Patents

Literature

879 results about "Isopropyl benzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cumene is the common name for isopropylbenzene, an organic compound that is based on an aromatic hydrocarbon with an aliphatic substitution. It is a constituent of crude oil and refined fuels. It is a flammable colorless liquid that has a boiling point of 152 °C.

Alkylaromatics production

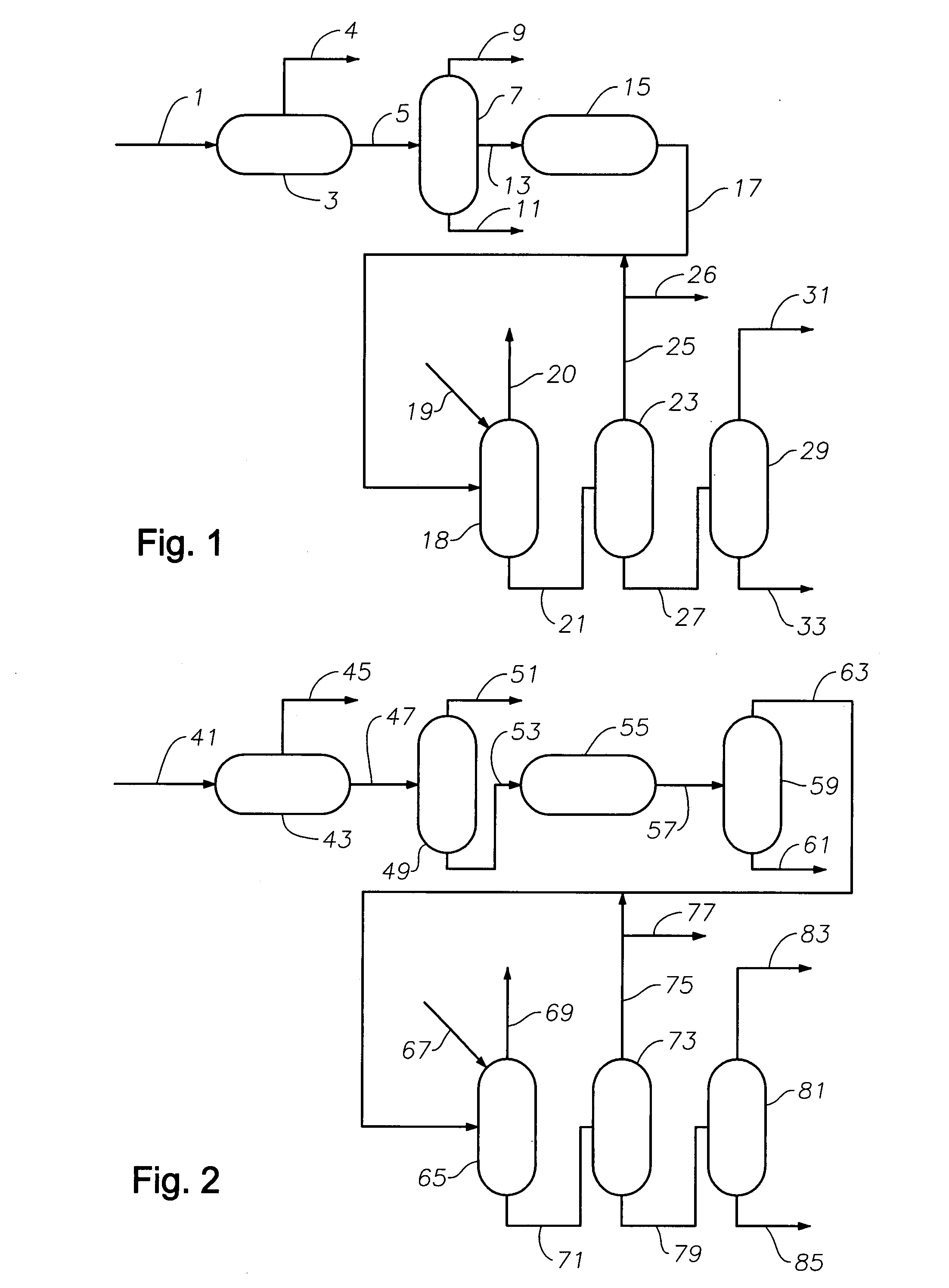

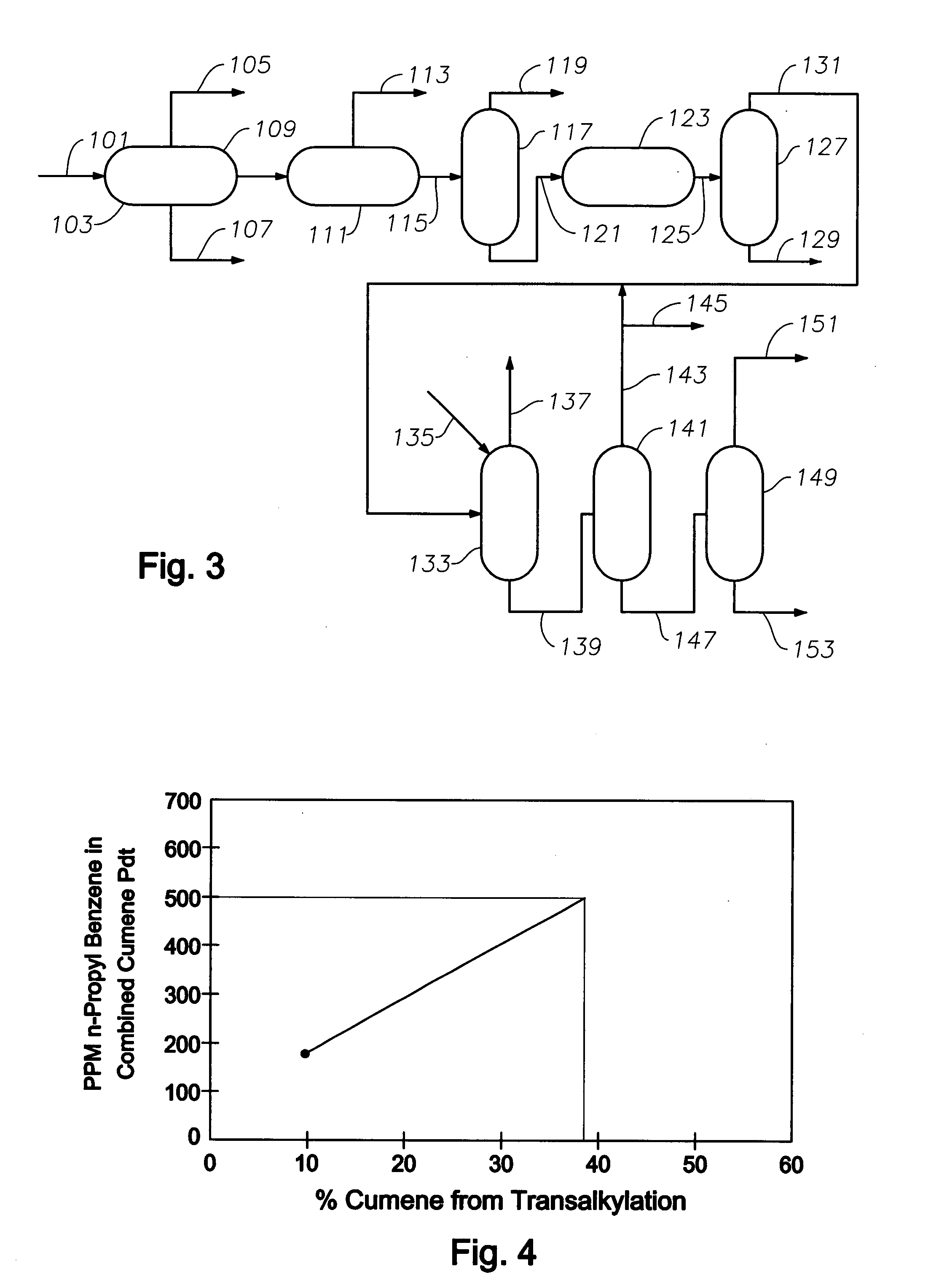

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

Modified Y-85 and LZ-210 Zeolites

InactiveUS20080171649A1Improved Diffusion PropertiesHigh catalytic activityMolecular sieve catalystsCatalyst activation/preparationX-rayCumene

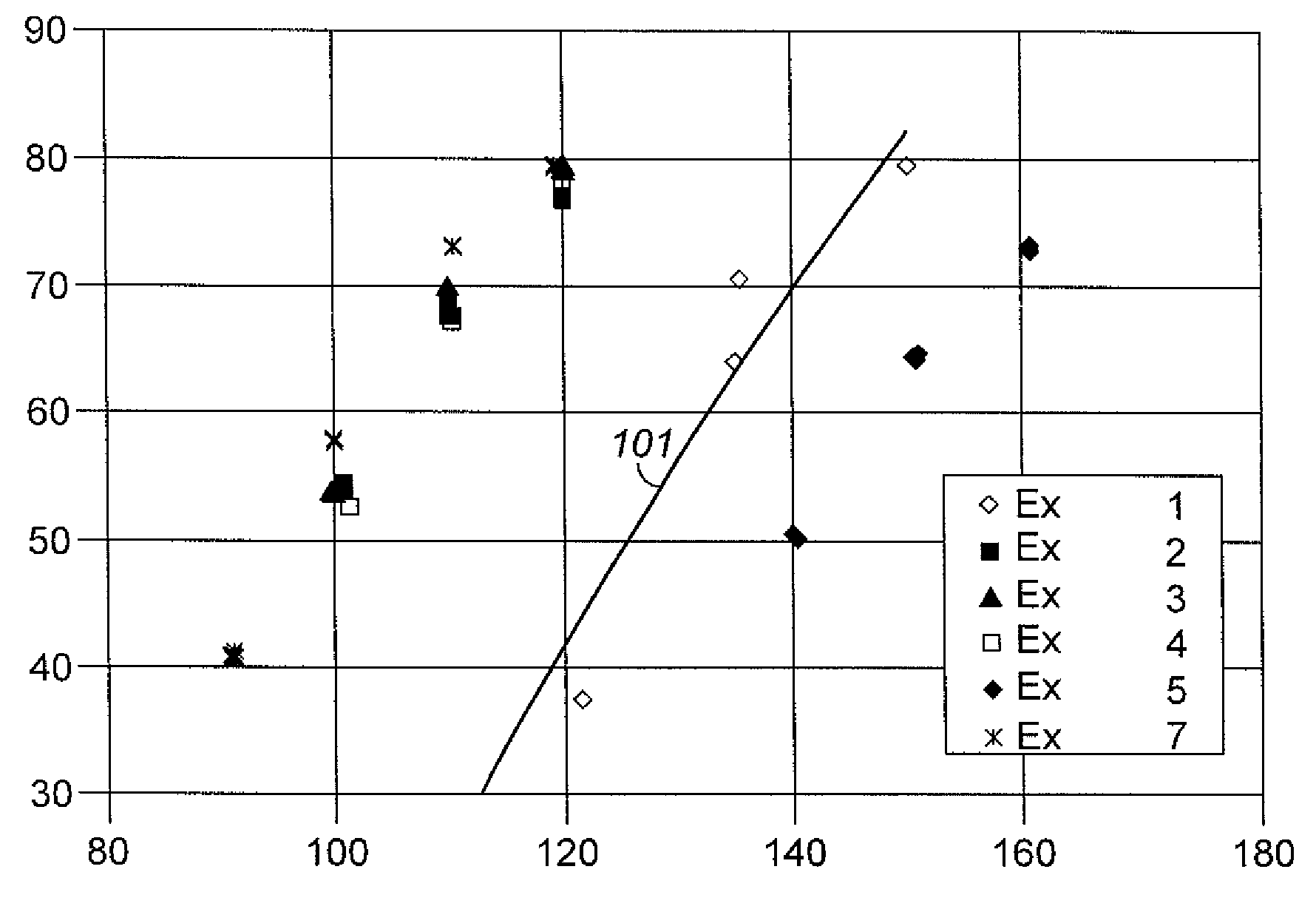

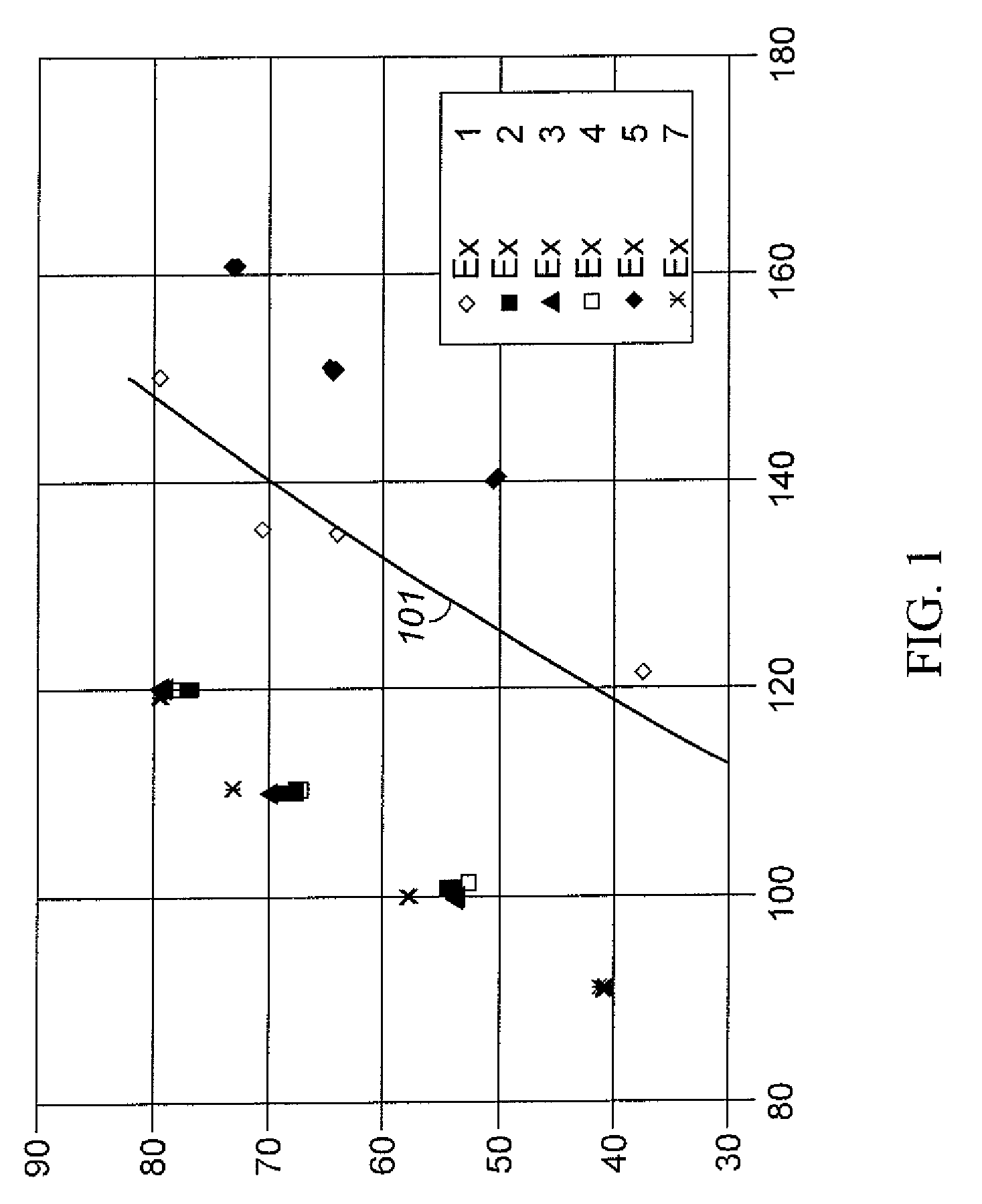

Catalysts for converting polyalkylaiomatics to monoalkylaromatics, particularly cumene and ethyl benzene are disclosed which comprise modified Y-85 or LZ-210 zeolites. For cumene and ethylbenzene production, a disclosed catalyst, made of 80 wt % zeolite and 20 wt % alumina binder on a volatile-flee basis, has one or more of the following physical characteristics: (1) an absolute intensity of the modified Y zeolite as measured by X-ray diffraction (XRD) of preferably at least 50 and (2) a framework aluminum of the modified Y zeolite of preferably at least 50% of the aluminum of the modified Y zeolite.

