Patents

Literature

70results about How to "Stable conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

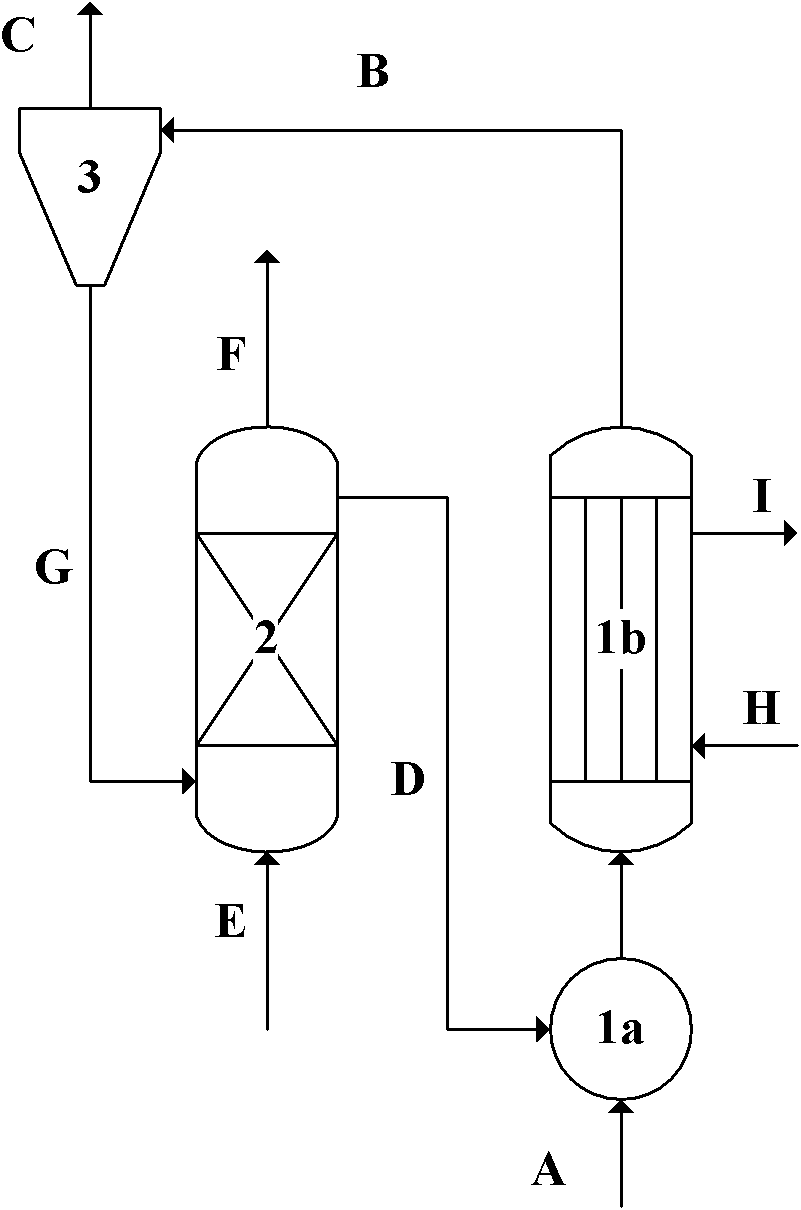

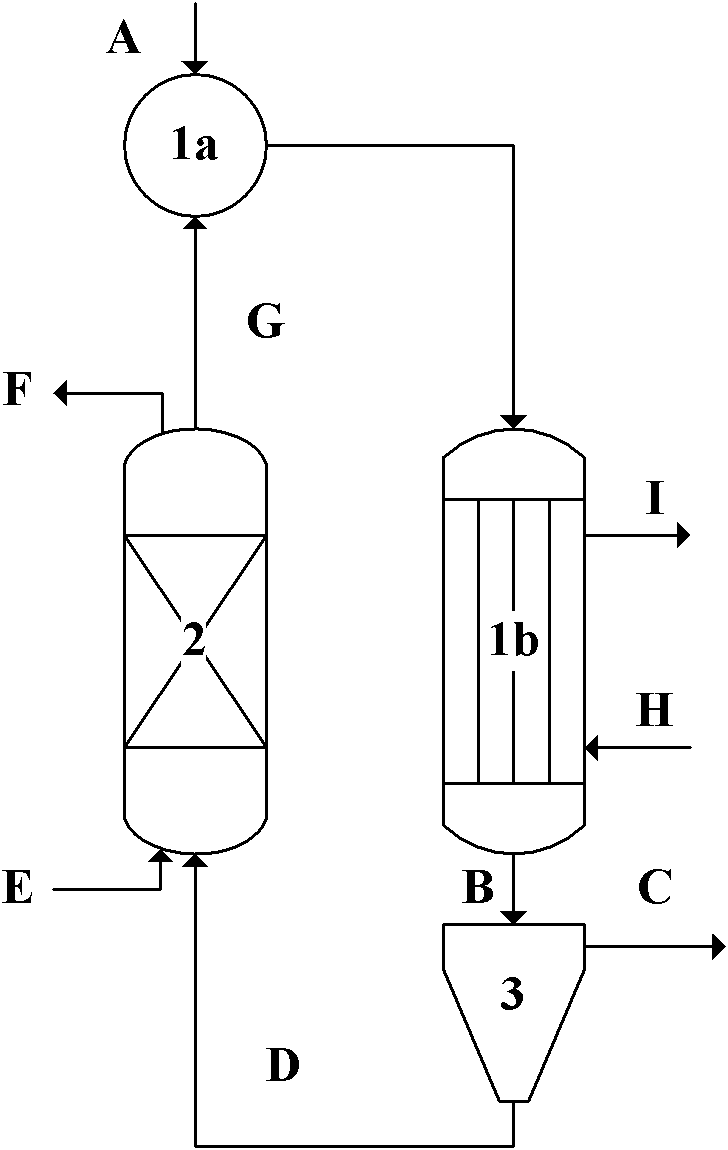

Method for direct methanation of recirculating fluidized bed synthesis gas

InactiveCN102180757AReduced inactivation rateNot easy to fall offHydrocarbon from carbon oxidesSyngasFluidized bed

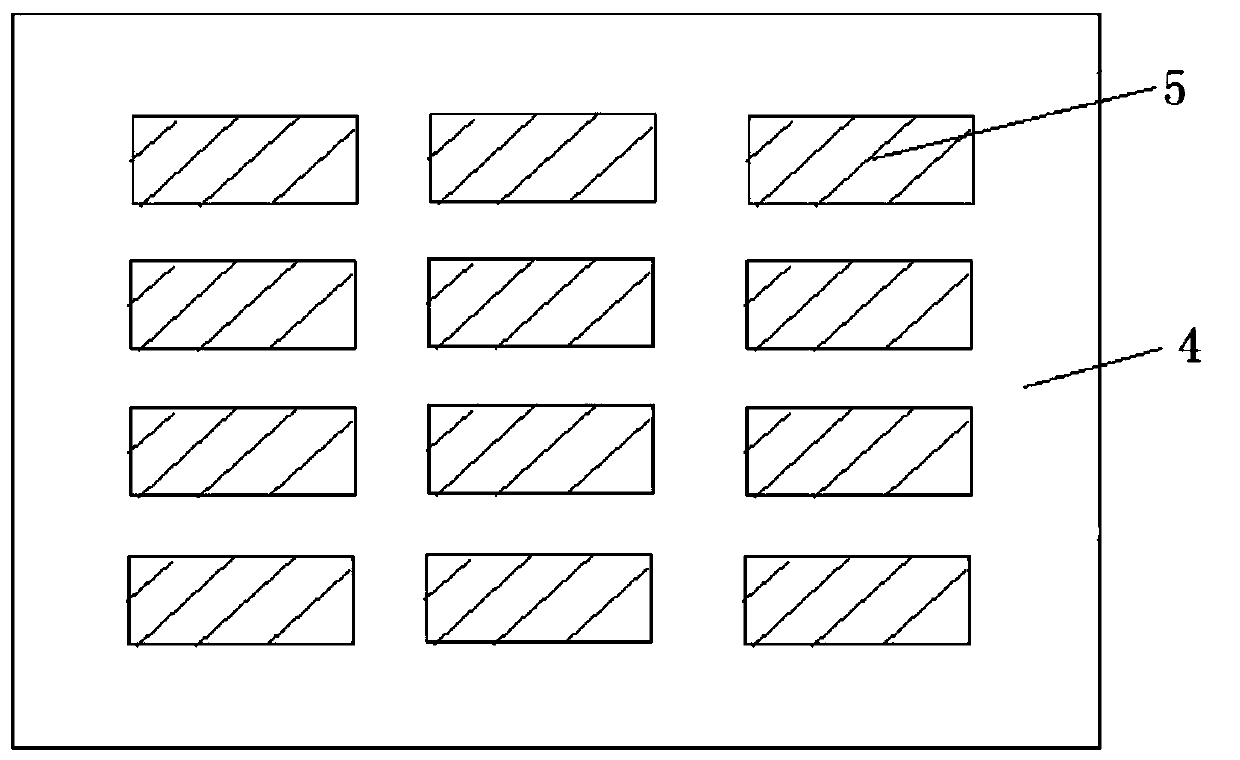

The invention discloses a method for direct methanation of recirculating fluidized bed synthesis gas, belonging to the technical field of natural gas prepared from coals. The method comprises three main steps: absorbing and strengthening direct methanation of synthesis gas through a channel type reactor; separating a product from an absorbent; and roasting the absorbent. In the channel type reactor for absorbing and strengthening the direct methanation of the synthesis gas, a catalyst is coated on the wall surface of the inner channel in grille in the reactor in a form of coating, and the absorbent is carried by reaction gas so as to pass through the grille type channel in the reactor, thereby avoiding the separation step of the catalyst and absorbent, and solving the problem that the catalyst is repeatedly oxidized and reduced so as to cause the loss of materials and the loss of energy, and the generated heat is rapidly removed by utilizing the efficient heat-transfer capability of amulti-layer channel wall surface, thereby retarding the deactivation speed of the catalyst and ensuring the stable operation of equipment.

Owner:TSINGHUA UNIV

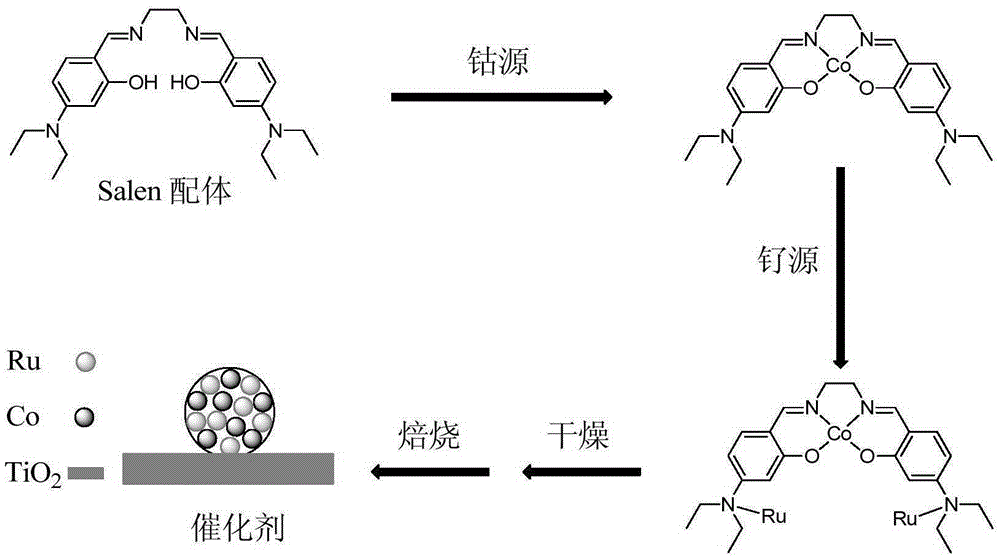

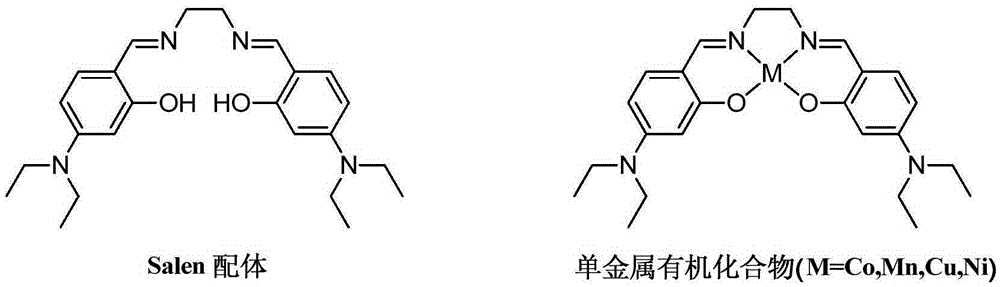

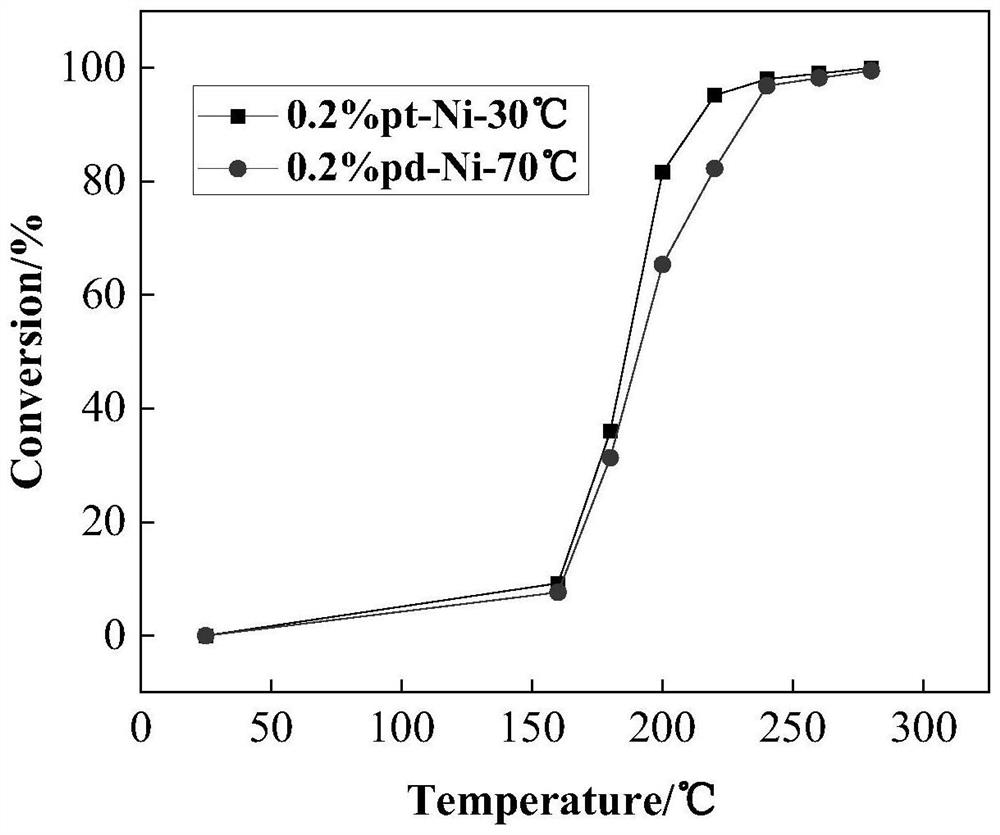

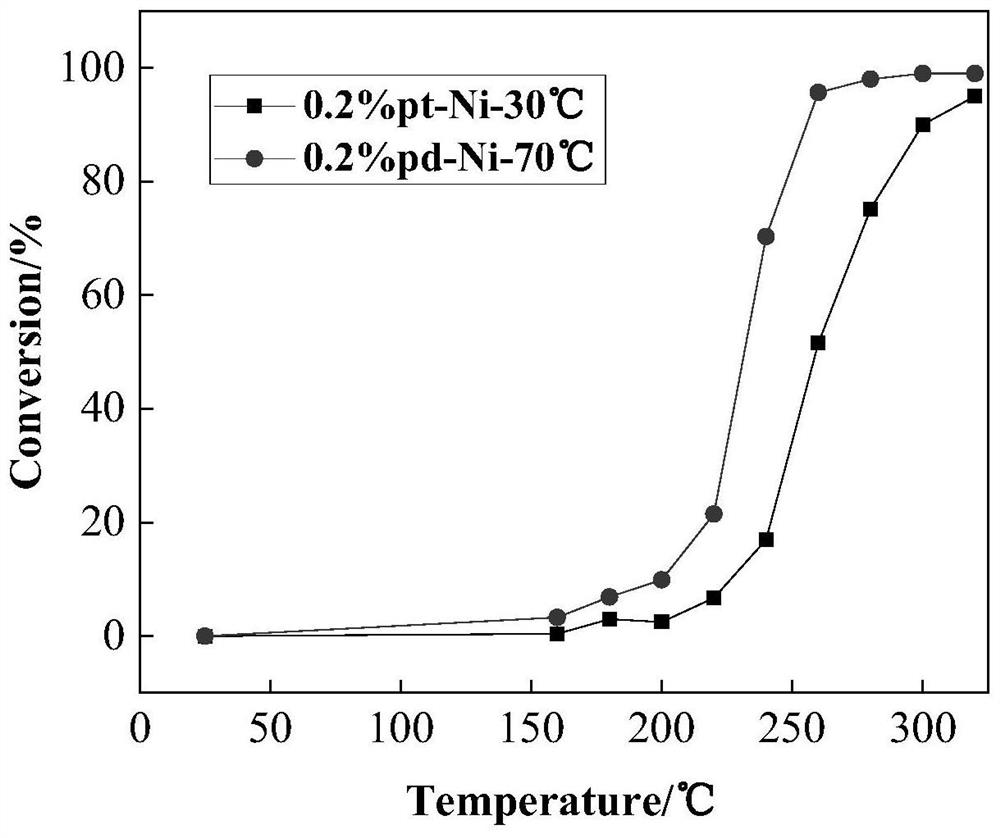

Bimetallic catalyst for catalytic oxidation of VOCs and preparation method and application of bimetallic catalyst

ActiveCN105289651AHigh catalytic activityUniversalOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationSalen ligandActive agent

The invention provides a bimetallic catalyst for catalytic oxidation of VOCs and a preparation method and application of the bimetallic catalyst. According to the catalyst, titanium dioxide is adopted as a carrier, an active agent is an elementary substance of any one of ruthenium, palladium and platinum and / or an oxide of the elementary substance, and a promoter is any one of cobaltosic oxide, manganese oxide, copper oxide and nickel oxide. Nano particles with the active agent and the promoter evenly compounded are synthesized through a nano regulation means and a Salen ligand, a high concerted catalysis function is achieved between the active agent and the promoter, and the catalytic oxidation efficiency of VOCs can be improved. The catalyst is high activity and high in universality, the complete oxidizing temperature on multiple kinds of VOCs ranges from 160 DEG C to 230 DEG C, the overall performance is superior to that of a commercial palladium-platinum catalyst, the selectivity of final reaction products CO2 is high, and good application prospects are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for selectively hydrogenating acetylene in ethylene under normal pressure

InactiveCN102898266AStable conversion rateSelective stabilityHydrocarbon purification/separationHydrocarbonsGas phaseMixed gas

The invention discloses a method for selectively hydrogenating acetylene in ethylene under normal pressure. Ethylene mixed gas containing the acetylene is subjected to gas phase hydrogenation under normal pressure by using bimetallic A-B / TiO2 as a catalyst, the acetylene is selectively hydrogenated and reduced into ethylene, and the catalyst is an A-B / TiO2 catalyst obtained by a continuous bimetal photo-deposition method, wherein A is Pd, Pt, Au or Rh, and B is Ag, Cu or Ni. The A-B / TiO2 catalyst is used for selectively hydrogenating the acetylene under normal pressure, the ethylene can be reduced under the mild condition to form a hydrocarbon using the ethylene as a main product, and the selectivity of the catalyst is 80 to 97 percent. The method has technical feasibility, does not have secondary pollution, has a remarkable effect of selectively hydrogenating the acetylene in the ethylene, and has high economic and environmental benefits.

