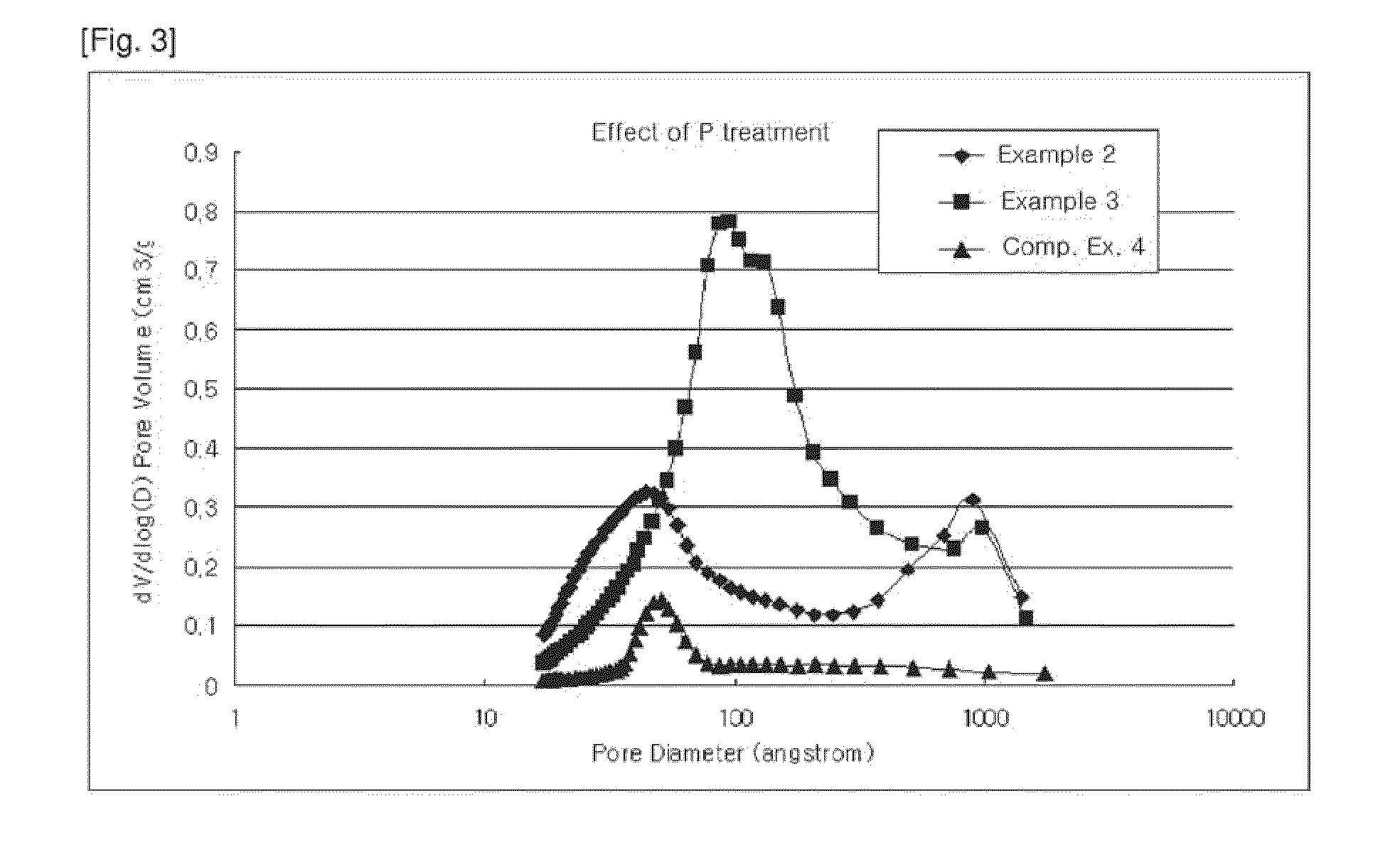

InactiveUS20100130349A1Increase heat and mass transferDecrease deactivation rateCatalyst activation/preparationLiquid hydrocarbon mixture productionSol-gelLiquid hydrocarbons

The present invention relates to a process of preparing of a phosphorus-containing phosphorus-alumina support by a sol-gel method and a cobalt / phosphorus-alumina catalyst where cobalt is supported onto the phosphorus-alumina support as an active ingredient. The phosphorus-alumina support is prepared by a sol-gel method and has wide specific surface area with bimodal pore size distribution and high cobalt dispersion, thereby enabling to increase heat and mass transfer, stabilize the structure by modifying the surface property of alumina and decrease the deactivation rate due to the reduced oxidation of cobalt component during the F-T reaction. When Fischer-Tropsch reaction (F-T) is conducted on the catalyst, the catalyst maintains a superior thermal stability, inhibits the deactivation due to water generation during the F-T reaction and also causes relatively high conversion of carbon monoxide and stable selectivity of liquid hydrocarbons.

Owner:KOREA GAS CORPORATION +2

Production method for preparing trialkoxysilane by adopting direct method

ActiveCN104387413AIndustrial production process improvementSimple production processSilicon organic compoundsAlcoholSilanes

The invention provides a production method for preparing trialkoxysilane by adopting a direct method. According to the production method, firstly a copper compound is used as a precursor for preparing a catalyst intermediate body, the catalyst intermediate body is activated to form a silicon-copper intermetallic compound catalyst with catalytic activity, and the silicon-copper intermetallic compound catalyst is applied to industrial production in which the direct reaction of silicon and alcohol is catalyzed by the silicon-copper intermetallic compound catalyst in order to prepare the trialkoxysilane. An intermittent-continuous operation method is adopted to replace intermittent operation process for production, liquid alcohol is added continuously and silicon powder is replenished in batches during production, and synthesis condition is regulated duly so as to adapt to a stable production process. Besides, technological processes such as product separation, purification, suspending agent recycling and tail gas recycling are improved as well. In crude products generated in the overall reaction process, the content of trimethoxy silane is about 80%; the utilization rate of silicon powder in production adopting an intermittent process is as high as 83%; if an improved intermittent-continuous production process is adopted, the utilization rate of the silicon powder can be increased by more than 10%.