Owner:UOP LLC

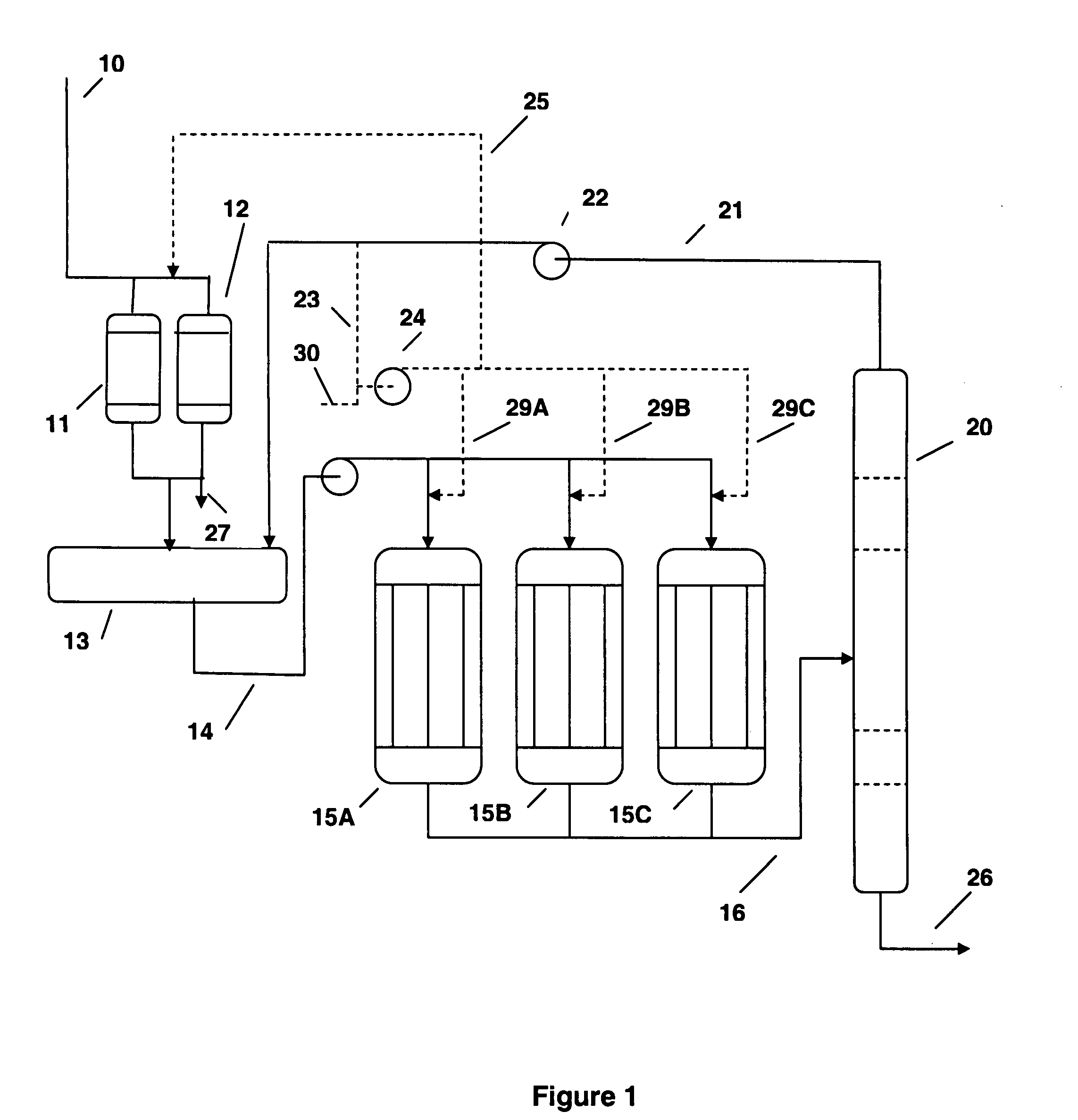

Olefin upgrading process with guard bed regeneration

InactiveUS20080029437A1Continuity of operation is assuredCatalytic crackingMolecular sieve catalystsPetrochemicalAlkylation

A process for the regeneration of materials used in the guard beds preceding the reactors used in an olefin conversion process which converts olefinic refinery streams to higher boiling hydrocarbon products by polymerization (oligomerization) or alkylation of aromatics including benzene. Products of the process may include olefin oligomers and alkylaromatics in the gasoline boiling range as well as alkylaromatic petrochemicals such as cumene and ethylbenzene. The process is integrated with the olefin conversion process to ensure continuous operation of the olefin conversion without sending the feedstock containing the contaminant(s) to the reactor. The process uses reaction products from the olefin conversion process to regenerate the guard bed material and so is economically attractive since it does not require the use of separate purge, regeneration feed and separation systems. A plurality of guard beds is used, each containing a material which removes catalyst poisons. The guard beds are operated on a swing system in which one or more beds is kept on stream to remove the contaminant(s) while one or more of the remaining beds is being purged or regenerated. In this way, continuity of operation is assured. The regeneration medium is a product stream from the olefin conversion process.

Owner:EXXON RES & ENG CO

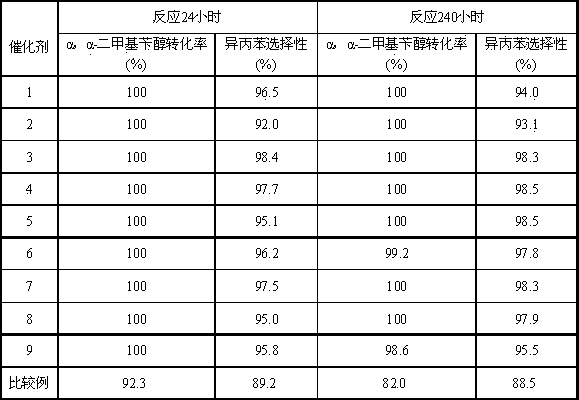

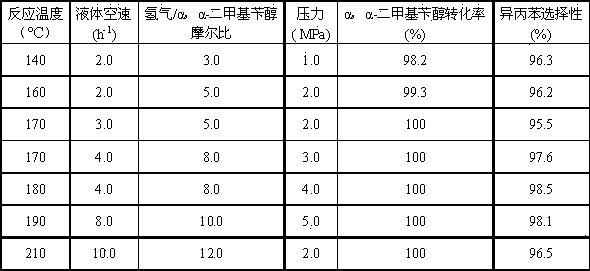

Alpha, alpha-dimethylbenzyl alcohol hydrogenolysis method for preparing isopropyl benzene

InactiveCN104230640AImprove technical effectHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAlcohol

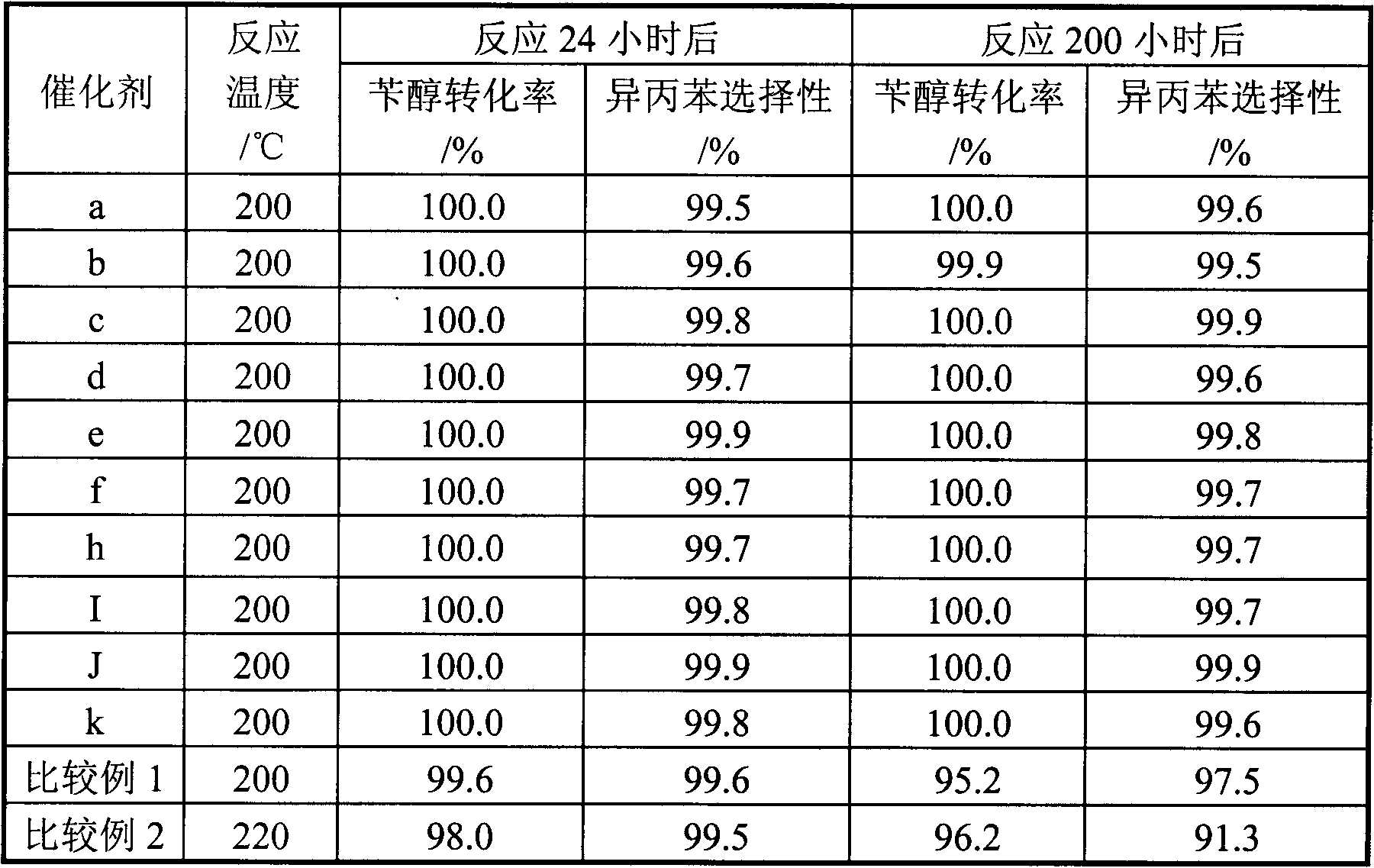

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problems of poor stability of catalyst and serious environmental pollution in the isopropyl benzene production process. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethylbenzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.1-2.0 parts of Pd metal or oxide; b) 85.0 to 97.0 parts of SiO2; c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, and Cu or oxide thereof; and d) 1.0 to 5.0 parts of at least one selected from Mg or oxide thereof, Ca or oxide thereof and Ba or oxide thereof. The method can be used in industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

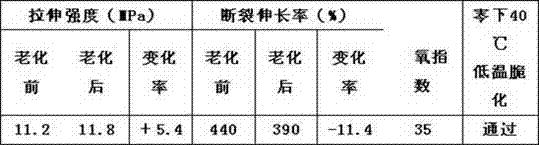

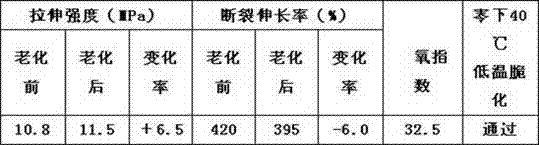

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Alkylation process using UZM-8 zeolite

InactiveUS7268267B2Reduce formationReduce the amount requiredMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkene

Owner:UOP LLC

Dual zone aromatic alkylation process

ActiveUS20080171900A1High selectivityLow molar ratioMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkylation

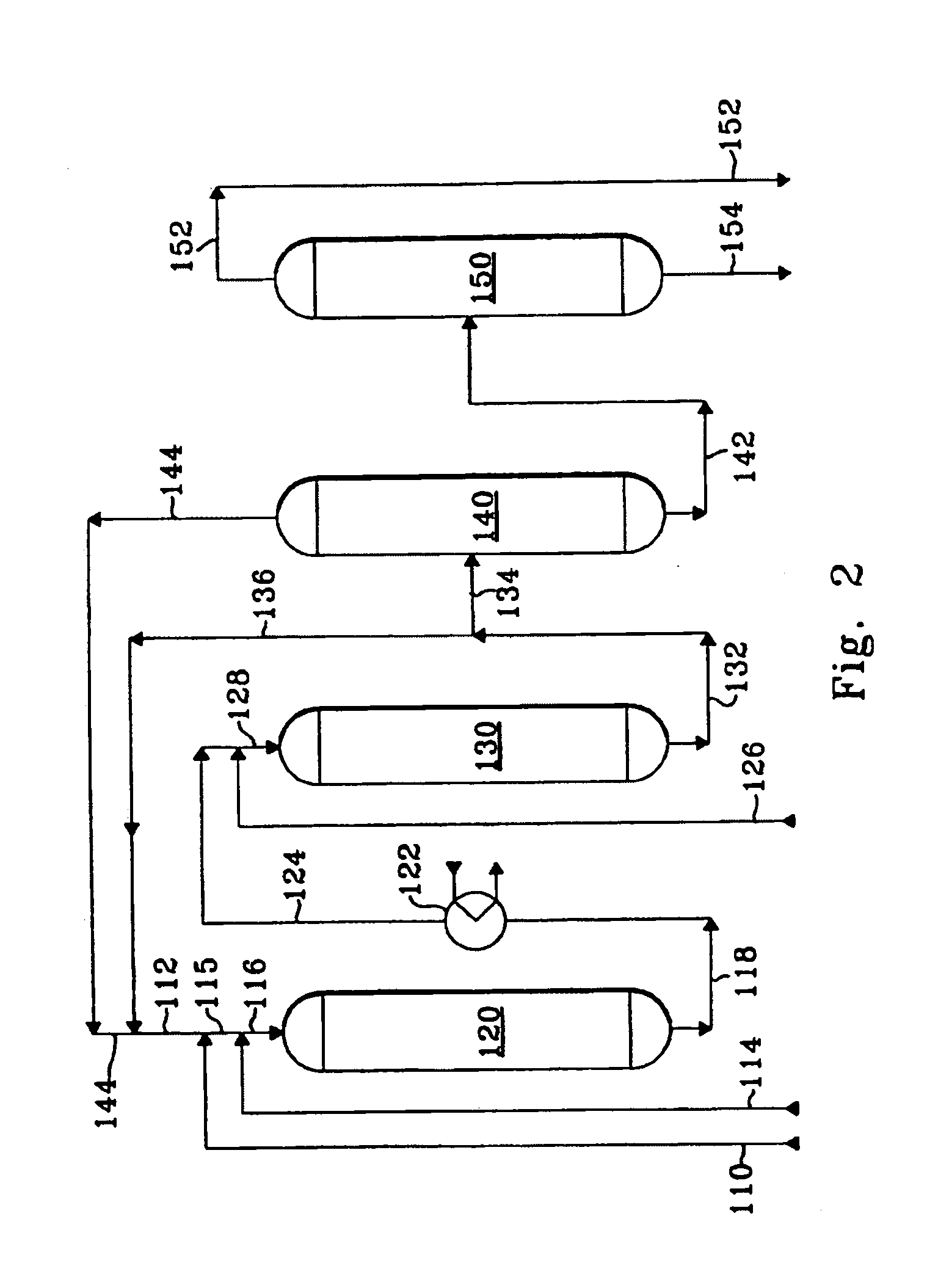

A process for the catalytic alkylation of an aromatic substrate with an alkylating agent is disclosed that comprises contacting the aromatic substrate and the alkylating agent in sequential alkylation zones to obtain an alkylaromatic. The first catalyst comprises UZM-8 zeolite and the second catalyst comprises beta zeolite. The process is particularly well suited for the alkylation of benzene with propylene to produce cumene.

