Patents

Literature

130 results about "Hydroxyacetone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

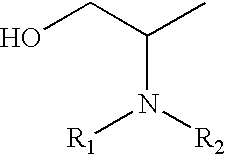

Hydroxyacetone, also known as acetol, is the organic chemical with the formula CH₃C(O)CH₂OH. It consists of a primary alcohol substituent on acetone. It is an α-hydroxyketone, also called a ketol, and is the simplest hydroxy ketone structure. It is a colorless, distillable liquid.

Compositions for improving the organoleptic qualities of cooked foodstuffs

Compositions for generating a cooked flavor in a foodstuff, comprising specified flavor precursors that react on heating to generate the flavor and maintain a reactive association after inclusion in the foodstuff. The compositions may include combination of a sulphur source, e.g. hydrogen sulphide, methane thiol, a sulfur-containing amino acid, thiamine, cystine, sodium sulphide, ammonium sulphide, ammonium polysulphide, onions, garlic, shallots, eggs, methionine, and mixtures thereof, and at least one reductone, e.g. a furanone, a ketone, a pyrone, an aldehyde, a carbonyl compound, isomaltol, maltol, pyruvaldehyde, hydroxyacetone, 3-deoxyglucosone, 5-hydroxy-5,6-dihydromaltol, 2,3-butanedione, 3-hydroxy-2-butanone, a process flavor, cooked vegetable concentrates, soy sauce, and mixtures thereof.

Owner:KERRY INGREDIENTS UK

Process for preparing acrolein by glycerin dewatering

ActiveCN101070276AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationAlcoholGlycerol

This invention relates to acidity zeolite catalyst used for glycerol dehydration to perpare acrolein and the reaction craft. Glycerine directly dehydrate to generate acrolein under the condition of acidity zeolite catalyst, 200 to 500deg temperature, 0.001 to 3.0MPa pressure and 0.1 to 100.0h - 1 liquid airspeed, at the same time produce byproduct pyruvic alcohol. The raw material raw glycerine could be mixed liquor of water solution, alcosol, fatty acid ester solution at any ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