Owner:湖北武大有机硅新材料股份有限公司 +1

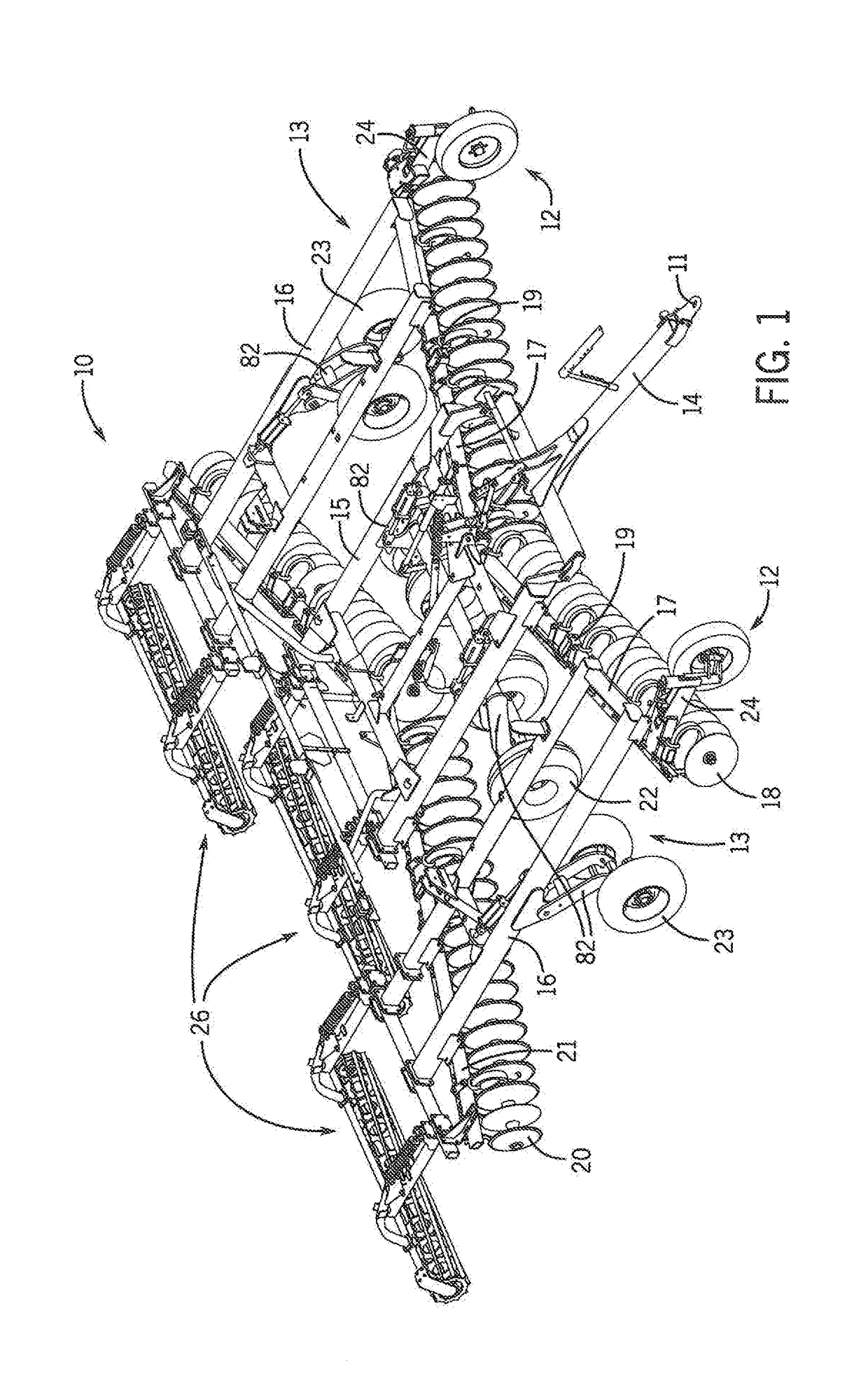

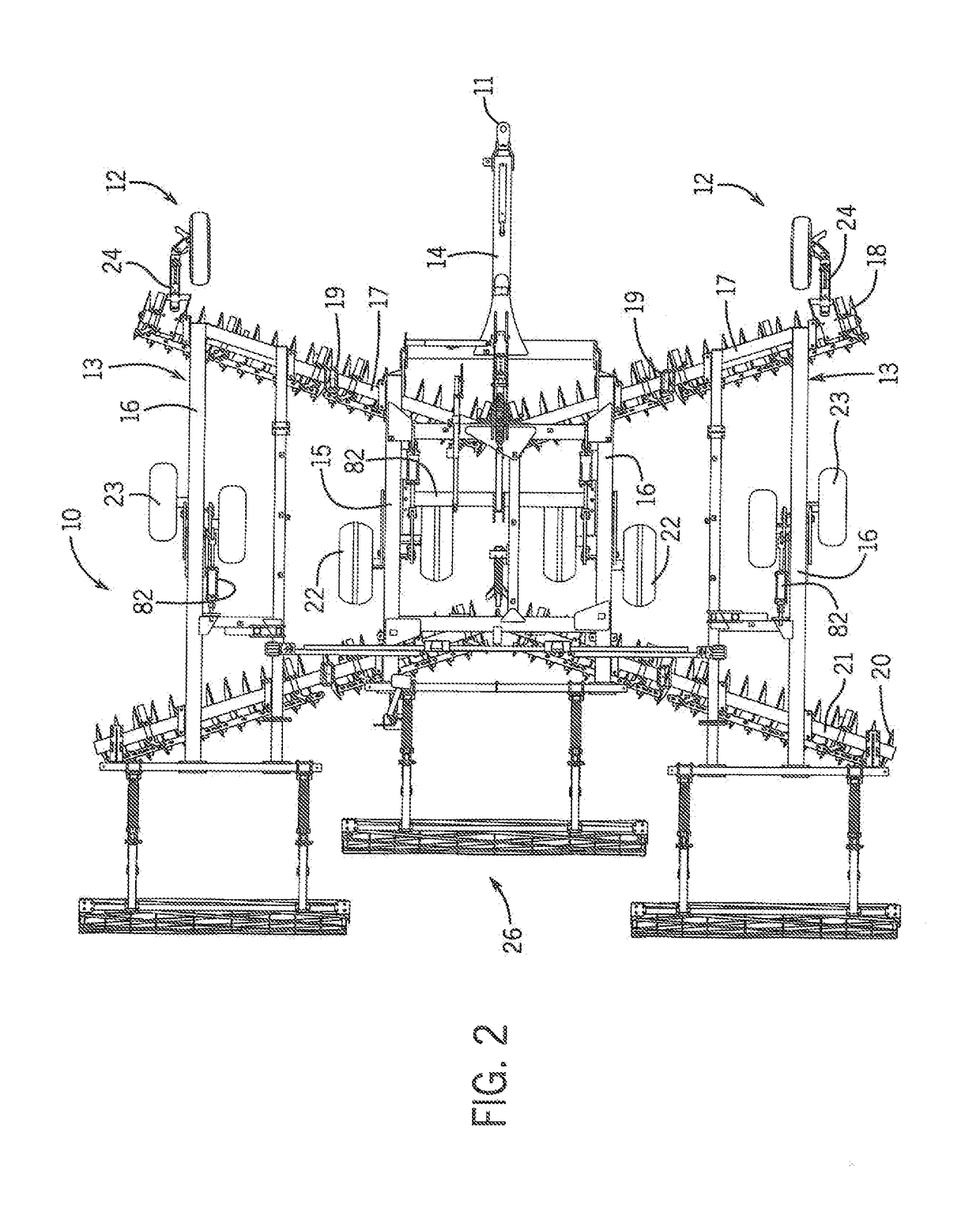

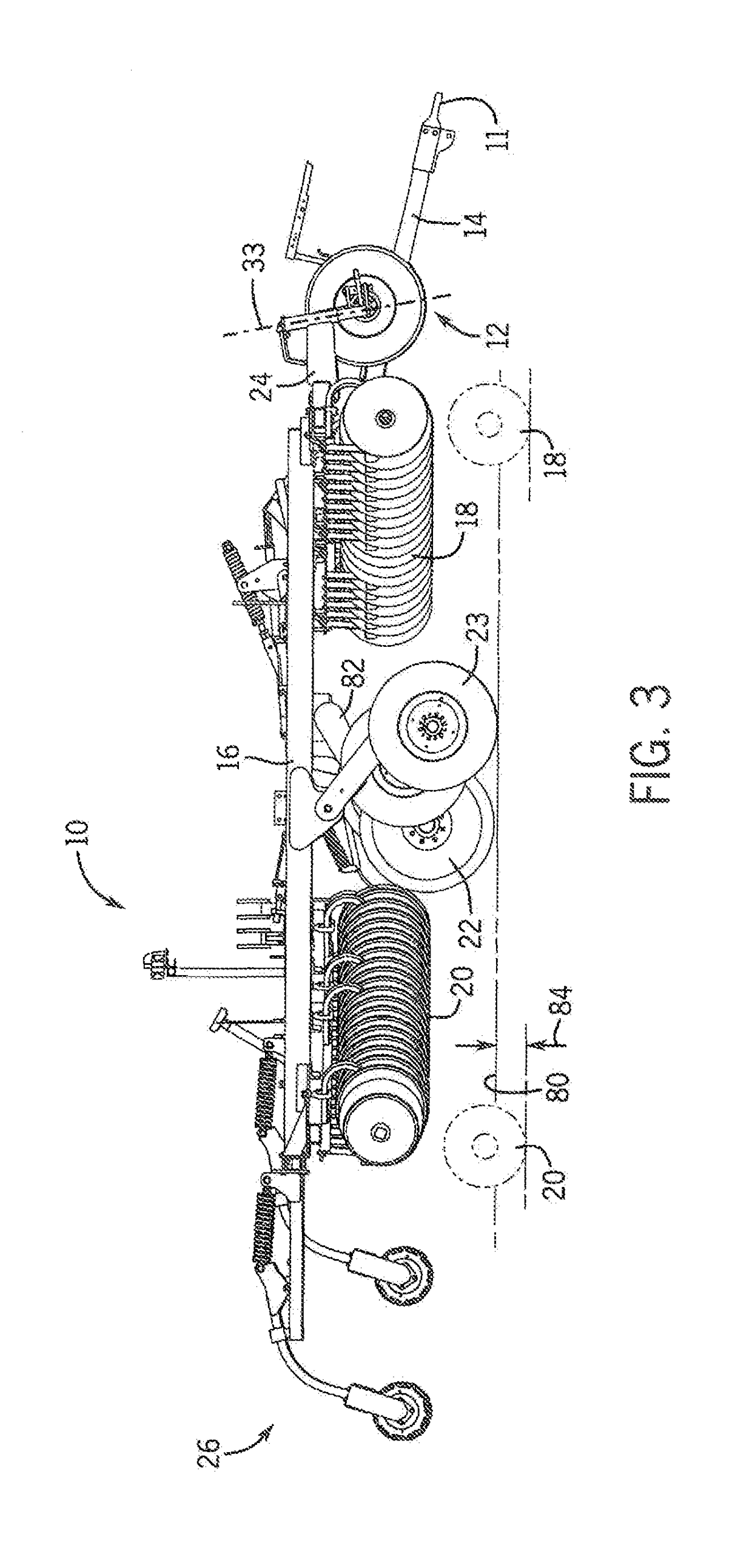

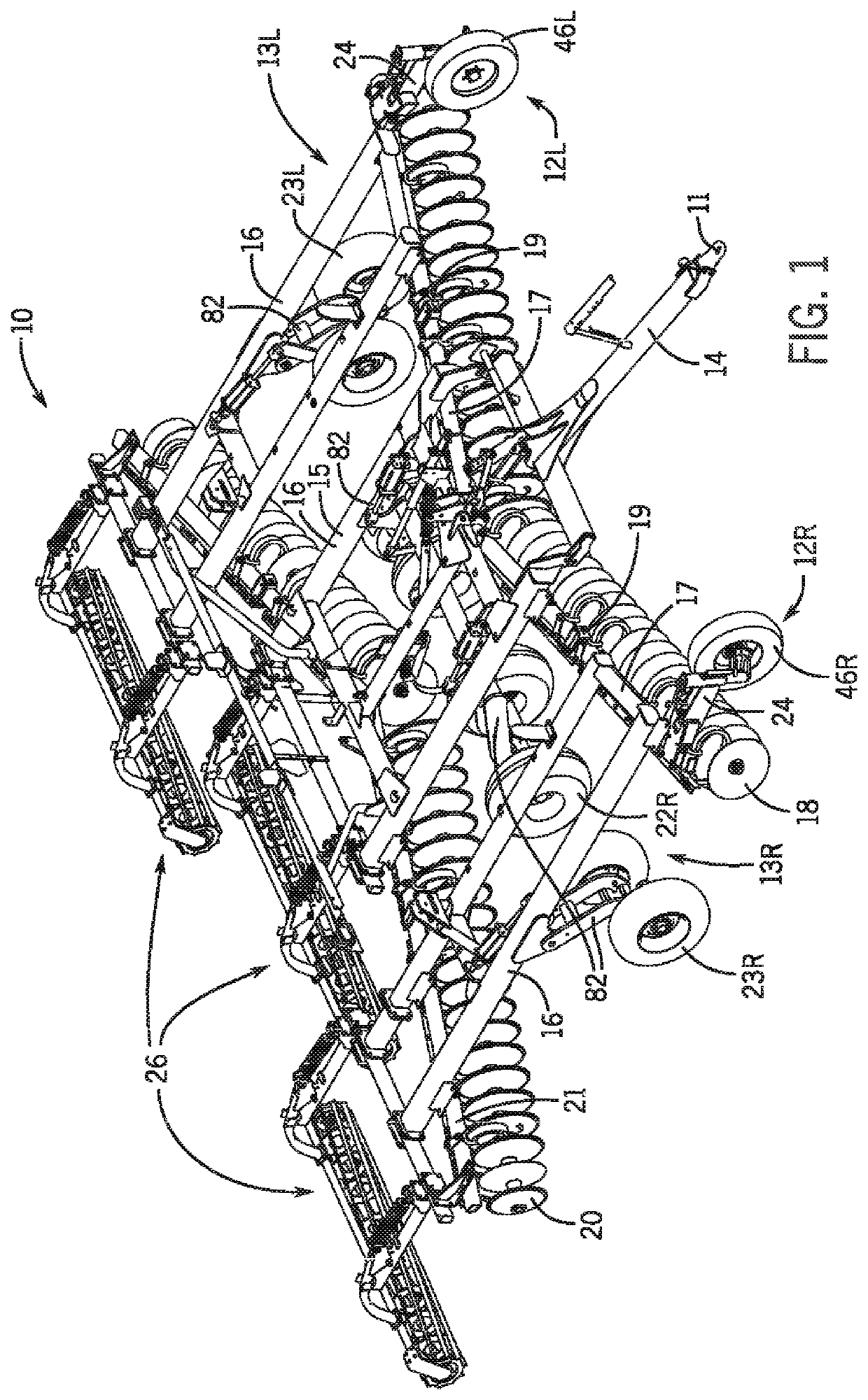

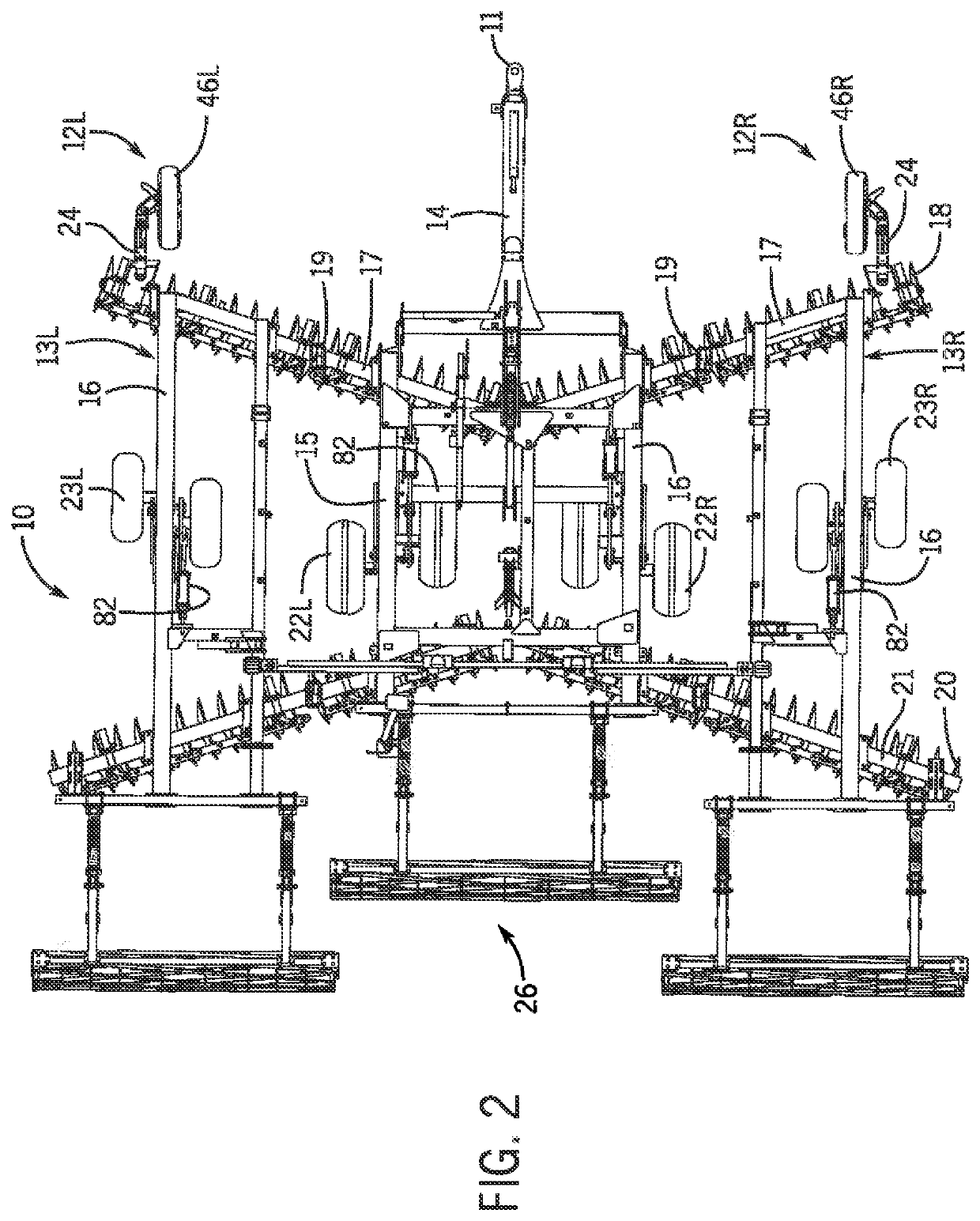

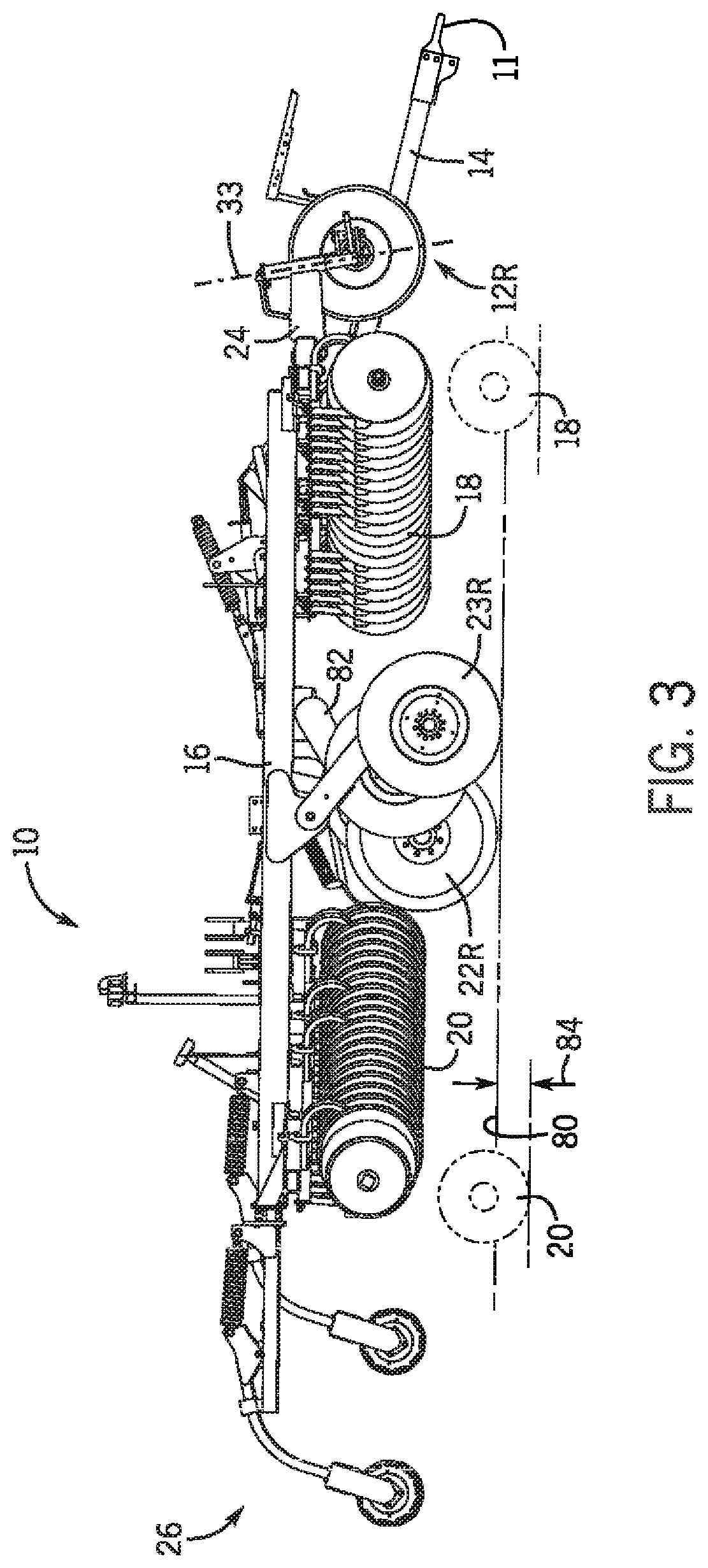

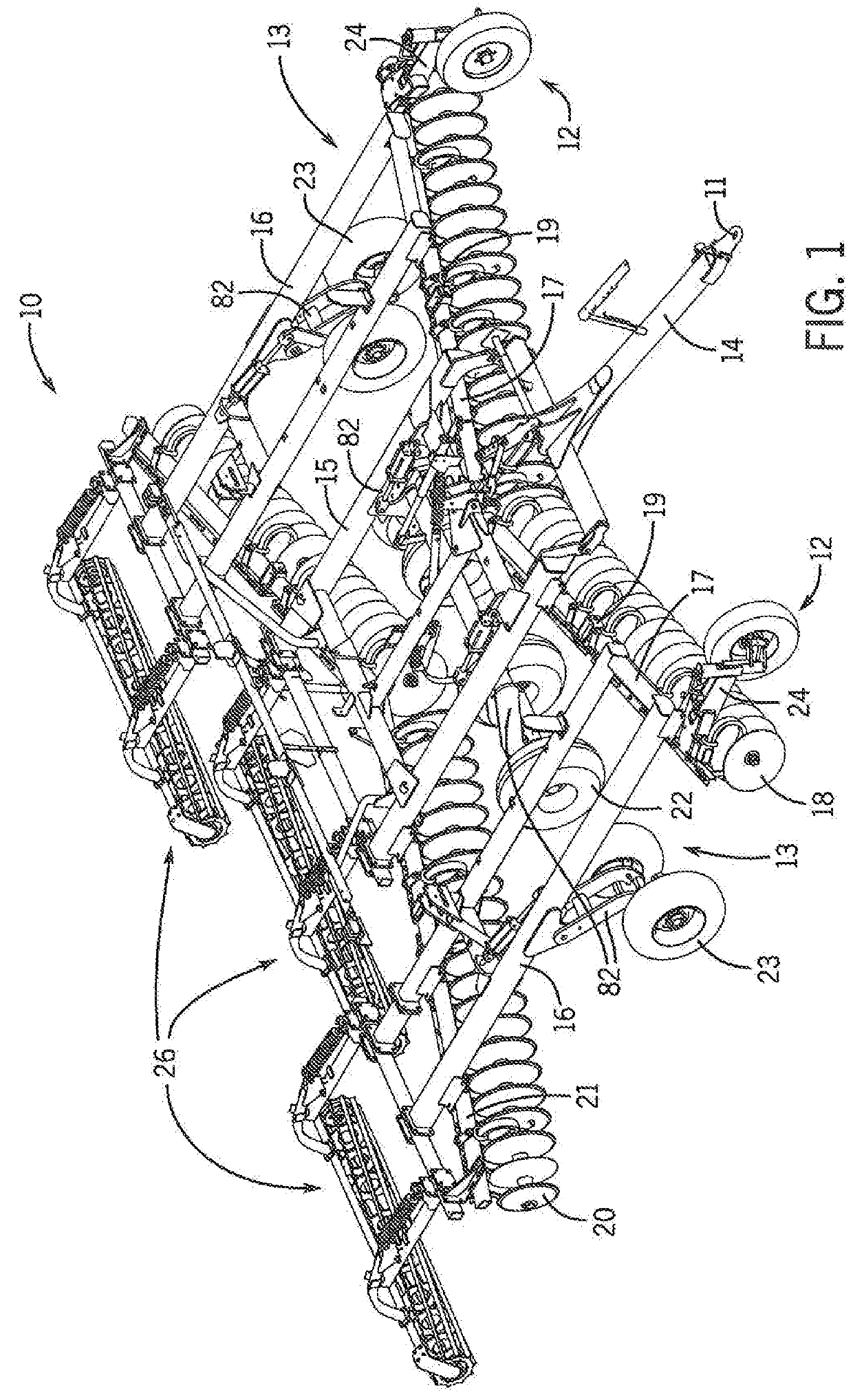

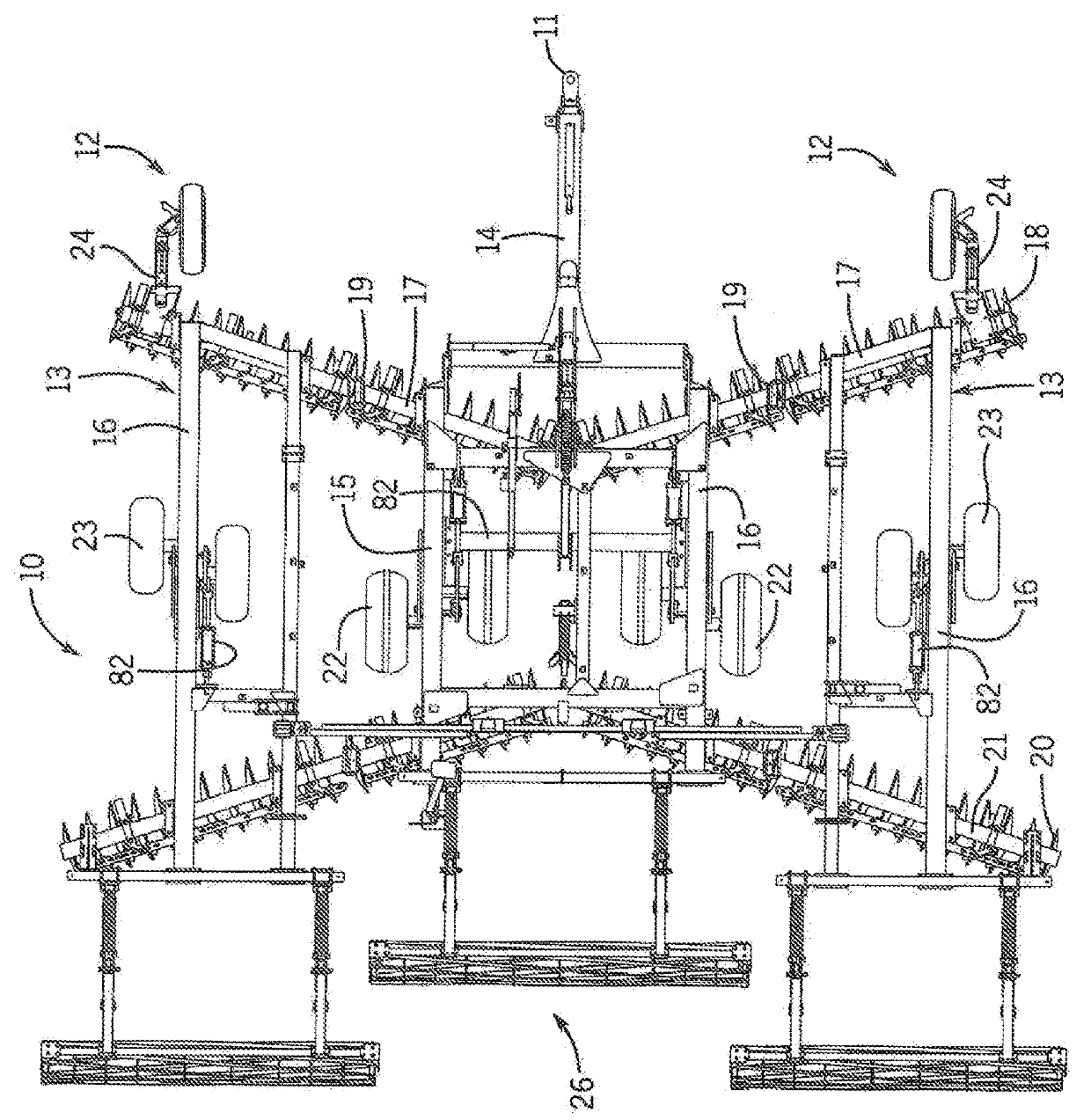

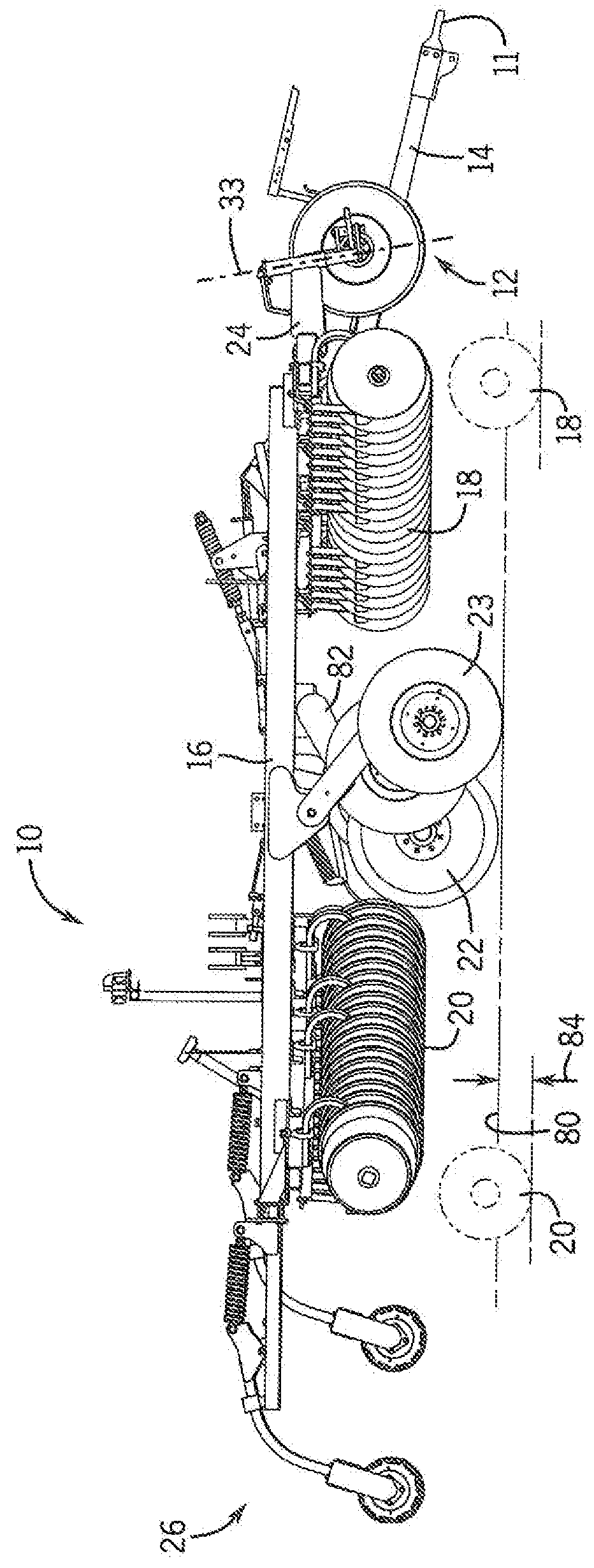

Remote hydraulic positioning of an implement stabilizer wheel

ActiveUS10225983B2Selective stabilityAgricultural machinesAdjusting devicesAutomatic controlDepth of penetration

A remotely positionable stabilizer wheel arrangement for a towable agricultural implement utilizes an electronic control unit that receives an input signal indicative of a desired position of the stabilizer wheel, and / or a desired depth of penetration of tillage tools operatively attached to the front and rear of the implement frame, to