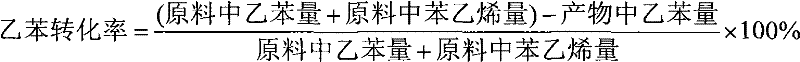

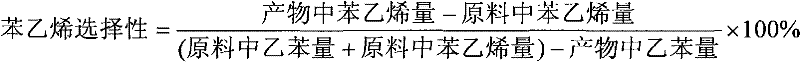

Ethylbenzene dehydrogenating catalyst and preparation method thereof

An ethylbenzene dehydrogenation and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of poor stability of ethylbenzene dehydrogenation catalyst, Problems such as rapid decline in activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

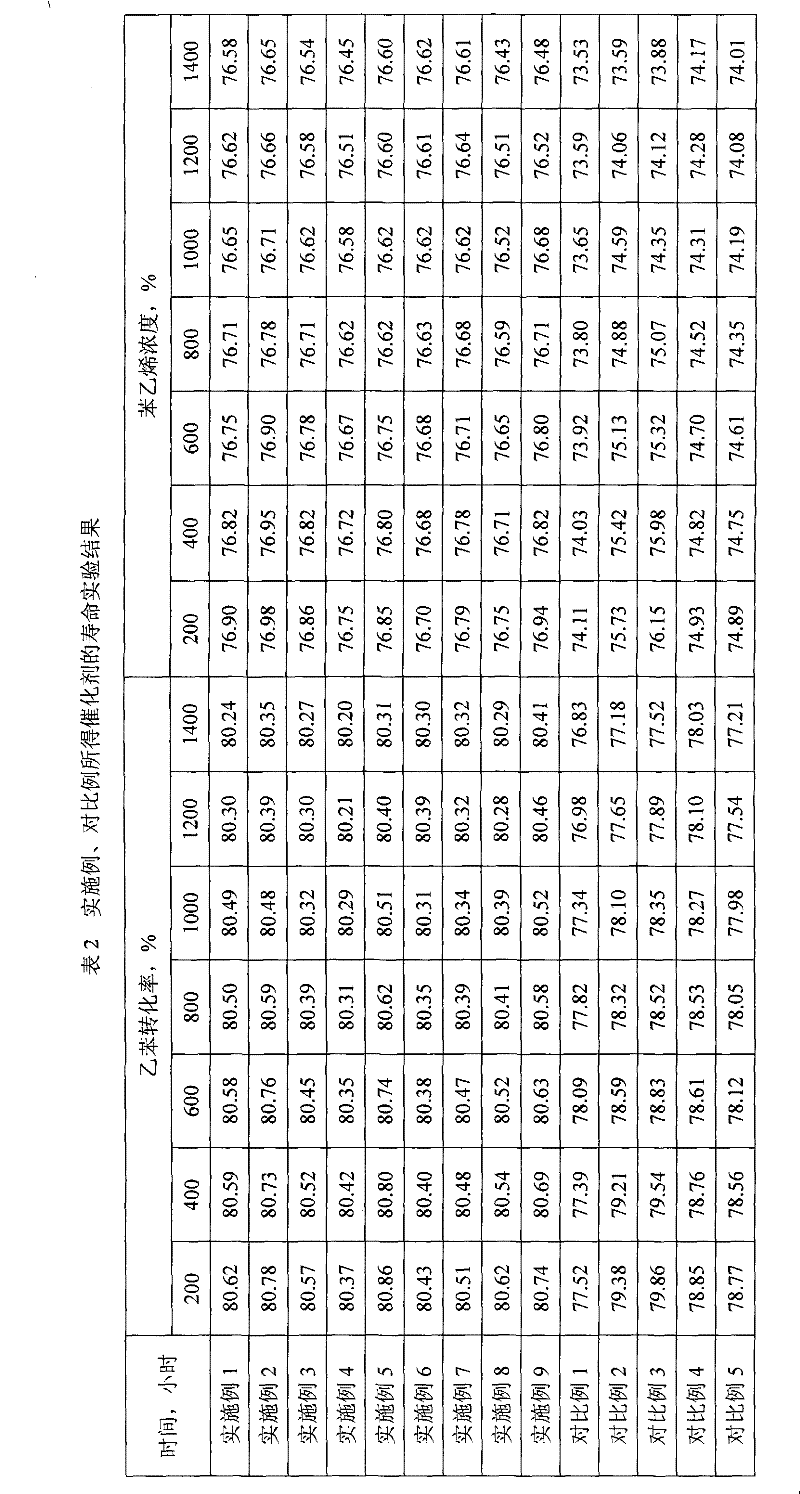

[0039] 306.1 grams of red iron oxide, 110.1 grams of potassium carbonate, 9.2 grams of ammonium tungstate, 12.2 grams of ammonium molybdate, 10.0 grams of calcium oxide, 10.0 grams of barium oxide, 11.3 grams of copper oxide, 4.25 grams of zinc oxide, 1.0 grams of vanadium pentoxide , 15.0 grams of cement, 15.0 grams of sodium carboxymethylcellulose, after adding to the kneader and dry mixing for 3 hours, 185.2 grams of cerium nitrate, 0.75 grams of cobalt nitrate and 0.25 grams of lanthanum nitrate were dissolved in deionized water and added therein, and kneaded for 1.5 hours, knead the material into an extrudable paste, take it out, and make a cylindrical catalyst of Φ(2.7~3.3)mm×(5~8)mm through extruding and breaking processes. Dry for 4 hours, dry at 120°C for 4 hours, place in a muffle furnace at 140°C, 260°C, 370°C, and 800°C for 2 hours, 2 hours, 2 hours, and 4 hours, and then cool down naturally to obtain the finished catalyst. Activity evaluation, the evaluation resul...

Embodiment 2

[0041] Catalyst is prepared by the method of embodiment 1, difference is, iron oxide red 346.9 grams, 88.1 grams of potassium carbonate, ammonium molybdate 18.4 grams, calcium oxide 12.5 grams, magnesium oxide 11.0 grams, barium oxide 7.5 grams, copper oxide 10.0 grams , 2.2 grams of zinc oxide, 1.5 grams of cobalt nitrate, 0.2 grams of lanthanum nitrate, 0.1 grams of titanium dioxide, 18.0 grams of sodium carboxymethyl cellulose, cerium is added in the form of cerium oxalate and cerium nitrate, of which 52.9 grams of cerium nitrate and 41.0 grams of cerium oxalate , and the evaluation results are shown in Tables 2 and 3.

Embodiment 3

[0043] Prepare catalyst by the method for embodiment 1, iron oxide red 372.4 grams, potassium carbonate 73.4 grams, ammonium tungstate 21.4 grams, calcium oxide 15.0 grams, barium oxide 7.5 grams, copper oxide 7.5 grams, zinc oxide 1.5 grams, lead dioxide 0.1 gram, cobalt nitrate 0.75 gram, lanthanum nitrate 0.15 gram, cerium adds with the form of cerium oxalate and cerium nitrate, and wherein cerium nitrate 46.3 grams, cerium oxalate 35.9 grams, evaluation result is shown in Table 2 and 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com