Owner:NANJING UNIV

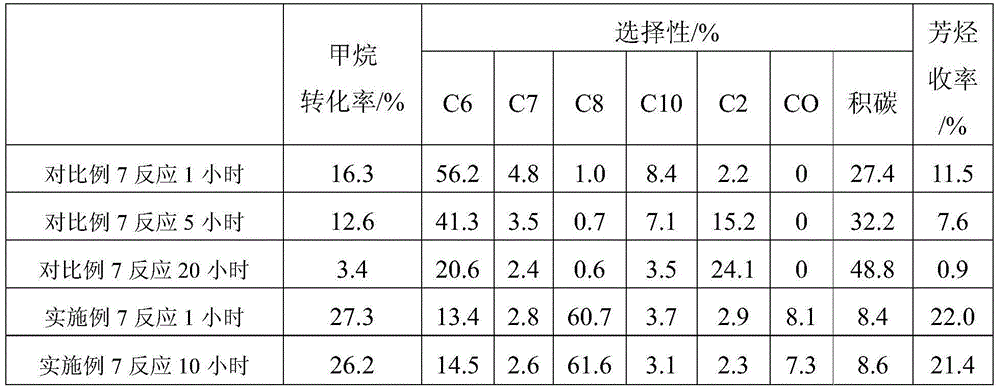

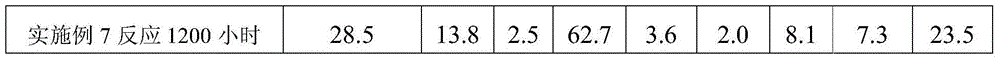

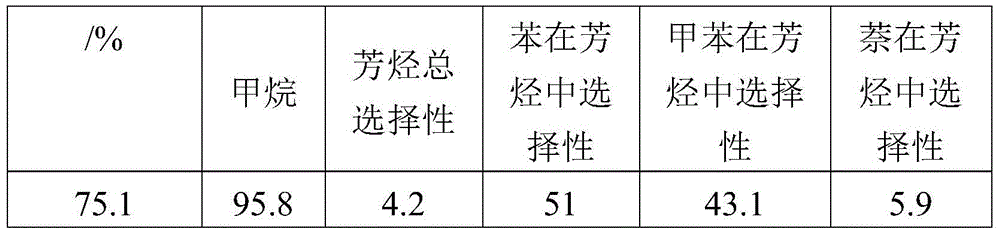

Method for preparing arene by directly converting methane

InactiveCN104557423AImprove conversion rateStable conversion rateMolecular sieve catalystCatalystsMesityleneMixed gas

Disclosed is a method for preparing an aromatic hydrocarbon by direct conversion of methane, comprising the following steps: a catalyst is placed in one reactor, at the same time, a mixed gas of CH4 and an alkylating agent is introduced for reaction, thus implementing coupling of two reactions to acquire the aromatic hydrocarbon. The beneficial effect of the present invention is such that: the present invention is capable of increasing significantly the conversion rate of methane and the yield of the aromatic hydrocarbon, inhibiting the generation of an oligomeric polycyclic aromatic hydrocarbon, and extending the service life of the catalyst. The method of the present invention allows for reaction within 30 minutes and keeps the conversion rate steady between 25% and 45%. When the reaction time reaches 1200 hours, the conversion rate is kept steady, while the catalyst still remains active. An anaerobic aromatization reaction of methane and an alkylation reaction of the aromatic hydrocarbon are conducted simultaneously, thus implanting heat coupling. The temperatures, space velocities, and raw materials of the two reactions are coordinated within a certain scope. The types of post-reaction products remain unchanged, thus facilitating analysis and comparison. Benzene and toluene are consumed in the reactions, while xylene and mesitylene are generated, which are of higher values.

Owner:BEIJING UNIV OF CHEM TECH

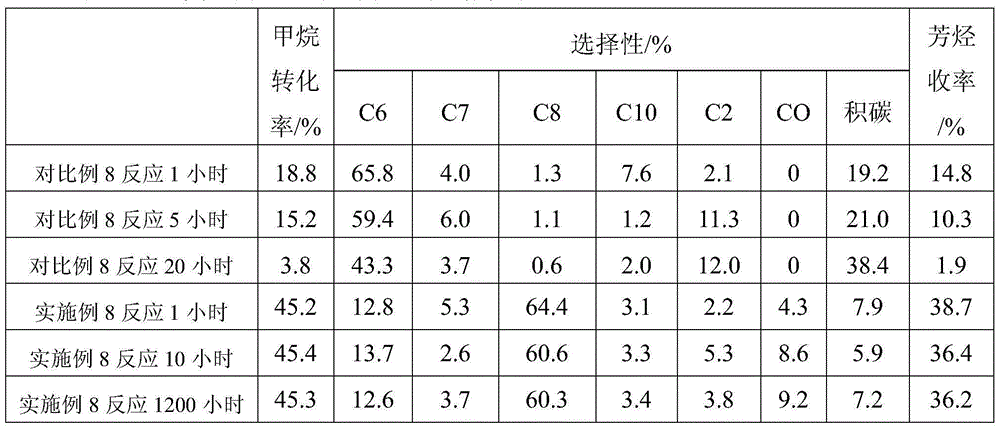

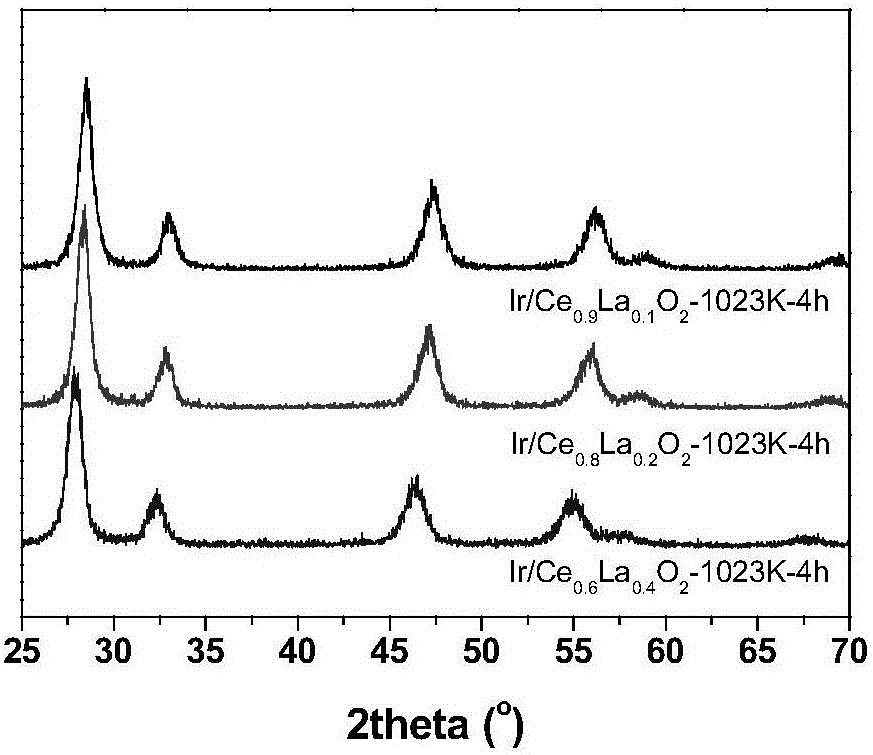

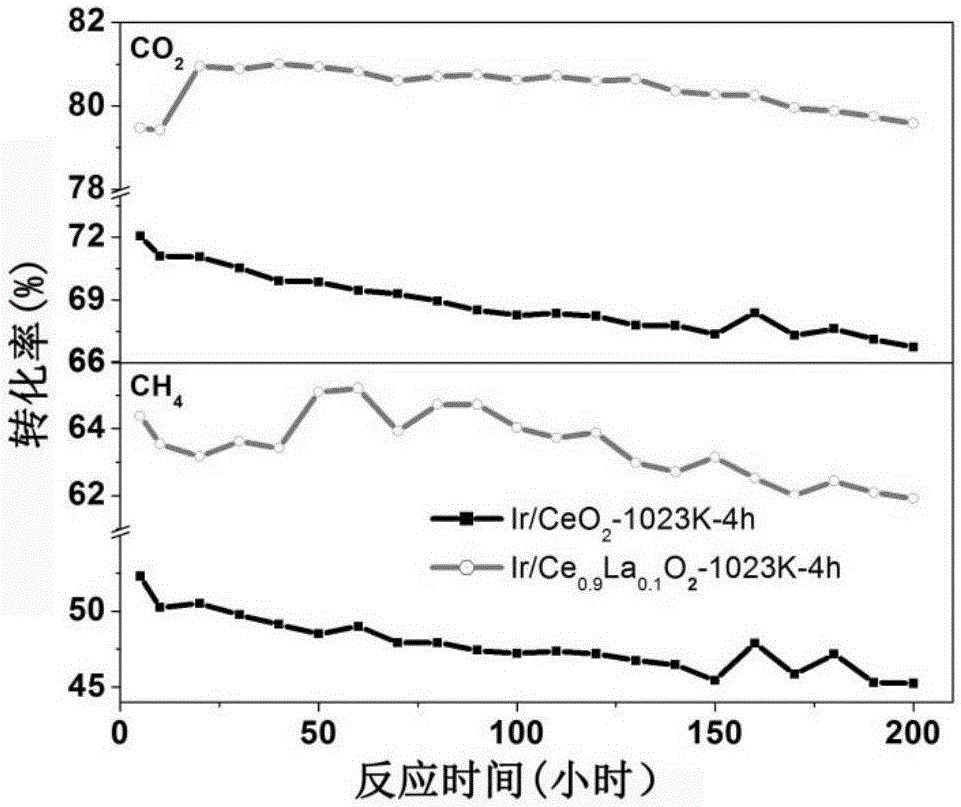

Cerium oxide-based precious metal nanometer catalyst and preparation method thereof

InactiveCN106475096AImprove structural stabilityMaintain stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNano catalyst

The invention provides a method for preparing a cerium oxide-based precious metal nanometer catalyst, the catalyst prepared by the method and application of the catalyst. The catalyst can still maintain the high dispersion of precious metals after the catalyst is calcinated at 750 DEG C or 850 DEG C, and the catalyst has higher activity and better stability in the methane activation conversion reaction. A preparation process is simple, and the structure of the catalytic material is stable at a high temperature. The catalyst has potential application value in the methane activation and conversion such as the high temperature gas phase reactions of methane dry reforming and methane steam reforming.

Owner:NAT UNIV OF SINGAPORE SUZHOU RES INST +1

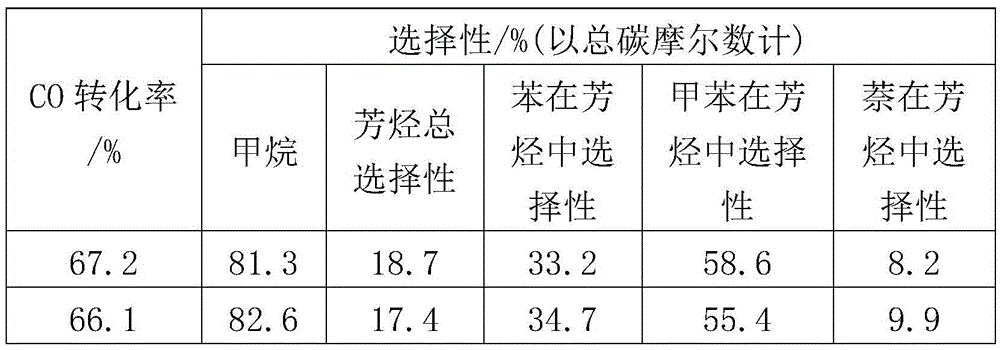

Method for coproduction of aromatic hydrocarbon and methane by direct conversion of synthesis gas

ActiveCN105622305AInhibition formationExtend your lifeHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasMethanation

The invention discloses a method for coproduction of aromatic hydrocarbon and methane by direct conversion of synthesis gas. The method includes: putting a catalyst in a reactor, feeding the synthesis gas for reaction, performing coupled reaction of methanation and methane non-oxidative aromatization to realize coupling of reagents, products and heat of a reaction system, and performing further preparation at 200-500 DEG C to directly obtain aromatic hydrocarbon. By series connection of the methanation reaction and the methane non-oxidative aromatization reaction, heat coupling of the two reactions is realized effectively, carbon deposit is effectively inhibited by effective combination of two active centers, the synthesis gas is directly converted into the aromatic hydrocarbon at a low temperature, and economic benefits are increased substantially. By reaction within 120min, aromatic hydrocarbon selectivity can be stabilized at 15-30%, and after the reaction time reaches 1000h, the conversion rate keeps stable, and the catalyst is still active.

Owner:BEIJING UNIV OF CHEM TECH

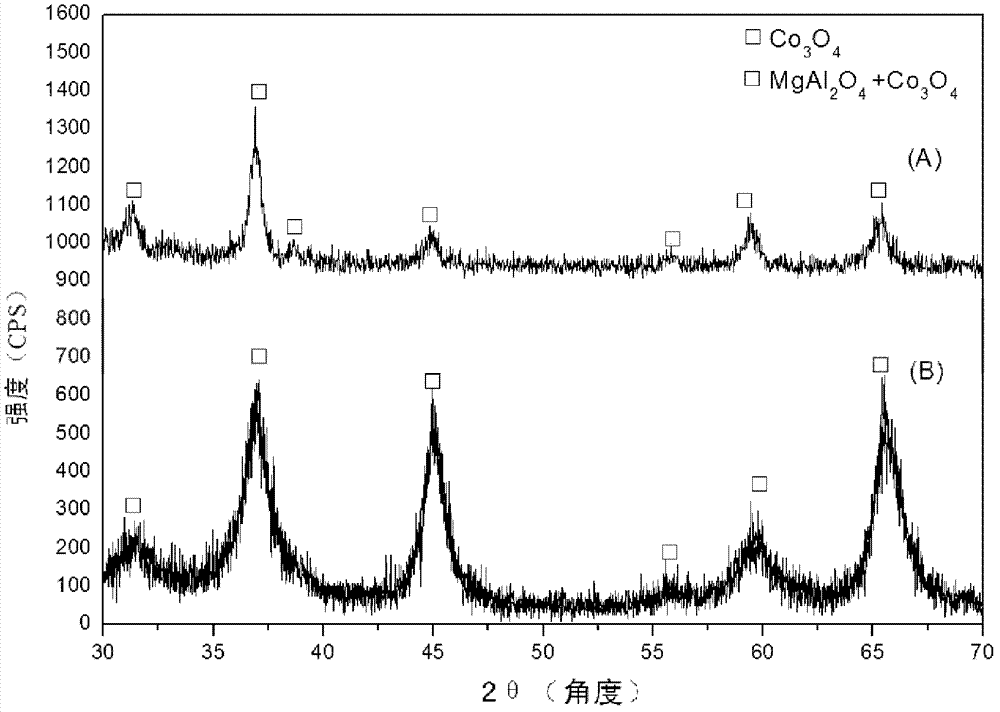

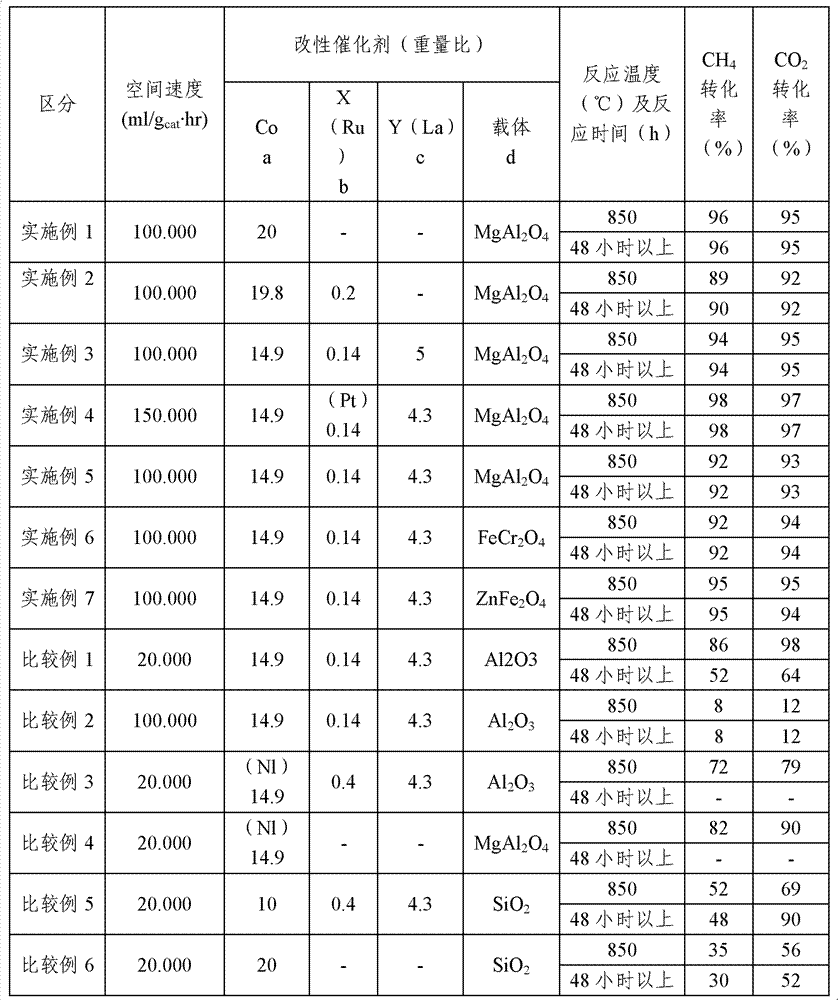

Effective carbon dioxide conversion catalyst and preparing method thereof

InactiveCN103170335AIncrease generation ratioStable conversion rateCarburetting gasesMetal/metal-oxides/metal-hydroxide catalystsForming gasSpinel

The invention relates to a preparing method of catalysts, and particularly relates to a preparing method of cobalt catalysts in [Formula 1], as well as a method for converting carbon dioxides to forming gases by using the method. In [Formula 1] (a) Co / (d)Z, [in Formula 1, Z denotes a spinel carrier formed by A, B, and O; A denotes more than one substance selected from the group formed by Mg, Cr, Mn, Fe, Co, Ni, Cu, Zn, Cd, and Sn; B denotes more than one substance selected from the group formed by A1, Ga, In, Ti, V, Cr, Mn, Fe, Ni, and Co; a denotes the weight of Co, D denotes the weight of spinel carrier Z; with respect to the d accounting for 100 by weight, a accounts for 1-100 by weight.] Compared with the catalysts in the prior art, the activity degree of hydrocarbon and carbon dioxide continuously maintain in the same conversion speed to maintain higher activity and stability.