automatically control a hydraulic positioning cylinder of the remotely positionable stabilizer wheel arrangement to position and hold the stabilizer wheel at the desired position of the stabilizer wheel.

Owner:BLUE LEAF I P INC

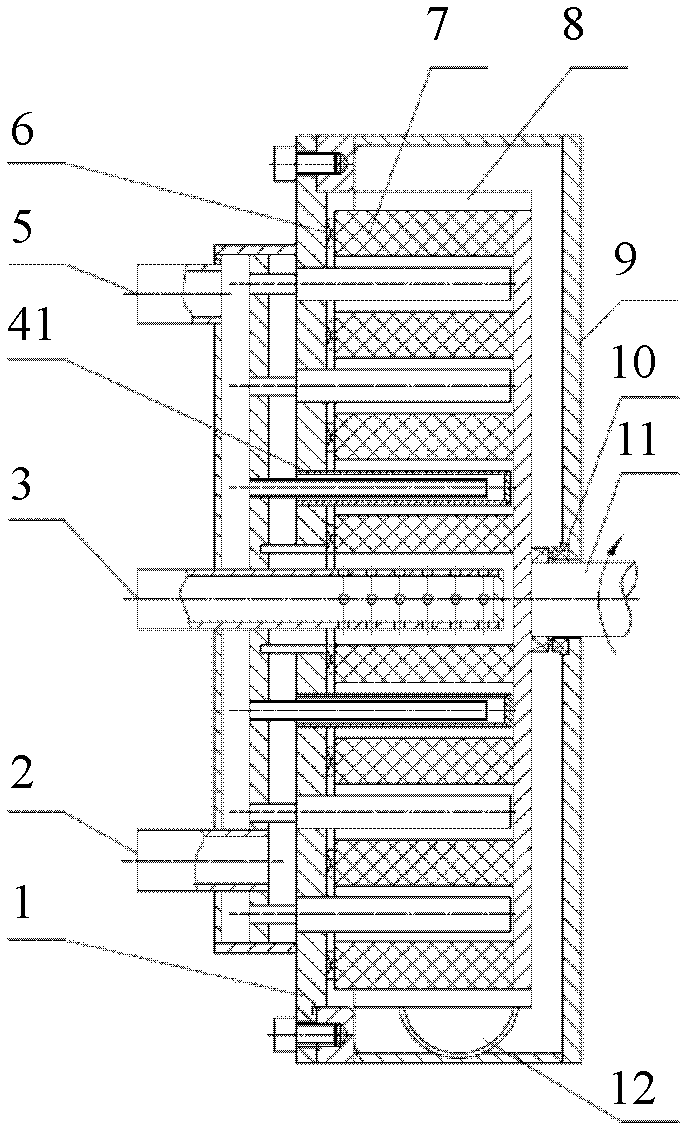

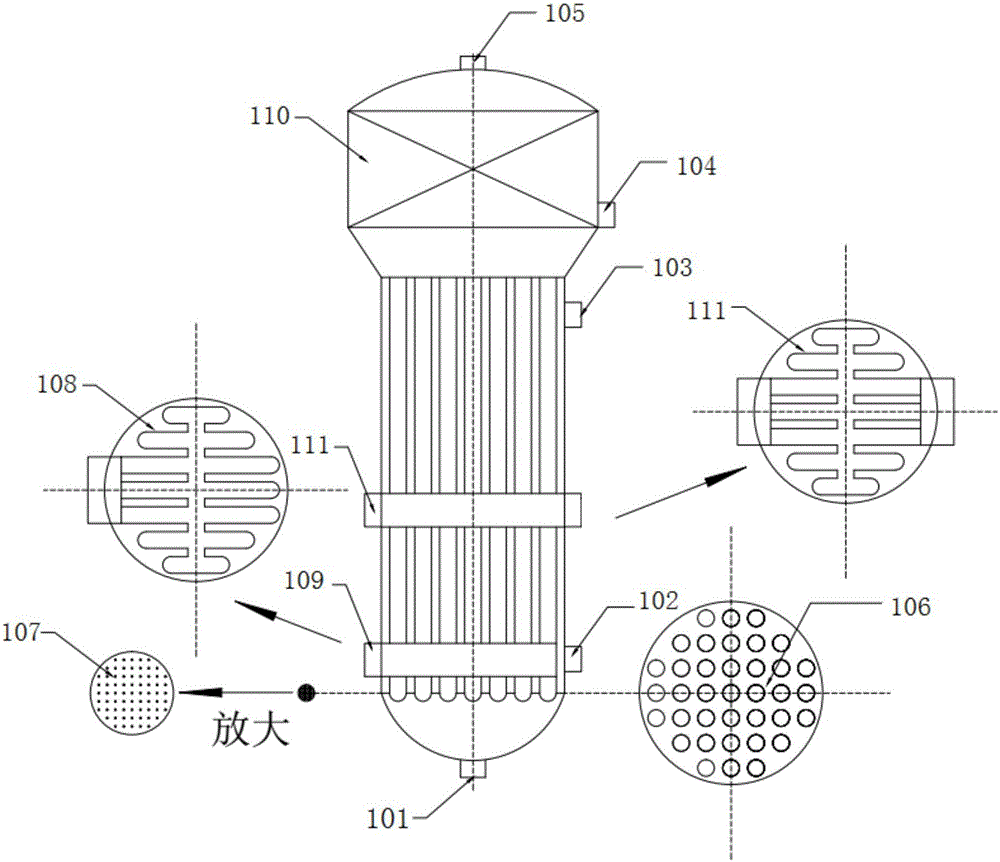

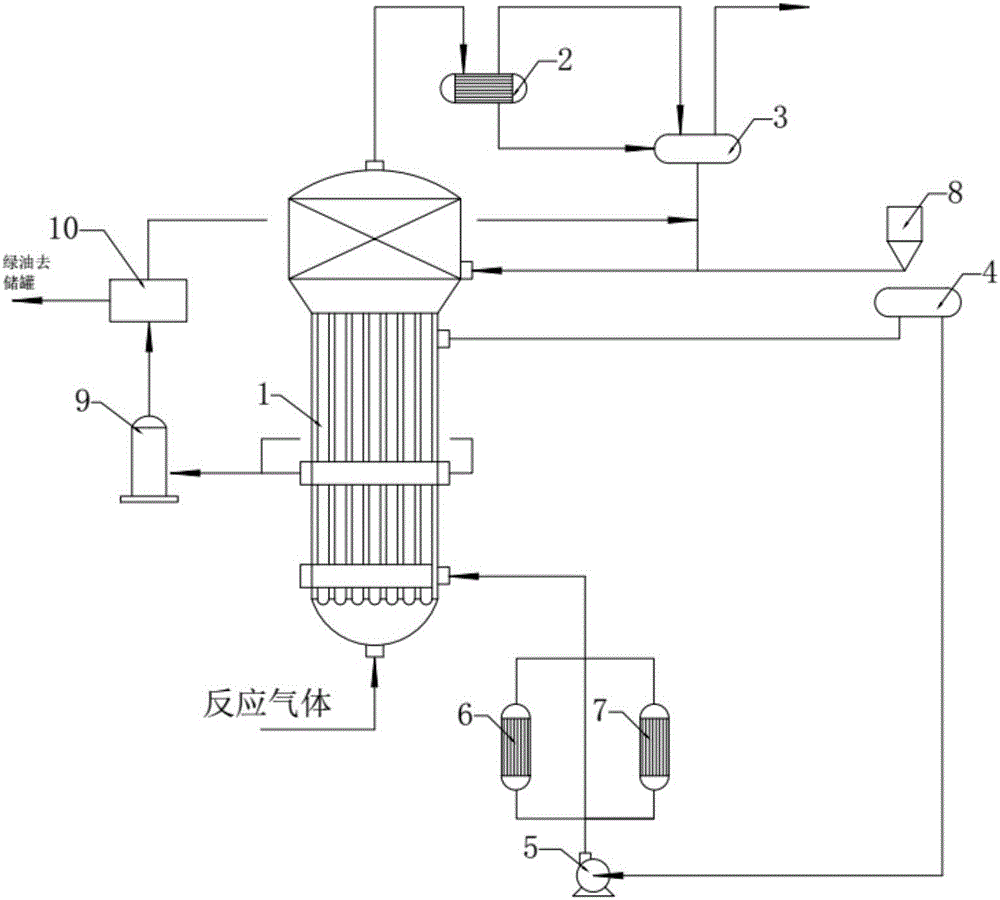

Multitubular slurry bed reactor and reaction system

PendingCN106824019AUniform liquid levelAvoid gas short circuitHydrocarbon by hydrogenationChemical/physical processesSolventProduct gas

The invention relates to a tubular slurry bed reactor and a reaction system. The tubular slurry bed reactor is a reactor for producing ethylene from high-concentration acetylene, which includes an inlet section, a tubular distribution section and an expansion section arranged in sequence, and also includes an upper section connected to the tubular distribution section Connecting area with the lower section of tubes, wherein, the gas inlet section is provided with a gas inlet for passing the reaction gas into the tube-and-tube slurry bed reactor; the tube distribution section is provided with a plurality of tubes for the reaction The gas reacts in the distribution section of the tubes to produce ethylene. Multiple tubes are provided with an upper tube communication area and a lower tube communication area. Filters are installed at both ends of the upper tube communication area, and the top of the expansion section is set. There is a gas outlet. The design of the tube-tube communication area in the tube-tube slurry bed reactor of the present invention can ensure that the liquid level in each tube is uniform and avoid gas short circuit, and the setting of the filter in the upper section of the communication area can ensure the replacement of the solvent and regeneration.