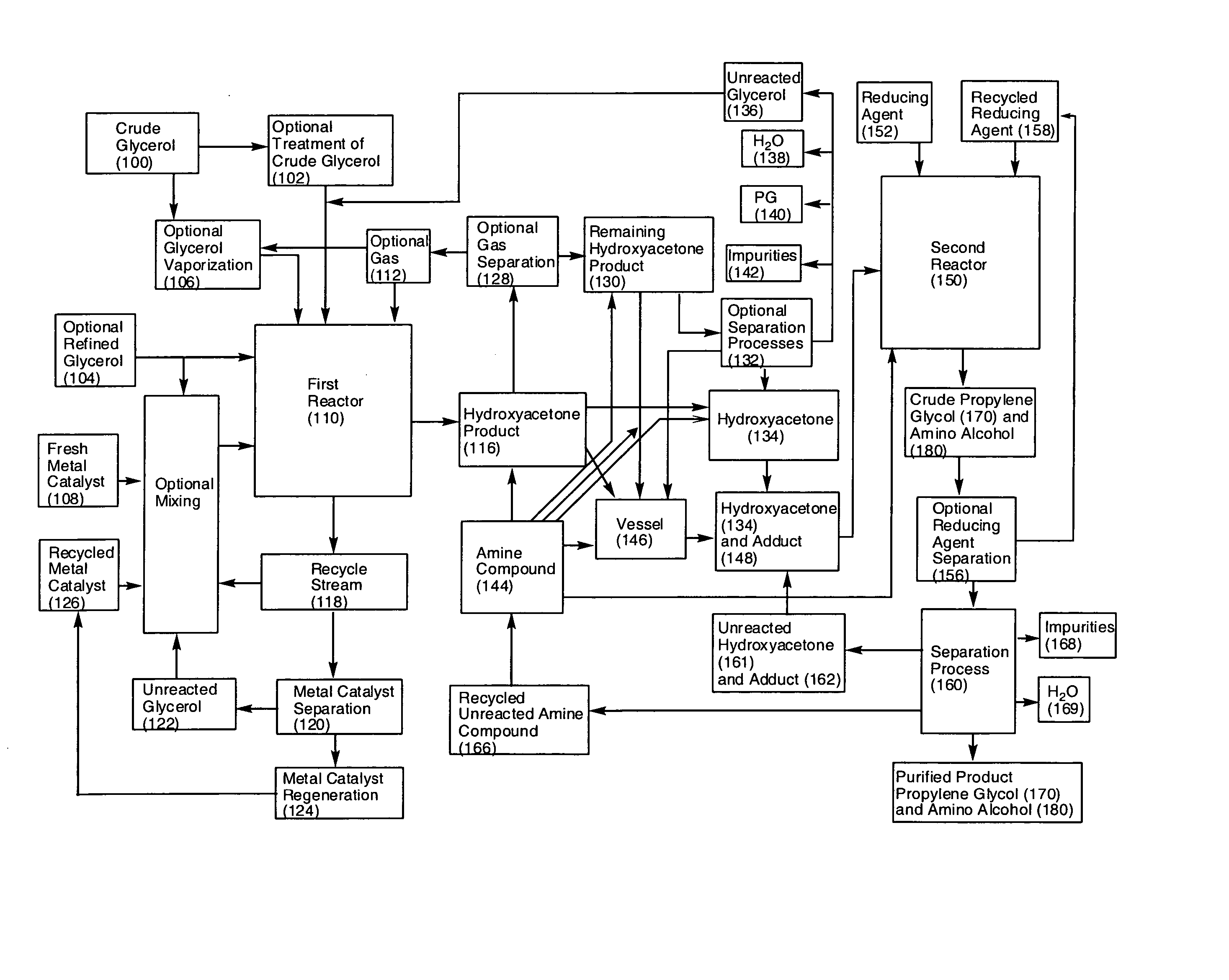

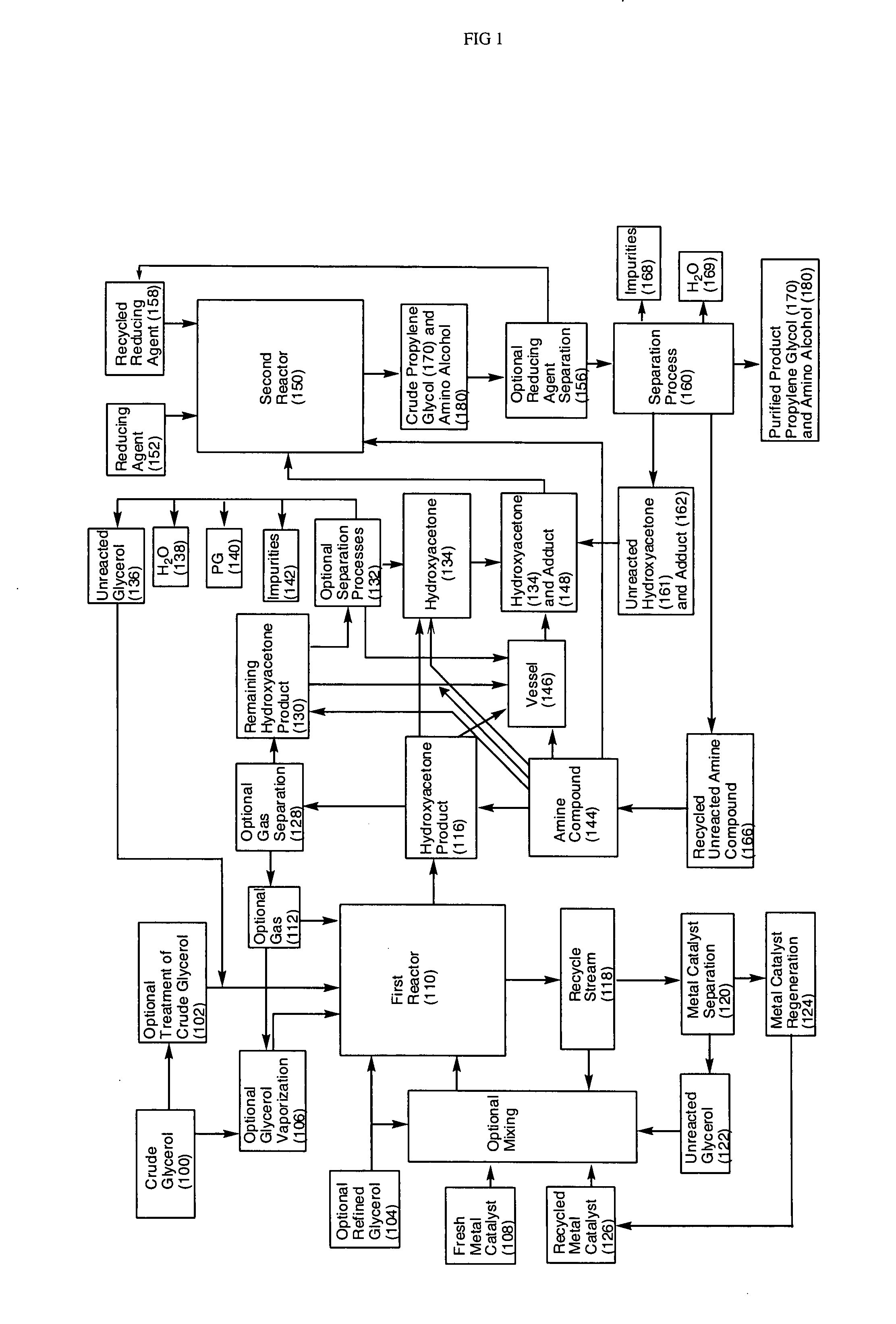

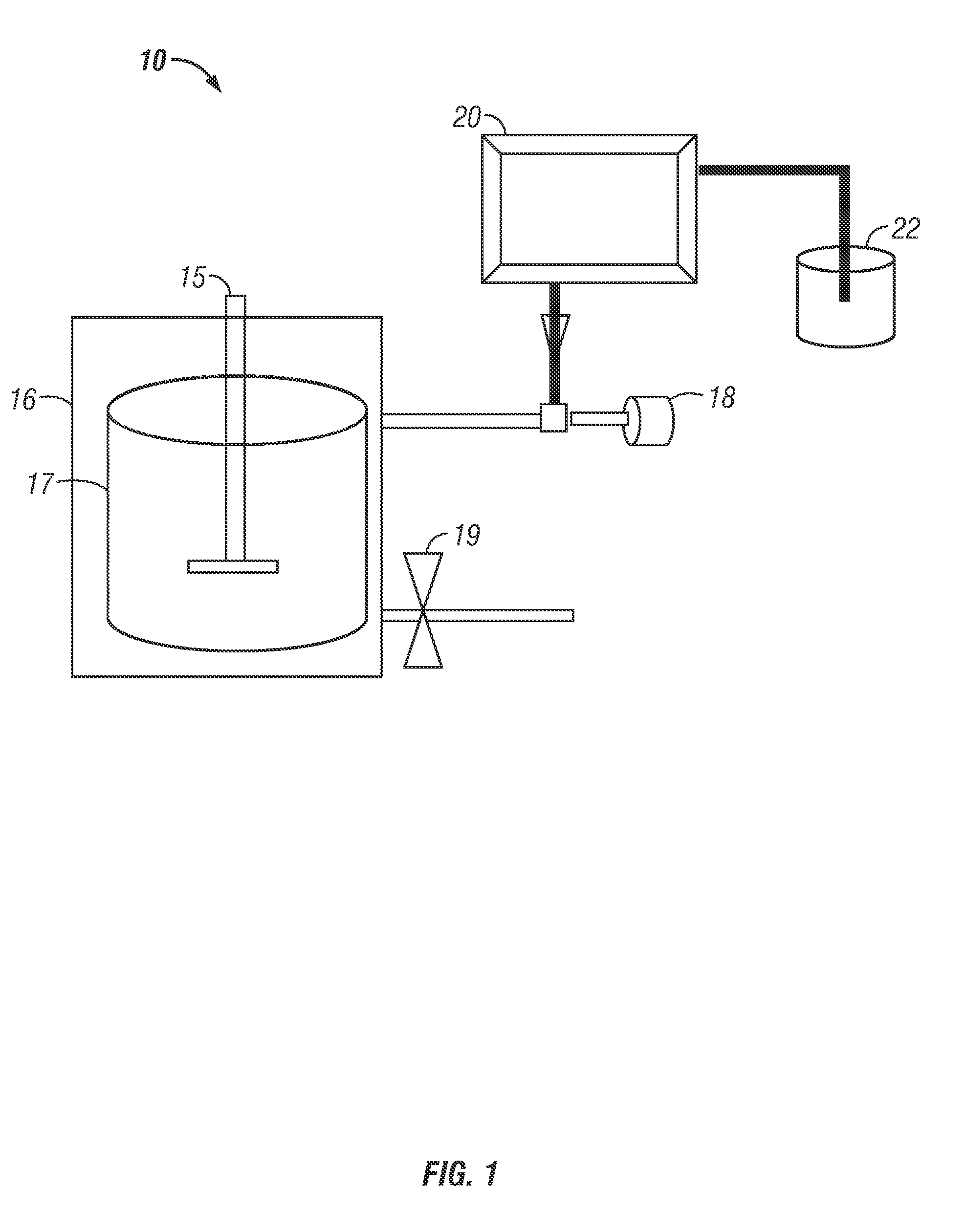

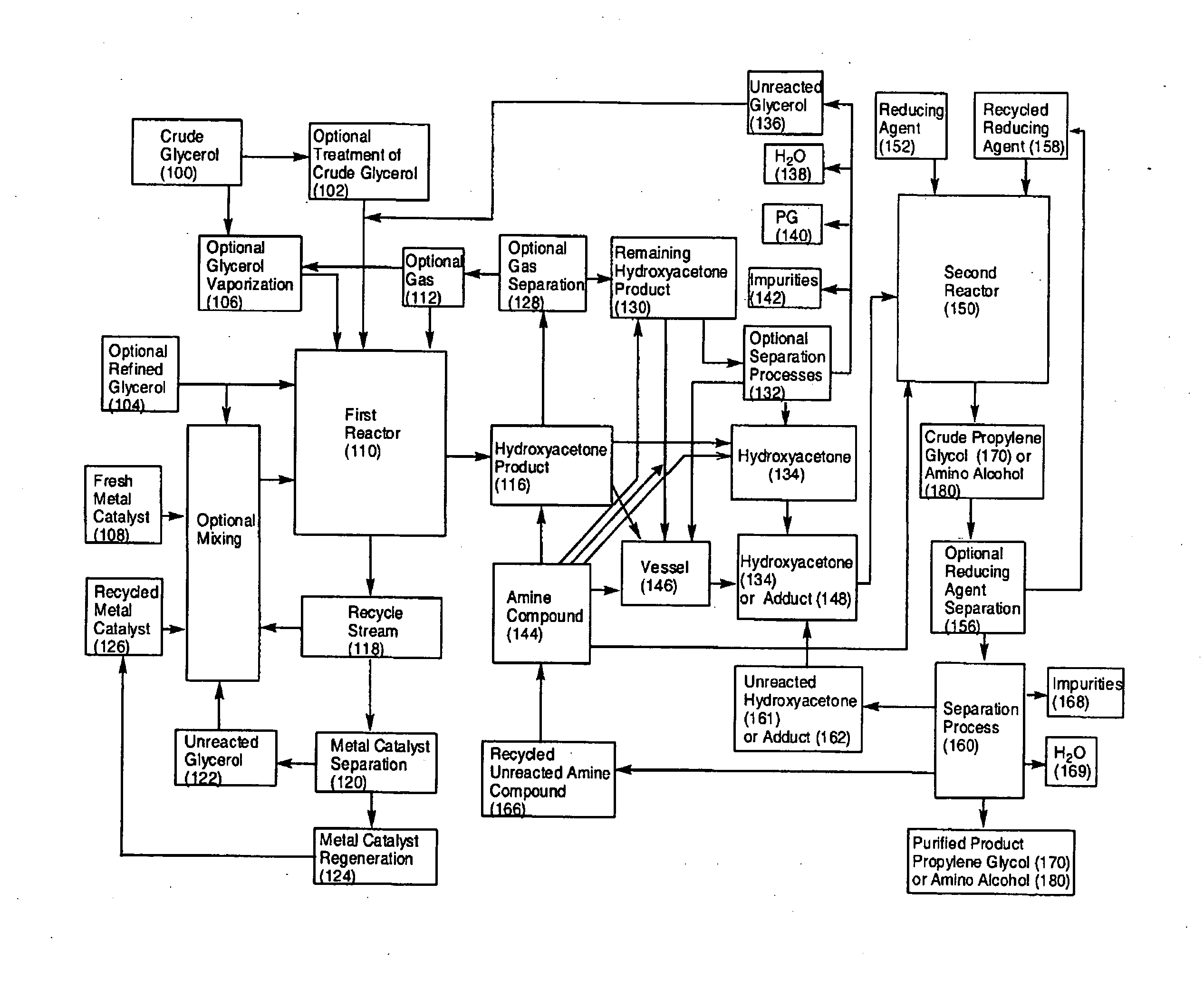

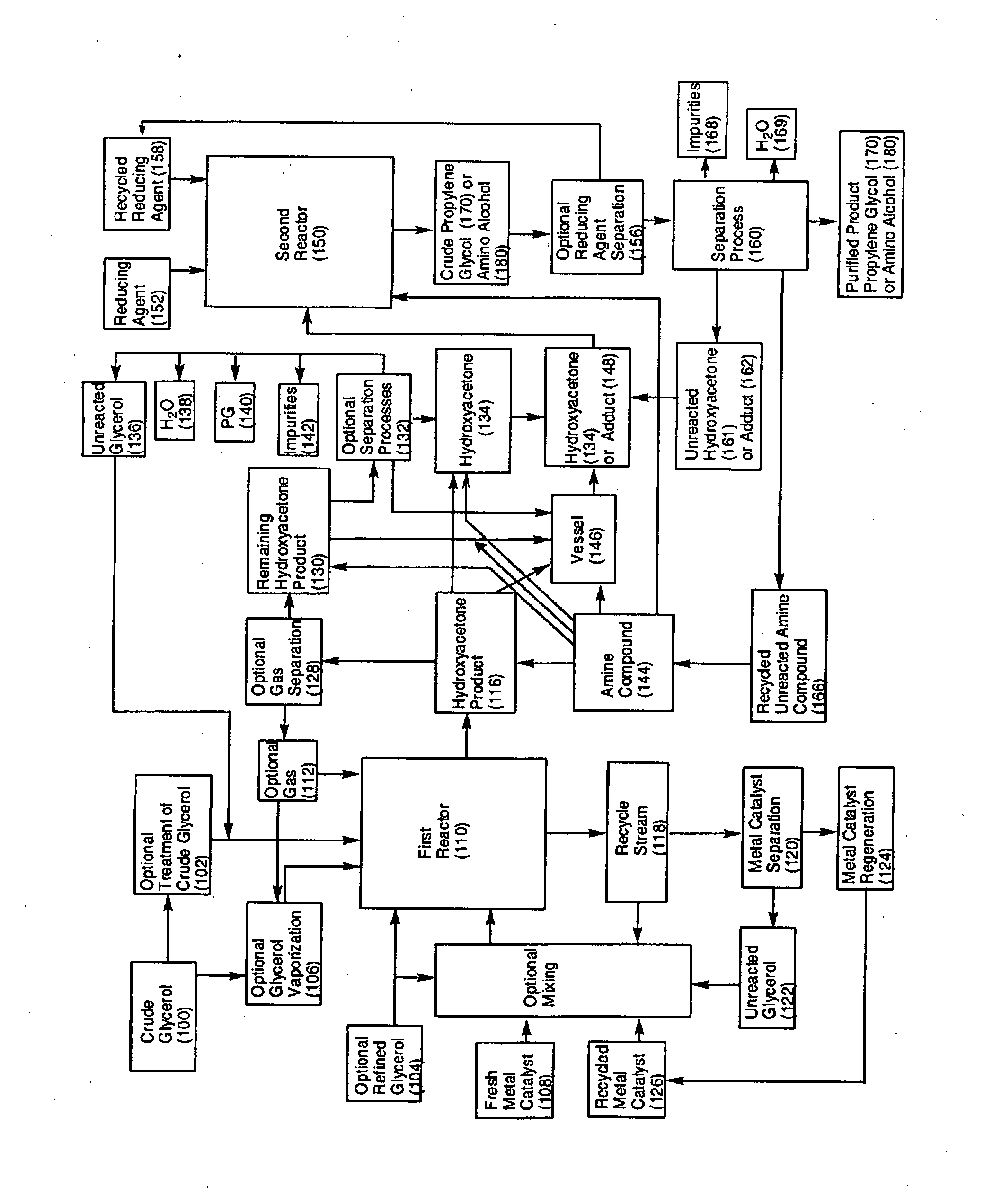

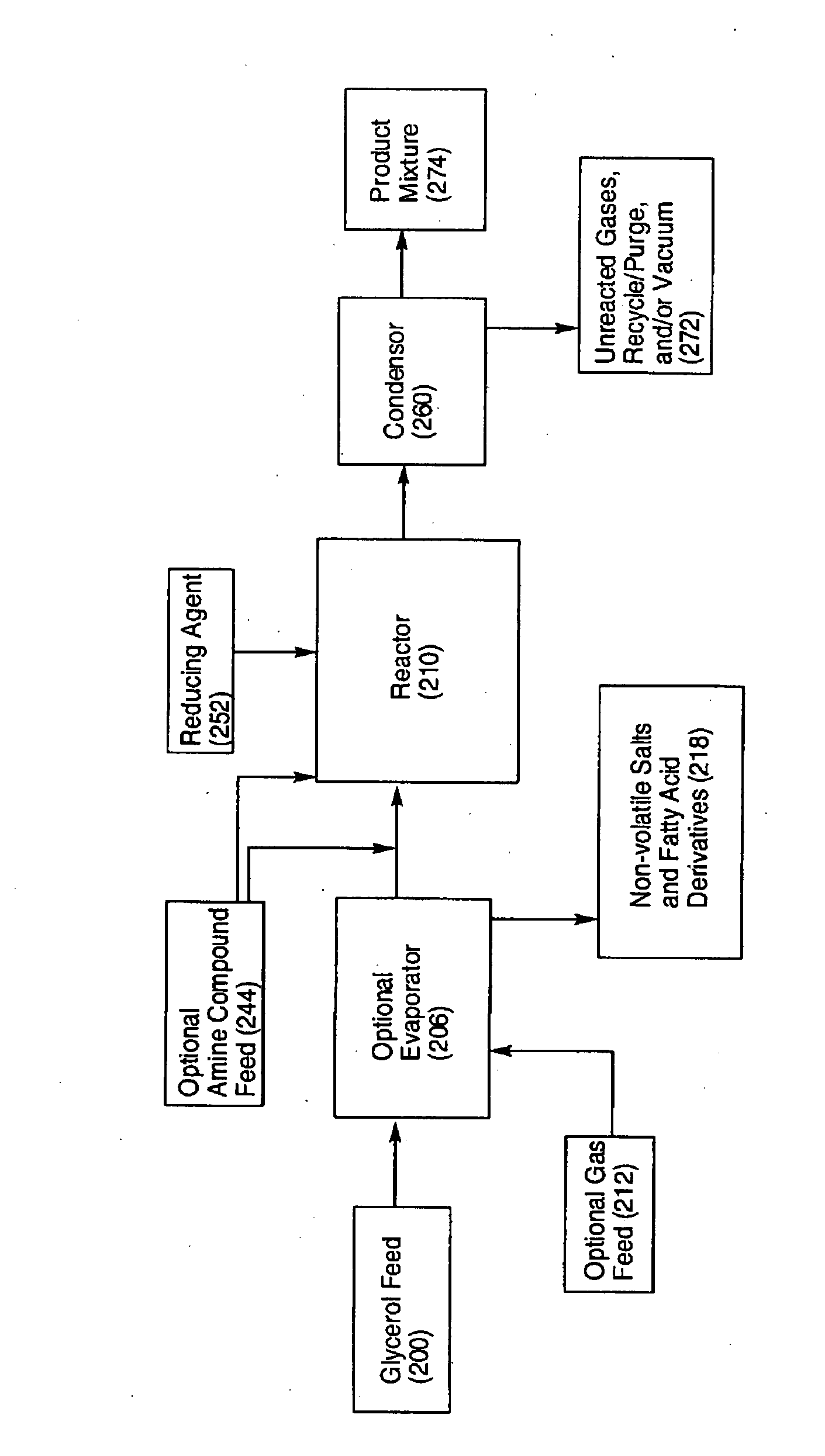

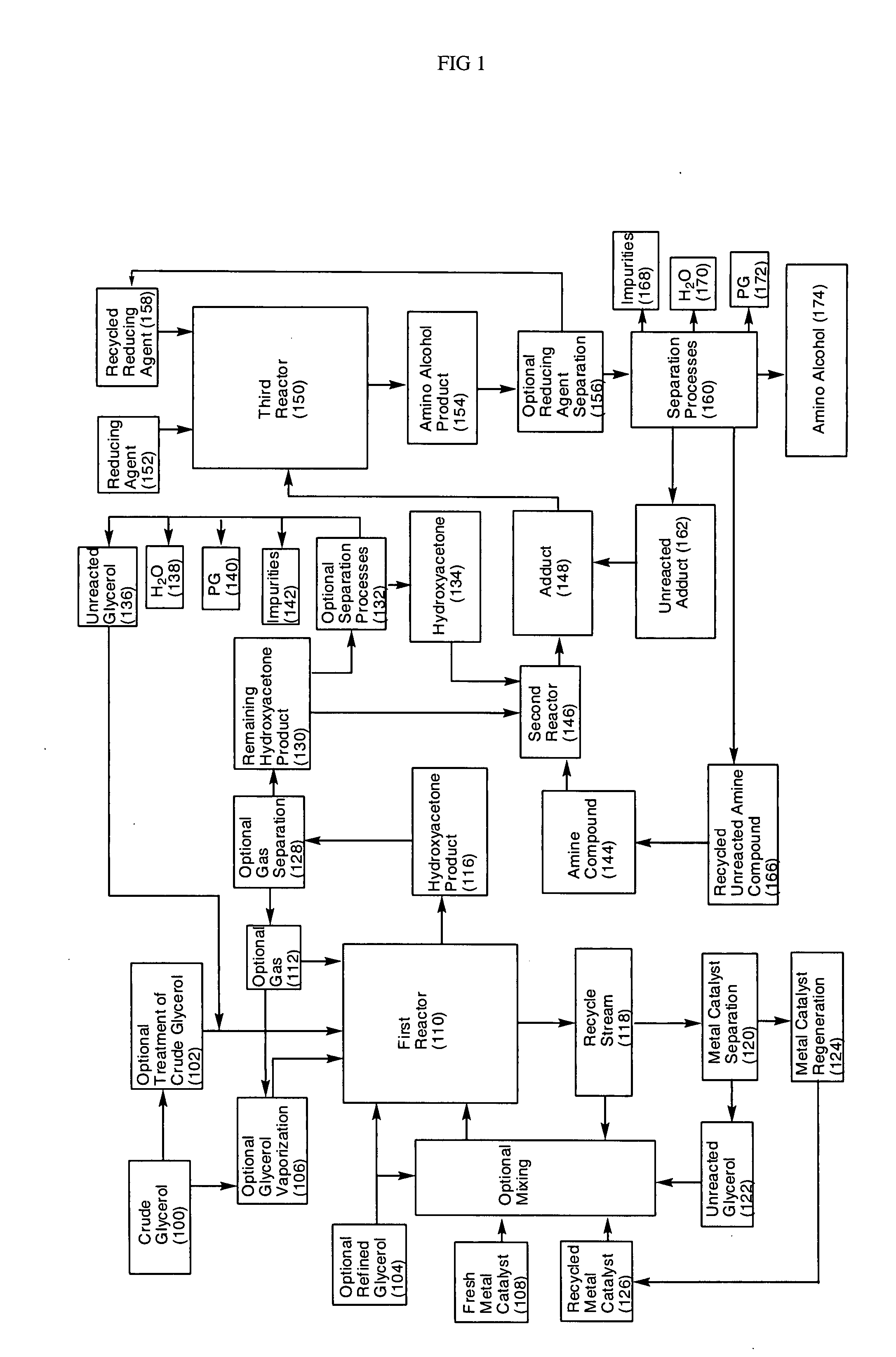

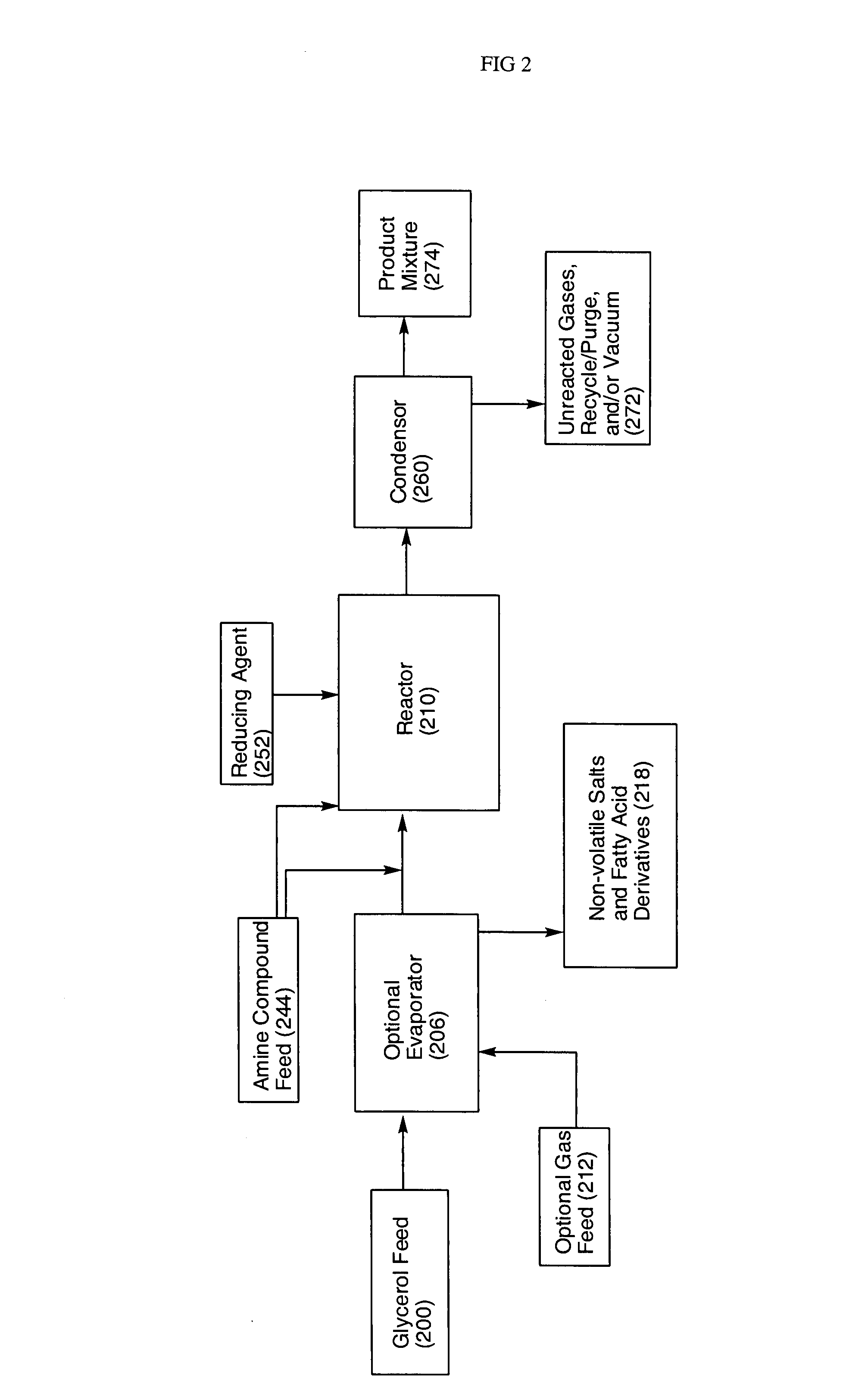

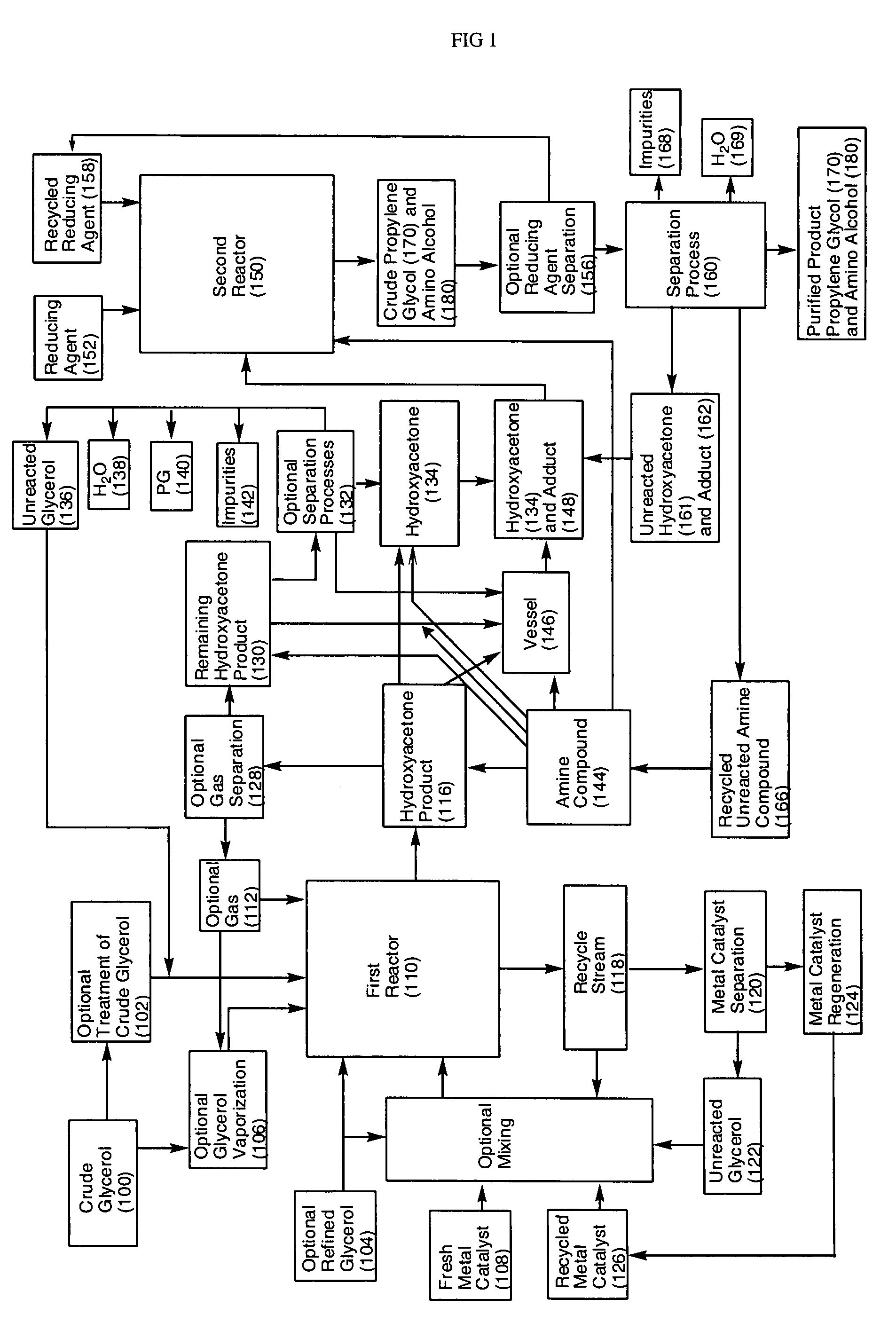

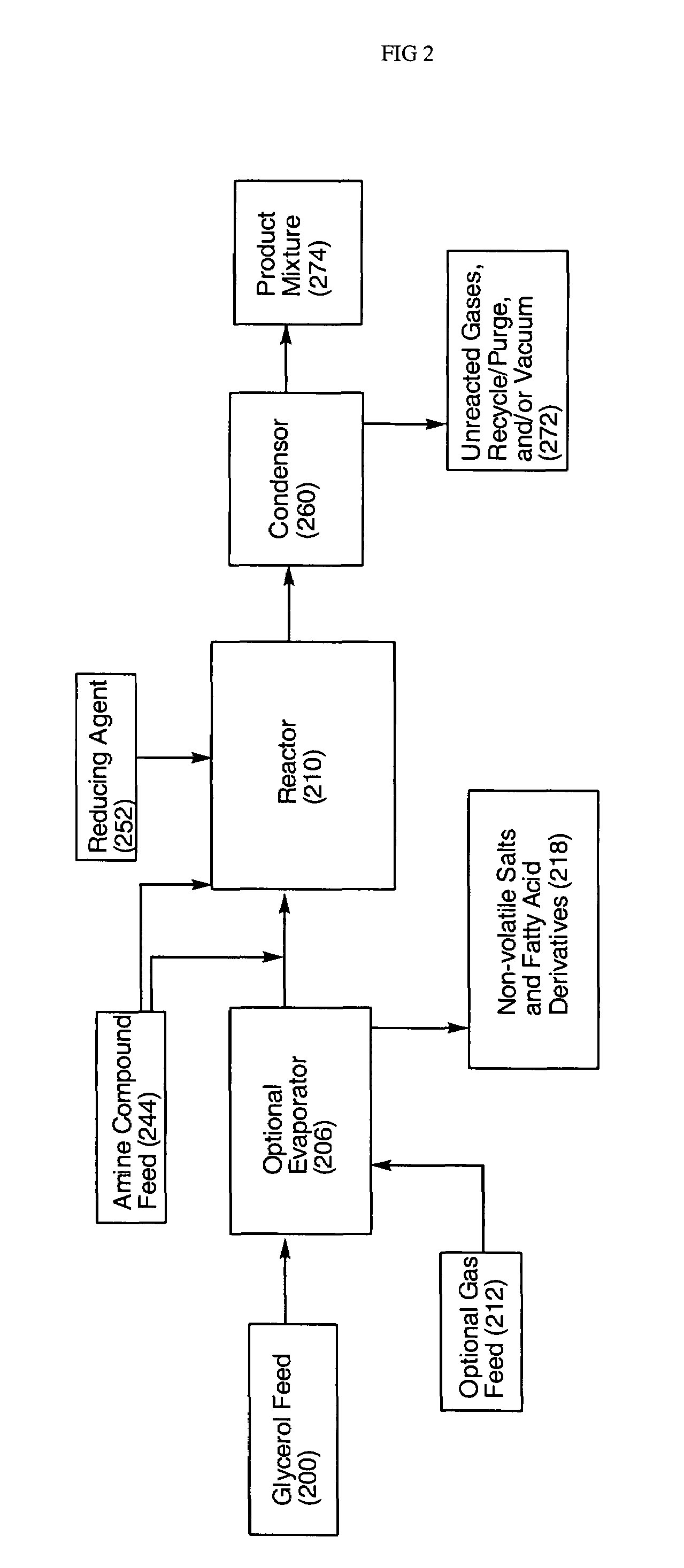

Process for the conversion of glycerol to propylene glycol and amino alcohols

ActiveUS20070287865A1Oxygen-containing compound preparationOrganic compound preparationGlycerolAlcohol products

Processes for the conversion of glycerol to a product mixture of an amino alcohol product and propylene glycol are disclosed. Glycerol is converted to hydroxyacetone and the hydroxyacetone is reduced with a reducing agent or reacted with an amine compound to give an adduct which is reduced using the reducing agent to obtain a product mixture of propylene glycol and an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