Owner:KOREA RES INST OF CHEM TECH

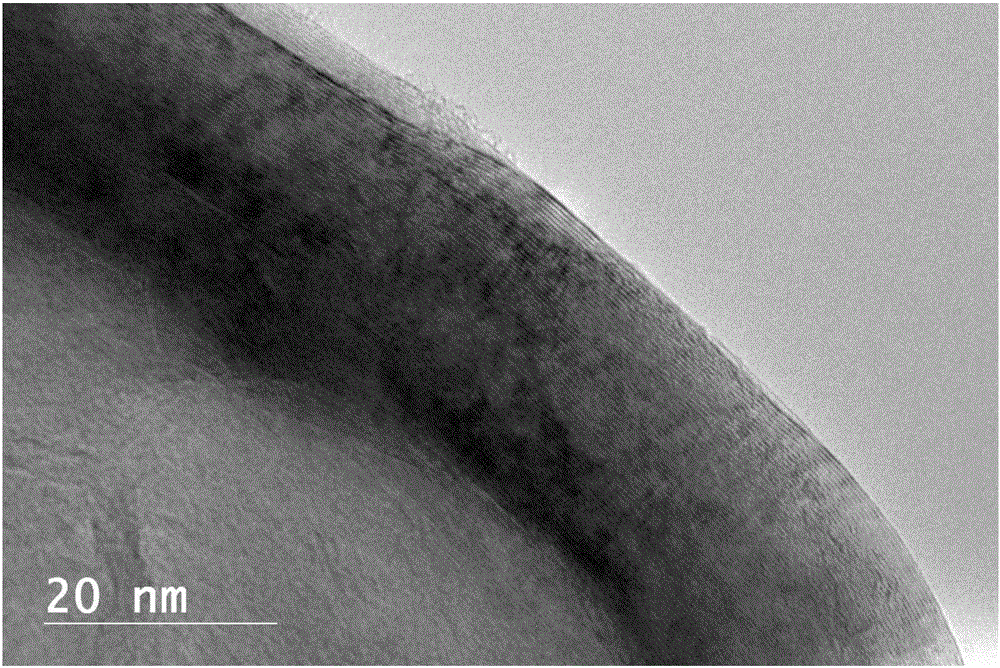

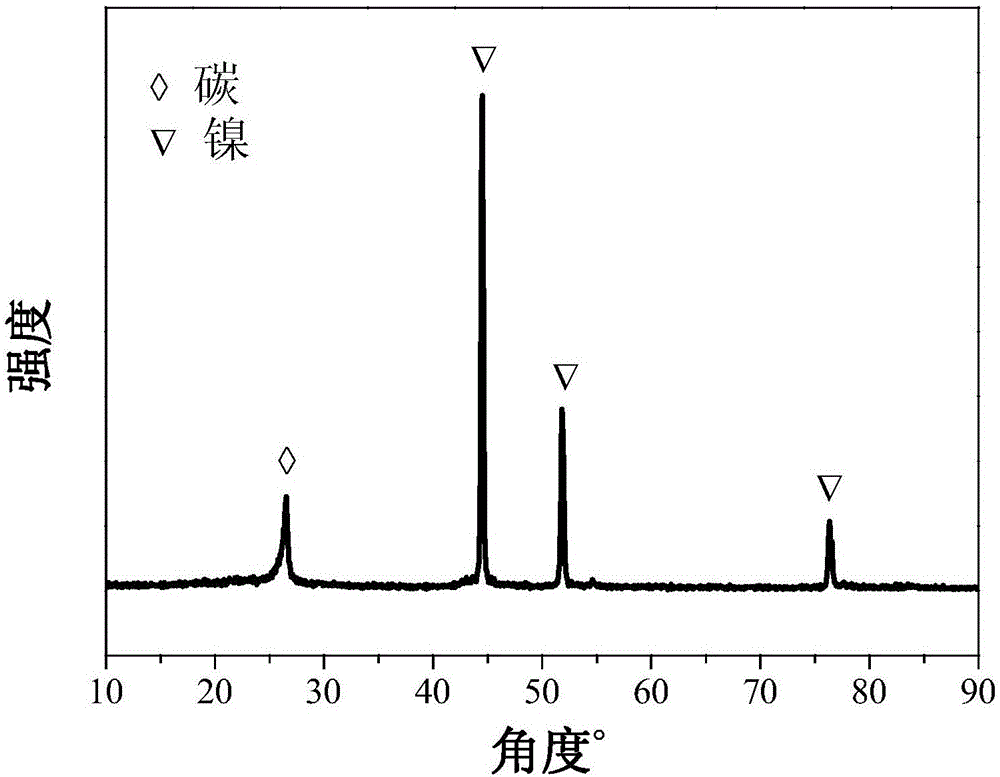

Carbon loaded nickel metal catalyst and preparation method thereof

InactiveCN106824200AHigh catalytic efficiencyImprove stabilityHydrogenCarbon preparation/purificationPhosphoric acidNickel compounds

The invention discloses a carbon loaded nickel metal catalyst and a preparation method thereof. The carbon loaded nickel metal catalyst is prepared by the following steps: mixing a carbon source with a nitric acid, sulfuric acid or phosphoric acid solution with the concentration of 0.1mol / L to 1mol / L according to the ratio of (200g to 350g) : (400mL to 1000mL); reflowing at temperature of 70 DEG C to 85 DEG C for 6h to 12h, and filtering; washing filter dreg with de-ionized water until the pH (Potential of Hydrogen) of a washing solution is equal to 7; drying at 100 DEG C to 110 DEG C for 8h to 12h to obtain a solid A; keeping the heat of the solid A at 150 DEG C to 180 DEG C for 12h to 24h, and washing; drying at 100 DEG C to 110 DEG C for 8h to 12h to obtain a solid B; dissolving a nickel-containing compound into de-ionized water; stirring until the nickel-containing compound is completely dissolved, so as to obtain a solution C; adding the solid B into the solution C with the volume the same as that of the solid B; standing at room temperature for 12h to 24h; drying at 100 DEG to 110 DEG C for 8h to 12h to obtain a solid D; putting the solid D into gas flow without oxygen, heating to 700 DEG C to 1100 DEG C, and keeping the heat for 1h to 5h; then naturally cooling to room temperature. The catalyst prepared by the method has high activity and good stability; pure methane or natural gas is used as a reactant at 850 DEG C, and the reforming reaction is stabilized for at least 1000h.

Owner:WUHAN UNIV OF SCI & TECH

Ultra-pure white phosphorus ordinary-pressure conversion method

ActiveCN102556988AHigh purityImprove pass ratePhosphorus compoundsWhite PhosphorusPhysical chemistry

The invention discloses an ultra-pure white phosphorus ordinary-pressure conversion method. Ultra-pure white phosphorus with the purity of 6N is produced, the produced white phosphorus with the purity of 6N is subjected to ordinary-pressure conversion to obtain red phosphorus, and then after drying, final products are obtained. Conversion adopts modes of cooling pressure reduction and tail gas pressure removal and also gradual temperature rise according to gradients. High-pure red phosphorus obtained through conversion with the method has stable quality and high purity and acceptability. Conversion rate is stabilized at more than 90%. The ultra-pure white phosphorus ordinary-pressure conversion method is safe in operation, low in energy consumption and cost and small in labor intensity, effectively prevents explosion from happening during ultra-pure phosphorus conversion, ensures production safety, is in the low-carbon environment during a production process, and lays the foundation for producing ultra-pure phosphorus in a large scale.

Owner:峨嵋半导体材料研究所

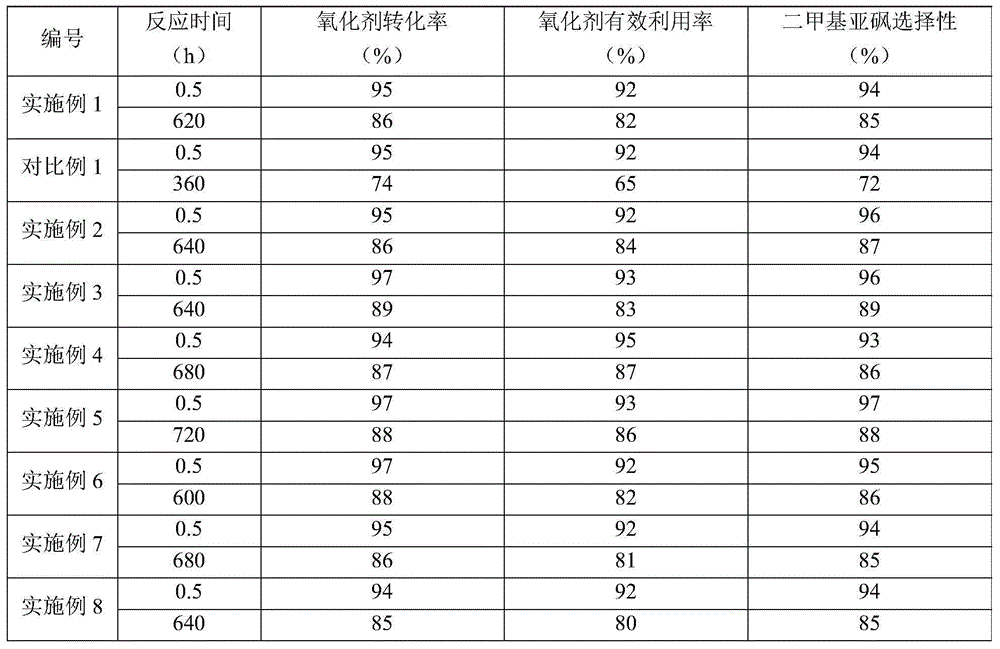

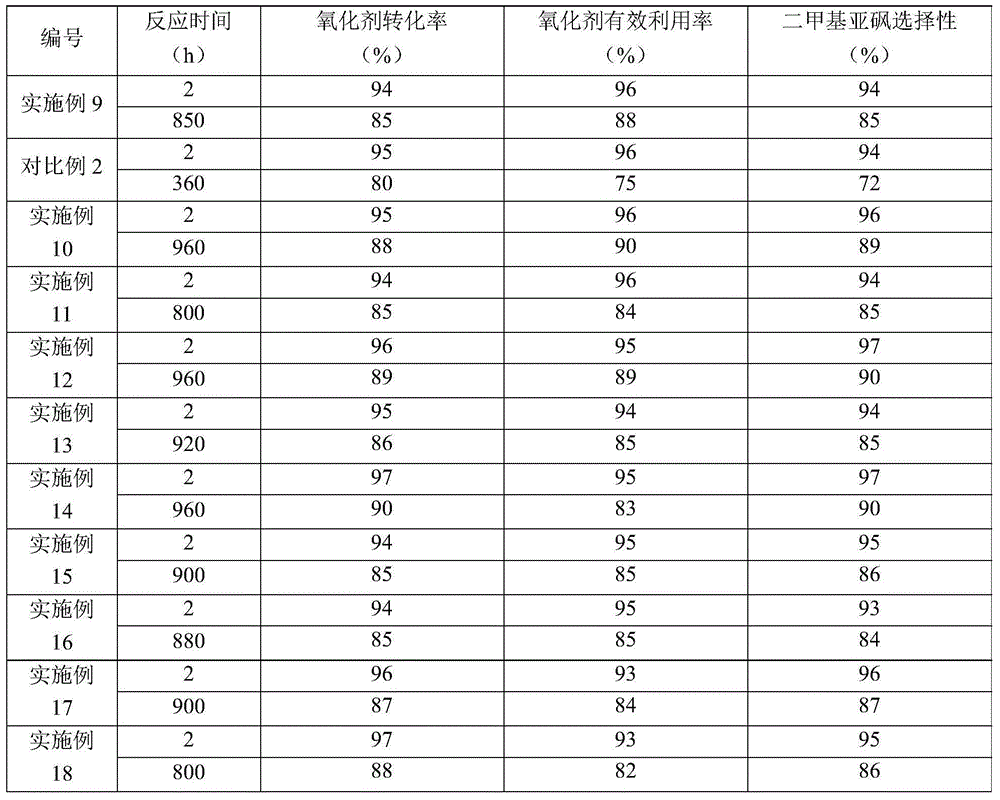

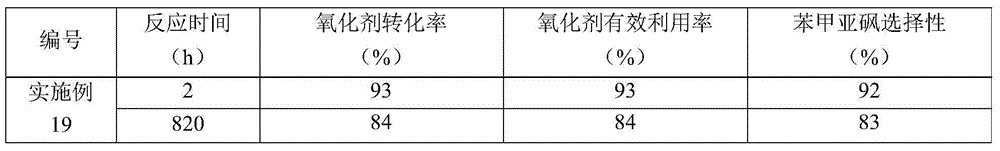

Thioether oxidation method

ActiveCN105384666AExtended one-way service lifeExtended service lifeOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The present invention discloses a thioether oxidation method, which comprises: continuously conveying a liquid mixture into a fixed-bed reactor to make the liquid mixture contact a titanium silicon molecular sieve loaded in the fixed-bed reactor under an oxidation reaction condition, wherein the liquid mixture contains thioether, at least an oxidizing agent and at least a solvent, and the method further comprises that: when the oxidizing agent conversion rate or the target oxidation product selectivity is reduced to a certain degree, the weight hourly space velocity of the solvent is improved until the oxidizing agent conversion rate and / or the target oxidation product selectivity meets the requirement. With the method of the present invention, the one way service life of the titanium silicon molecular sieve adopted as the catalyst can be effectively prolonged, the regeneration frequency of the catalyst can be reduced, the production efficiency can be improved, the operation stability can be improved, and the total service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

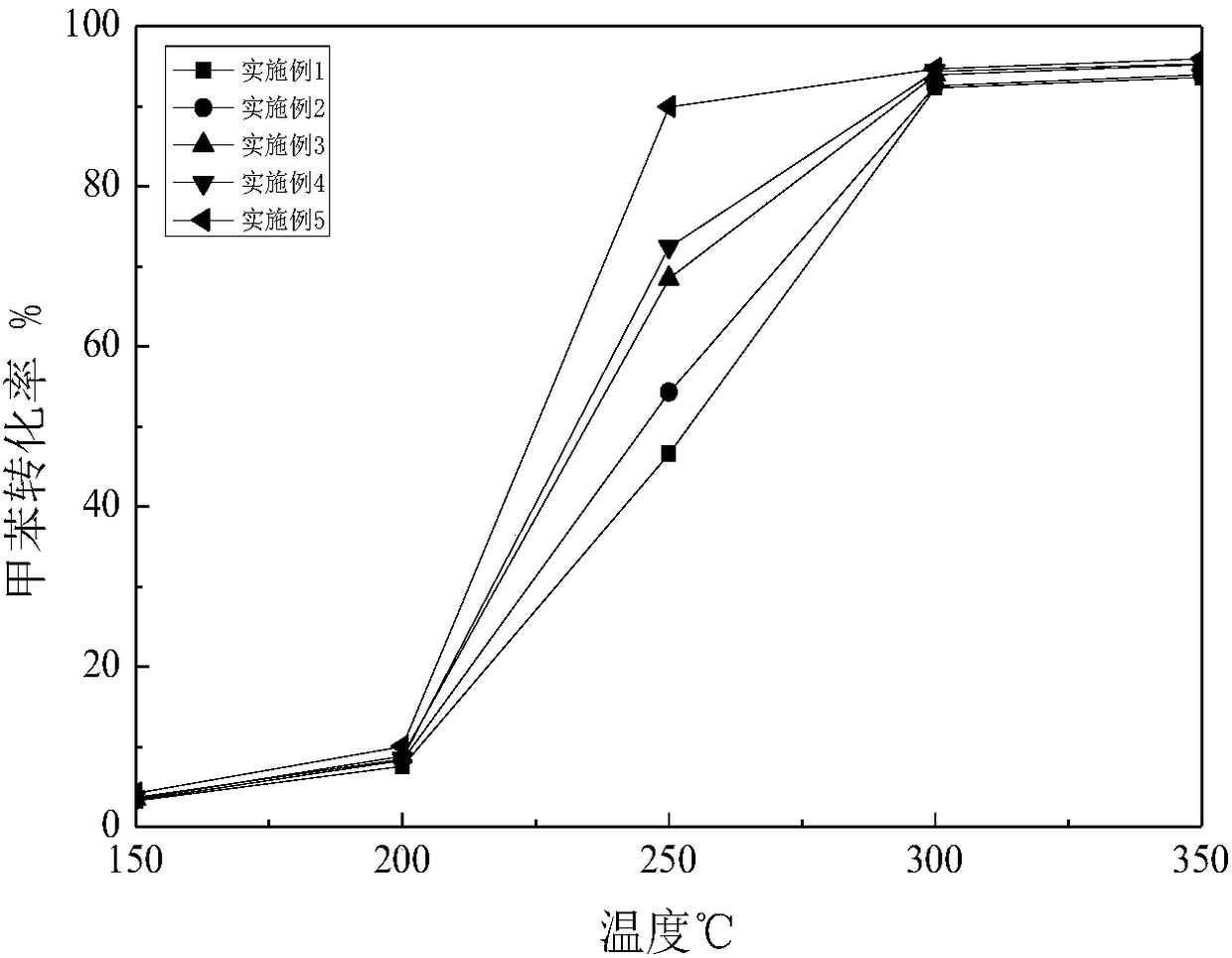

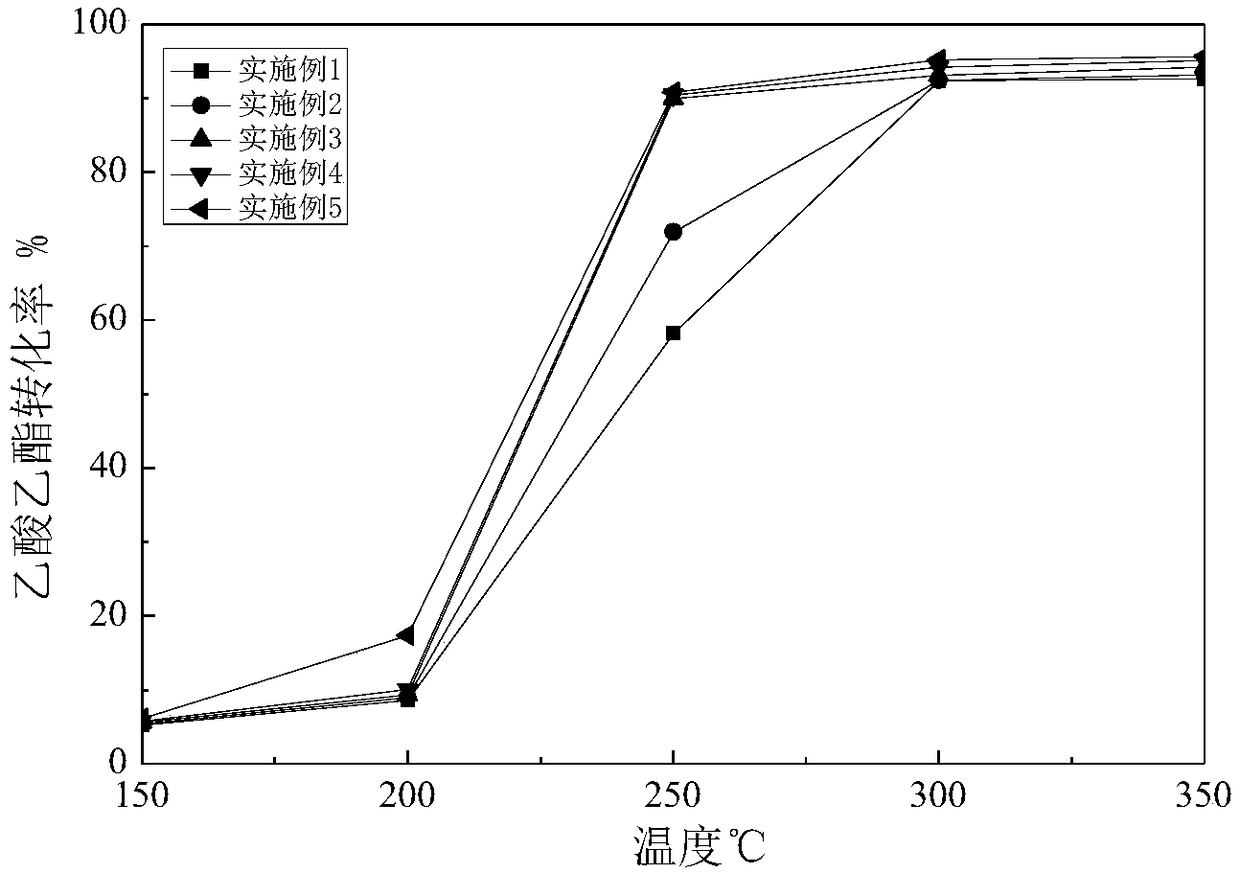

Catalyst for VOCs catalytic combustion and its preparation method

InactiveCN108144624ALarge specific surface areaMany active sitesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAcetic acidEthyl ester

The catalyst provided by the invention is an integrated catalyst; the catalyst takes a honeycomb ceramic matrix as a framework, an aluminum oxide as a coating, and Co, La and Ce as active components;the components are matched with specific content, the catalyst has big specific area and many activity sites while good structure and coating stability. The catalyst is applied to the catalytic combustion reaction of methylbenzene and ethyl acetate, and has high catalytic activity. Meanwhile, the catalyst has stable repeat using activity, and overcomes the shortcomings of poor high-temperature stability and bad repeat using activity of the traditional noble metal catalyst. The experiment indicates that through sonic oscillation, the drop rate of coating is 2% below. When the catalytic combustion temperature is 350 DEG C, the methylbenzene conversion rate is 93.67-95.97%, the ethyl acetate conversion rate is 92.65-95.64%. Through evaluation for continuous 1000 hours, the reaction conversionrate keeps stable.