Owner:SHENWU TECH GRP CO LTD

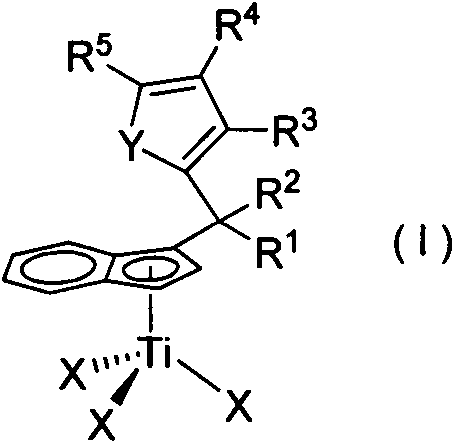

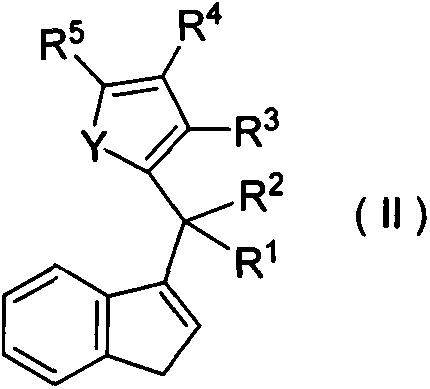

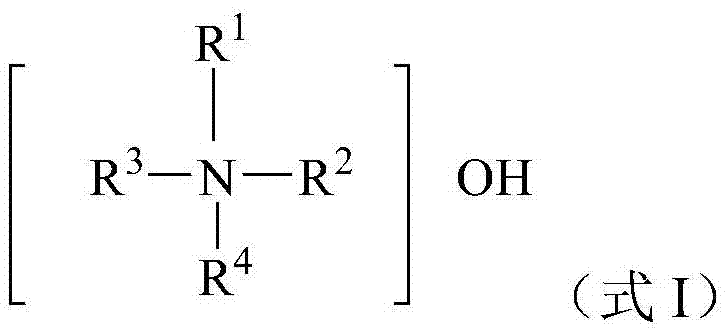

Preparation method and application of high-selectivity ethylene trimerization catalyst

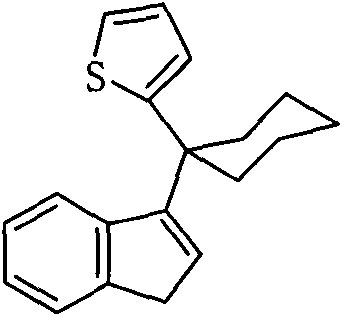

InactiveCN103059059AImprove catalytic performanceImprove temperature resistanceOrganic-compounds/hydrides/coordination-complexes catalystsTitanium organic compoundsTitanium metalSide chain

The invention relates to a high-selectivity ethylene trimerization catalyst, and discloses an indene titanium metal complex of which a side chain contains a suspension aromatic heterocyclic group as well as a preparation method and an application of the metal complex in olefin oligomerization. The indene titanium metal catalyst (I) explained by the invention is characterized in that R<1> and R<2> are same or different C1-C12 alkyl of straight chains, branched chains or ring structures, or C4-C12 ring alkyl formed by combination of R<1> and R<2>; R<3> to R<5> are hydrogen, same or different C1-C12 alkyl of straight chains, branched chains or ring structures or silicyl; X is halogen atom; and Y is oxygen, sulfur or selenium. The indene titanium metal complex catalyst of which the side chain contains the suspension aromatic heterocyclic group designed by the invention has good catalytic effect to the olefin oligomerization, and can high-actively catalyze ethylene trimerization in the existence of a cocatalyst, and no other C6 isomers exist in the trimerization product, so that subsequent separation links are avoided, industrialization cost is reduced, and partial requirement of industry can be met.