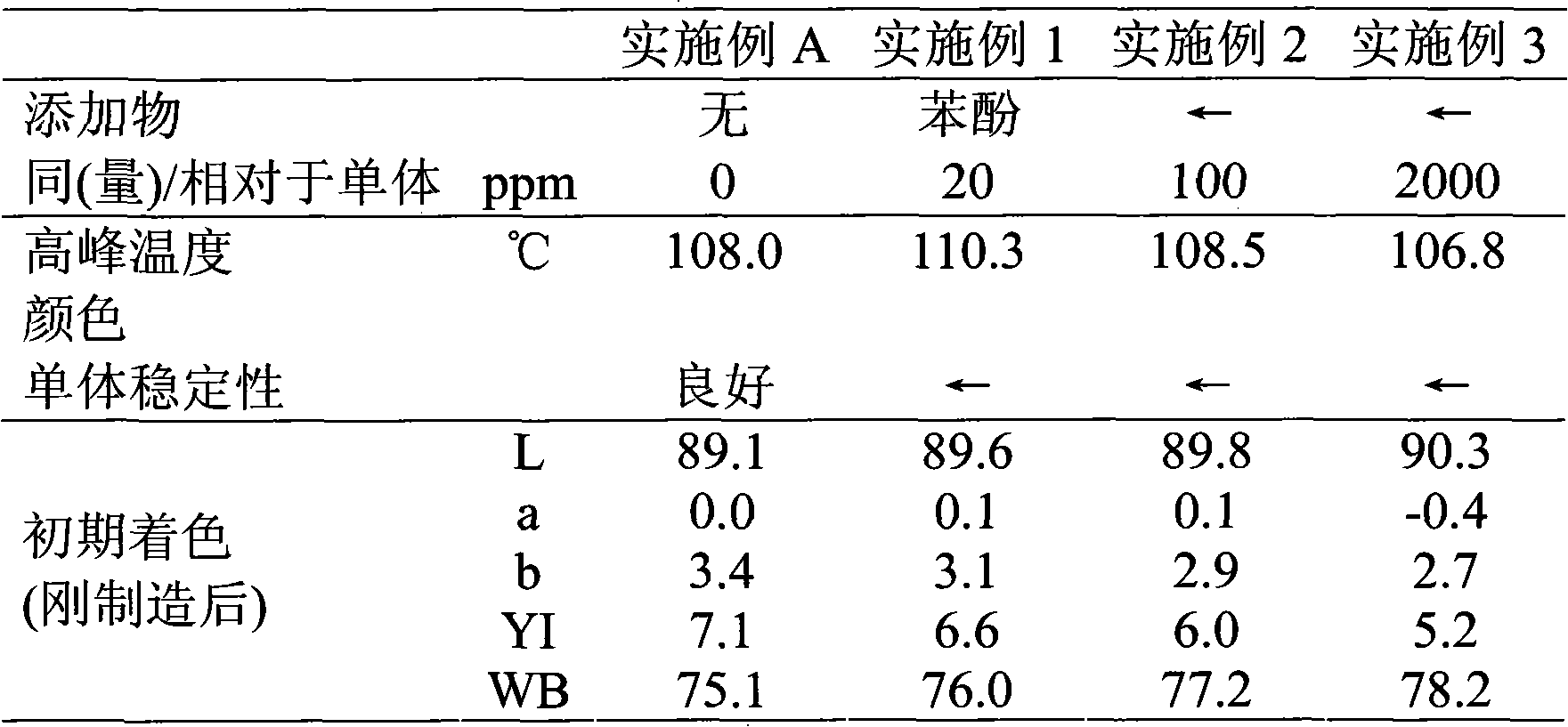

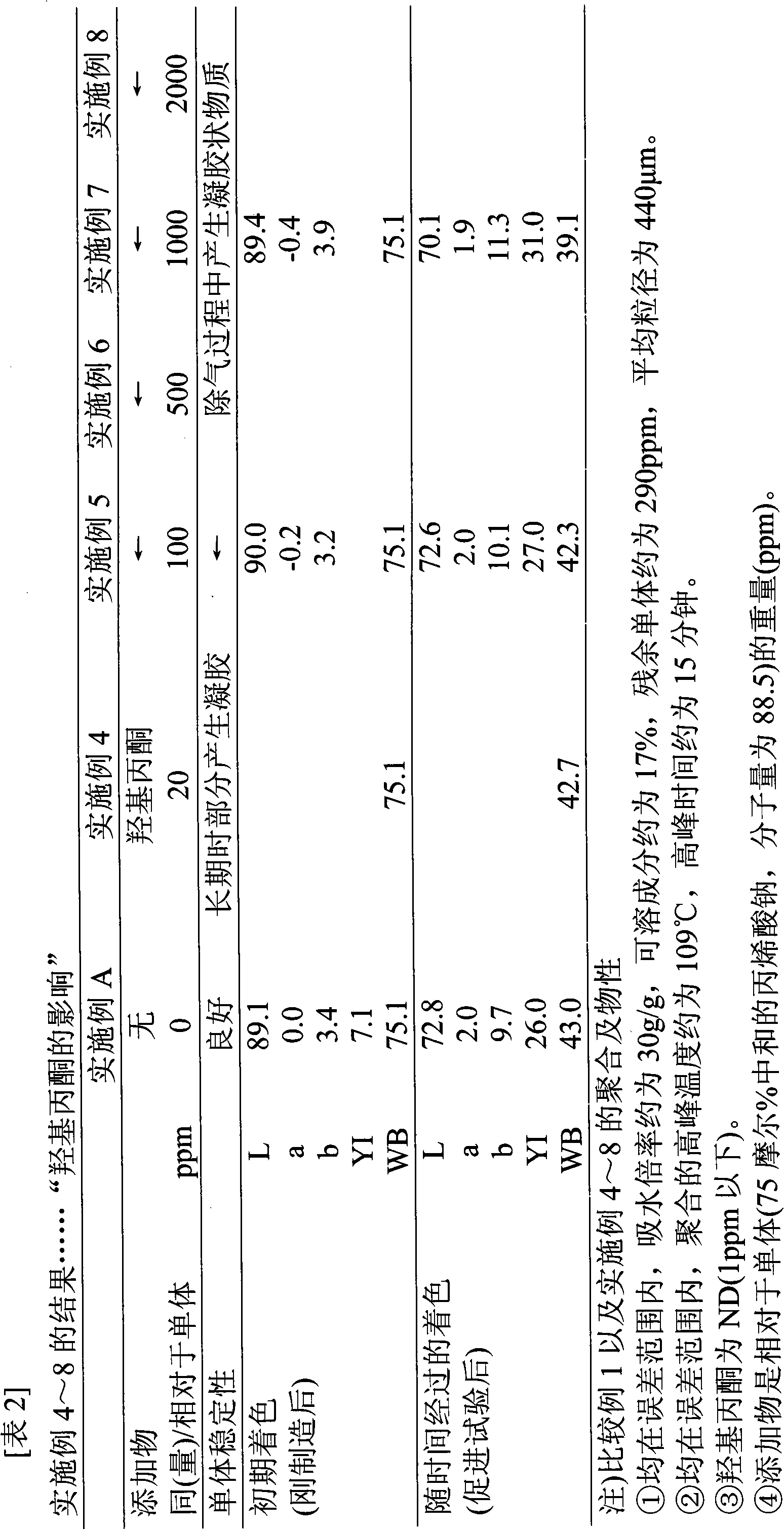

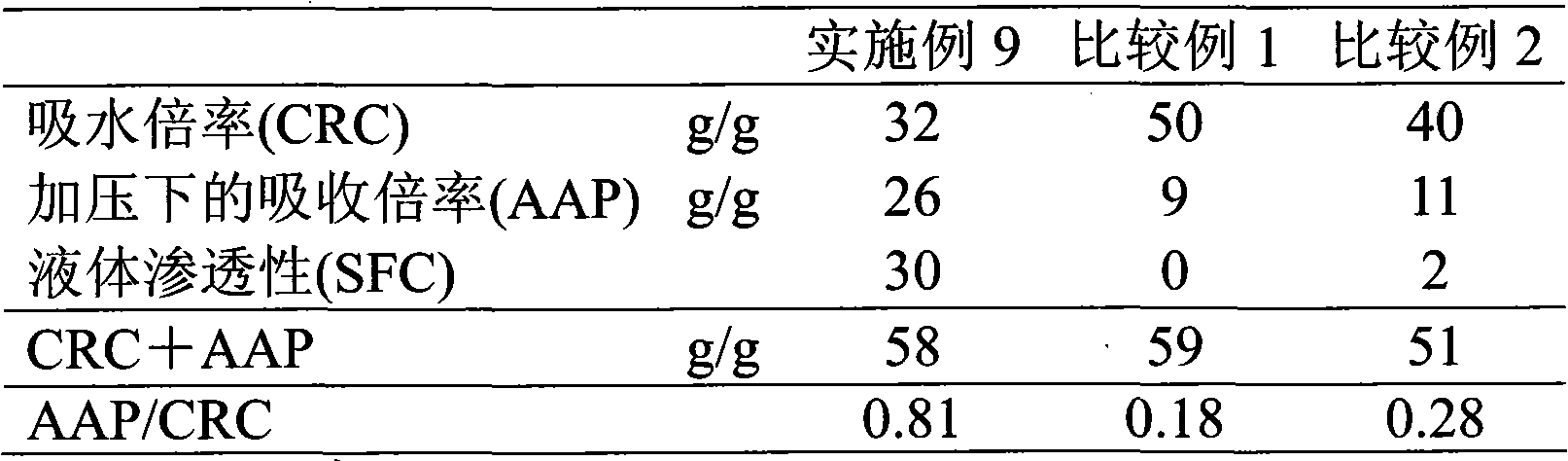

Polyacrylic acid (salt)-based water-absorbent resin and method for producing same

InactiveUS20110034603A1Color stableHigh whitenessAbsorbent padsEmulsion paintsPolymer scienceALLYL SUCROSE

In order to realize, while preventing gelatification of a monomer not yet to be polymerized, a water-absorbent resin which is more stable in color over time and has a significant enhancement in a problem concerning surface color and an excellent absorption property, a method for producing a polyacrylic acid-based water-absorbent resin includes: a preparation step in which a monomer is prepared from acrylic acid including hydroxyacetone in an amount not larger than 300 mass ppm; a polymerization step in which the monomer is polymerized so that a hydrogel is obtained; and a drying step in which the hydrogel is dried. Also, a method of the present invention for producing polyacrylic acid-based water-absorbent resin includes: a preparation step in which a monomer is prepared from acrylic acid; a polymerization step in which the monomer is polymerized in presence of phenol so that a hydrogel is obtained; and a drying step in which the hydrogel is dried.

Owner:NIPPON SHOKUBAI CO LTD

Production and purification of phenol: hydroxyacetone removal by hydrotalcite

InactiveUS6486365B1High mechanical strengthLose significant efficiencyOrganic compound preparationCatalystsDistillationBoiling point

A process for converting carbonyl-type impurities contained in a phenolic solvent to high-boiling derivatives is provided by contacting the phenolic solvent with a hydrotalcite-type material (HTM). The phenol can be separated from the high-boiling derivatives using conventional separation techniques, such as distillation, so the invention also provides a process for separating carbonyl-type impurities, such as hydroxyacetone (HA), from a phenolic solvent. The process can be applied in the conventional industrial process for converting cumene to phenol to remove carbonyl-type impurities from the phenol product. A process and a facility for producing purified phenol by converting cumene to phenol are provided. In the conversion of cumene to phenol, the phenol often contains carbonyl-type impurities. The phenol and carbonyl-type impurities are reacted in the presence of an HTM to produce phenol and high-boiling derivatives. The phenol may be further purified using conventional separation techniques, such as distillation, to remove the high-boiling derivatives.

Owner:SABIC GLOBAL TECH BV

Novel method for the conversion of cellulose and related carbohydrate materials to low-molecular-weight compounds

ActiveUS20110137085A1Eliminate needOrganic compound preparationPreparation by OH group eliminationCelluloseChemical compound

Methods of converting cellulose or related biorenewable carbohydrate materials into high-value chemical compounds. The methods provide a means of converting low-cost materials such as cellulose and biomass into high yields of compounds such as ethylene glycol, propylene glycol, glycerin, methanol, hydroxyacetone, glycolaldehyde and dihydroxyacetone.

Owner:IOWA STATE UNIV RES FOUND

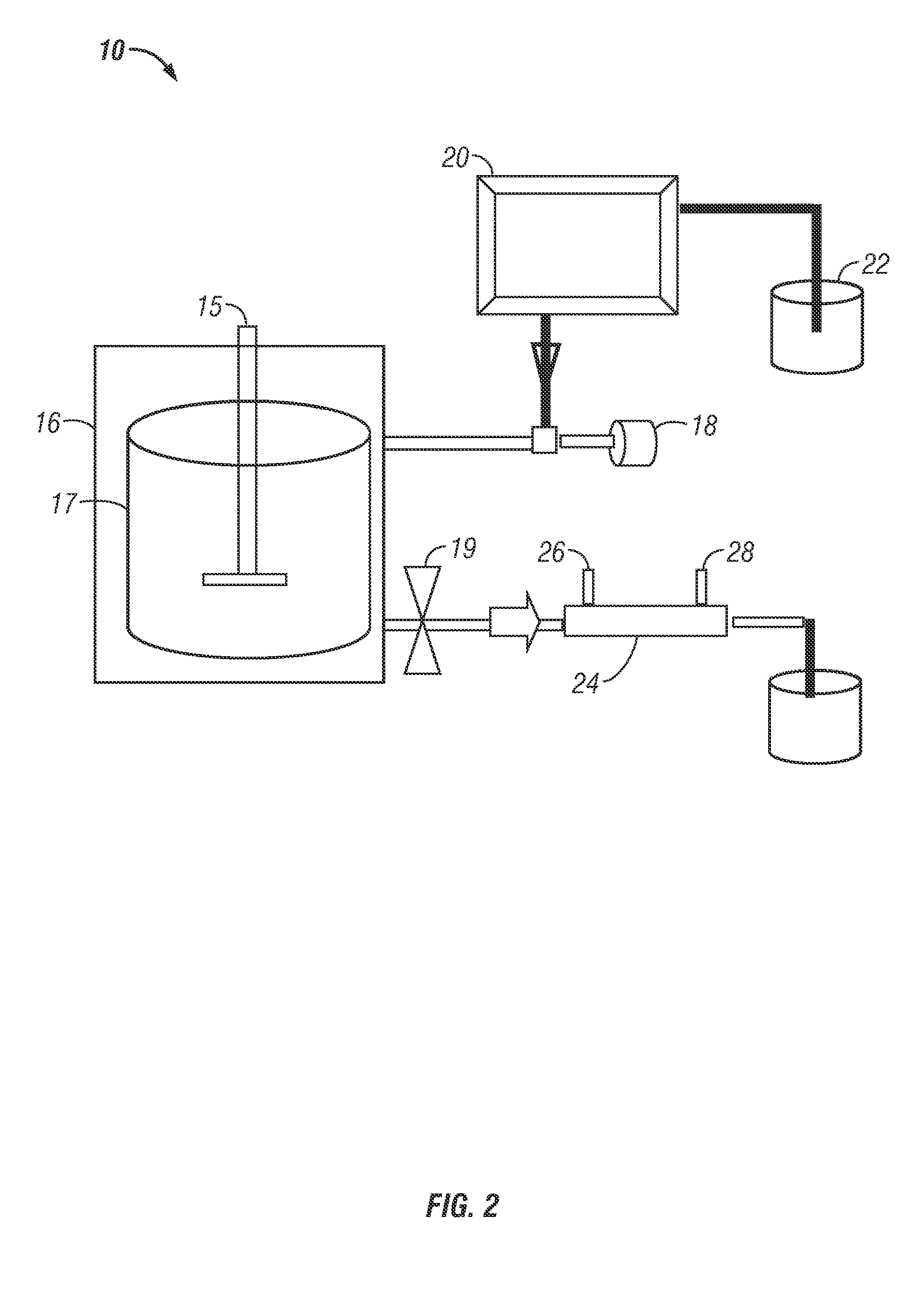

Process for the alternating conversion of glycerol to propylene glycol or amino alcohols

InactiveUS20080045749A1Reducing hydroxyacetoneOrganic compound preparationOxygen compounds preparation by reductionGlycerolAlcohol products

Industrial processes for the alternating conversion of glycerol to either an amino alcohol product or propylene glycol are disclosed. Glycerol is converted to hydroxyacetone which may then be directly reduced to obtain propylene glycol or optionally reacted with an amine compound to produce an adduct that may be reduced to obtain an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

Method for the production of phenol and acetone

ActiveUS7482493B2Organic compound preparationCarbonyl compound preparationPhenolCumene hydroperoxide

A method for the production of phenol and acetone from a cumene hydroperoxide mixture comprises: decomposing the cumene hydroperoxide mixture in the presence of a catalyst mixture to form a mixture comprising phenol and acetone, wherein the method further comprises: a) forming the catalyst mixture in a catalyst formation reactor by combining sulfuric acid and phenol in a weight ratio of from 2:1 to 1:1000; b) holding the catalyst mixture in the catalyst formation reactor at a temperature of about 20 to 80° C. for about 1 to 600 minutes; and c) adding the catalyst mixture to the cumene hydroperoxide mixture to form the phenol and acetone mixture. Running the process in this manner reduces the yield of hydroxyacetone and, consequently, improves the quality of the commercial phenol. Moreover, this method reduces consumption of sulfuric acid in comparison with the process in which sulfuric acid is used as catalyst.

Owner:SABIC GLOBAL TECH BV

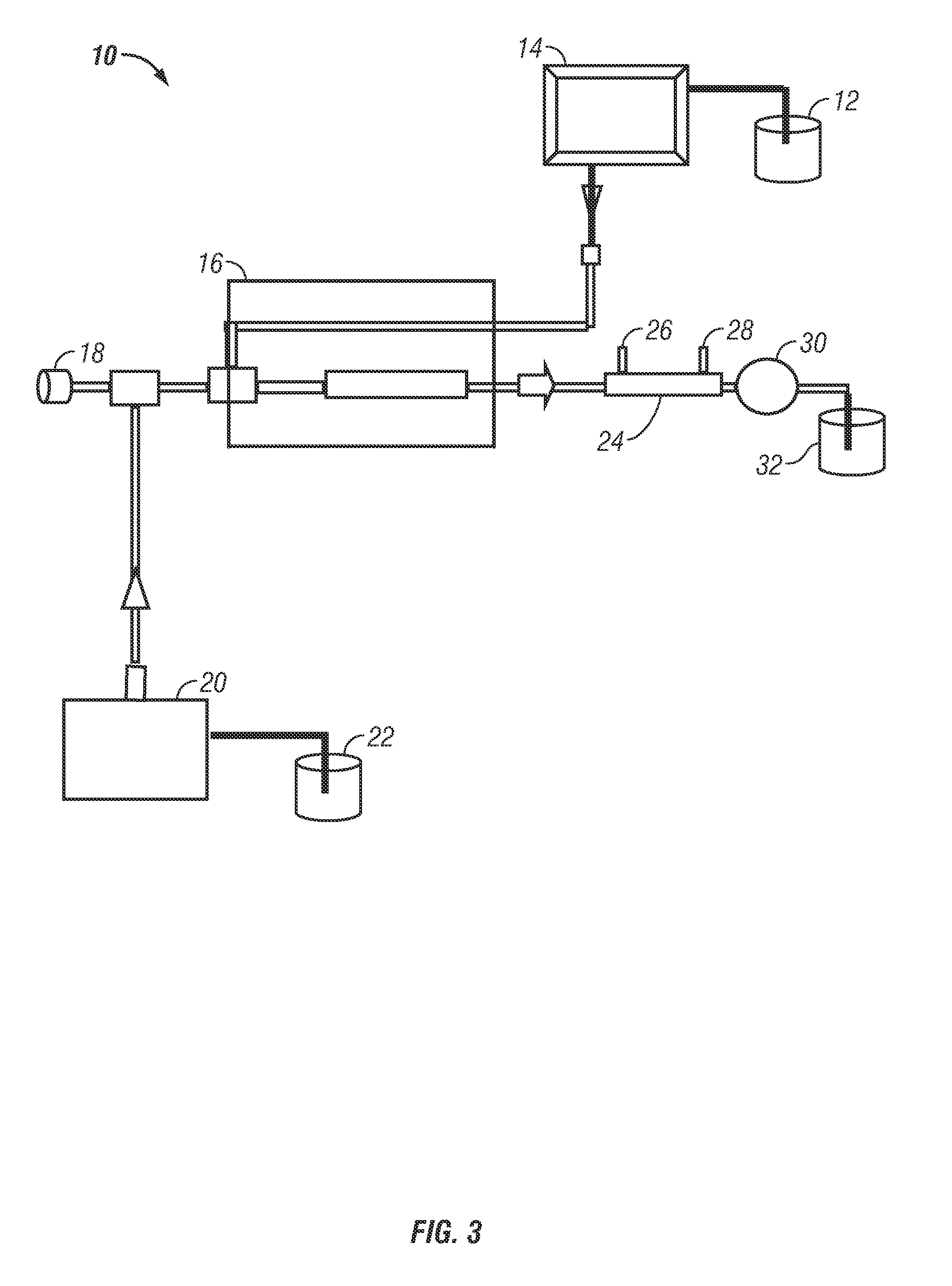

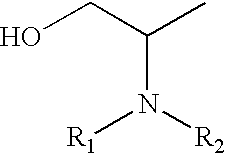

Processes for converting glycerol to amino alcohols

ActiveUS20070287868A1Reducing adductOrganic compound preparationAmino compound preparationMetal catalystGlycerol

Processes for converting glycerol to an amino alcohol product involving reacting glycerol with a metal catalyst to obtain hydroxyacetone, and reacting the hydroxyacetone with an amine compound to obtain an adduct that is then reduced using a reducing agent to obtain an amino alcohol product are described.