Owner:SHANGHAI SHENGJIAN ENVIRONMENTAL SYST TECH

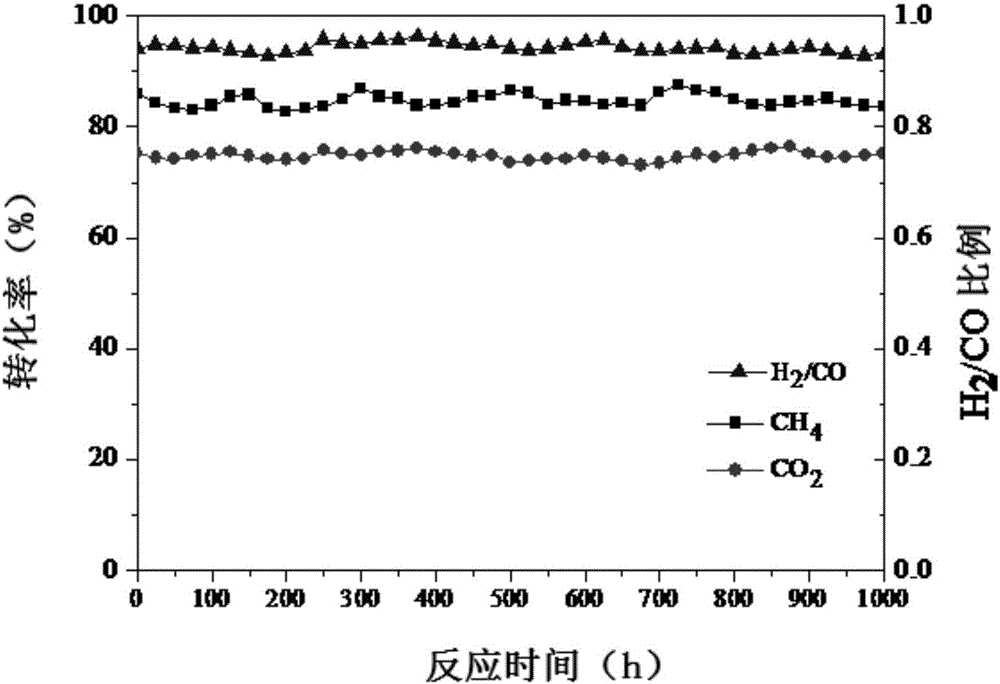

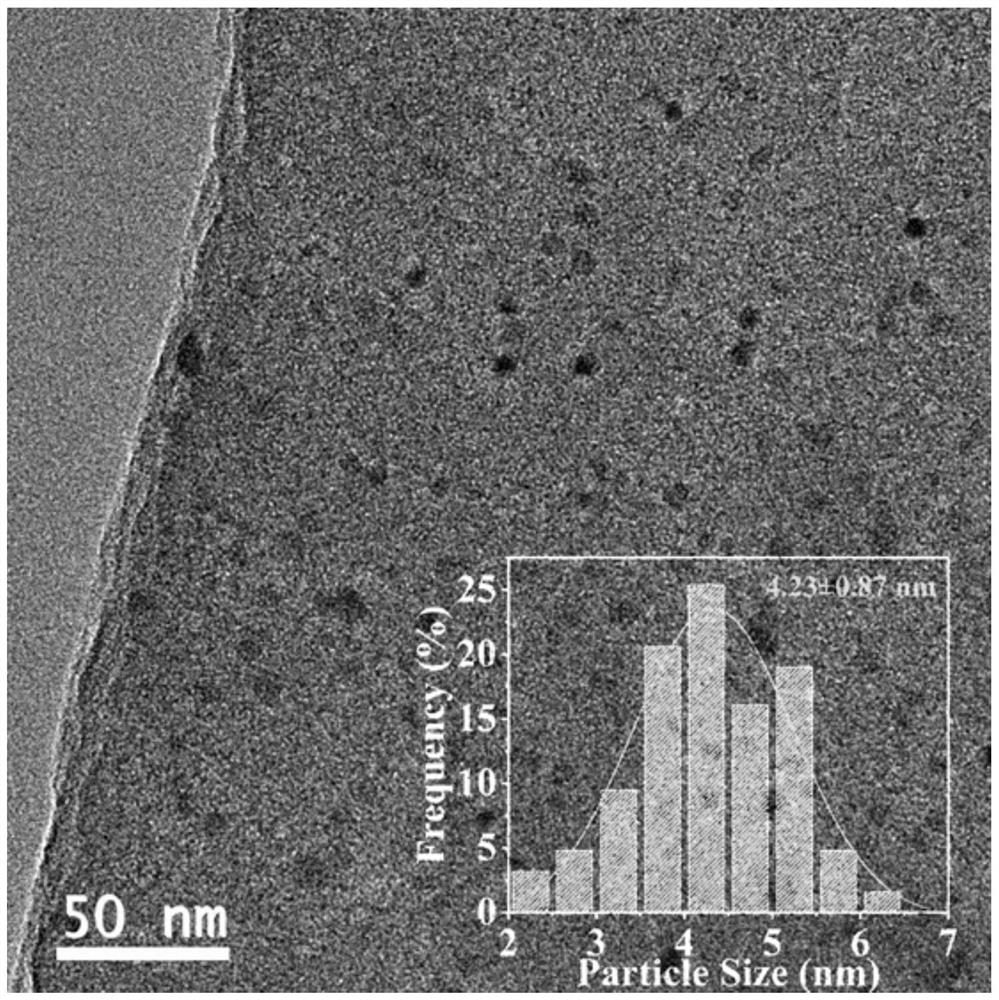

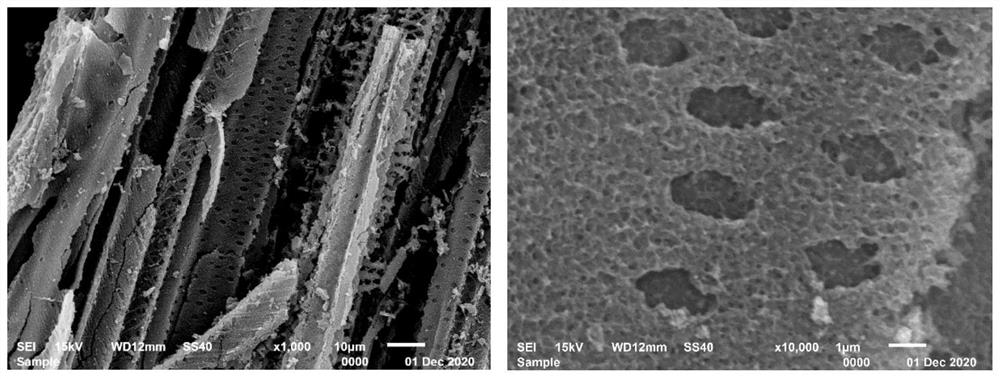

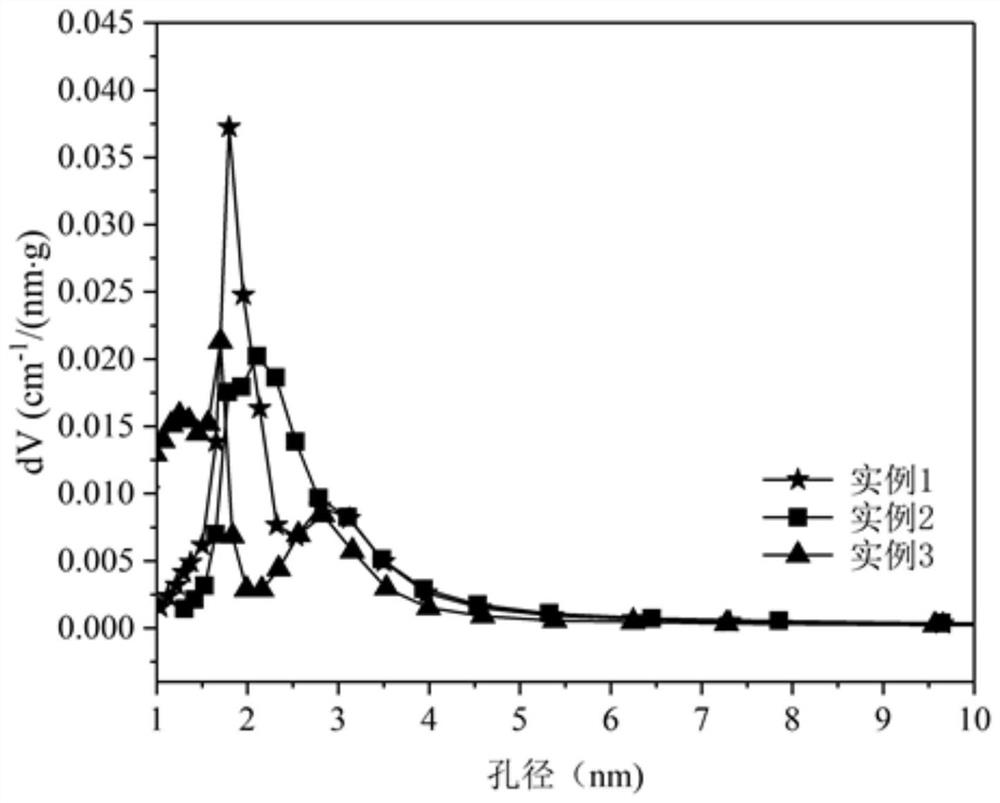

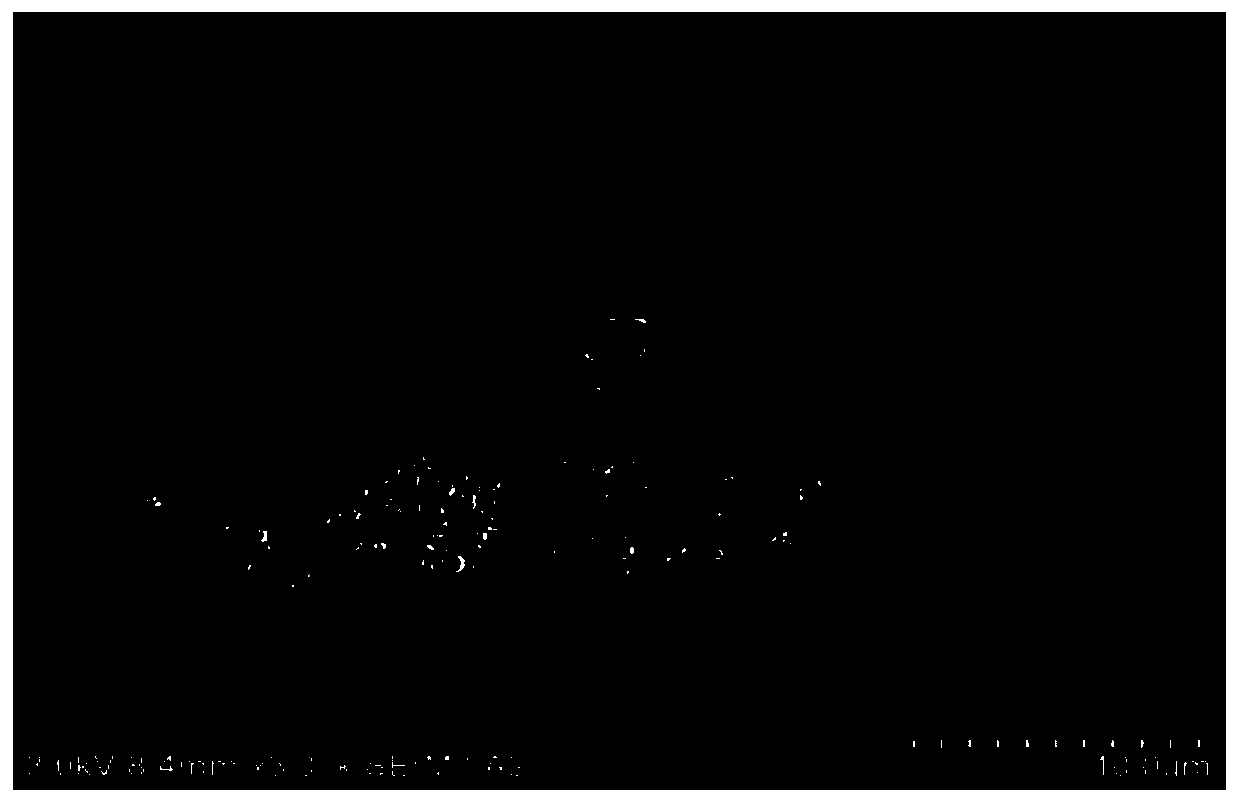

Biomass-based carbon material supported nano-nickel catalyst, preparation method and application thereof

ActiveCN112844476AEasy to prepareLow costHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsNickel catalystBiomass carbon

The invention discloses a biomass-based carbon material loaded nano nickel catalyst, a preparation method and application thereof. According to the invention, the catalyst is synthesized from biomass carbon and metallic nickel through a one-step hydrothermal method, wherein the metallic nickel is loaded into degraded gaps of the carbon material while the carbon material is generated, the content of the metallic nickel is 5-10 wt%, the content of a carbon-based carrier is 90-95 wt%, the particle size of metal nickel can reach 4.23 nm, and the dispersity of nickel reaches 23.64%; low-cost biomass carbon is used as a carrier, and nickel nanoparticles which are small in particle size and uniform in distribution are obtained; the used catalyst can be used for recovering nickel metal through simple calcination, so that cyclic utilization of the nickel metal is realized; the catalyst is applied to the technical field of synthesis gas preparation through carbon dioxide reforming; the catalyst prepared by the invention can be maintained for at least 500 hours and is not inactivated in a carbon dioxide reforming stability experiment, and the conversion rates of methane and carbon dioxide can be respectively stabilized at 80-92% and 90-98%; and the catalyst has high activity and stability, and carbon deposition is hardly generated in the reaction process.