Owner:EAST CHINA UNIV OF SCI & TECH

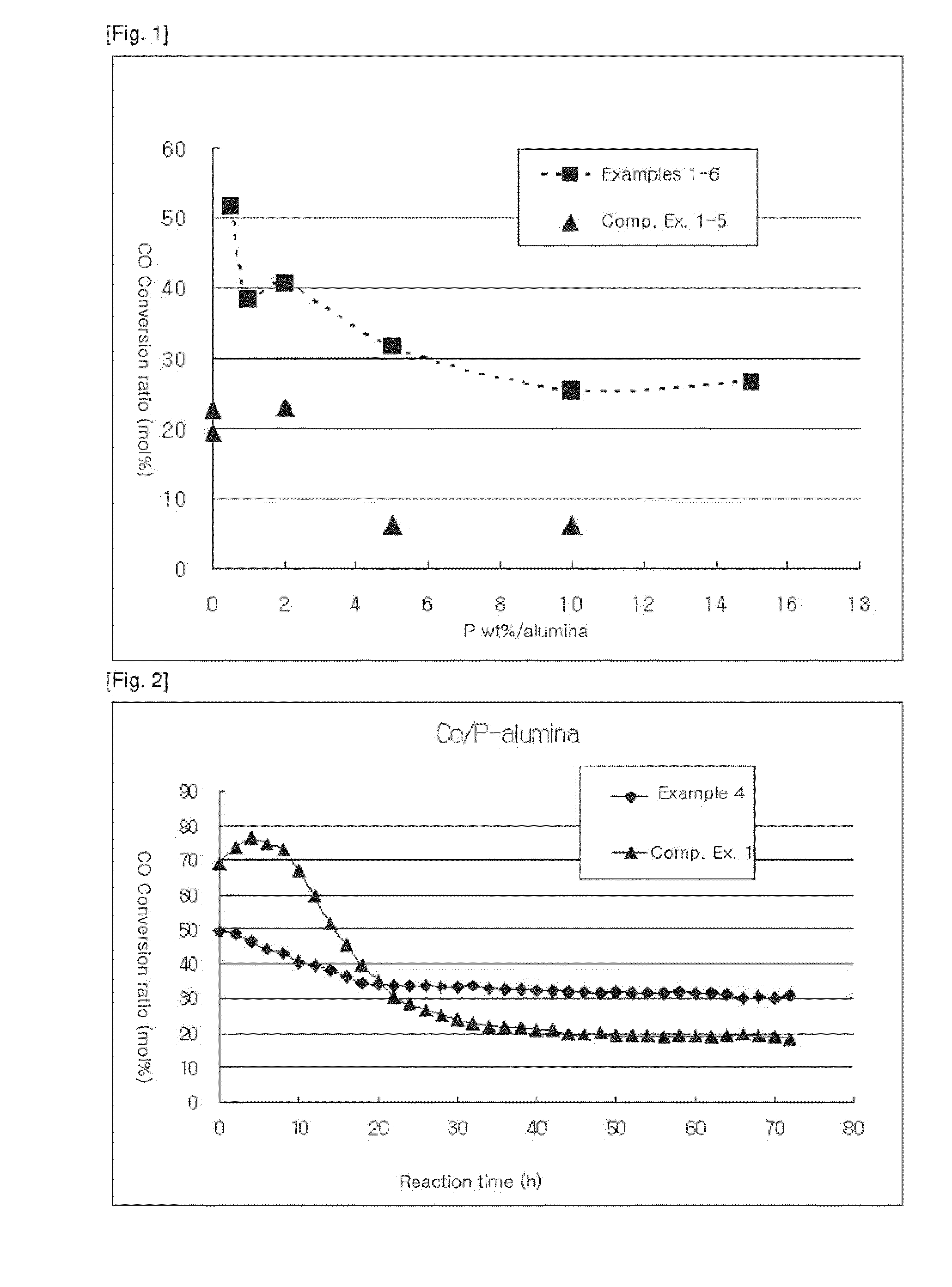

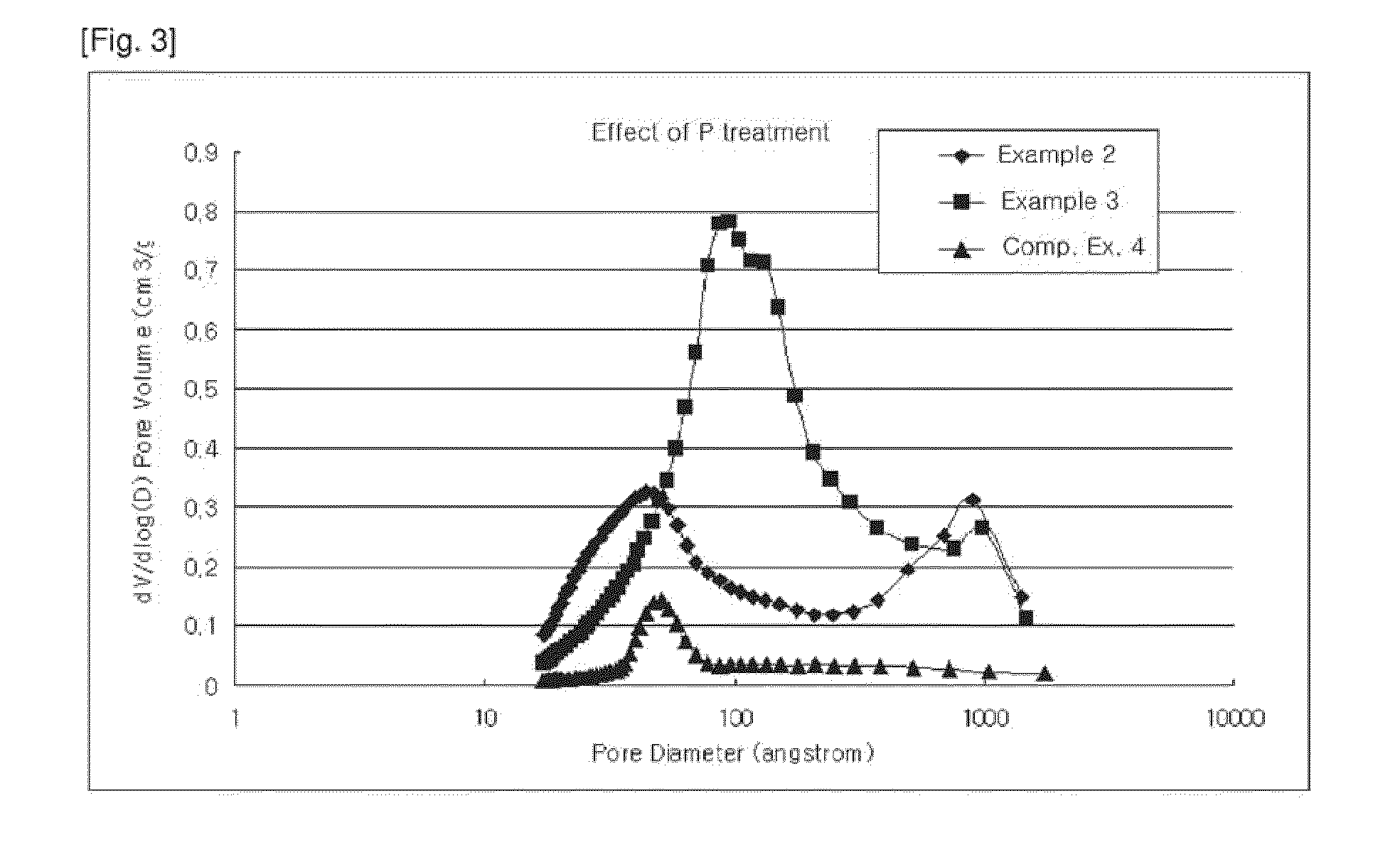

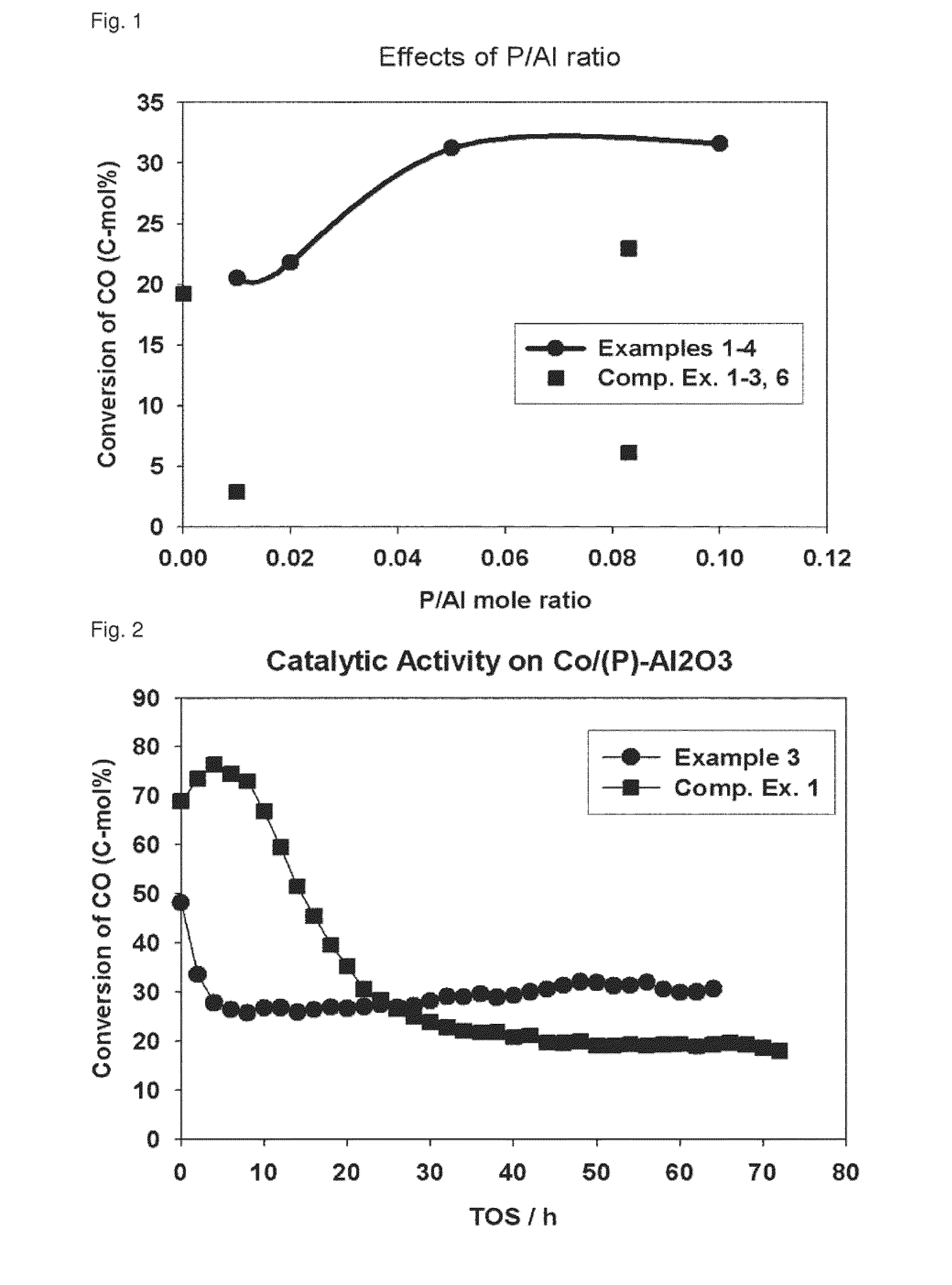

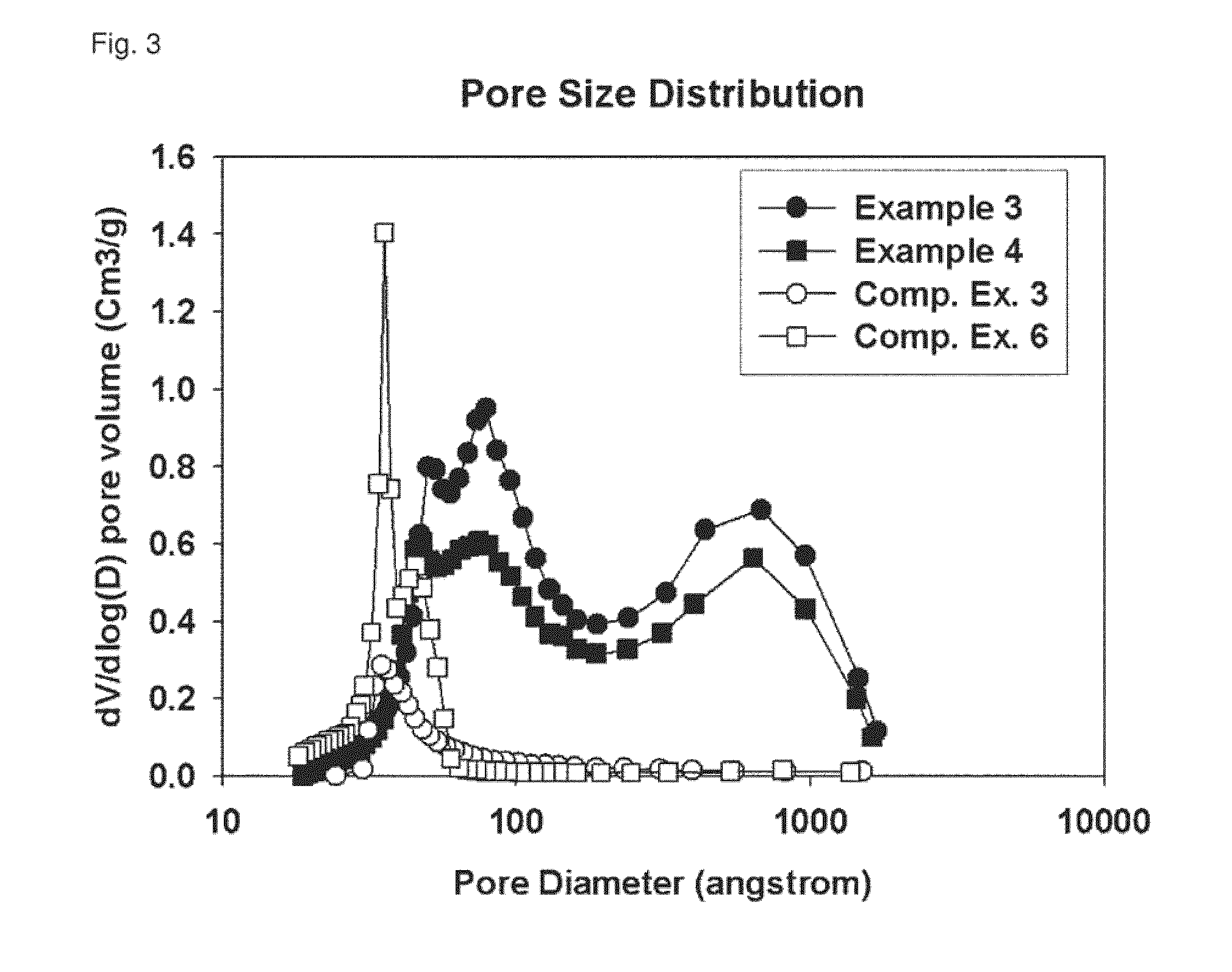

Catalysts for fischer-tropsch synthesis on cobalt/phosphorus-aluminum oxide and preparation methods thereof

ActiveUS20100093523A1Optimize F-T reactionLow selectivityOrganic compound preparationOxygen compounds preparation by reductionActive componentLiquid hydrocarbons

The present invention relates to a cobalt / phosphorus-alumina catalyst in which cobalt is supported as an active component on a phosphorus-alumina support wherein phosphorus is supported on alumina surface. With a bimodal pore structure of pores of relatively different pore sizes, the catalyst provides superior heat- and matter-transfer performance and excellent catalytic reactivity. Especially, when Fischer-Tropsch (F-T) reaction is performed using the catalyst, deactivation by the water produced during the F-T reaction is inhibited and, at the same time, the dispersion and reducing property of cobalt and other active component are improved. Therefore, the cobalt / phosphorus-alumina catalyst for F-T reaction in accordance with the present invention provides good carbon monoxide conversion and stable selectivity for liquid hydrocarbons.

Owner:SK INNOVATION CO LTD +2

Catalysts for fischer-tropsch synthesis on cobalt/phosphorus-aluminum oxide and preparation methods thereof

ActiveUS8084387B2Low selectivitySelective stabilityOrganic compound preparationOxygen compounds preparation by reductionPtru catalystLiquid hydrocarbons

The present invention relates to a cobalt / phosphorus-alumina catalyst in which cobalt is supported as an active component on a phosphorus-alumina support wherein phosphorus is supported on alumina surface. With a bimodal pore structure of pores of relatively different pore sizes, the catalyst provides superior heat- and matter-transfer performance and excellent catalytic reactivity. Especially, when Fischer-Tropsch (F-T) reaction is performed using the catalyst, deactivation by the water produced during the F-T reaction is inhibited and, at the same time, the dispersion and reducing property of cobalt and other active component are improved. Therefore, the cobalt / phosphorus-alumina catalyst for F-T reaction in accordance with the present invention provides good carbon monoxide conversion and stable selectivity for liquid hydrocarbons.