Owner:THE PROCTER & GAMBLE COMPANY

One-pot or one-step method for preparing diesel oil or aviation kerosene

ActiveCN108130112AImprove efficiencyEnhanced inhibitory effectLiquid hydrocarbon mixture productionBio-feedstockKeroseneHigh energy

The invention relates to a novel synthesis route of liquid chain hydrocarbon fuel from platform compounds obtained on the basis of lignocellulose as a raw material completely independent of fossil energy. A reported method comprises two-step reactions as follows: 1) lignocellulose-based carbonyl-containing platform compounds (such as levulinic acid, levulinate, acetone, hydroxyacetone, furfural and the like) and furan platform compounds (such as furan, methylfuran, hydroxymethyl furfuran and the like) are taken as raw materials on a solid acid catalyst and subjected to an acid catalysis alkylation reaction, and oxygen-containing organic compounds with the carbon chain length ranging from 8 to 16 are prepared; 2) hydrogenation and hydrodeoxygenation are performed on an alkylation product byuse of a metal-solid acid dual-function catalyst, so that biomass aviation kerosene or high-grade diesel which has the carbon chain length ranging from 8 to 16 and has higher energy density and stability is obtained. The two steps are integrated into one step innovatively in the invention, the reaction course is shortened, and the production efficiency is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

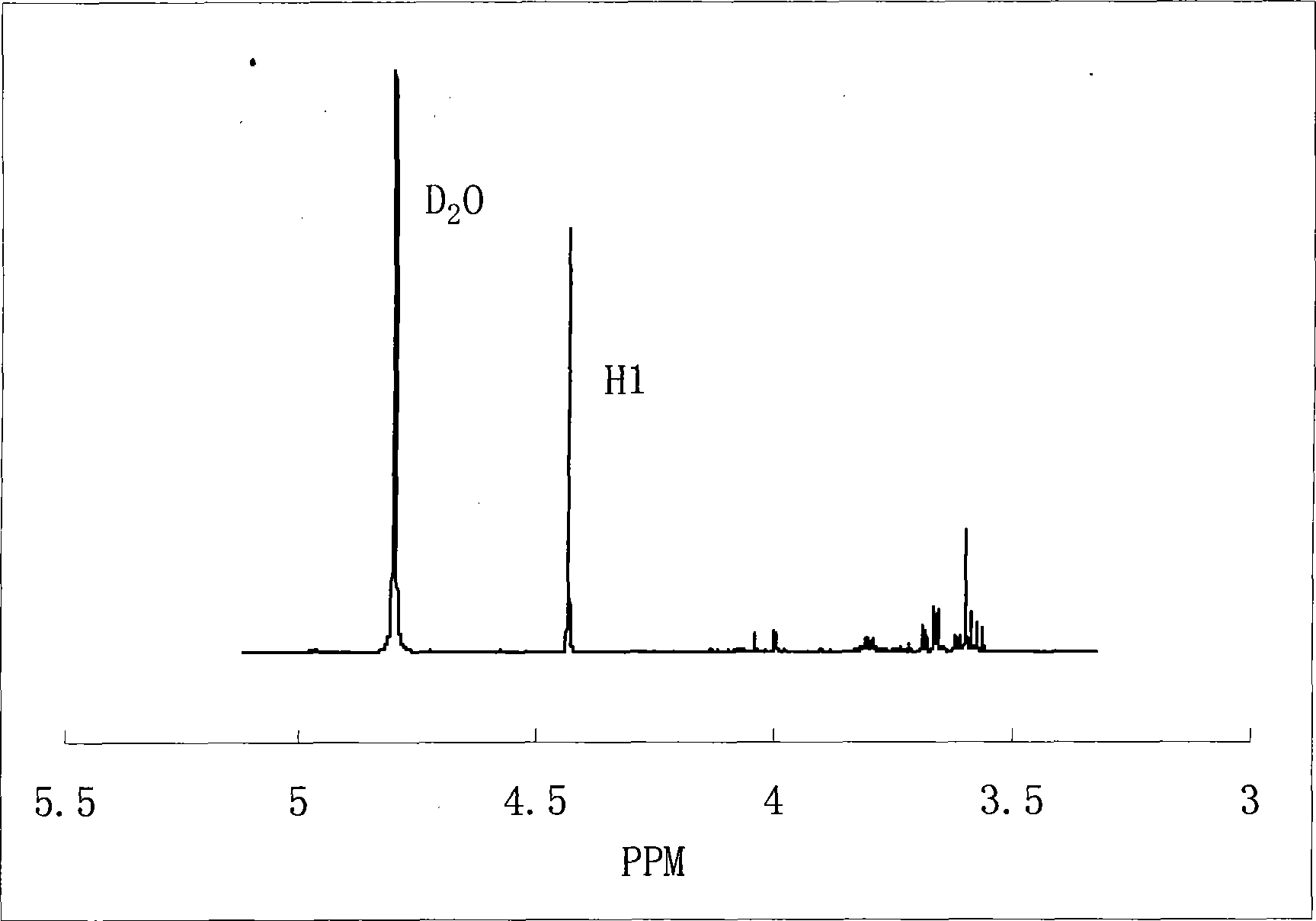

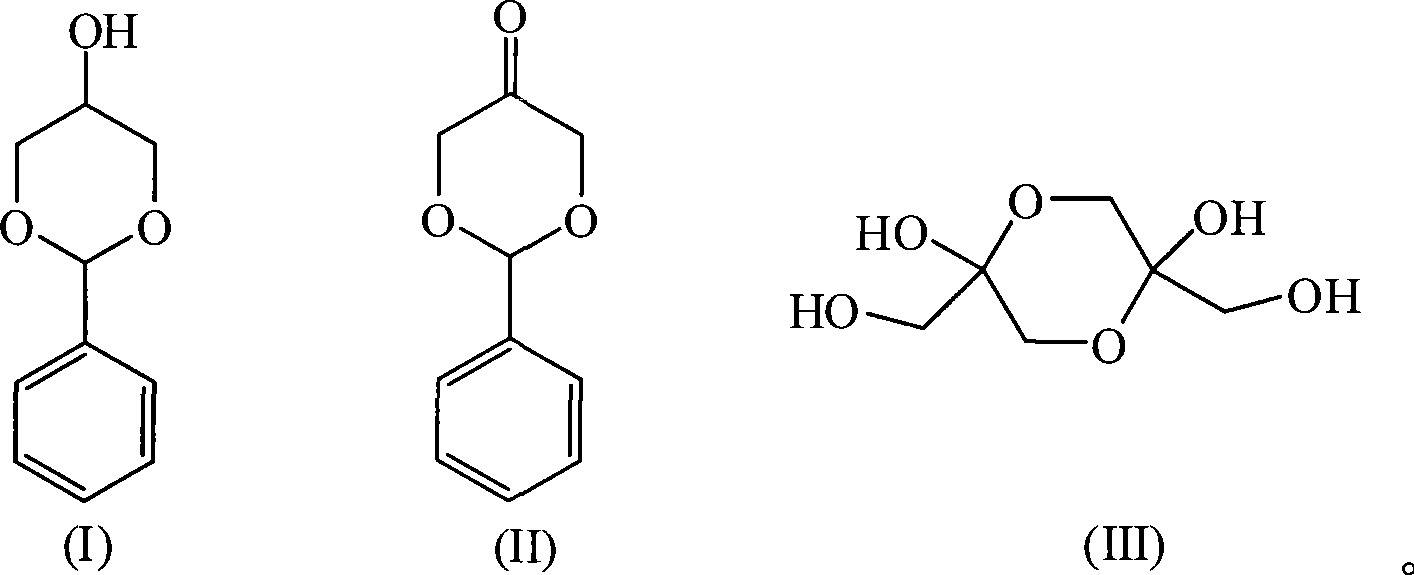

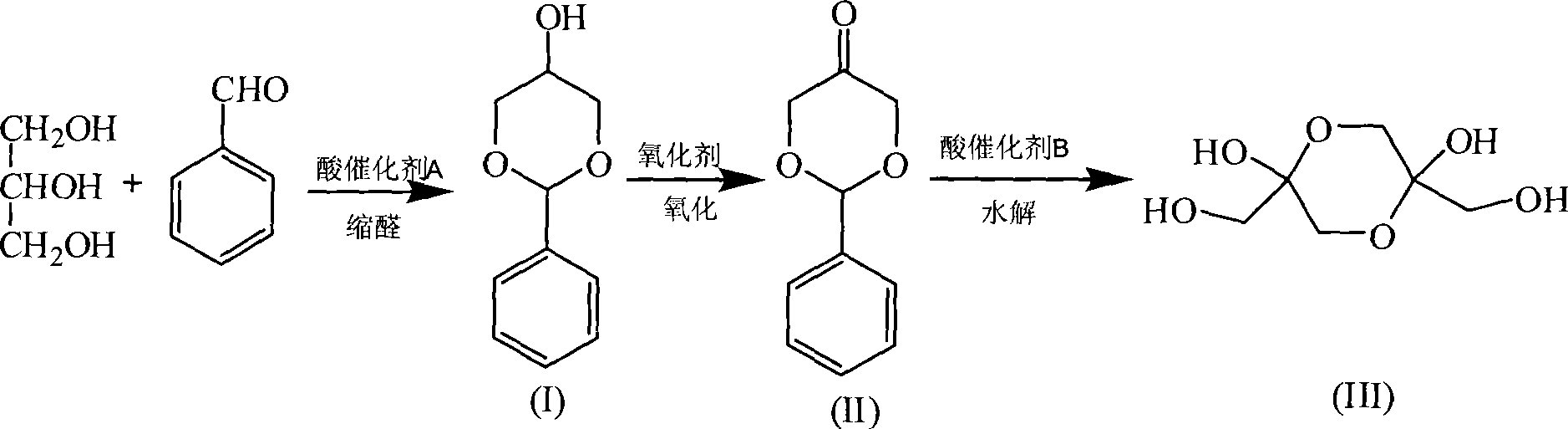

Novel method for preparing 1,3-dihydroxy acetone from glycerol

ActiveCN101412706AEasy to separateHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventBenzaldehyde

The invention discloses a new method for preparing 1, 3-dihydroxyacetone from glycerol, which comprises the following steps: (1) acetalation reaction, which is to perform acetalation reaction of the glycerol and benzaldehyde in the presence of a water-carrying agent and under the action of an acid catalyst A so as to obtain glycerol benzaldehyde acetal ester having a structure as shown in the formula (I); (2) oxidation reaction, which is to oxidize the glycerol benzaldehyde acetal ester in an organic solvent and under the action of an oxidizer so as to obtain 5-carbonyl-2-phenyl -1, 3-dioxane having a structure as shown in the formula (II); and (3) hydrolysis reaction, which is to hydrolyze the obtained 5-carbonyl-2-phenyl -1, 3-dioxane in the presence of an acid catalyst B so as to prepare a 1, 3-dihydroxyacetone dimer having a structure as shown in the formula (III). The synthetic route of the method uses the glycerin as a raw material, thus both the selectivity and the yield are higher than that by a method of direct oxidation, the target product is simple and convenient to separate, and the product purity can reach 99 percent; and compared with the prior art, the synthetic route of the method has stronger market competitiveness.

Owner:ZHEJIANG UNIV OF TECH

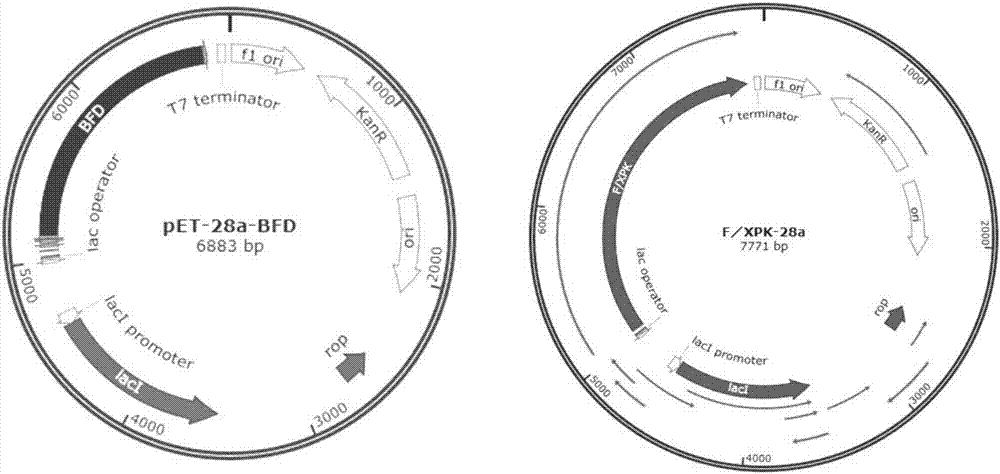

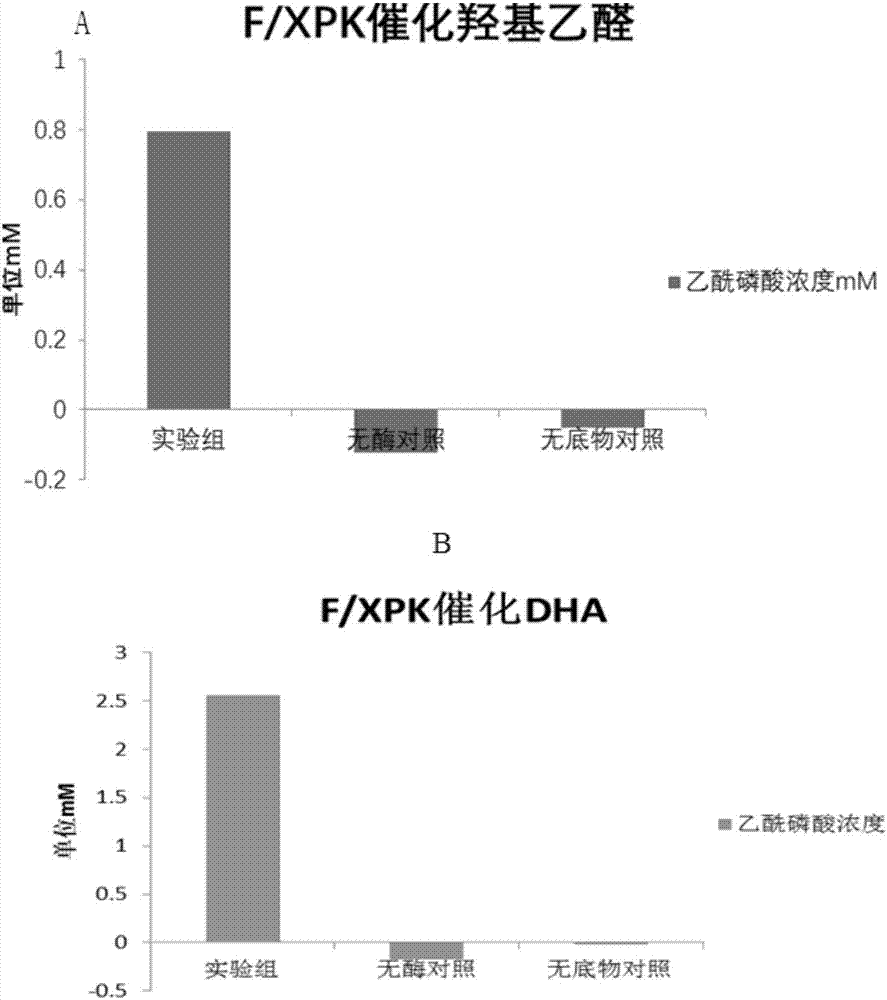

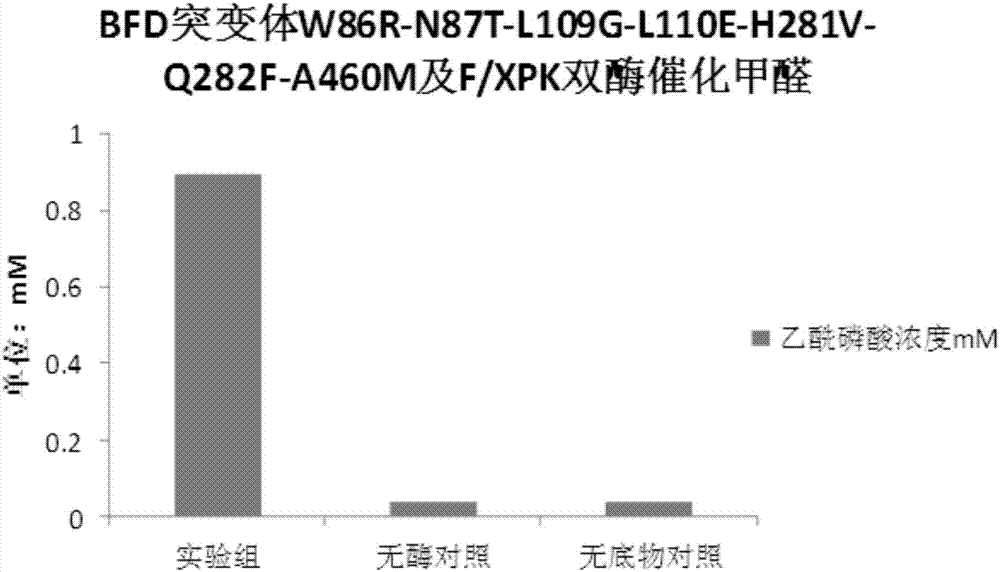

Enzyme for catalyzing formaldehyde to synthesize hydroxyl acetaldehyde and application thereof

ActiveCN106916794AEfficient aggregationNo inputFermentationCarbon-carbon lyasesPhosphate acetyltransferasePhosphoric acid

The invention discloses an enzyme for catalyzing formaldehyde to synthesize hydroxyl acetaldehyde and an application thereof. In the invention, through site-directed mutation of BFD, a mutant of the enzyme is found; and by means of the mutant of the enzyme, high-effect polymerization of the formaldehyde is achieved; meanwhile, through F / XPK, generation of acetyl phosphoric acid from the hydroxyl acetaldehyde or 1,3-dihydroxyacetone is achieved; with combination of phosphotransacetylase (Pta), a route from the formaldehyde to acetyl coenzyme A is achieved in three steps with the enzyme, thereby creating a new formaldehyde assimilation route, namely, synthesizing the acetyl coenzyme A from the formaldehyde in three steps. The route is short and is free of carbon loss and ATP input.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

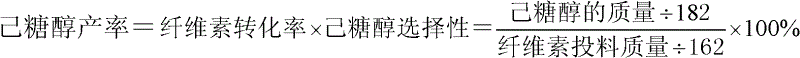

Method for preparing hexitol or hydroxy-acetone

ActiveCN102617287AHigh selectivityLower requirementOrganic compound preparationHydroxy compound preparationCelluloseActivated carbon

The invention discloses a method for preparing hexitol or hydroxy-acetone, which comprises the steps as follows: cellulose reacts with glucose or fructose in water under the action of hydrogen atmosphere and catalytic agents, so as to obtain hexitol or hydroxy-acetone; the catalytic agents are supported metal catalysts; active constituents of the supported metal catalysts are metal modified by modifiers; the metal is any one of Pt, Ru, Ni and Cu; and a carrier of the supported metal catalysts is any one of Al2O3, TiO2, ZrO2, SiO2 and activated charcoal. The provided method selectively obtains hexitol or hydroxy-acetone through a one-pot reaction based on cellulose and glucose or fructose, achieves simple process, rapid reaction, high efficiency and energy conservation, and is easy to industrialize; the catalytic agents can be recovered and recycled, so that the cost is saved, and environmental protection can be achieved; in addition, the method has low requirements on equipment, cannot corrode equipment, and achieves low investment.