Owner:UOP LLC

Method for producing isopropylbenzene by hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol

InactiveCN101735004AHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention relates to a method for producing isopropylbenzene by the hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol, which mainly solves the problems of environmental pollution of a chromium-containing catalyst system in the traditional hydrogenolysis production of the alpha, alpha-dimethyl benzyl alcohol, higher reaction temperature and pressure, large energy consumption and power consumption and corrosion of an additive to equipment. The invention better solves the problems by adopting the technical scheme that the catalytic hydrogenolysis of the alpha, alpha-dimethyl benzyl alcohol is carried out to convert the raw material of the alpha, alpha-dimethyl benzyl alcohol after alkali wash into the isopropylbenzene by hydrogen gas and a bifunctional catalyst containing Pd or Pd-Pt metal under the conditions that the temperature is 80-200 DEG C and the hydrogen pressure calculated by the gage pressure is 0.1-2.0MPa. The invention can be used for the industrial production of the isopropylbenzene prepared by the hydrogenolysis of the alpha, alpha-dimethyl benzyl alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

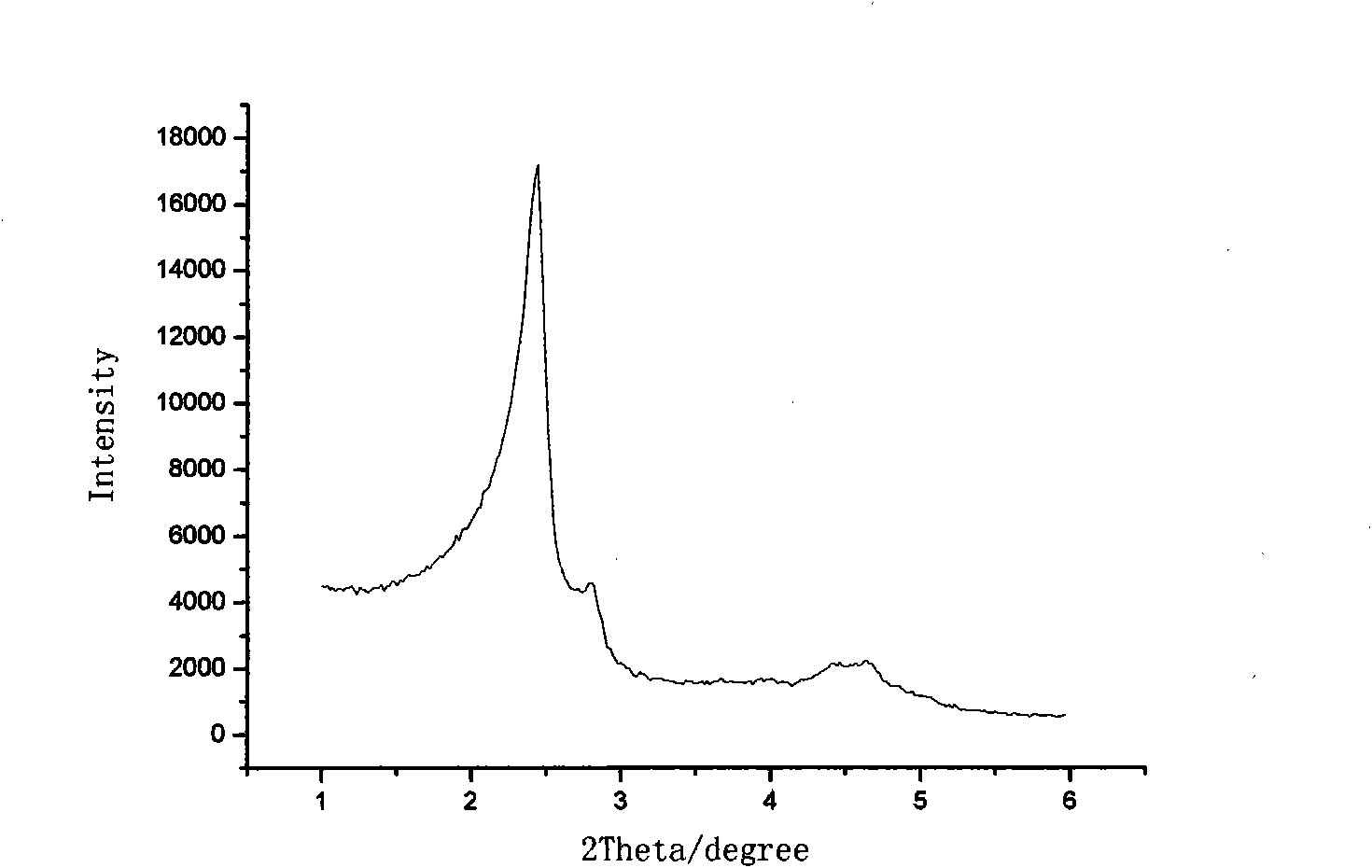

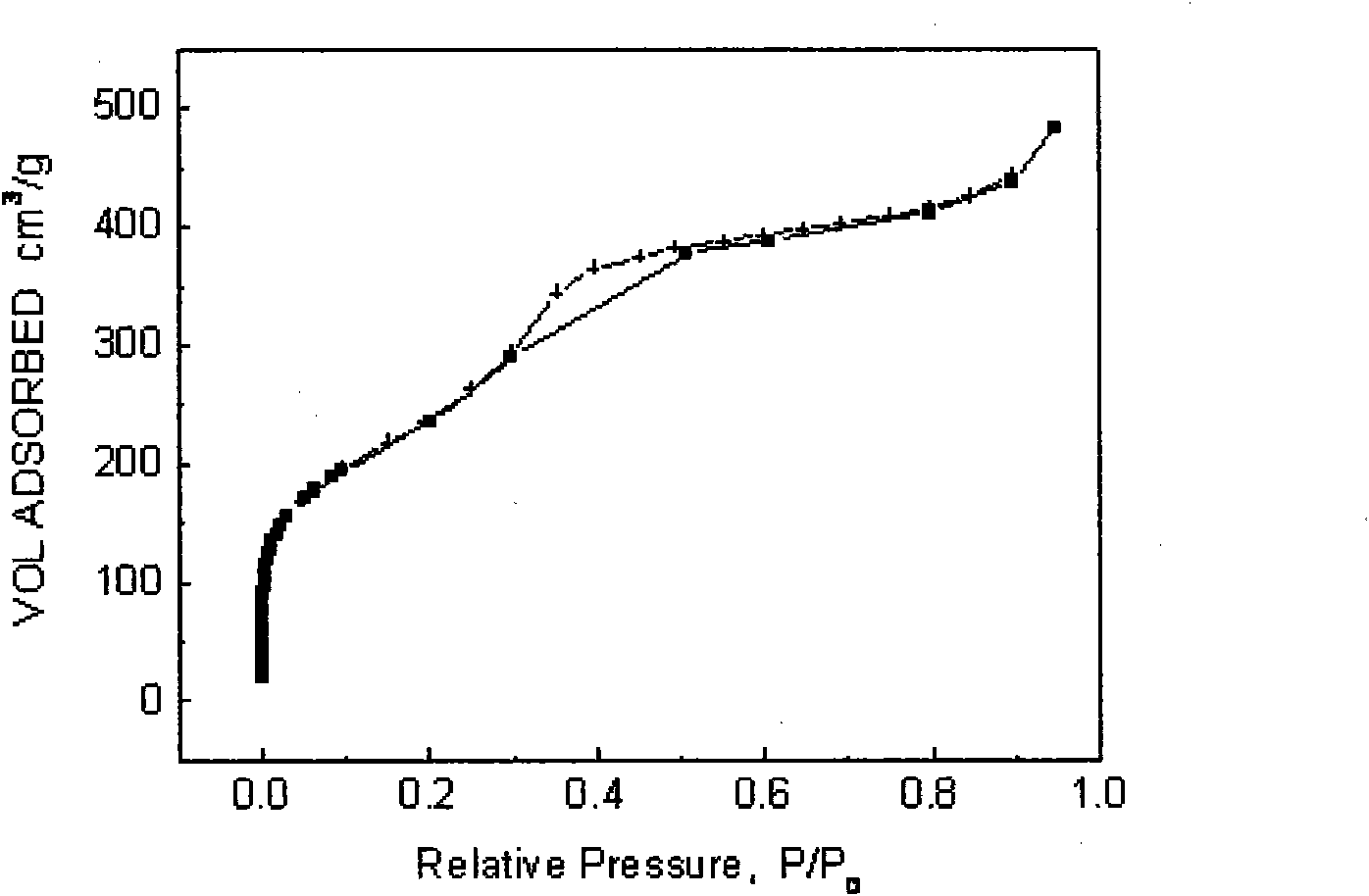

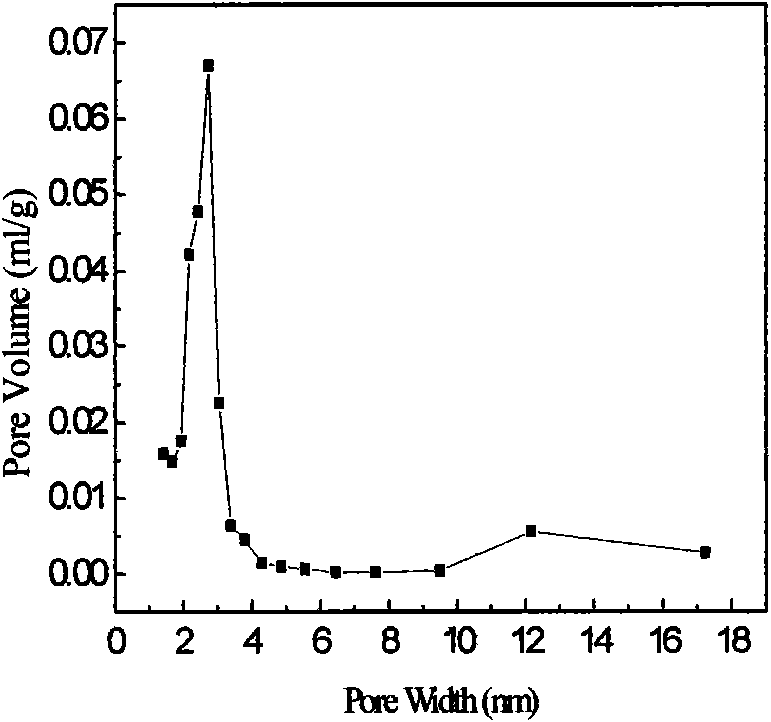

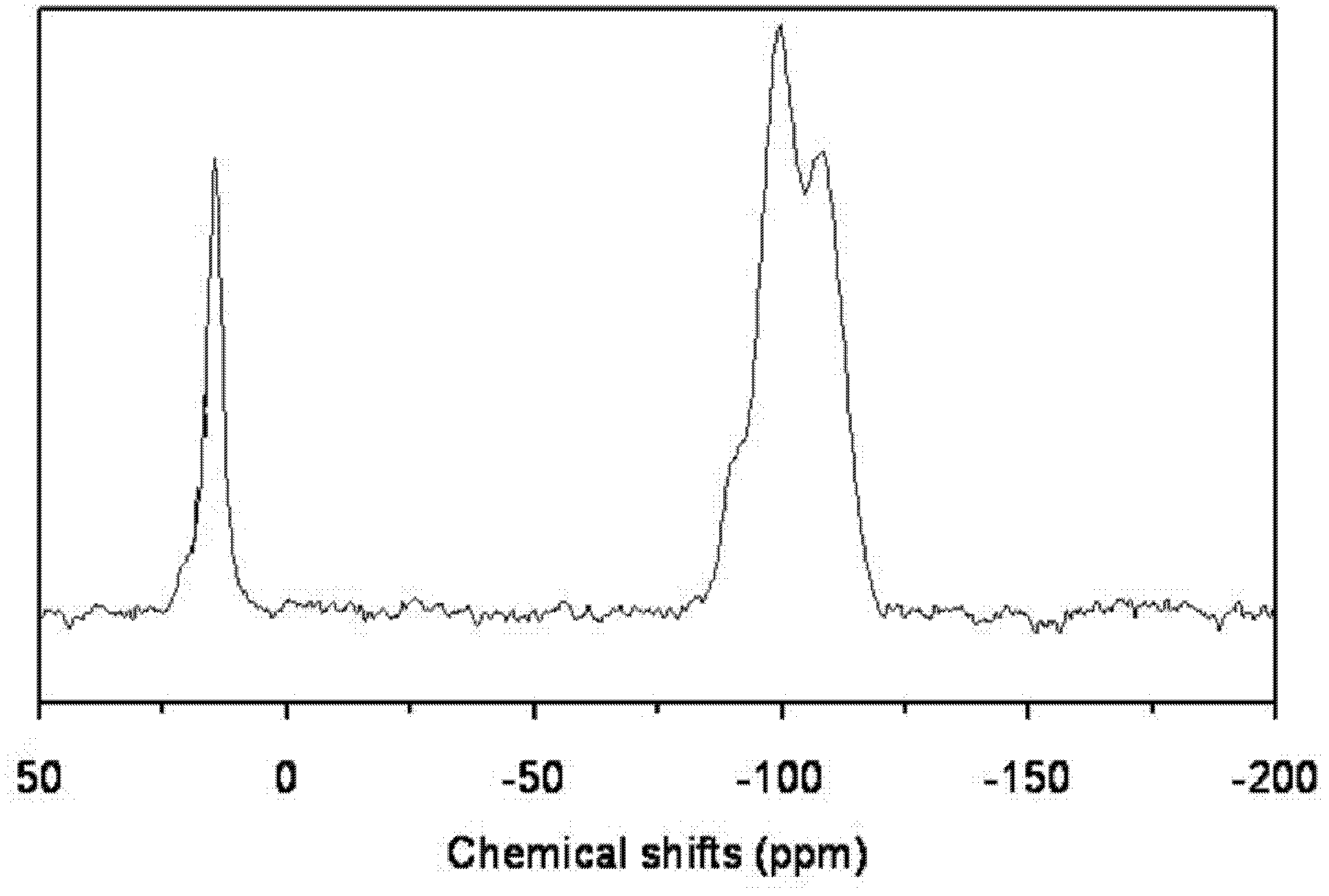

Cubic mesoporous molecular sieve catalyst with micropore canals, preparation method and use thereof

InactiveCN101683620AHigh catalytic activityGood choiceMolecular sieve catalystsHydrocarbonsMicrowaveSynthesis methods

The invention relates to a cubic mesoporous molecular sieve catalyst with micropore canals, a preparation method and use thereof. The catalyst comprises the raw materials of an aluminium source, a silicon source, sodium hydroxide, a template, surfactant and de-ionized water, and is prepared through the following steps: firstly preparing a silicon-aluminium precursor; and then utilizing a self-assembly function between the precursor and the surfactant to obtain stable molecular sieve materials. The preparation method comprises two methods of hydro-thermal synthesis and microwave synthesis. Dueto the adoption of the microwave synthesis method, the cubic mesoporous molecular sieve catalyst in the invention has the advantages of shortening the crystallization time, obtaining a synthesized molecular sieve with a cubic mesoporous structure, having micropore canals, having acid strength similar to that of a ZSM-5 molecular sieve, and having relatively higher catalytic activity when used forthe catalytic cracking reaction of 1,3,5-tri-isopropyl benzene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Production and purification of phenol: hydroxyacetone removal by hydrotalcite

InactiveUS6486365B1High mechanical strengthLose significant efficiencyOrganic compound preparationCatalystsDistillationBoiling point

A process for converting carbonyl-type impurities contained in a phenolic solvent to high-boiling derivatives is provided by contacting the phenolic solvent with a hydrotalcite-type material (HTM). The phenol can be separated from the high-boiling derivatives using conventional separation techniques, such as distillation, so the invention also provides a process for separating carbonyl-type impurities, such as hydroxyacetone (HA), from a phenolic solvent. The process can be applied in the conventional industrial process for converting cumene to phenol to remove carbonyl-type impurities from the phenol product. A process and a facility for producing purified phenol by converting cumene to phenol are provided. In the conversion of cumene to phenol, the phenol often contains carbonyl-type impurities. The phenol and carbonyl-type impurities are reacted in the presence of an HTM to produce phenol and high-boiling derivatives. The phenol may be further purified using conventional separation techniques, such as distillation, to remove the high-boiling derivatives.

Owner:SABIC GLOBAL TECH BV

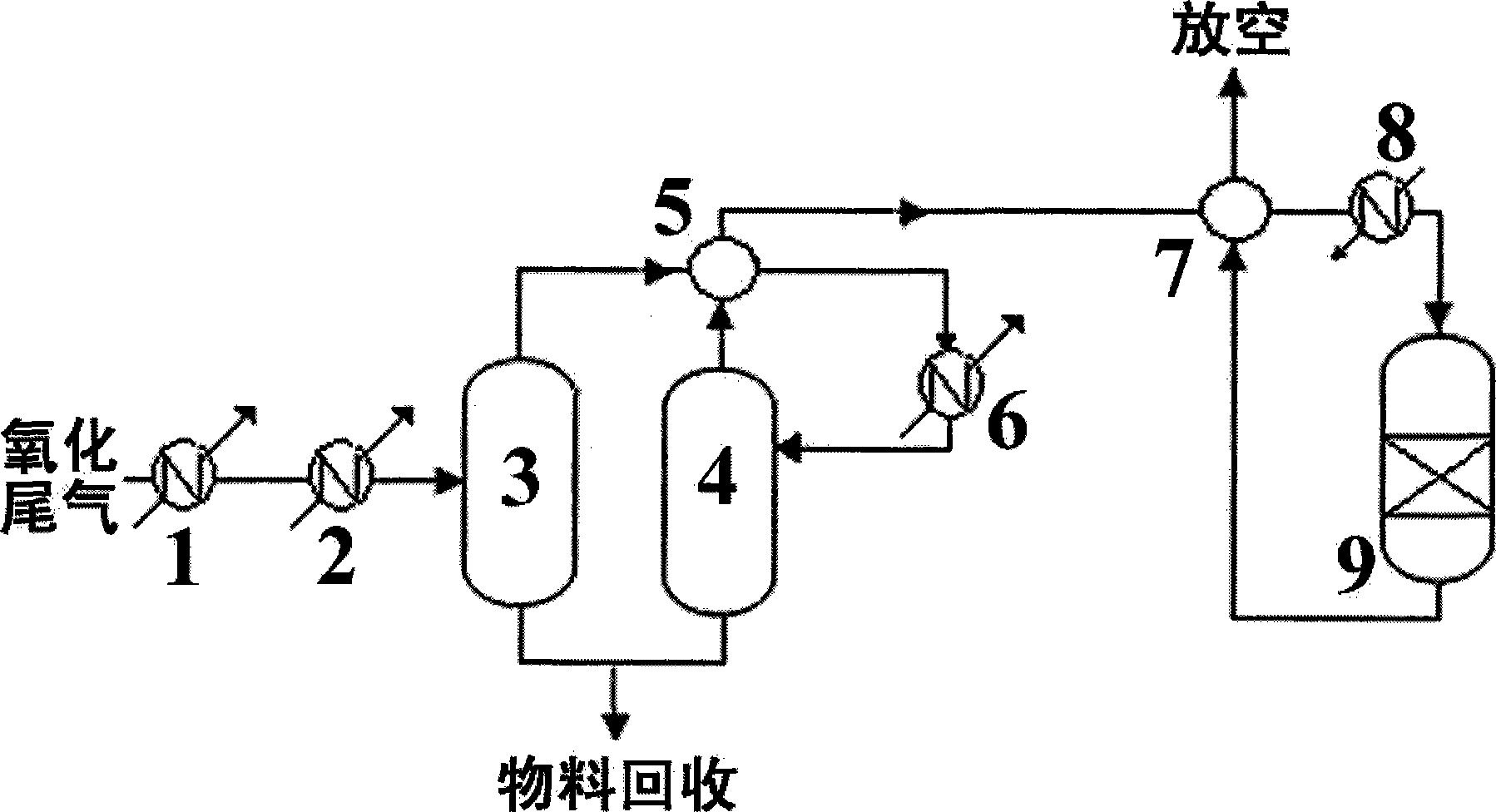

Process for treating oxidized exhaust gas

ActiveCN101543684AReduce the temperatureAchieve reuseOrganic compound preparationChemical industryLoss rateDevice material

The invention discloses a novel method for recovering and treating oxidized exhaust gas generated in phenol production, which comprises the following steps: adopting deep cooling to achieve liquefaction separation of organic matters by reducing the temperature of the exhaust gas to below 5 DEG C, wherein the material recovery rate reaches more than 95 percent; and adopting a Pt catalyst to decompose residual total hydrocarbons and cumene in the exhaust gas at a temperature of between 220 and 450 DEG C to achieve emission after reaching standards. The method can improve the exhaust emission quality, recover effective components in the exhaust gas, and reduce the device loss rate and the device material consumption on the basis of raw water cooling and activated carbon adsorption.