Owner:WUHAN UNIV OF SCI & TECH

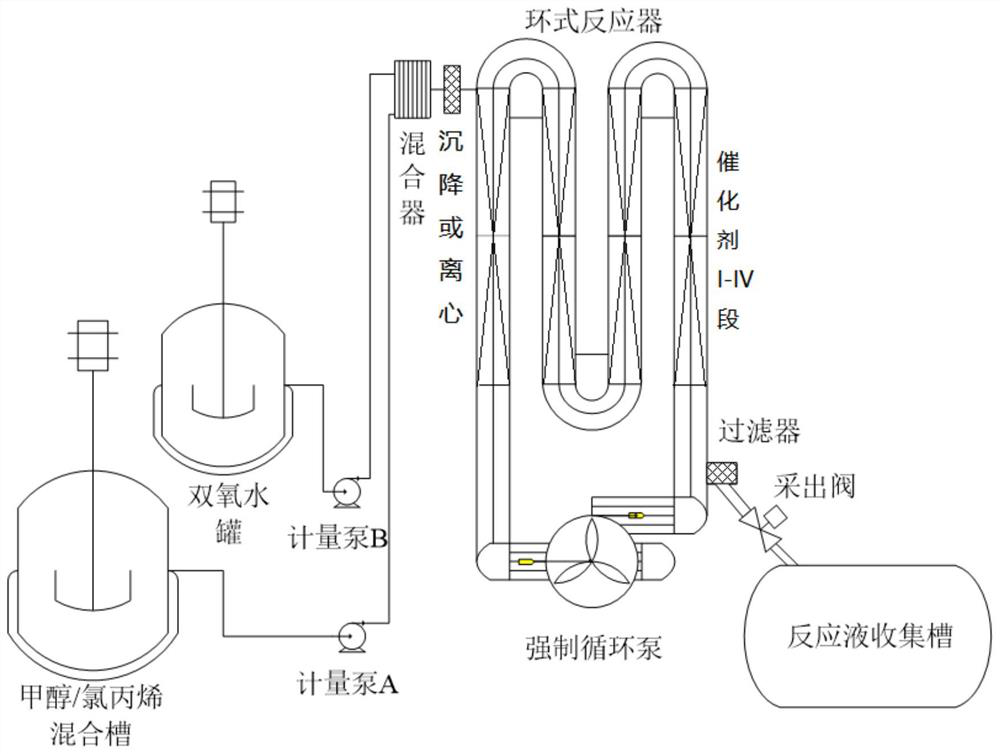

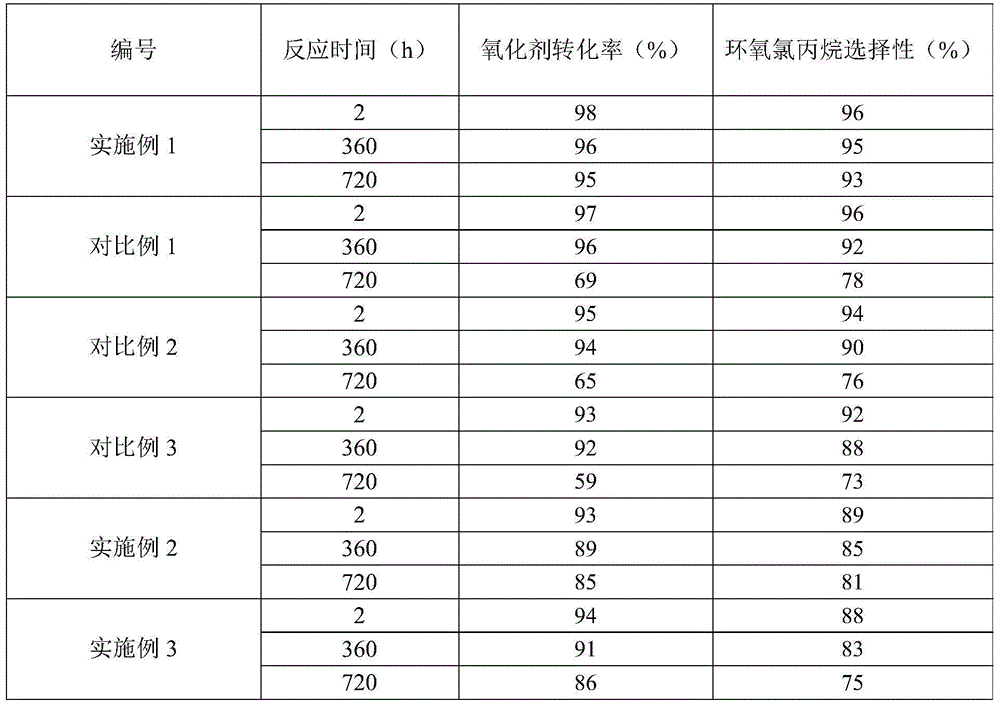

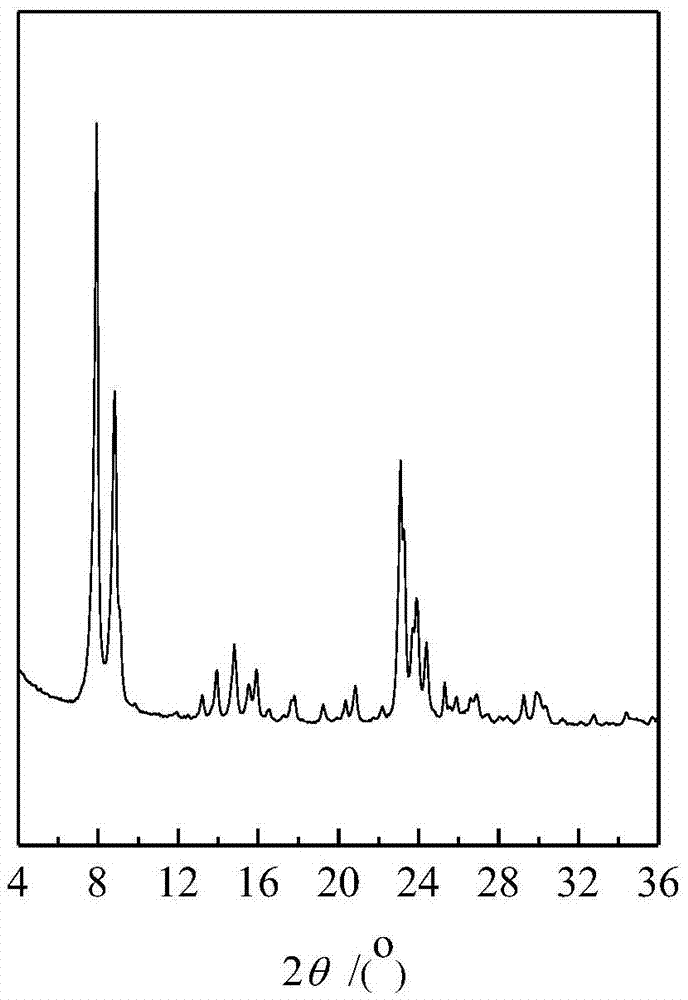

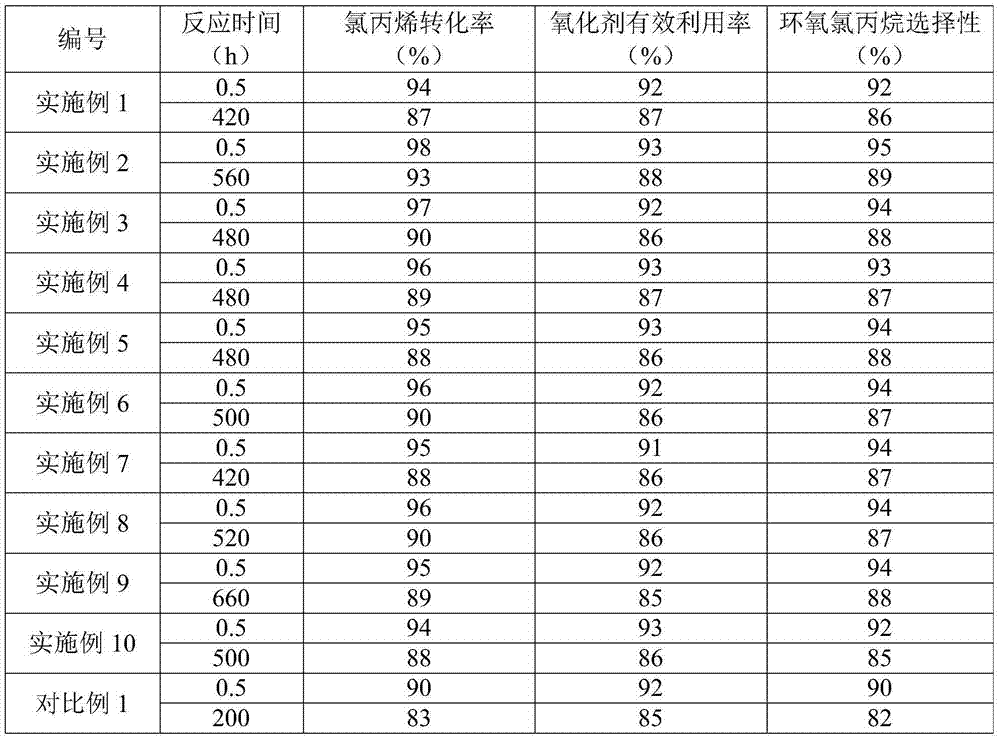

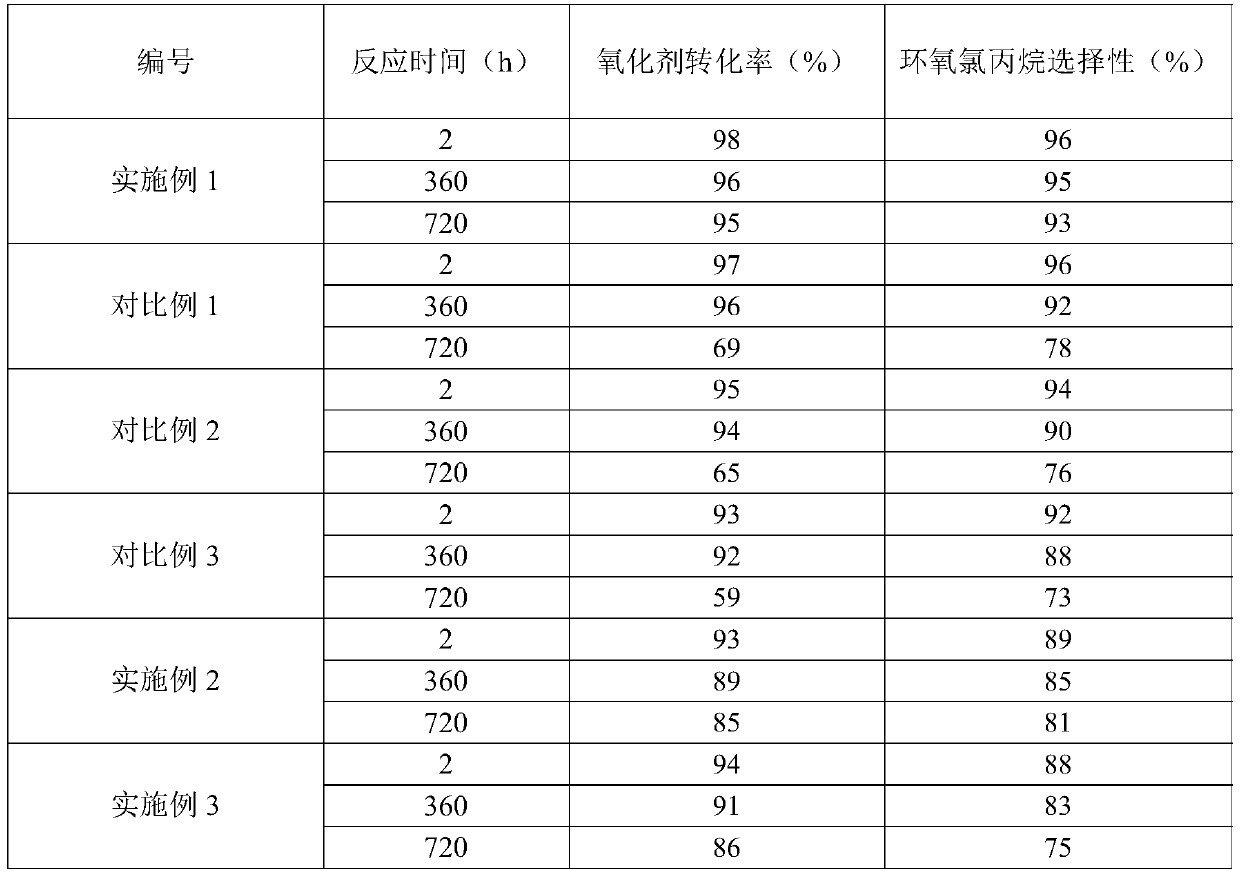

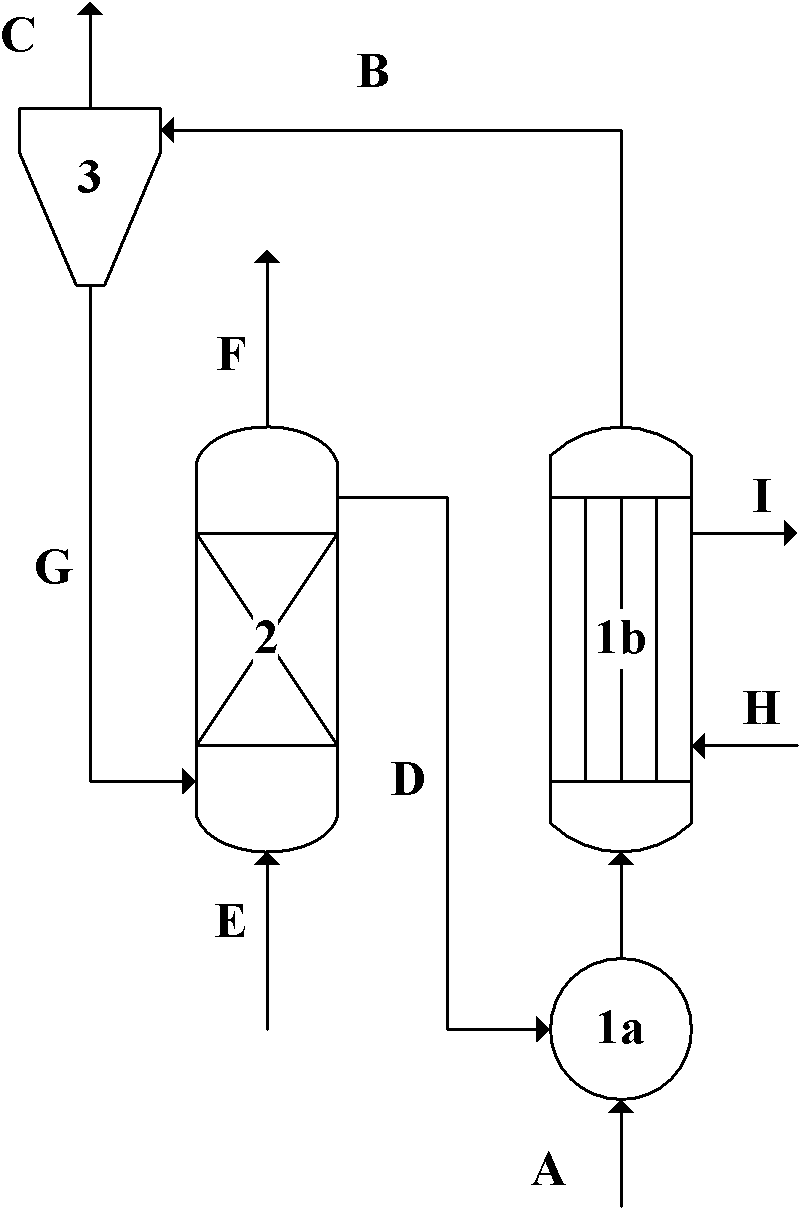

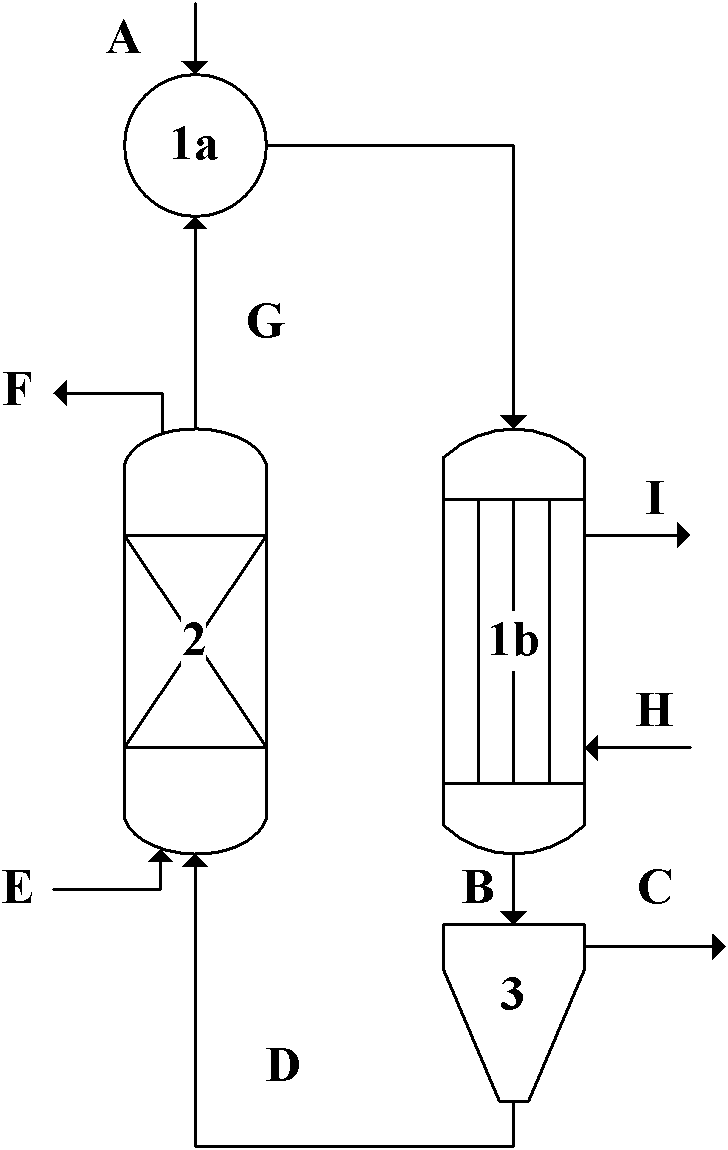

Continuous synthesis process of epoxy chloropropane by hydrogen peroxide method

PendingCN111978273AAchieve separationHigh selectivityOrganic chemistryPtru catalystProcess engineering

The invention provides a continuous synthesis process of epoxy chloropropane by hydrogen peroxide method. The continuous synthesis process comprises the following steps of adding hydrogen peroxide, methanol, chloropropene and a catalyst into a reactor for epoxidation reaction, wherein the reactor is a ring reactor, and the catalyst is pre-loaded into the ring reactor; enabling the chloropropene and the methanol to form a chloropropene and methanol mixed solution in a mixing tank, pumping chloropropene and methanol mixed solution into the ring reactor by a metering pump A, and pumping hydrogenperoxide into the ring reactor by a metering pump B. The synthesis process provided by the invention has the advantages of low methanol consumption, long service life of the catalyst, simple process device, realization of continuous operation, and realization of stable hydrogen peroxide conversion rate and high epichlorohydrin selectivity in a long-term continuous operation process.

Owner:JIANGSU YANGNONG CHEM GROUP +2

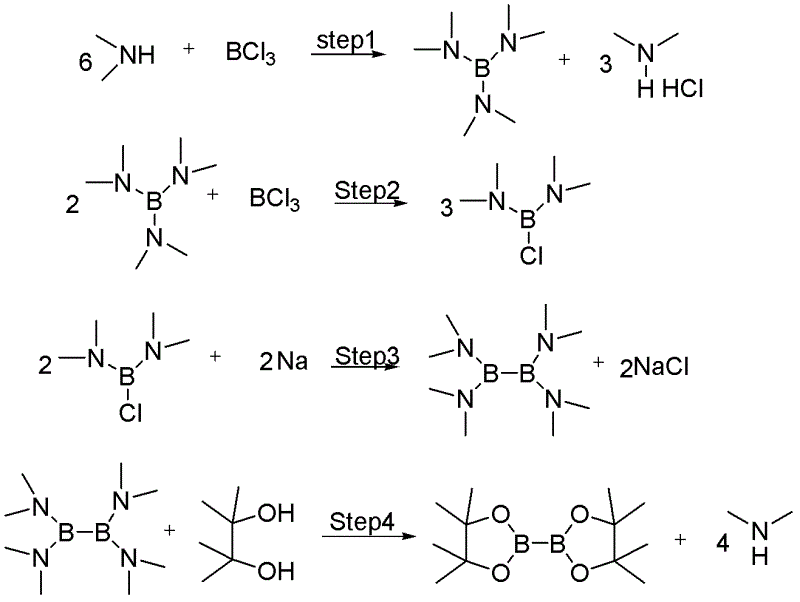

Method for synthesizing bis(pinacolato)diboron

ActiveCN102617623ALow raw material costEasy solvent recoveryGroup 3/13 element organic compoundsBoron trichlorideChemical reaction

The invention relates to a method for synthesizing bis(pinacolato)diboron. In the method, commercial boron trichloride, dimethylamine and pinacol in the market are used as starting raw materials, and two-step substitution, coupling and esterification are performed to synthesize bis(pinacolato)diboron, and the product obtained in each step is continuously fed to next step in a solution state, so that the operation is simplified and the loss is reduced. According to the synthesis method, the adopted raw materials are inexpensive and easily available, the chemical reaction conditions are mild, and the conversion rate, yield and purity are very high. The synthesis method can be amplified to near kintal scale, thereby providing a feasible synthesis method for large-scale production of bis(pinacolato)diboron.

Owner:ASYMCHEM LAB TIANJIN +4

Chloropropene oxidation method

ActiveCN105524028AExtended one-way service lifeReduce regeneration frequencyOrganic chemistryEpoxideMolecular sieve

The invention provides a chloropropene oxidation method. The method comprises the following steps: under oxidation reaction conditions, a liquid mixture comprising chloropropene and an oxidant flows through a catalyst bed layer. The catalyst bed layer comprises a first catalyst bed layer and a second catalyst bed layer. With the flow direction of the liquid mixture as a standard, the first catalyst bed layer is positioned upstream of the second catalyst bed layer. The titanium silicalite molecular sieve loaded in the first catalyst bed layer is hollow titanium silicalite molecular sieve. The titanium silicalite molecular sieve loaded in the second catalyst bed layer is a titanium silicalite molecular sieve different from the hollow titanium silicalite molecular sieve. When the method provided by the invention is used for oxidizing chloropropene, during a long-time continuous running process, a relatively stable oxidant conversion rate and a relatively high target oxidation product selectivity can be obtained. Especially, with the method provided by the invention, epoxide selectivity is high, such that subsequent separation purification difficulty is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Allyl chloride oxidation method

ActiveCN106967010AExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveApparent velocity

The present invention discloses an allyl chloride oxidation method, which comprises that a reaction material containing allyl chloride, an oxidizing agent and a solvent sequentially flows through catalyst bed layers from 1 to n under an oxidation reaction condition, wherein n is an integer of more than 2, and the catalyst bed layer is filled with at least a titanium-silicon molecular sieve; and when the reaction material passes through the catalyst bed layers from 1 to n, at least a flow carrier is introduced into the position between at least a pair of the adjacent catalyst bed layers among the catalyst bed layers from 1 to n, such that the apparent velocity of the reaction stream positioned in the downstream catalyst bed layer is higher than the apparent velocity of the reaction stream positioned in the upstream catalyst bed layer in the pair of the adjacent catalyst bed layers by adopting the flowing direction of the reaction material as the reference. With the method of the present invention, the one-way service life of the titanium-silicon molecular sieve can be effectively prolonged, the effective utilization rate of the oxidizing agent can be improved, and the target product selectivity can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultra-pure white phosphorus ordinary-pressure conversion method

ActiveCN102556988BHigh purityImprove pass ratePhosphorus compoundsWhite PhosphorusPhysical chemistry

The invention discloses an ultra-pure white phosphorus ordinary-pressure conversion method. Ultra-pure white phosphorus with the purity of 6N is produced, the produced white phosphorus with the purity of 6N is subjected to ordinary-pressure conversion to obtain red phosphorus, and then after drying, final products are obtained. Conversion adopts modes of cooling pressure reduction and tail gas pressure removal and also gradual temperature rise according to gradients. High-pure red phosphorus obtained through conversion with the method has stable quality and high purity and acceptability. Conversion rate is stabilized at more than 90%. The ultra-pure white phosphorus ordinary-pressure conversion method is safe in operation, low in energy consumption and cost and small in labor intensity, effectively prevents explosion from happening during ultra-pure phosphorus conversion, ensures production safety, is in the low-carbon environment during a production process, and lays the foundation for producing ultra-pure phosphorus in a large scale.