Owner:SK INNOVATION CO LTD +2

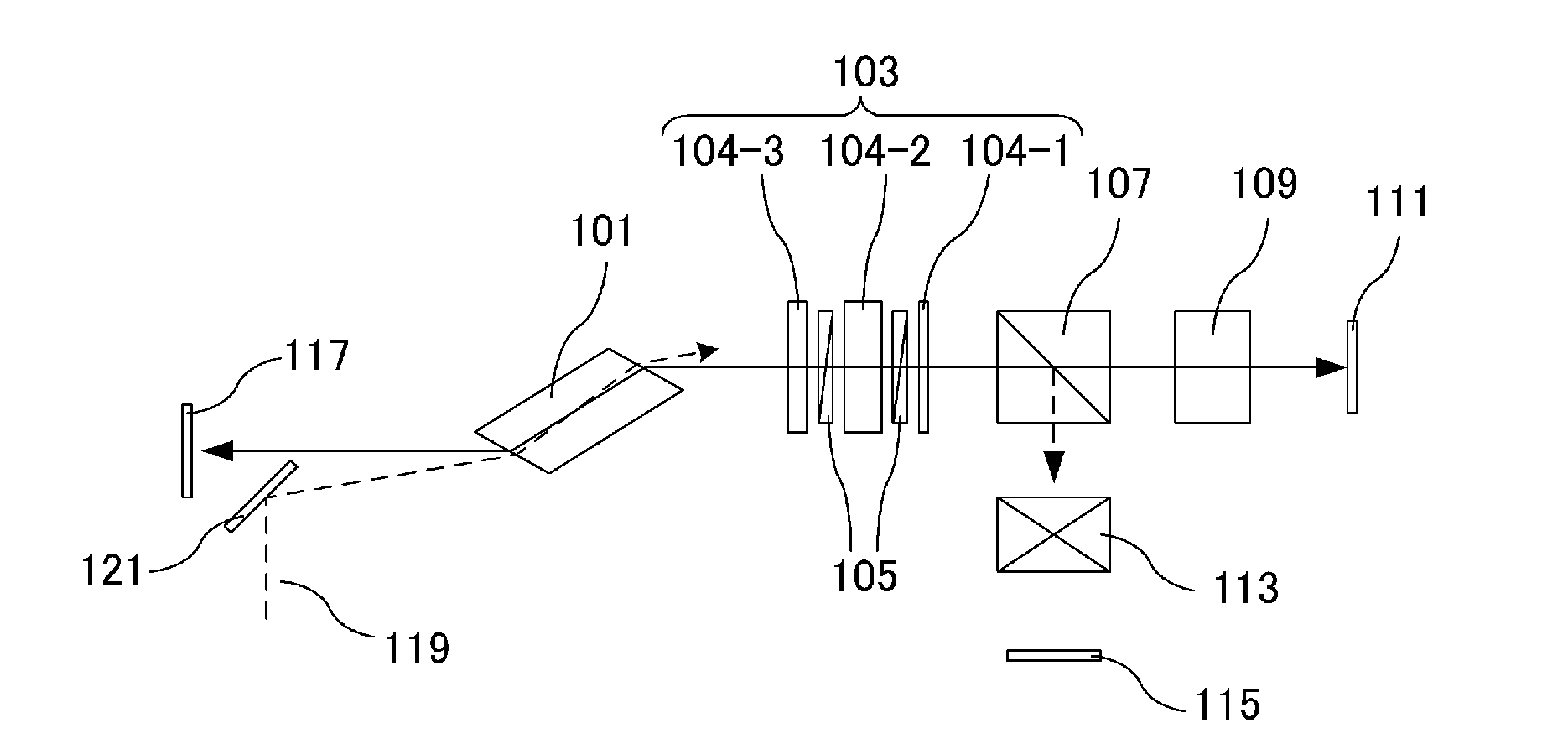

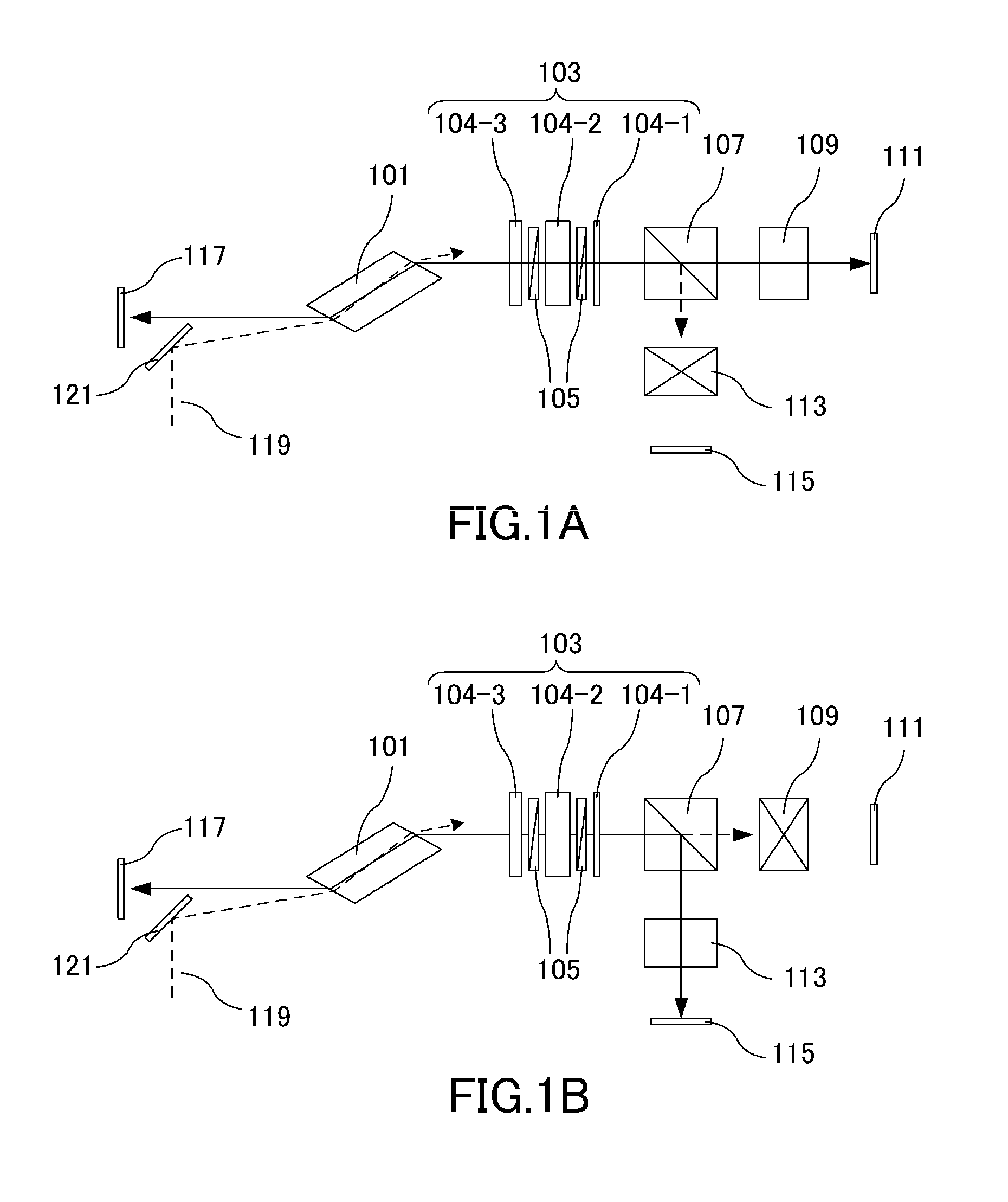

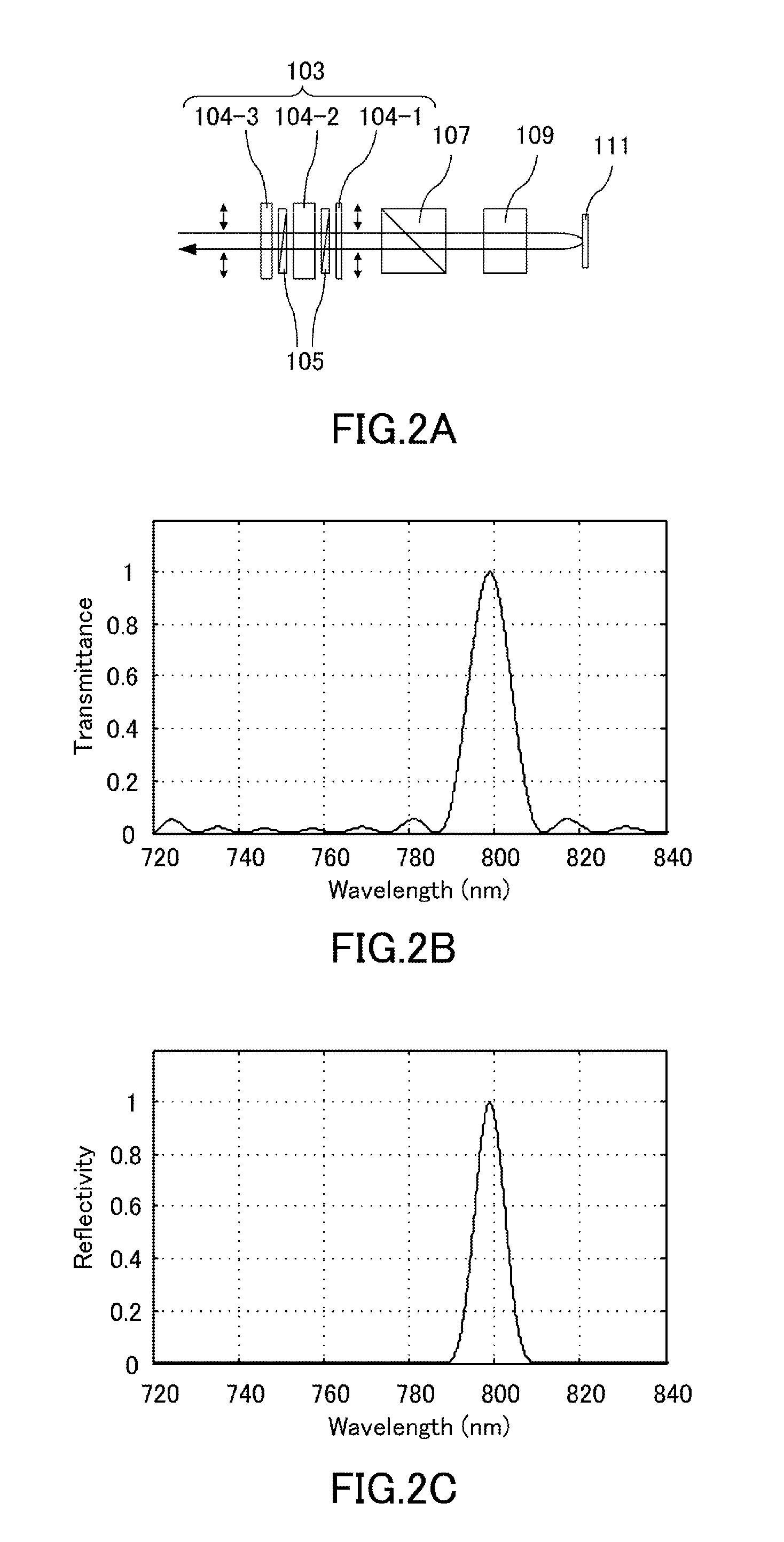

Laser apparatus and photoacoustic apparatus using laser apparatus

InactiveUS20140123762A1Oscillation stabilitySelective stabilityVibration measurement in solidsLaser detailsWavelength filterLight beam

A laser apparatus comprises a cavity having an output unit, and a branch unit arranged between the output unit and first and second reflection unit, an optical path in the cavity including a common part and separate parts, respectively; a laser medium and a wavelength filter disposed in the common part; a pump unit configured to pumping the laser medium; and first and second shielding units respectively disposed in the first and second separate parts, the transmittance of the wavelength filter is varied based on the wavelength and polarization of incident light, the branch unit splits a light beam into the first polarized light and the second polarized light, and one of the first and second shielding units being opened and the other closed to select one of the wavelengths of light to be emitted.

Owner:CANON KK

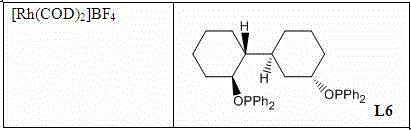

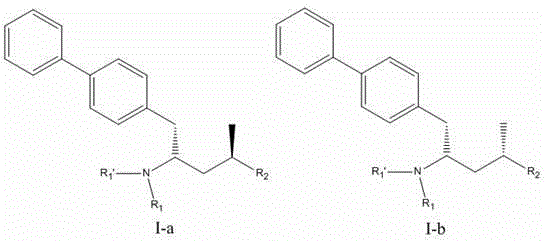

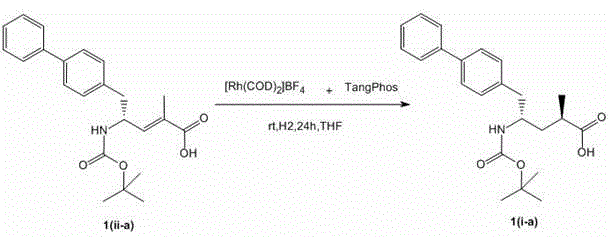

Preparation method and application of biaryl substituted 4-amino-butyric acid or derivative of biaryl substituted 4-amino-butyric acid

ActiveCN106146351AHigh stereoselectivityHigh selectivityCarbamic acid derivatives preparationOrganic compound preparationHydrogenButyric acid

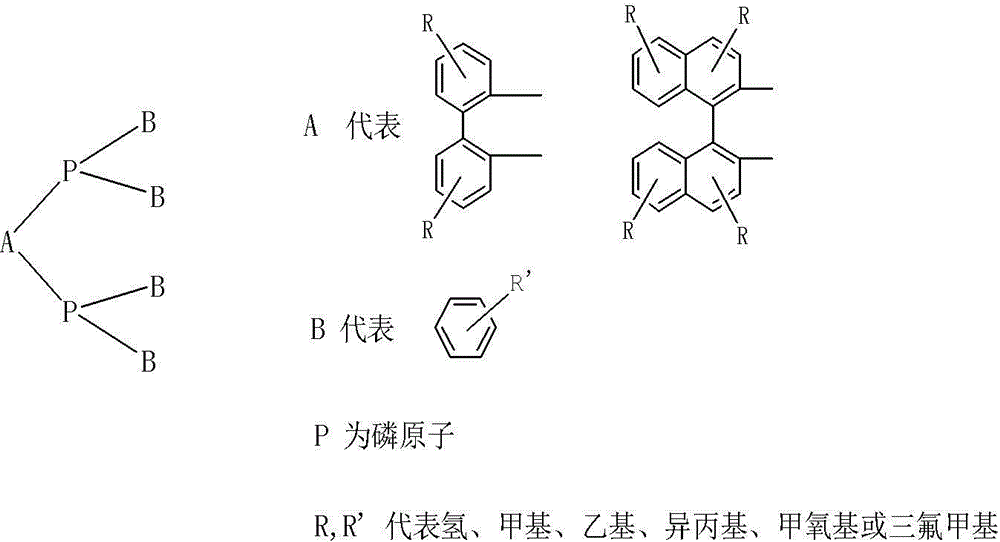

The invention relates to a preparation method of biaryl substituted 4-amino-butyric acid or a derivative of biaryl substituted 4-amino-butyric acid. The preparation method comprises the step as follows: a compound (II) is subjected to a reaction with hydrogen under the condition of presence of a transition metal catalyst and a chiral ligand, and a compound (I) is generated, wherein the transition metal catalyst is a rhodium catalyst, the chiral ligand is a chiral phosphorous ligand with a conformational stiffening ring structure, phosphorus can be in bond linkage with the ring structure or taken as one part of the ring structure, and biaryl substituted 4-amino-butyric acid or the derivative of biaryl substituted 4-amino-butyric acid is prepared from the compound (I) through further processing.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

Method for producing oxime

InactiveCN101628880ASelective stabilityHigh yieldOrganic compound preparationOximes preparationKetoneSolvent

The present invention provides a method for producing an oxime by carrying out an ammoximation reaction of a ketone with an organic peroxide and ammonia in a solvent in the presence of a titanosilicate, characterized in that the reaction is carried out by feeding the ketone and ammonia to a reactor in which the solvent, the titanosilicate and the organic peroxide are charged.