Owner:CHINA PETROLEUM & CHEM CORP

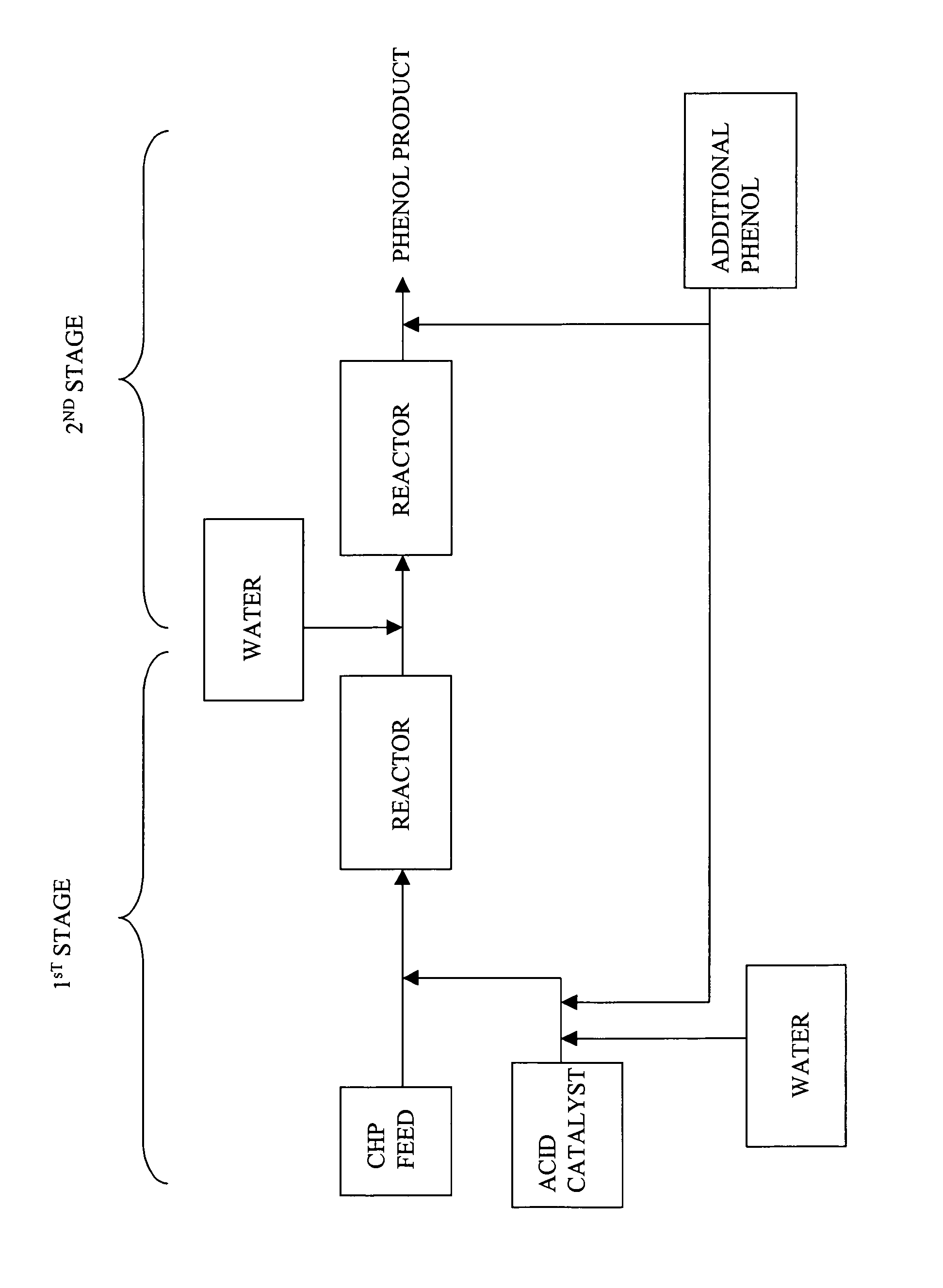

Process for producing phenol

A process for producing a phenol product generally comprises a first step comprising reacting in a first reactor a feed stream comprising cumene hydroperoxide and water with an acid catalyst to produce an effluent comprising the phenol product, acetone, and at least 1% by weight residual cumene hydroperoxide, and a second step comprising passing the effluent into a second reactor and decomposing the residual cumene hydroperoxide, wherein during said process the ratio of phenol to acetone is maintained at a molar ratio of greater than 1:1, and wherein the water in each of the first and second steps is present in an amount more than 0 and less than or equal to 5 weight percent based on the total weight of the feed stream or effluent, and wherein the process is continuous.

Owner:SABIC GLOBAL TECH BV

Process for preparing isopropyl benzene by catalytically hydrogenolysis alpha, alpha dimethyl benzyl alcohol

InactiveCN1616383ACreate pollutionMild reaction conditionsHydrocarbon from oxygen organic compoundsReaction temperatureSolvent

The present invention hydrogenolyzes alpha, alpha-dimethyl benzyl alcohol in solvent into isopropyl benzene with hydrogen or organic compound as hydrogen source at reaction temperature of 30-100 deg.c under multiphase Pd base catalyst. The present invention has alpha, alpha-dimethyl benzyl alcohol converting rate greater than 96 % and isopropyl benzene selectivity greater than 99 %. The said process may be used in the hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol as the co-product of propylene epoxidation process to prepare propylene oxide with cumene hydroperoxide as oxidant to realize circular utilization of isopropyl benzene. The said technology may be used in recovering propylene from tail gas generated in the process of producing propylene chloride or polypropylene, and may be also used in the propylene oxide producing line.

Owner:EAST CHINA UNIV OF SCI & TECH

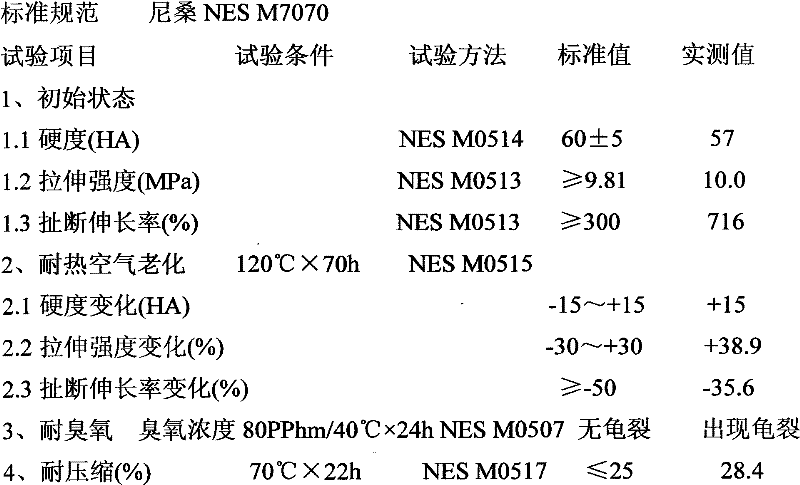

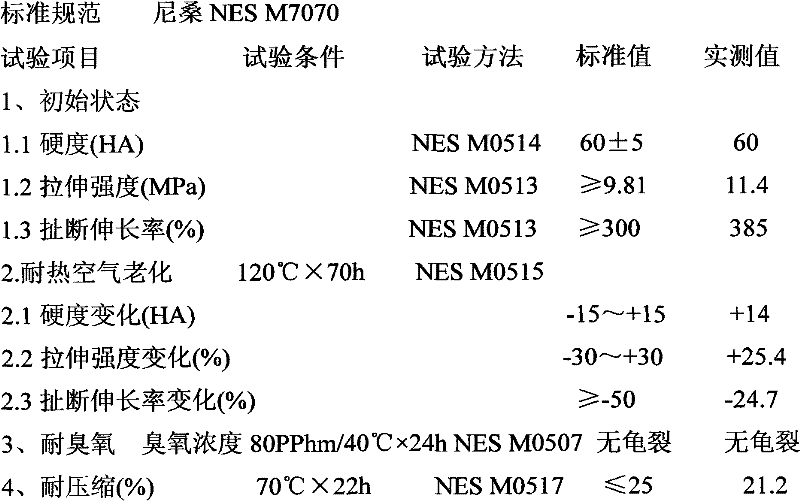

Preparation method of heat/ozone/compressive deformation resistant rubber material for automobile sealing element

The invention discloses a preparation method of a heat / ozone / compressive deformation resistant rubber material for an automobile sealing element, and the method comprises a formula and a preparation process. In the invention, nitrile rubber / polyvinyl chloride resin and rubber are adopted; in the formula, a vulcanizing system of dicumyl peroxide and N,N'-m-phenylene dimaleimide is adopted, the anti-aging agents of 2,2,4-trimethyl-1,2-dihyaroquinoline polymer and 2-mercaptobenzimidazole are added, the anti-aging agent of N-isopropyl-N'-phenyl-p-phenylenediamine and a paraffin lubricating agent with ozone resistance are added, and the technical scheme of the corresponding preparation process is provided, thus the problems and defects of low temperature / ozone / permanent compressive deformation resistances in the prior art are overcome, and through the heat / ozone / compressive deformation resistant rubber material prepared by the method, the manufactured rubber article of an automobile oil tank pumping hole sealing element achieves the purpose of improving the heat / ozone / compressive deformation resistances to conform to the Nissan NES M707 standard.

Owner:宁波市天普橡胶科技股份有限公司

Process for preparing isopropyl benzene by catalytically hydrogenolysis alpha, alpha dimethyl benzyl alcohol

InactiveCN1308273CCreate pollutionMild reaction conditionsHydrocarbon from oxygen organic compoundsPtru catalystBENZYL ALCOHOL/WATER

The present invention hydrogenolyzes alpha, alpha-dimethyl benzyl alcohol in solvent into isopropyl benzene with hydrogen or organic compound as hydrogen source at reaction temperature of 30-100 deg.c under multiphase Pd base catalyst. The present invention has alpha, alpha-dimethyl benzyl alcohol converting rate greater than 96 % and isopropyl benzene selectivity greater than 99 %. The said process may be used in the hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol as the co-product of propylene epoxidation process to prepare propylene oxide with cumene hydroperoxide as oxidant to realize circular utilization of isopropyl benzene. The said technology may be used in recovering propylene from tail gas generated in the process of producing propylene chloride or polypropylene, and may be also used in the propylene oxide producing line.