Owner:PEKING UNIV

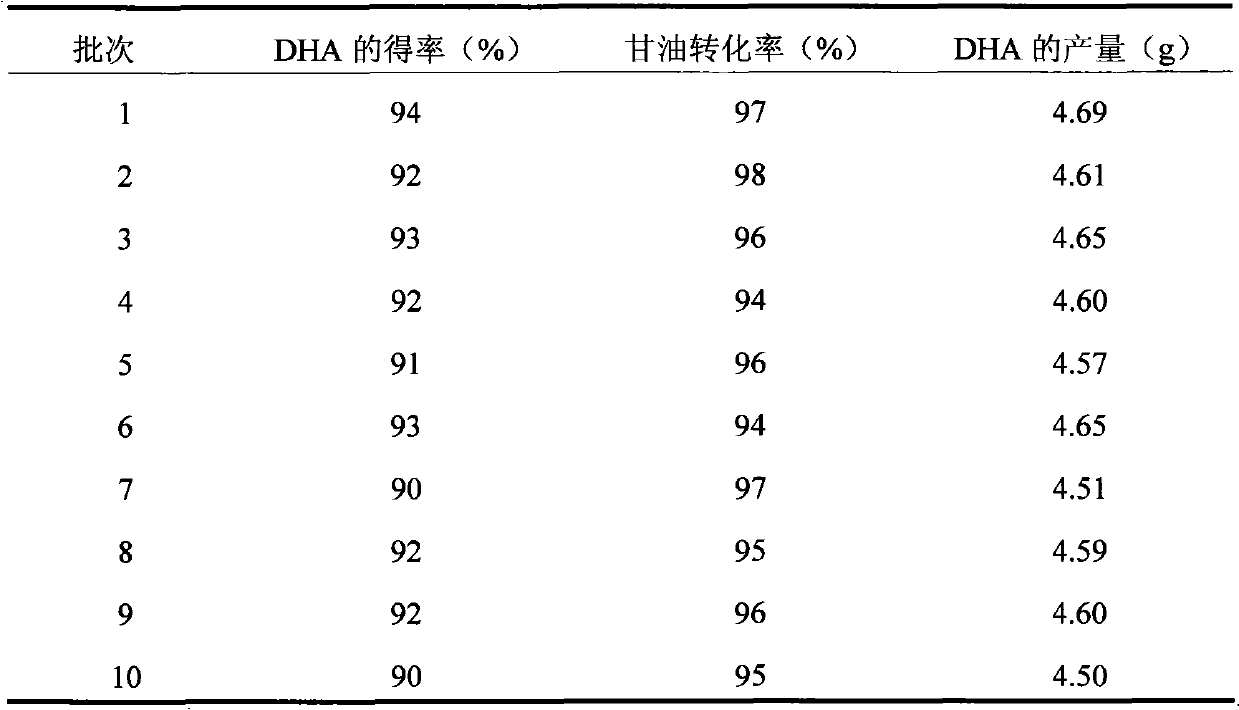

Application of gluconobacter oxydans in preparing 1,3-dioxyacetone

InactiveCN101948878AStrong dehydrogenation reaction abilityEasy to separate and purifyBacteriaMicroorganism based processesHigh concentrationMicroorganism

The invention discloses application of gluconobacter oxydans in preparing 1,3-dioxyacetone. The gluconobacter oxydans is named gluconobacter oxydans NH-10, and preserved in the China General Microbiological Culture Collection Center with the number of CGMCC No.2709 and the preservation data of October 14, 2008. The gluconobacter oxydans NH-10 can convert glycerol in high efficiency under a condition of high concentration glycerol to produce the 1,3-dioxyacetone. Under the technical condition of the application, the conversion rate of the glycerol can reach 99.7 percent (w / w), and the yield of the 1,3-dioxyacetone can reach 97 percent, the concentration of the 1,3-dioxyacetone in the conversion solution reaches 166.2g / L, and other components are scarcely contained in the conversion solution. The microorganism strain is applicable to industrial production of dioxyacetone.

Owner:NANJING UNIV OF TECH

Methods for purification of phenol

InactiveUS20050137429A1Reduce concentrationOrganic compound preparationHydroxy compound separation/purificationPHENOL LIQUIDIon-exchange resin

A process for producing a purified phenol stream generally includes contacting a phenol stream containing an initial concentration of hydroxyacetone and methylbenzofuran with an acidic ion exchange resin at a temperature of 50° C. to 100° C. to concurrently reduce the initial concentration of the hydroxyacetone and the methylbenzofuran in the phenol stream to produce the purified phenol stream.

Owner:SABIC INNOVATIVE PLASTICS IP BV

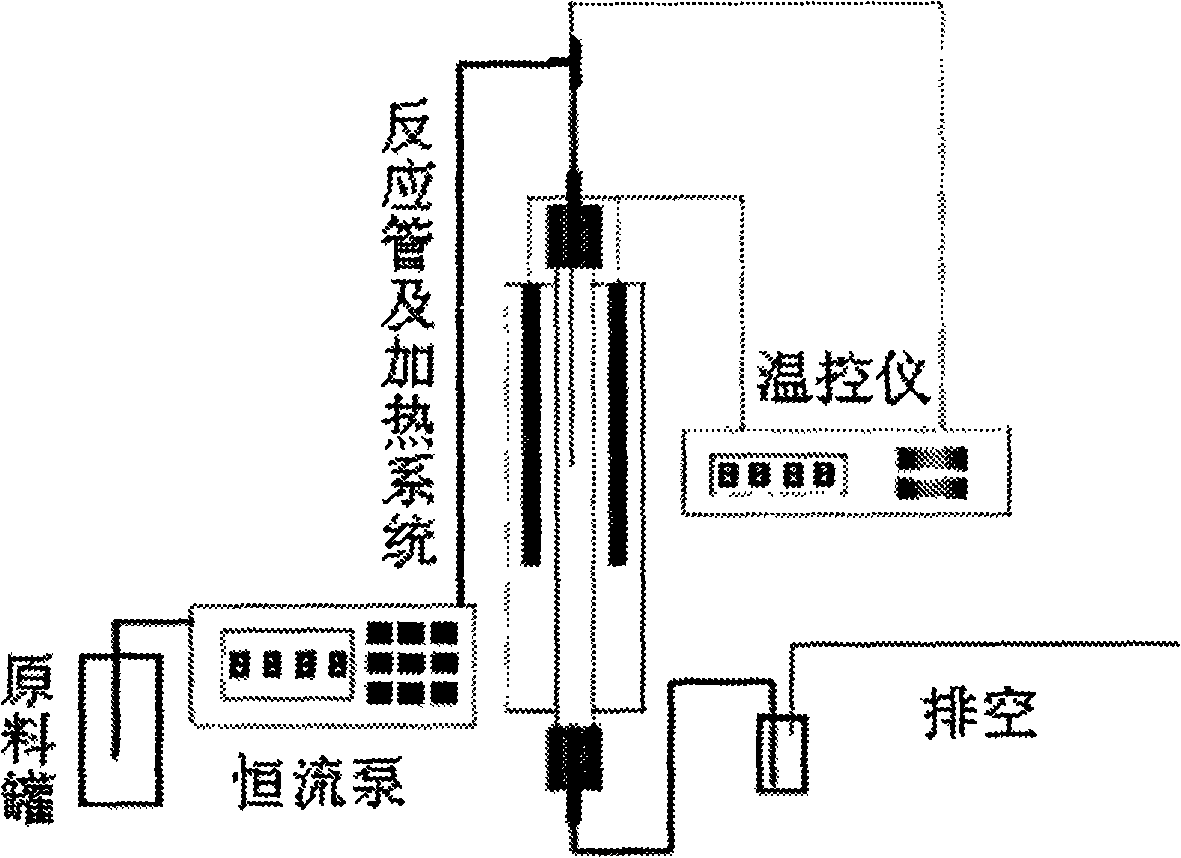

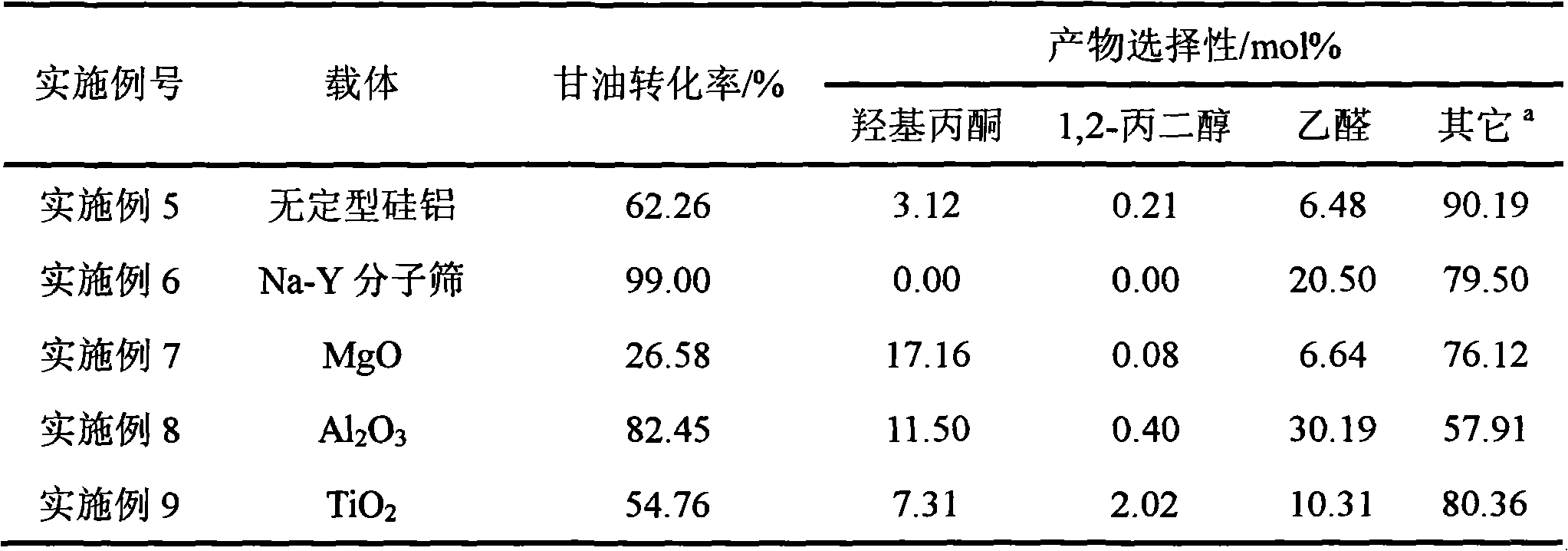

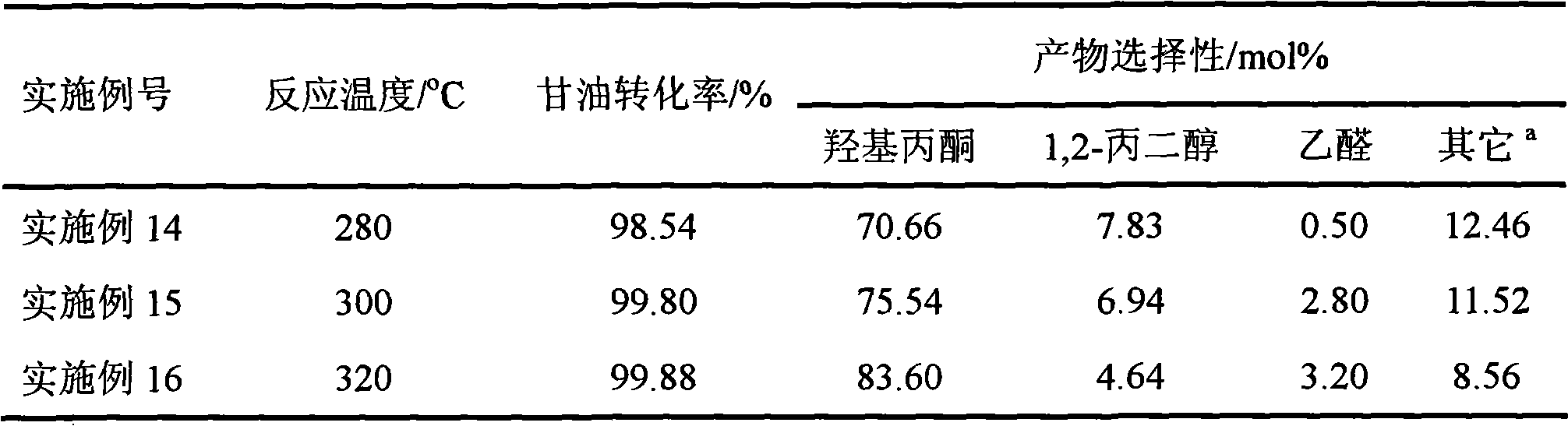

Reaction for preparing hydroxyacetone by selectively dewatering natural glycerol and catalyst

InactiveCN101284234AHigh selectivityEasy to makeOrganic compound preparationCarbonyl compound preparationRare-earth elementFixed bed

The invention relates to a reaction technology for manufacturing hydroxyacetone through selective dehydration of natural glycerin, and a corresponding catalyst. The catalyst is composed of low-activity carriers such as SiO2, etc. and active metal components of 20 to 90wt percent, and is prepared by adopting an insuccation loading method. The active metal components which are used are IB group elements, or the combination of IB and VIB group elements, or the combination of IB, VIB and light rare earth elements. The reaction for manufacturing the hydroxyacetone through selective dehydration of the natural glycerin is performed in a fixed bed flowing-type reactor; the glycerin conversion rate can reach up to 99.89 percent, and the molar selectivity of the hydroxyacetone can reach up to 89.74 percent under the conditions that the material concentration can reach 10 to 100 percent, the normal atmosphere is provided, the temperature ranges from 200 to 400 DEG C, and the liquid hourly space velocity (LHSV) satisfies 0.01 to 0.60h<-1>. The catalyst has simple preparation technology and low price, and the concentration of the reaction material that is glycerin water solution and the liquid hourly space velocity has wide range.

Owner:HUNAN UNIV

Catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and application thereof

InactiveCN101698151AHigh activityHigh yieldCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsCopper chromiteGlycerol

The invention relates to a catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and an application thereof. The main component of the catalyst is copper chromite. A metal auxiliary agent is respectively one of the components of zinc, aluminum, magnesium, zirconium, titanium and the like and is prepared by a dipping method. The auxiliary agent metal is in the catalyst in an oxide form of the auxiliary agent metal. The catalyst is suitable for preparing the hydroxy acetone by crude glycerine dewatering. The catalyst has simple preparation process, and the introduction of the metal auxiliary agent can enhance the activity of the catalyst, lower the reaction temperature obviously, enhance the yield of the hydroxy acetone and prolong the service life of the catalyst.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Water-absorbable polyacrylic acid (salt) resin and process for production thereof

ActiveCN102015777AHigh whitenessNo loss of productivityAbsorbent padsBandagesPolymer scienceALLYL SUCROSE

The object aims to provide a water-absorbable resin which is prevented from the occurrence of gelatinization of a monomer before polymerization, hardly causes discoloration over time, has a remarkably improved surface color, and also has excellent absorption properties. For achieving the object, provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid having a hydroxyacetone content of 300 ppm by mass or less; a polymerization step of polymerizing the monomer to produce a hydrogel; and a drying step of drying the hydrogel. Also provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid; a step of polymerizing the monomer in the presence of phenol to produce a hydrogel; and a drying step of drying the hydrogel.

Owner:NIPPON SHOKUBAI CO LTD

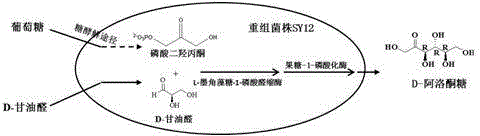

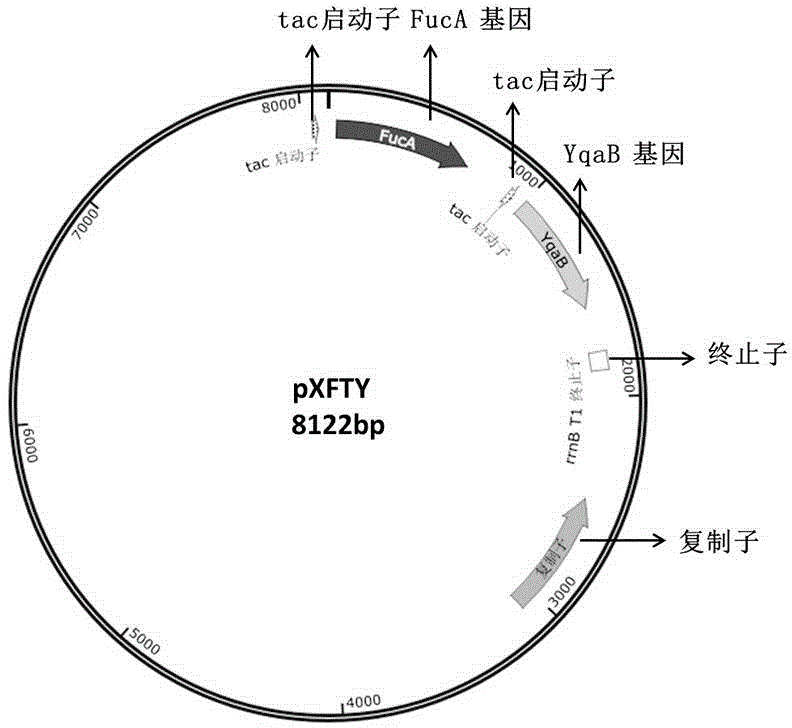

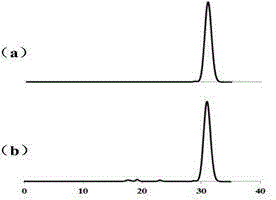

Method for synthesis of D-psicose by aldolase whole cell

The invention discloses a method for synthesis of D-psicose by microbiological fermentation, specifically a method for synthesis of D-psicose by aldolase whole cell. The method includes: firstly constructing recombinant corynebacterium glutamicum SY12 carrying L-fucose-1-phosphate aldolase gene and fructose-1-phosphorylase gene (i.e. with aldehyde condensation approach), then adding glucose and D-glyceraldehyde into a basic salt medium, synthesizing dihydroxyacetone phosphate from glucose by means of intracellular glycolysis, synthesizing a single product D-psicose from D-glyceraldehyde and dihydroxyacetone phosphate (DHAP) under the action of the L-fucose-1-phosphate aldolase and fructose-1-phosphorylase carried by the corynebacterium glutamicum recombinant strain SY12, with the conversion rate of D-glyceraldehyde being 53%. Therefore, compared with the existing method for in vitro synthesis of D-psicose by ketose3-epimerase, the biosynthesis method of D-psicose provided by the invention has the advantages of high conversion rate, single product, easy separation and the like, and lays certain foundation for mass production of D-psicose.