Owner:SUMITOMO CHEM CO LTD

Preparing phosphorus containing alumina support by sol-gel method for fischer-tropsch synthesis and catalyst preparation thereof

InactiveUS8598066B2Improve thermal stabilityIncrease conversionsCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid hydrocarbonsThermal stability

Owner:KOREA GAS CORPORATION +2

Remote hydraulic actuation and positioning of a plurality of implement stabilizer wheels

ActiveUS10645856B2Selective stabilitySpadesAgricultural machinesControl engineeringAgricultural engineering

A system, apparatus and method for remotely and individually controlling a plurality of remotely positionable stabilizer wheels of a towable agricultural implement utilize an electronic control unit that receives an input signal indicative of a desired position of the stabilizer wheel, and / or a desired depth of penetration of tillage tools operatively attached to the front and rear of the implement frame, to automatically and individually control a plurality of hydraulic positioning cylinders for individually positioning and holding the plurality of stabilizer wheel at the desired position of the stabilizer wheels.

Owner:BLUE LEAF I P INC

Hydrodechlorination palladium-carbon catalyst and preparation method

InactiveCN105688952AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationActivated carbonAcetic acid

The invention discloses a hydrodechlorination palladium-carbon catalyst and a preparation method. The catalyst is prepared from, by mass, 0.5-1.5% of Pd, 0.5-2% of Re, 0.5-3% of Cl and the balance an activated carbon carrier. The prepared catalyst is high in activity and selectivity, and long in service life. The preparation method is easy to implement and good in repeatability. The catalyst is mainly used for purifying a chlorination solution in the chloroacetic acid industry, high-purity monochloro acetic acid can be obtained after the chlorination solution is subjected to the hydrodechlorination reaction through the catalyst, and meanwhile mother solution zero release is achieved.

Owner:CHINA TIANCHEN ENG +1

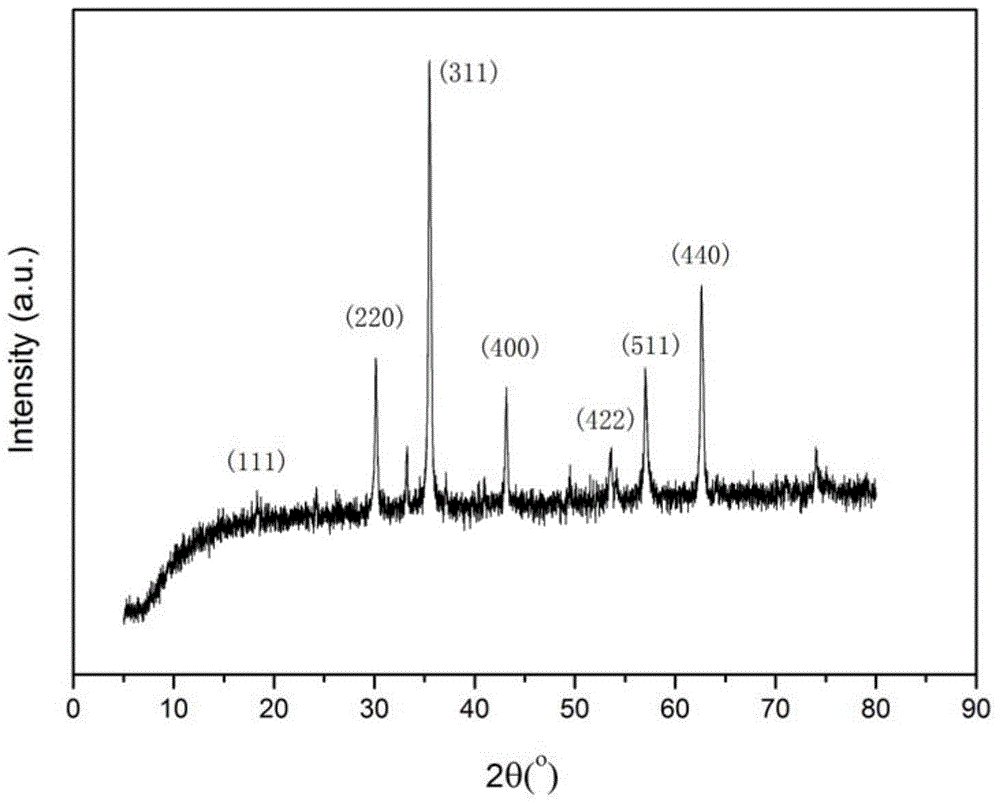

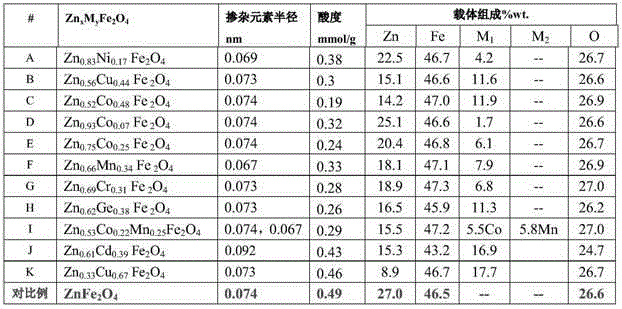

Low-carbon olefin platinum catalyst made through dehydrogenation of low-carbon alkane

ActiveCN105363473AGood dispersionReduced activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneCooking & baking

The invention relates to a low-carbon alkane dehydrogenation platinum catalyst and a preparation method thereof and mainly solves the problems that in an existing preparation technology, the catalyst conversion rate is low, and the selectivity is lowered in the use process. The preparation method includes the steps that firstly, a coprecipitation method is adopted, copper, nickel, manganese, cobalt and other transition metal elements are introduced into a zinc ferrite carrier, and a composite metal oxide carrier is obtained; then, an impregnation method is adopted, platinum components are loaded, in other words, a water solution of soluble salt of platinum is dipped, and the platinum catalyst is obtained after drying, baking and steam treatment are conducted. Propane / iso-butane are adopted as raw materials, the raw materials are in contact with the catalyst in the conditions that the reaction temperature is 520-620 DEG C, the reaction pressure is 0-0.4 MPa, the alkane mass airspeed is 0.1-8.0 h<-1>, the H<2>O / C<n>H<2n+2> volume ratio is 1-18, a reaction is conducted, and propane / iso-butane are generated, by means of the technical scheme, the problem is well solved, and the low-carbon alkane dehydrogenation platinum catalyst and the preparation method thereof can be used for industrial preparation of low-carbon olefin catalysts made through dehydrogenation of low-carbon alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

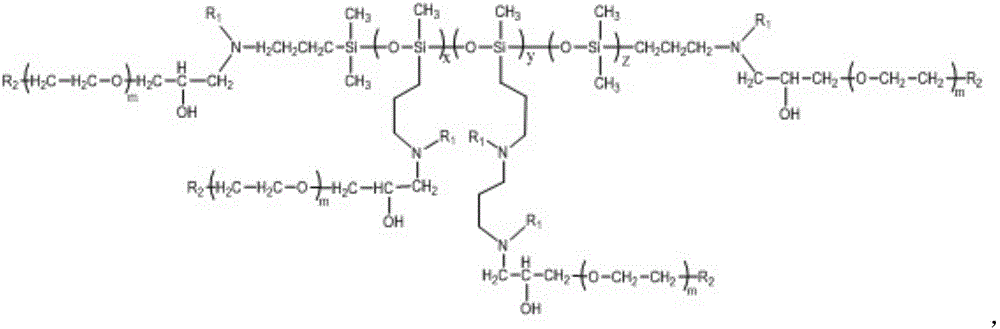

Durable hydrophilic silicone oil and preparation method thereof

ActiveCN106496569AMolecular chain structure is stableImprove hydrophilicityGrip property fibresVegetal fibresEpoxySide chain

The invention discloses durable hydrophilic silicone oil which is characterized that the silicone oil comprises side chain-amino-terminated silicane with a general formula A and single-ended polyether epoxy with a general formula B, the mole ratio of the side chain-amino-terminated silicane to the single-ended polyether epoxy is 1:(4-8), the components react under the alkaline environment to obtain a structural formula which is as shown in the specification, wherein x is 0-10, y is 0-10, z is 10-200, m is 5-20, R1 is one of -H, -CH3-, -CH2CH2- and -CH2CH3, and R2 is one of -CH3, -OCH3, -CH2CH3, -OCH2CH3 and -CH2CH(OH)CH3. The durable hydrophilic silicone oil can give smooth and soft hand feeling for fabrics, is high in chemical stability and has self-emulsifying function, so that the fabrics can have continuous hydrophilic properties.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

Remote Hydraulic Positioning Of An Implement Stabilizer Wheel

ActiveUS20180271020A1Selective stabilityAgricultural machinesAdjusting devicesAutomatic controlDepth of penetration

A remotely positionable stabilizer wheel arrangement for a towable agricultural it utilizes an electronic control unit that receives an input signal indicative of a desired position of the stabilizer wheel, and / or a desired depth of penetration of tillage tools operatively attached to the front and rear of the implement frame, to automatically control a hydraulic positioning cylinder of the remotely positionable stabilizer wheel arrangement to position and hold the stabilizer wheel at the desired position of the stabilizer wheel.

Owner:BLUE LEAF I P INC

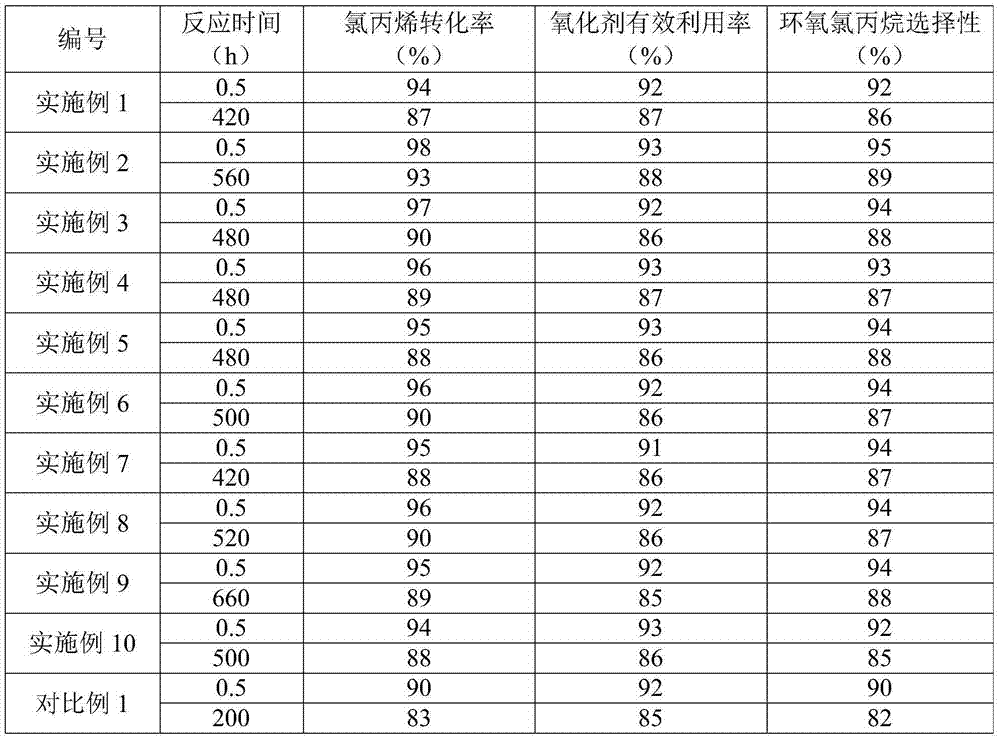

Allyl chloride oxidation method

ActiveCN106967010AExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveApparent velocity

The present invention discloses an allyl chloride oxidation method, which comprises that a reaction material containing allyl chloride, an oxidizing agent and a solvent sequentially flows through catalyst bed layers from 1 to n under an oxidation reaction condition, wherein n is an integer of more than 2, and the catalyst bed layer is filled with at least a titanium-silicon molecular sieve; and when the reaction material passes through the catalyst bed layers from 1 to n, at least a flow carrier is introduced into the position between at least a pair of the adjacent catalyst bed layers among the catalyst bed layers from 1 to n, such that the apparent velocity of the reaction stream positioned in the downstream catalyst bed layer is higher than the apparent velocity of the reaction stream positioned in the upstream catalyst bed layer in the pair of the adjacent catalyst bed layers by adopting the flowing direction of the reaction material as the reference. With the method of the present invention, the one-way service life of the titanium-silicon molecular sieve can be effectively prolonged, the effective utilization rate of the oxidizing agent can be improved, and the target product selectivity can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com