Owner:EAST CHINA UNIV OF SCI & TECH

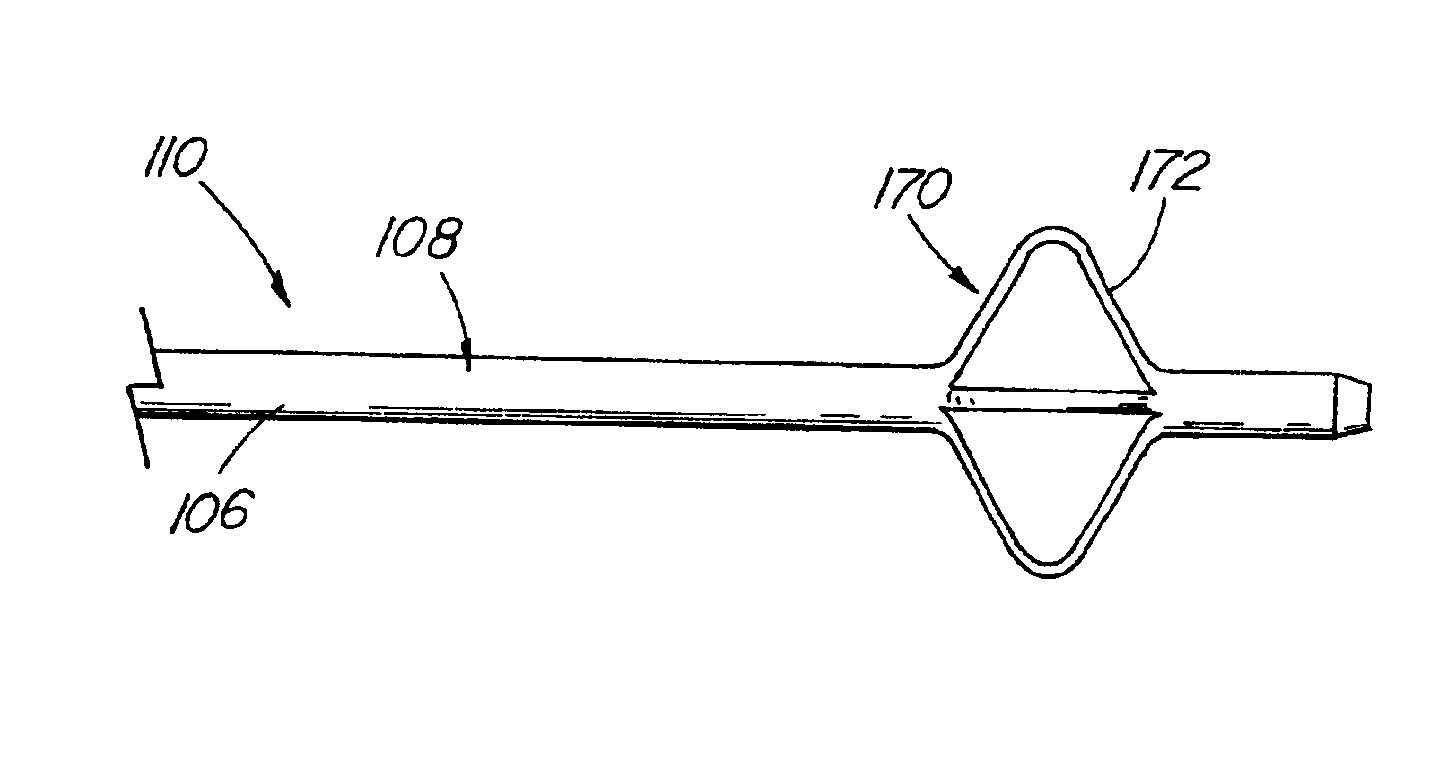

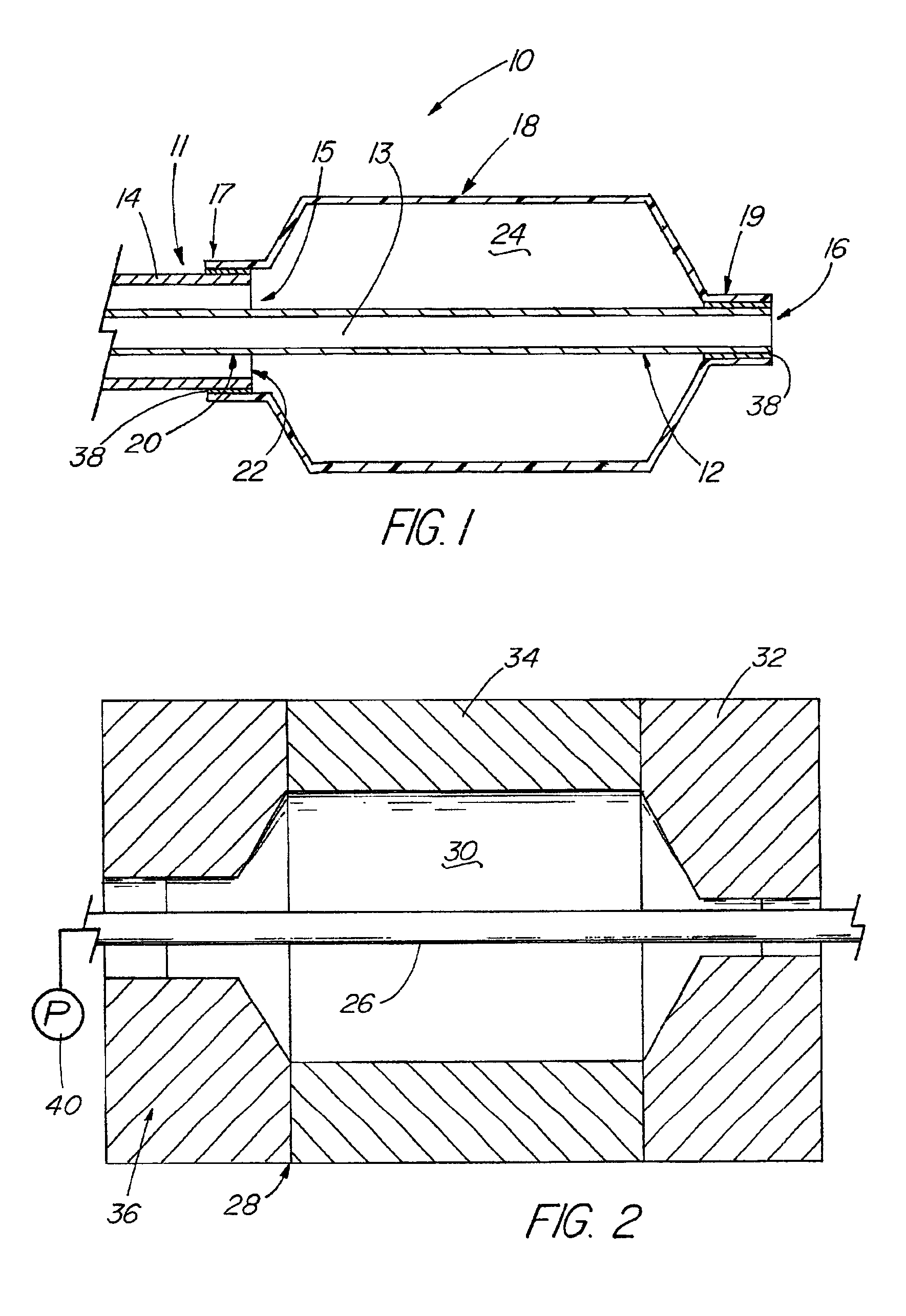

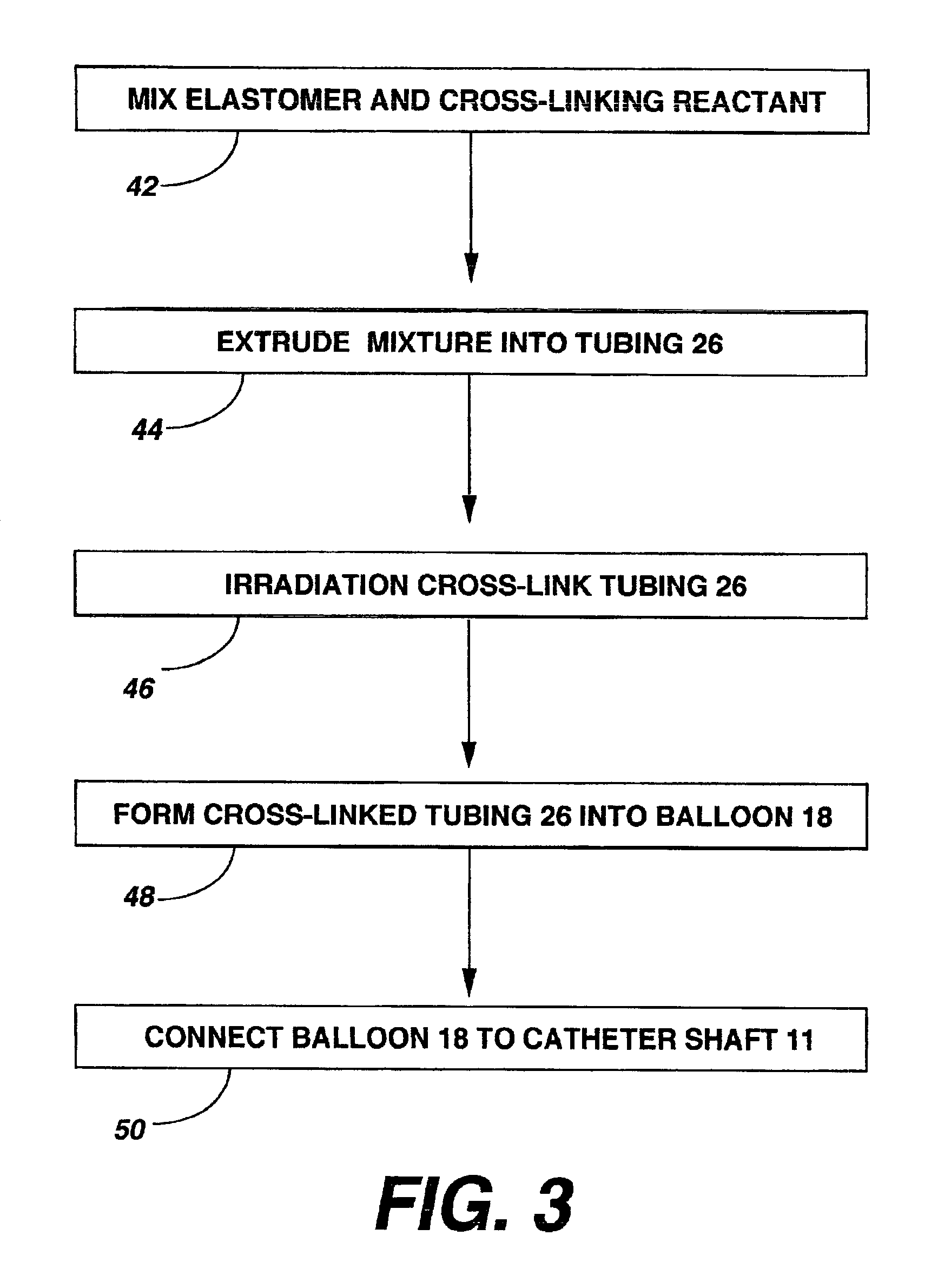

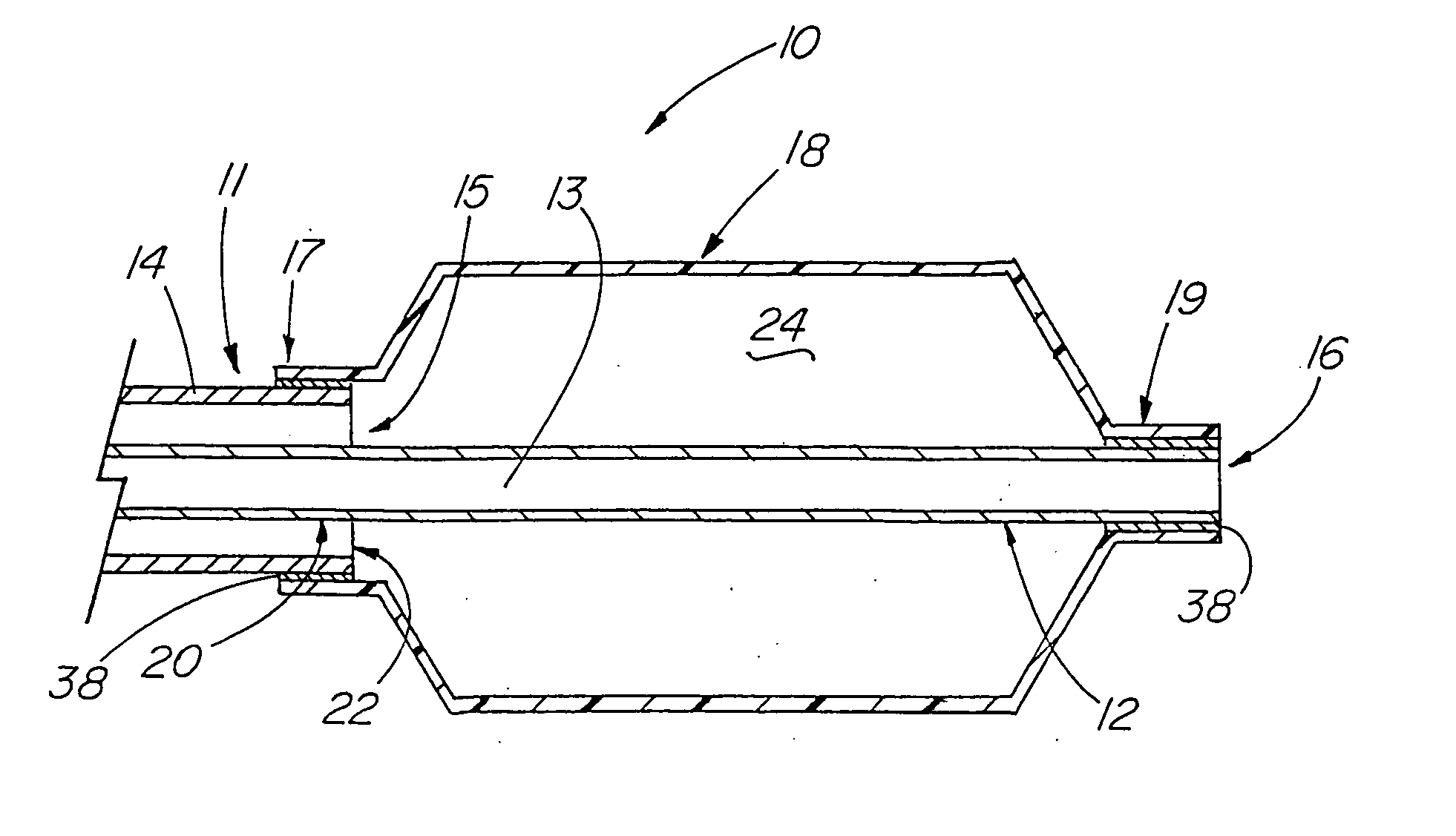

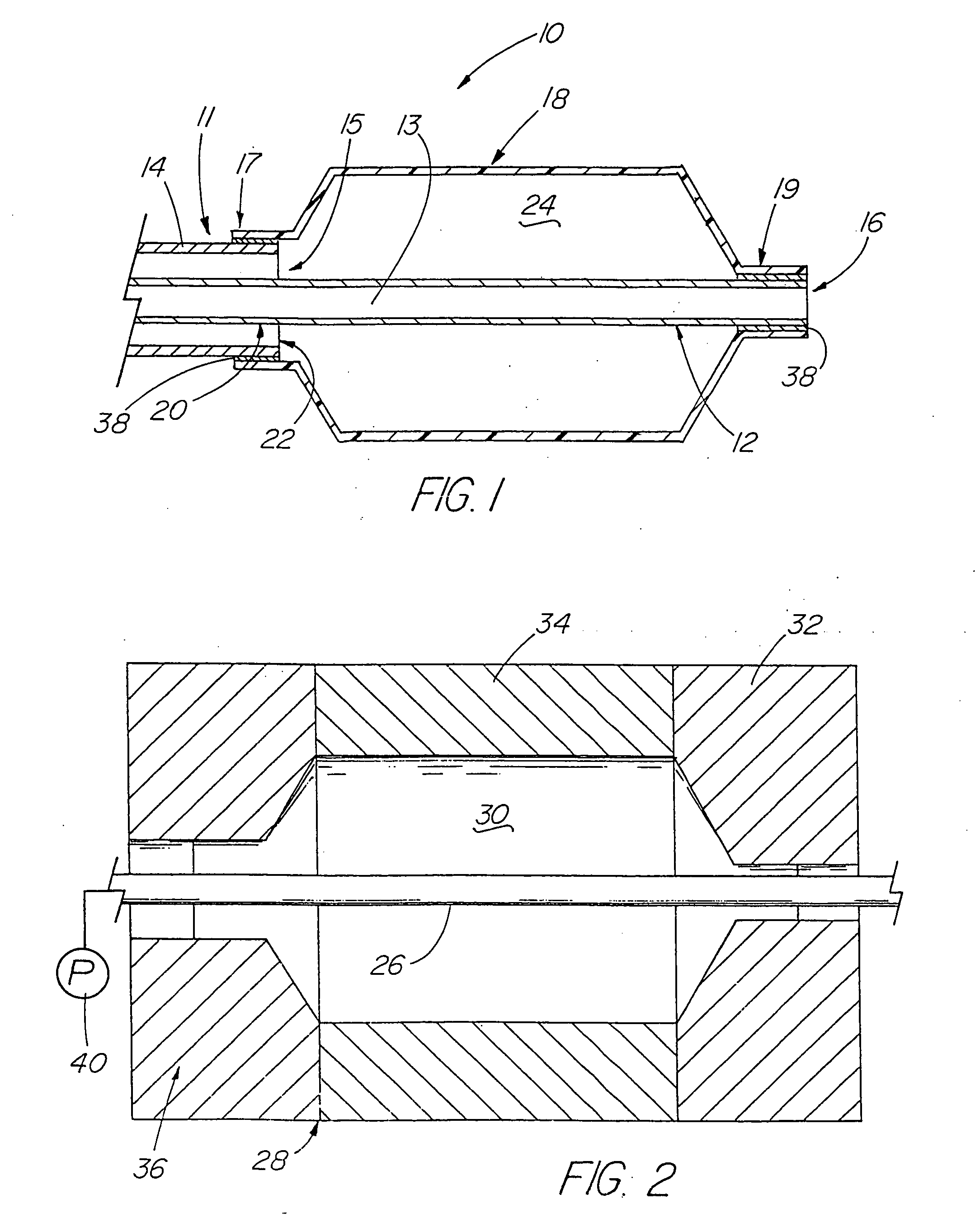

Medical device including unitary, continuous portion of varying durometer

InactiveUS6881209B2Improved combination of strengthPrevent restenosisLaminationLamination apparatusPolyesterCross-link

A medical device (110) including a catheter shaft (111) and a unitarily and continuously formed portion (108) having a varying durometer, and optionally including an expandable balloon (18, 118). One or both of the unitarily and continuously formed portion (108) and the balloon (18, 118) are made from an irradiation cross-linked or cross-linkable mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The aromatic molecule can be 1,3,5 triethyl benzene; 1,2,4 triethyl benzene; and 1,3,5 triisopropyl benzene. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide.

Owner:COOK MEDICAL TECH LLC

Alkylation process using UZM-8 zeolite

InactiveUS20060224031A1Reduce formationReduce the amount requiredMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkene

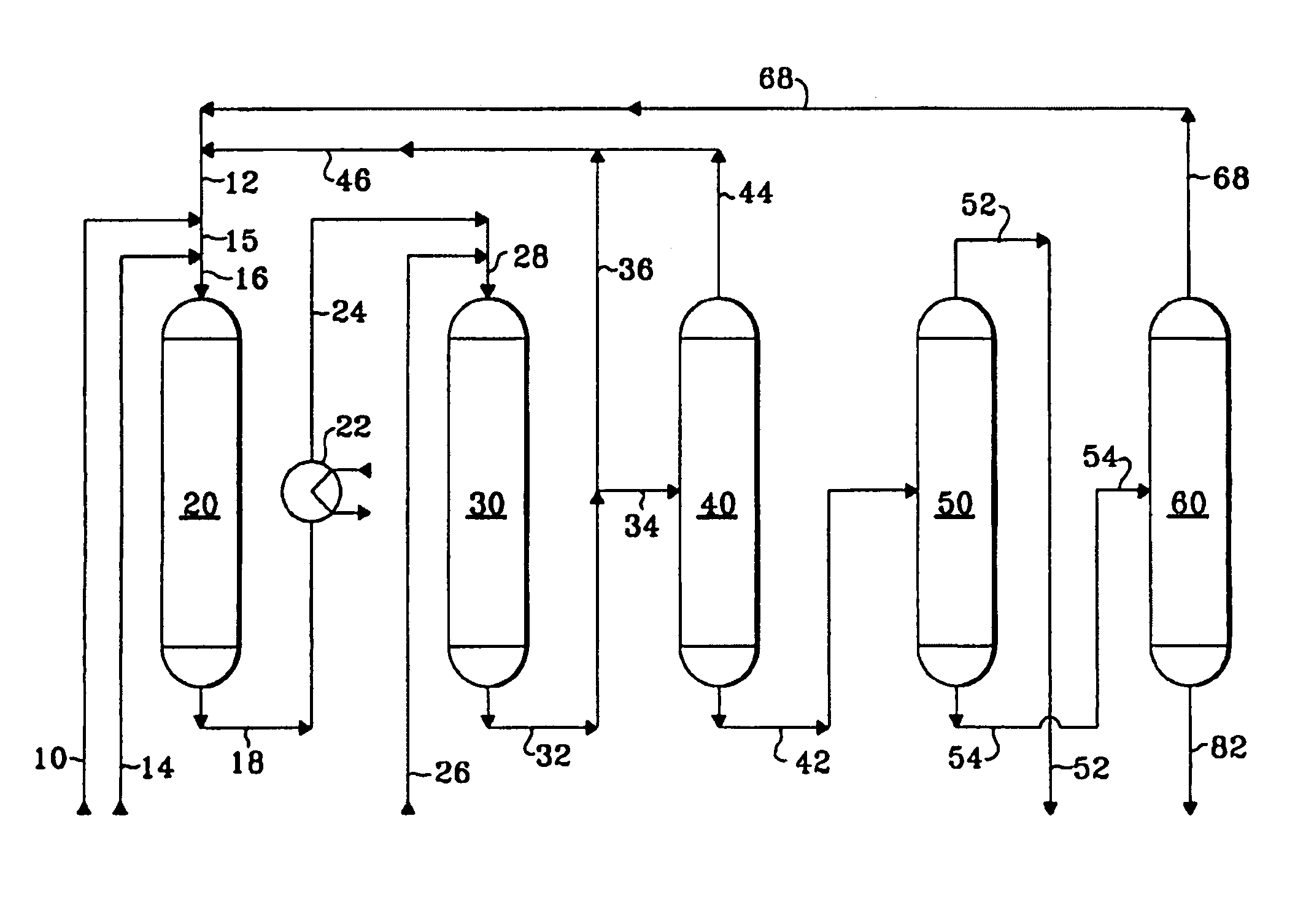

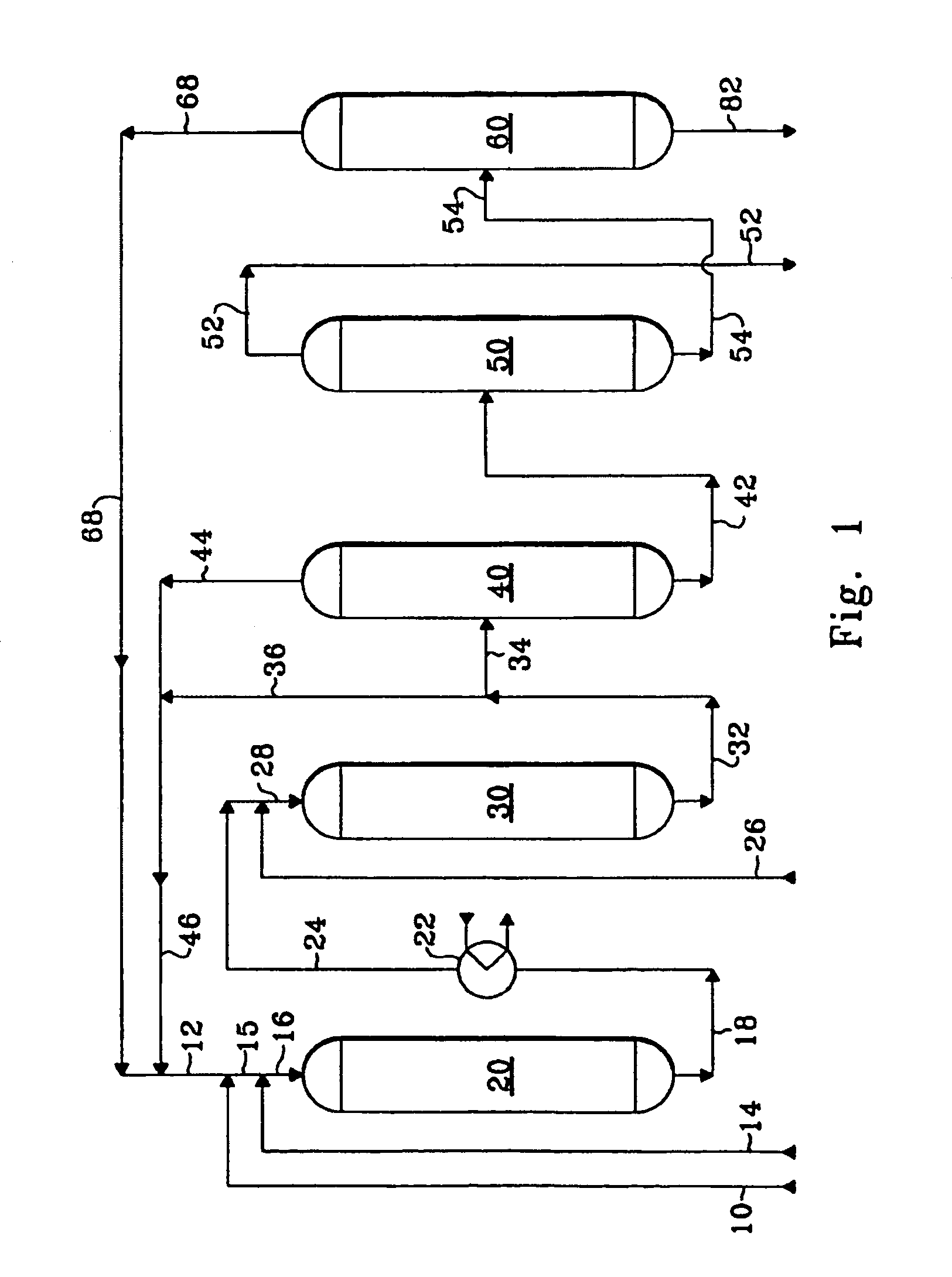

A process for the alkylation of aromatics with olefins using a solid catalyst bed containing UZM-8 zeolite is disclosed. A polyalkylated aromatic is passed to the catalyst bed to reduce the concentration of the olefin at alkylation conditions. A portion of the effluent recovered from the catalyst bed may be recycled to the catalyst bed. Such operation can decrease the catalyst deactivation rate and the formation of diphenylalkanes. The process disclosed herein is applicable to processes for the production of a wide variety of commercially important alkylated aromatics, including ethylbenzene and cumene.

Owner:UOP LLC

Container for 4-allylanisole and analog scolytid pesticides

A projectile can be used to administer pesticides such as one or more from the group consisting of 4-allylanisole, anisole, allylbenzene, 4-isopropylanisole, p-anisaldehyde, ethylbenzene, cumene, 4-methoxyacetophenone, 4-methylstyrene, 2-propylphenol, phenetole, and toluene, for scolytid infestation. Conifers, which are a target for scolytids, are protected by the application of the pesticides by use of a projectile containing the compound which explodes upon contact with the conifer thereby emitting the compound.

Owner:US SEC AGRI +1

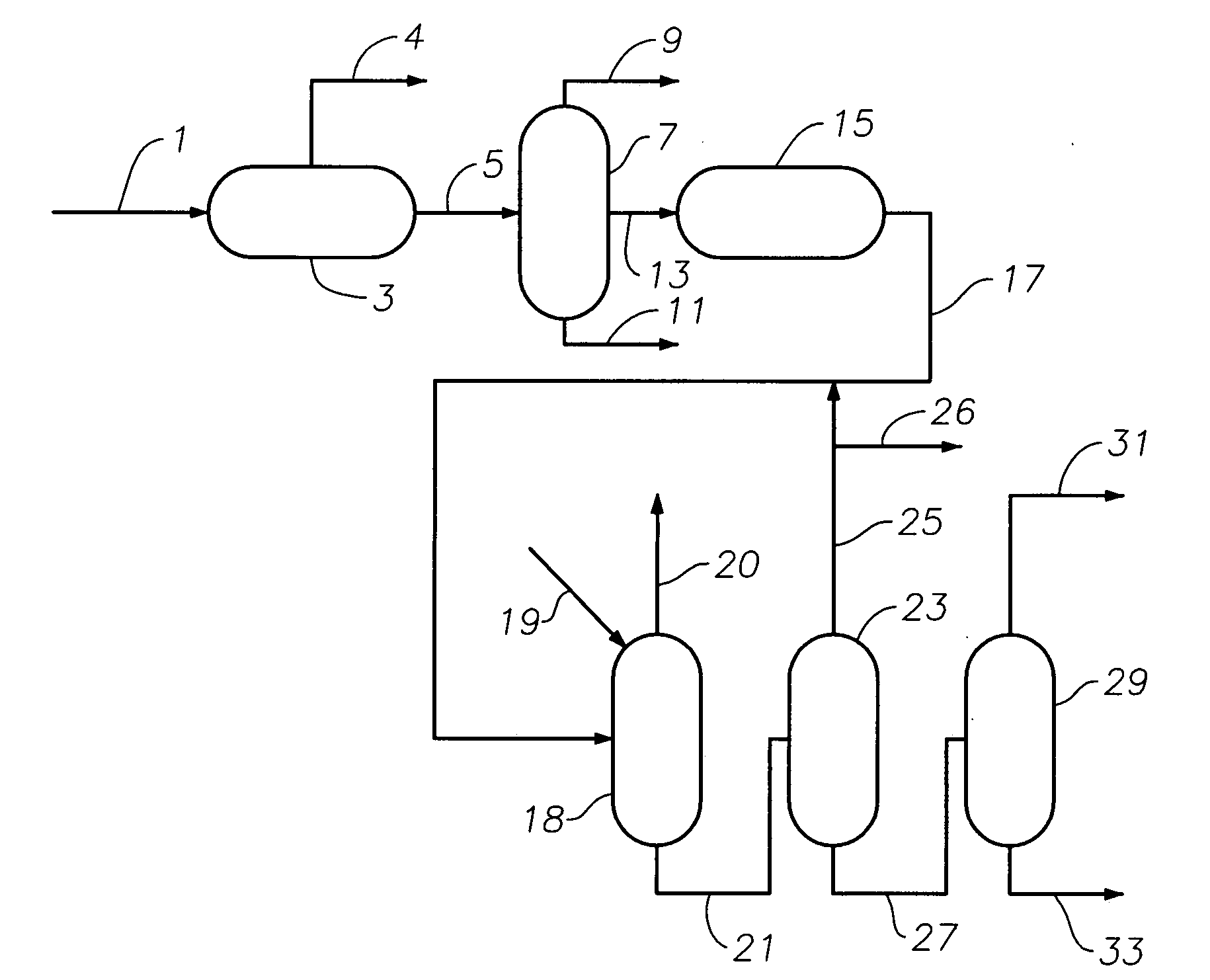

Process for preparing hydroperoxides

InactiveUS6291718B1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSulfurNitrogen

A process for preparing hydroperoxides which comprises oxidizing hydrocarbon by a gas containing oxygen in the presence of a specific compound and converting them selectively to corresponding hydroperoxides. The specific compound is the compound that can capture radicals. The preferable example may be a compound selected from radicals of oxygen, nitrogen, phosphorus, sulfur, carbon or silicon or a compound that forms radicals of these in the reaction system. The present invention can be applied to oxidation of hydrocarbons including arylalkylhydrocarbons such as cumene, m-diisopropylbenzene, p-diisopropylbenzene, 1,3,5-triisopropylbenzene, isopropylnaphthalene, diisopropylnaphthalene, isopropylbiphenyl, diisopropylbiphenyl, etc.

Owner:MITSUI CHEM INC

Aromatic Transalkylation Using A LZ-210 Zeolite

InactiveUS20080171901A1Decreased NPB formationHigh activityHydrocarbon by isomerisationMolecular sieve catalystsOrganic chemistryCumene