Owner:峨嵋半导体材料研究所

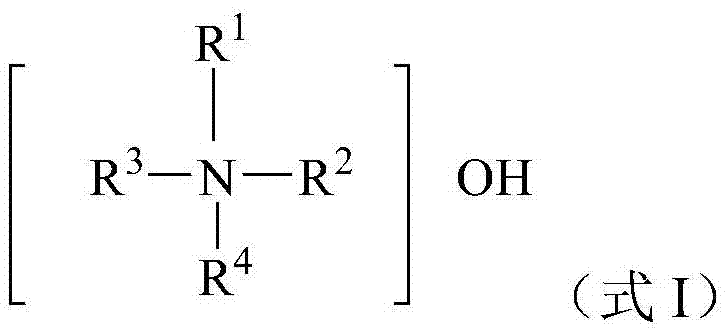

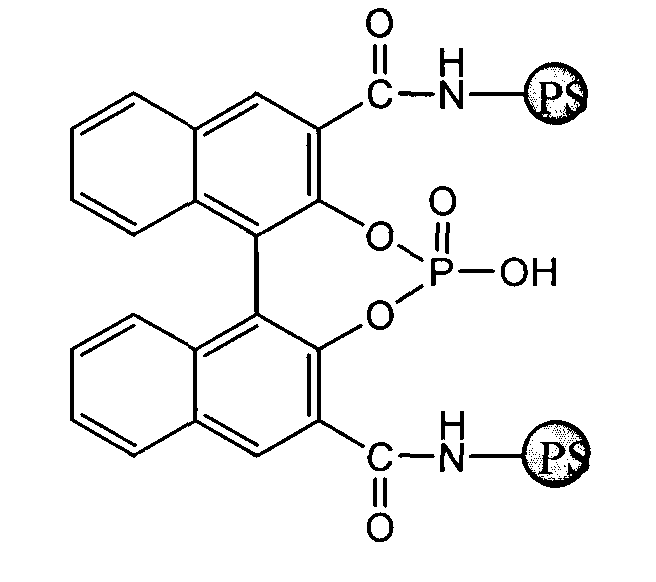

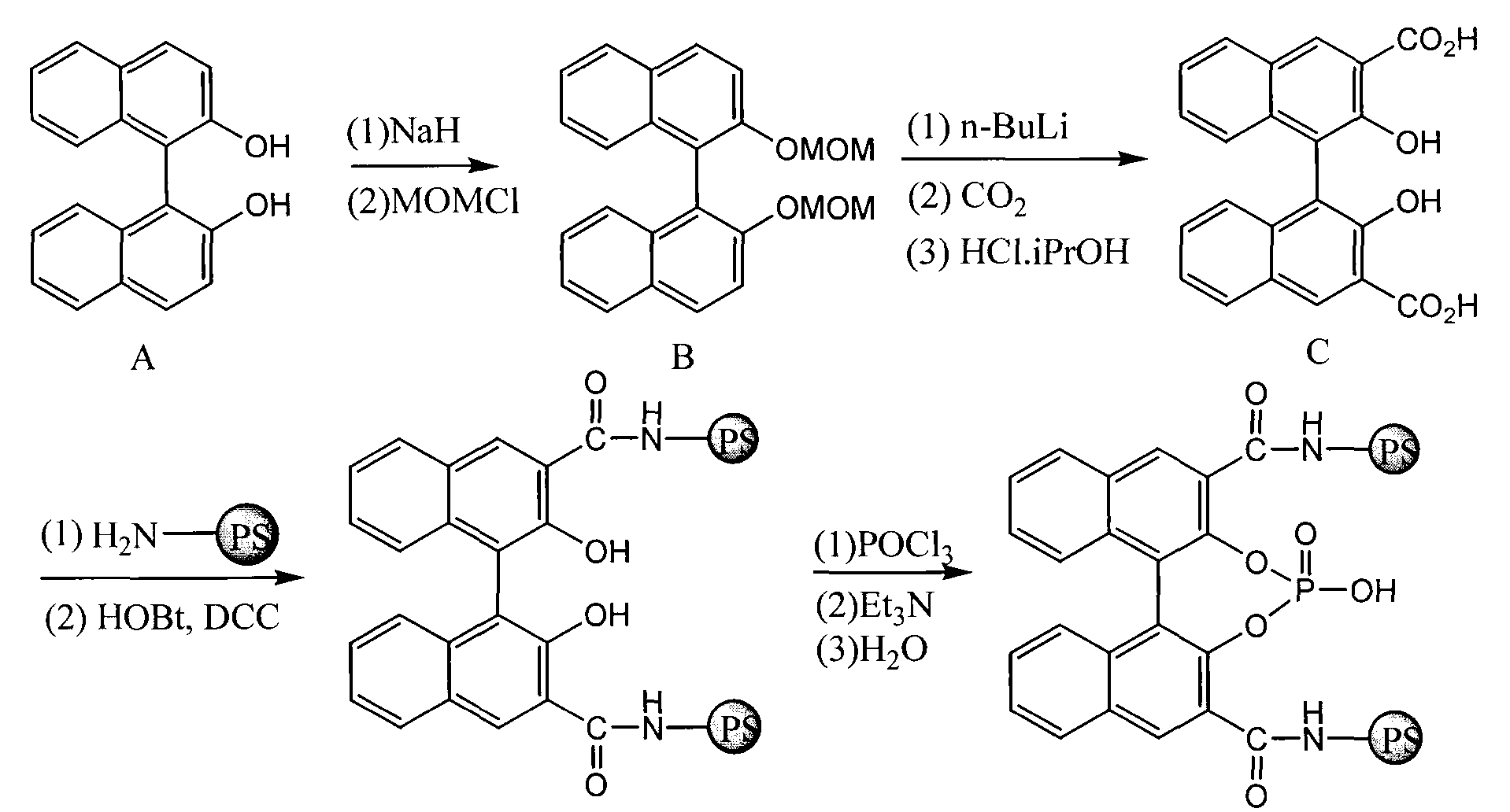

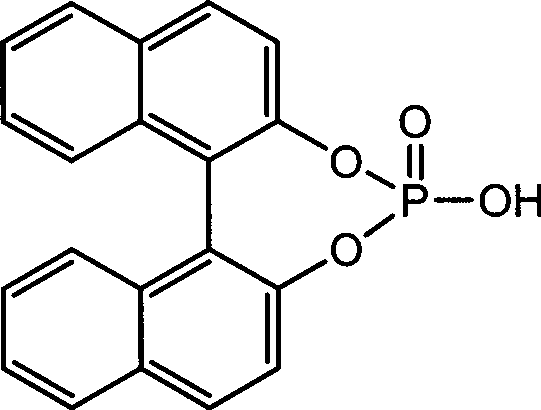

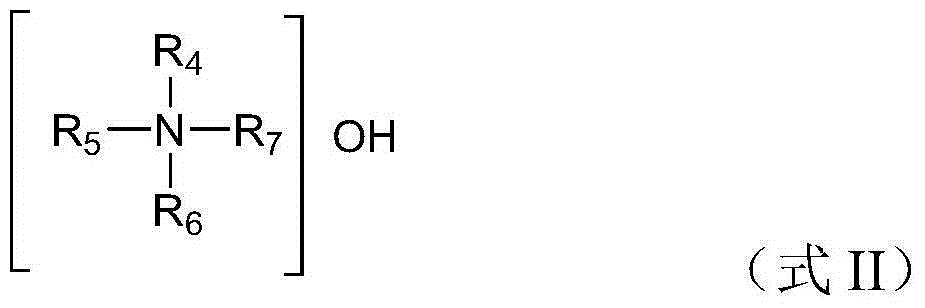

Immobilized chiral phosphoric acid catalyst and preparation method thereof

InactiveCN103008006AEasy to manufactureEasy to purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferPhosphoric acid

The invention discloses an immobilized chiral phosphoric acid catalyst and a preparation method thereof. A structural formula of the catalyst is as Formula I as shown in the specification; a carrier PS (polystyrene) is aminomethylated polystyrene. HCl, 1%DVB, and an amido substitution value is 1.0mmol / g, and the catalyst is in a chiral binaphthol structure, i.e. BINOL (binaphthol) can be in an R configuration or an S configuration. The preparation method of the catalyst comprises the following steps of a) synthesizing aminomethylated polystyrene immobilized chiral binaphthol, and b) allowing immobilized chiral binaphthol to react with POCl3 when Et3N exists, and obtaining polystyrene immobilized chiral phosphoric acid (Formula I). The heterogeneous catalyst can be prepared easily, the treatment operation after reaction is simple, the catalyst (Formula I) is applied to an asymmetric Friedel-Crafts alkylation reaction, the chemical yield of a product can reach 85%, and the enantiomeric selectivity ee value can reach 91%.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

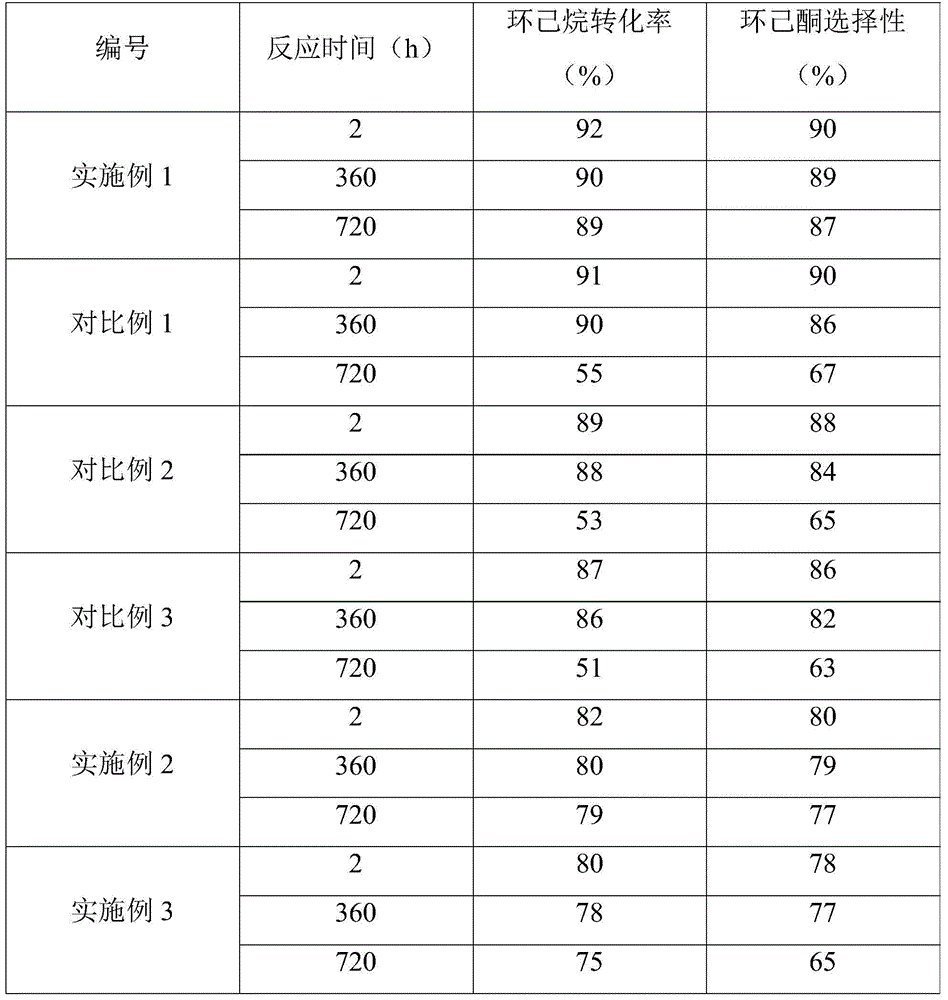

Oxidation method for cyclohexane

ActiveCN105523910AStable conversion rateHigh selectivityMolecular sieve catalystsCarbonyl compound preparation by oxidationMolecular sieveTitanium

The invention provides an oxidation method for cyclohexane. The method comprises the step of subjecting a liquid mixture containing cyclohexane and an oxidant to passing through catalyst beds under the condition of oxidation reaction, wherein the catalyst beds comprise a first catalyst bed and a second catalyst bed; on the basis of the flow direction of the liquid mixture, the first catalyst bed is located at the upper stream of the second catalyst bed; a titanium-silicon molecular sieve filled in the first catalyst bed is a hollow titanium-silicon molecular sieve; and the titanium-silicon molecular sieve filled in the second catalyst bed is the titanium-silicon molecular sieve different from the hollow titanium-silicon molecular sieve. The method provided by the invention can effectively prolong the single-way service life of the titanium-silicon molecular sieve used as a catalyst, reduce regeneration frequency of the catalyst, improve production efficiency, and enhance operation stability and prolong the total service life of the catalyst at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of chloropropene oxidation method

The invention provides a method for oxidizing allyl chloride, the method comprising: under oxidation reaction conditions, making a liquid mixture containing allyl chloride and an oxidizing agent flow through a catalyst bed; the catalyst bed includes a first catalyst bed and a second catalyst bed. The catalyst bed is based on the flow direction of the liquid mixture, the first catalyst bed is located upstream of the second catalyst bed, and the titanium-silicon molecular sieve packed in the first catalyst bed is a hollow titanium-silicon molecular sieve; The titanium-silicon molecular sieve packed in the second catalyst bed is a titanium-silicon molecular sieve different from the hollow titanium-silicon molecular sieve. By adopting the method for oxidizing chloropropene of the present invention, a relatively stable oxidant conversion rate and a relatively high selectivity of target oxidation products can be obtained during long-term continuous operation. In particular, by adopting the method of the present invention, the selectivity of epoxides is high, thereby reducing the difficulty of subsequent separation and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

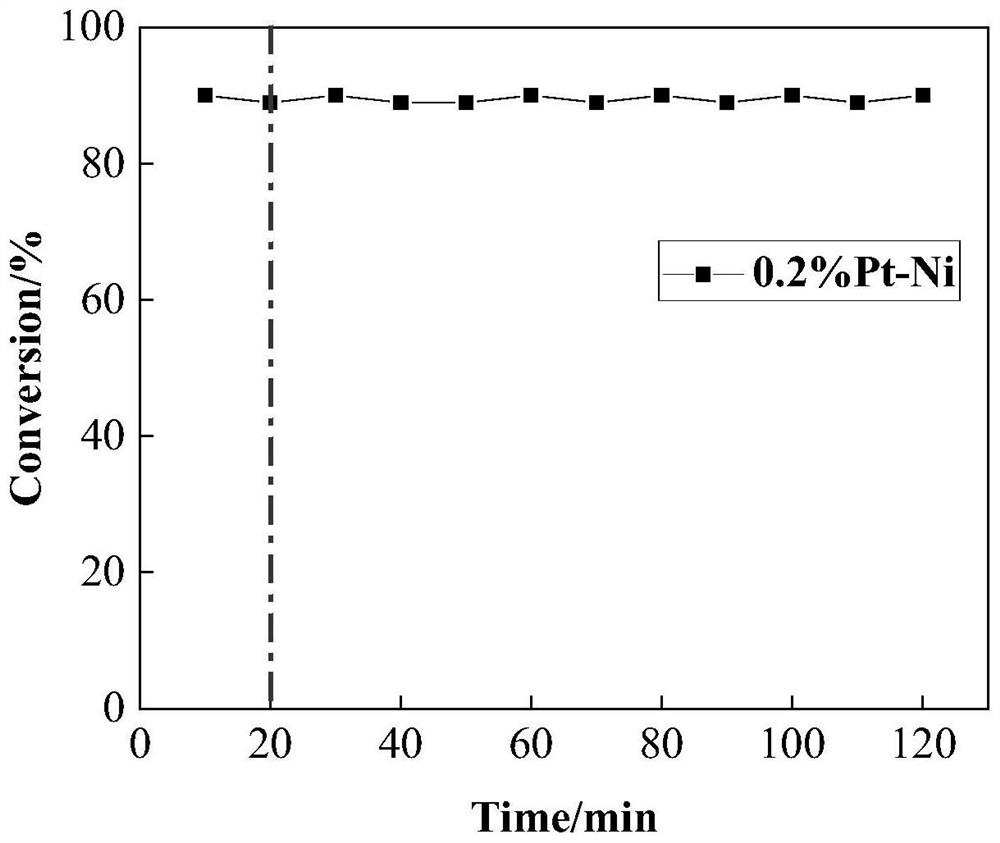

VOCs catalytic combustion monolithic metal foam catalyst and preparation and application thereof

PendingCN112044448AThe preparation method is simple and flexibleStrong thermal shock resistance and stabilityCatalyst activation/preparationIncinerator apparatusIon exchangeNoble metal

The invention provides a noble metal monolithic catalyst which takes foamed nickel as a carrier and Pt or Pd as an active component, and the mass loading capacity of the active component is 0.1-1%. The catalyst is prepared by an ion exchange method, and the reaction temperature is 20-90 DEG C; the preparation method of the noble metal integral foam nickel catalyst is simple and flexible, and the noble metal integral foam nickel catalyst has excellent activity in catalytic combustion of VOCs, and has excellent water resistance, thermal shock resistance and very high stability.

Owner:ZHEJIANG UNIV OF TECH

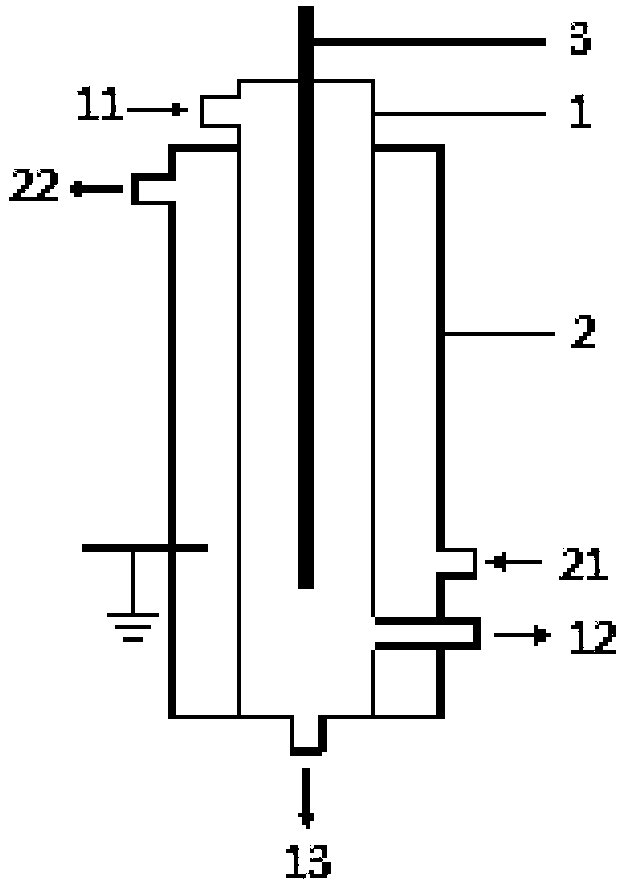

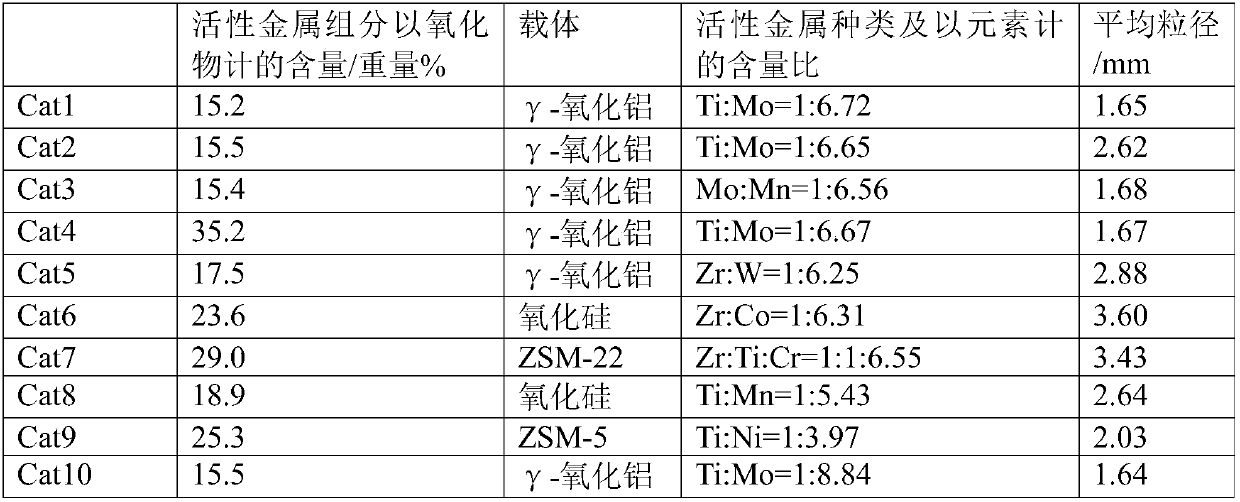

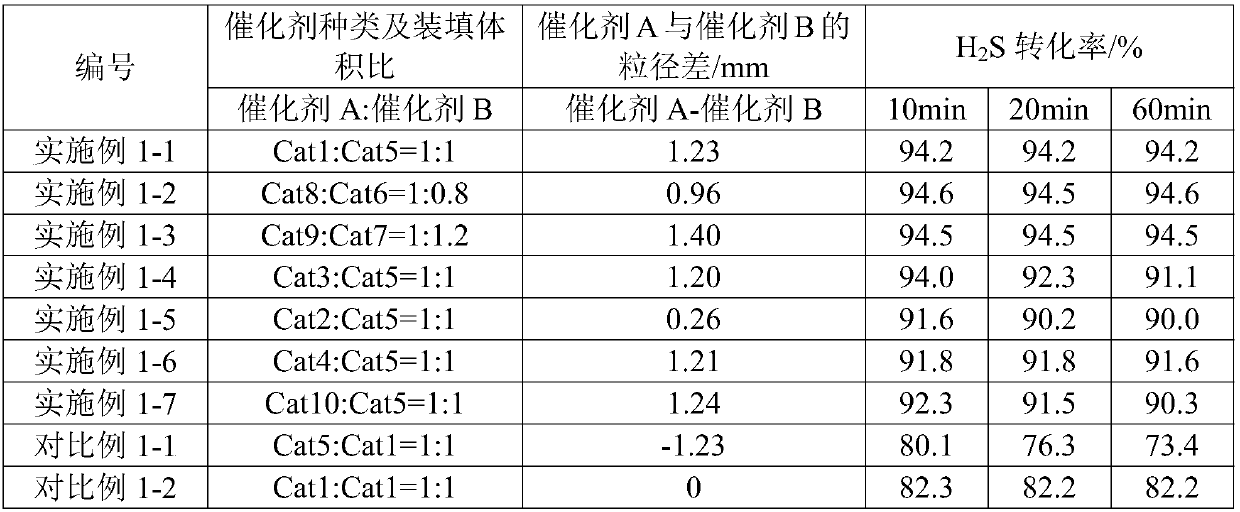

Catalyst filling method for decomposing hydrogen sulfide, and method for decomposing hydrogen sulfide

