Method for direct methanation of recirculating fluidized bed synthesis gas

A circulating fluidized bed and synthesis gas technology, applied in the field of coal-to-natural gas, to slow down the deactivation rate, ensure smooth operation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

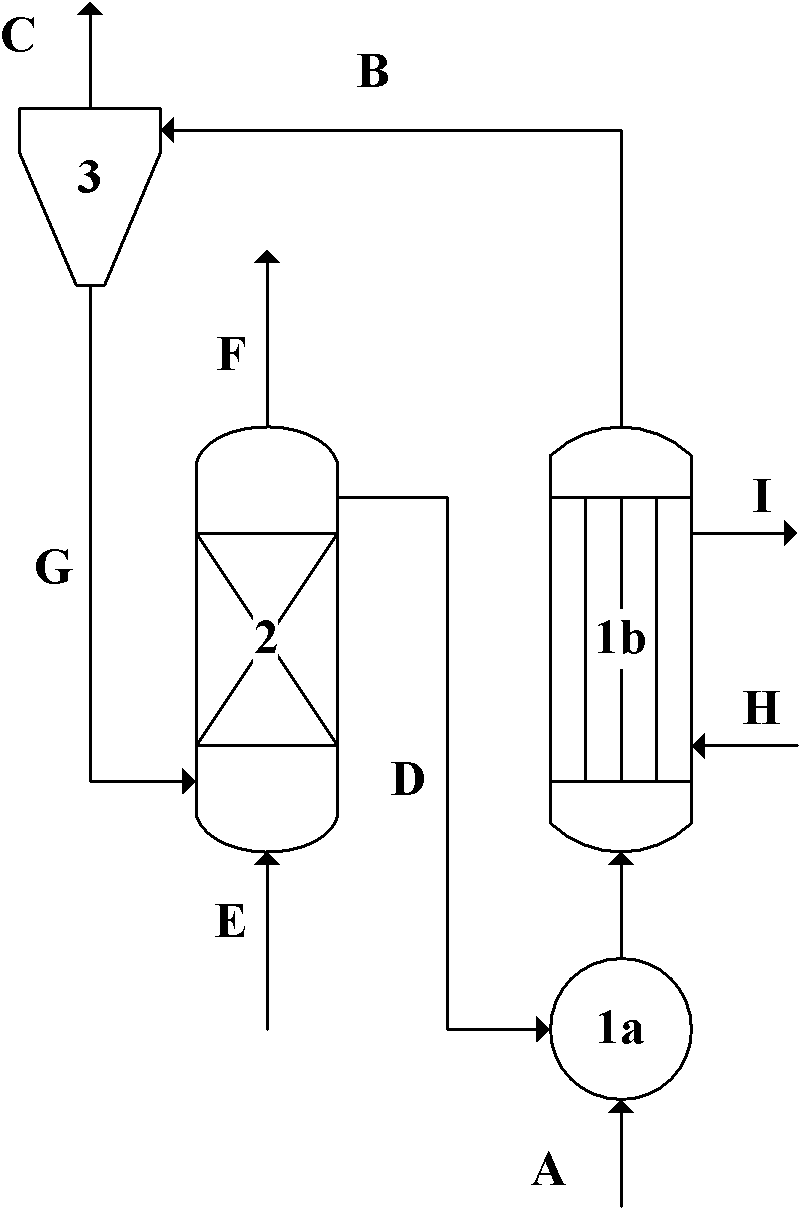

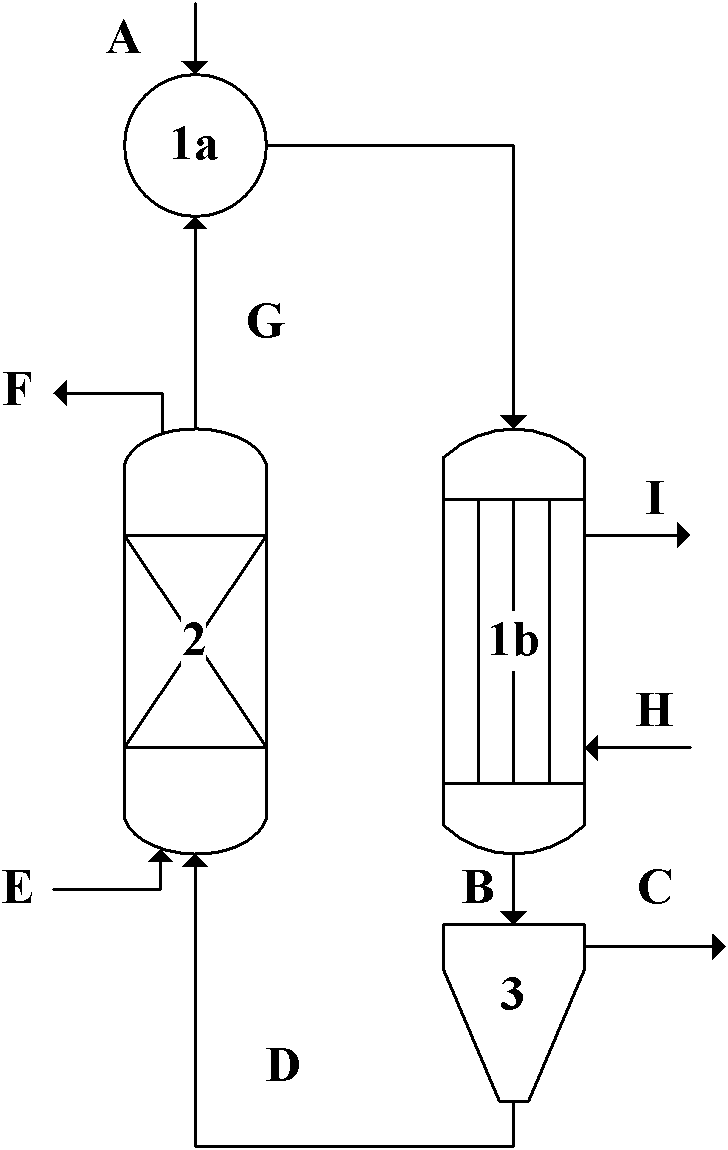

[0022] use as figure 1 The shown circulating fluidized bed synthesis gas direct methanation device, the steps are as follows:

[0023] (1) Use hydrogen and carbon monoxide as the raw material gas, mix the raw material gas and CaO particles in the mixer, enter the channel reactor after mixing, and fully contact and react with the catalyst coating coated on the wall; hydrogen The molar ratio to carbon monoxide is 1, and the total volumetric flow rate is 5m 3 / h; the particle size of CaO particles is 30 microns, and the volume fraction is 5%; the operating temperature of the reactor is 650 ° C, and the operating pressure is 2.5 MPa; the channel reactor is composed of 4 internal channels, and the size of each internal channel is 10cmX2cmX0.08cm, Ni-based catalyst on the wall of the reactor;

[0024] (2) The gas-solid mixture coming out from the channel reactor enters the cyclone separator for separation, and the separated gas product is processed by an industrial processing devi...

Embodiment 2

[0028] use as figure 1 The shown circulating fluidized bed synthesis gas direct methanation device, the steps are as follows:

[0029] (1) With hydrogen and carbon monoxide as the raw material gas, the mixture particles of CaO and MgO formed by calcining the raw material gas and dolomite are mixed in the mixer, and after mixing, they enter the channel reactor and are mixed with the catalyst coated on the wall. The coating is fully contacted and reacted; the molar ratio of hydrogen to carbon monoxide is 1, and the total volume flow rate is 5m 3 / h; the particle size of the mixture of CaO and MgO is 25 microns, and the volume fraction is 5%; the operating temperature of the reactor is 600 ° C, and the operating pressure is 2 MPa; the channel reactor is composed of 4 internal channels, each internal channel The size is 10cmX2cmX0.08cm, and the Ni-based catalyst is on the wall of the reactor;

[0030] (2) The gas-solid mixture coming out from the channel reactor enters the cyclo...

Embodiment 3

[0034] use as figure 1 The shown circulating fluidized bed synthesis gas direct methanation device, the steps are as follows:

[0035] (1) With hydrogen and carbon monoxide as the raw material gas, the raw material gas is mixed with CaO and Al 2 o 3 (Particles mixed in a mass ratio of 1:1) The mixture is mixed in the mixer, and then enters the channel reactor to fully contact and react with the catalyst coating coated on the wall; the mole of hydrogen and carbon monoxide The ratio is 0.9 and the total volumetric flow rate is 5m 3 / h; CaO and Al 2 o 3 The particle size of the mixture is 15 microns, and the volume fraction is 7%; the operating temperature of the reactor is 650°C, and the operating pressure is 3MPa; the channel reactor is composed of 4 internal channels, and the size of each internal channel is 10cmX2cmX0.08cm , on the wall of the reactor is a Ni-based catalyst;

[0036] (2) The gas-solid mixture coming out from the channel reactor enters the cyclone separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com