Owner:UOP LLC

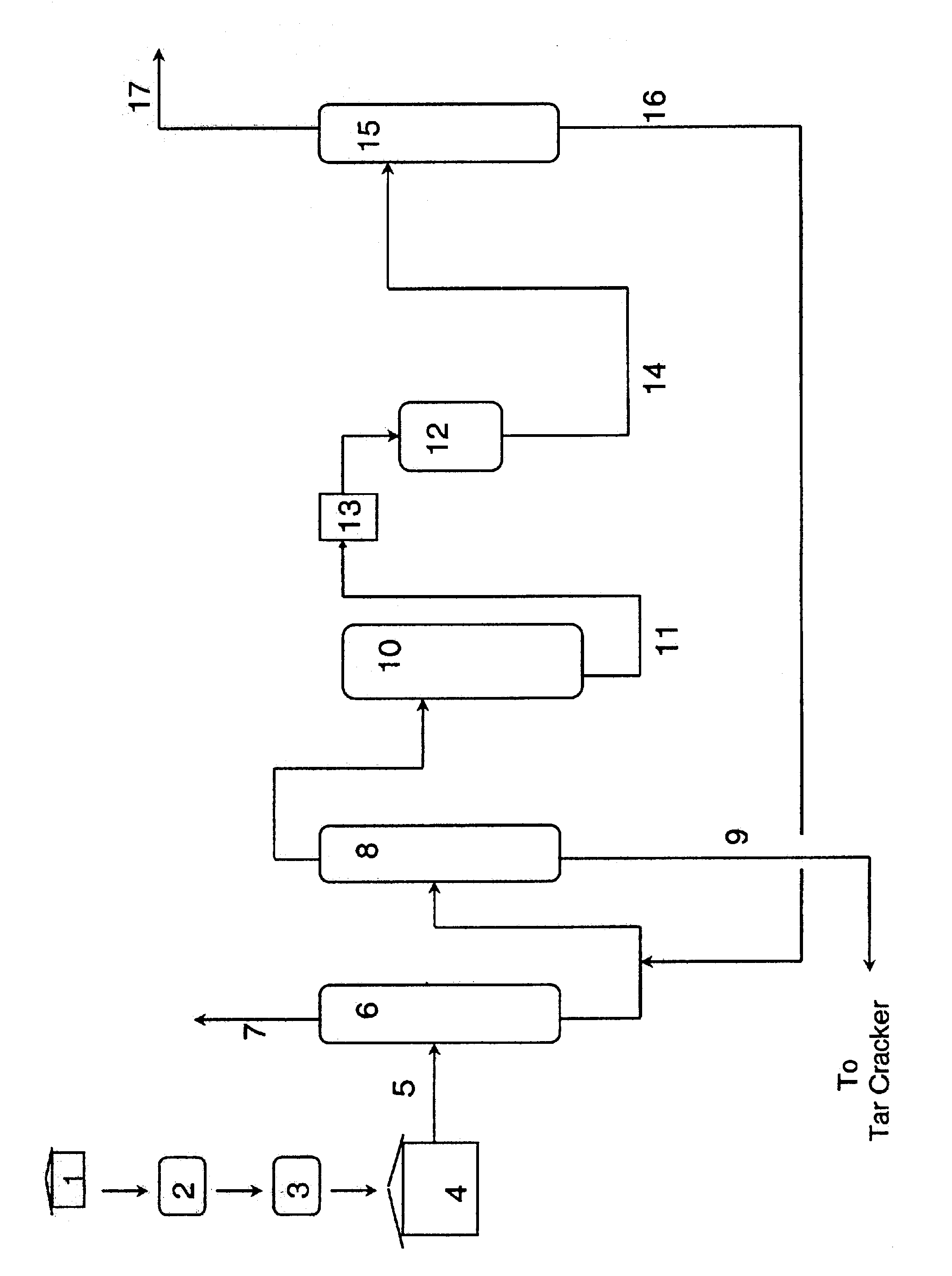

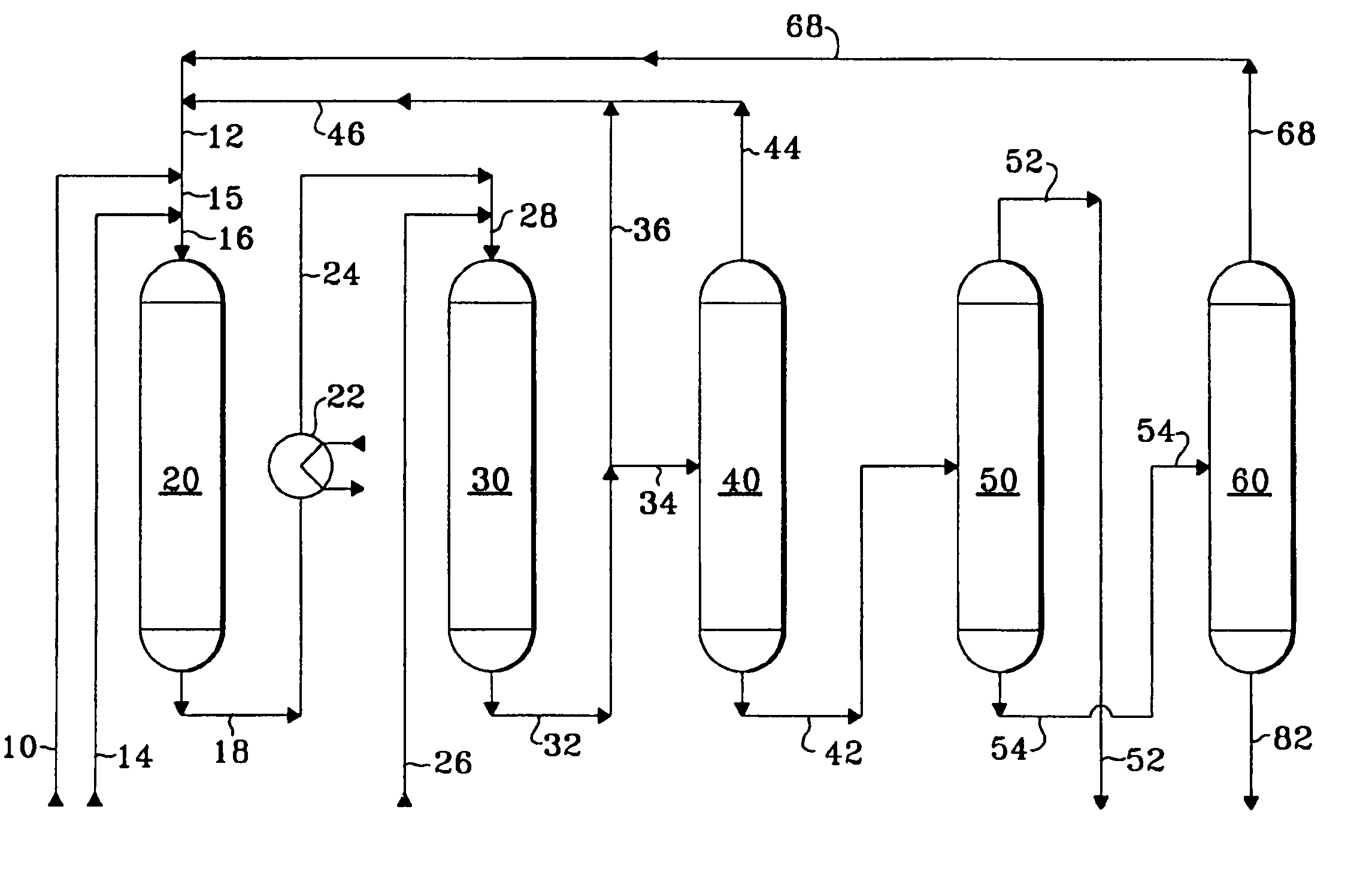

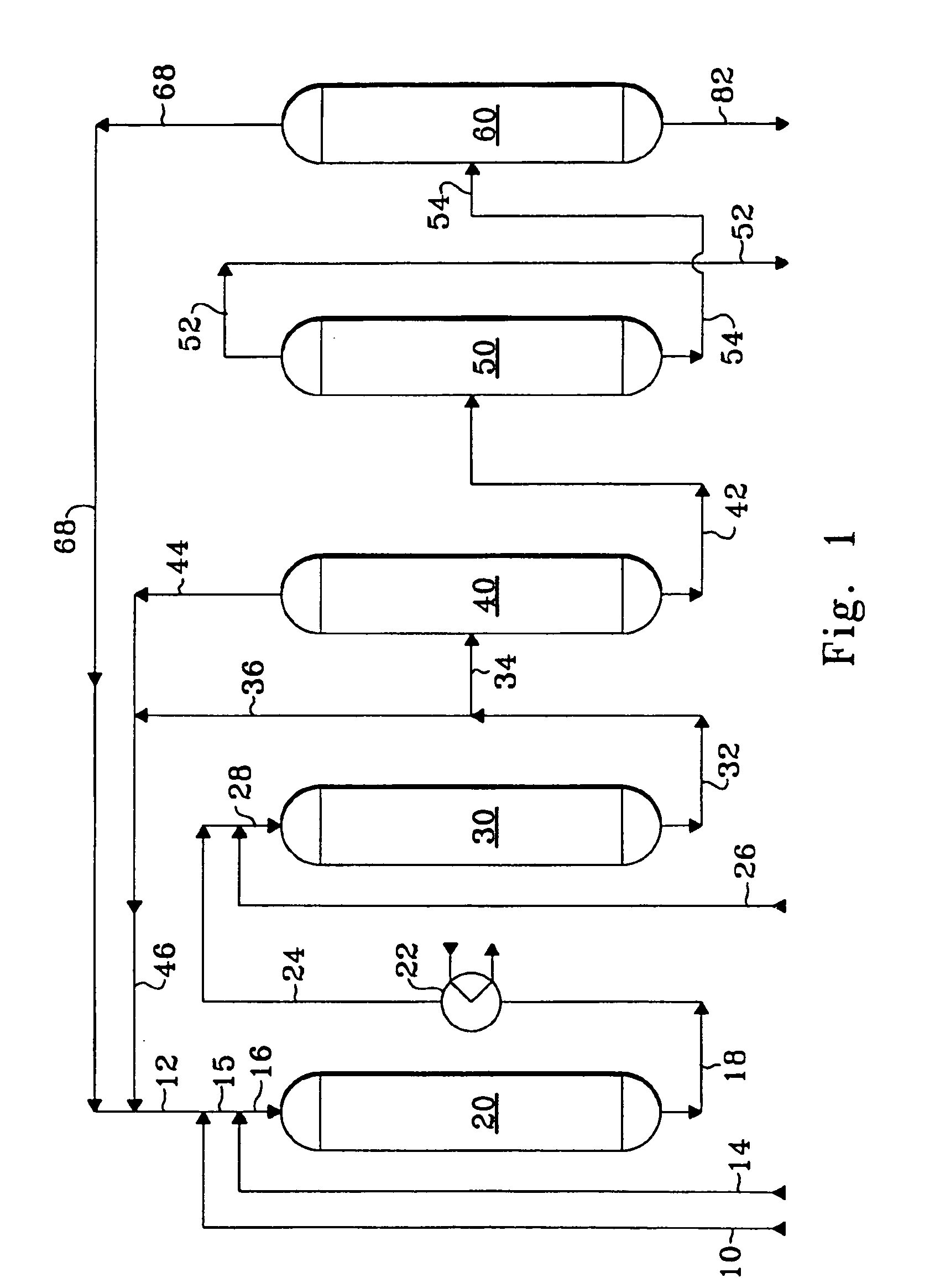

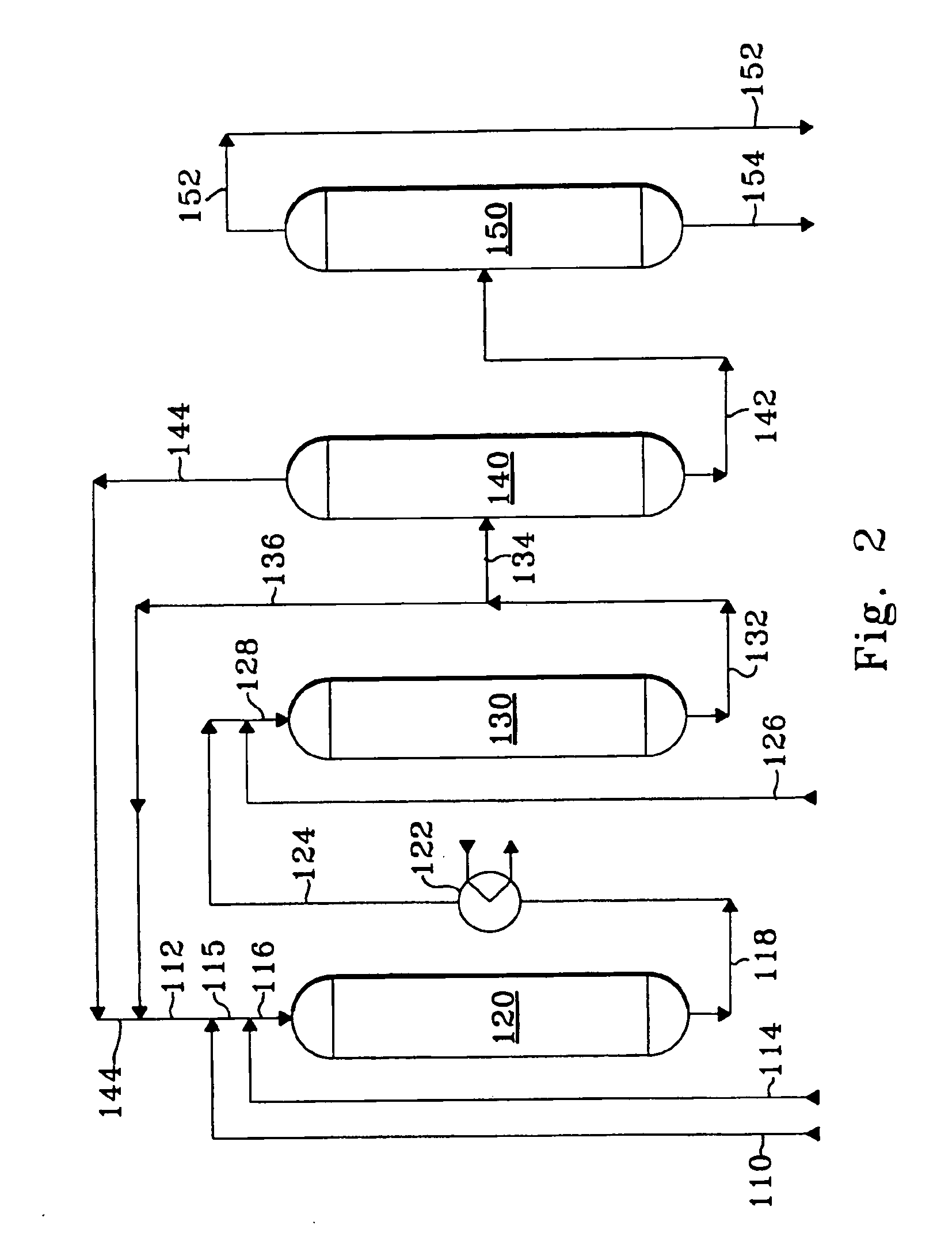

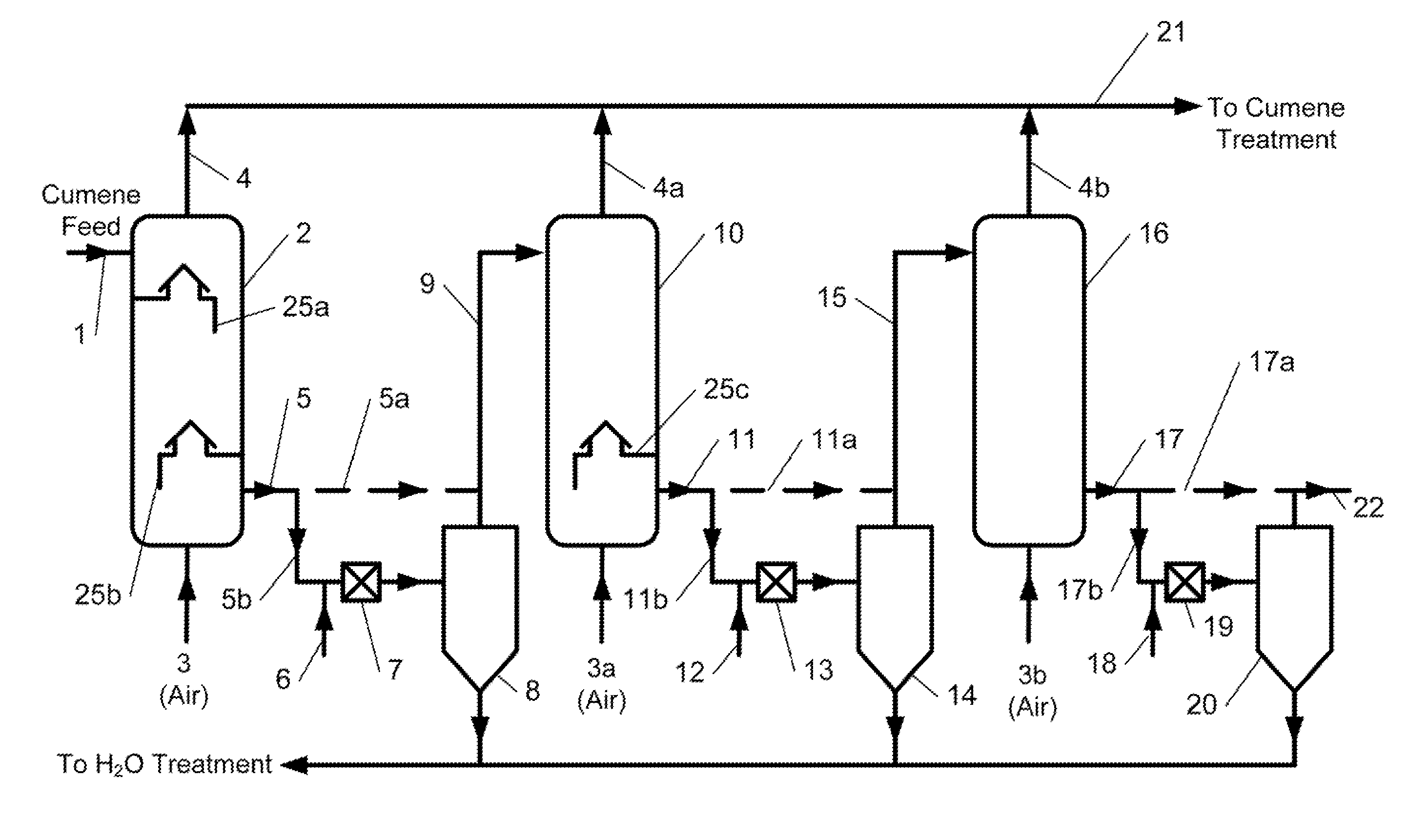

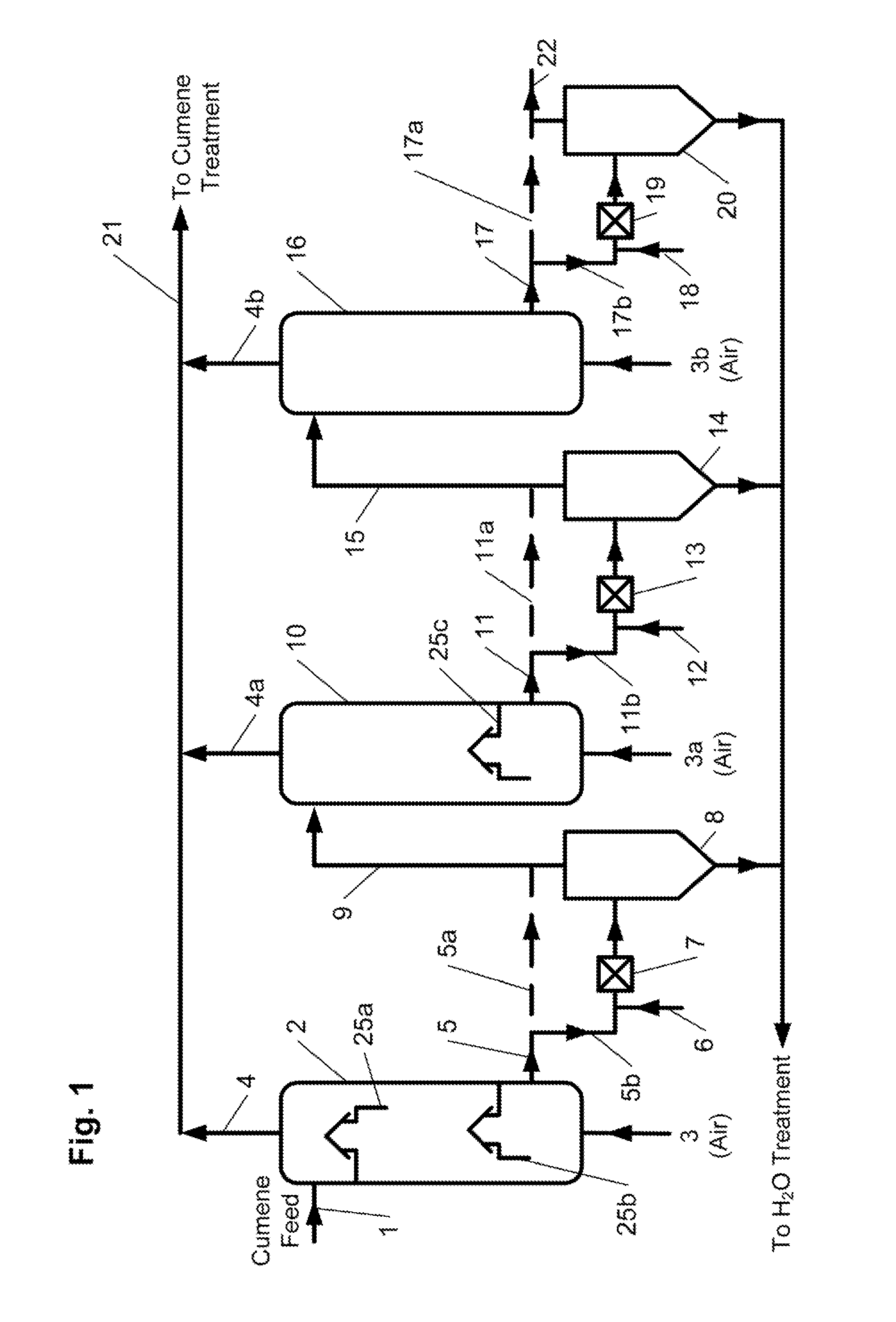

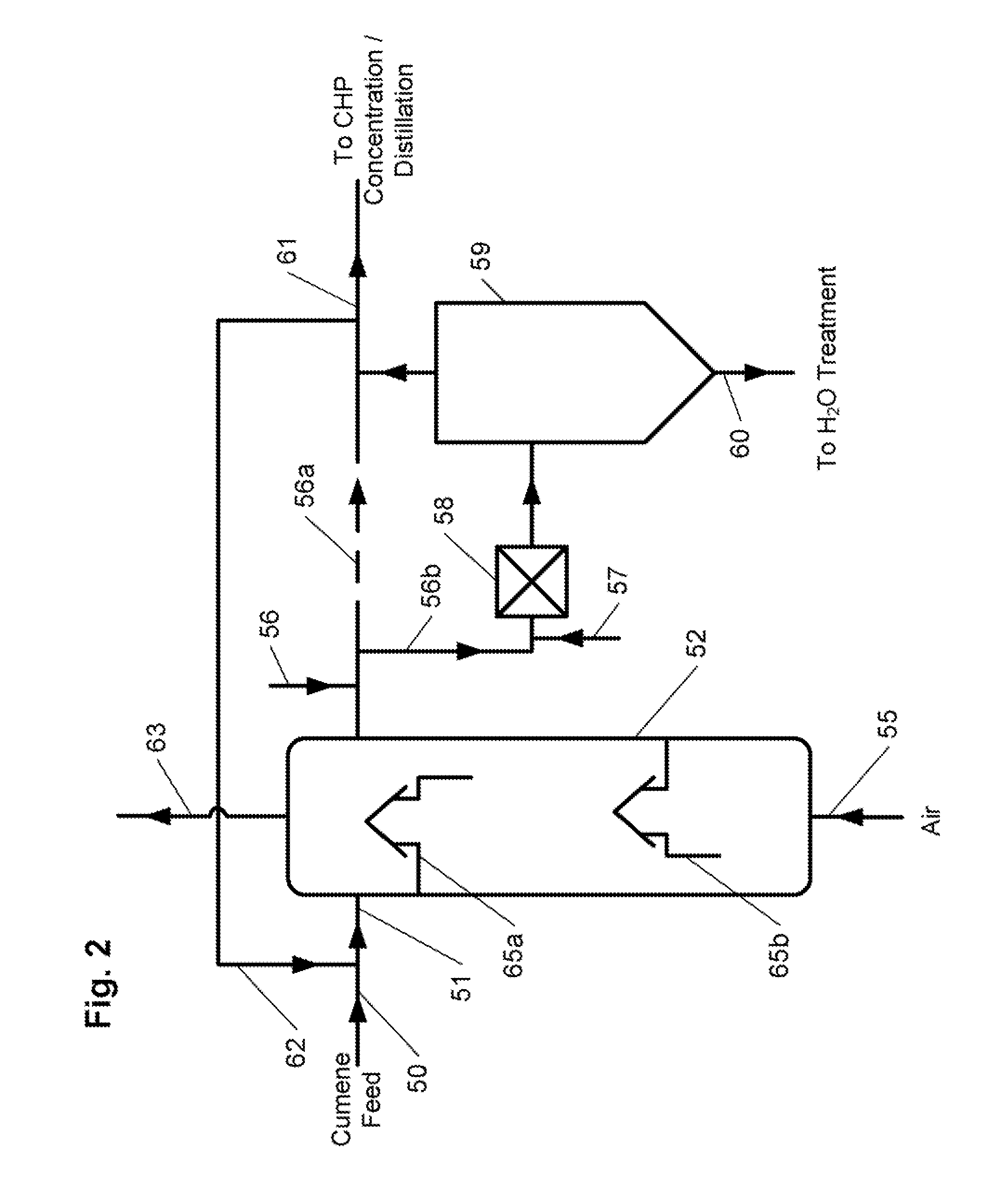

Method for production of cumene hydroperoxide

ActiveUS7393984B1Improve productivityRemoving and reducing formation of undesirableOrganic compound preparationPeroxy compound preparationBenzoic acidGas phase

A continuous method of cumene oxidation in a gas-liquid system is provided, where the liquid phase is represented by cumene and its oxidation products and the gas phase is represented by air. The oxidation process can be carried out either in a reactor series or in a single reactor at least one of which is preferably equipped with at least two airlift-type trays. When specific CHP concentration is achieved, the oxidation products are discharged from the to reaction zone and treated in a mixing device with aqueous ammonia or water to remove organic acids such as formic acid, benzoic acid, etc. and to remove phenol, which is an inhibitor of oxidation reaction. The cumene oxidation product stream, free of organic acids and phenol is recycled to the same reactor in the case of single reactor, or is passed to the next reactor of the series in the case of reactor series. In all cases, the oxidation products treated with water or aqueous ammonia is first directed to a unit for separation of aqueous phase from organic products and then anhydrous organic product stream is forwarded to the next reactor of the series, or recycled to the single reactor for the continued cumene oxidation until the required CHP concentration is achieved. The airlift-type trays in at least one process reactor accelerate the cumene oxidation reaction therein while increasing the process selectivity and enabling the process to be conducted at lower temperature, improving safety thereof. Advantageously, lower quality cumene having impurities such as sulfur-containing trace elements, can be used in the inventive process while maintaining a high process selectivity.

Owner:ILLA INT

Production of high purity cumene from non-extracted feed and hydrocarbon composition useful therein

A process for producing an cumene product having a purity of at least 99.50 percent based on the weight of cumene present in the product by the propylation of the benzene present in non-extracted hydrocarbon composition feed, e.g., non-extracted reformate. The non-extracted hydrocarbon composition feed is substantially free of both C4− hydrocarbons and the C7+ aromatic hydrocarbons and contains benzene and benzene coboilers. The process is carried out in the liquid phase, in the presence of an acid-active catalyst containing MCM-22 family molecular sieve, and under specified conditions.

Owner:EXXONMOBIL CHEM PAT INC

Aromatic Transalkylation Using a Y-85 Zeolite

InactiveUS20080171902A1Decreased NPB formationHigh activityHydrocarbon by isomerisationMolecular sieve catalystsOrganic chemistryCumene

Owner:UOP LLC

Copper catalyst for preparing isopropyl benzene by alpha, alpha-dimethyl benzyl alcohol hydrogenolysis and preparation method thereof

InactiveCN101992098ACatalyst activation/preparationHydrocarbon from oxygen organic compoundsCopperBENZYL ALCOHOL/WATER

The invention relates to a copper catalyst for preparing isopropyl benzene by alpha, alpha-dimethyl benzyl alcohol hydrogenolysis and a preparation method thereof, and mainly solves the problem of poor stability of the Cu catalyst prepared in the prior art. The invention well solves the problem by adopting the technical schemes of the catalyst and the preparation method thereof, wherein the catalyst comprises the following components in percentage by weight: 20.0 to 55.0 percent of CuO, 15.0 to 50.0 percent of ZnO, 10.0 to 45.0 percent of Al2O3 and 1.0 to 20.0 percent of at least one of MnO2, TiO2 and ZrO2; and the catalyst can be used in the industrial production of producing the isopropyl benzene by the alpha, alpha-dimethyl benzyl alcohol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

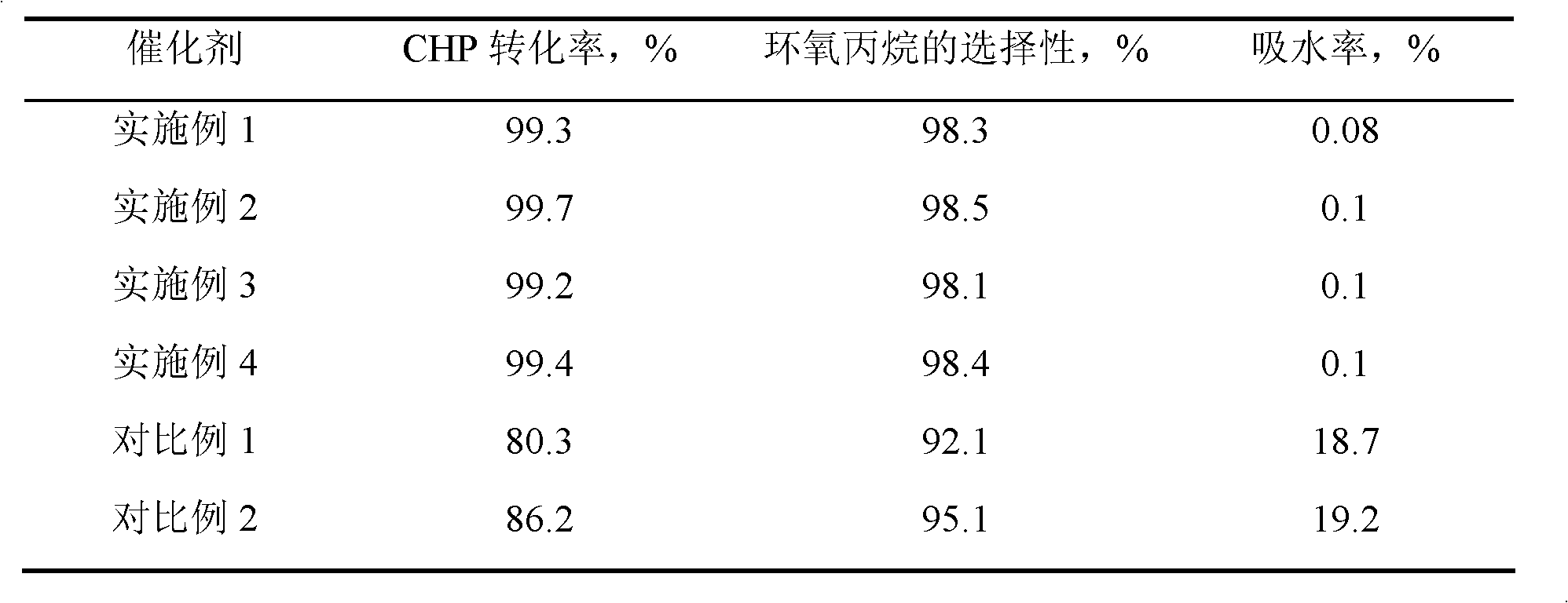

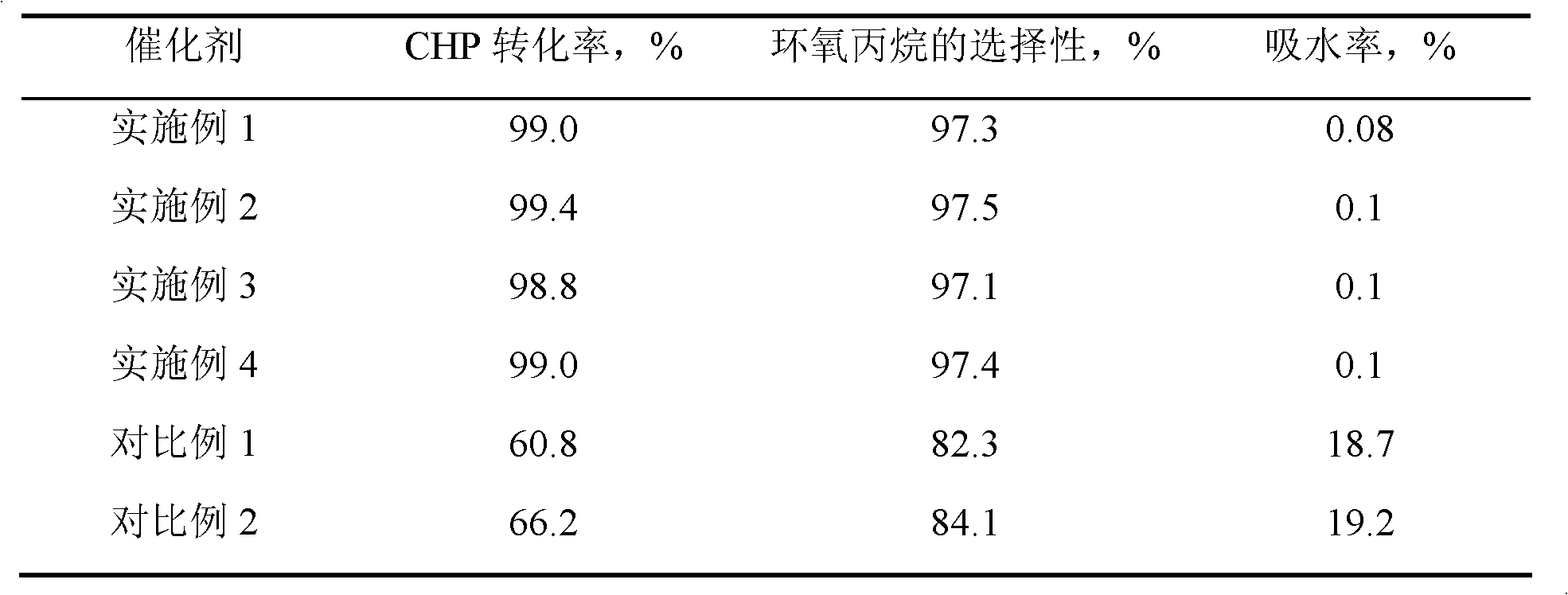

Method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene

ActiveCN103030612AImprove catalytic performanceReduce in quantityOrganic chemistryMolecular sieve catalystsSilanesReaction temperature