ActiveCN110124477AImprove conversion rateStable conversion rateGas treatmentDispersed particle separationHydrogenDecomposition

The invention relates to the field of hydrogen sulfide decomposition, discloses a catalyst filling method for decomposing hydrogen sulfide, and a method for decomposing hydrogen sulfide. The filling method comprises: sequentially loading a decomposition catalyst A and a decomposition catalyst B in a low-temperature plasma reactor according to a stream direction, wherein the decomposition catalystA and the decomposition catalyst B respectively contain a carrier and an active metal component supported on the carrier, and the average particle size of the decomposition catalyst B is larger than the average particle size of the decomposition catalyst A. According to the present invention, with the application of the filling method in the decomposition of hydrogen sulfide into elemental sulfurand hydrogen, the high hydrogen sulfide conversion rate can be obtained compared with the methods in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

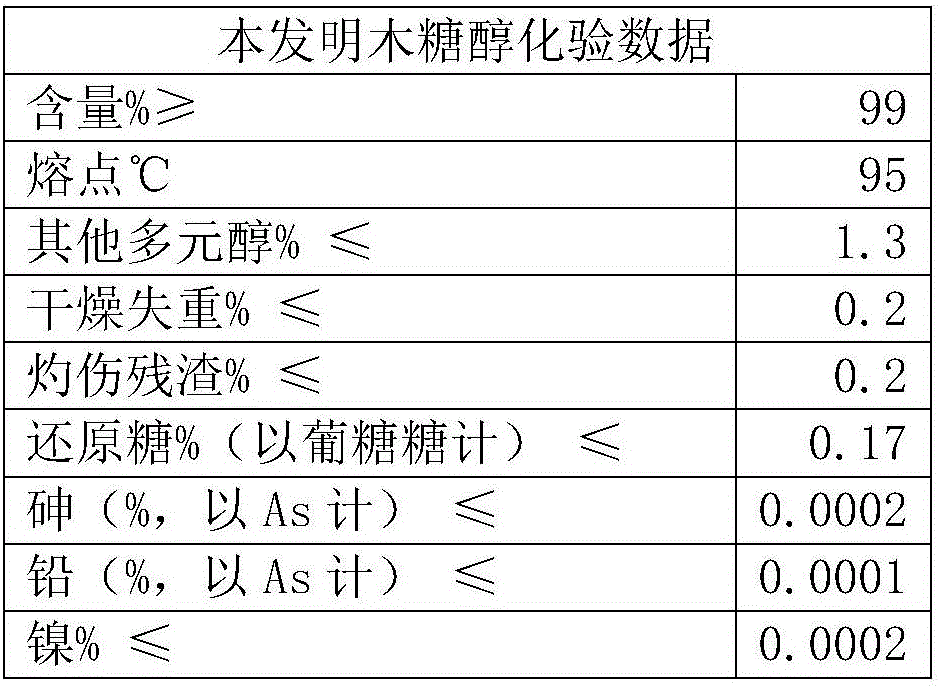

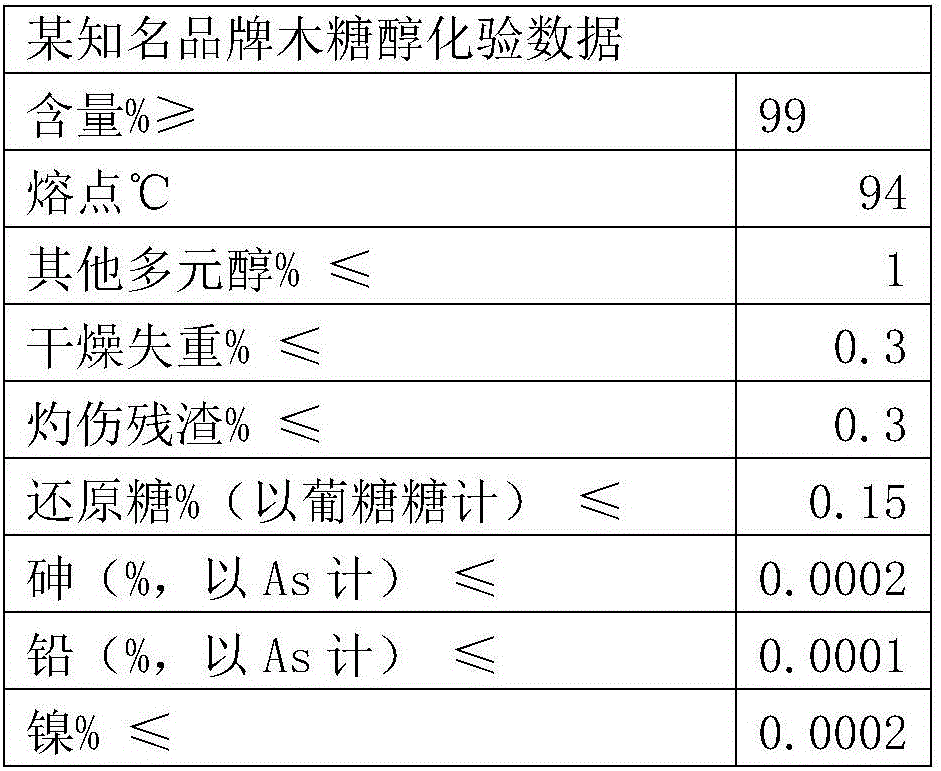

Method for producing xylitol with hemicellulose extracted from liquid waste of regenerated cellulose fiber production or papermaking

ActiveCN106349012AExpand sourceReduce pretreatment processXylose productionPreparation by oxygen reductionLiquid wasteHydrolysate

The invention relates to a method for producing xylitol with hemicellulose extracted from liquid waste of regenerated cellulose fiber production or papermaking. The method includes: collecting the liquid waste of regenerated cellulose fiber production or papermaking as an original hemicellulose solution; splitting the original hemicellulose solution under the sulphuric acid catalyst action and allowing the hemicellulose in the original hemicellulose solution and water to combine to form pentose to obtain hydrolysate; subjecting the hydrolysate to decoloration by the aid of a decolorizing agent; after decoloration, subjecting the hydrolysate to primary ion exchange with anion exchange resin to remove sulfate ions from the hydrolysate; subjecting the hydrolysate to primary concentration, secondary ion exchange, hydrotreating, tertiary ion exchange and secondary concentration to finally obtain the xyliton product. With the method that hemicellulose in the liquid waste of the regenerated cellulose fiber production or papermaking is taken as the raw material, source of the raw material of the xylitol is expanded, and full utilization of the resource is realized; a conventional pretreatment process of the xylitol is omitted, and the problem about pollution caused by acidic water and waste sludge discharge is solved.

Owner:唐山三友集团兴达化纤有限公司

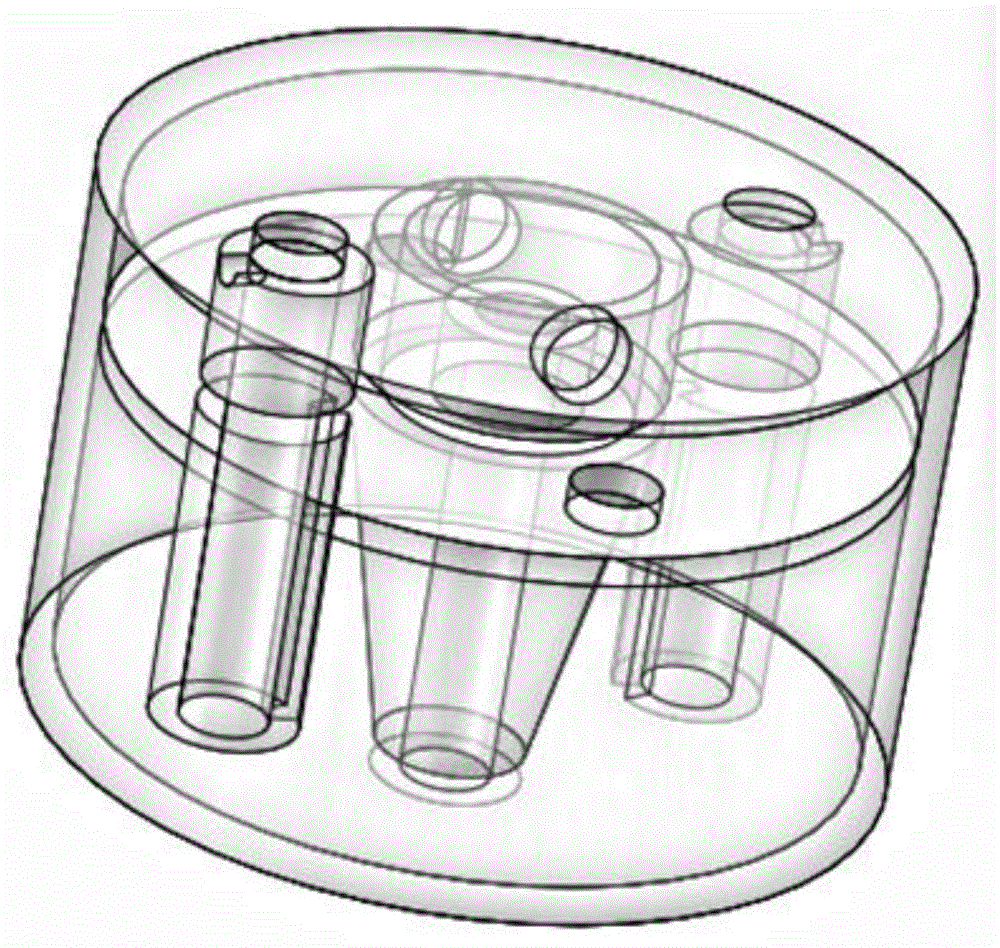

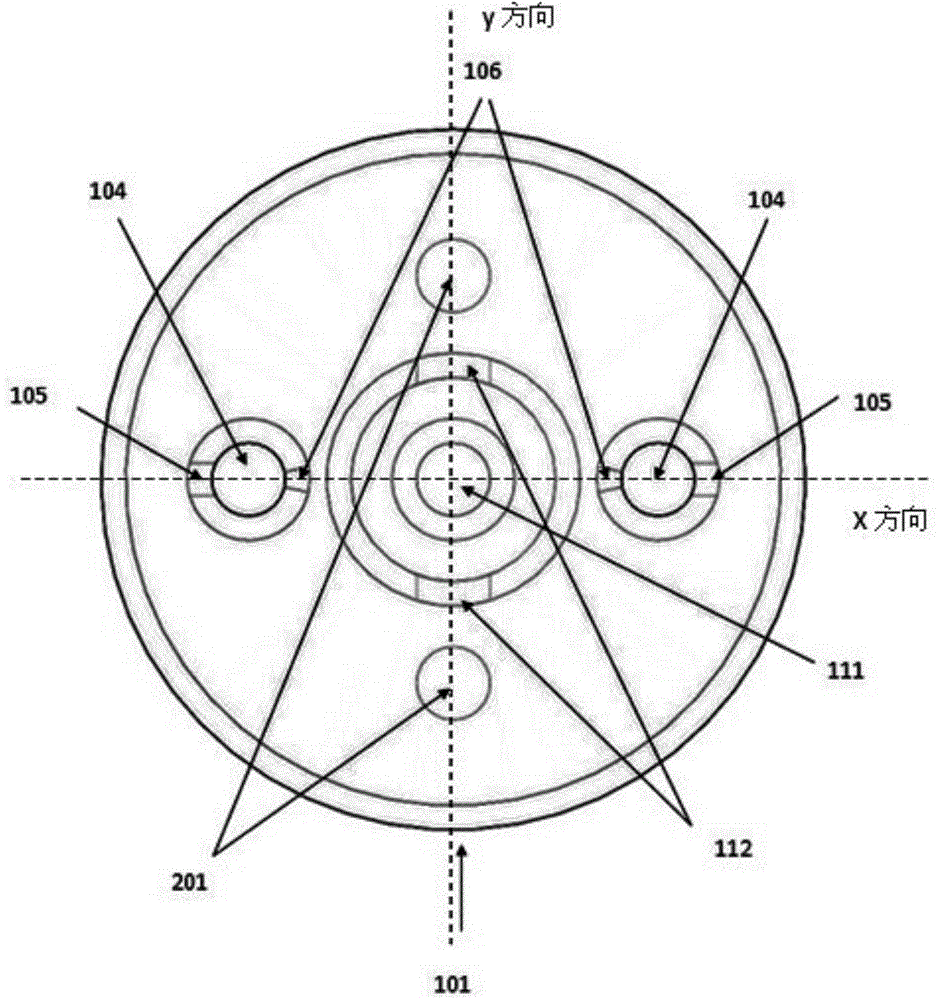

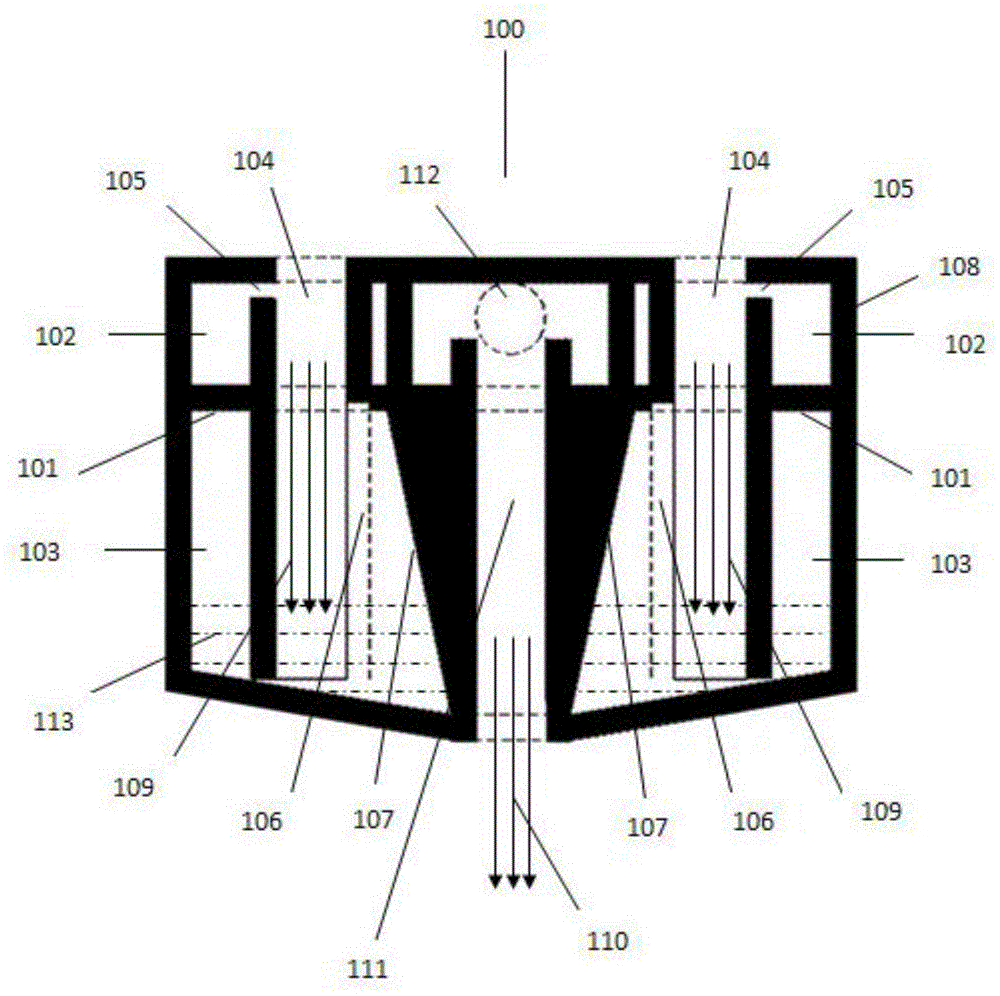

Reactor used for semiconductor single crystal material vapor phase epitaxy growth

ActiveCN105986314AExtended stayQuality improvementPolycrystalline material growthFrom chemically reactive gasesRetention timeGas phase

The invention provides a reactor used for semiconductor single crystal material vapor phase epitaxy growth. The reactor is composed of a baffle, gas inlet pipes, an inverted-trapezoidal truncated cone, gas outlet holes, a metal-containing precursor outlet pipe, and an outer wall. The baffle divides the reactor into an upper-layer zone and a lower-layer zone. Openings are provided at the tops of the gas inlet pipes, such that part of halide gas or halogen gas is preserved at the upper-layer zone of the reactor, and can be subjected to a reaction with a metal source steam escaped from the lower-layer zone to the upper-layer zone. Therefore, the metal source is effectively prevented from mixing into a reaction precursor, and quality and yield of crystals obtained through epitaxy growth are greatly improved. Also, with the inner side wall openings of the gas inlet pipes, the baffle, the inverted-trapezoidal truncated cone and the gas outlet holes, halide or halogen gas flow direction and process can be changed, such that the retention time of the halide or halogen gas in the lower-layer zone is increased. The chance for the halide or halogen gas to contact the metal source is increased, such that the efficiency for the halide or halogen gas to be converted into the metal-containing precursor is not sensitive to the height of metal source liquid level. Therefore, conversion efficiency is stable; epitaxy growth rate and crystal quality are stable and controllable. The reactor facilitates the large-scale production of nitride single crystal materials.