Owner:天津怡和生物科技有限责任公司

Method for selectively preparing acraldehyde and hydroxy-acetone

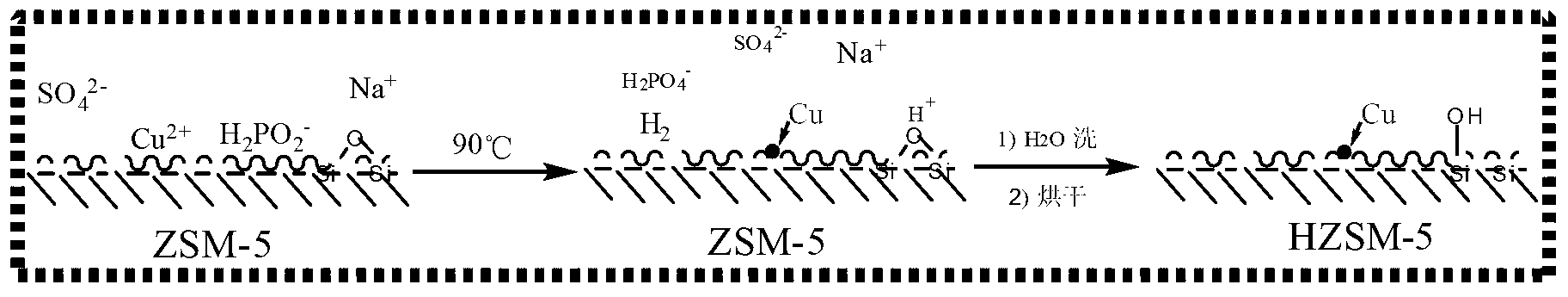

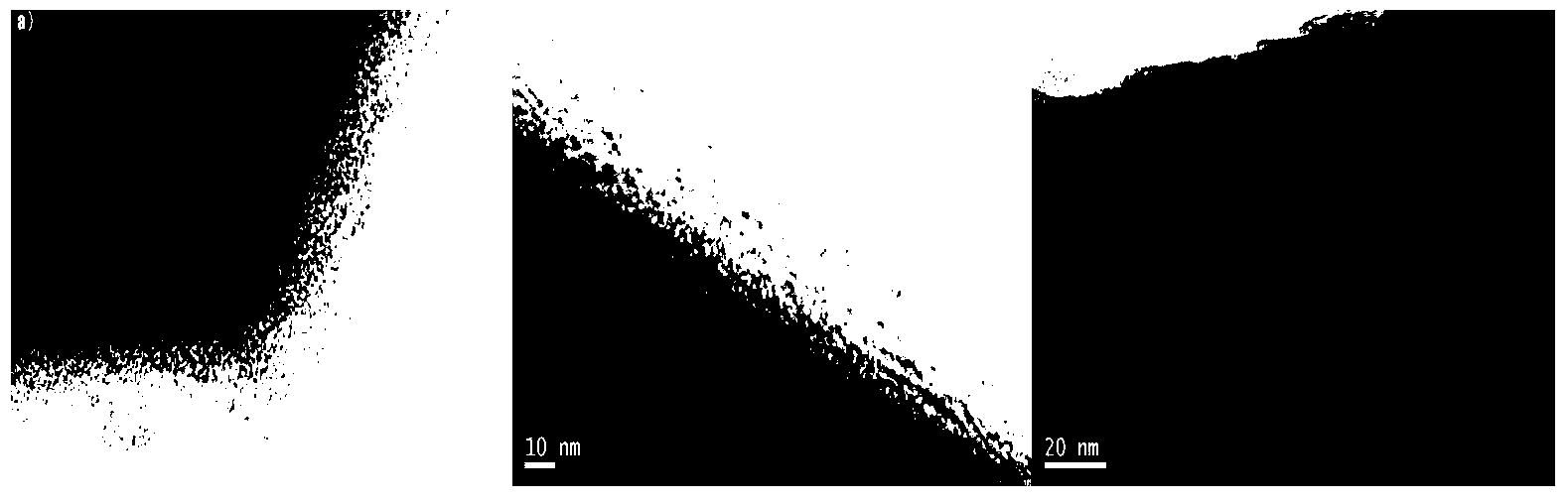

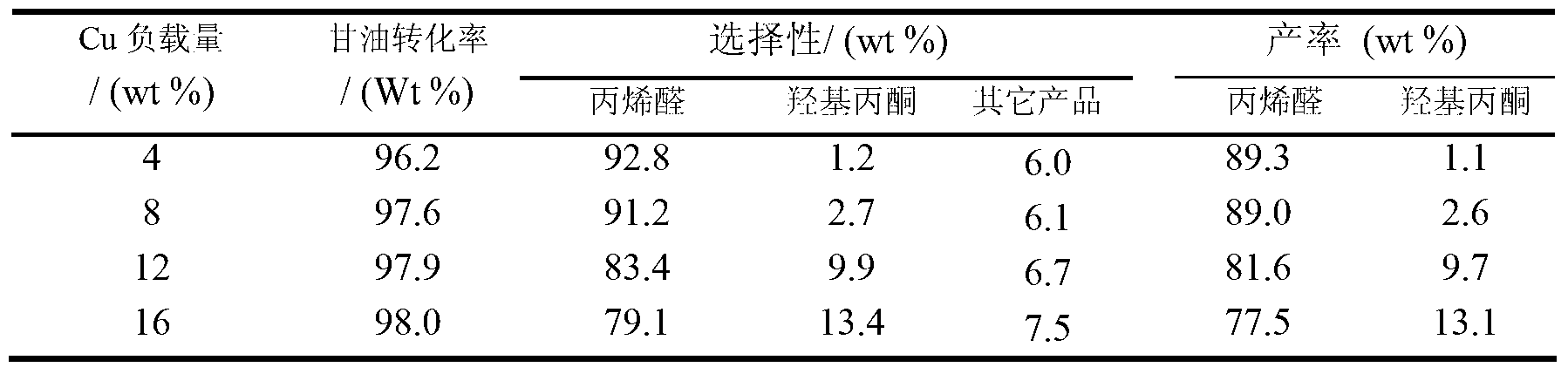

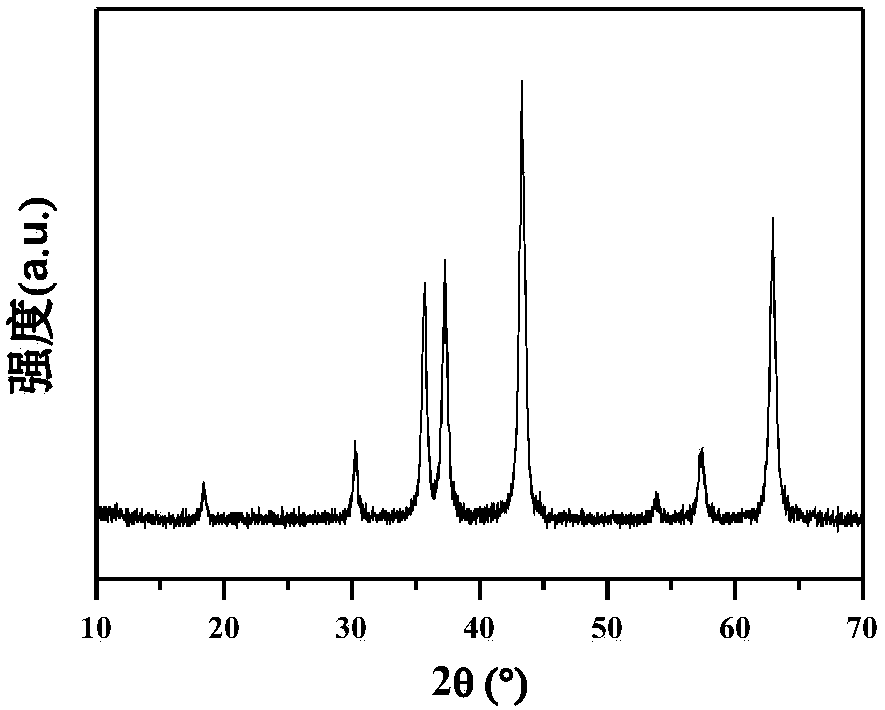

InactiveCN103242149ALow costEasy to makeOrganic compound preparationCatalyst activation/preparationGlycerolReactive distillation

The invention discloses a catalyst for selectively preparing acraldehyde and hydroxy-acetone from biological glycerol in a controllable manner and a preparation method of the catalyst. The catalyst is prepared by adopting a novel impregnation in-situ reduction method; the Cu / HZSM-5 catalyst, which is prepared from pure glycerol by using the method, has a glycerol catalytic conversion rate of 92.1% in a reaction kettle under gentle condition and has controllable selectivity of 87.3wt% and 12.4wt% to acraldehyde and hydroxy-acetone, respectively; and 98.2wt% conversion rate for glycerol and 86.2wt% selectivity for hydroxy-acetone can be obtained by similar glycerol catalytic dehydration reaction in a reaction distillation device. The dispersed and stable catalyst, which is obtained by adopting a catalyst preparation method, is simple and easy to operate and favorable for large-scale production. Moreover, the catalytic glycerol is gentle in solvent-free dehydration reaction, high in catalytic activity, strong in controllable selectivity, and therefore, the method is a green process with advantages of environment friendliness and low cost.

Owner:常州市赫利来塑料有限公司

Method for preparing dihydroxy acetone by selectively oxidizing glycerin with hydrogen peroxide

ActiveCN102432445AEasy to prepareEasy to operateCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsGlycerolHydrotalcite

The invention discloses a method for preparing dihydroxy acetone by selectively oxidizing glycerin with hydrogen peroxide and belongs to the field of preparation of the dihydroxy acetone. The method comprises the following steps of: adding a transition metal hydrotalcite-like compound as a catalyst in 10 to 100 mass percent of glycerin aqueous solution, and controlling the dosage of the catalyst to be 5 to 20 percent of the mass of the glycerin; raising the temperature of a mixture to 25 to 90 DEG C by heating, dripping 3 to 50 mass percent of hydrogen peroxide, and reacting for 1 to 24 h; after reaction, centrifugally separating the catalyst from a reaction solution; and recovering the catalyst for reusing, and feeding the reaction solution to a liquid chromatogram for identification analysis. By using the glycerin and the hydrogen peroxide as raw materials, under the action of the transition metal hydrotalcite-like compound which serves as the catalyst, the conversion rate of the glycerin and the yield of the dihydroxy acetone are high; any acid base and any organic additive are not added in a reaction system; and the method has the advantages of high yield, low cost, no environmental pollution, easiness in separation, good repeatability, and the like.

Owner:NANJING INST OF TECH

Method for the production of phenol and acetone

A method for the production of phenol and acetone from a cumene hydroperoxide mixture comprises a first stage and a second stage and at least two serially connected reactors, wherein the first stage comprises decomposition of a cumene hydroperoxide mixture in the presence of a catalyst mixture to form a dicumyl peroxide mixture, and the second stage comprises formation of a phenol and acetone mixture from decomposition of the dicumyl peroxide mixture formed in the first stage, wherein, the first stage further comprises: a) forming a catalyst mixture by combining sulfuric acid and phenol in a weight ratio of from 2:1 to 1:1000 in a catalyst formation reactor, b) holding the catalyst mixture in the catalyst formation reactor at a temperature of about 20 to 80° C. for about 1 to 600 minutes; and, c) adding the catalyst mixture to the cumene hydroperoxide mixture to form the phenol and acetone mixture. The proposed method permits a significant reduction in the yield of hydroxyacetone that causes deterioration in the quality of commercial phenol.

Owner:SABIC GLOBAL TECH BV

Catalyst for 1,3-dihydroxyacetone prepared from glycerin and preparation method thereof

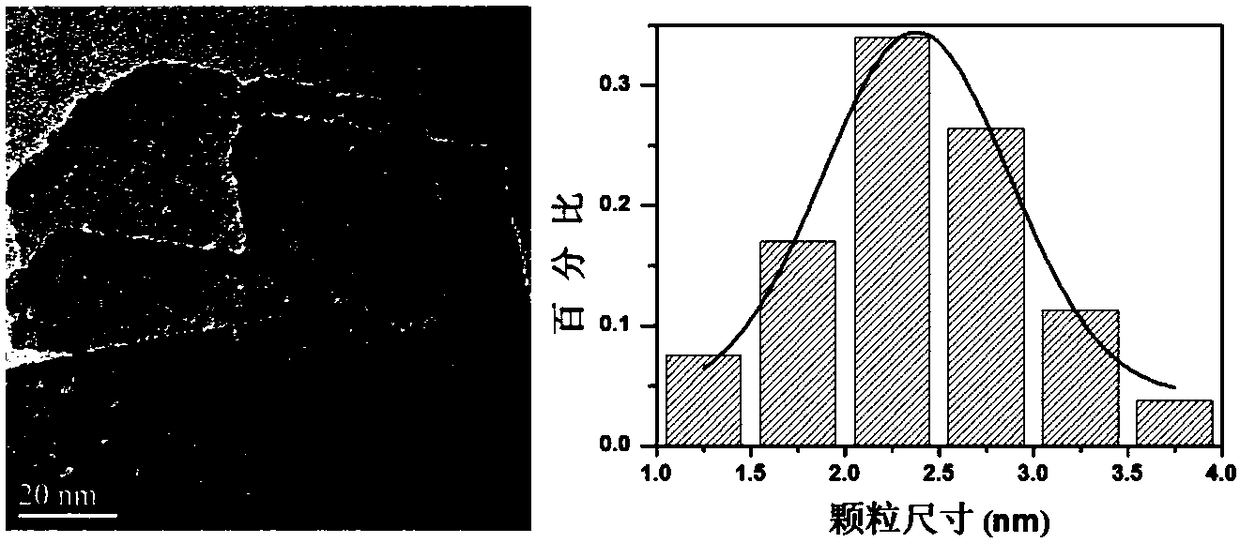

InactiveCN108273502AInhibit migrationInhibition of agglomerationOrganic compound preparationHeterogenous catalyst chemical elementsCatalytic oxidationHydrotalcite

The invention provides a catalyst for 1,3-dihydroxyacetone prepared from glycerin and a preparation method thereof. The catalyst is prepared by the steps: introducing an auxiliary component M into a hydrotalcite slab to form M-Zn-Y ternary hydrotalcite M-ZnY-LDHs, and calcining to obtain MOx / ZnYOz; taking the composite oxide as a carrier, supporting an Au salt onto the carrier, drying and reducing, thereby obtaining the Au-MOx / ZnYOz. The active ingredient Au of the catalyst is small in granule size, highly dispersed and stable under the actions of highly dispersed transition metal oxide MOx, has high catalytic oxidation activity of the glycerin and maintains excellent recyclability. The catalyst is applied to a reaction for preparing dihydroxy acetone by virtue of selective glycerin oxidation, and has high dihydroxy acetone yield under non-alkali conditions.

Owner:BEIJING UNIV OF CHEM TECH

High performance modified polyurethane coating

InactiveCN105567073AImprove thermal stabilityImprove heat resistancePolyurea/polyurethane coatingsBenzoic acidSulfolane

The invention discloses a high performance modified polyurethane coating. The coating comprises isophorone diisocyanate, polytetramethylene ether glycol, alkynyl group-containing polyol, phenylboronic acid, trimethylol propane, N,N-dimethylbenzylamine, cerium hydroxide, acidified carbon nanotubes, organic modified montmorillonite, 2,3-dibromo tripropylborate, triethylamine, 3,3'-diamino-4,4'-dihydroxydiphenylsulphone, 1-sulfolane-3-ethoxycarbonyl-5-hydroxypyrazole, 1,4-bis(dimethylhydroxysily)benzene, a leveling agent, methylsilicone oil, a wetting agent, benzoic acid, propylene glycol, dihydroxyacetone, adipic dihydrazide, liquid styrene butadiene rubber, liquid nitrile butadiene rubber and water. The high performance modified polyurethane coating has the advantages of excellent flame retardation performance, high strength, good heat stability, strong adhesion to a substrate, and long service life.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