The invention relates to a method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene, mainly aiming at solving the problems of low catalyst activity, low epoxypropane selectivity and poor reaction stability existing in the prior art. Reaction raw materials are in contact with catalyst to produce the epoxypropane by using the cumyl hydroperoxide and the propylene as the raw materials under the conditions that the molar ratio of the cumyl hydroperoxide to the propylene is 1:1 to 1:10, the reaction temperature is 50-100DEG C, the reaction pressure is 1-5MPa and the mass space velocity of the cumyl hydroperoxide is 1-30h<-1>. The catalyst is prepared by adopting a method which comprises the following steps of: a) evenly mixing organic silicon sources, inorganic silicon sources, titanium sources and organic templates with water, and filtering, water-washing, drying and roasting the product to obtain precursors I, wherein the inorganic silicon sources are selected from at least one of silica sol, silicate ester and solid silicon oxide, and the organic silicon sources are methyltrimethoxysilane; and b) by taking inert gas as carriers, feeding silanization agent into the precursors I for reaction to obtain the catalyst, wherein the silanization agent is selected from at least one of organic silane, organic silicylamine, organic silicylamide and organic silazane. By adopting the technical scheme, the problems are better solved and the method can be used for the industrial production of the epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of directly catalytic epoxidation

InactiveCN101045717AUniversal applicabilityOrganic chemistryPhysical/chemical process catalystsHeteropoly acidReaction temperature

This invention relates to a method of directly catalyze epoxide. In existing technology takes low concentration H2O2 water solution as oxidizer, phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer to prepare epoxide. This invention mainly solve the problem in existing technology of separation energy high caused by water, as well as catalyst stability low caused by decompound of phosphorus tungsten heteropoly acid quaternary ammonium salt, and problem of H2O2 activity factor descending. This invention takes olefine, cyclenes or aromatic alkene contain 1 to 10 carbon atom and aqueous hydrogen peroxide solution as raw material, takes phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer, takes at least one of toluene, benzene, ethylbenzene, cumene , chloroform or tributyl phosphate as solvent, takes phosphatic inorganic salt as additive, under 20 to 100deg reaction temperature and 0 to 3.0 Mpa reaction pressure, to carry out reaction for 0.5 to 24 hours. It best solve existing problem, can be used in industrial production of epoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing isopropyl benzene

ActiveCN101768044AHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenActive component

The invention relates to a method for producing isopropyl benzene by using a material containing isopropyl benzene hydroperoxide and alpha-alpha-dimethyl benzyl alcohol, which mainly solves the problems that in the production process of the isopropyl benzene in the prior art, the isopropyl benzene hydroperoxide decomposes and releases phenol easily to reduce the yield of the isopropyl benzene, and a catalyst containing Cr easily causes environmental pollution. The method comprises the following steps: after alkali washing, allowing the material containing isopropyl benzene hydroperoxide and alpha-alpha-dimethyl benzyl alcohol which is adopted as a raw material to enter a pre-hydrogenation unit for converting the isopropyl benzene hydroperoxide in the raw material into the alpha-alpha-dimethyl benzyl alcohol; and allowing the raw material to enter a hydrogenolysis reaction unit for converting the raw material into the isopropyl benzene, wherein an active component of a pre-hydrogenation catalyst is Pd, Pt or a mixture of Pd and Pt or a mixture of the oxide of Pd and Pt; an active component of a hydrogenolysis atalyst is Pd, or a mixture of Pd and Pt or a mixture of the oxide of Pd and Pt; a technical scheme solves the problem; and the method can be applied to industrial production of the isopropyl benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Medical device including unitary, continuous portion of varying durometer

InactiveUS20060016064A1Point becomes highLess reactiveElectric discharge tubesHollow filament manufactureCross-linkPolyester

A medical device (110) including a catheter shaft (111) and a unitarily and continuously formed portion (108) having a varying durometer, and optionally including an expandable balloon (18, 118). One or both of the unitarily and continuously formed portion (108) and the balloon (18, 118) are made from an irradiation cross-linked or cross-linkable mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The aromatic molecule can be 1,3,5 triethyl benzene; 1,2,4 triethyl benzene; and 1,3,5 triisopropyl benzene. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide.

Owner:COOK MEDICAL TECH LLC

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com