Owner:SINO NITRIDE SEMICON

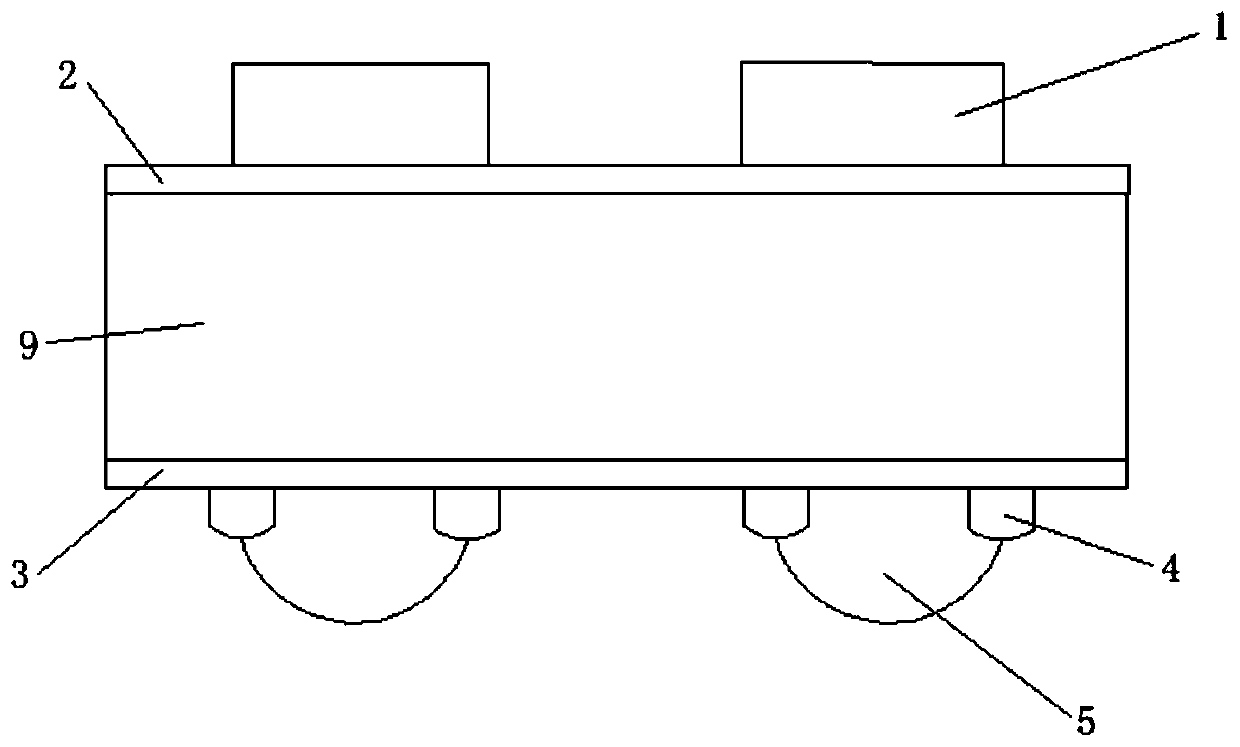

Solar cell and preparation method thereof

ActiveCN110289339AImprove stabilityStrictly limit the contact areaFinal product manufacturePhotovoltaic energy generationSilver pasteSlurry

The invention discloses a solar cell and a preparation method thereof, belongs to the technical field of solar cells. The preparation method of the solar cell comprises the following steps: carrying out double-sided texturing; performing tubular phosphorus diffusion on the suede; performing etching; coating the front surface of the silicon wafer with a film; performing Al2O3 passivation on the back surface of the silicon wafer; after passivation is finished, printing a back electrode with silver paste and performing drying; printing and drying the back electric field by adopting ceramic slurry, and reserving an aluminum slurry printing position; performing aluminum paste printing and drying on the back electric field at the reserved position; performing silver paste printing and drying on the positive electrode; and feeding a battery piece into a sintering furnace for sintering. Compared with a PERC battery piece manufacturing process, the method has the advantages that the processes of back silicon nitride coating and laser grooving are omitted, and the equipment transformation and investment cost can be greatly reduced. The invention also provides the solar cell which contains the ceramic slurry, so that the stability of the average conversion rate of the cell is improved.

Owner:江苏辉伦太阳能科技有限公司

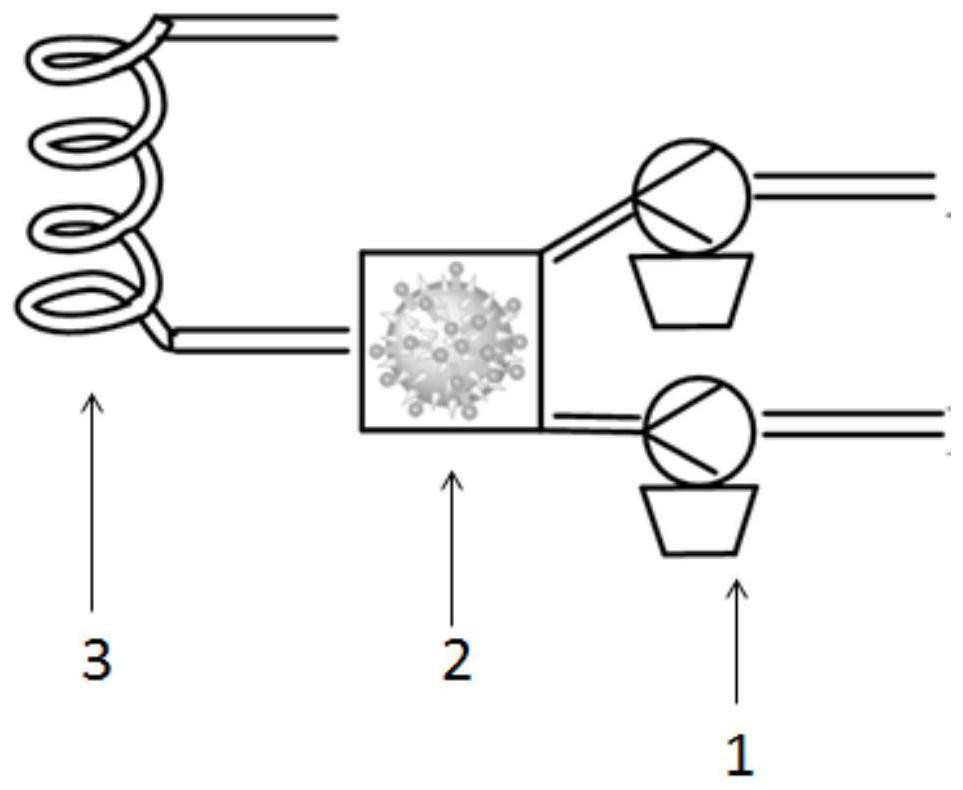

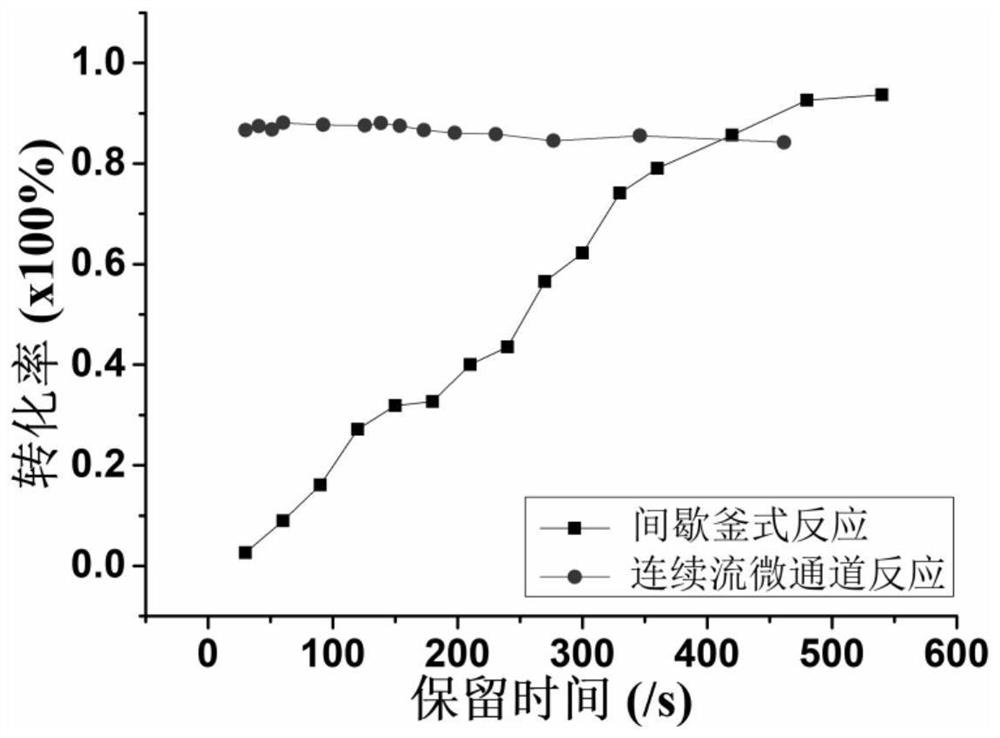

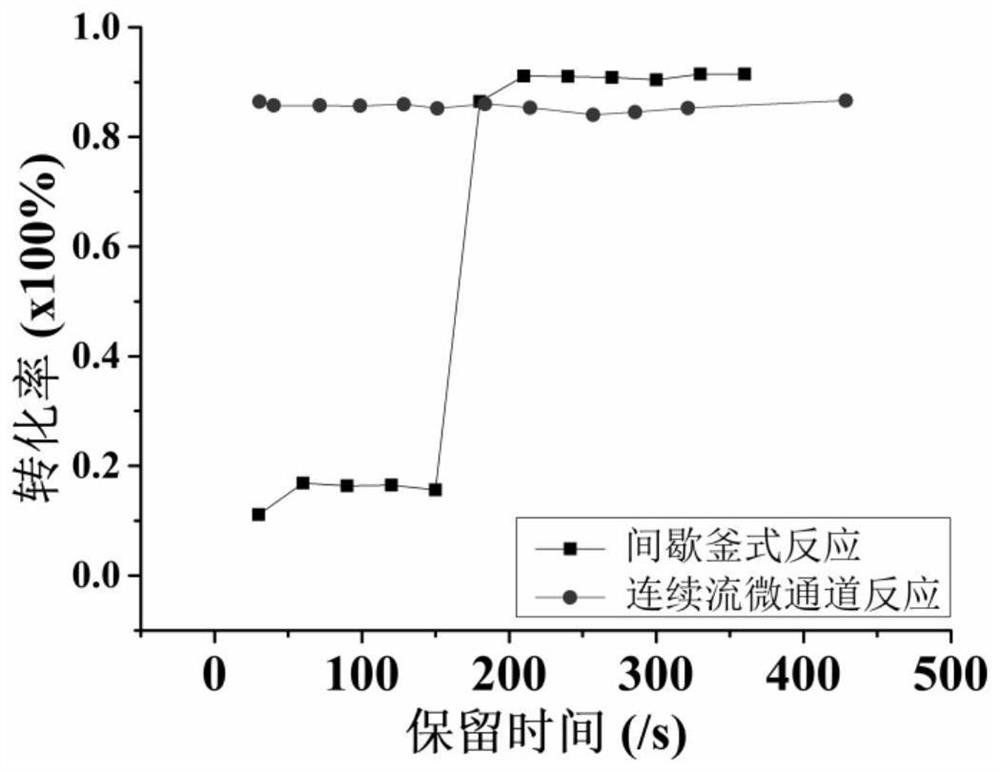

Preparation method of organosilicon auxiliary agent

PendingCN112661965AEasy to produceStable conversion rateFoam dispersion/preventionPtru catalystHydrosilylation

The invention relates to a preparation method of an organosilicon auxiliary agent, which comprises the following steps: respectively introducing a mixture of hydrogen-containing silicone oil and a catalyst, and one or more of aliphatic hydrocarbon, ether and alcohol containing double bonds into a tubular continuous flow reactor, and carrying out hydrosilylation reaction to obtain the organosilicon auxiliary agent, wherein the catalyst is salt of transition metal, the temperature in the tubular continuous flow reactor is controlled to be 50-300 DEG C, and the retention time of the material in the tubular continuous flow reactor is 1-600s. The preparation method provided by the invention can realize continuous production of different types of organosilicon polymer assistants, and greatly simplifies the production process of different door products; the conversion rate of the raw materials can reach 90% or above in a short time, and the conversion rate of the raw materials is stable; the preparation method provided by the invention can effectively ensure the product quality, can improve the production efficiency and can reduce the production cost.

Owner:AFCONA CHEM HAIMEN

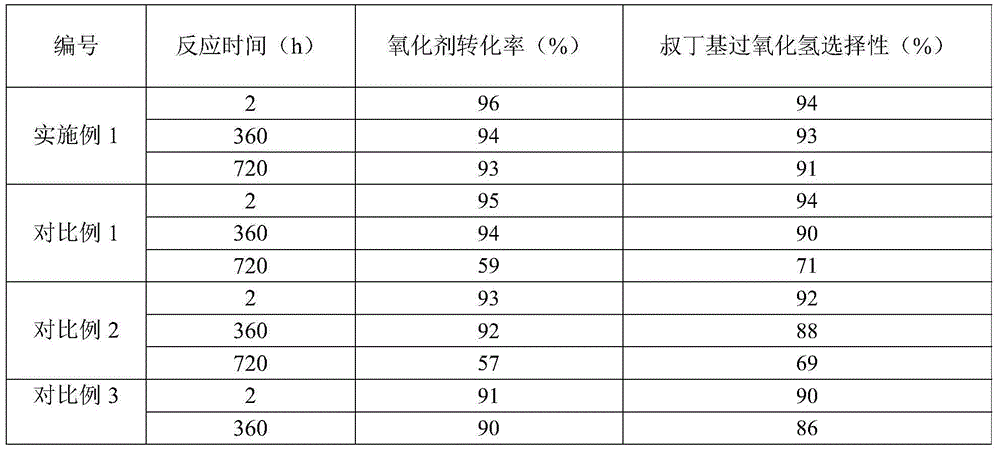

Oxidation method for tert-butyl alcohol

InactiveCN105523983AStable conversion rateHigh selectivityOrganic compound preparationChemical recyclingMolecular sieveTitanium

The invention provides an oxidation method for tert-butyl alcohol. The method comprises the step of subjecting a liquid mixture containing cyclohexane and an oxidant to passing through catalyst beds under the condition of oxidation reaction, wherein the catalyst beds comprise a first catalyst bed and a second catalyst bed; on the basis of the flow direction of the liquid mixture, the first catalyst bed is located at the upper stream of the second catalyst bed; a titanium-silicon molecular sieve filled in the first catalyst bed is a hollow titanium-silicon molecular sieve; and the titanium-silicon molecular sieve filled in the second catalyst bed is the titanium-silicon molecular sieve different from the hollow titanium-silicon molecular sieve. The method provided by the invention can effectively prolong the single-way service life of the titanium-silicon molecular sieve used as a catalyst, reduce regeneration frequency of the catalyst, improve production efficiency, and enhance operation stability and prolong the total service life of the catalyst at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for direct methanation of recirculating fluidized bed synthesis gas

InactiveCN102180757BReduced inactivation rateNot easy to fall offHydrocarbon from carbon oxidesSyngasFluidized bed

The invention discloses a method for direct methanation of recirculating fluidized bed synthesis gas, belonging to the technical field of natural gas prepared from coals. The method comprises three main steps: absorbing and strengthening direct methanation of synthesis gas through a channel type reactor; separating a product from an absorbent; and roasting the absorbent. In the channel type reactor for absorbing and strengthening the direct methanation of the synthesis gas, a catalyst is coated on the wall surface of the inner channel in grille in the reactor in a form of coating, and the absorbent is carried by reaction gas so as to pass through the grille type channel in the reactor, thereby avoiding the separation step of the catalyst and absorbent, and solving the problem that the catalyst is repeatedly oxidized and reduced so as to cause the loss of materials and the loss of energy, and the generated heat is rapidly removed by utilizing the efficient heat-transfer capability of amulti-layer channel wall surface, thereby retarding the deactivation speed of the catalyst and ensuring the stable operation of equipment.

Owner:TSINGHUA UNIV

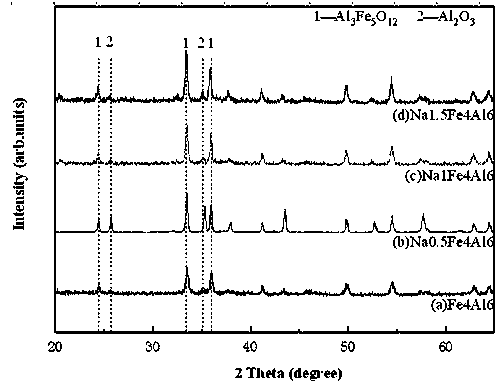

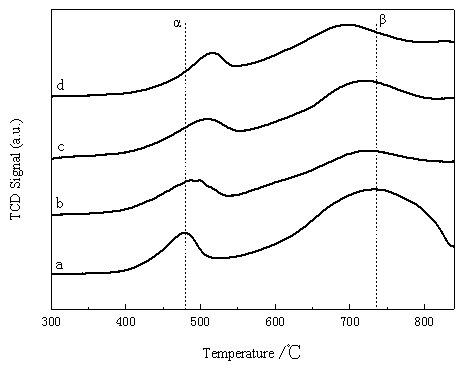

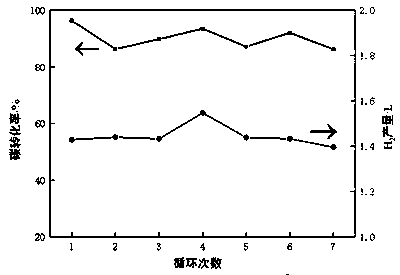

Sodium-modified chemical-looping hydrogen production synergistic CO2 trapping system

ActiveCN111153381ALess investmentLow running costCarbon compoundsHydrogen productionTemperature controlFuel gasification

The invention relates to a device for solid fuel chemical-looping hydrogen production and application, also relates to a chemical-looping hydrogen production oxygen carrier, provides a chemical-looping hydrogen production oxygen carrier, which has high reaction activity and avoids cyclic inactivation of the oxygen carrier caused by adding alkali metal K, and provides a chemical-looping hydrogen production oxygen carrier, which is prepared by adding NaAlO2 into a Fe2O3 / Al2O3 oxygen carrier and modulating through alkali metal Na. The designed CO2 trapping device comprises a gas distribution system, a steam generator, a coal high-temperature feeding hopper, a reactor, an automatic temperature control device, a cyclone separator, a condenser and a gas collecting and testing system. Fuel can befully pyrolyzed, the energy for solid fuel gasification can be reduced, the energy consumption is reduced, and the system has an industrial value.

Owner:NINGXIA UNIVERSITY

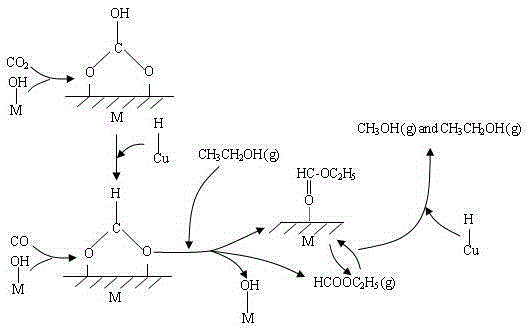

A kind of synthesis method of fixed bed low temperature methanol with heat and mass transfer catalysis triple effect

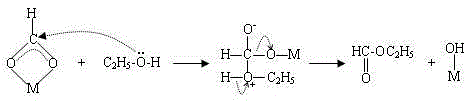

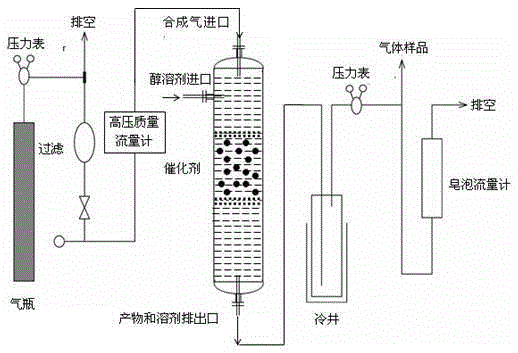

ActiveCN103193585BHigh selectivityStable conversion rateOrganic compound preparationHydroxy compound preparationPtru catalystFormate

A method for synthesizing low-temperature methanol in a fixed-bed with heat-mass-transfer catalysis, involving a method for synthesizing methanol. In this method, the alcohol solution acts as a homogeneous catalyst to participate in and catalyze the reaction, and acts as a nucleophile to attack the formate adsorbed on the surface of the catalyst. , to generate formate; at the same time, the alcohol solution acts as a mobile phase to quickly remove heat. The methanol synthesis reaction is a strong exothermic reaction, and the low temperature is conducive to the positive direction of the methanol synthesis reaction; in addition, the alcohol solution is used as a mass transfer medium. The reaction product methanol and by-product water are taken away from the surface of the catalyst and the reactor to make the reaction proceed smoothly. The alcohol used may be methanol, ethanol, propanol, 2-propanol, butanol and isomers of butanol and the like. The present invention systematically studies the synthesis gas with CO2 content of 0-60%. At 180°C and 5.0MPa, with 2-propanol as solvent, the conversion rate of total carbon is stable above 80%, and the selectivity of methanol is high. at 95%.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com