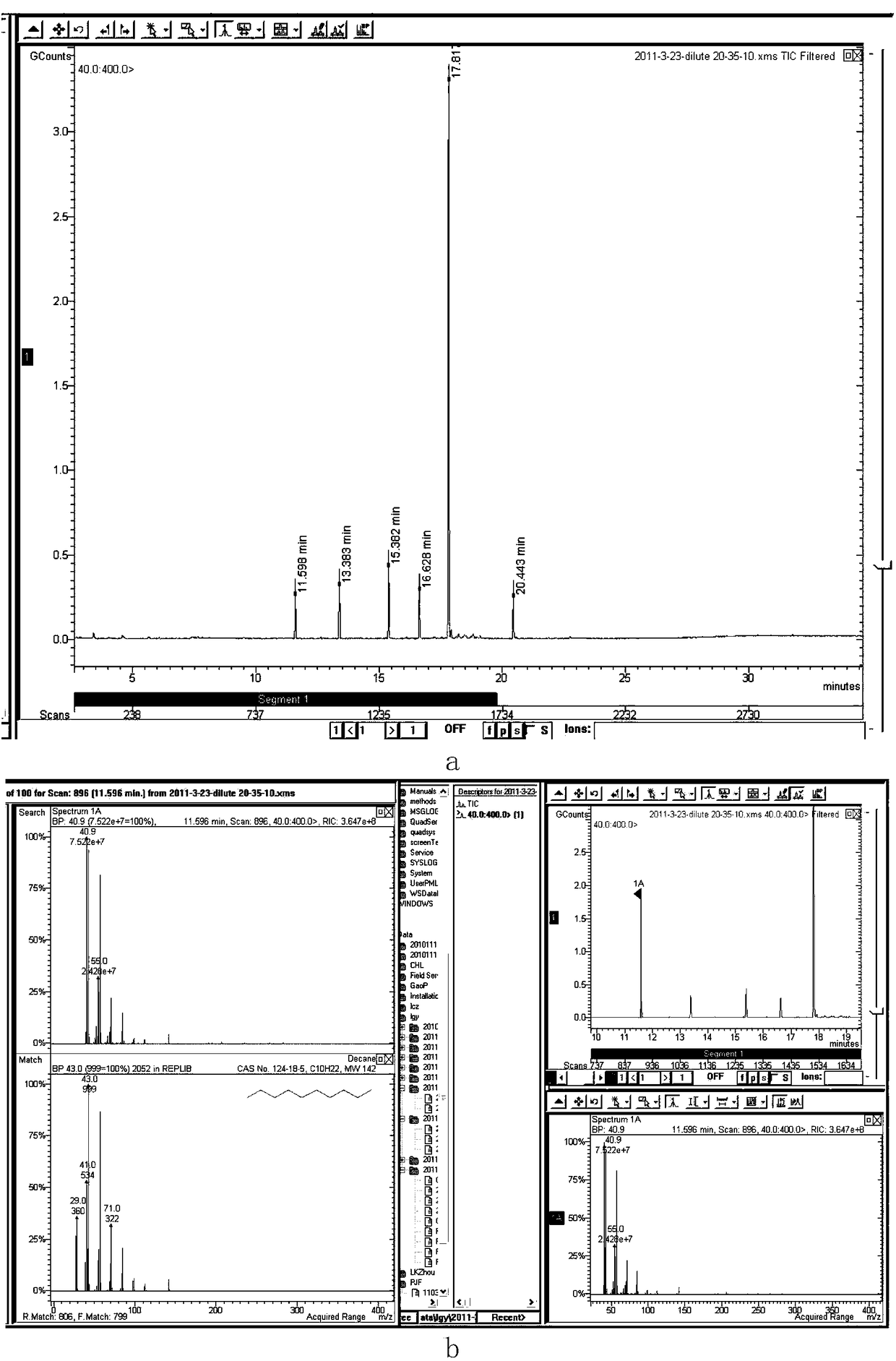

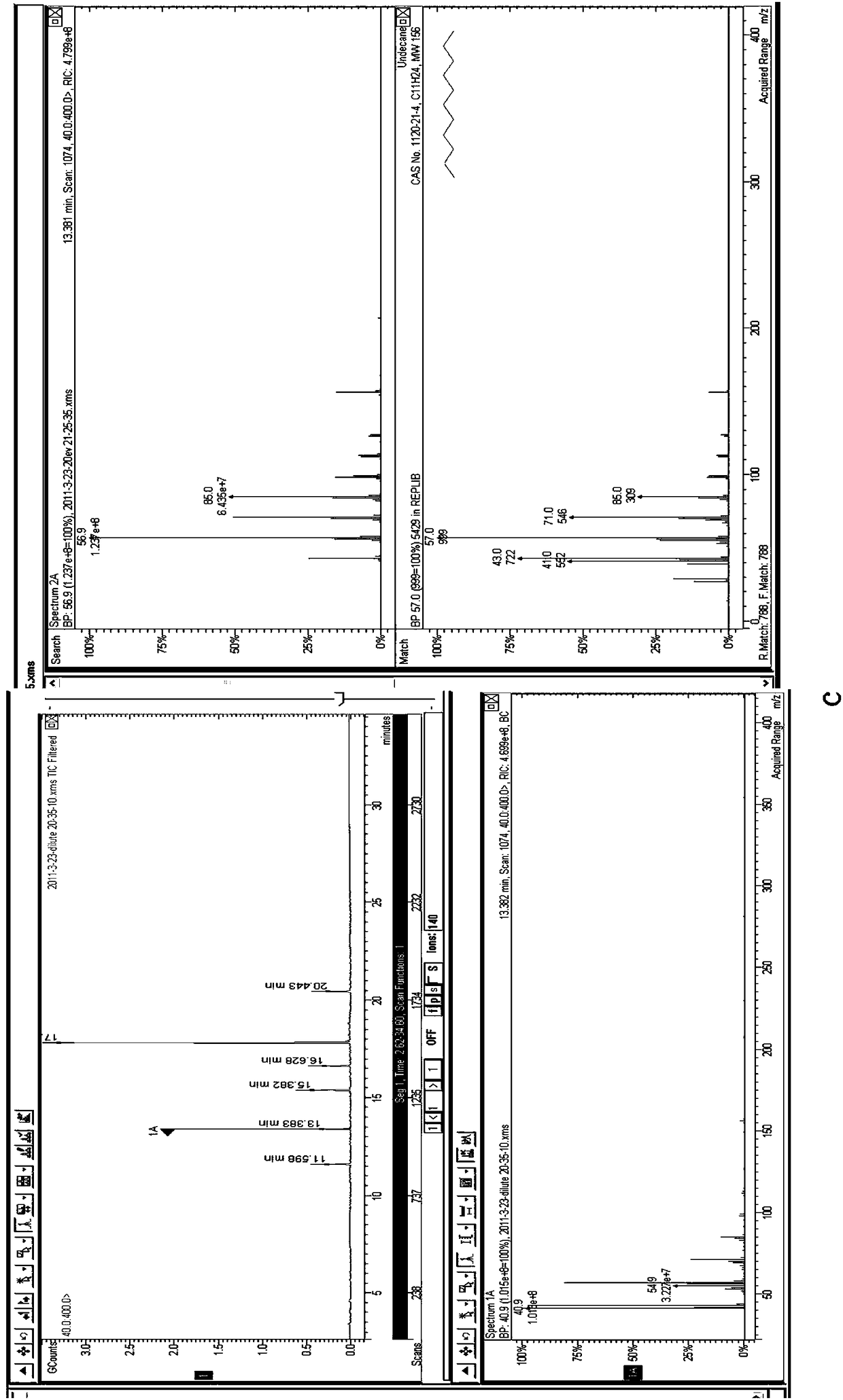

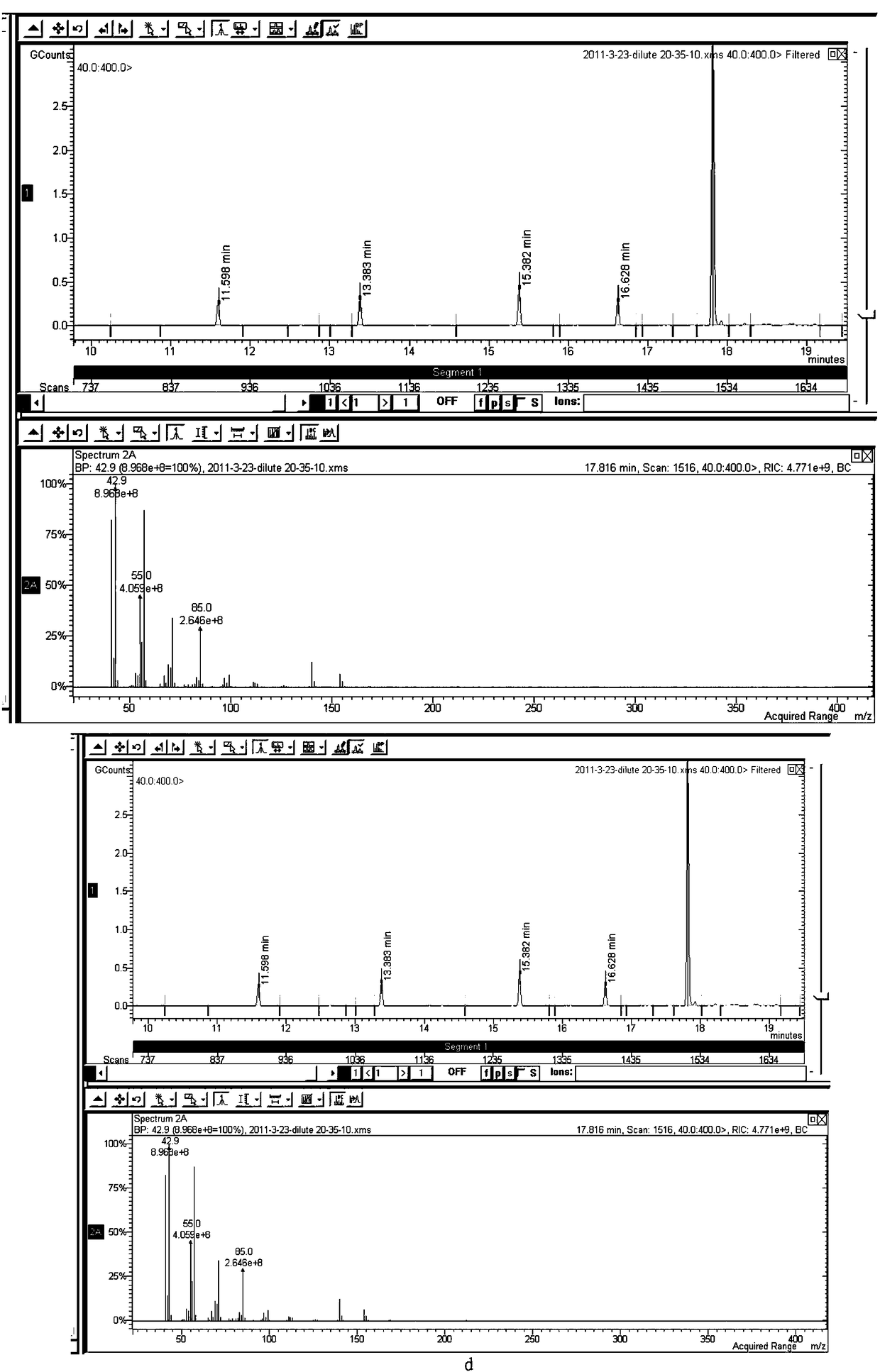

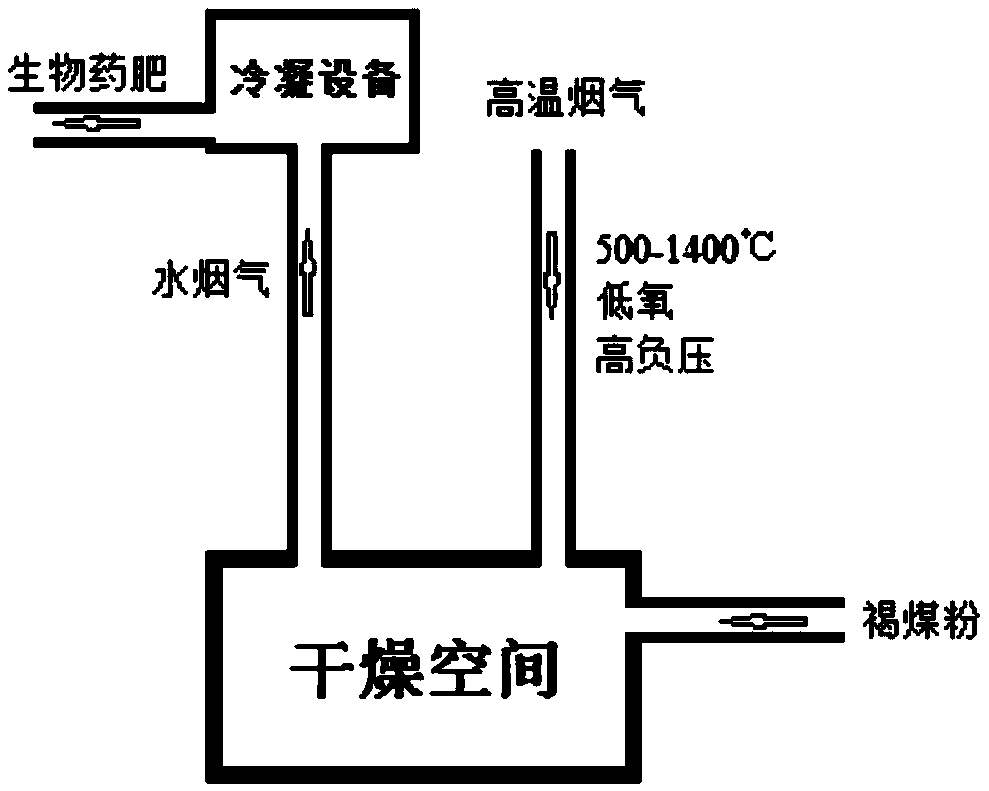

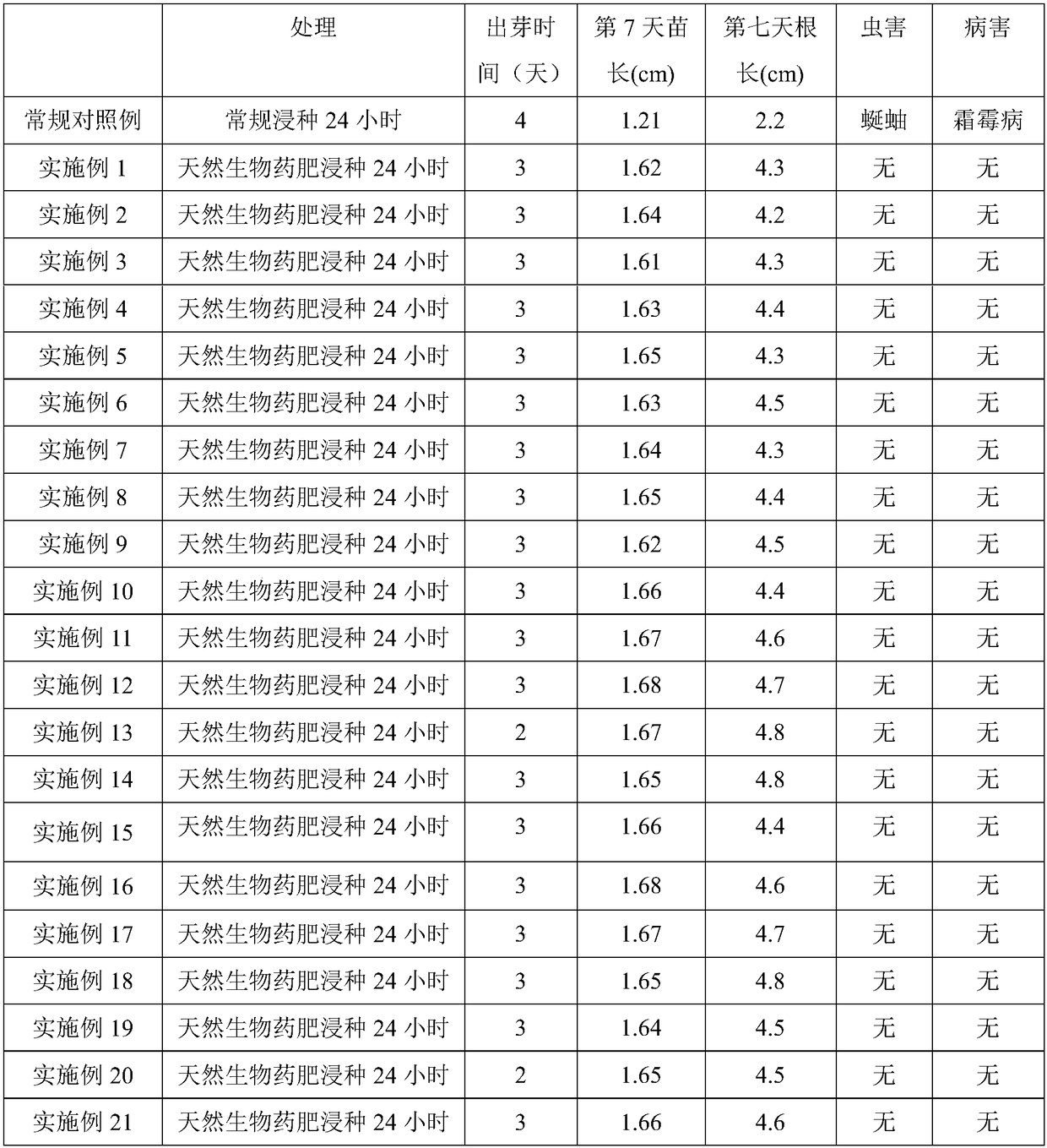

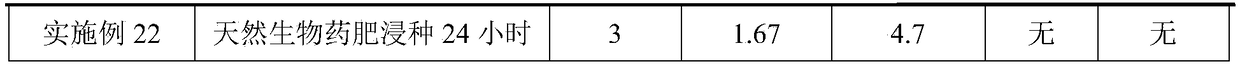

Natural biological pesticide fertilizer, preparation method and use method thereof

InactiveCN109503253APromote absorptionBoosts the autoimmune systemBiocidePlant growth regulatorsPropanoic acidPlanting seed

The invention relates to a natural biological pesticide fertilizer, a preparation method and a use method thereof. Through detection on the basis of a chromatography and mass spectrometry combined measuring process, the natural biological pesticide fertilizer provided by the invention comprises the following components: 8-52% of acetic acid, 1-4.3% of formic acid, 0.6-3.2% of propionic acid, 0.02-0.1% of hydroxyacetone, 0.4-2% of isoquinoline, 0.2-0.9% of guaiacol, 0.8-2.3% of p-cresol, 0.3-1.8% of m-cresol and the balance of water. The invention has the beneficial effects that the natural biological pesticide fertilizer is easy to dissolve in water, can be easily absorbed by plants, is beneficial to sterilization, parasite expelling and inhibition of plant diseases and insect pests, and is capable of enhancing immunity system of plants, strengthening roots, boosting seedlings, promoting plant absorption, regulating plant metabolism, improving soil and promoting quality and stress resistance of crops; the natural biological pesticide fertilizer can be widely applied to economic crops, such as cereals, vegetables, melon and fruit, tea leaves, edible mushrooms, garden plants and Chinese herbal medicines; the natural biological pesticide fertilizer can be used for treating plant seeds, dipping roots, spraying, performing drop irrigation, watering, and preventing and controlling pests.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

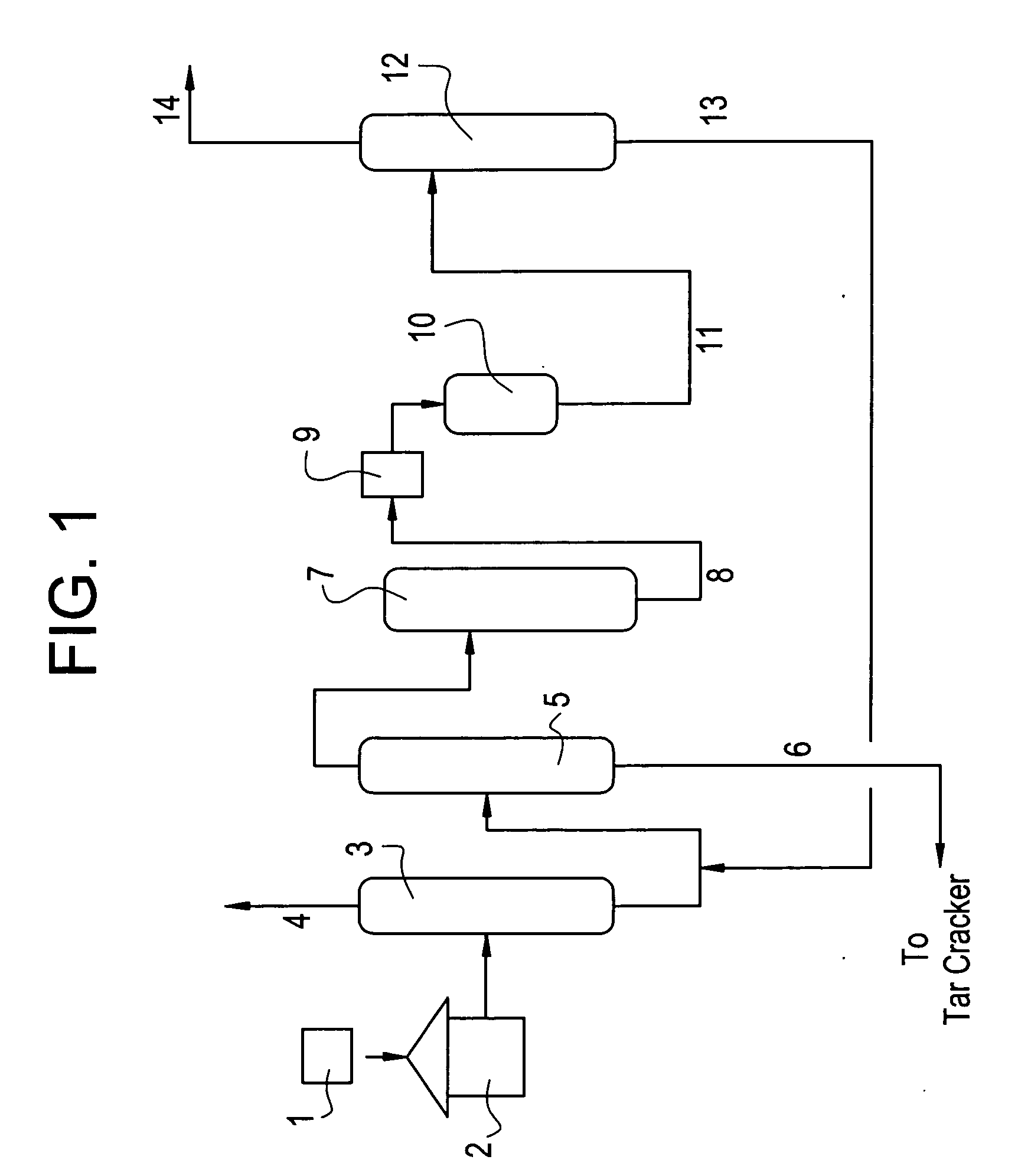

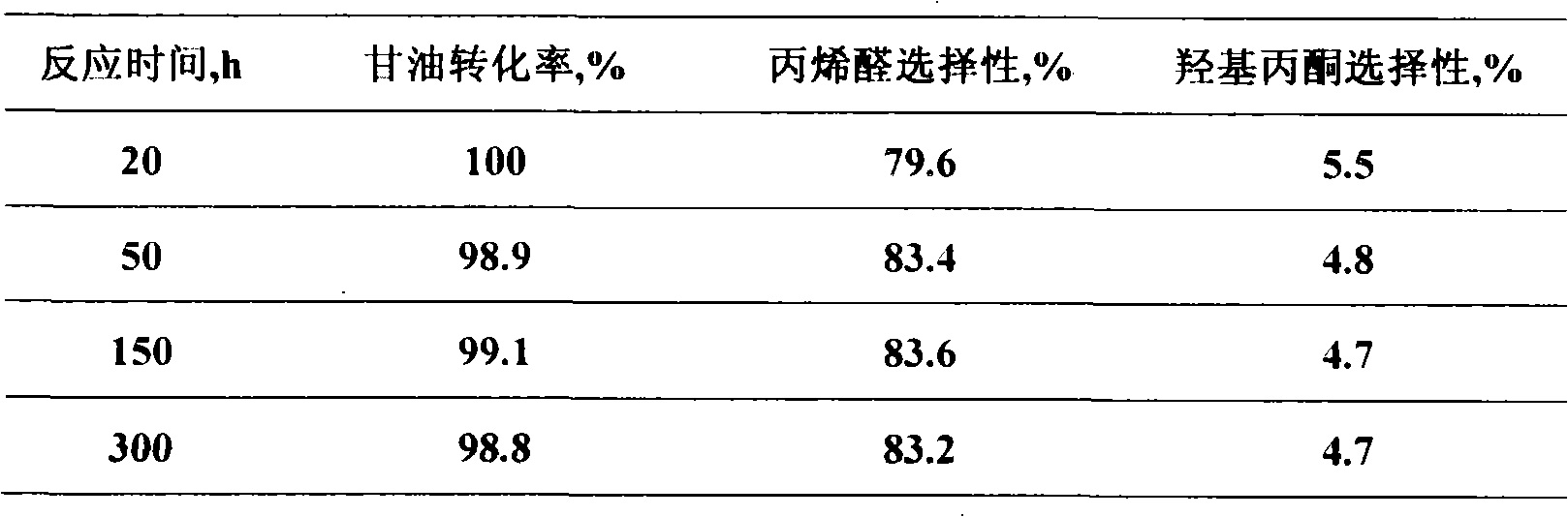

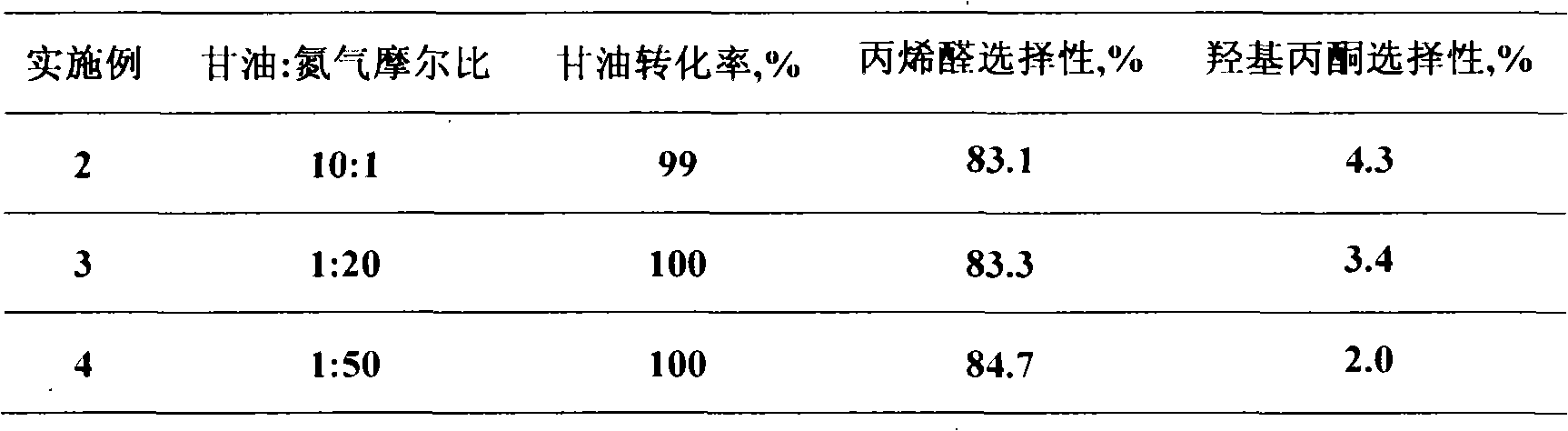

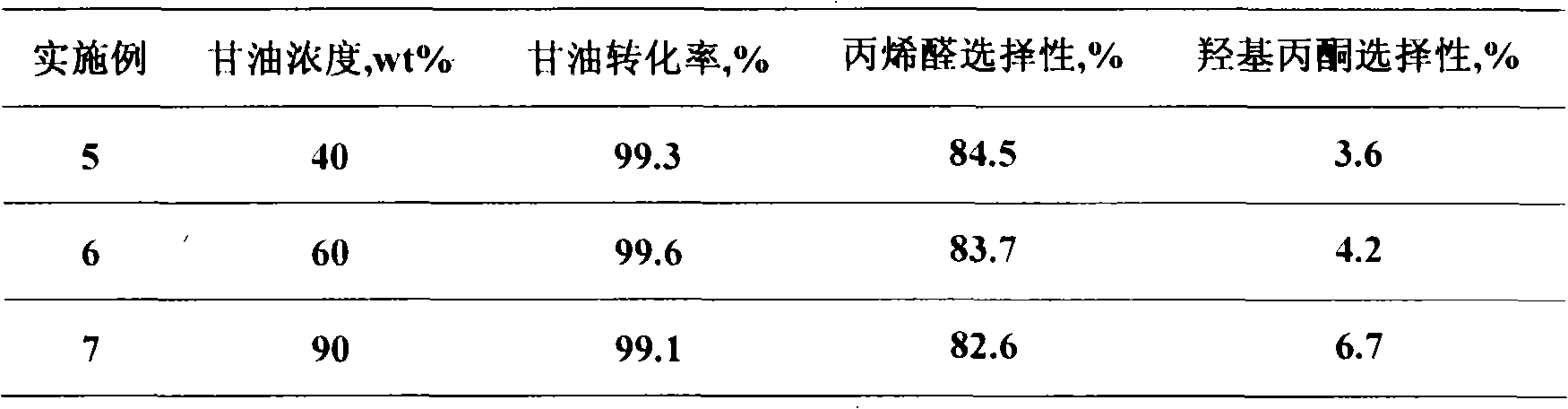

Acrylaldehyde preparation method by glycerin dehydration under inert gas dilution

InactiveCN101538195AHigh selectivityReduce processingMolecular sieve catalystsOrganic compound preparationHigh concentrationBiodiesel

The invention relates to an acrylaldehyde preparation method by glycerin dehydration under inert gas dilution, particularly an acrylaldehyde preparation method by the glycerin which is the byproduct of the preparation of biodiesel. Under inert gas atmosphere, alumina and acid zeolite are taken as catalyst; under the conditions that the reaction temperature is 200-500 DEG C, the reaction pressure is 0.001-3.0MPa and the liquid airspeed is 0.1-100.0h<-1>, the glycerin is directly dehydrated to generate acrylaldehyde and byproduct hydroxyacetone. The technique is characterized in that dehydration reaction is carried out under inert gas atmosphere, thus the activity, selectivity and stability of the reaction are high, especially high concentration glycerin can be taken as raw material and is high in selectivity and stability; thus reducing waste liquid treatment capacity of post treatment and greatly reducing energy consumption and production cost.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

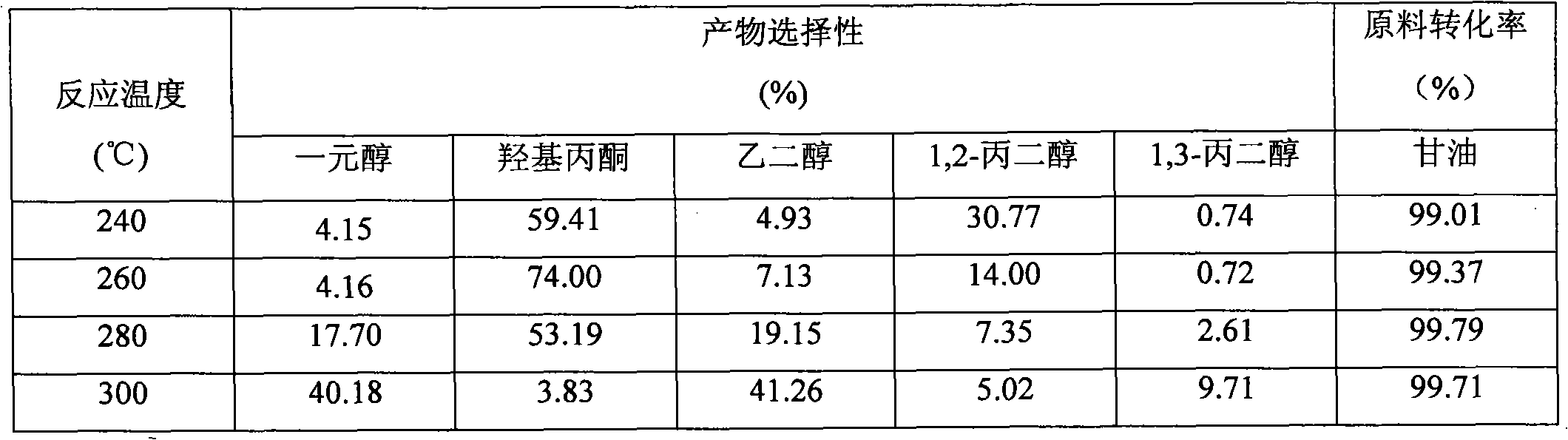

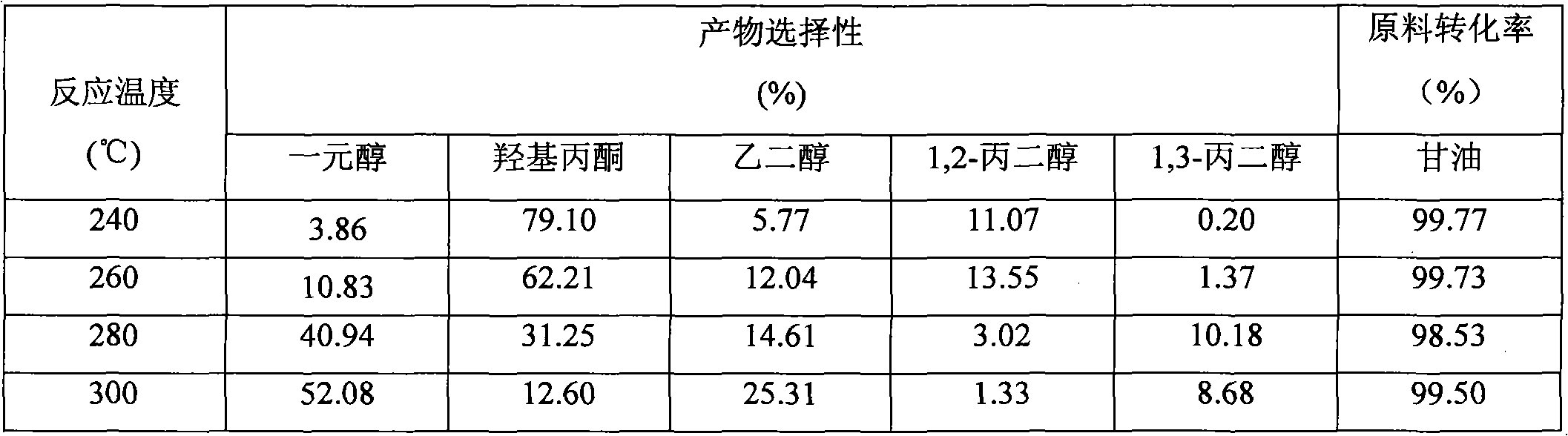

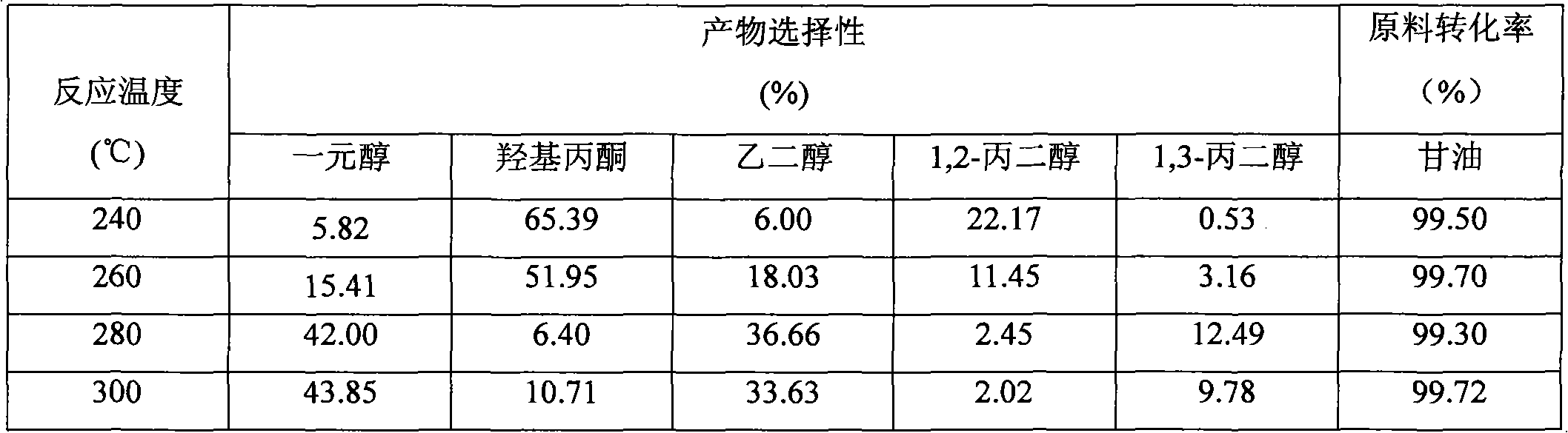

Method for hydrogenolysis catalysis of glycerin

InactiveCN101898946AHigh activityImprove conversion rateOrganic compound preparationPreparation by OH group eliminationGas phaseFixed bed

The invention discloses a method for the hydrogenolysis catalysis of glycerin, in which an atmospheric fixed bed reactor is adopted for reaction and which is characterized in that Cu-Zn-Ti or Cu-Zn-Zr with different elemental proportions is used as catalyst to catalyze glycerin at normal atmosphere between 240 DEG C to 300 DEG C to achieve hydrogenolysis at gas phase, and hydroxyacetone, ethyleneglycol and propylene glycol products are selectively prepared. The method, having the advantages of high catalyst activity, high conversion rate of glycerin, good product selectivity, mild reaction conditions, small environmental pollution and the like, provides a new effectual way of the hydrogenolysis catalysis of glycerin, thereby effectively solving the problems in the prior art.

Owner:JIANGSU UNIV

Process for separating phenol from a mixture comprising at least hydroxyacetone, cumene, water and phenol

Phenol is separated from a mixture containing hydroxyacetone, cumene, water and phenol, by fractionating the mixture in a process with a fractional distillation step and a phase separation step to provide a single phenol fraction containing less than 300 ppm of hydroxyacetone. In the work-up by distillation of cleavage product mixtures, the hydroxyacetone can be removed from the cleavage product mixture together with a phenol fraction from which the hydroxyacetone has to be removed. A process can be used for purifying cleavage product mixtures obtained in the cleavage of alkylaryl hydroperoxides such as cumene hydroperoxide. The process allows separation of phenol and acetone from mixtures obtained in the cleavage of cumene hydroperoxide.

Owner:PHENOLCHEM

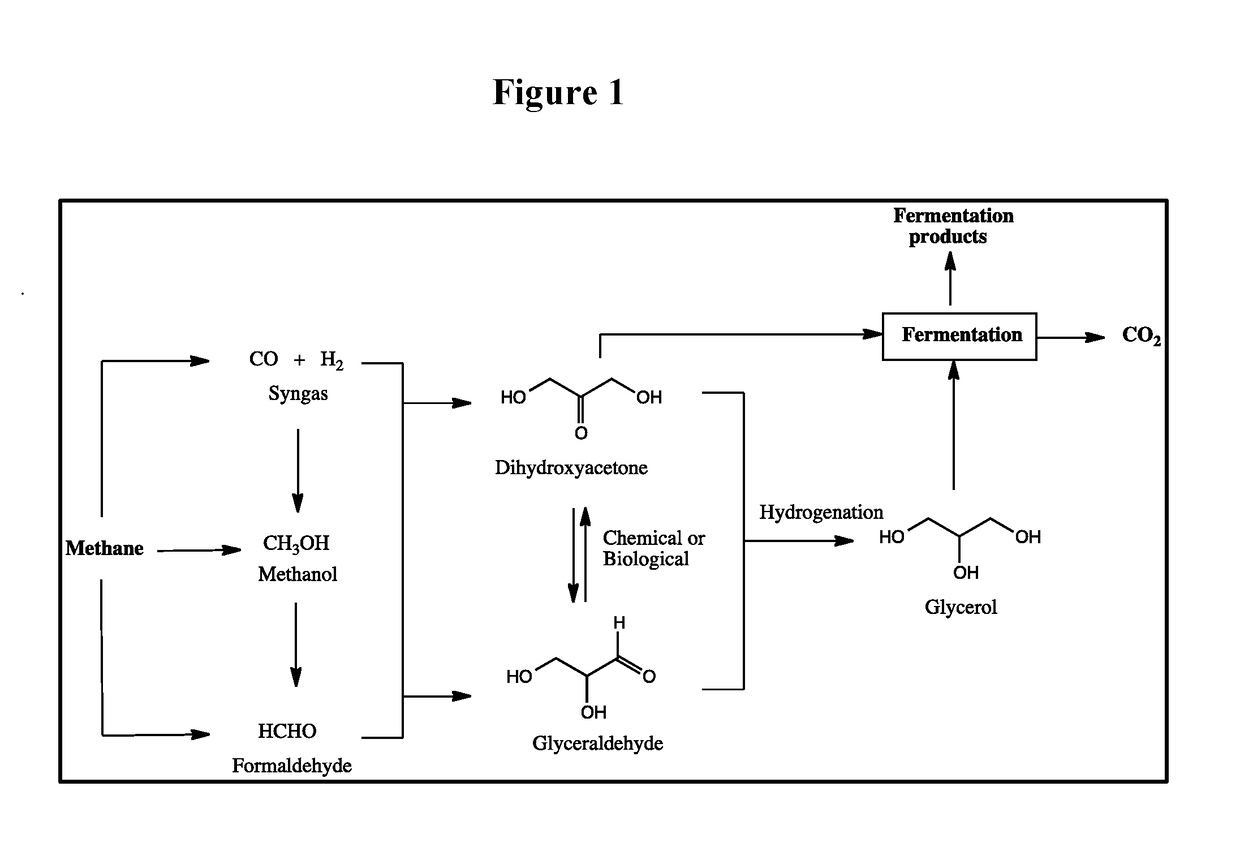

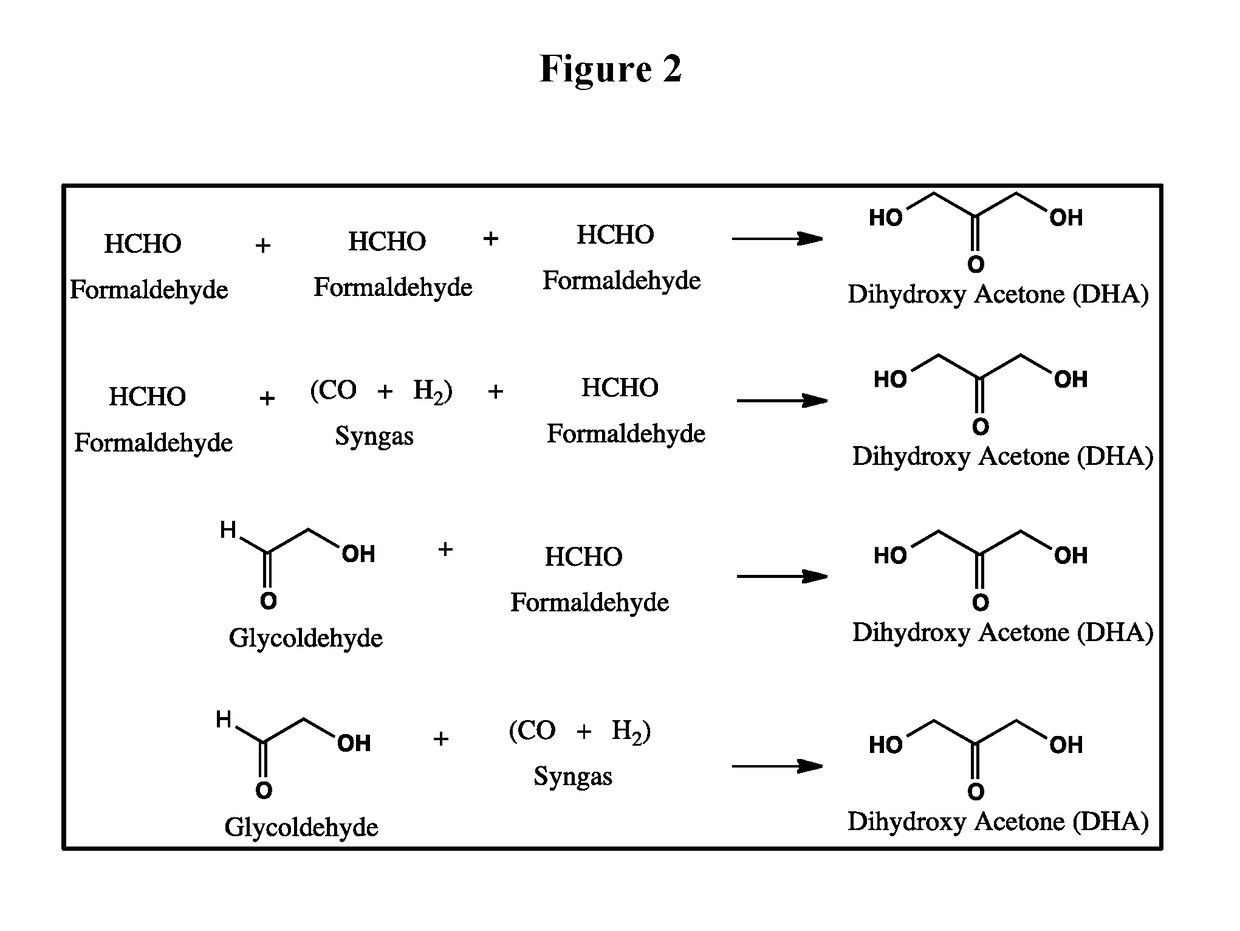

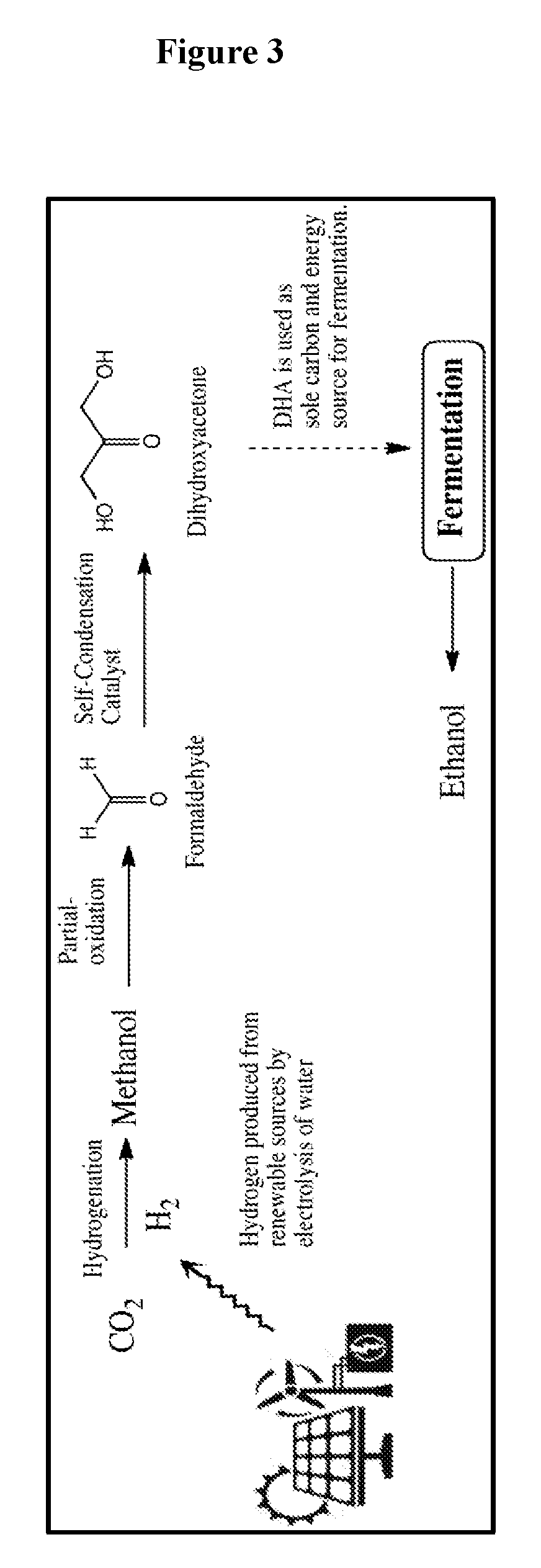

Biological fermentation using dihydroxyacetone as a source of carbon

The present invention relates to the use of hydrocarbons derived from natural gas in the fermentative production of biochemicals including biofuels. More specifically, the present invention provides the method for manufacturing dihydroxyacetone (“DHA”) from natural gas, biogas, biomass and CO2 released from industrial plants including electricity-generating plants, steel mills and cement factories and the use of DHA as a source of organic carbon in the fermentative production of biochemicals including biofuels. The present invention comprises three stages. In the first stage of the present invention, syngas and formaldehyde are produced from natural gas, biogas, biomass and CO2 released from industrial plants. In the second stage of the present invention, formaldehyde and syngas are condensed to produce DHA. In the third stage of the present invention, biochemicals including biofuels are produced from DHA using fermentation process involving wild type or genetically modified microbial biocatalysts.

Owner:KEMBIOTIX LLC

Process for the conversion of glycerol to propylene glycol and amino alcohols

Processes for the conversion of glycerol to a product mixture of an amino alcohol product and propylene glycol are disclosed. Glycerol is converted to hydroxyacetone and the hydroxyacetone is reduced with a reducing agent or reacted with an amine compound to give an adduct which is reduced using the reducing agent to obtain a product mixture of propylene glycol and an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com